Preparation method of rapid absorption type super absorbent resin

A super absorbent resin, absorbing technology, applied in the field of super absorbent resin preparation, can solve the problems of unbalanced water absorption, unfavorable industrial production, low product absorption, etc. Glue strength, smooth polymerization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

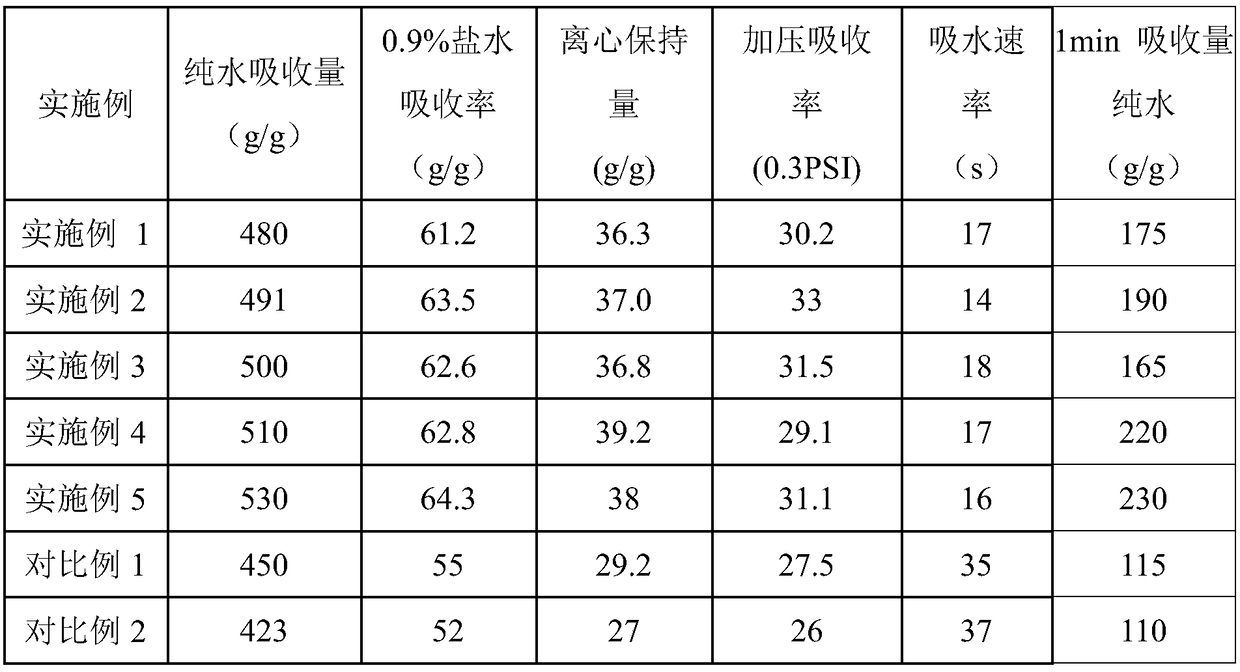

Examples

Embodiment 1

[0041] Add 100g of acrylic acid and 70g of deionized water into a 1000ml three-necked bottle with stirring, put the three-necked bottle into a water constant temperature water bath with cold water, install a normal pressure dropping funnel, insert a thermometer, and weigh 32wt% of the Add sodium hydroxide solution into the dropping funnel, start stirring, add lye dropwise for neutralization, it depends on controlling the neutralization reaction temperature. 41% of the liquid to be polymerized.

[0042] Add N,N'-methylenebisacrylamide (MBA) aqueous solution 1.1g (MBA concentration 2wt%), foaming agent: F-36+NaHCO 3 (0.6:2.0) 2.6g, wood fiber 1.0g, polyethylene glycol 0.15g, plus 10g ≥100 mesh resin powder, fully disperse and swell for 15min, and keep the temperature at 41-42°C.

[0043] Add 3.5g of 3wt% 2,2'-azobisisobutylamidine dihydrochloride (initiator V-50) aqueous solution, 3.5g of 2wt% sodium persulfate aqueous solution, stir well, add 1.5wt% sulfite 4g of sodium bisul...

Embodiment 2

[0048] Add 100g of acrylic acid and 70g of deionized water into a 1000ml three-necked bottle with stirring, put the three-necked bottle into a water constant temperature water bath with cold water, install a normal pressure dropping funnel, insert a thermometer, and weigh 32wt% of the Add sodium hydroxide into the dropping funnel, start stirring, add lye dropwise for neutralization, and control the neutralization reaction temperature. The temperature is controlled below 42°C. After neutralization, the neutralization degree is 75%, and the monomer concentration is 41. % of the liquid to be polymerized.

[0049] After neutralization, add polyethylene glycol diacrylate (PEGDA) 5wt% aqueous solution 1.3g, foaming agent: F-36+NaHCO 3 (1.0:1.0) 2.0g, wood fiber 1.0g, polyethylene glycol 0.15g, plus 10g ≥100 mesh resin powder, fully disperse and swell for 15min, and keep the temperature at 41-42°C.

[0050] Add 5g of 3wt% 2,2'-azobisisobutylamidine dihydrochloride (initiator V-50) a...

Embodiment 3

[0054] Add 100g of acrylic acid and 70g of deionized water into a 1000ml three-necked bottle with stirring, put the three-necked bottle into a water constant temperature water bath with cold water, install a normal pressure dropping funnel, insert a thermometer, and weigh 32wt% of the Add sodium hydroxide into the dropping funnel, start stirring, add lye dropwise for neutralization, and control the neutralization reaction temperature. The temperature is controlled below 42°C. After neutralization, the neutralization degree is 75%, and the monomer concentration is 41. % of the liquid to be polymerized.

[0055] After neutralization, add polyethylene glycol diacrylate (PEGDA) 5wt% aqueous solution 1.3g, foaming agent: F-36+NaHCO 3 (0.2:4.0) 4.2g, wood fiber 1.0g, polyethylene glycol 0.15g, plus 10g ≥100 mesh resin powder, fully disperse and swell for 15min, keep the temperature at 41~42℃, add 3wt% 2,2'- Azobisisobutylamidine dihydrochloride (initiator V-50) aqueous solution 5g,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com