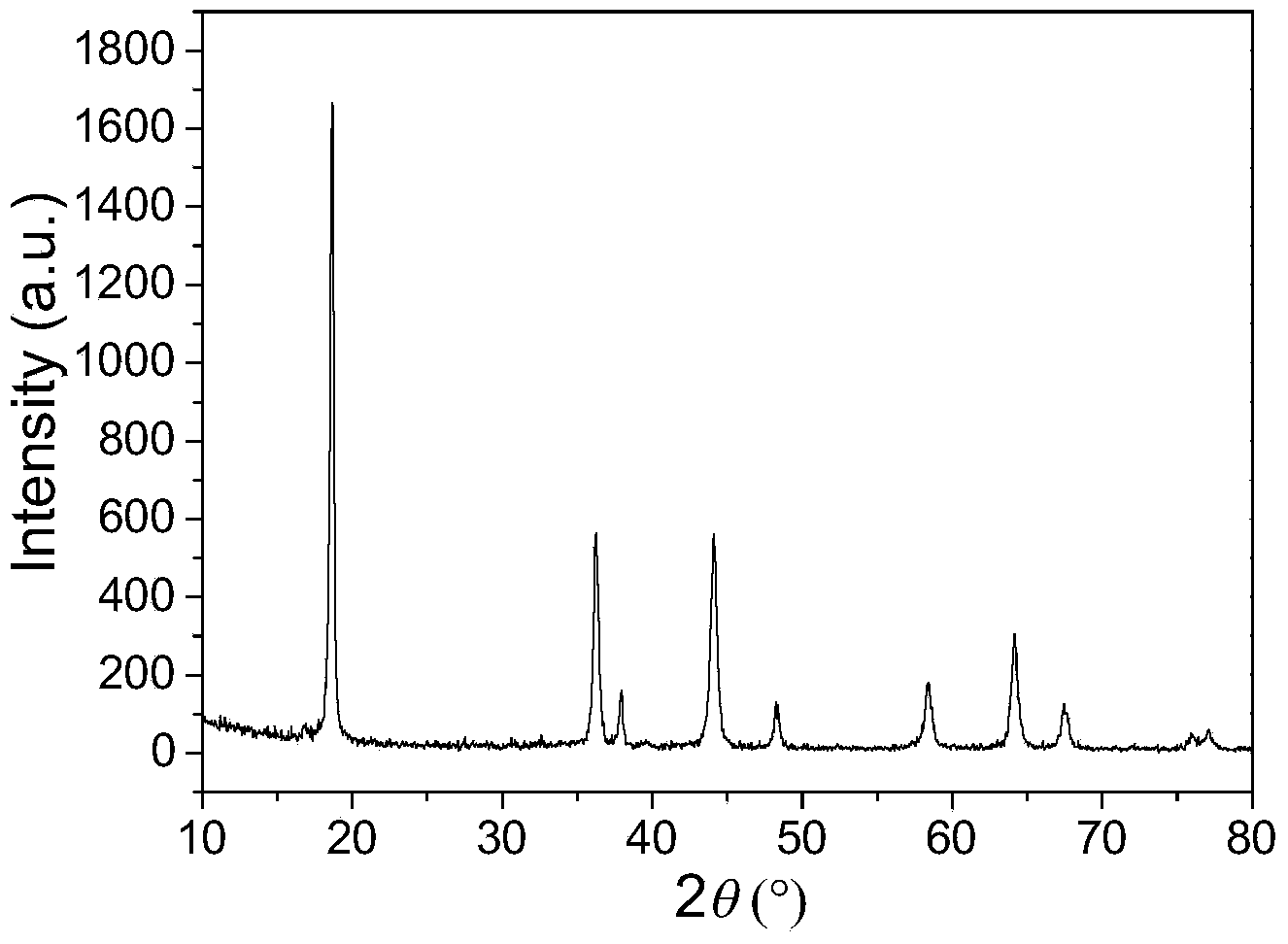

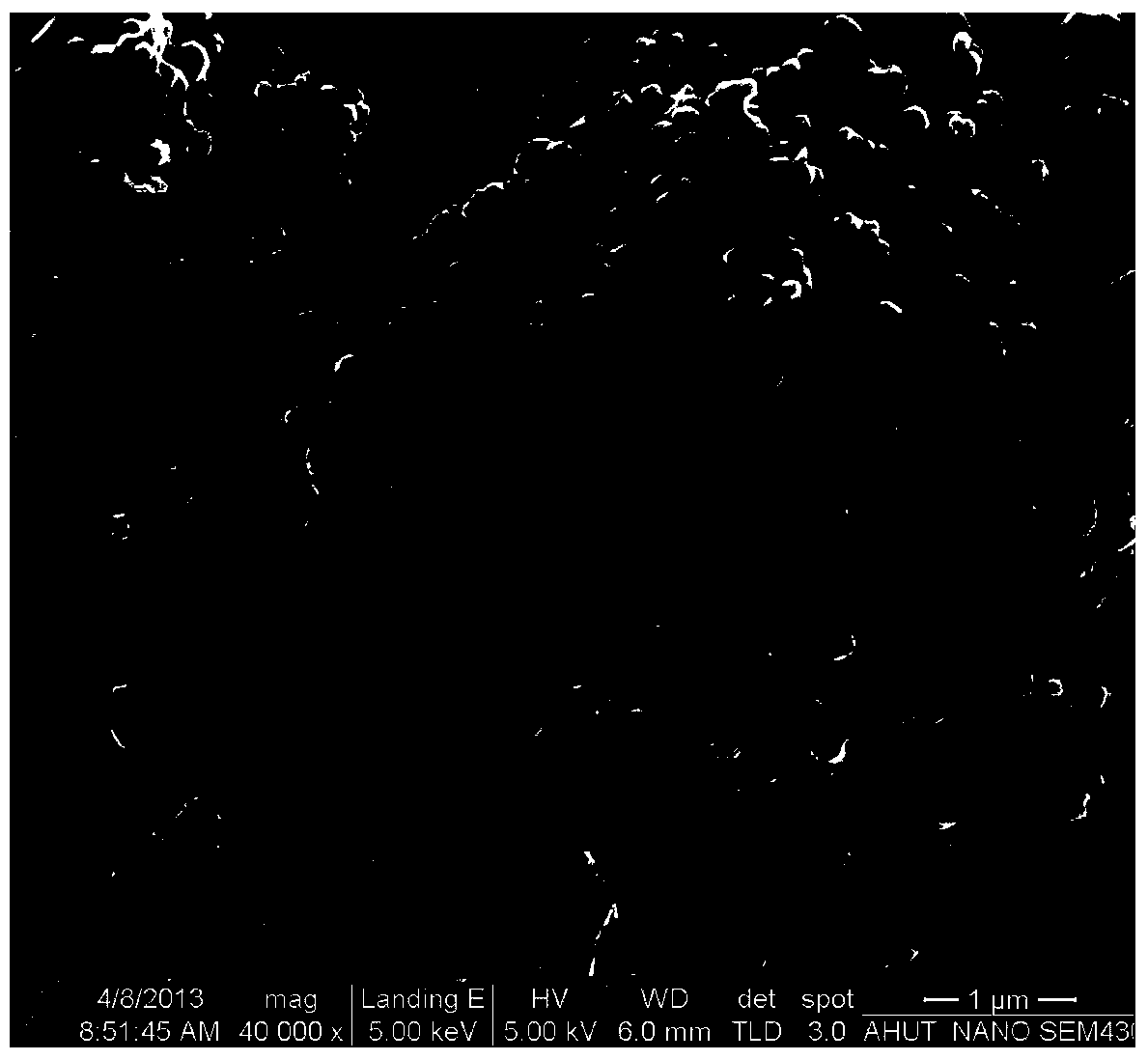

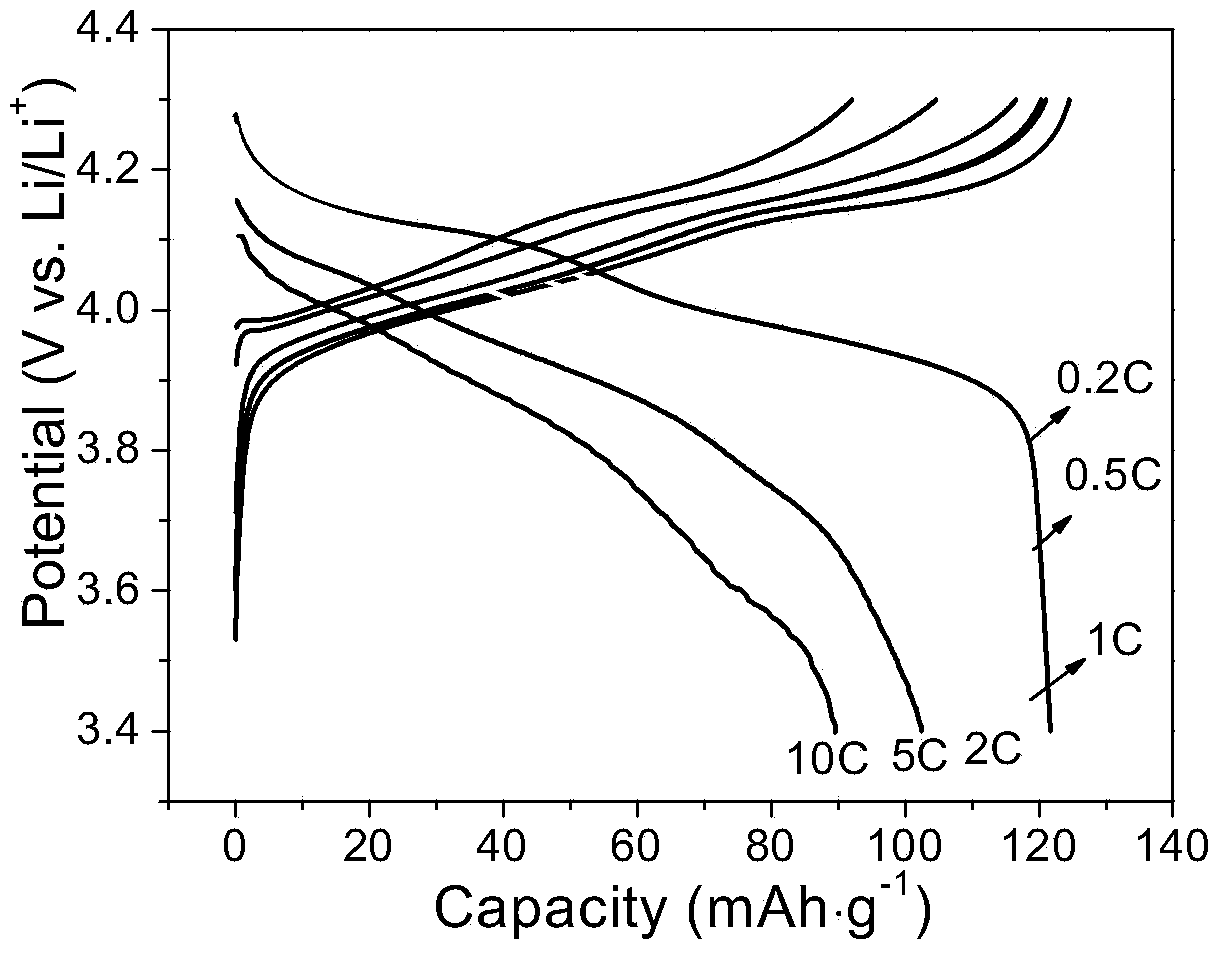

Doping modification method of spinel lithium manganate anode material

A cathode material, lithium manganate technology, applied in the nano field, can solve the problems of difficult to accurately control doping ion stoichiometry, complex sol-gel process, limited application and other problems, and achieve excellent electrochemical performance and good dispersibility. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) According to the chemical formula LiMn doped lithium manganate 1.95 co 0.05 o 4 , weigh lithium hydroxide (LiOH·H 2 O) 4.1941g, cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) 1.4552g, citric acid (C 6 h 8 o 7 ·H 2 (2) 11.0324g, lithium hydroxide, cobalt nitrate and citric acid are dissolved in 50mL deionized water respectively, are mixed with solution, the citric acid solution is magnetically stirred, add lithium hydroxide solution first, then add cobalt nitrate solution, use dilute nitric acid (HNO 3 ) and dilute ammonia (NH 3 ·H 2 O) adjust the pH value to 6, add ethylene glycol (C 2 h 6 o 2 ) 1.6294g, stirred at a constant temperature of 65°C for 1h to form a sol;

[0031] (2) Manganese tetraoxide (Mn 3 o 4 ) powder (primary particle size ≤ 200nm, specific surface area ≥ 10m 2 / g) 14.8727g was added to the above-mentioned sol, mixed evenly, placed in a ball mill tank, and ball milled on a planetary ball mill for 3h, the ball-to-material ratio was 5:1, and...

Embodiment 2

[0036] (1) According to the chemical formula LiMn doped lithium manganate 1.91 co 0.055 Al 0.035 o 4 , weigh lithium hydroxide (LiOH·H 2 O) 4.1941g, cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) 1.6007g, aluminum nitrate (Al(NO 3 ) 3 9H 2 O) 1.3130g, citric acid (C 6 h 8 o 7 ·H 2 (2) 13.7431g, lithium hydroxide, cobalt nitrate, aluminum nitrate and citric acid are dissolved in 50mL deionized water respectively, are mixed with solution, citric acid solution is magnetically stirred, add lithium hydroxide solution first, then add cobalt nitrate, nitric acid Aluminum solution, dilute nitric acid (HNO 3 ) and dilute ammonia (NH 3 ·H 2 O) adjust the pH value to 5, add ethylene glycol (C 2 h 6 o 2 ) 2.4356g, stirred at 70°C for 1.5h to form a sol;

[0037] (2) Manganese tetraoxide (Mn 3 o 4 ) powder (primary particle size ≤ 200nm, specific surface area ≥ 10m 2 / g) 14.5676g was added to the above-mentioned sol, mixed evenly, placed in a ball mill tank, and ball milled on ...

Embodiment 3

[0042] (1) According to the chemical formula LiMn doped lithium manganate 1.95 Ni 0.05 o 4 , weigh lithium nitrate (LiNO 3 )6.895g, nickel acetate (Ni(CH 3 COO) 2 4H 2 O) 1.2442g, citric acid (C 6 h 8 o 7 ·H 2 (2) 15.4519g, lithium nitrate, nickel acetate and citric acid were dissolved in 60mL of deionized water respectively, prepared into a solution, the citric acid solution was magnetically stirred, lithium nitrate solution was added, then nickel acetate solution was added, and dilute ammonia (NH 3 ·H 2 O) adjust the pH value to 6, add ethylene glycol (C 2 h 6 o 2 ) 1.3035g, stirred at a constant temperature of 70°C for 2h to form a sol;

[0043] (2) Manganese tetraoxide (Mn 3 o 4 ) powder (primary particle size ≤ 200nm, specific surface area ≥ 10m 2 / g) 14.8727g was added to the above-mentioned sol, mixed evenly, placed in a ball mill tank, and ball milled on a planetary ball mill for 2 hours, the ball-to-material ratio was 9:1, and the rotating speed was 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com