Preparation method of powdery, water-insoluble high hydroscopicity resin capable of adsorbing water, urine or blood and containing low content soluble substance

A super absorbent resin, a technology for absorbing water, applied in absorbent pads, medical science, bandages, etc., can solve the problems of low soluble content, difficult control of polymerization reaction, unstable preparation method, etc. Improve process stability and improve the effect of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a method for preparing a powdery, water-insoluble, superabsorbent resin that can absorb water, urine or blood and has a low soluble content, which at least includes:

[0030] 1) Add a crosslinking agent to the acid group-containing monomer aqueous solution with a neutralization rate of 50 mole% or more. The acid group-containing monomer can be selected from acrylic acid, methacrylic acid, 2-propenylamine-2-methylpropanesulfonic acid or the above A mixture of groups, and the acid group-containing monomer aqueous solution contains 0-5 wt% of water-soluble polymer compounds;

[0031] 2) The acid group-containing monomer solution and the polymerization initiator are retained in the twin-screw mixer for a period of 3 to 600 seconds to provide a gel after the radical polymerization reaction; and

[0032] 3) The gel is dried, crushed, sieved, coated with a surface crosslinking agent at a temperature of 100°C to 250°C with hot air, heated at a tempera...

example 1

[0055] 1) First add 17.35kg of 49% sodium hydroxide aqueous solution and 30.52kg of water into the 100L (liter) reaction tank, then slowly add 22.53kg of acrylic acid to the sodium hydroxide aqueous solution for neutralization under ice bath; The monomer concentration is 38.6wt% aqueous solution, of which 68mol% of acrylic acid is partially neutralized to sodium acrylate.

[0056] 2) Add 33.80 g of glycerol polyethylene glycol triglycidyl ether (n=7) to the partially neutralized aqueous acrylic acid solution, and maintain the temperature at about 20°C.

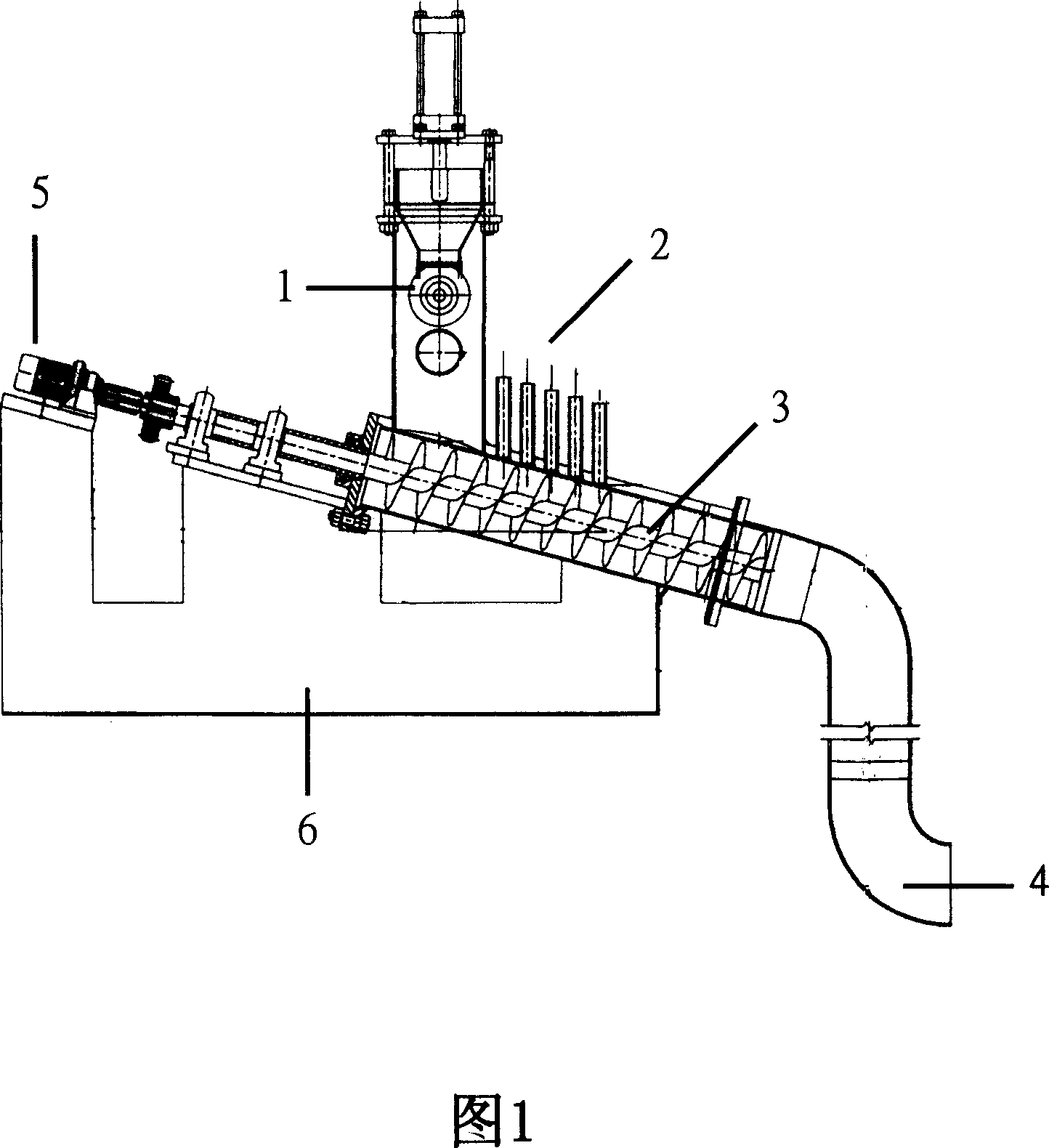

[0057] 3) Control the flow rate of the sodium acrylate solution to 70.4 kg / hr, so that it enters the twin-screw mixer body from the feed pipe of FIG. 1.

[0058] 4) Control the flow rates of L-ascorbic acid, sodium persulfate and 2,2-azobis(2-amidinopropane) to 12.99g / hr, 162.40g / hr and 162.40g / hr, respectively, and make them pass Figure 2 The feed pipe of the gas enters the twin-screw mixer body.

[0059] 5) Use parallel twin scr...

example 2

[0066] Repeat Example 1, but the residence time of step 5) was changed to 20 seconds, and the viscosity of the discharged reactant was 12.5 cp. Although no polymer was found inside the twin-screw mixer, the viscosity was higher than that of Example 1. It is not easy to disperse on the reactor, and there is a phenomenon that a small part of the local reaction heat is higher; the rest of the steps are the same as in Example 1, and the soluble content of the super absorbent resin obtained by analysis is 3.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com