Synthetic method of strong-basic anion exchange resin used in compact bed

A technology of exchange resin and synthesis method, applied in the direction of anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problem of large difference in particle size of cross-linked polystyrene white sphere skeleton, different resin particle size, and inapplicability to a wide range of promotion and other issues, to achieve the effects of fine granularity, short diffusion path during exchange, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: a kind of synthetic method of solid bed strong basic anion exchange resin comprises the following steps:

[0056] Using a homogeneous wet chemical method to synthesize a cross-linked polystyrene white ball skeleton with a particle size of 100-150 μm on the surface of an inert crystal nucleus, the inert crystal nucleus includes an inert material with a highly uniform particle size such as silicon dioxide;

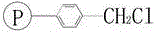

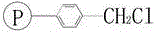

[0057]Adding chloromethyl ether as a chloromethylation reagent to perform a Friedel-Crafts reaction with the benzene ring in the original styrene in the crosslinked polystyrene white ball to obtain an intermediate product A;

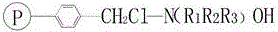

[0058] The intermediate product A is subjected to an amination reaction with a tertiary amine containing a long carbon chain to generate a strongly basic anion exchange resin with a particle diameter of 180-280 μm.

[0059] Swell the cross-linked polystyrene white ball skeleton in the chloromethyl ether and add anhydrous ferric chl...

Embodiment 2

[0080] Embodiment 2: a kind of synthetic method of solid bed strong basic anion exchange resin comprises the following steps:

[0081] Using a homogeneous wet chemical method to synthesize a cross-linked polystyrene white ball skeleton with a particle size of 100-150 μm on the surface of an inert crystal nucleus, the inert crystal nucleus includes an inert material with a highly uniform particle size such as silicon dioxide;

[0082] Adding chloromethyl ether as a chloromethylation reagent to perform a Friedel-Crafts reaction with the benzene ring in the original styrene in the crosslinked polystyrene white ball to obtain an intermediate product A;

[0083] The intermediate product A is subjected to an amination reaction with a tertiary amine containing a long carbon chain to generate a strongly basic anion exchange resin with a particle diameter of 180-280 μm.

[0084] Swell the cross-linked polystyrene white ball skeleton in the chloromethyl ether and add anhydrous ferric ch...

Embodiment 3

[0105] Embodiment 3: a kind of synthetic method of solid bed strong basic anion exchange resin comprises the following steps:

[0106] Using a homogeneous wet chemical method to synthesize a cross-linked polystyrene white ball skeleton with a particle size of 100-150 μm on the surface of an inert crystal nucleus, the inert crystal nucleus includes an inert material with a highly uniform particle size such as silicon dioxide;

[0107] Adding chloromethyl ether as a chloromethylation reagent to perform a Friedel-Crafts reaction with the benzene ring in the original styrene in the crosslinked polystyrene white ball to obtain an intermediate product A;

[0108] The intermediate product A is subjected to an amination reaction with a tertiary amine containing a long carbon chain to generate a strongly basic anion exchange resin with a particle diameter of 180-280 μm.

[0109] Swell the cross-linked polystyrene white ball skeleton in the chloromethyl ether and add anhydrous ferric ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com