InP quantum dot and preparation method thereof

A technology of quantum dots and precursors, applied in the field of InP quantum dots and their preparation, can solve the problems of difficulty in obtaining blue light InP quantum dots, large half-height width and poor repeatability of InP quantum dots, and achieve high-quality and low-defect increase. Thick, low cost, reducing the effect of surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

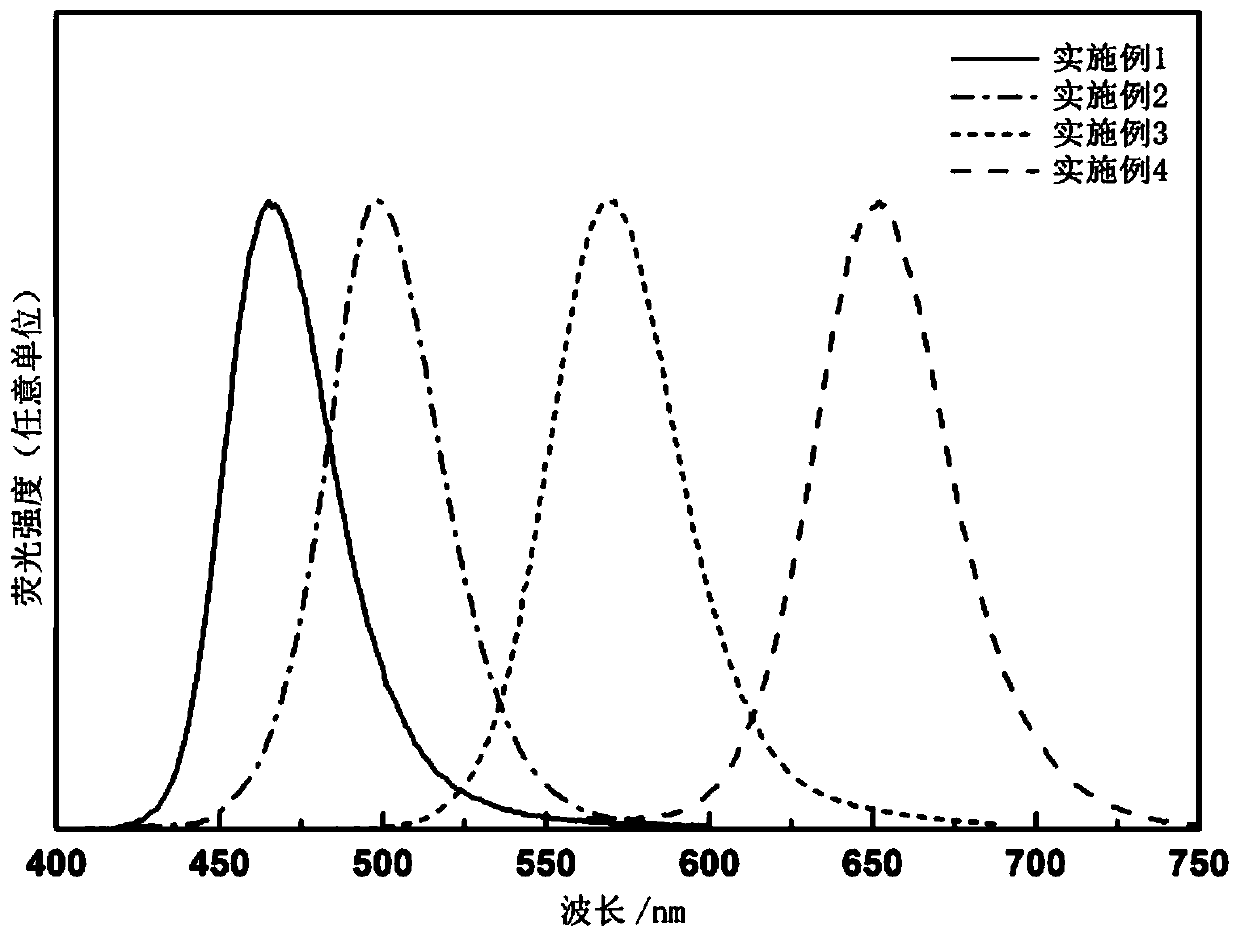

[0032] figure 1 It is the fluorescence emission spectrum figure of the InP quantum dot of multiple preferred embodiments of the present invention, as figure 1 As shown, the InP quantum dots synthesized by the method for preparing InP quantum dots provided by the present invention have a fluorescence emission peak in the range of 450-700 nm, and a full width at half maximum of less than 55 nm. Concrete preparation method comprises the following steps:

[0033] 1) Preparatory stage: continuously feed dry protective gas into the reaction vessel to fully remove moisture and oxygen in the reaction vessel;

[0034] 2) Precursor preparation: adding the indium precursor, the zinc precursor, and the amine ligand coordination solution into the reaction vessel respectively and mixing them thoroughly to obtain a uniform precursor solution mixed with indium and zinc;

[0035] 3) Nucleation: after controlling the temperature of the precursor solution to the first temperature, adding the p...

Embodiment 1

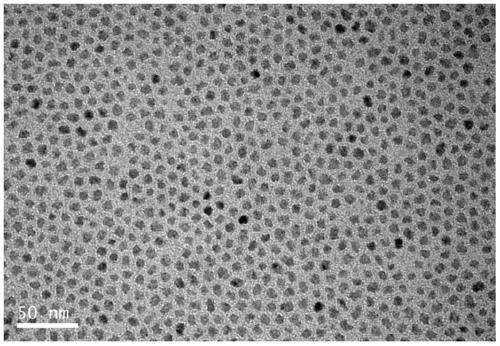

[0040] In this preferred embodiment, a three-necked flask is used as a reaction vessel, nitrogen is used as a protective gas, indium chloride is used as an indium precursor, zinc iodide is used as a zinc precursor, oleylamine is used as an amine ligand coordination solution, and three (dimethyl Amino) phosphine is used as the phosphorus precursor, and dodecanethiol is used as the precursor solution for forming the shell layer to prepare blue light InP / ZnS quantum dots. Such as figure 1 As shown, the fluorescence emission peak of the InP / ZnS quantum dots obtained in this preferred embodiment is 465nm, and the full width at half maximum is 39nm. figure 2 It is the TEM detection picture of the purified InP quantum dots of this embodiment, as shown in the figure, the crystal nucleus size of the blue light InP / ZnS quantum dots obtained in this embodiment is uniform, and the particle size is ≈10nm. The specific operation steps are as follows:

[0041] 1) Preparatory stage: contin...

Embodiment 2

[0047] In this preferred embodiment, a three-necked flask is used as a reaction vessel, nitrogen is used as a protective gas, indium chloride is used as an indium precursor, zinc bromide is used as a zinc precursor, oleylamine is used as an amine ligand coordination solution, and three (dimethyl Amino) phosphine is used as the phosphorus precursor, and dodecanethiol is used as the precursor solution for forming the shell layer to prepare green light InP / ZnS quantum dots. Such as figure 1 As shown, the fluorescence emission peak of the InP / ZnS quantum dots obtained in this preferred embodiment is 500 nm, and the full width at half maximum is 41 nm. The specific operation steps are as follows:

[0048] 1) Preparatory stage: continuously feed nitrogen into the three-necked bottle to fully remove the moisture and oxygen therein;

[0049] 2) Precursor preparation: Add 180 mg of indium chloride, 800 mg of zinc bromide and 10 ml of oleylamine into a three-necked flask, and under a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com