Numerically controlled fluidized rotary floating drying machine

A dryer and fluid technology, applied in drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of difficult maintenance, high equipment failure rate, poor drying effect, etc., and achieve weight reduction and operation stability. Good, smooth drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

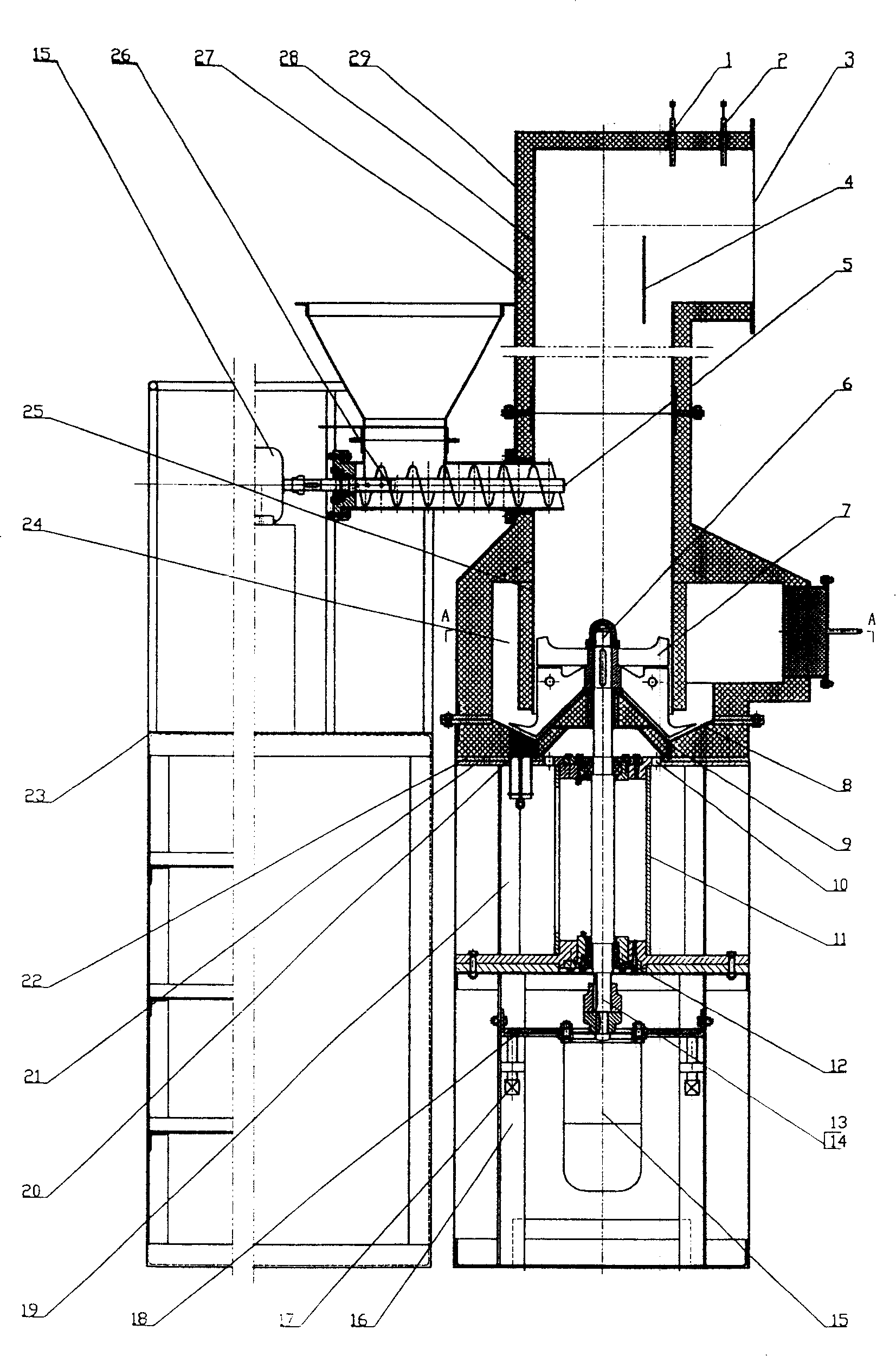

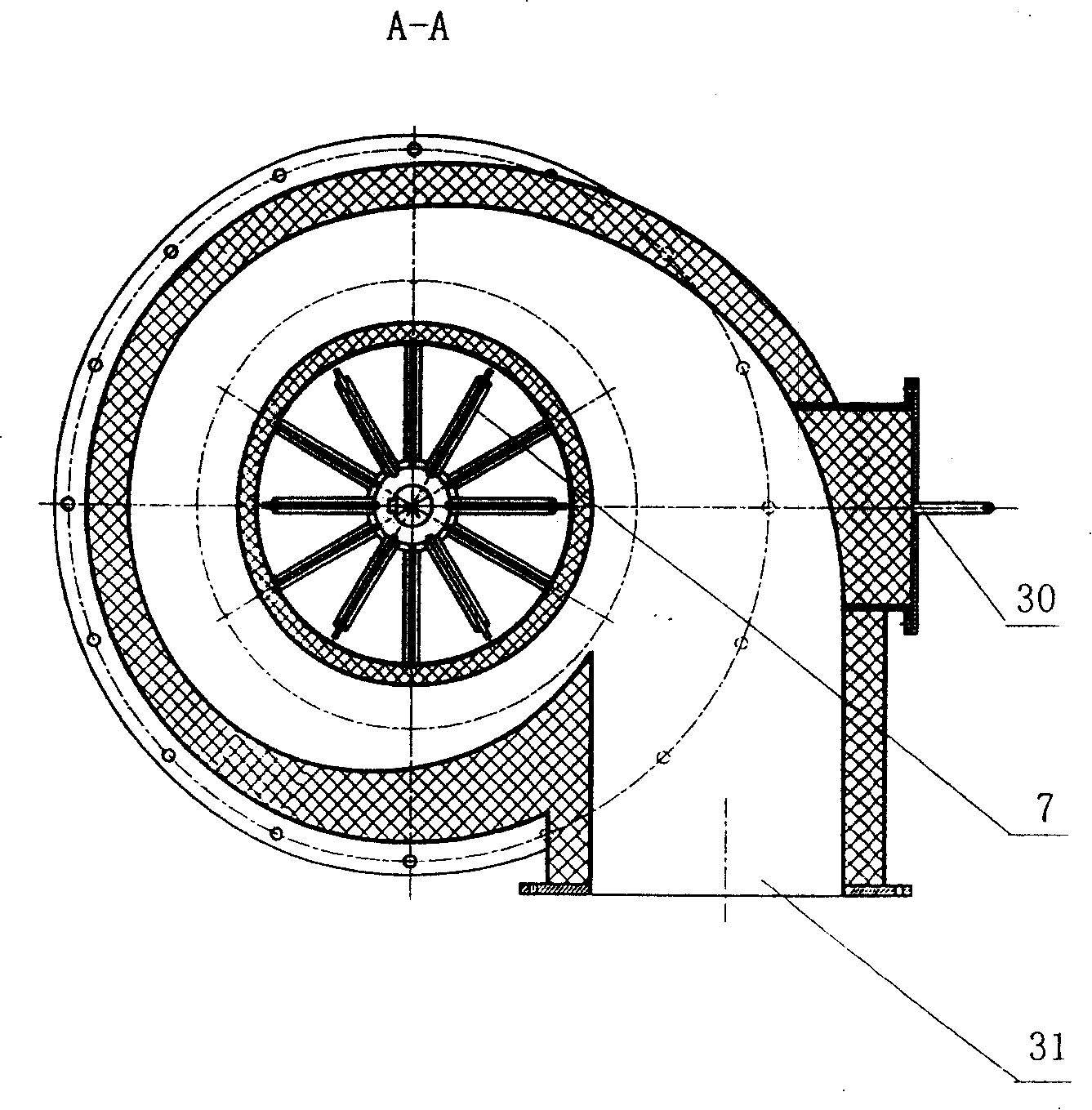

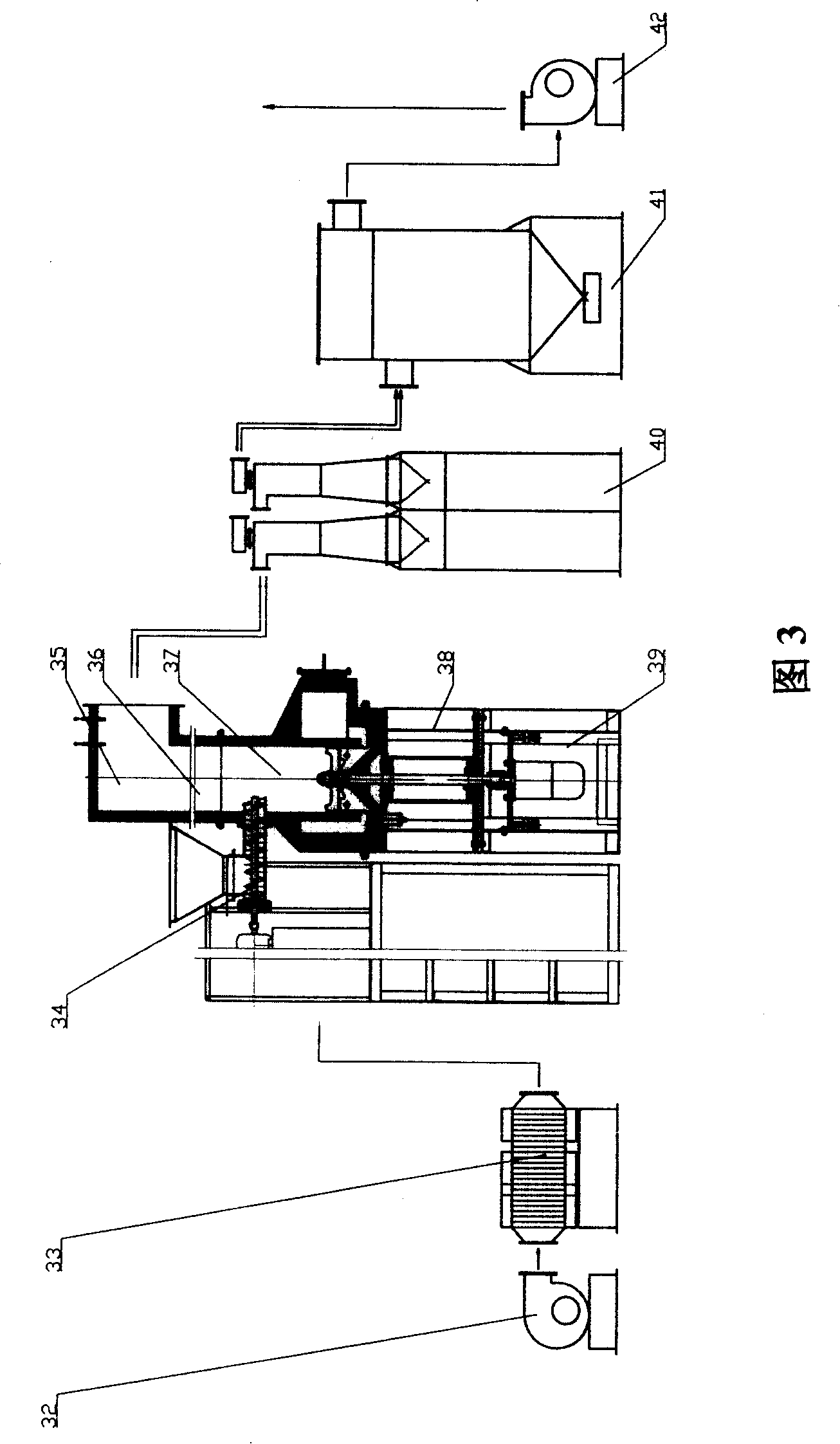

[0018] according to figure 1 -3 Describe the specific structure of the present invention in detail. The device includes an assembled frame, a hot air source 33 connected to the air inlet 31 of the body of the frame, a discharge pump 42 connected to the air outlet 3 of the body, a driving device and an electrical control circuit. Among them, each control element and transmission signal in the electrical control circuit are respectively connected with the numerical control device of the unit (provided by the user according to actual needs) according to the common circuit and conventional control method. The frame includes a body 28 with a material inlet 5, an air inlet 31 and a material outlet 3, a body support 16, and a support 19 thereof. From top to bottom, the frame is assembled with a rotary-floating drying section 36 with a specific gravity separation section 35, an atomizing and throwing section 37, and a power section 39 sequentially using flanges and fasteners.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com