High-efficiency annealing method for novel amorphous oxide thin film transistor (TFT)

A thin film transistor and amorphous oxide technology, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid state devices, etc., can solve the problems of inability to anneal, complex thermal annealing methods, easy to produce pollution, etc., to improve performance and growth parameters. Independently adjustable, stain-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below through specific embodiments in conjunction with the drawings.

[0041] In the present invention, the indium oxide, titanium oxide, and zinc oxide powders used to make the ITZO target are all purchased from Sigma-Aldrich Company, with a purity greater than 99.99%.

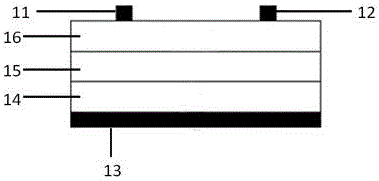

[0042] The preparation process of the bottom gate thin film transistor with amorphous ITZO as the semiconductor layer is:

[0043] (1) Using thermal oxygen oxidation method to grow SiO 2 Gate dielectric layer:

[0044] Step 1: Use commercially purchased p-type heavily doped Si as the substrate, and wash it with acetone and alcohol ultrasonically for 10 minutes, and then repeatedly rinse with deionized water, and then blow dry with high-purity nitrogen; then p-type heavily doped Doped Si grows SiO by thermal oxygen oxidation method 2 ;SiO 2 It is grown at 900-1200℃ for 1-3 h, and the thickness is 60-200 nm;

[0045] (2) Using pulsed laser deposition technology, in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com