Method for stabilizing surface conducting layer of transition oxide through hafnium oxide film

A technology of hafnium oxide and transition group, which is applied in the direction of coatings, circuits, electrical components, etc., can solve the problem of ion bombardment of transition group oxide surface conductive layer instability and other problems, achieve good lattice matching characteristics, good protection performance, high The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

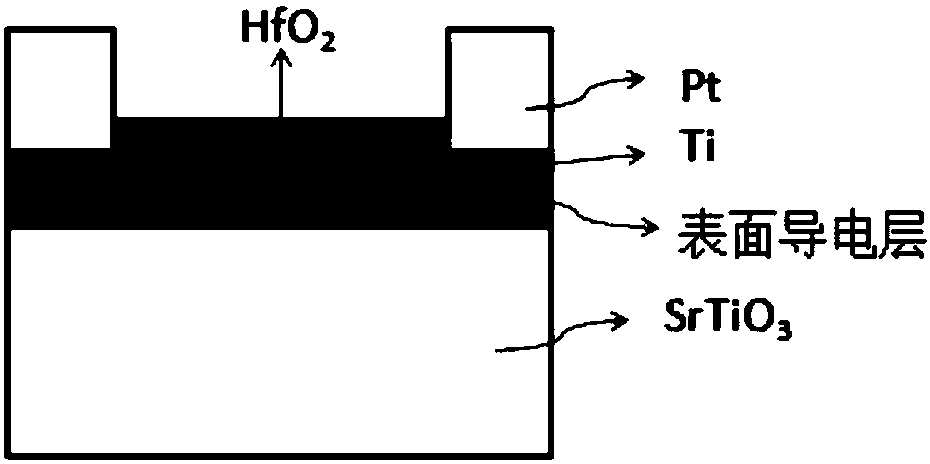

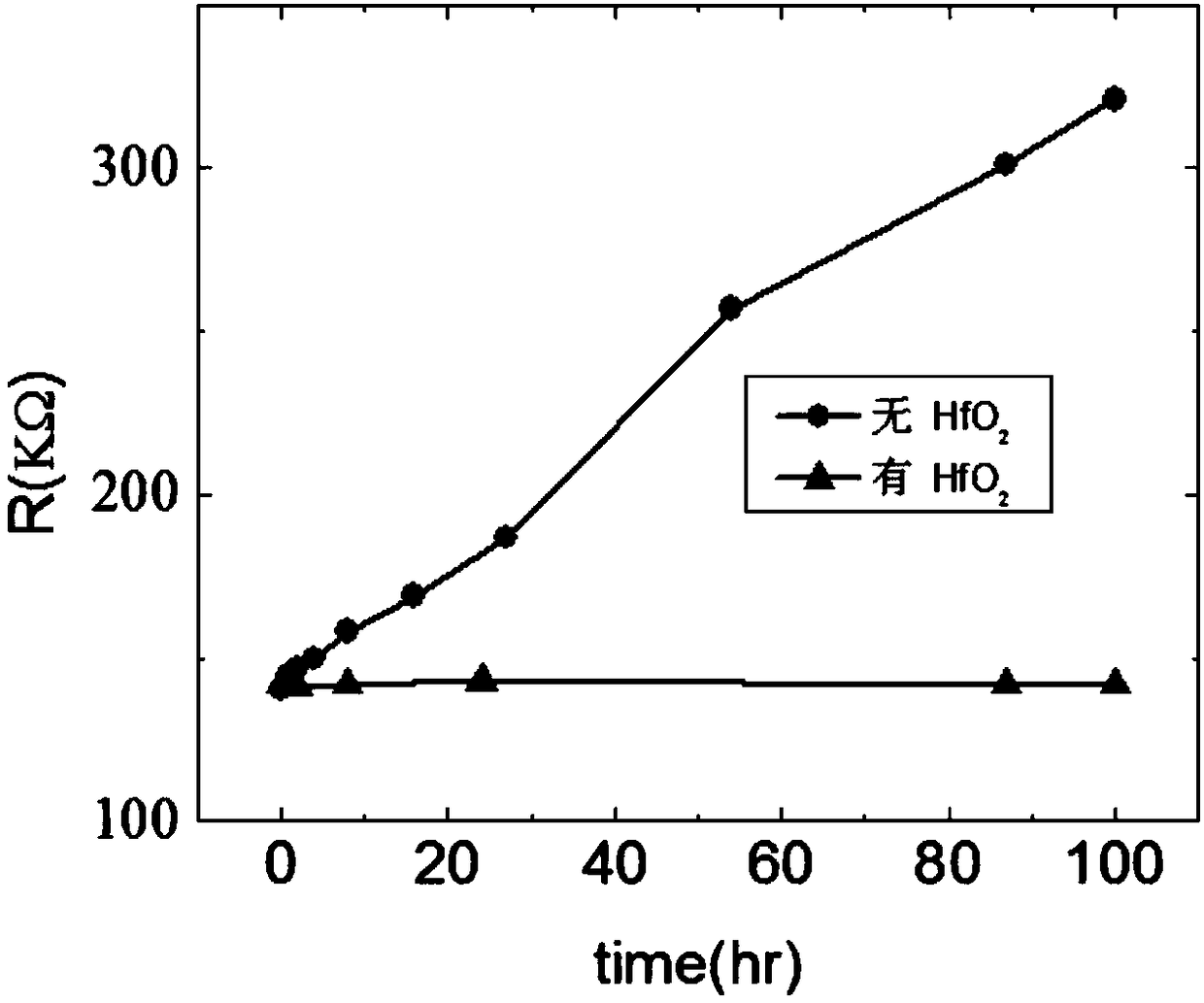

[0015] In this embodiment, a method for stabilizing the conductive layer on the surface of transition group oxides with a hafnium oxide thin film, the structure is as follows figure 1 As shown, in this embodiment, hafnium oxide ceramics are used as the target material, and single crystal strontium titanate of 5mm*5mm, (100) crystal orientation is used as the substrate, and the specific steps are as follows:

[0016] Step 1: Clean the 5mm*5mm, (100) crystalline monocrystalline strontium titanate as the substrate with acetone / alcohol;

[0017] Step 2: Using Ar + The above-mentioned single crystal strontium titanate substrate was bombarded. Fix the substrate on the stage, and then evacuate the cavity to 3.0×10 -4 Pa below, then pass pure argon into the cavity to keep the pressure at 2.0×10 -2 Pa, after the air pressure is stabilized, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com