Manufacturing method of rolled ion exchange homogeneous membrane

A technology of ion exchange and manufacturing method, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of local composition and structure errors of impregnated base membrane, difficult to control accurately, and unable to obtain uniform microstructure structure, etc., to achieve impregnation. Easy and stable, reasonable homogeneous film structure, stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

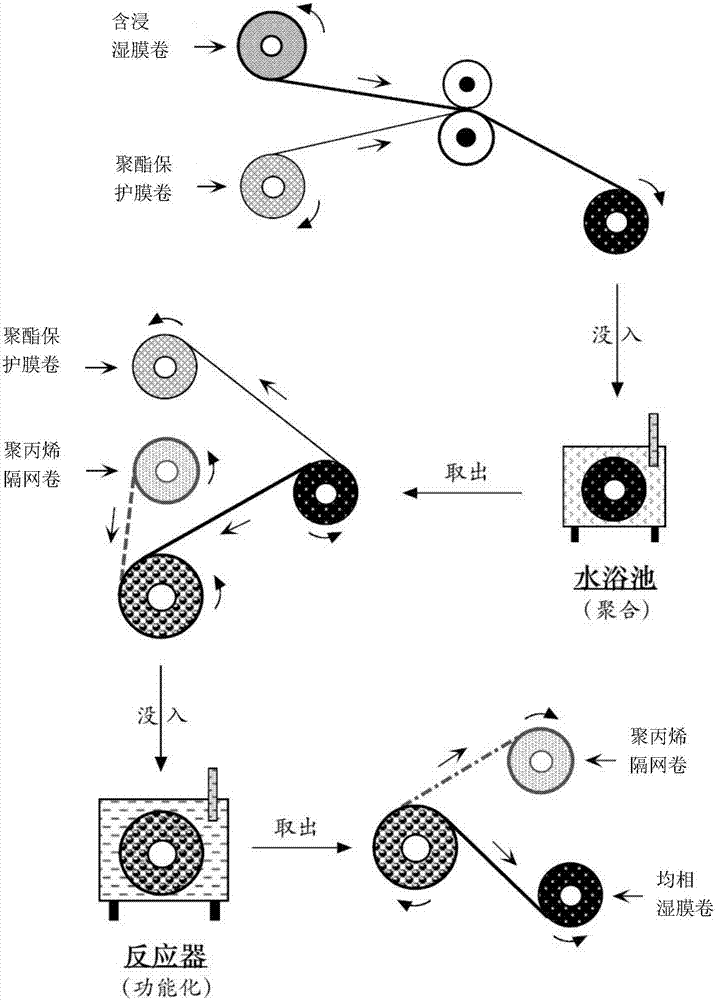

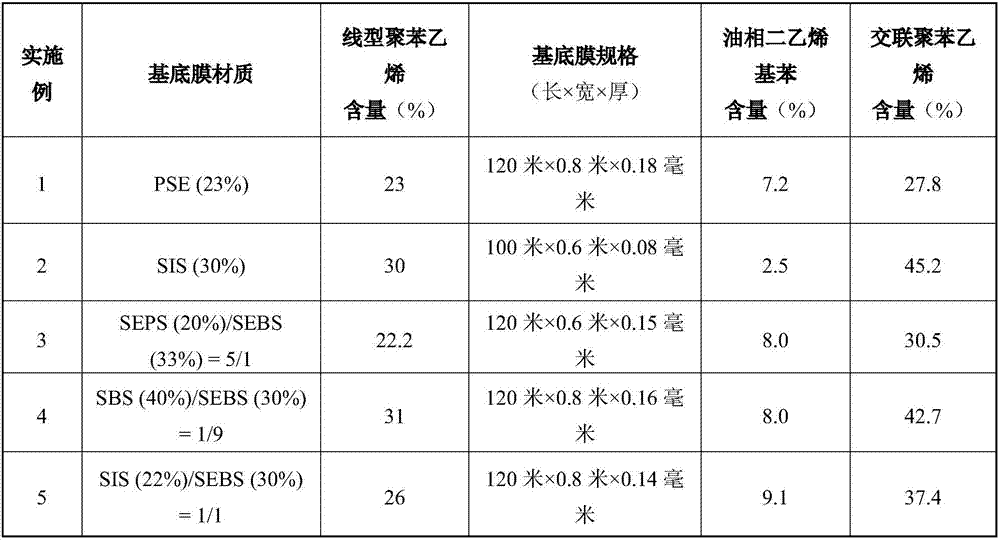

[0033] Embodiment 1: the manufacture method of roll type cation exchange homogeneous membrane (standard positive membrane), concrete steps are as follows:

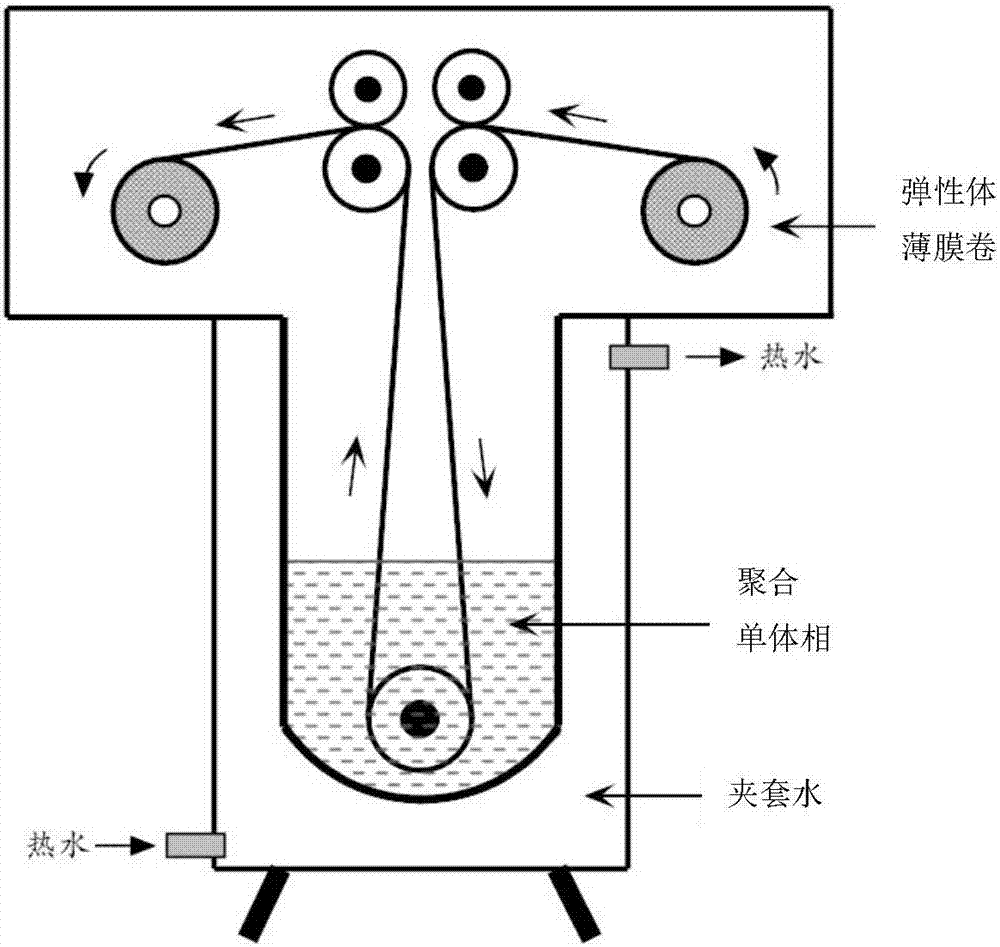

[0034] Step 1: Take poly(styrene-ethylene) alternating copolymer (PSE) dense particles (Ningbo Carl New Material Technology Co., Ltd., brand: K1123, linear polystyrene content 23%), and successively pass through twin-screw extrusion, flow Stretching, stretching, air cooling, winding and other processes to make linear polystyrene elastomer film rolls with a width of 0.8 meters and a thickness of 0.18 mm. Take a film roll with a length of 120 meters (net mass: 15,923 grams), first fix it on the left roller shaft above the impregnation tank with a clip, turn on the motor, and slowly finish winding; stop the motor and then manually unwind the roll, and bypass it in turn Left top roller (left pressure roller), groove bottom roller, right top roller (right pressure roller), right roller shaft, and are fixed on the right roller s...

Embodiment 2

[0039] Embodiment 2: the manufacture method of roll type anion exchange homogeneous membrane (diffusion dialysis negative membrane), concrete steps are as follows:

[0040] Step 1: Take fluffy granules of styrene-isoprene-styrene block copolymer (SIS) (Kraton Polymers Company of the United States, trade mark: D1124K, linear polystyrene content 30%), and extrude them successively through twin-screw Out, casting, stretching, air cooling, winding and other processes to make linear polystyrene elastomer film rolls with a width of 0.6 meters and a thickness of 0.08 mm. Take a film roll with a length of 100 meters (the net mass is 4,416 grams), first fix it on the left roller shaft above the impregnation tank with a clip, turn on the motor, and slowly finish winding; stop the motor and then unwind the roll manually, bypassing in turn Left top roller (left pressure roller), groove bottom roller, right top roller (right pressure roller), right roller shaft, and are fixed on the right ...

Embodiment 3

[0045] Embodiment 3: the manufacture method of roll type cation exchange homogeneous membrane (standard positive membrane), concrete steps are as follows:

[0046] Step 1: get styrene-ethylene / propylene-styrene block copolymer (SEPS) dense granules (U.S. Kraton polymer company, brand: G1730M, linear polystyrene content 20%) and styrene-ethylene / butylene Styrene-styrene block copolymer (SEBS) powder (Kraton Polymers Company of the United States, brand: G1641H, linear polystyrene content 33%), uniformly mixed according to the mass ratio of 5 / 1, and then extruded through twin-screws successively , casting, stretching, air cooling, winding and other sections to make linear polystyrene elastomer film rolls with a width of 0.6 meters and a thickness of 0.15 mm. Take a film roll with a length of 120 meters (net weight is 9,936 grams), first fix it on the left roller shaft above the impregnation tank with a clip, turn on the motor, and slowly finish the winding; stop the motor and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com