Patents

Literature

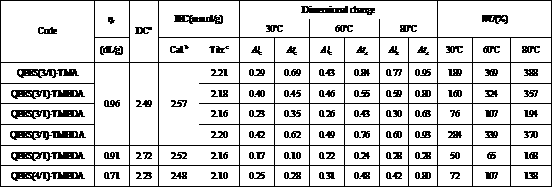

133 results about "Chloromethyl Ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bis(chloromethyl) ether is an organic compound with the chemical formula (CH2Cl)2O. It is a colourless liquid with an unpleasant suffocating odour and it is one of the chloroalkyl ethers.

Polymeric adsorbent and preparation method thereof

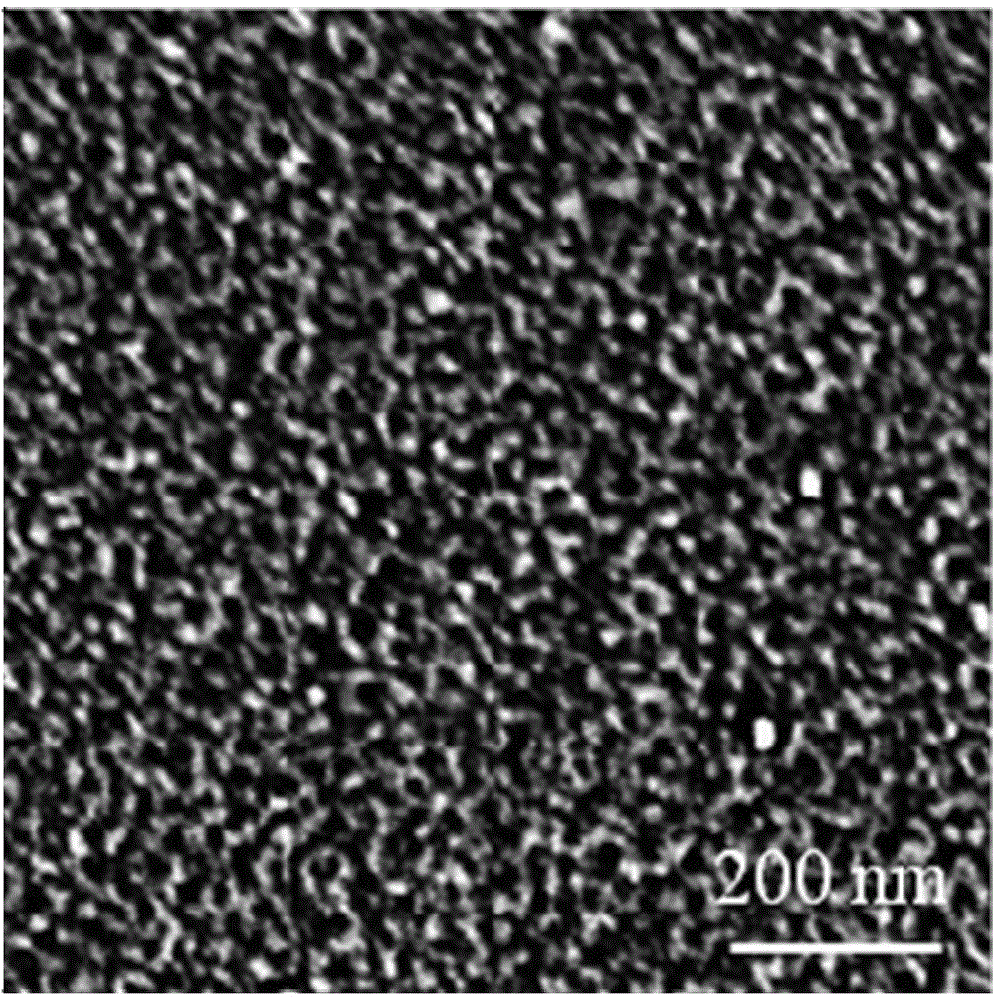

ActiveCN101912770ALarge specific surface areaSmall apertureOther chemical processesCross-linkChloromethyl Ether

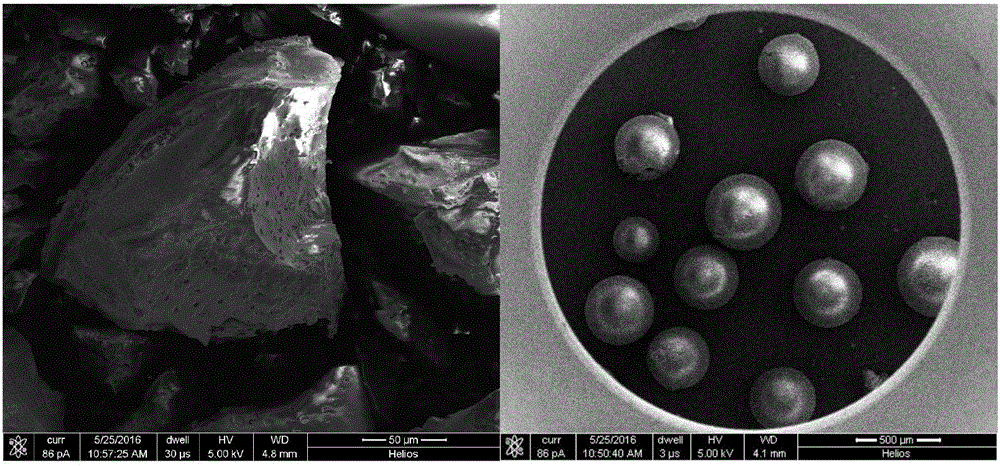

The embodiment of the invention discloses a polymeric adsorbent and a preparation method thereof. The preparation method comprises the following steps of: preparing a bead-like resin from chloromethyl styrene serving as a polymerization monomer and divinyl benzene serving as a cross-linking agent by a suspension polymerization method; and adding a hydroxyl-containing monomer at the post-crosslinking stage to perform super cross-linking reaction so as to prepare the polymeric adsorbent. In the method, pores are formed in the polymeric adsorbent at the post-crosslinking stage of polychloromethyl styrene by using a chemical modification method, and polar groups are formed on the frame of the polymeric adsorbent by introducing the hydroxyl-containing monomer for modification, so the adsorption of an adsorbent substance by the polymeric adsorbent is increased. The preparation method provided by the invention is simple and the substances harmful to human body such as chloromethyl ether and the like and pore-forming agents are not used in the method. Experimental results show that the polymeric adsorbent prepared by the invention has the advantages of high specific surface area, small aperture, high adsorption selectivity and particularly high capacity of absorbing aromatic compounds.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

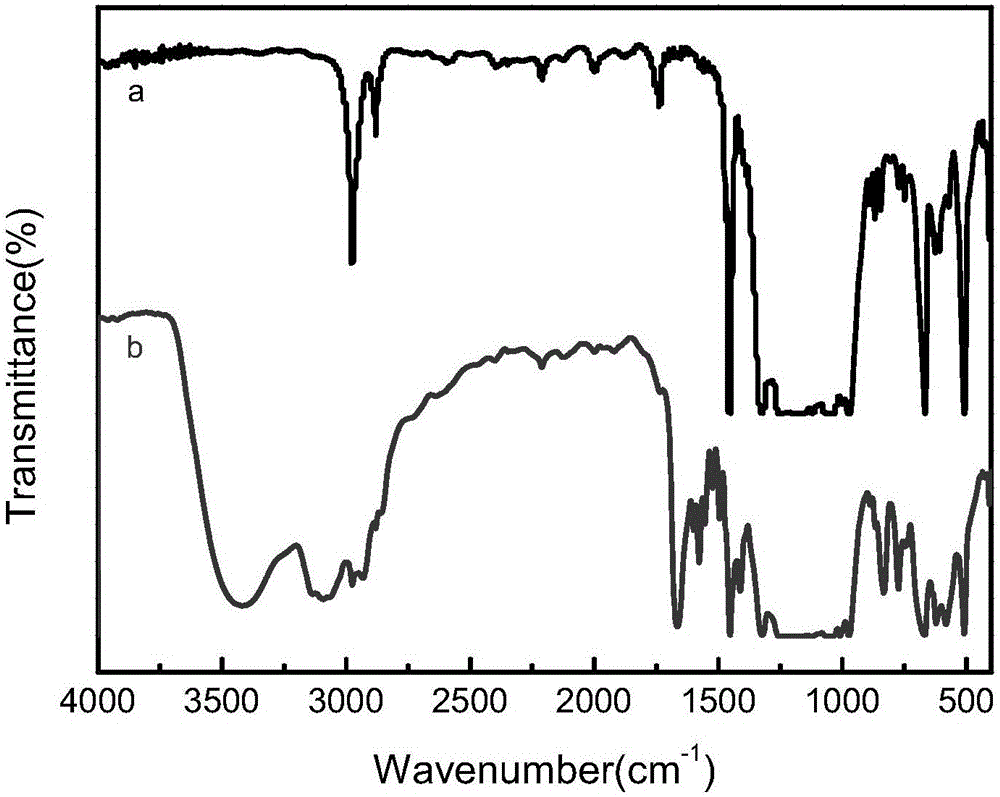

Ultrahigh cross-linked macro-porous adsorption resin applicable to removal of patulin

ActiveCN103772573ADense channelsUnique Pore Size DistributionIon-exchange process apparatusOther chemical processesCross-linkFunctional monomer

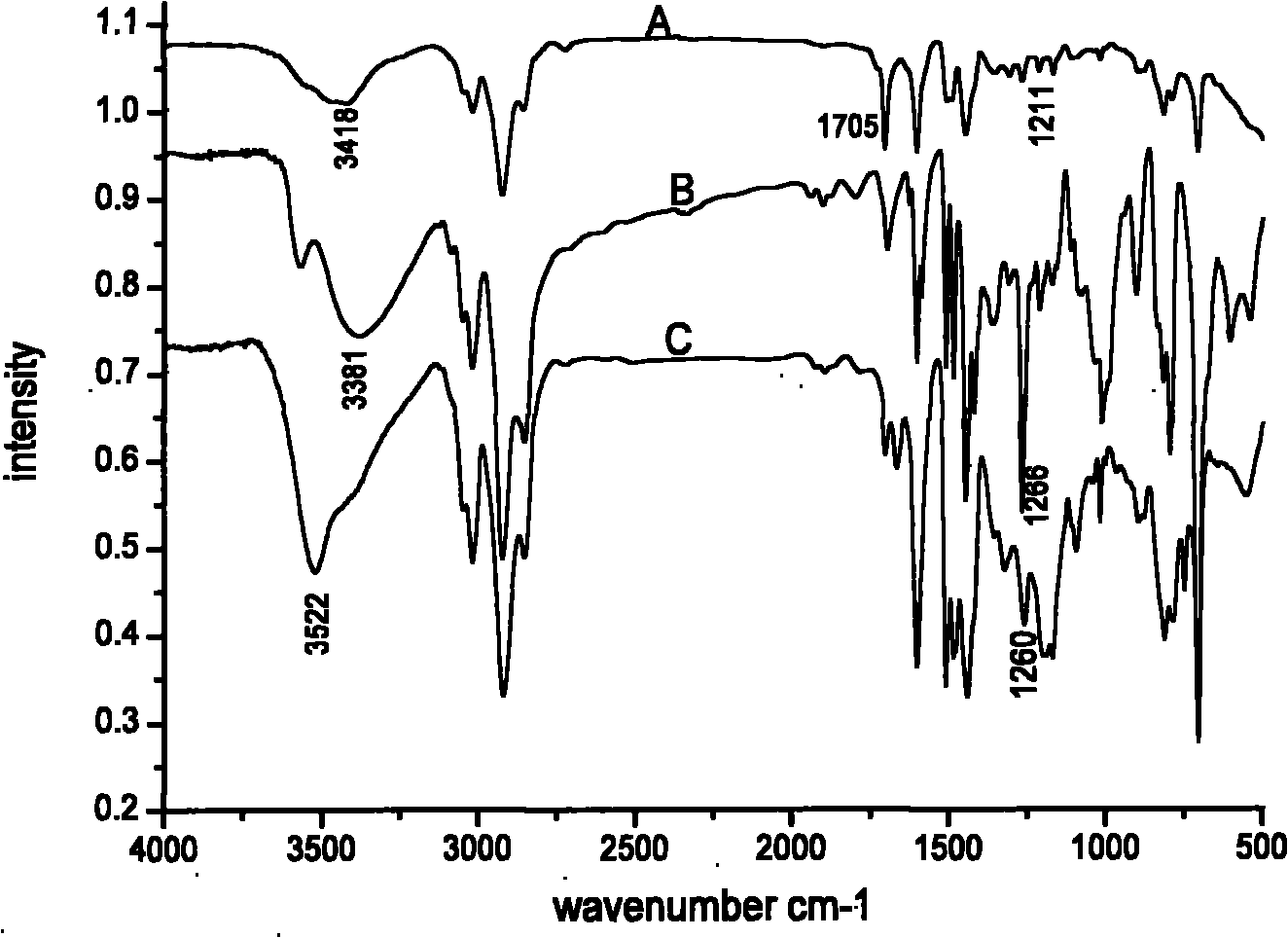

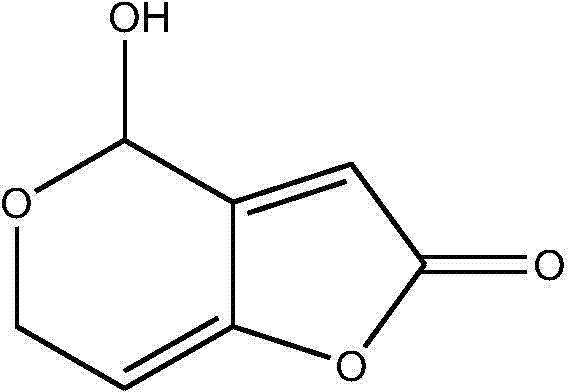

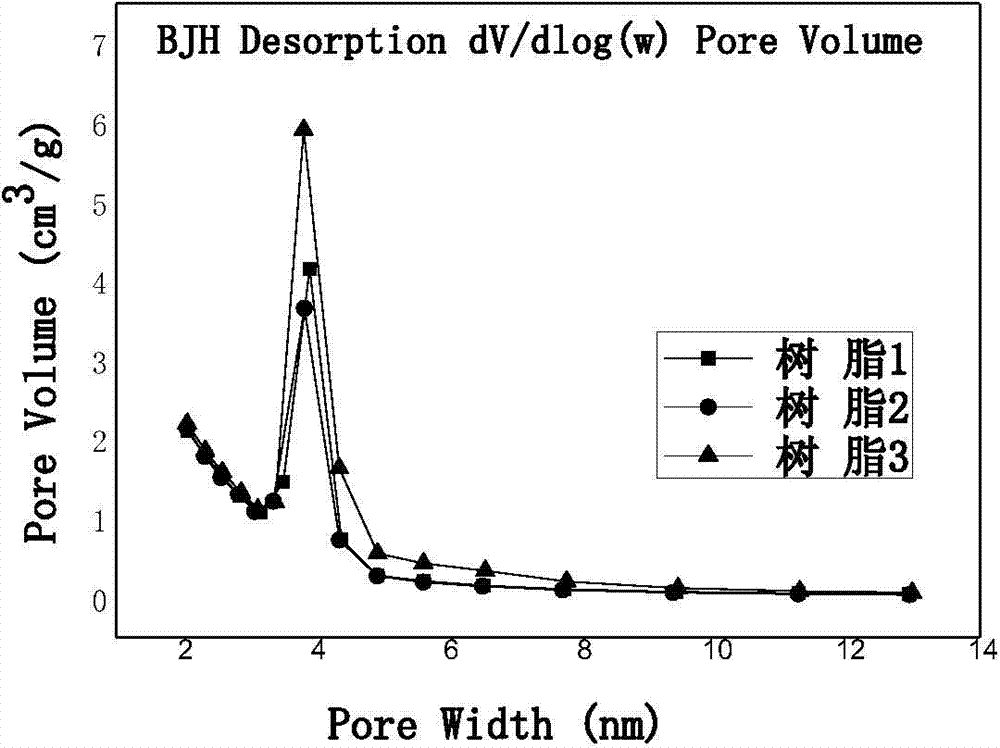

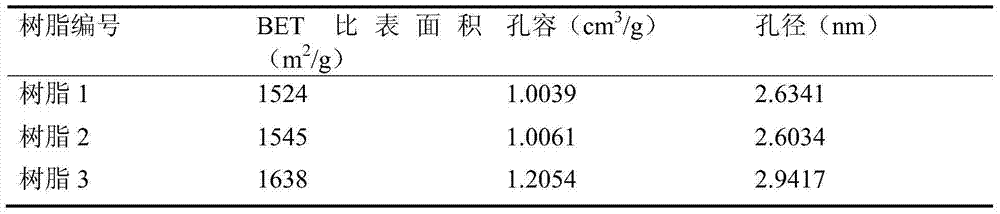

The invention provides ultrahigh cross-linked macro-porous adsorption resin which is obtained by taking a styrene monomer as a functional monomer, taking a multi-vinyl monomer as a cross-linking agent, suspending and polymerizing in the presence of a pore forming agent to obtain low-cross-linked macro-porous polystyrene white ball, reacting the obtained white ball with chloromethyl ether under the catalysis of lewis acid to obtain chloromethylation macro-porous polystyrene resin, and carrying out a Friedel-Crafts alkylation reaction on the obtained chloromethylation macro-porous polystyrene resin in the presence of a swelling agent by taking the lewis acid as a catalyst. Through adopting a novel cross-linking agent and pore forming agent system, the obtained resin has the advantages of high specific surface area and uniform pore diameter; the specific surface area is up to 1500-1800m<2> / g, the pore diameter distribution is uniform, a pore channel is dense and the average pore diameter is small; the pore diameter of the obtained macro-porous resin is rightly applicable to removal of patulin in juice and the removing efficiency is high; the resin can be used for pointedly removing the patulin which stably exists in the juice and the potential hazards on the human health, caused by the patulin in the juice, are solved; the ultrahigh cross-linked macro-porous adsorption resin has great social and economic benefits.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

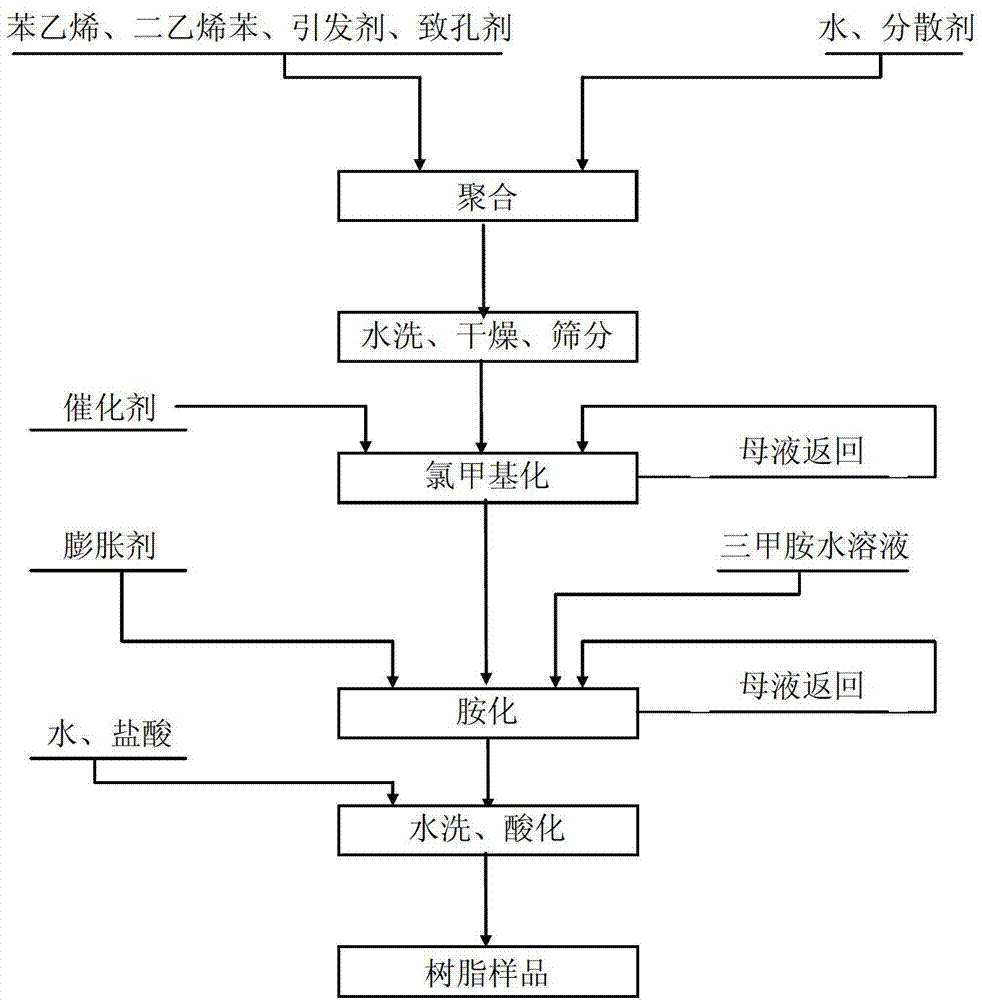

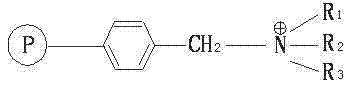

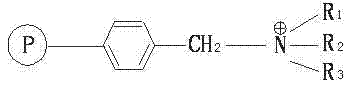

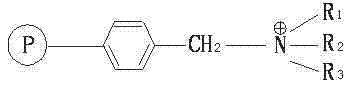

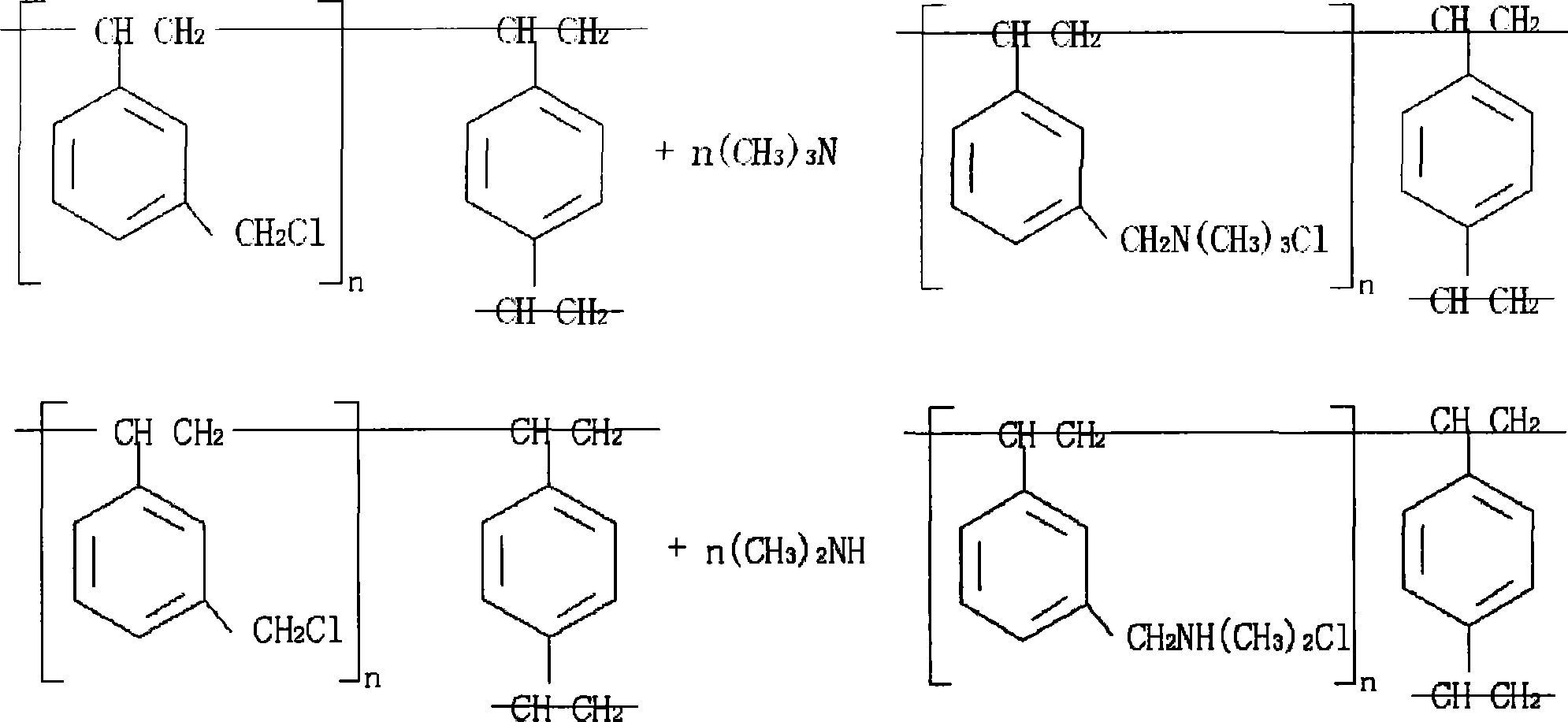

Preparation method of ion exchange resin

InactiveCN102898569AReduce consumptionGood rinse effectAnion exchangersChloromethyl EtherIon exchange

The invention provides a preparation method of an ion exchange resin, which comprises the following steps: (1) mixing a dispersant solution and an organic phase, and gradually heating to carry out polymerization reaction; (2) adding chloromethyl ether into the obtained white ball, and adding a catalyst zinc chloride to carry out chloromethylation reaction; and (3) adding methanol into the obtained chlorine ball, dropwisely adding a trimethylamine water solution, adding a 10% sodium chloride solution, adding hydrochloric acid for neutralization, and washing with water to obtain the resin. The ion exchange resin provided by the invention has the advantages of favorable selectivity, high uranium adsorption capacity and high exchange speed.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

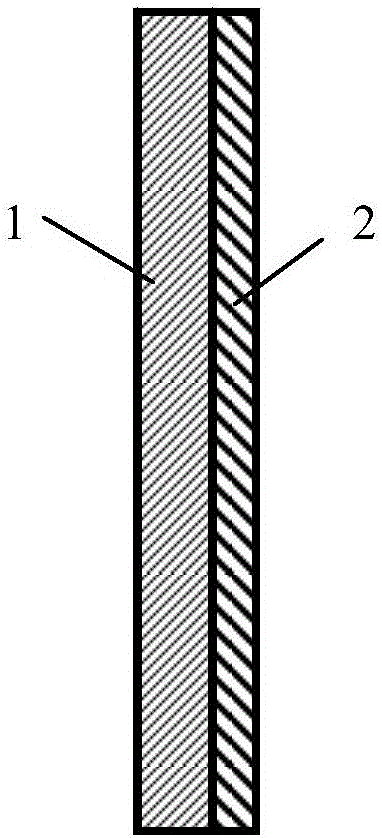

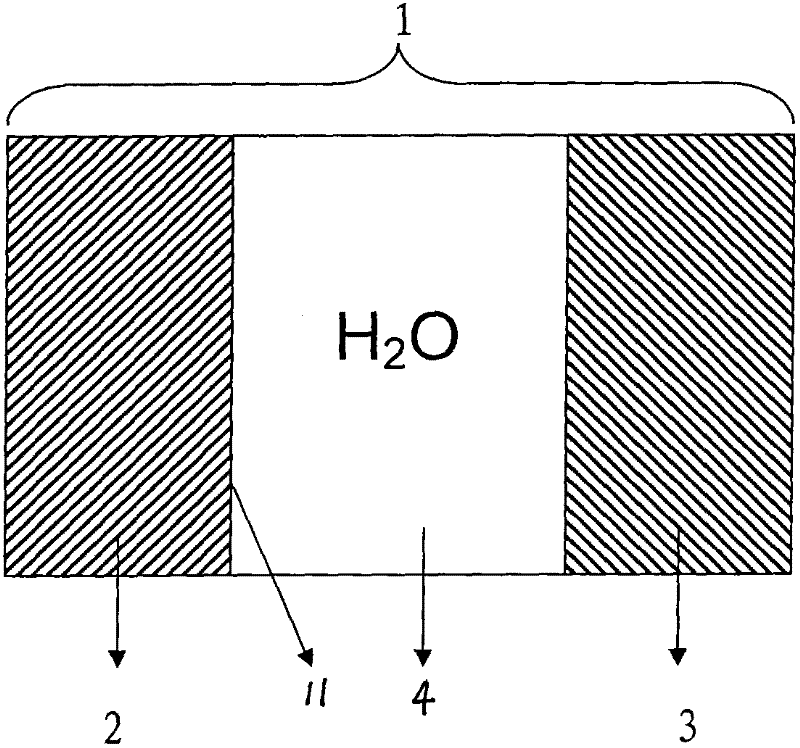

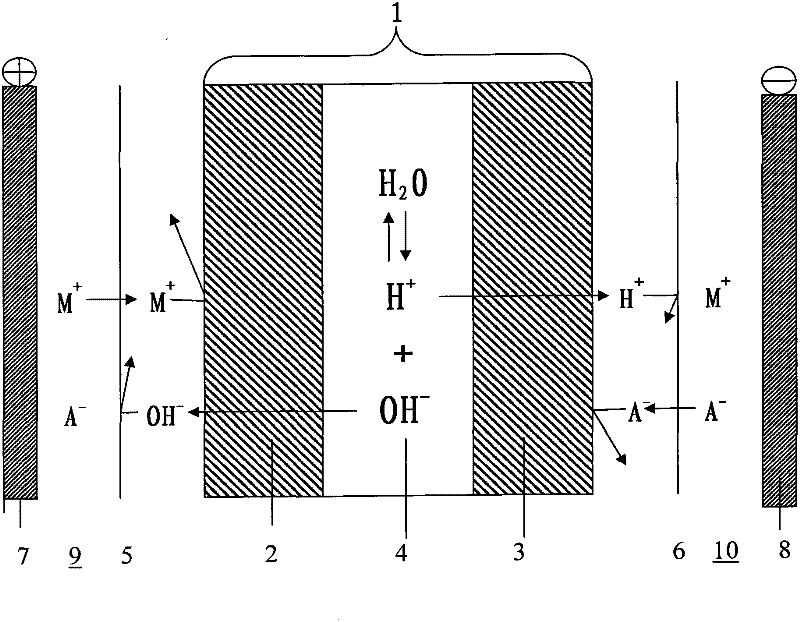

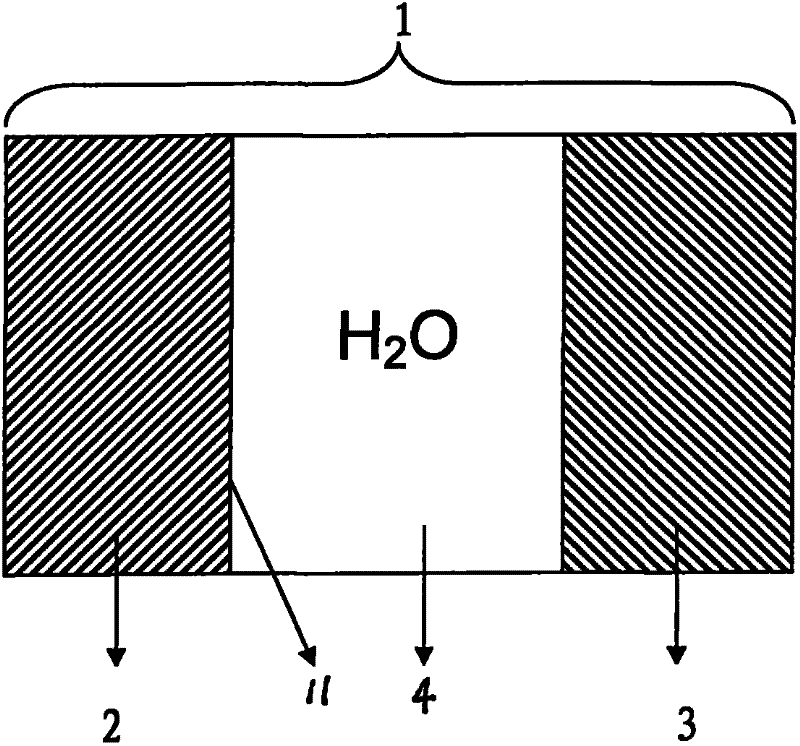

Single-sheet type bipolar membrane and preparation method thereof

InactiveCN105833737AEliminate film forming processImprove thermal stabilityMembranesSemi-permeable membranesChloromethyl EtherHeat stability

A monolithic bipolar membrane and a preparation method thereof relate to functional polymer membrane materials. The monolithic bipolar membrane includes a cation exchange layer and an anion exchange layer. Preparation method 1: basement membrane pre-irradiation; simultaneous grafting on both sides; sulfonation; quaternization. Preparation method two: basement membrane pre-irradiation; double-sided step-by-step grafting; sulfonation; quaternization. The preparation of bipolar membranes by radiation grafting technology not only saves the film-forming process in the traditional bipolar membrane preparation process, but also does not need to add initiators and catalysts during the grafting process, and the prepared bipolar membranes are very uniform and pure. The steps are simple, and the thermal stability and chemical stability of the film are better. Even if it is used for a long time, there will be no problems such as bubbling and cracking in the middle interface layer that are easy to occur during the use of composite bipolar membranes. Good mechanical properties, thermal stability and chemical stability. Avoid the use of strong carcinogenic reagents such as chloromethyl ether, and reduce the harm to the human body and the environment.

Owner:XIAMEN UNIV

A kind of 6-aminopyridine-3-carboxylic acid chelating resin and preparation method thereof

ActiveCN102295723AHigh stability constantGood choiceOther chemical processesPolymer scienceChloromethyl Ether

The invention discloses a 6-aminopyridine-3-carboxylic acid chelating resin and its preparation method, which belongs to the field of chelating resin. The resin has a following structural unit: a functional group is 6-aminopyridine-3-carboxylic acid, wherein the color is yellowish, the particle size is 0.45-0.6 mm, the content of the functional group is 1.37-2.38 mmol / g. The preparation method comprises the following steps: using styrene as a monomer, employing a suspension polymerization method to prepare a low crosslinking degree macroporous styrene-divinylbenzens copolymer, air-flow dryingto obtain low crosslinking macroporous polystyrene-divinylbenzens resin (white ball for short); immersing the white ball in chloromethyl ether, adding zinc chloride as a catalyst, carrying out a chloromethylation reaction to obtain chloromethylated low crosslinking polystyrene-divinylbenzens resin (chlorine ball for short); taking N,N-dimethyl formamide as a swelling agent, taking DMF as a swelling agent to swell the chlorine ball, dissolving 6-aminopyridine-3-carboxylic acid and sodium carbonate in N, N-dimethyl formamide for reaction, then adding the above swelled chlorine ball, stirring for reacting to prepare 6-aminopyridine-3-carboxylic acid chelating resin. The resin prepared by the invention is suitable for selectively absorbing and separating heavy metal ions of copper and the like.

Owner:NANJING UNIV

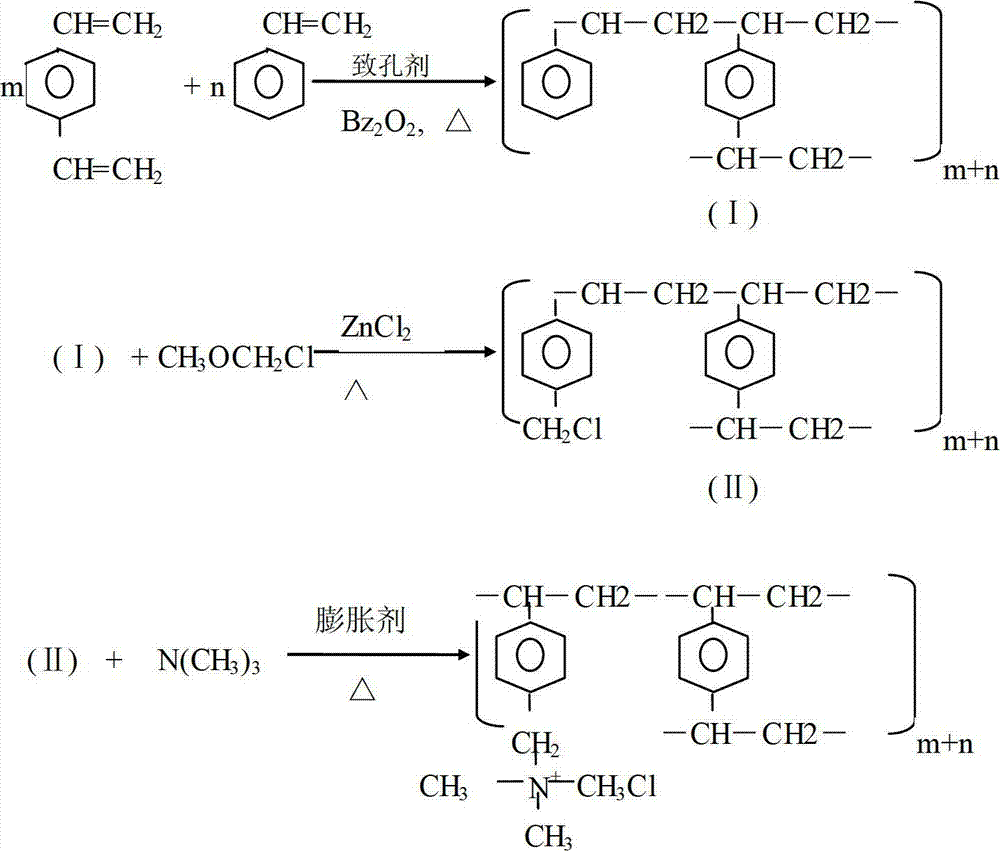

Method for manufacturing monolithic bipolar membrane

ActiveCN102061004BIncrease elasticityImprove flexibilitySemi-permeable membranesElastomerBenzoyl peroxide

The invention relates to a method for manufacturing a monolithic bipolar membrane, which comprises the following steps of: immersing a substrate membrane in a solution containing styrene, divinybenzene and benzoyl peroxide, pressurizing the immersed membrane, wherein the substrate membrane is a thin alloy membrane formed by two-element blending of polyethylene and ethylene-octylene copolymer elastomer or by three-element blending of polyethylene, ethylene-octylene copolymer elastomer and polyisobutylene rubber; and pressurizing the membrane immersed in the solution and polymerizing under the condition of heating to obtain a base membrane; sulfonating one side face of the base membrane by heating in concentrated sulfuric acid; performing chloromethylation reaction of the membrane with one sulfonated side face in chloromethyl ether containing anhydrous stannic chloride so that the other side face of the membrane is chloromethyl; and immersing the membrane in a trimethylamine aqueous solution or a trimethylamine aqueous solution containing dimethylamine to carry out an aimination or quaterisation reaction to obtain the monolithic bipolar membrane. The method has the advantages that the immersing temperature is greatly reduced, the styrene and divinybenzene solution can be repeatedly used, and the electric resistance of the bipolar membrane is low. The bipolar membrane has a catalytic layer for accelerating water decomposition, the method is simple and convenient and is easy for large-scale industrialized production.

Owner:福建省延润膜环保科技有限公司

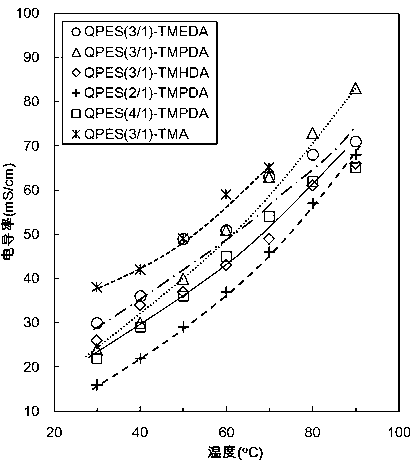

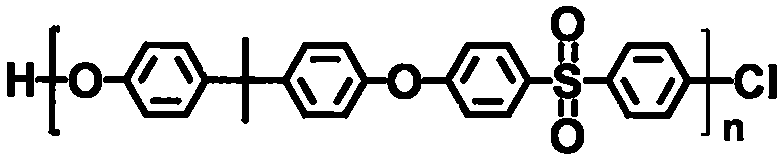

Preparation method of side chain crosslinked polymer and side chain crosslinked polymer anion exchange membrane of side chain crosslinked polymer

The invention discloses a preparation method of a side chain crosslinked polymer and a side chain crosslinked polymer anion exchange membrane of the side chain crosslinked polymer. The invention mainly comprises the steps of the preparation of a polyether sulfone polymer precursor, the preparation of a chloromethyl ether sulfone polymer and the preparation of the side chain crosslinked polymer anion exchange membrane. The preparation process provided by the invention has the advantages of simplicity, and controllable ion exchange capacity and degree of crosslinking. Compared with the existing non-crosslinked membrane, the membrane prepared by the method provided by the invention has the advantages of uniform structure, good stability of size and high ion conductivity under a lower IEC (ion-exhange column chromatography) level.

Owner:NANJING UNIV OF SCI & TECH

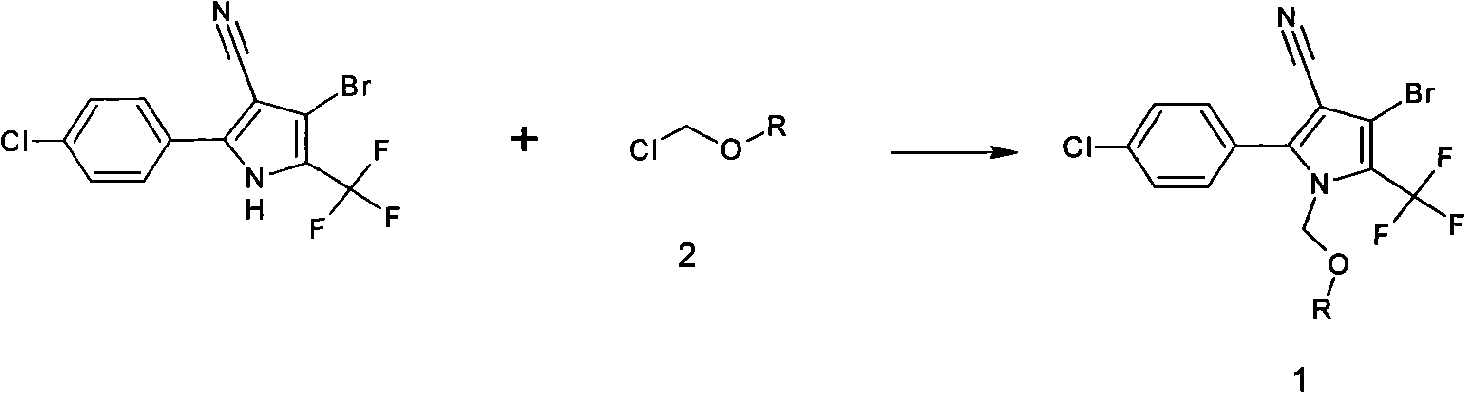

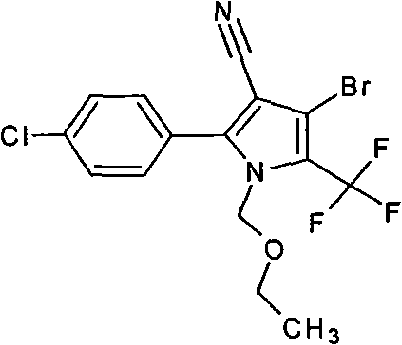

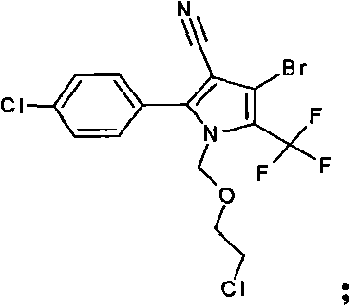

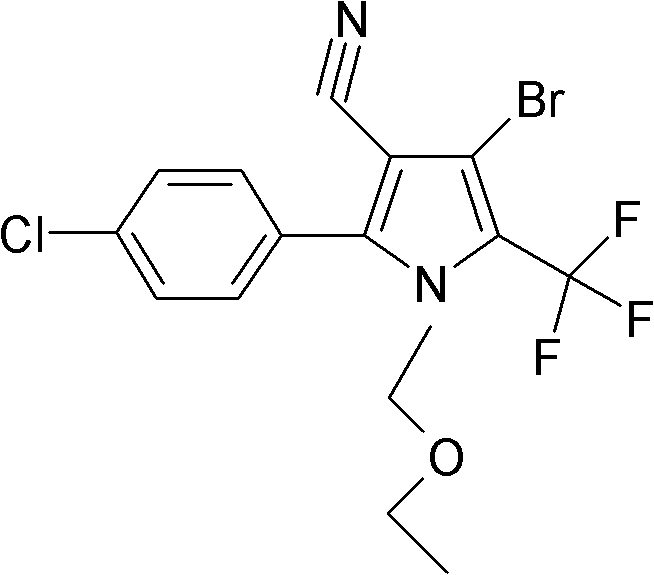

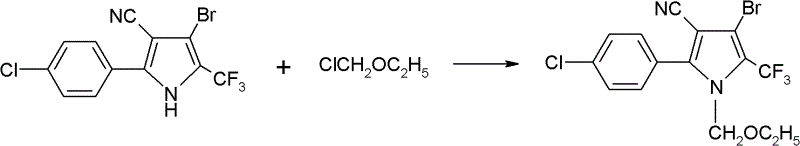

Method for preparing chlorfenapyr and analog thereof

ActiveCN101591284ASimple processMild reaction conditionsOrganic chemistryChemical reactionKetone solvents

The invention discloses a method for preparing chlorfenapyr and analog thereof by using 4-bromo-2-(4-chlorphenyl)-5-trifluoromethylpyrrole-3-nitrile and chloromethyl ether as raw materials in the presence of ketones solvent and inorganic alkali acid-binding agent. The chemical reaction formula is as above. The method for synthesizing the chlorfenapyr and the analog thereof by adopting the ketones solvent and the inorganic alkali acid-binding agent has the advantages of simple process, mild reaction condition, low production cost and the like, and has good industrial application prospect.

Owner:HUNAN CHEM RES INST

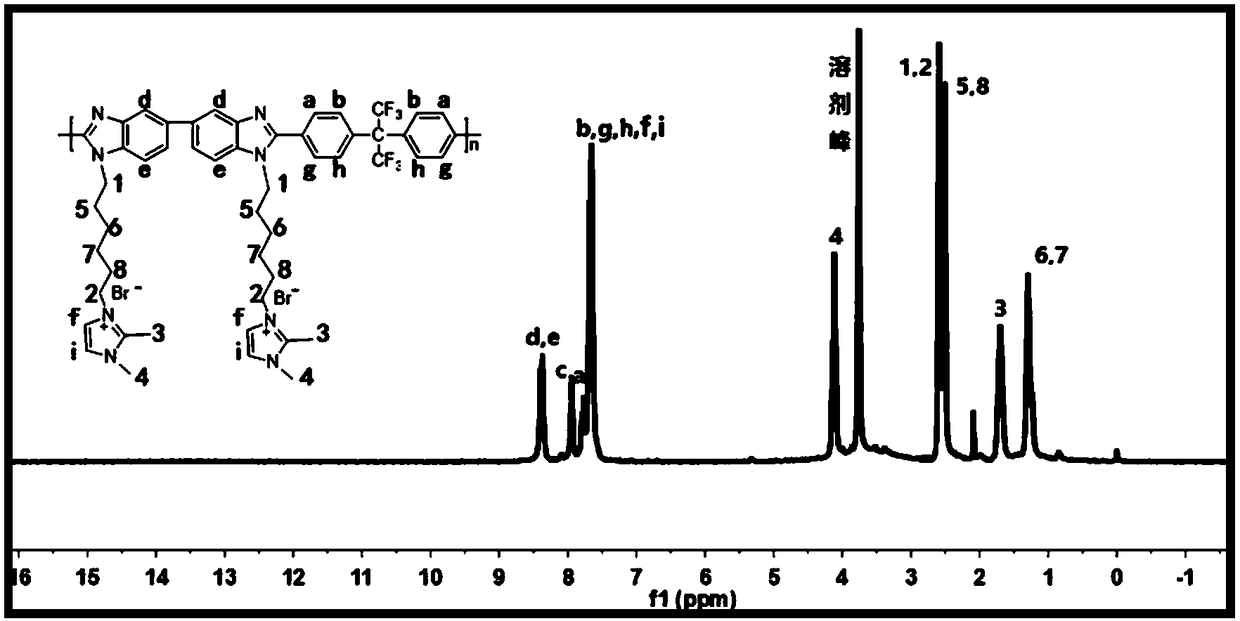

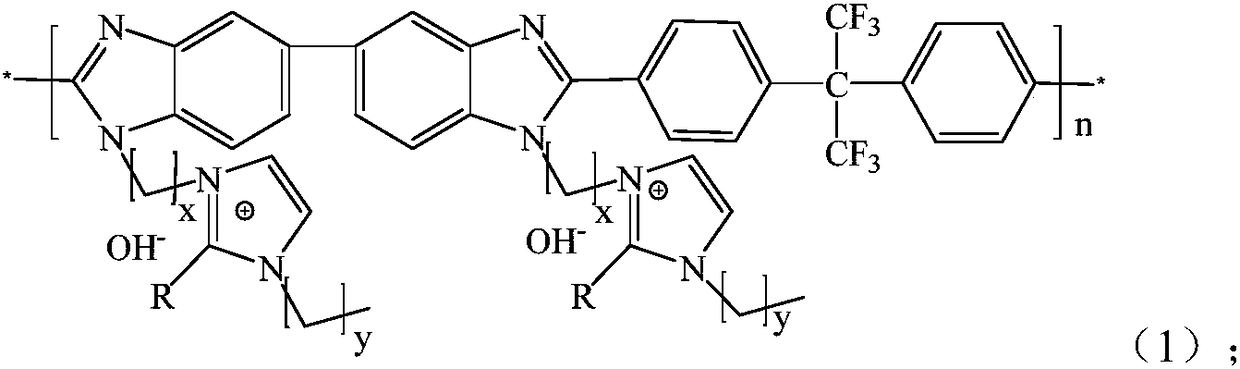

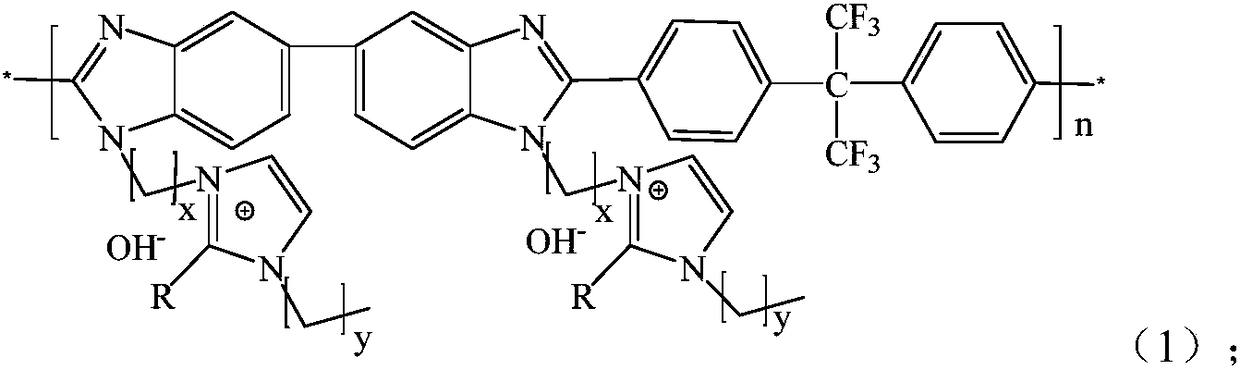

Anion exchange membrane based on fluorinated polybenzimidazole and preparation method of anion exchange membrane

ActiveCN108586745AImprove mechanical propertiesGood alkali resistanceFuel cellsSubstance usePolymer science

The invention relates to an anion exchange membrane based on fluorinated polybenzimidazole and a preparation method of the anion exchange membrane. The general structure formula of the anion exchangemembrane based on the fluorinated polybenzimidazole comprises a repetitive unit as shown in formula (1), in formula as shown in specification, n is degree of polymerization; x is an integer of 2-12, yis an integer of 0-11; and R is H, methyl, ethyl, isopropyl or phenyl. The prepared membrane has excellent mechanical property, alkali resistance, heat resistance, low water absorption and high electrical conductivity; and moreover, the preparation process of the membrane is relatively simple and safe, and chloromethyl ether as a cancerogenic substance used in a preparation process of a traditional quaternary ammonium salt type anion membrane is avoided.

Owner:CHANGZHOU UNIV

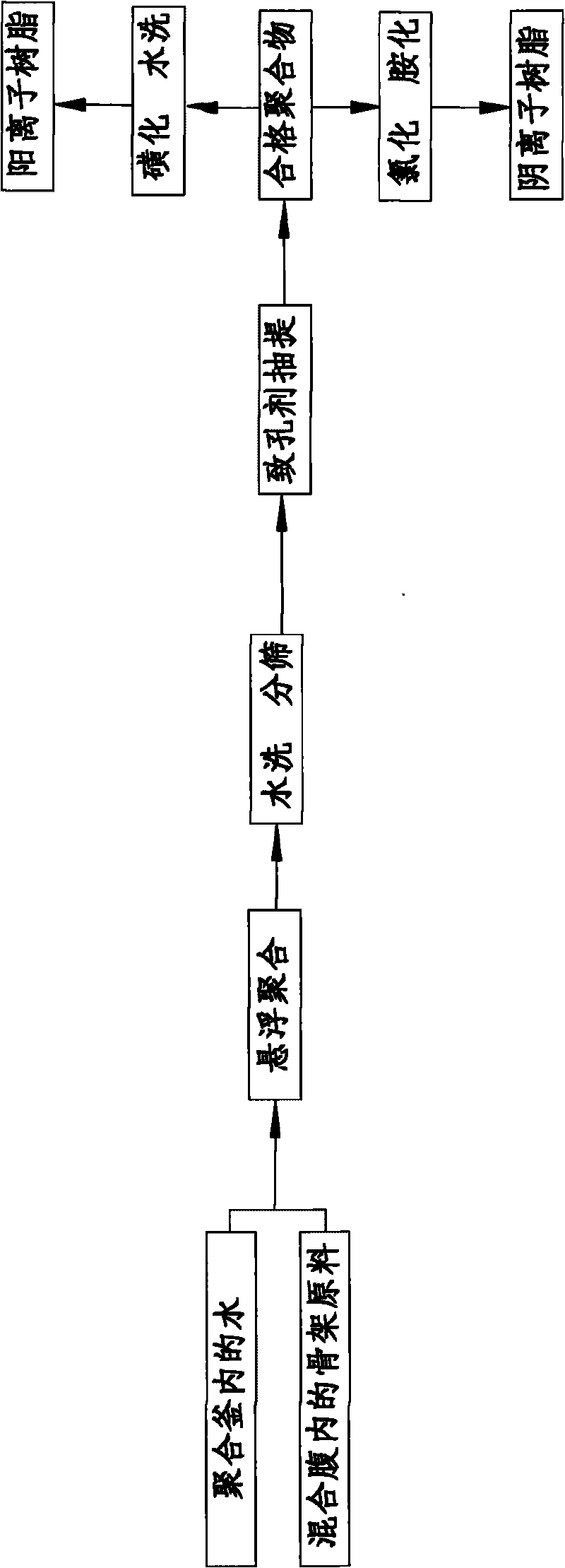

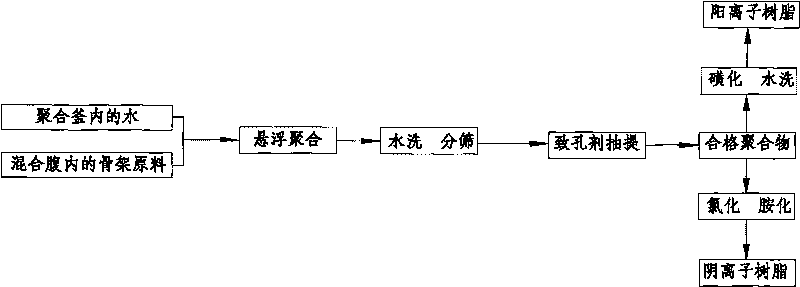

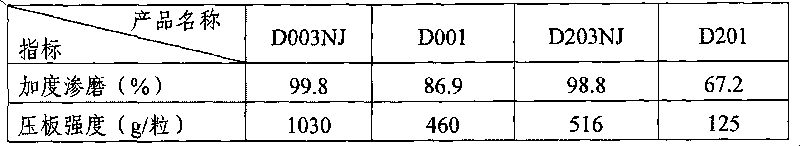

Dedicated ion exchange resin for condensed water precision processing and preparation method thereof

InactiveCN101703950AGood resistance to organic matterHigh mechanical strengthCation exchanger materialsWater/sewage treatment by ion-exchangeBenzoyl peroxidePolyvinyl alcohol

The invention discloses a dedicated ion exchange resin for condensed water precision processing and a preparation method thereof. The resin comprises a framework polymerized by styrene and divinylbenzene; the framework is connected with a cationic functional group taking concentrated sulfuric acid and dichloroethane as main components or an anionic functional group taking chloromethyl ether, trimethylamine and zinc chloride as man components; the functional group also contains sodium hydroxide, benzoyl peroxide, polyving akohol, solid paraffin, cyclohexane and sodium chloride; and the appearance of the ion exchange resin is in ball shape. The preparation method comprises the following steps: evenly mixing raw materials, carrying out polymerization reaction, then extracting, sulfonating or chloridizing and alinating; and finally post-processing. The resin has favorable heat resistance and oxidation resistance, anti-seepage strength and granularity uniformity, organic matter resistance, high mechanical strength and simple preparation process and the like.

Owner:JIANGSU SUQING WATER TREATMENT ENG GROUP

Hyper cross-linking resin as well as preparation method and application thereof

InactiveCN105884956ASimple production methodReduced compatibilityOther chemical processesAlkali metal oxides/hydroxidesCross-linkOrganic acid

The invention discloses hyper cross-linking resin which is prepared by taking alpha methyl styrene and divinylbenzene as raw materials, changing the cross-linking degree or adding different pore-foaming agents, performing suspension polymerization so as to obtain aperture controllable gel type and porous precursor resin, enabling the precursor resin to react with a catalyst in a swelling state, performing Friedel-Crafts reaction, thereby obtaining the hyper cross-linking resin with a high specific surface area, a large pore volume and a controllable aperture. The invention further discloses a preparation method and application of the hyper cross-linking resin. Compared with the prior art, the preparation method is simple, carcinogenic substances such as chloromethyl ether is not adopted for chloromethylation, the cost is low, industrial production can be achieved, and the prepared hyper cross-linking resin is relatively good decoloring effect on organic acid.

Owner:NANJING UNIV OF TECH

Synthetic method of strong-basic anion exchange resin used in compact bed

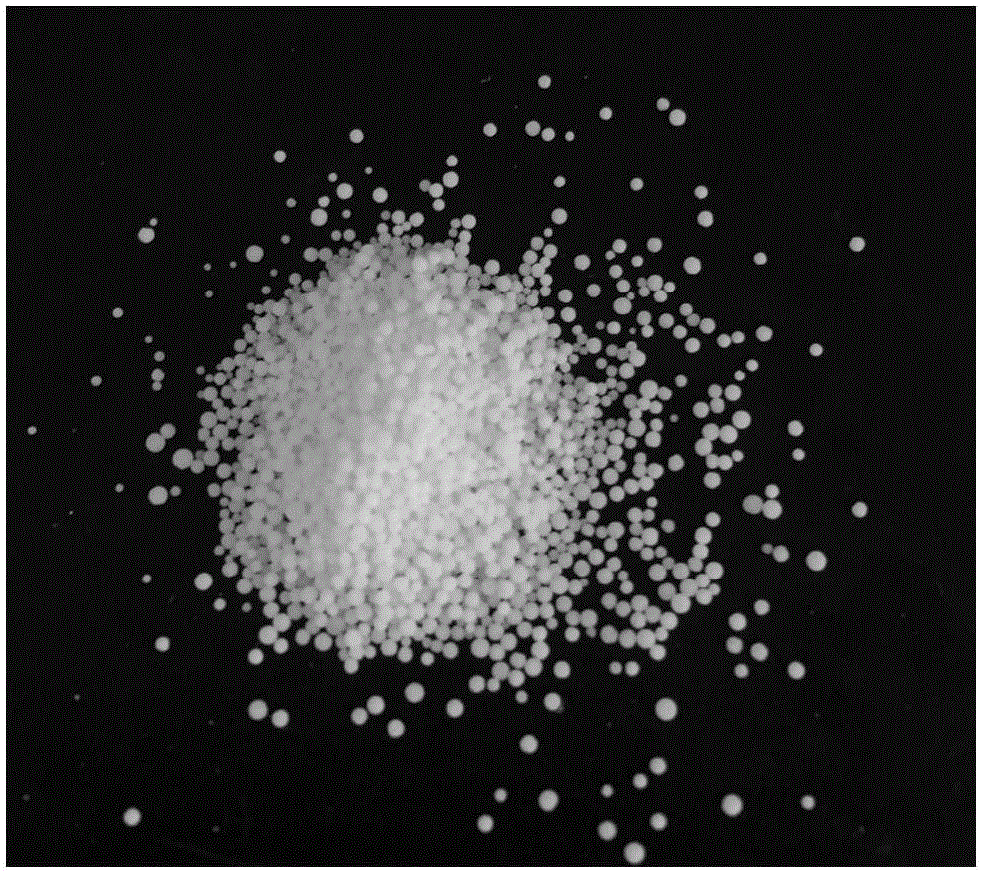

ActiveCN106243265ANovel granularityFine and uniform particle sizeAnion exchangersPolymer scienceChloromethyl Ether

The invention belongs to the technical field of synthetic methods of ion exchange resin and especially relates to a synthetic method of strong-basic anion exchange resin used in a compact bed. The synthetic method includes the steps of: 1) synthesizing a crosslinked polystyrene white sphere framework being 100-150 nm in particle size on the surface of inert crystal nucleus in a homogenous-phase wet chemical manner; adding chloromethyl ether as a chloromethylation reagent to carry out a Friedel-Crafts reaction to benzene rings in the styrene in the crosslinked polystyrene white spheres to obtain an intermediate product A; 2) performing an amination reaction to the intermediate product A with a tertiary amine containing a long carbon chain to generate the strong-basic anion exchange resin being 180-280 [mu]m in particle size. The framework synthetic method is novel and unique. The exchange resin is fine and uniform in particle size, has large specific surface area, is short in diffusion path and has high exchange speed during exchange, and is low in cost and has good application effects. The exchange resin can satisfy application demands in the compact bed.

Owner:ZHEJIANG XINGYU ENVIRONMENTAL TECH CO LTD

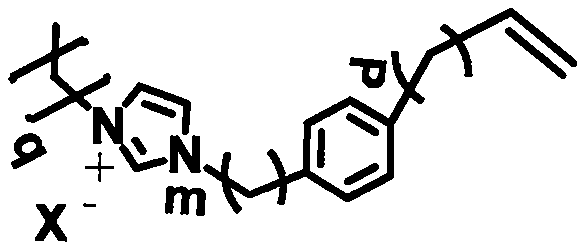

Polymer anion exchange membrane based on imidazole onium salt and preparation method thereof

InactiveCN103035932AReduce usageAvoid damage phenomenonAnion exchangersCell component detailsChloromethyl EtherPolymer solution

The invention discloses a polymer anion exchange membrane based on imidazole onium salt and a preparation method thereof, and relates to an ion exchange membrane and a preparation method thereof. The preparation method comprises the following steps of: (1) synthesizing of an imidazole onium salt polymer through a radical copolymerizationic compound: adding a monomer A, a monomer B, a vehicle and an initiating agent in a reactor, carrying out sealing and a heating regurgitation reaction under the inert gas protection, and drying and washing a product to obtain the imidazole onium salt polymer; and (2) membrane formation: dissolving the obtained imidazole onium salt polymer in step (1) in an organic solvent to prepare a polymer solution, 5%-10% of mass percent concentration, casting to form a membrane through a phase inversion method, and drying to obtain the polymer anion exchange membrane based on the imidazole onium salt, wherein the imidazole onium salt polymer accounts for 5-10% of the organic solvent. The polymer anion exchange membrane provided by the invention has the advantages that the preparation method is simple, the cost is lower, the electric conductivity is higher, the anion exchange membrane has good heat stability and chemical stability, meanwhile, the use of chloromethyl ether in the traditional polymeric compound anion exchange membrane preparation process is avoided, and the polymer anion exchange membrane can reduce harms to human bodies and environment.

Owner:XIAMEN UNIV

Synthetic method of high temperature-resistant strongly basic anion exchange resin

InactiveCN103755846AImprove thermal stabilityThe synthesis process is simpleAnion exchangersPolymer scienceChloromethyl Ether

The invention relates to a synthetic method of strongly basic anion exchange resin, and particularly relates to a synthetic method of high temperature-resistant strongly basic anion exchange resin containing a long-carbon chain alkylamine group. A crosslinked polystyrene white ball is adopted as a skeleton, chloromethyl ether is adopted as an alkylating reagent to graft benzyl chloride on the white ball skeleton by Fourier reaction, and amination reaction is carried out on the long-carbon chain alkylamine, so as to obtain the strongly basic anion exchange resin. The synthetic method has the advantages that the strongly basic anion exchange resin with relatively high heat stability can be synthesized by adopting a simple production technology and cheap materials, so that the strongly basic anion exchange resin can be applied to unit operation in a high-temperature environment, such as preparation of super-pure water in a semiconductor industry, high-temperature condensate refined treatment of a power plant, removal of silicic acid of water in a high-pressure boiler, and use under a high-temperature condition as a catalyst.

Owner:NINGBO ZHENGGUANG RESIN CO LTD +1

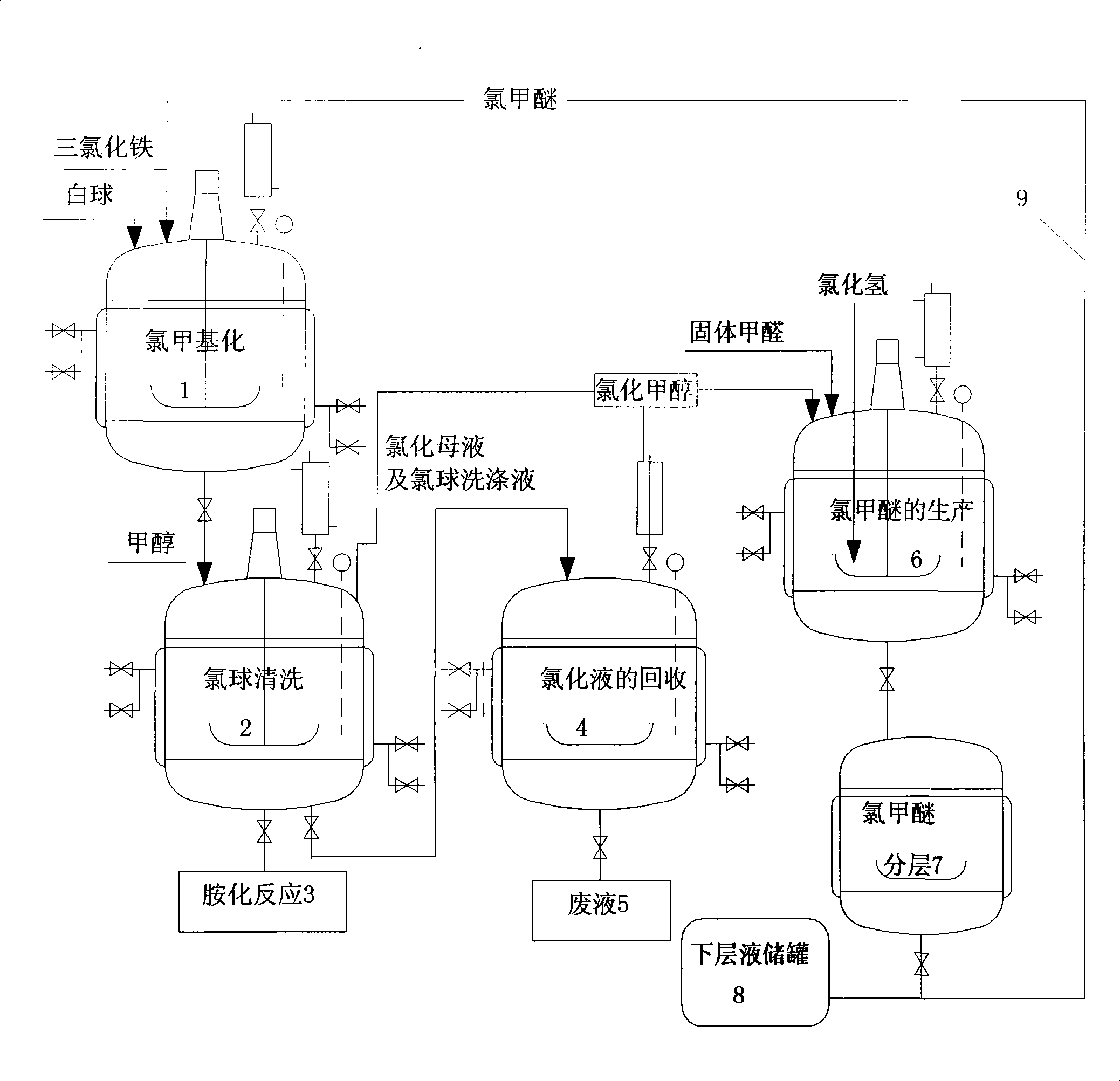

Recycling system of chlorination mother solution and recycling method thereof

InactiveCN101518747AEmission reductionReduce manufacturing costOrganic chemistryAnion exchangersChloromethyl EtherIon-exchange resin

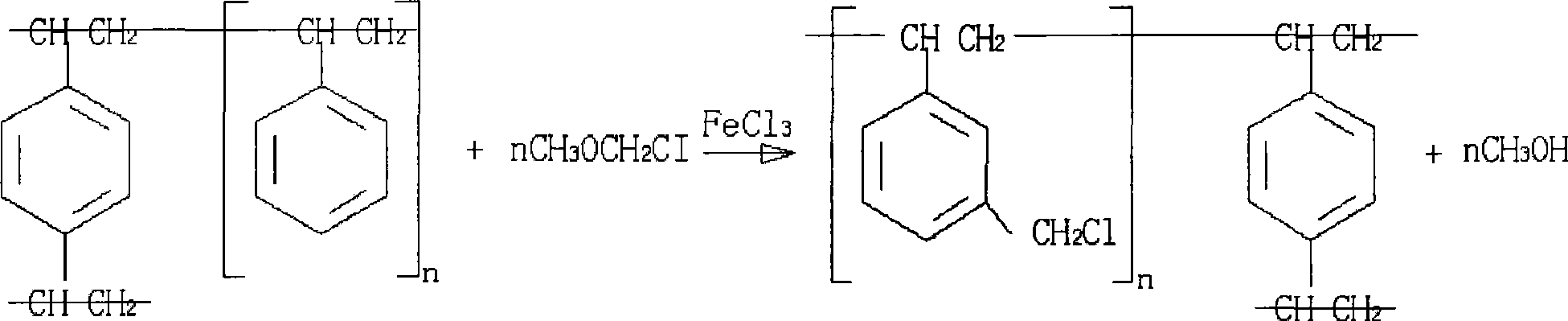

The invention relates to a recycling system of chlorination mother solution and a recycling method thereof in an automatic anion exchange resin production system, white ball and chloromethyl ether are sent to a chloromethylation reaction kettle respectively by an airflow transmitting system and pump transmission, stirring is carried out at normal temperature; after inflating, ferric trichloride dissolvable in the chloromethyl ether is added for catalysis, and exothermic reaction is generated, the adding speed of the chloromethyl ether is regulated according to temperature, chlorine ball is prepared after the temperature is raised to 48 DEG C and temperature insulation is carried out for 10 hours, temperature reduction is carried out, the separated chlorine ball is washed sequentially by chloride methanol for two times, and by methanol for one time; then, solid-liquid separation is carried out, solid-phase chlorine ball enters amination reaction, liquid-phase chlorination mother solution and chlorine ball cleaning solution enter a chlorination liquid recycling reaction kettle, chloride methanol generated in the chlorination liquid recycling reaction kettle enters a chloromethyl ether reaction kettle; and then, solid methanol and chlorine hydride are added in the chloromethyl ether reaction kettle for reaction, chloromethyl ether volatilized in the reaction process enters a chloromethylation reaction kettle after condensation by a condenser, and noncondensable gas enters an alkali spray tower for absorption treatment.

Owner:ZHEJIANG ZHENGGUANG IND

Diethylamine anion exchange resin and preparation method thereof

InactiveCN105153344ATroubleshoot Ion Exchange Performance IssuesAvoid secondary crosslinkingAnion exchangersPolymer scienceChloromethyl Ether

The invention relates to a diethylamine anion exchange resin and a preparation method thereof, belonging to the technical field of anion exchange resins. The resin is prepared from the following raw materials in parts by weight: 10-20 parts of macroporous styrene-divinylbenzene copolymer microsphere, 100-120 parts of dichloromethane, 15-25 parts of anhydrous aluminum trichloride, 10-20 parts of chloracetyl chloride, 5-9 parts of chloracetylated resin, 50-60 parts of diethylamine, 50-60 parts of tetrahydrofuran and 3-12 parts of NaHCO3. Chloracetylation reaction is performed on crosslinked polystyrene microspheres by Friedel-Crafts reaction to introduce chloracetyl group, and amination is performed to obtain the weakly alkaline tertiary-amine anion exchange resin. The method avoids using chloromethyl ether and other carcinogenic substances, and avoids secondary crosslinking, polysubstitution and other side reactions.

Owner:BLUESTAR CHENGDU NEW MATERIALS

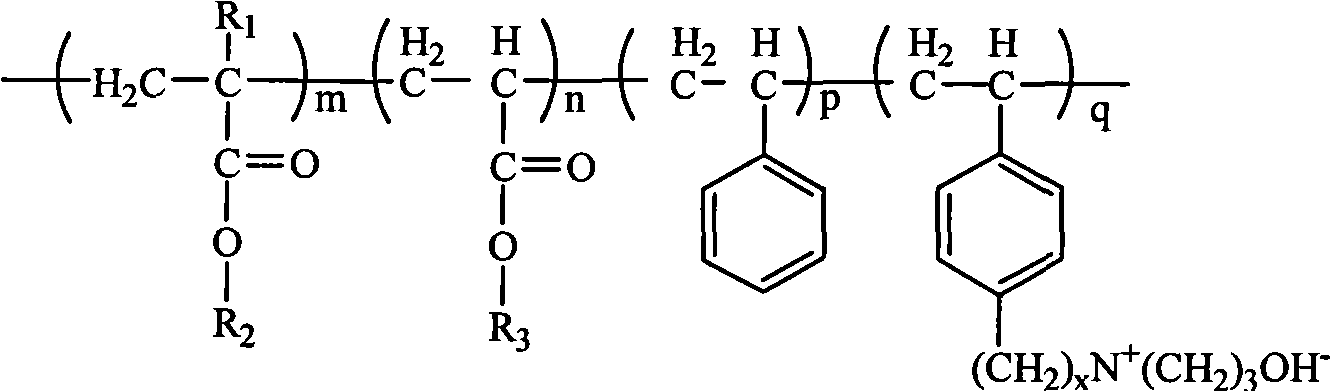

Alkaline polymer electrolyte membrane and preparation method thereof

InactiveCN102020820AReduce usageStable structure and performanceCell component detailsFuel cell detailsPolymer electrolytesPhosphonium

The invention relates to an alkaline polymer electrolyte membrane and a preparation method thereof, in particular to a method for preparing an alkaline polymer electrolyte membrane by preparing a quaternary random copolymer from styrene, 4-chloromethyl styrene, an alkyl acrylate monomer and an acrylic ester monomer as raw materials, and carrying out quaternization or quaternary phosphonium reaction and membrane forming. In the invention, the 4-chloromethyl styrene is directly adopted and chloromethyl ether is not used, thereby solving the problems of the additional crosslinking of methylenem, the pollution of a metal catalyst and the like. The prepared alkaline polymer electrolyte membrane has stable structural performance and good electrochemical stability, and the conductivity of the alkaline polymer electrolyte membrane reaches 10-3S / cm.

Owner:DONGHUA UNIV

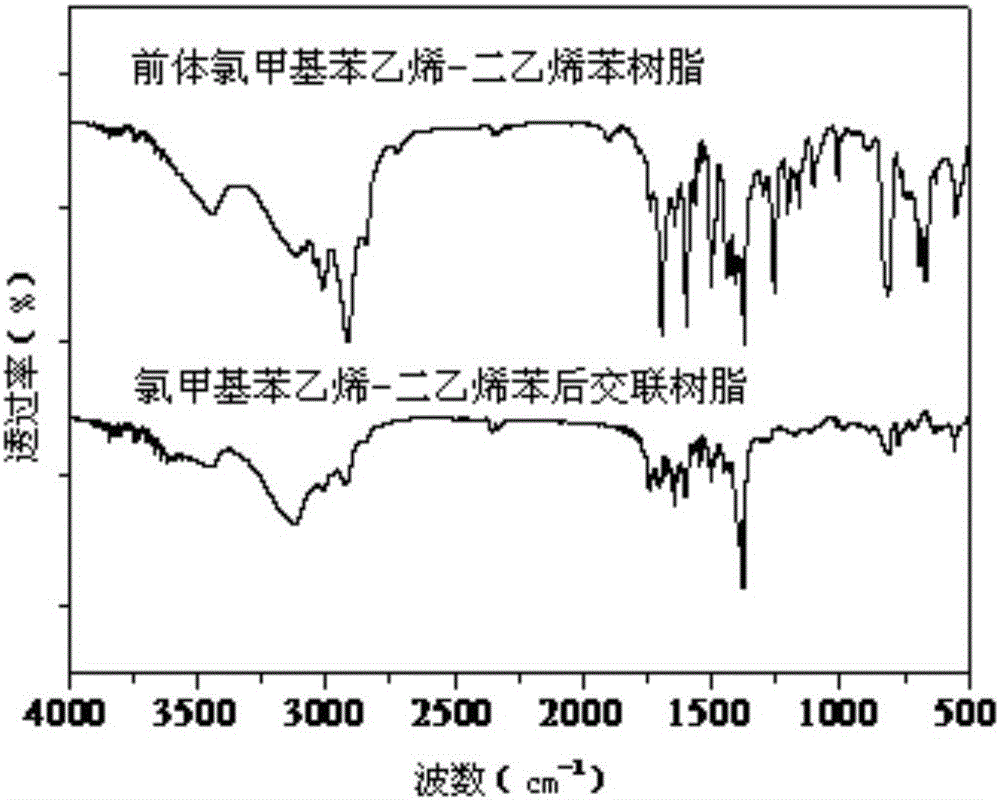

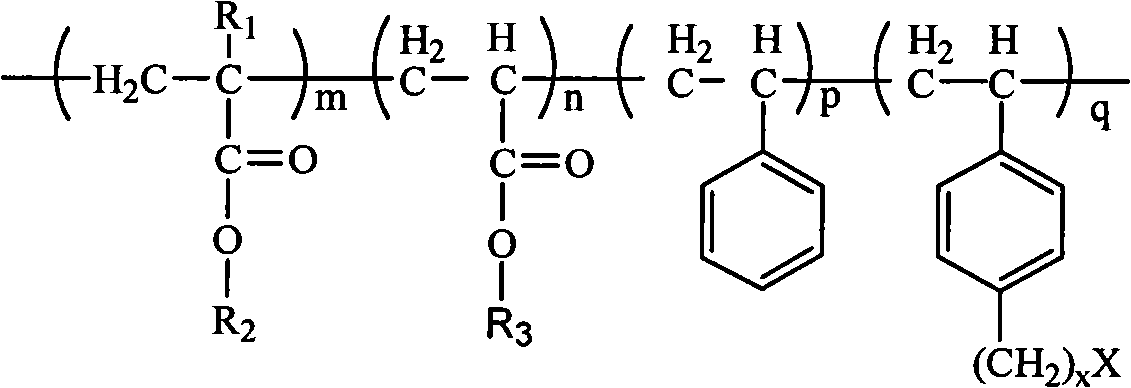

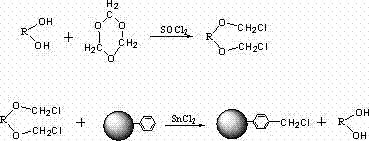

Preparation method of chloromethyl styrene resin

InactiveCN103709278AReduce manufacturing costMaintain personal safetySulfonyl chloridePolymer science

The invention discloses a preparation method of chloromethyl styrene resin. The preparation method is as follows: first reacting a long chain diol with trioxymethylene in the presence of dry hydrogen chloride, thionyl chloride or benzene sulfonyl chloride for preparing long chain chloromethyl ether; performing chloromethylation reaction of the obtained long chain chloromethyl ether and styrene resin in conditions of aluminum chloride, stannous chloride, concentrated sulfuric acid or titanium tetrachloride catalysis, filtering an obtained reaction liquid to obtain resin balls, and washing with a mixed solution to remove a surface catalyst to obtain the chloromethyl polystyrene resin. The preparation method of the chloromethyl styrene resin has the advantages of environmental protection and no pollution, at the same time, the used long chain diol also can be recycled, so that the preparation method has the characteristic of low production cost.

Owner:SHANGHAI INST OF TECH

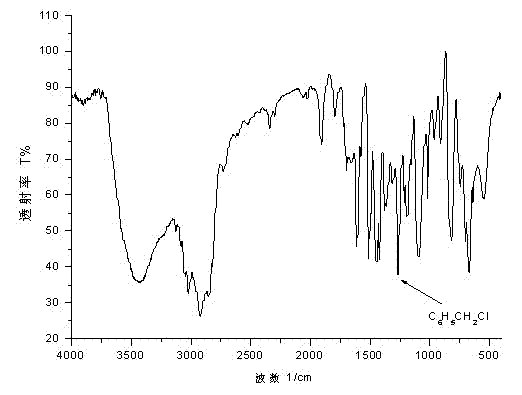

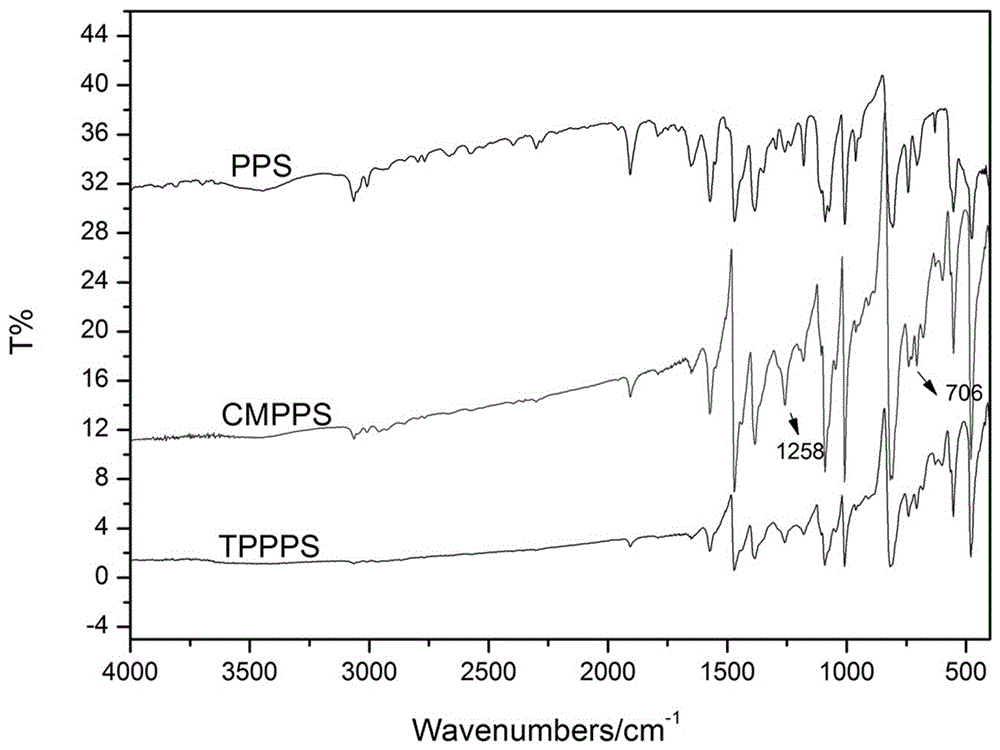

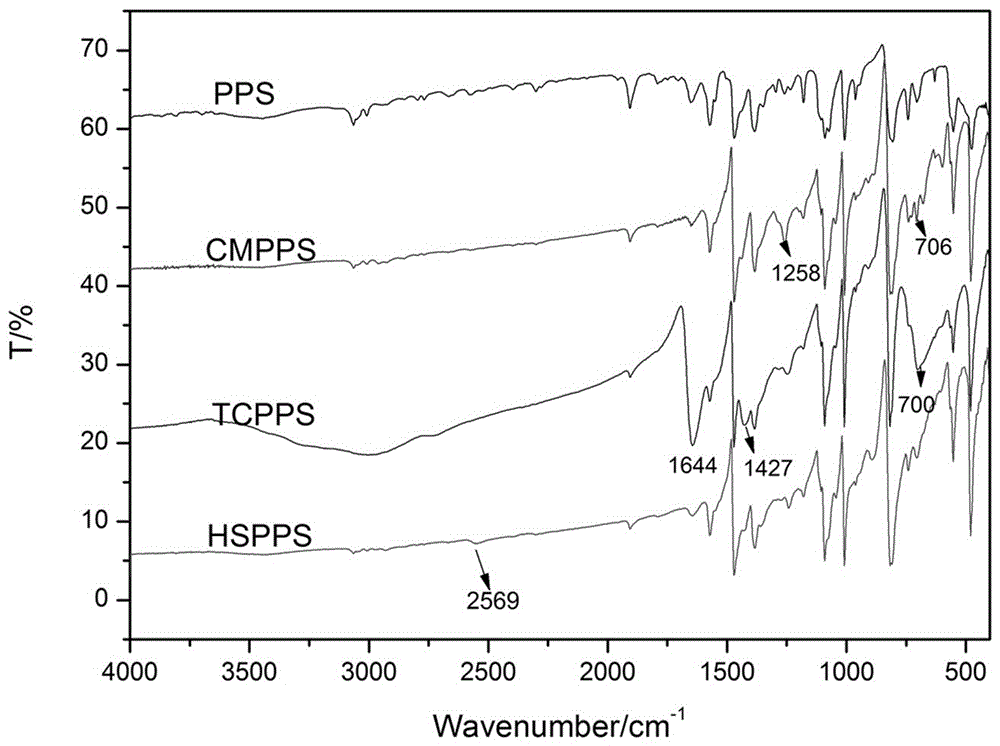

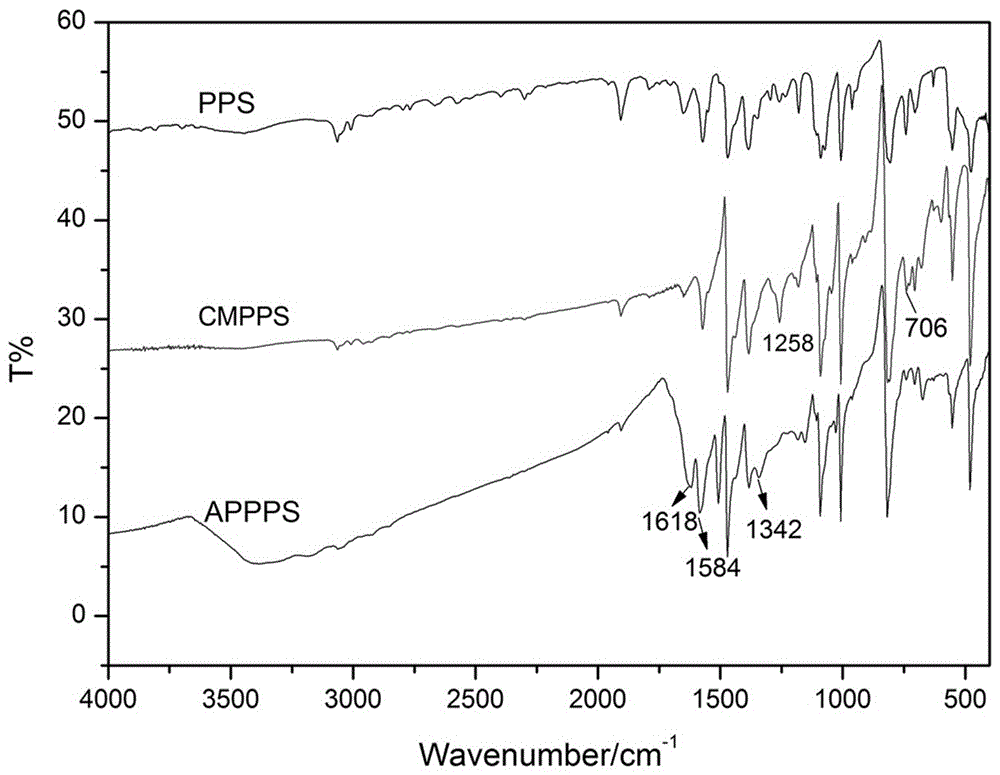

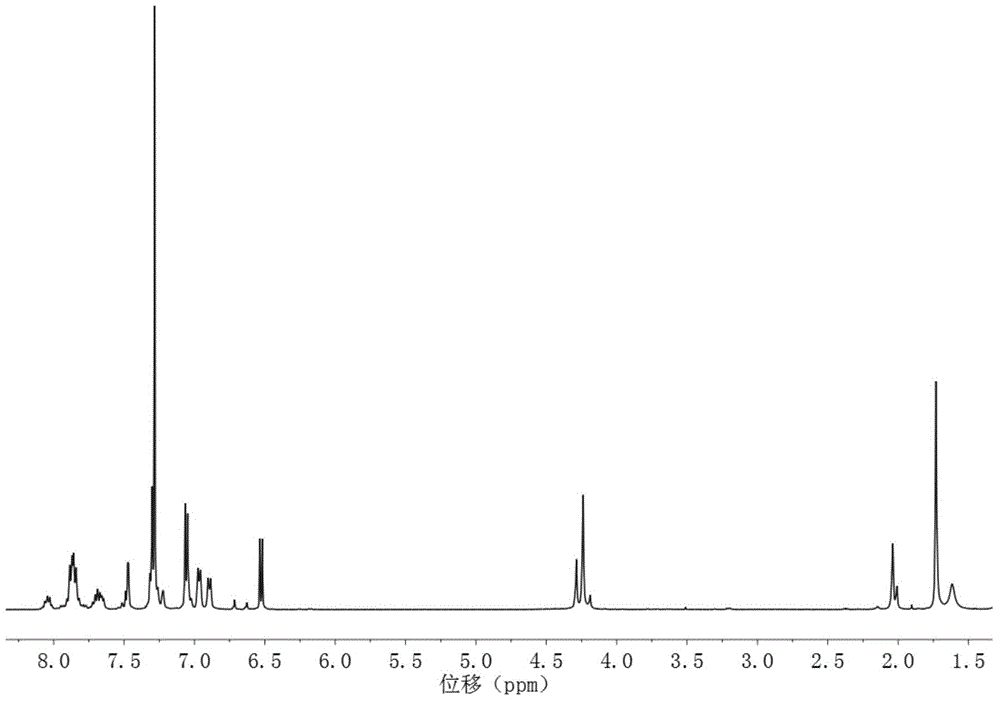

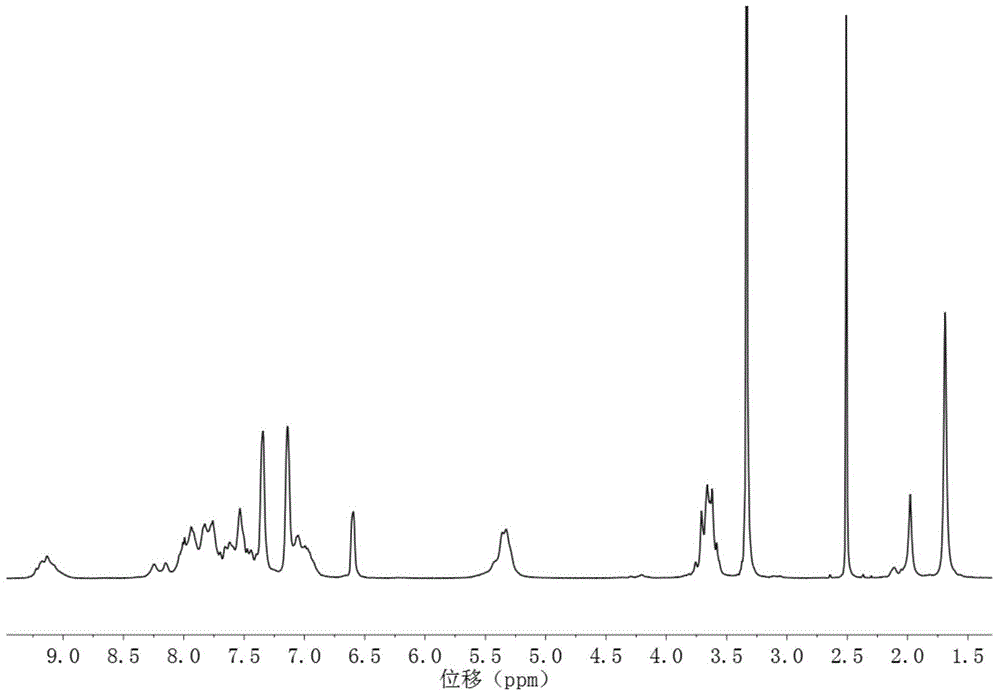

Production method of polyphenylene sulfide-based adsorption separation resin

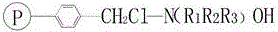

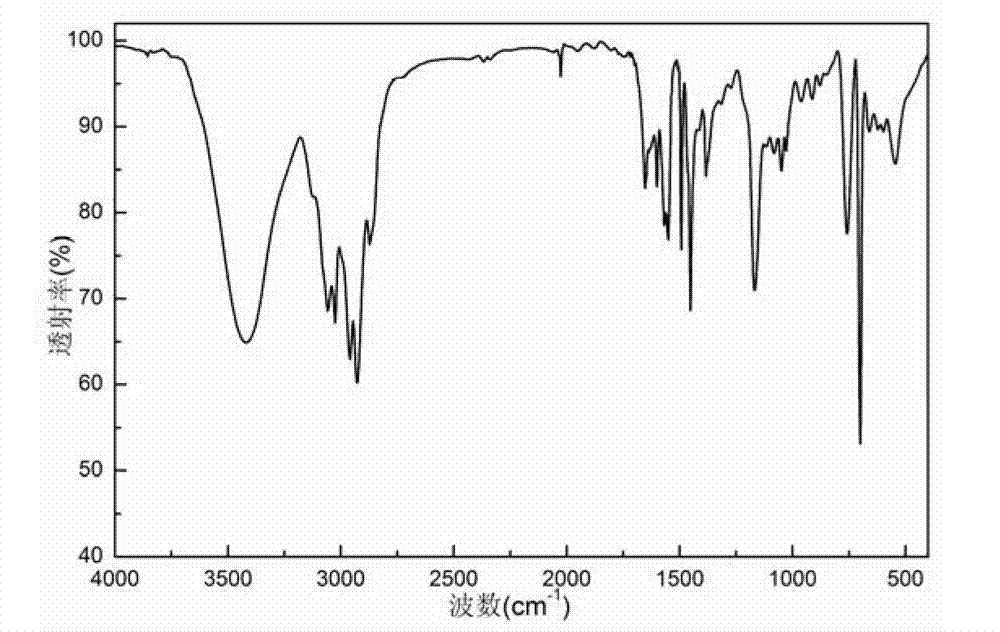

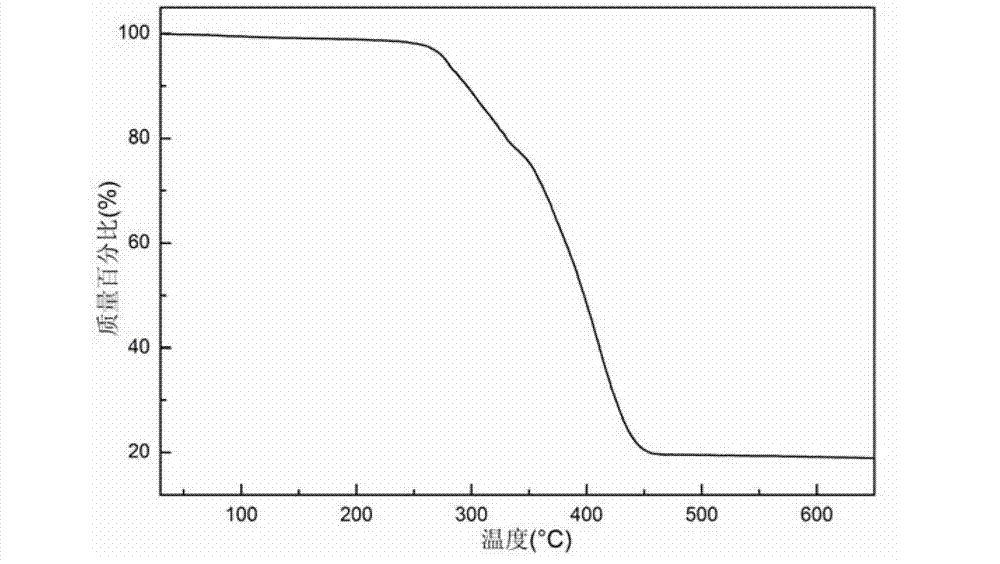

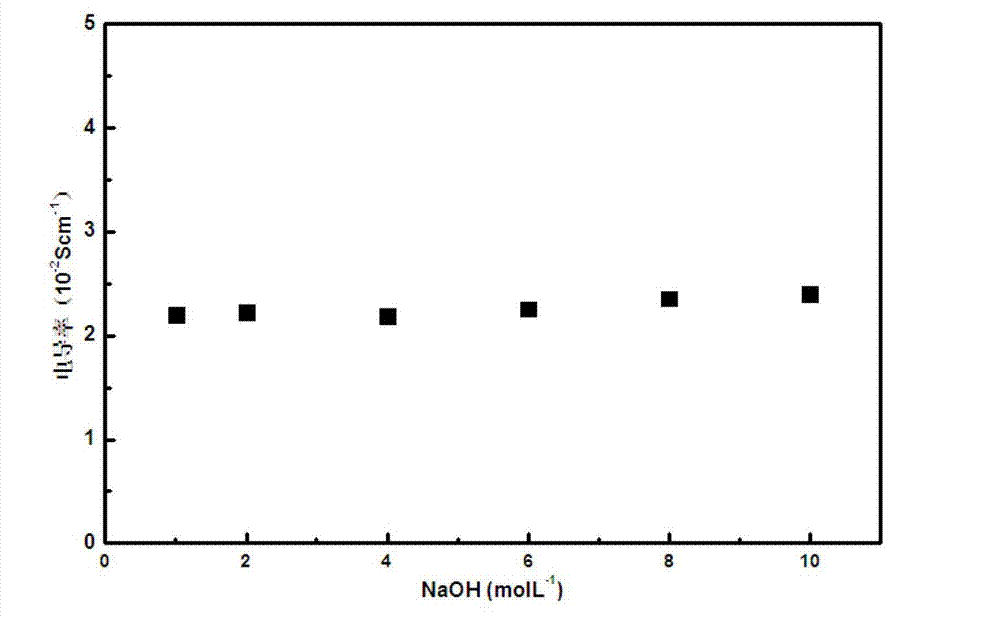

ActiveCN105860077AImprove thermal stabilityImprove heat resistanceOther chemical processesWater contaminantsPtru catalystChloromethyl Ether

The invention discloses a production method of polyphenylene sulfide-based adsorption separation resin. The production method comprises the following steps: adding a solvent to polyphenylene sulfide resin to swell the polyphenylene sulfide resin adding anhydrous tin tetrachloride and chloromethyl ether, heating and reacting above materials, and post-processing the obtained reaction product to obtain CH2Cl-containing CMPPS resin; and adding a solvent to the obtained CMPPS resin to swell the CMPPS resin, adding a catalyst and a functionalized monomer, heating and reacting above materials, and post-processing the obtained reaction product to obtain the final product polyphenylene sulfide-based adsorption separation resin. Functional groups comprising a thienyl group, a 3-aminopyridyl group and a mercapto group, introduced to the invention, have good coordination adsorption ability to heavy metal ions, and the functional groups contain N and S hetero atoms, have small relative molecular mass, and can easily coordinate with the heavy metal ions, so an excellent adsorption purpose can be reached.

Owner:佛山市安芯纤维科技有限公司 +1

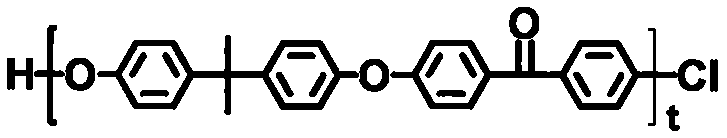

Block copolymer anion-exchange membrane for fuel battery and preparation method of block copolymer anion-exchange membrane

ActiveCN104530723AWell-developed ion transport channelsIncrease moisture contentSolid electrolyte fuel cellsFuel cell detailsSwelling capacityPhenolphthalein

The invention discloses a block copolymer anion-exchange membrane for a fuel battery and a preparation method of the block copolymer anion-exchange membrane, and relates to an alkaline fuel battery. The molecular structure of the block copolymer anion-exchange membrane comprises a hydrophilic segment containing a phenolphthalein side group and a hydrophobic segment containing a benzonitrile structure. The preparation method comprises the following steps: (1) synthesizing the hydrophilic segment; (2) synthesizing the hydrophobic segment; (3) synthesizing a block copolymer; (4) synthesizing a bromomethylated block copolymer; and (5) preparing the block copolymer anion-exchange membrane. In the preparation process, a chloromethyl ether reagent is not used, and a phenolphthalein side group structure is introduced into the hydrophilic segment of the membrane and a strong-polarity nitrile group structure is introduced into the hydrophobic segment of the membrane by virtue of molecular design to ensure that the membrane has the characteristics of developed ion transport passage, high water content and low swelling capacity, and shows relatively high ionic conductivity and relatively good fuel battery performance.

Owner:XIAMEN UNIV

Preparation method of chlorfenapyr

InactiveCN102617439AReduce moisture contentReduce processing difficultyOrganic chemistryChlorfenapyrKetone solvents

The invention relates to a preparation method of chlorfenapyr, wherein, 4-bromine-2-(4-chlorphenyl)-5-trifluoromethyl pyrrole-3-nitrile and chloromethyl ethers are taken as raw material, alkali carbonate or organic amine is taken as acid-binding agents, and esters are taken as reaction solvent so as to prepare chlorfenapyr. The preparation method adopts ester solvent, reduces the treatment difficulty of waste water in the later period, lowers the manufacturing cost greatly, and reduces the environmental protection treatment pressure; the manufacturing cost is 20 percent lower than the diethoxymethane technology and is 10 percent lower than the ketones solvent technology; the wastewater quantity is only about 10 percent of the diethoxymethane technology and is about 25 percent of the ketones solvent technology; and unforeseen benefits can be achieved by compared with the traditional ketones solvent.

Owner:山东潍坊双星农药有限公司

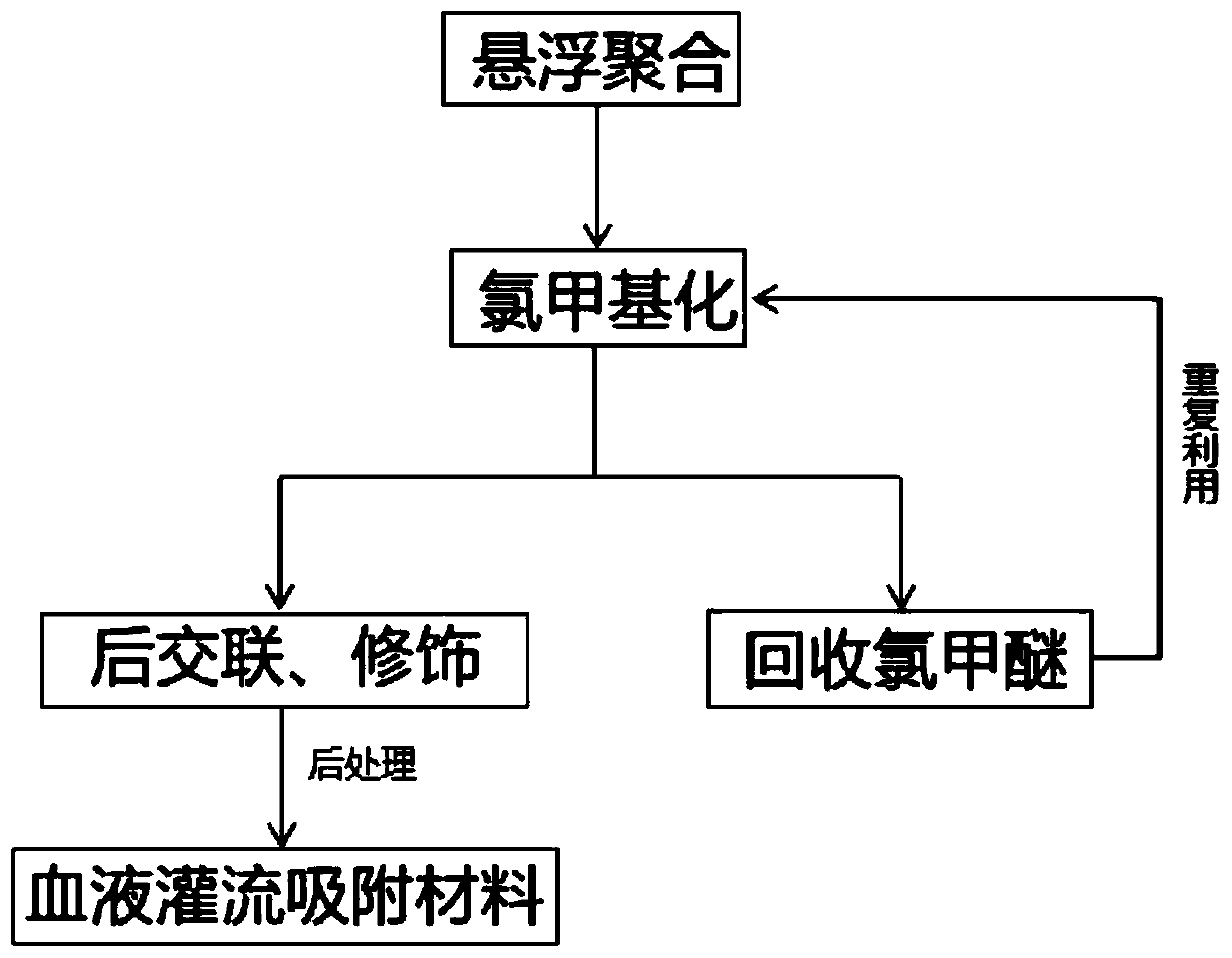

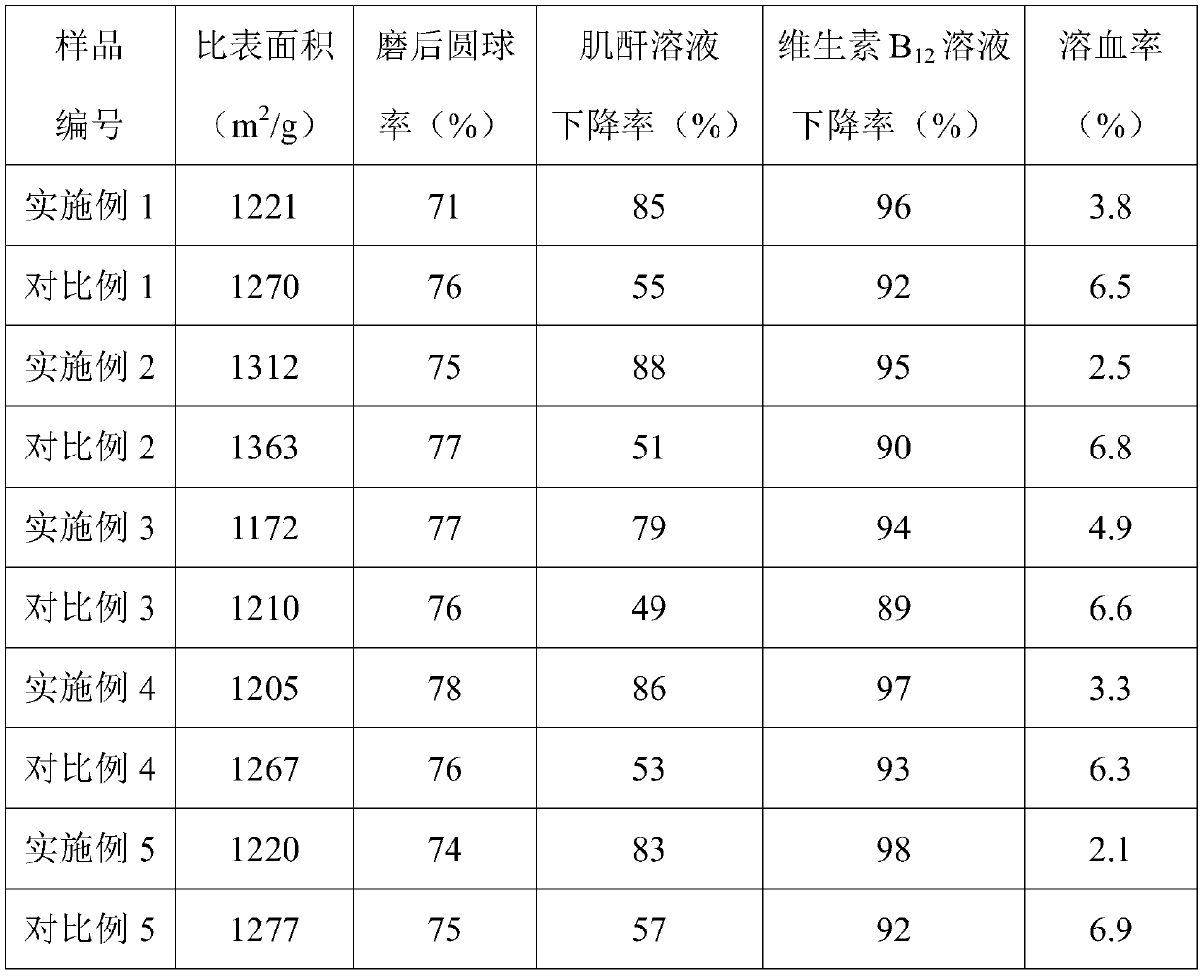

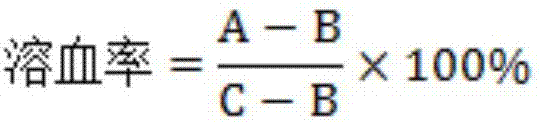

Preparation method of adsorbing material for blood perfusion

ActiveCN111530432AImprove adsorption capacityThe synthetic route is simpleOther blood circulation devicesOther chemical processesChloromethyl EtherOil phase

The invention discloses a preparation method of an adsorption material for blood perfusion. The preparation method comprises the following steps: preparing an oil phase and a water phase, by a suspension polymerization process, preparing a macroporous adsorption resin precursor with the particle size distribution being 0.315-0.8 mm from the the prepared oil phase and water phase, carrying out chloromethylation on the prepared macroporous adsorption resin precursor to prepare a chloromethylated macroporous adsorption resin precursor, carrying out post-crosslinking on the prepared chloromethylated macroporous adsorption resin precursor to prepare macroporous adsorption resin of which the residual chlorine content is less than or equal to 2%, and carrying out post-treatment on the prepared macroporous adsorption resin to prepare the surface functionalized macroporous adsorption resin with adsorption capacity for blood perfusion. According to the invention, recycling of residual chloromethyl ether after the chloromethylation reaction in the synthesis process of the macroporous adsorption resin for blood perfusion is realized, and remarkable economic benefits and environmental protection benefits are brought.

Owner:XIAN LANSHEN NEW MATERIAL TECHNOLOGY CO LTD +1

Synthetic method for chelate adsorbing resin suitable for heavy oil wastewater

ActiveCN102827393AIncrease the rate of the exchange reactionPrevent leakageOther chemical processesWater/sewage treatment by sorptionChloromethyl EtherPolystyrene

The invention relates to a synthetic method for chelate adsorbing resin suitable for heavy oil wastewater. The method comprises the following steps: adding an initiator in an oil phase, stirring the initiator to fully dissolve, adding the oil phase to a water phase in a stirring state, heating the temperature to 60-75 DEG C and insulating for 8-10 hours, heating to the temperature of 80-90 DEG C and insulating for 14-16 hours, cooling to obtain polystyrene series white ball, mixing the polystyrene series white ball and chloromethyl ether for chloromethylation reaction to obtain polystyrene series chlorine ball, mixing the polystyrene series chlorine ball and acetate phthalimide for esteryl reaction to obtain polystyrene series ester ball, mixing the polystyrene series ester ball and liquid alkali for hydrolysis reaction to obtain polystyrene series amine ball, mixing the polystyrene series amine ball, liquid alkali and chloroacetic acid for chelating reaction to obtain the chelate adsorbing resin suitable for the heavy oil wastewater. The chelate adsorbing resin suitable for heavy oil wastewater has good organic matter pollution resistance performance, and can be taken as secondary softening to prevent ions leakage in the heavy oil wastewater water quality.

Owner:PETROCHINA CO LTD

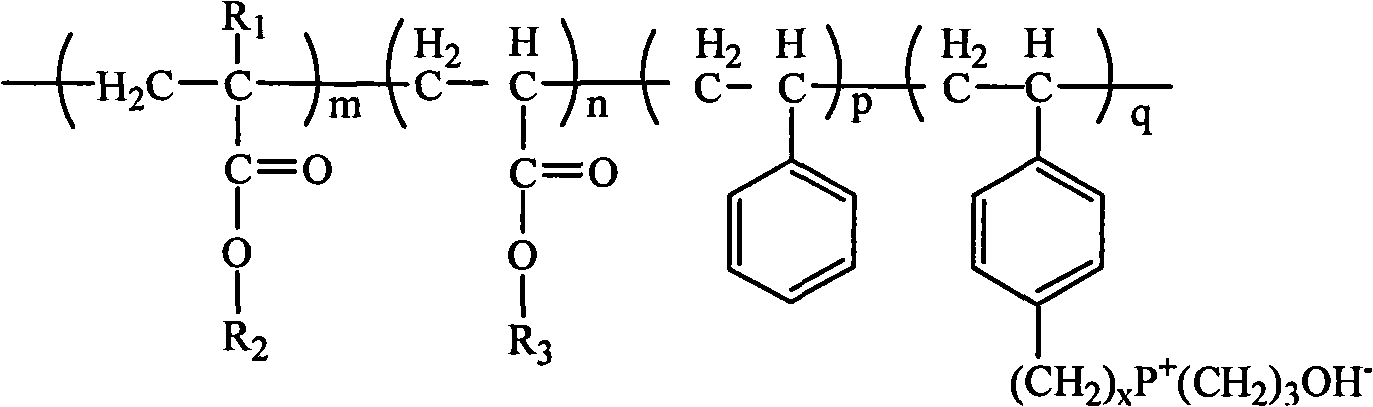

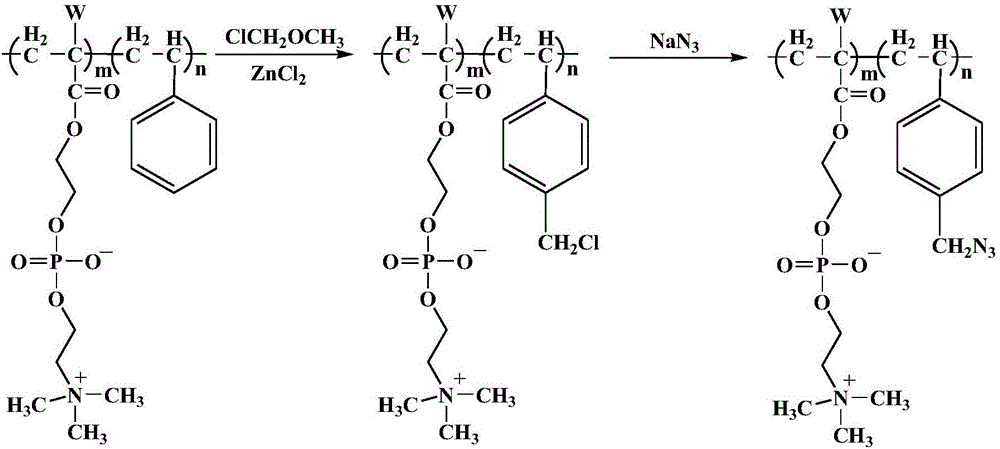

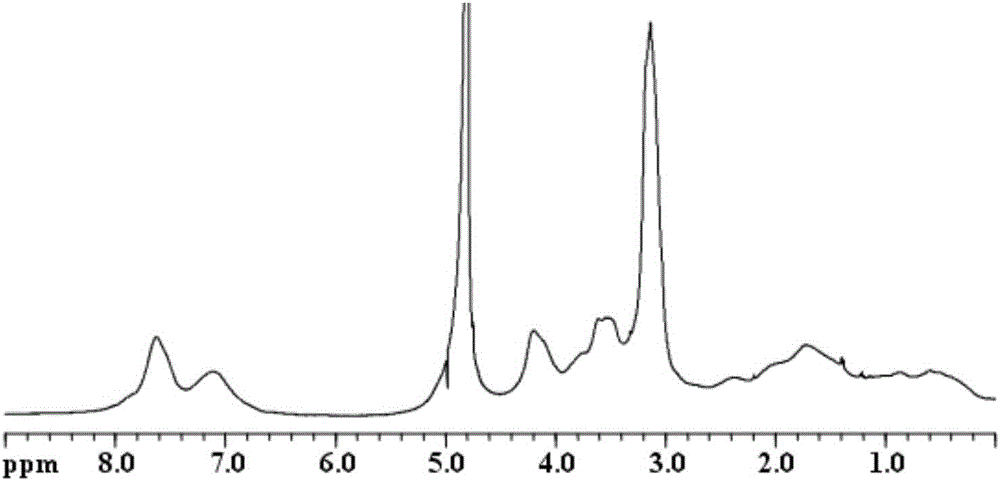

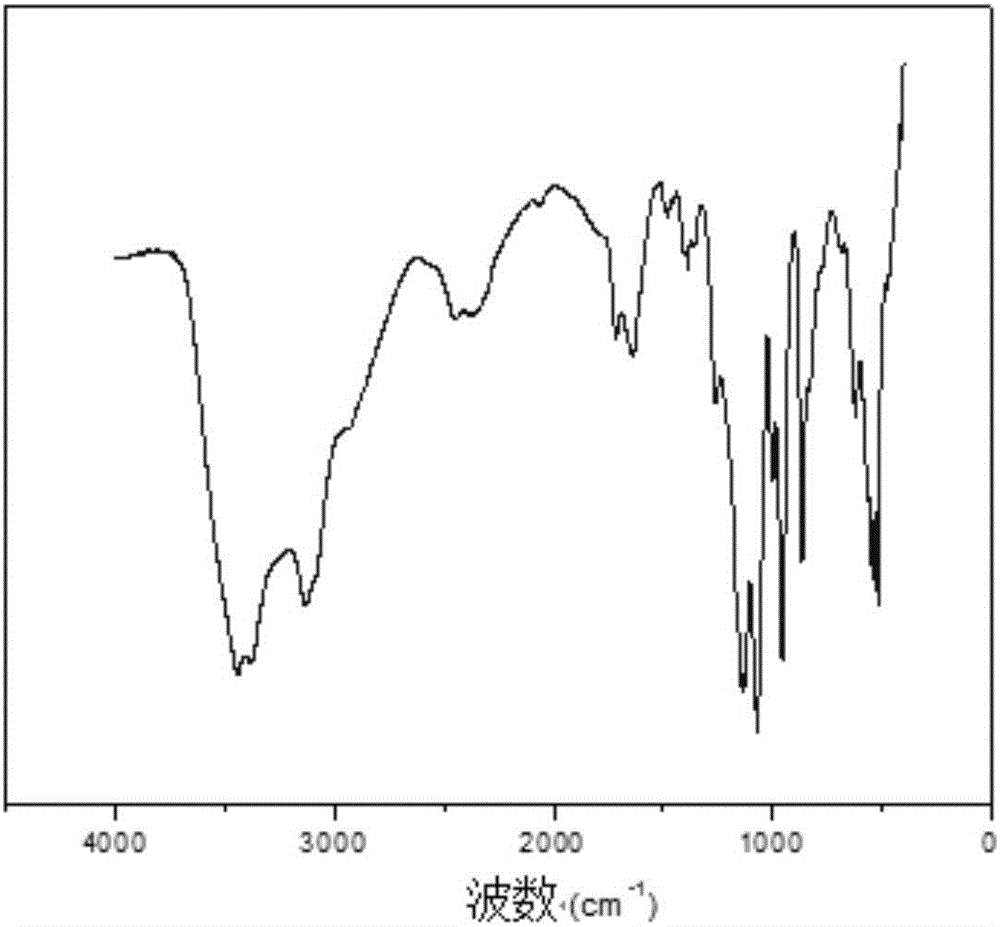

Preparation method of photocurable phosphorylcholine polymer

InactiveCN106380542AEasy to prepareMild conditionsSurgeryProsthesisPolymer scienceChloromethyl Ether

The invention discloses a preparation method of a photocurable phosphorylcholine polymer, comprising the following steps: Step 1, carrying out free radical polymerization on a styrene monomer and a vinyl monomer containing a phosphorylcholine group under the action of an initiator so as to obtain a phosphorylcholine polymer containing phenyl ring; Step 2, mixing zinc chloride, chloromethyl ether and the phosphorylcholine polymer containing phenyl ring to carry out chloromethylation so as to obtain a chloromethylated phosphorylcholine polymer; and Step 3, carrying out nucleophilic substitution on the chloromethylated phosphorylcholine polymer by the use of sodium azide under the alkaline condition so as to obtain the photocurable phosphorylcholine polymer. The preparation method is simple and the conditions are mild. The invention provides a new approach to obtaining of the photocurable phosphorylcholine polymer. The invention is of great academical significance for modification of biocompatibility of biological materials. The prepared photocurable phosphorylcholine polymer will have a wide application prospect in fields of material implantation in vivo, tissue engineering, drug sustained release and biosensor, etc.

Owner:XIAN UNIV OF SCI & TECH

Modification method of polystyrene resin for adsorbing flavones

InactiveCN104610473AImprove adsorption capacityReaction conditions require mildOther chemical processesWater bathsFiltration

The invention discloses a modification method of a polystyrene resin for adsorbing flavones, which comprises the following steps: adding the polystyrene resin and chloromethyl ether into a three-neck flask which is provided with a stirrer, a thermometer and a reflux condenser, carrying out chloromethylation reaction under the action of a catalyst zinc chloride, carrying out vacuum filtration on the chloromethylation resin obtained by reaction, separating from the reaction solution, cleaning with ethanol, and swelling; and adding a chloromethylated resin and an amino reagent methylamine into the three-neck flask which is provided with the stirrer, thermometer and reflux condenser, and heating in a water bath to 45 DEG C to react for 12 hours, thereby obtaining the amino modified resin. When the modified resin is used for extracting total flavones in the ethanol extract, the adsorption capacity of every gram of modified resin reaches 58.776mg. The modification method has the advantages of mild reaction conditions, high practicality and the like, and is widely applicable to the polystyrene resin.

Owner:BEIHAI HESI TECH

Preparation method of alcohol-soluble quaternary amine type or tertiary amine type anion exchange resin

ActiveCN108080039AHigh ion exchange capacityUniform compositionAnion exchangersDistillationChloromethyl Ether

The invention discloses a preparation method of alcohol-soluble quaternary amine type or tertiary amine type anion exchange resin. The preparation method of the alcohol-soluble quaternary amine type or tertiary amine type anion exchange resin comprises the following steps: taking a linear poly(styrene-ethylene) alternating copolymer as a raw material, completely dissolving the linear poly(styrene-ethylene) alternating copolymer into halogenated hydrocarbon, then adding an industrial chloromethyl ether solution dissolved with a catalyst, and carrying out homogeneous-phase chloromethylation reaction; then enabling a reaction product to pass through a stainless steel high-pressure nozzle; extruding the reaction product into water which contains a dispersing agent and sodium hydroxide; rapidlydispersing into a suspension system by using a stirring paddle with a cutting function; carrying out reduced pressure distillation to recycle the halogenated hydrocarbon; after filtering and drying the suspension particles, washing the suspension particles with water thoroughly, and adding an organic amines aqueous solution to react; filtering and drying residual reaction liquid, adding diluted hydrochloric acid to neutralize, filtering and drying, and then washing for multiple times by using deionized water; and finally filtering and drying, and blowing and drying the solid particles to obtain an alcohol-soluble quaternary amine type or tertiary amine type anion exchange resin product. Quaternary amine or tertiary amine groups in the product prepared by the method are distributed uniformly, and can be completely dissolved in low-toxicity organic alcohol.

Owner:雷引林

Preparation method of ion exchange membrane used in vanadium battery

ActiveCN105932317AImprove mechanical propertiesReduce penetrationRegenerative fuel cellsCross-linkChloromethyl Ether

The invention provides a preparation method of an ion exchange membrane used in a vanadium battery. The preparation method comprises the steps of dissolving sulfonated polycondensate and a sulfonated addition polymer in a first solvent; pouring at 60-80 DEG C for membrane formation so as to obtain the ion exchange membrane used in the vanadium battery. Compared with the prior art, the ion exchange membrane prepared by the method abovementioned has the characteristics of a polymer imidazole salt ionic liquid membrane and a polycondensate membrane; the polymer imidazole salt ionic liquid membrane and the polycondensate membrane are cross-linked through an ionic bond to further improve the chemical stability and mechanical property thereof; and the ionic bond is good for formation of an ionic channel, so that the ionic conductivity thereof is also ensured while good mechanical property and good chemical stability are ensured. According to the preparation method of the ion exchange membrane used in the vanadium battery, use of chloromethyl ether and concentrated sulfuric acid is avoided, and damage to a human body and the environment is reduced. The prepared ion exchange membrane used in the vanadium battery has relatively low vanadium ion permeability, relatively high ionic conductance and chemical stability and relatively good mechanical property. In addition, the preparation method of the membrane is simple in preparation and low in price, and has low requirements on equipment.

Owner:深圳市益达兴科技股份有限公司

Polymeric adsorbent, secondary crosslinking post-modification method of polymeric adsorbent, and blood perfusion device

ActiveCN107159156AHigh strengthSpatial structure is stableOther chemical processesOther blood circulation devicesEpoxyResin microsphere

The invention discloses a secondary crosslinking post-modification method of a polymeric adsorbent. The secondary crosslinking post-modification method comprises the following steps: epoxying and activating a residual double bond on a poly styrene-co-divinyl benzene resin, forming a polyhydroxy surface through hydrolysis, and enabling a hydroxide radical and an epoxy group to perform secondary crosslinking. The hydrophobic polymeric adsorbent forms the polyhydroxy surface through activation and hydrolysis, the hydrophily is improved, the modified functional group is also provided, and the polymeric adsorbent does not need to be modified on a benzene ring. The epoxy chloropropane is used for secondary crosslinking to obtain a poly styrene-co-divinyl benzene resin microsphere with higher strength and more stable space structure. The chloromethyl ether with strong cancerogen or the expensive vinylbenzyl chloride is not used, and the cost is relatively low. The invention further discloses the polymeric adsorbent prepared through the secondary crosslinking post-modification method and a blood perfusion device using the polymeric adsorbent.

Owner:佛山市博新生物科技有限公司

Industrial preparation method of sevoflurane

ActiveCN104529721AAvoid it happening againAdd filter and impurity removal stepsEther separation/purificationChloromethyl EtherRetention time

The invention discloses an industrial preparation method of sevoflurane. The method comprises the following steps: adding chloromethyl ether and alkali metal fluoride to a solvent, uniformly stirring and heating for a reflux reaction; after the reaction, cooling a reaction liquid to be less than 20 DEG C and filtering, combining a filtrate with reaction residual liquor and distilling under normal pressure; collecting fraction less than 80 DEG C so as to obtain crude sevoflurane, and rectifying so as to obtain a finished sevoflurane product. By optimizing the crude sevoflurane preparing step, namely adding a filtering and impurity removing step after fluoridation reaction, the industrial preparation method disclosed by the invention can be used for relieving a side reaction during distilling and avoiding the generation of some impurities, and especially impurities similar to the sevoflurane in retention time, so that rectifying difficulty is reduced, rectifying time is reduced and product quality is guaranteed; the content of the finished sevoflurane product can reach 99.999%, so that manpower and material resources can be saved and product yield can be improved to 92.4%; and meanwhile, generated cauldron bottom residue can be recycled, so that the industrial preparation method can be used for further improving yield and reducing cost, and the preparation method is more conducive to industrial production.

Owner:HEBEI YIPIN PHARMA

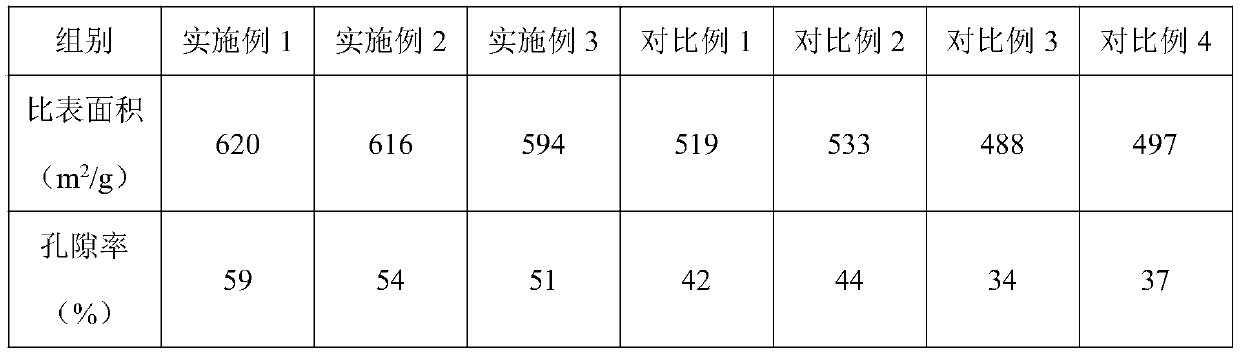

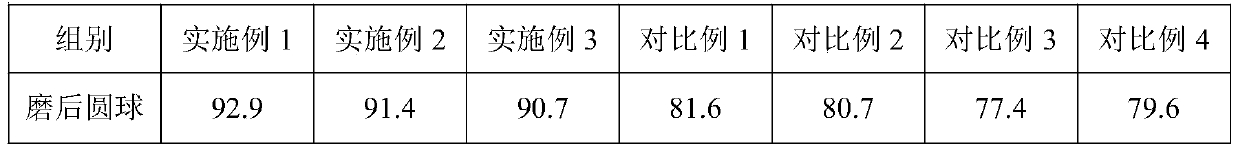

Macroporous adsorption resin and preparation method thereof

ActiveCN109833854AIncrease the areaHigh mechanical strengthOther chemical processesAlkali metal oxides/hydroxidesPorosityPolymer science

The invention provides macroporous adsorption resin which is prepared from the following raw materials: water, gelatin, styrene, divinylbenzene, white oil, an initiator, a pore-foaming agent, solventoil, 1,2-dichloroethane, zinc chloride and chloromethyl ether by the the following steps: carrying out white ball polymerization, white ball drying and screening, carrying out wax extraction, wax balldrying and screening, chlorination, chlorine ball drying and post-crosslinking reaction. The prepared resin is relatively large in specific surface area and porosity and has relatively good mechanical strength, high temperature resistance, simple preparation process and easy industrial production.

Owner:蚌埠市天星树脂有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com