Shock resistance optical resin lens and method of manufacture

A technology for optical resin lenses and manufacturing methods, applied in optics, optical components, optical components, etc., can solve the problems of low technical starting point, high dispersion, poor impact resistance, etc., to eliminate internal polymerization stress, ensure optical accuracy, and ensure optical quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

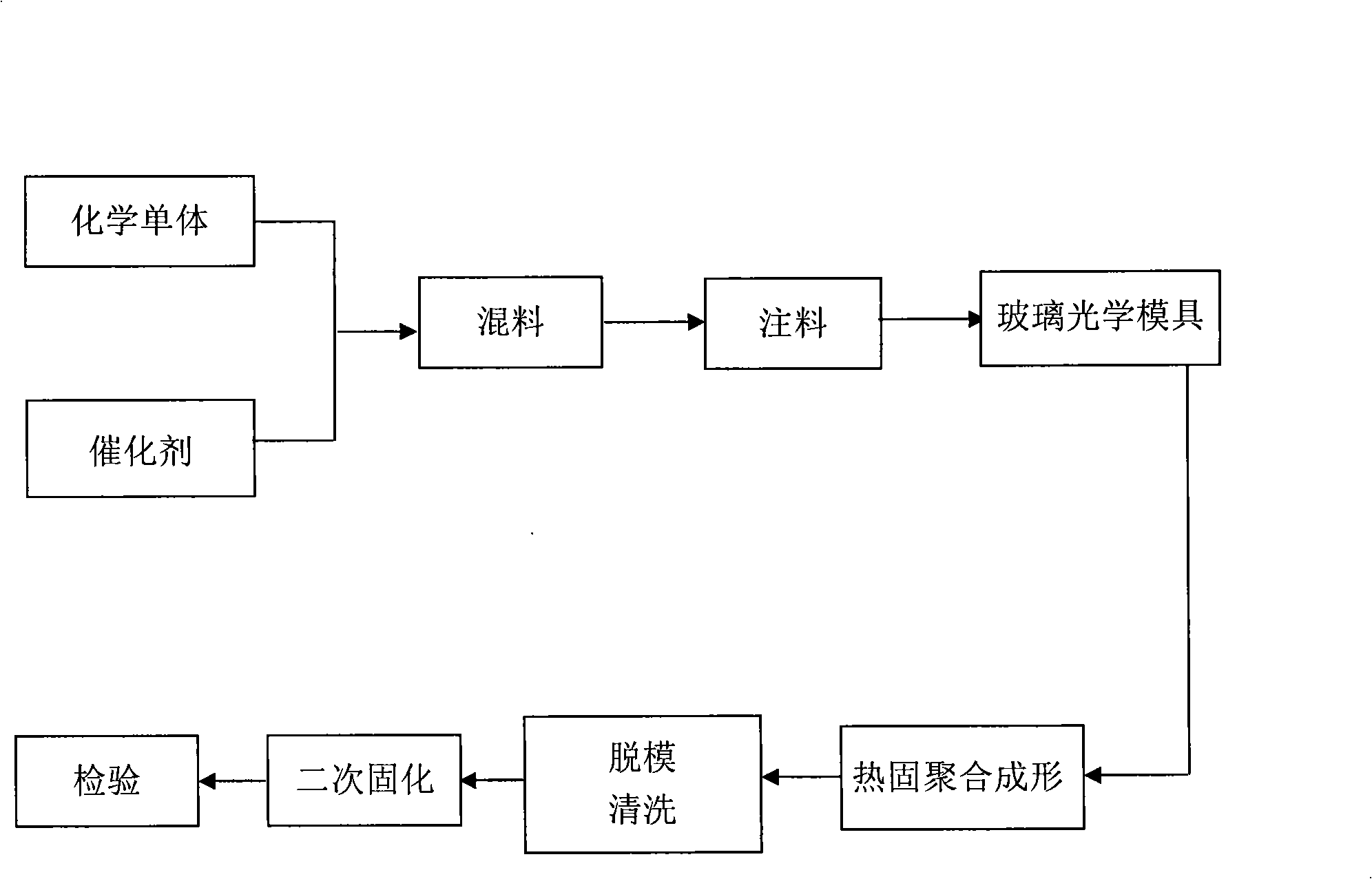

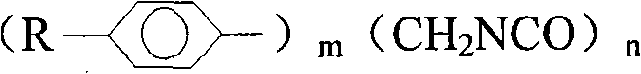

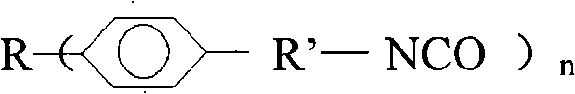

Method used

Image

Examples

Embodiment 1

[0026] First weigh 9.4Kg of the chemical monomer A component, seal and stir at room temperature (22°C-28°C) for 11 minutes, add 14g of dibutyltin dichloride catalyst and then seal and stir at room temperature (22°C-28°C) 30 minutes, then cool down to 8°C in an ice-water bath and maintain this temperature, add 10.6Kg of chemical monomer B component, stir at 8°C under vacuum (vacuum degree at -0.08Mpa) for 35 minutes, then stop stirring and keep the vacuum degree at - After 10 minutes at 0.08Mpa, keep the temperature at 8°C, pressurize it with nitrogen to 0.06Mpa, filter through a polytetrafluoroethylene filter membrane with a pore size of 0.3μm, and inject it into the mold (350 pieces) that has been closed. Thermosetting polymerization molding in the computer temperature-controlled curing furnace of the device. The curing temperature change steps are as follows: the starting temperature is 35°C, keep warm for 2 hours, rise to 50°C after 3 hours, rise to 70°C after 3 hours, then...

Embodiment 2

[0028] First weigh 10Kg of the chemical monomer A component, and then seal and stir at room temperature (22°C-28°C) for 10 minutes, then add 13g of dibutyltin dichloride catalyst and then seal and stir at room temperature (22°C-28°C) for 30 minutes. Minutes, then cool down to 6°C in an ice-water bath and maintain this temperature, add 10Kg of chemical monomer B component, stir at 6°C under vacuum (vacuum degree at -0.09Mpa) for 40 minutes, then stop stirring and keep the vacuum degree at -0.09Mpa After 12 minutes, keep the temperature at 8°C, pressurize it with nitrogen to 0.08Mpa, filter through a polytetrafluoroethylene filter membrane with a pore size of 0.3μ, and inject it into the mold that has been closed (360 pieces). Thermosetting molding in a computer temperature-controlled curing furnace, the curing temperature change steps are as follows: the initial temperature is 35°C, heat for 1 hour, rise to 45°C after 4 hours, rise to 65°C after 4 hours, then hold for 4 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com