Patents

Literature

144results about How to "Reduce surface oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

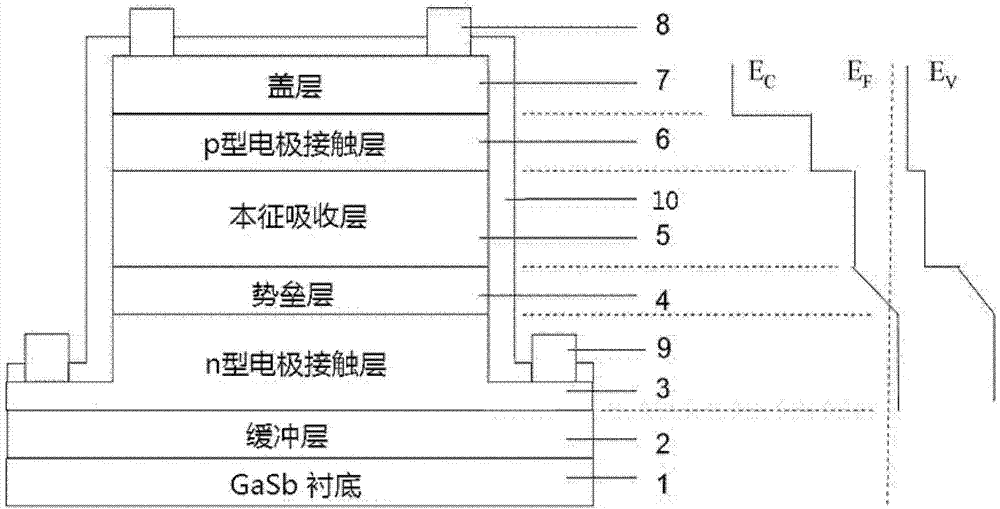

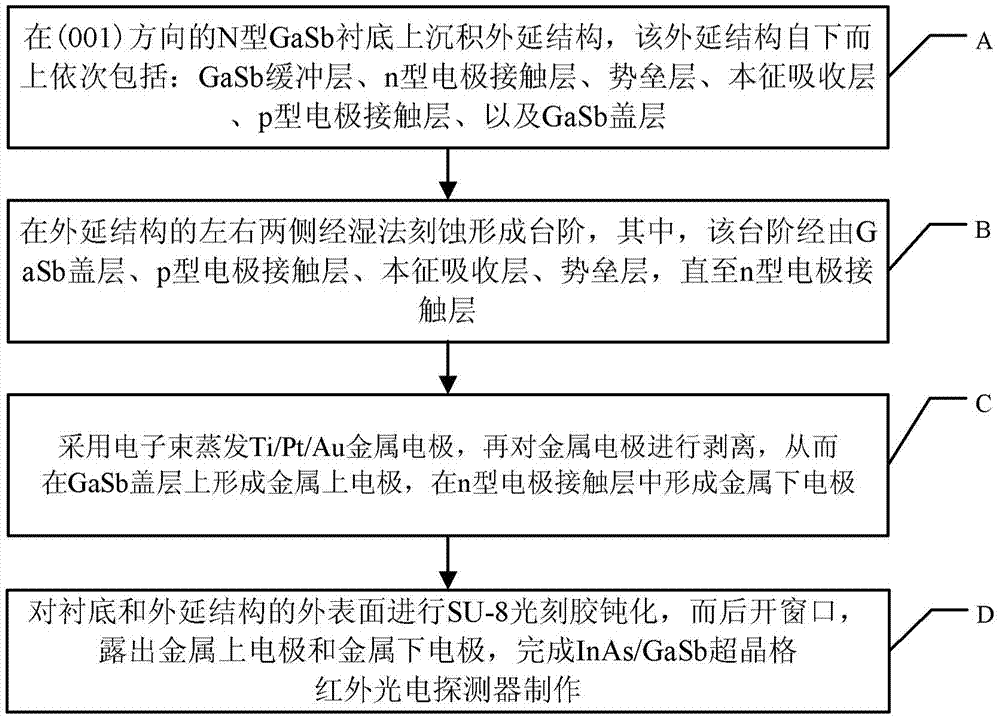

InAs/GaSb superlattice infrared photoelectric detector and manufacturing method thereof

ActiveCN103887360AImprove performanceSuppression-recombination dark currentFinal product manufactureSemiconductor devicesPhotovoltaic detectorsElectrode Contact

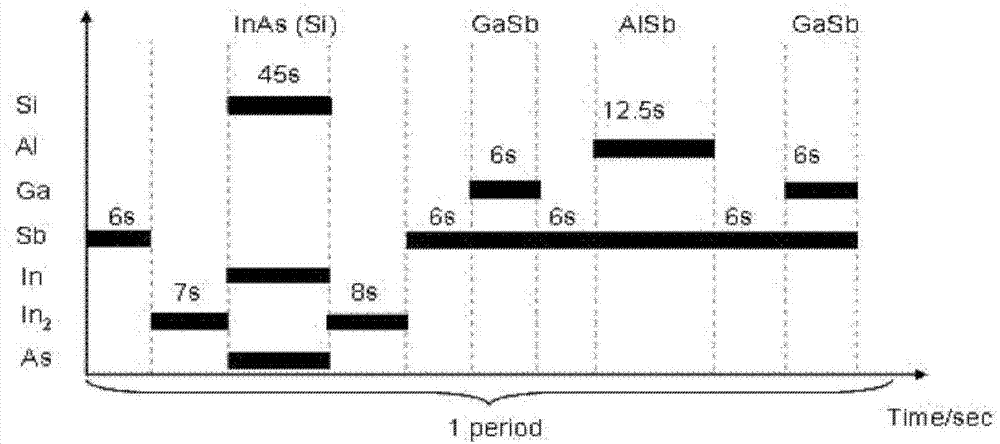

The invention provides an InAs / GaSb superlattice infrared photoelectric detector and a manufacturing method thereof. The InAs / GaSb superlattice infrared photoelectric detector comprises a substrate, an epitaxy structure deposited on the substrate, an upper metal electrode formed above steps, a lower metal electrode formed under the steps and a passivation layer, wherein the epitaxy structure comprises an n-type doping buffer layer, an n-type electrode contact layer, a barrier layer, an intrinsic absorption layer, a p-type electrode contact layer and a cover layer, the steps are formed on two sides of the epitaxy structure through etching, the intrinsic absorption layer is composed of a plurality of periodical InAs / InSb / GaSb / InSb superlattice structures. In the InAs / GaSb superlattice infrared photoelectric detector, InSb is respectively inserted into two interfaces of each superlattice period of the intrinsic absorption layer to form strained superlattices, the stress between the superlattices and the substrate is effectively balanced, the material growing quality is improved, and accordingly the photoelectric performance of the detector is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

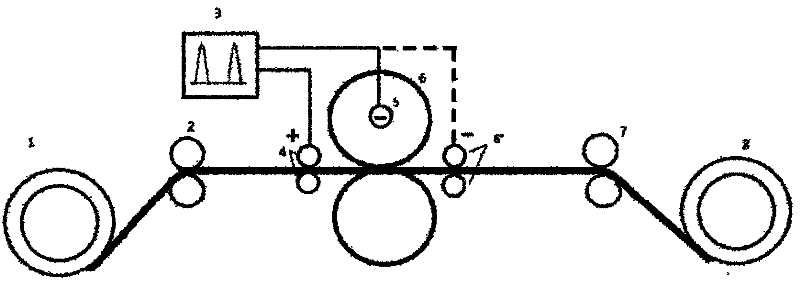

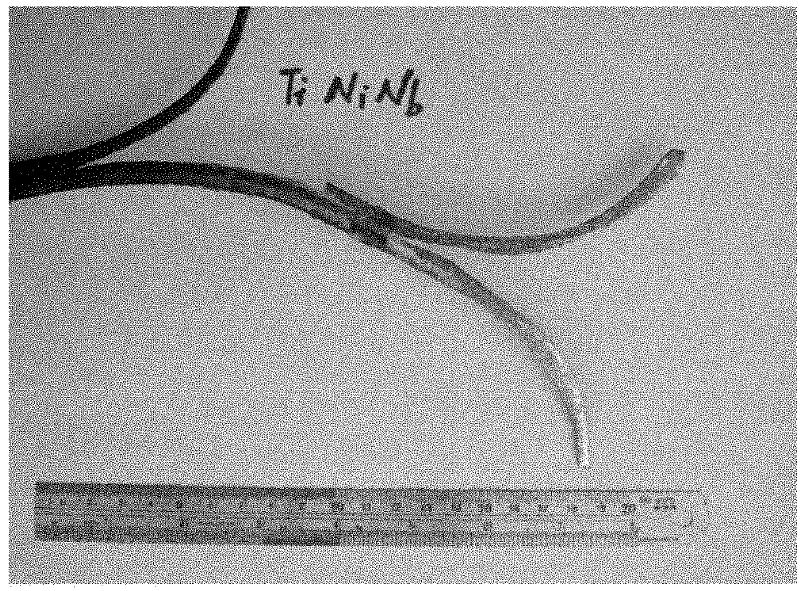

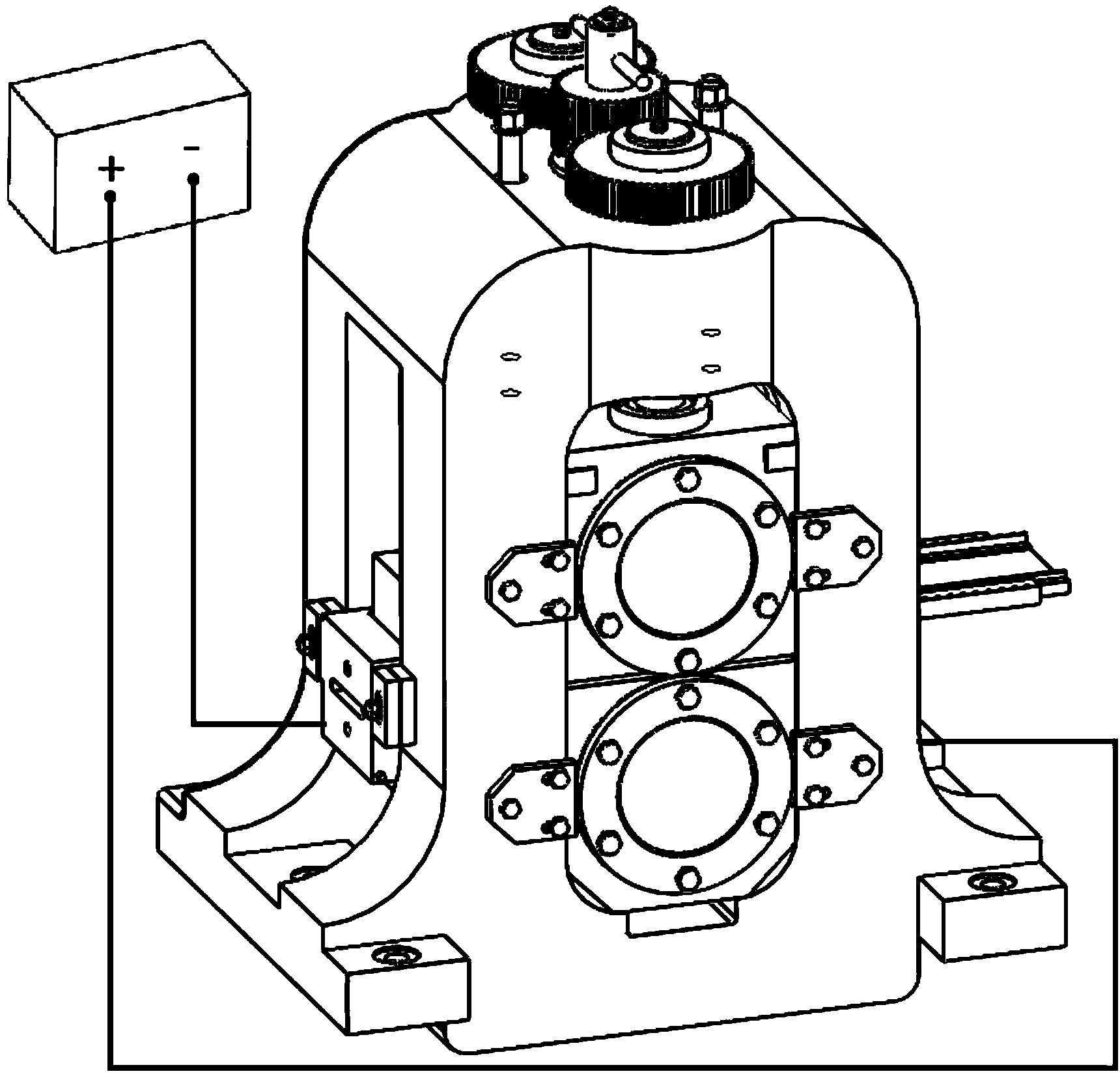

Method and system for rolling difficult-to-machine metal material by combining electro-plasticity with temperature plasticity

InactiveCN102172620ARaise the barrierInternal electron movement intensifiesTemperature control deviceMetal rolling arrangementsHigh energyCrystallographic defect

The invention relates to a method for rolling a difficult-to-machine metal material by combining electro-plasticity with temperature plasticity. The method comprises the following steps of: preheating a roller to the recovery temperature of a machined metal material and lower than the recrystallization temperature of the metal material; and inputting high-energy pulse current into a machining section of the moving metal material, performing electro-plastic treatment under the actions of the thermal effect and non-thermal effect of the metal material, and feeding the machining section into the preheated roller for rolling by combining electro-plasticity with temperature plasticity. In the rolling process, electro-plasticity and temperature plasticity are combined and unbalanced kinetic energy produced by the material due to the rise of atomic potential energy and strong electric stimulation of pulse current under heating condition is fully utilized, so that movement of crystal defects such as diffusion, dislocation and the like of atoms is facilitated, the internal microstructure of the metal material is improved, a tissue which is beneficial to enhancing of intensity and toughness (plasticity) is formed, and the plasticity of the material at low temperature is enhanced. The method is suitable for rolling difficult-to-machine metal materials such as magnesium alloys, nickel-titanium alloys, tungsten alloys and the like.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

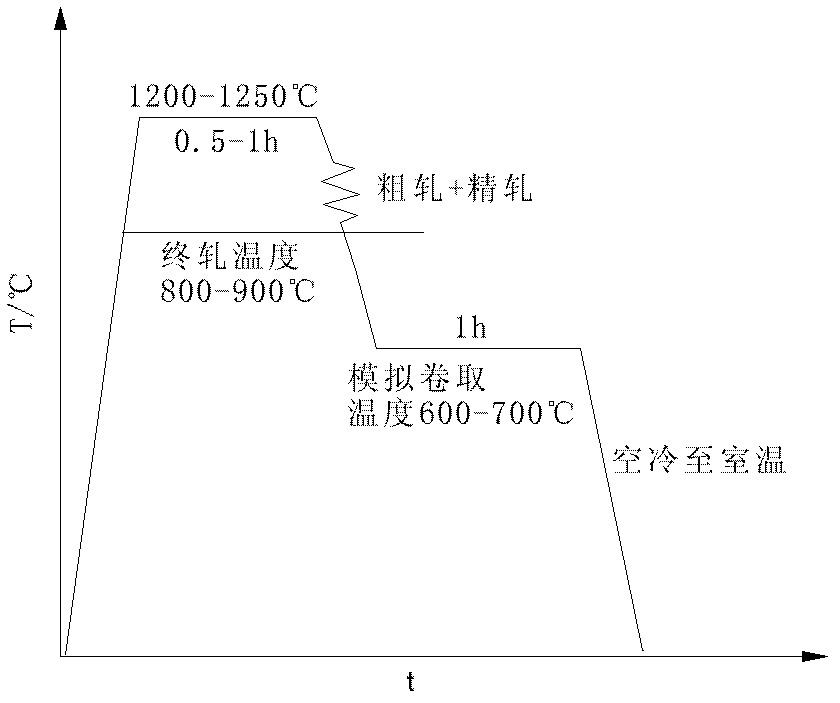

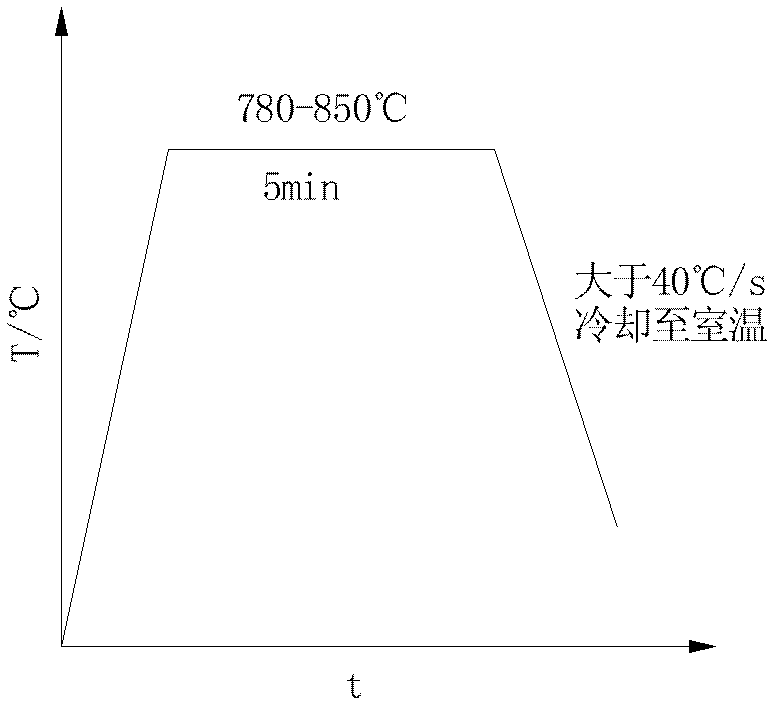

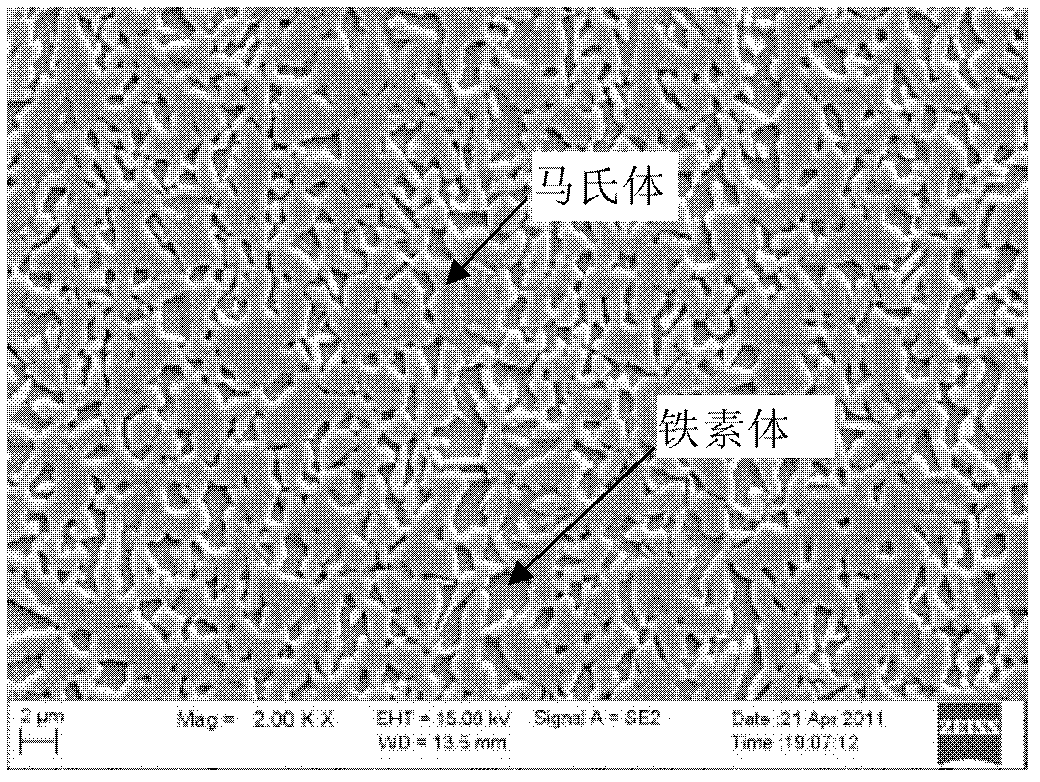

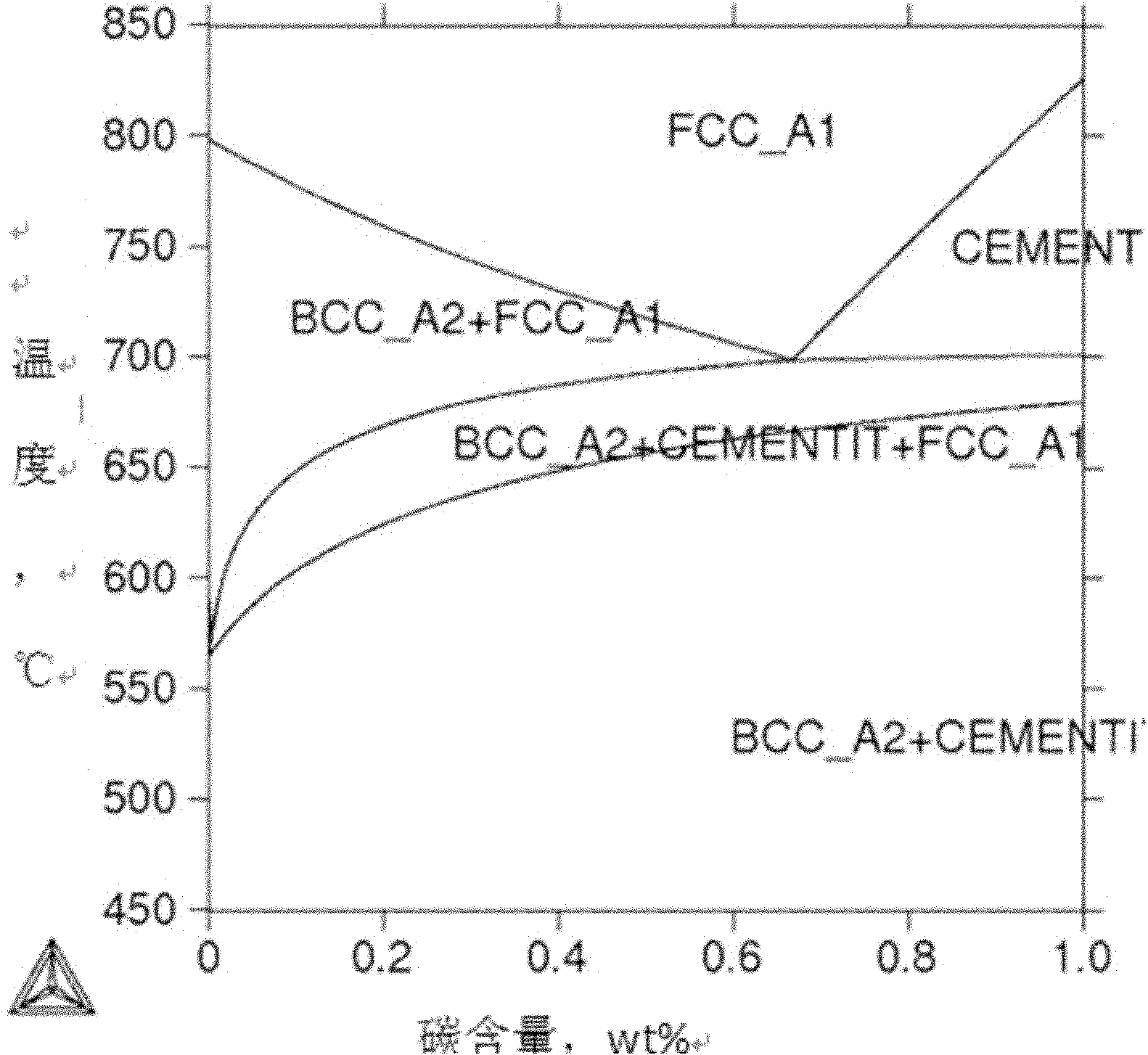

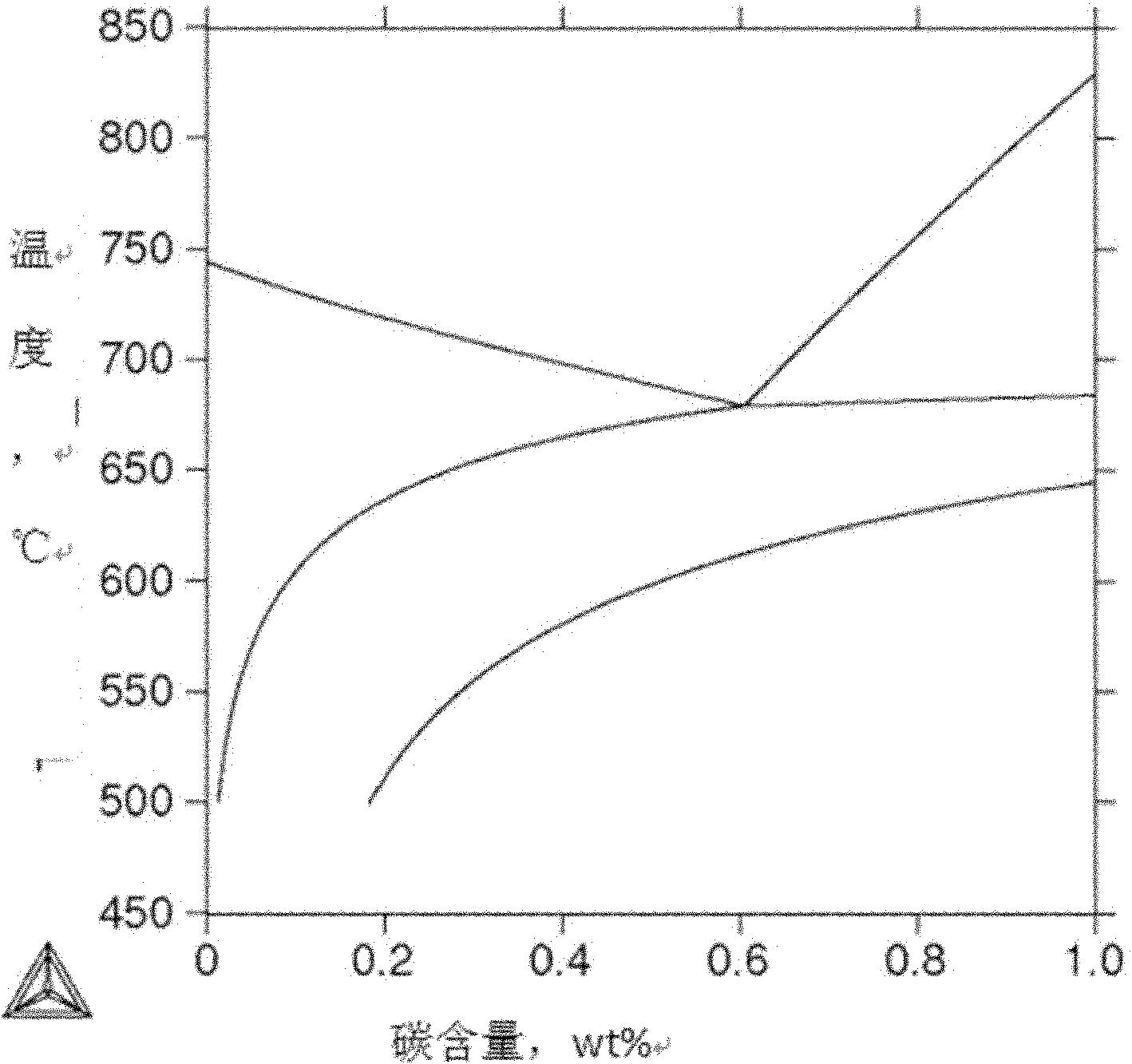

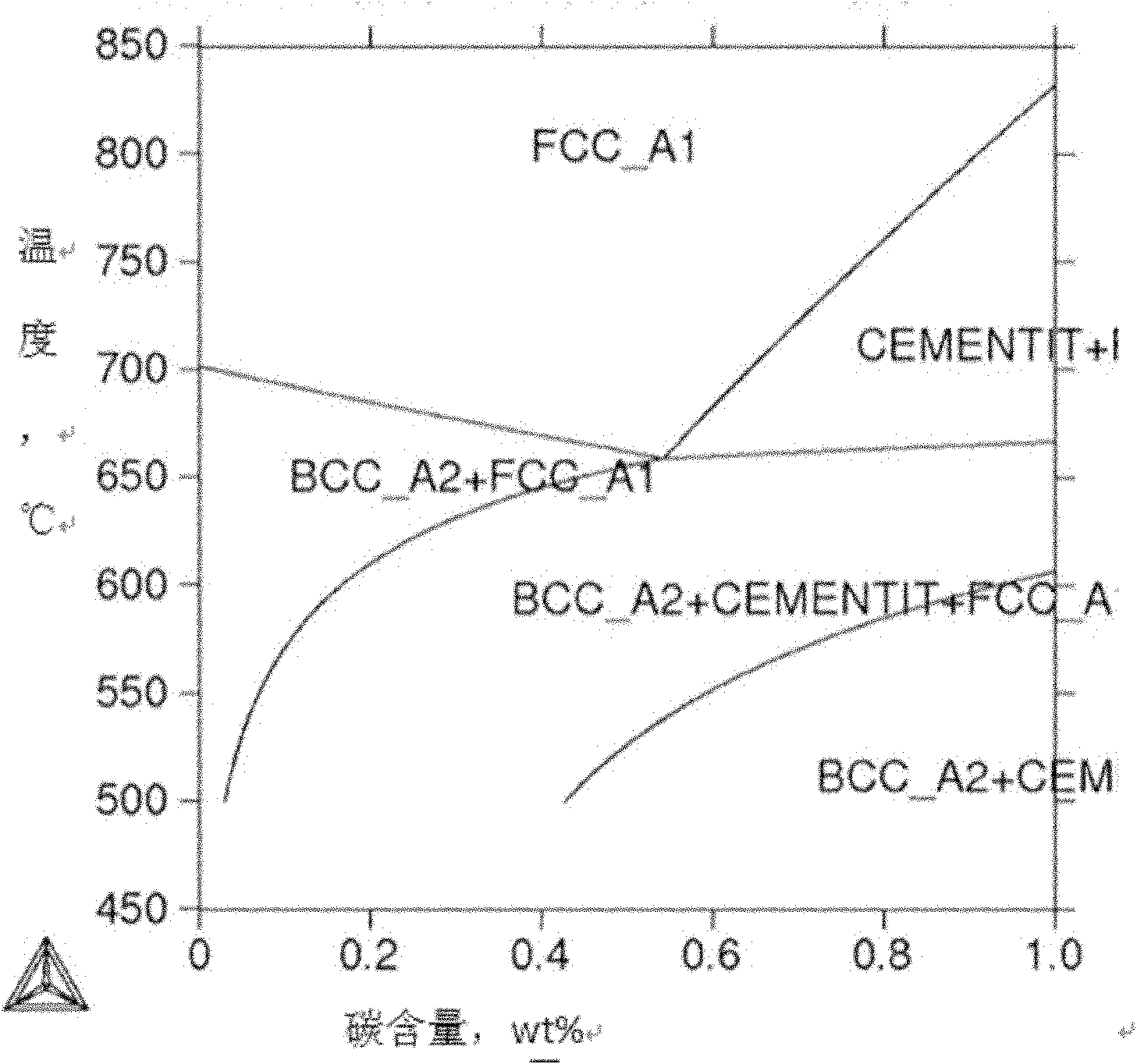

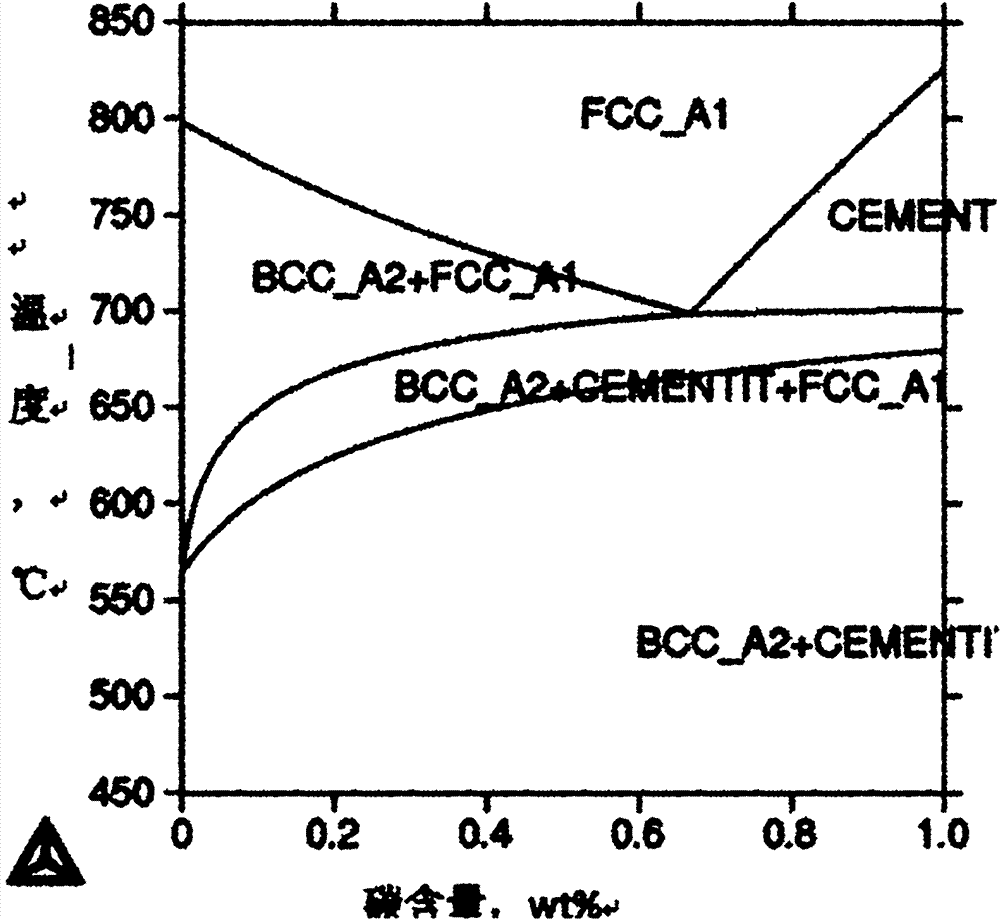

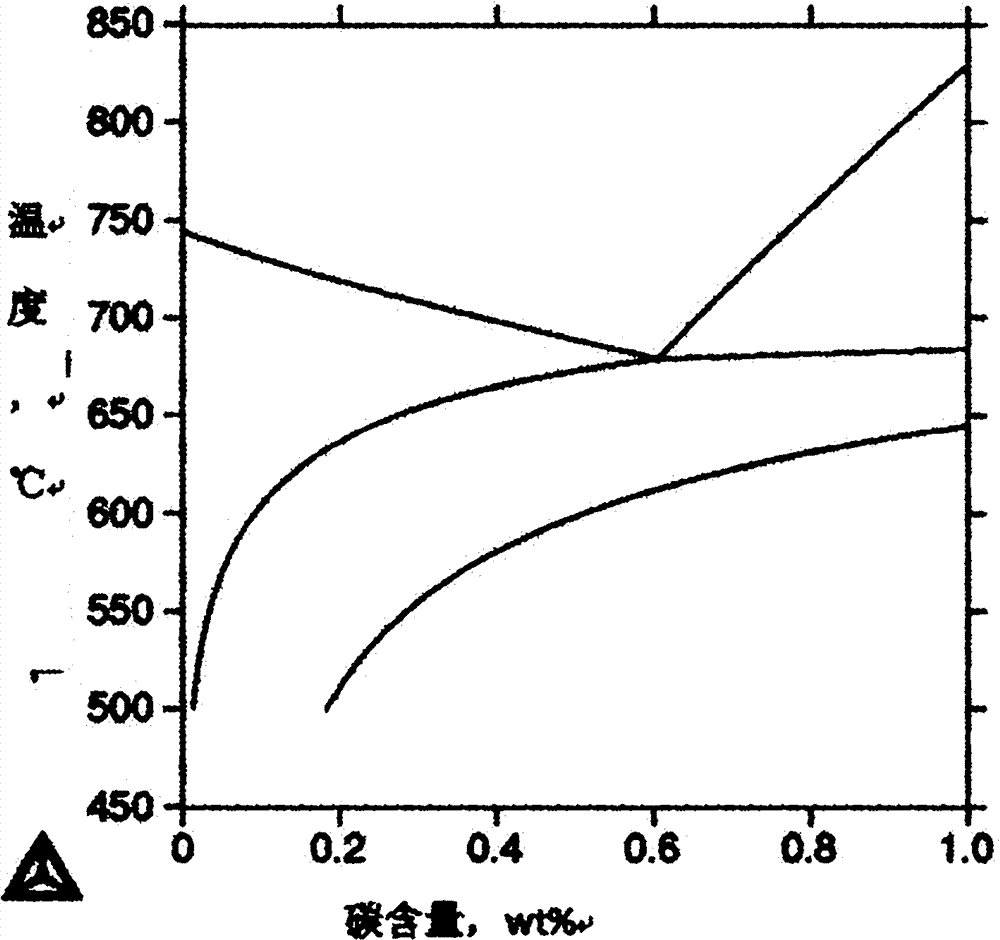

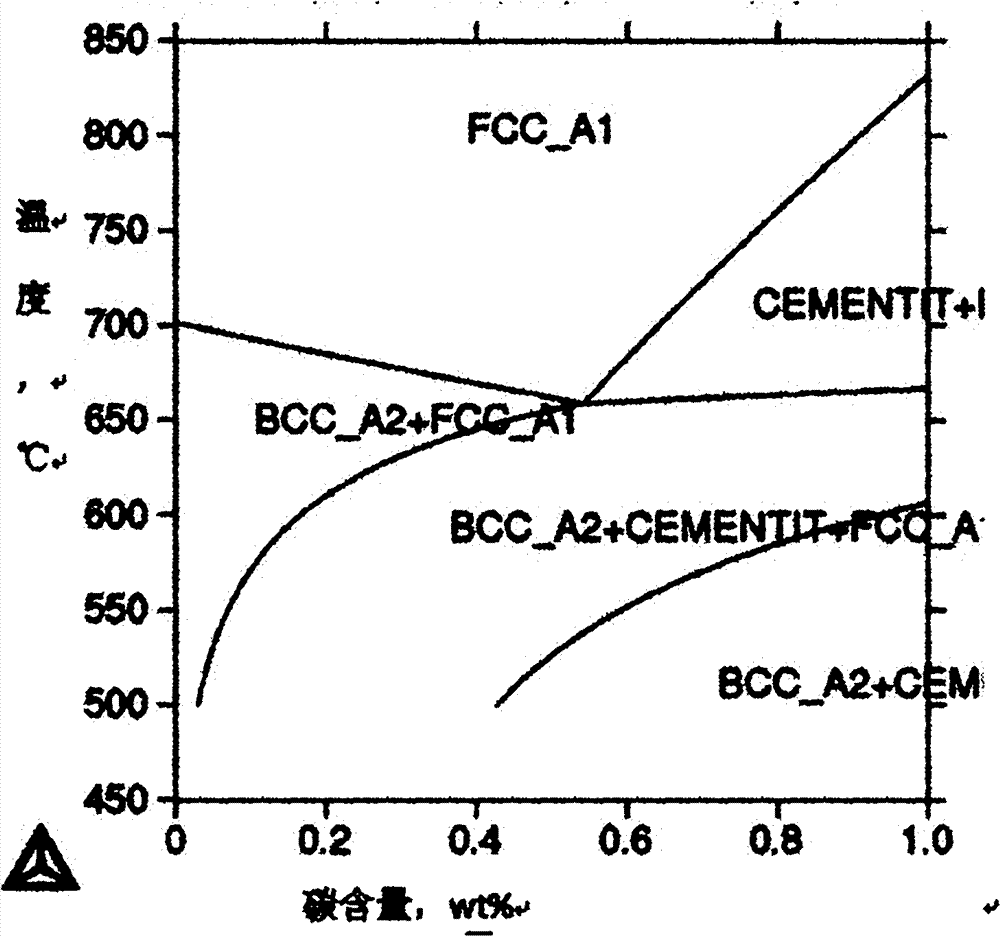

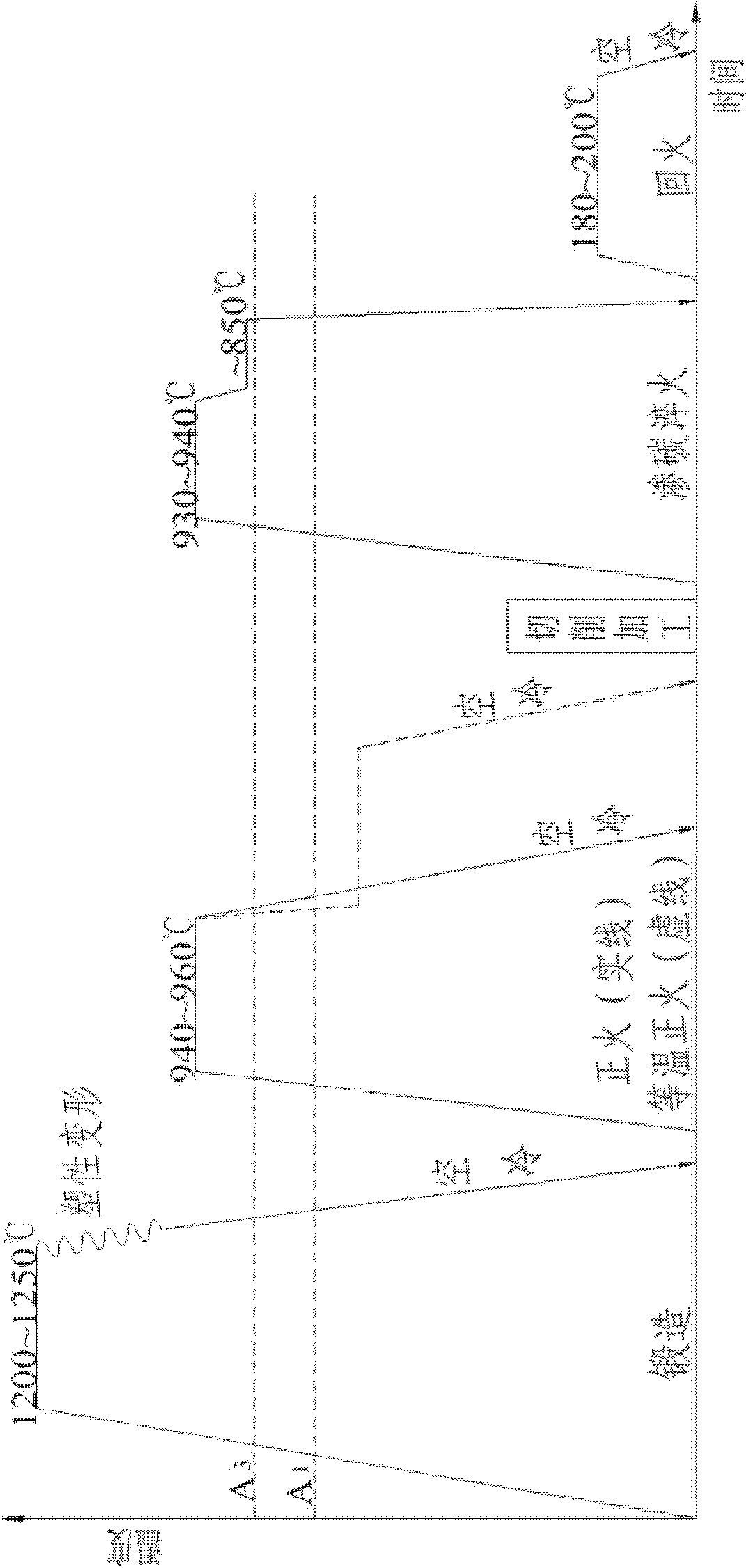

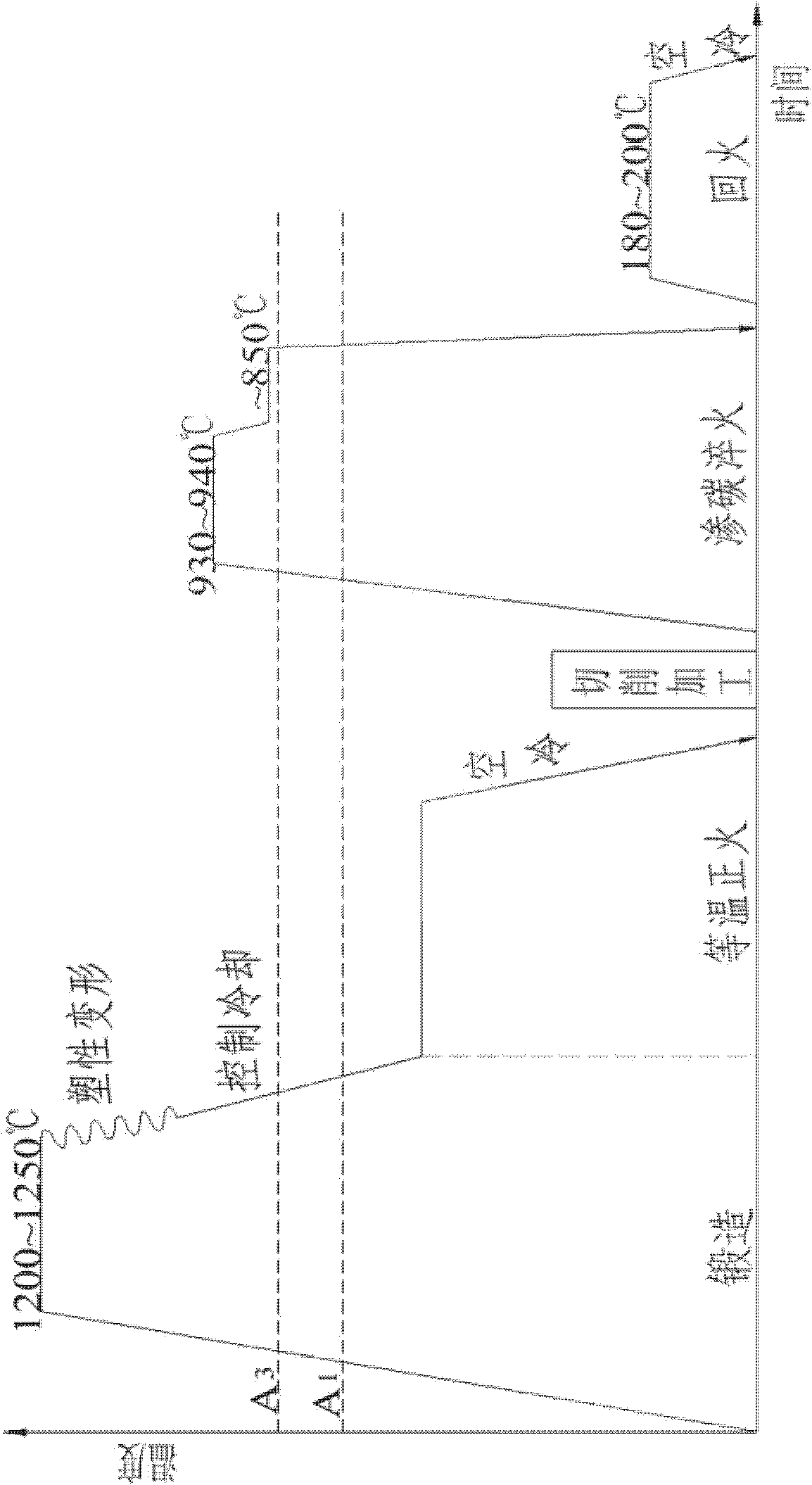

A kind of preparation method of dual-phase hot forming steel

The invention provides a preparation method for double-phase forming steel, which belongs to the technical field of high-intensity steel for automobiles. The steel comprises the following ingredients by mass percent: 0.1 to 0.5 percent of C, 0.3 to 2.5 percent of Si, 1.0 to 3.0 percent of Mn, 1.0 to 3.0 percent of Al, at most 0.02 percent of P, at most 0.01 percent of S, at most 0.01 percent of Nand the balance iron and unavoidable impurities. A production process comprises the following steps of: smelting, hot rolling and hot forming process simulation after the hot rolling. The controlled process parameters are as follows: hot rolling plate blanks are heated to 1200 to 1250 DEG C, the heat insulation is carried out for 0.5 to 1 hour, the final rolling temperature is 800 to 900 DEG C, and the coiling temperature is 600 to 700 DEG C. The hot forming process comprises the following steps of: carrying out heat insulation for 5min at the heating temperature being 750 to 850 DEG C and cooling the materials to the room temperature at the speed greater than 40 DEG C / s. The preparation method adopts the Al micro alloying treatment. Compared with the traditional thermal forming manganeseboron steel, the double-phase forming steel has the advantages that: 1, the hot forming heating temperature is low, and the surface oxidation is reduced; and 2, tissues after the hot forming are ferrite and martensite double-phase tissues.

Owner:UNIV OF SCI & TECH BEIJING

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

Steel plate warm formed parts with high efficiency, low energy consumption and high quality and production method thereof

The invention relates to steel plate warm formed parts with high efficiency, low energy consumption and high quality and a production method thereof, belonging to the technical field of part forming. The steel plate for producing parts comprises the following components in percent by weight: 0.02-0.45% of C, 3.50-9.0% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. On the basis of these components, one or more of the following components (in percent by weight) are additionally added: 0.1-3.0% of Ni, 0.2-3.0% of Cr, 0.1-0.8% of Mo, 0.3-2.3% of Si, 0.5-2.0% of Cu, 0.0005-0.0050 of B, 0.02-0.30% of Nb, 0.002-0.250% of [N], 0.05-0.25% of Ti, 0.02-0.25% of V, 0.015-3.0% of Al, 0.002-0.005% of RE, and 0.005-0.03% of Ca. The production method comprises the following steps: steel plate heating, steel plate transferring, steel plate precooling, part forming, part cooling, and part temperature control treatment. The production method provided by the invention has the advantages of low cost and high efficiency, and improves the forming rate and final mechanical properties of workpieces.

Owner:CENT IRON & STEEL RES INST

Doped pnictogen chalcogenide nanoplates, methods of making, and assemblies and films thereof

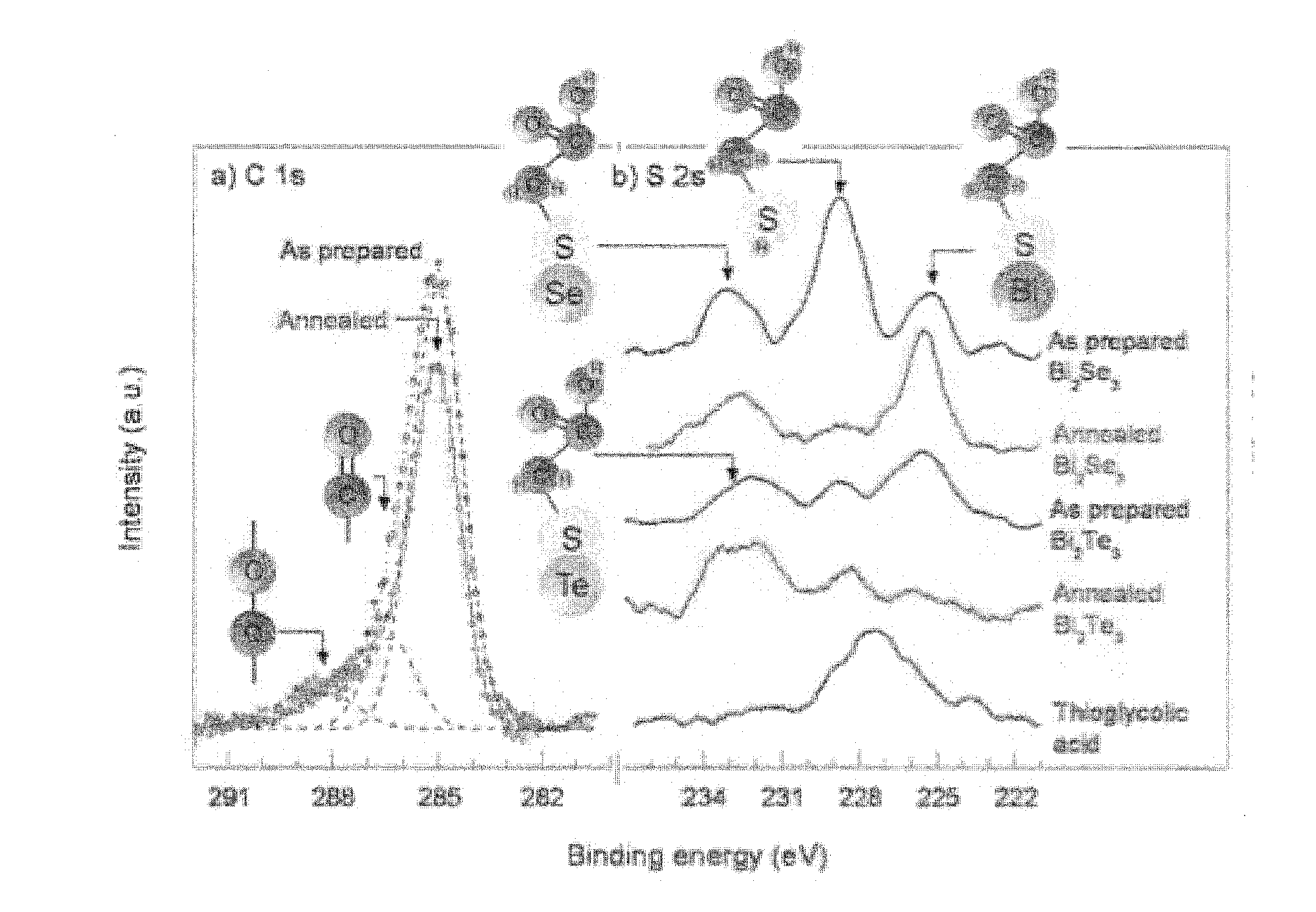

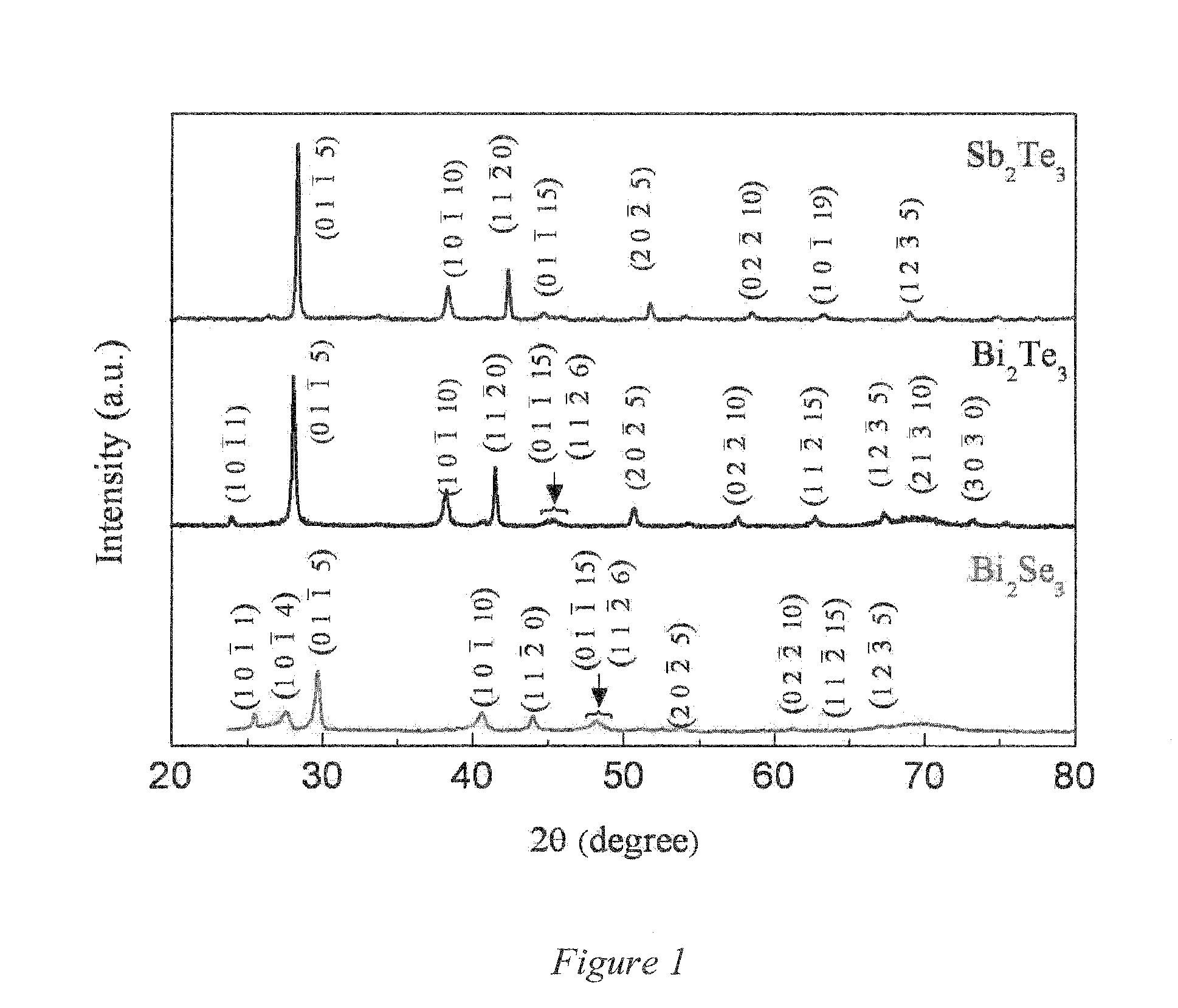

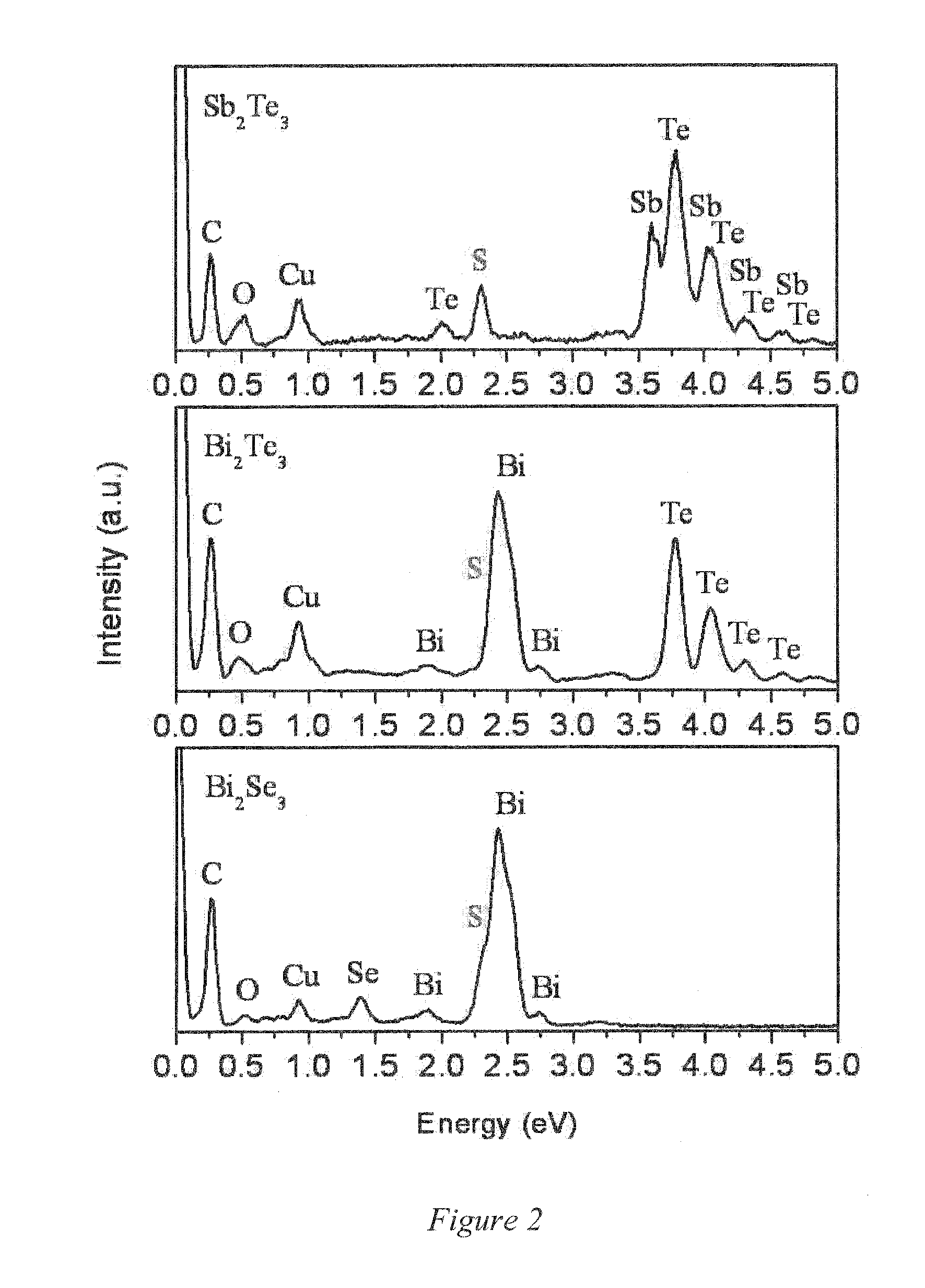

ActiveUS20120111385A1Easy to optimizeReduce surface oxidationMaterial nanotechnologyThermoelectric device with peltier/seeback effectMicrowaveSulfur

Embodiments of the invention are directed to doped pnictogen chalcogenide nanoplates, where each nanoplate comprises a rhombohedral crystal of Bi2Te3, Bi2Se3, or Sb2Te3 that is sulfur doped. Another embodiment of the invention is directed to a microwave activated method of preparation of the doped pnictogen chalcogenide nanoplates. Other embodiments of the invention are directed to bulk assemblies or fused films of the doped pnictogen chalcogenide nanoplates and their preparation from the doped pnictogen chalcogenide nanoplates such that the bulk assembly or fused film can be employed in a thermoelectric device.

Owner:SAVITR ENERGY INC +1

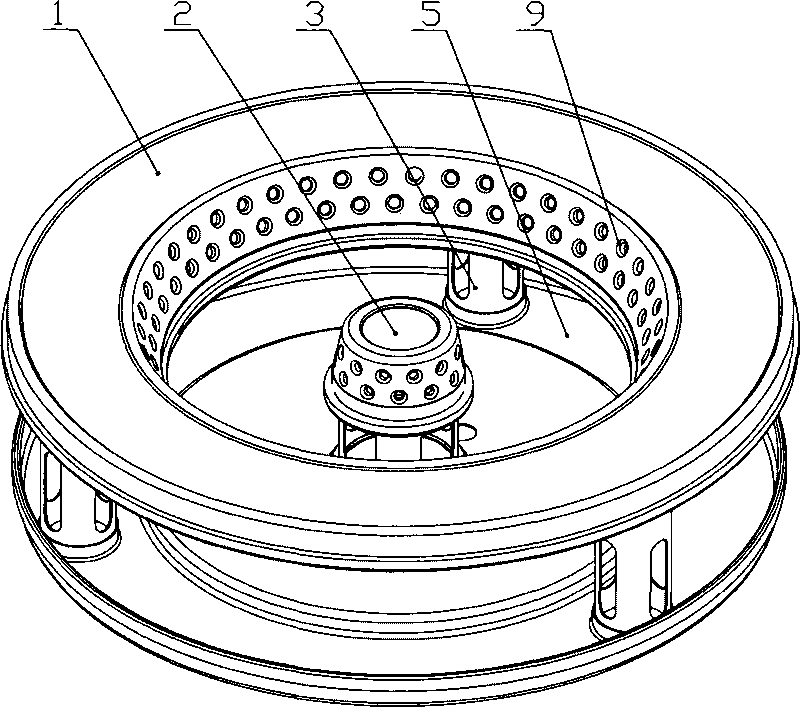

Runner type online degassing device

The invention belongs to the technical field of metallurgy, and relates to a runner type online degassing device, which comprises a runner shell, a degassing chamber, gas permeable bricks, a heat insulating cover, a vent, a first baffle plate, a second baffle plate, a middle baffle plate, a gas inlet, an inlet and an outlet; the degassing chamber is arranged in the runner shell; the heat insulating cover is movably connected with the runner shell, and is provided with the vent; two ends of the degassing chamber are provided with the inlet and the outlet; the middle of the degassing chamber is provided with the middle baffle plate; the first baffle plate is arranged between the middle baffle plate and the inlet; the second baffle plate is arranged between the middle baffle plate and the outlet; gaps are reserved between the bottoms of the first and second baffle plates and the degassing chamber; the bottom of the middle baffle plate is fixedly connected with the degassing chamber; the gas permeable bricks are embedded on the bottom of the degassing chamber and arranged between the first baffle plate and the middle baffle plate and between the second baffle plate and the middle baffle plate; and the bottoms of the gas permeable bricks are provided with the gas inlet. The runner type online degassing device has low requirement on space, is provided with the submerged baffle plates and the heat insulating cover, reduces gas absorption again and surface oxidation of degassed aluminium liquid, and has good degassing purification effect.

Owner:江西金达通新材料科技有限公司

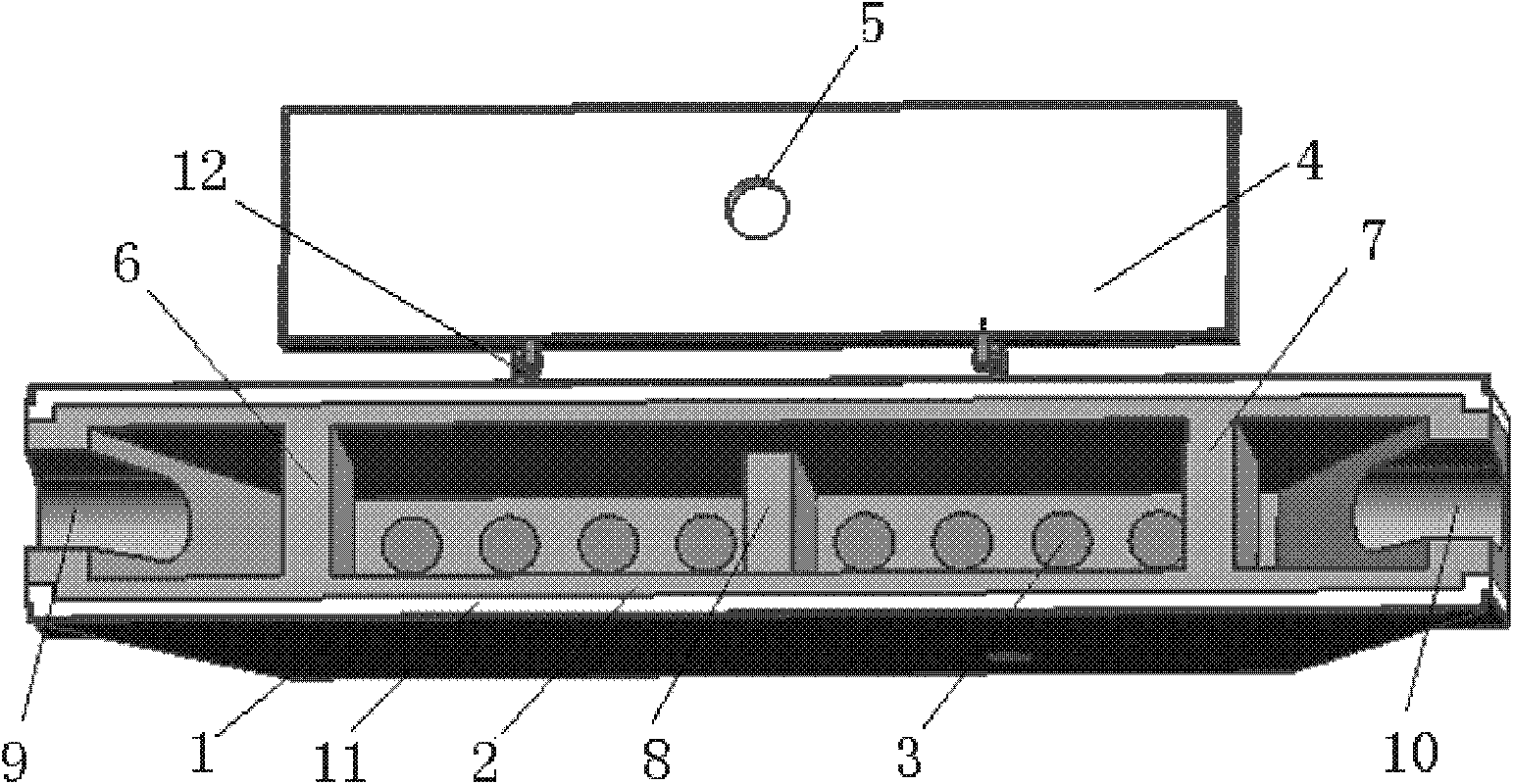

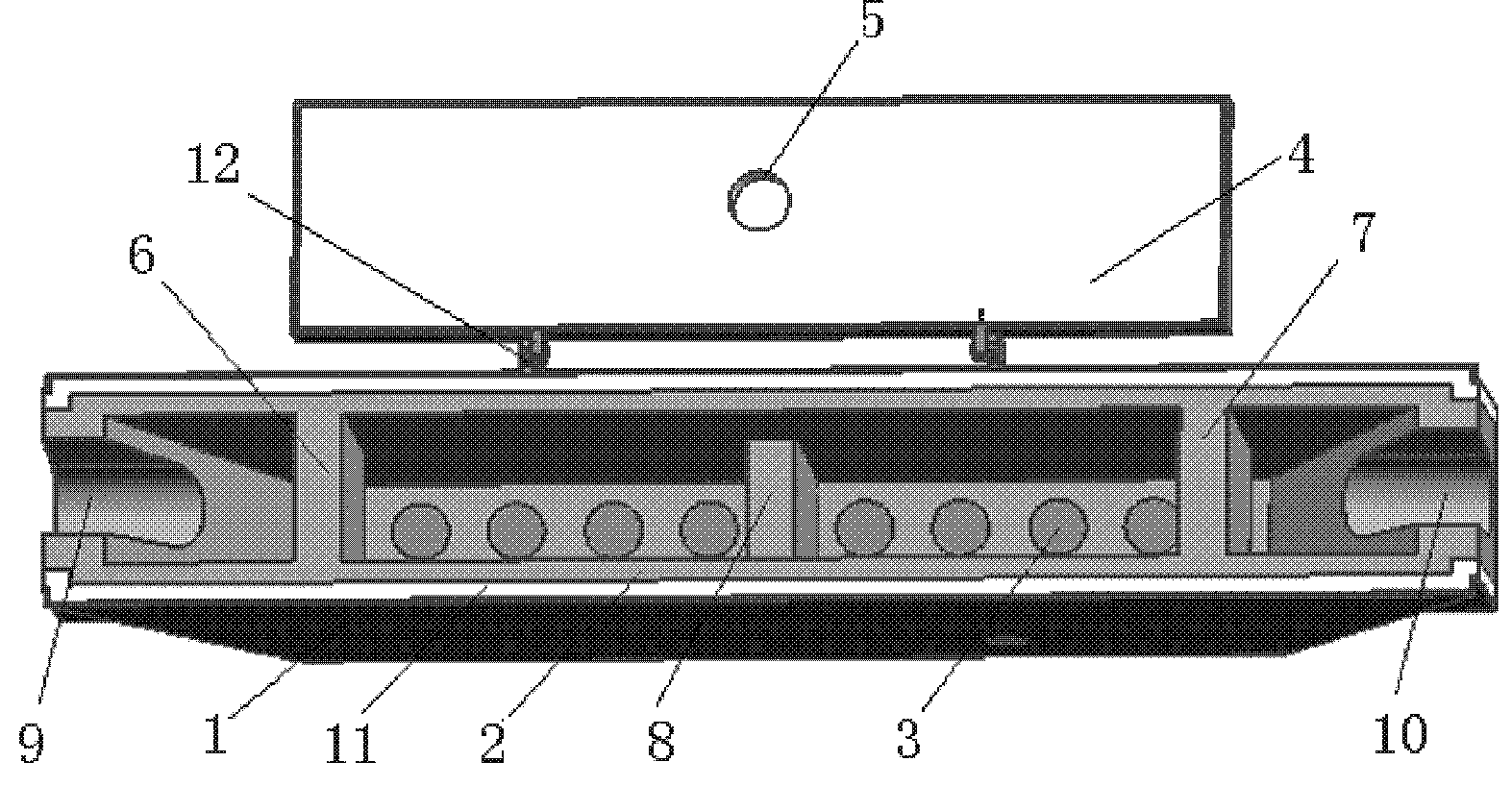

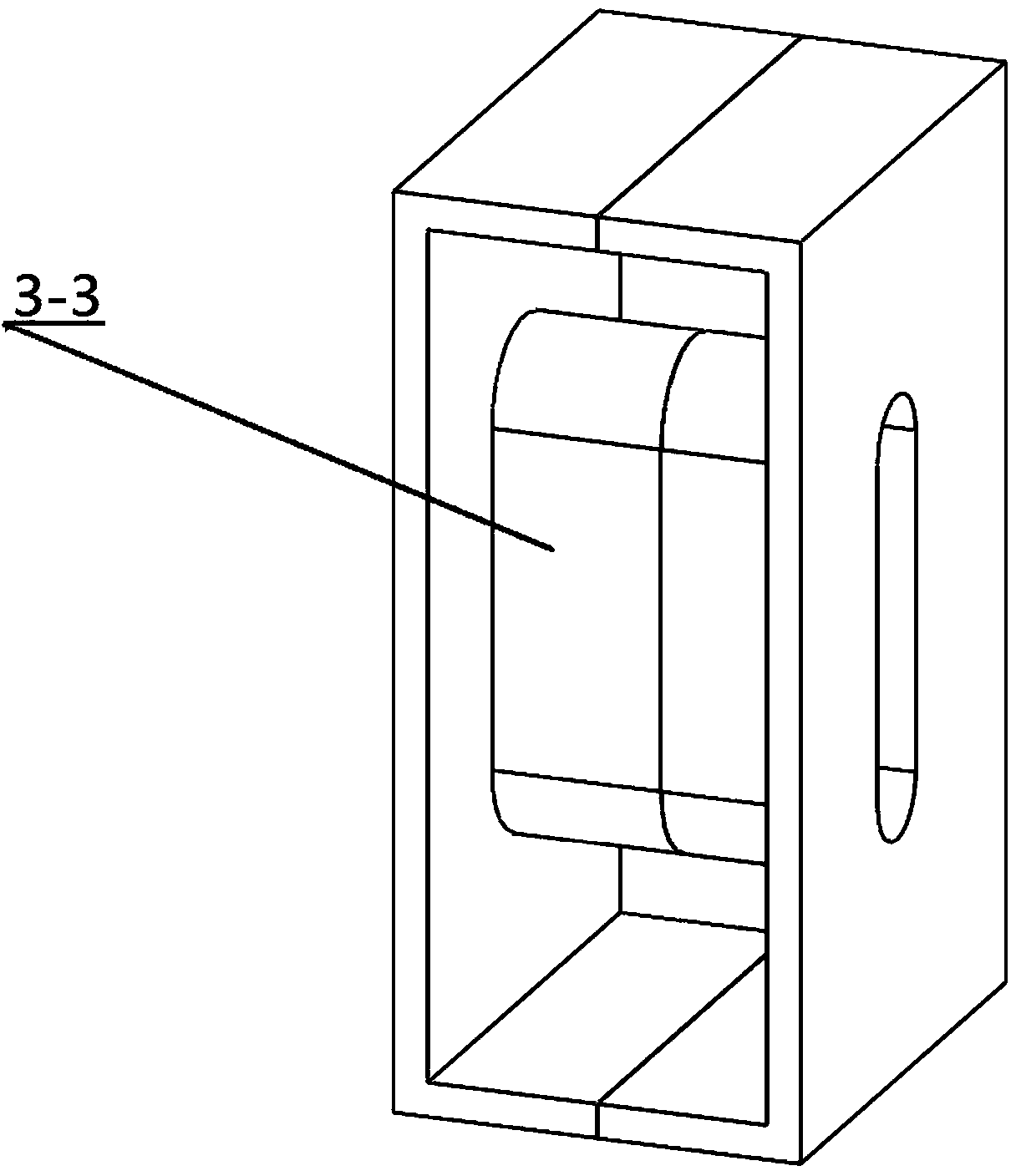

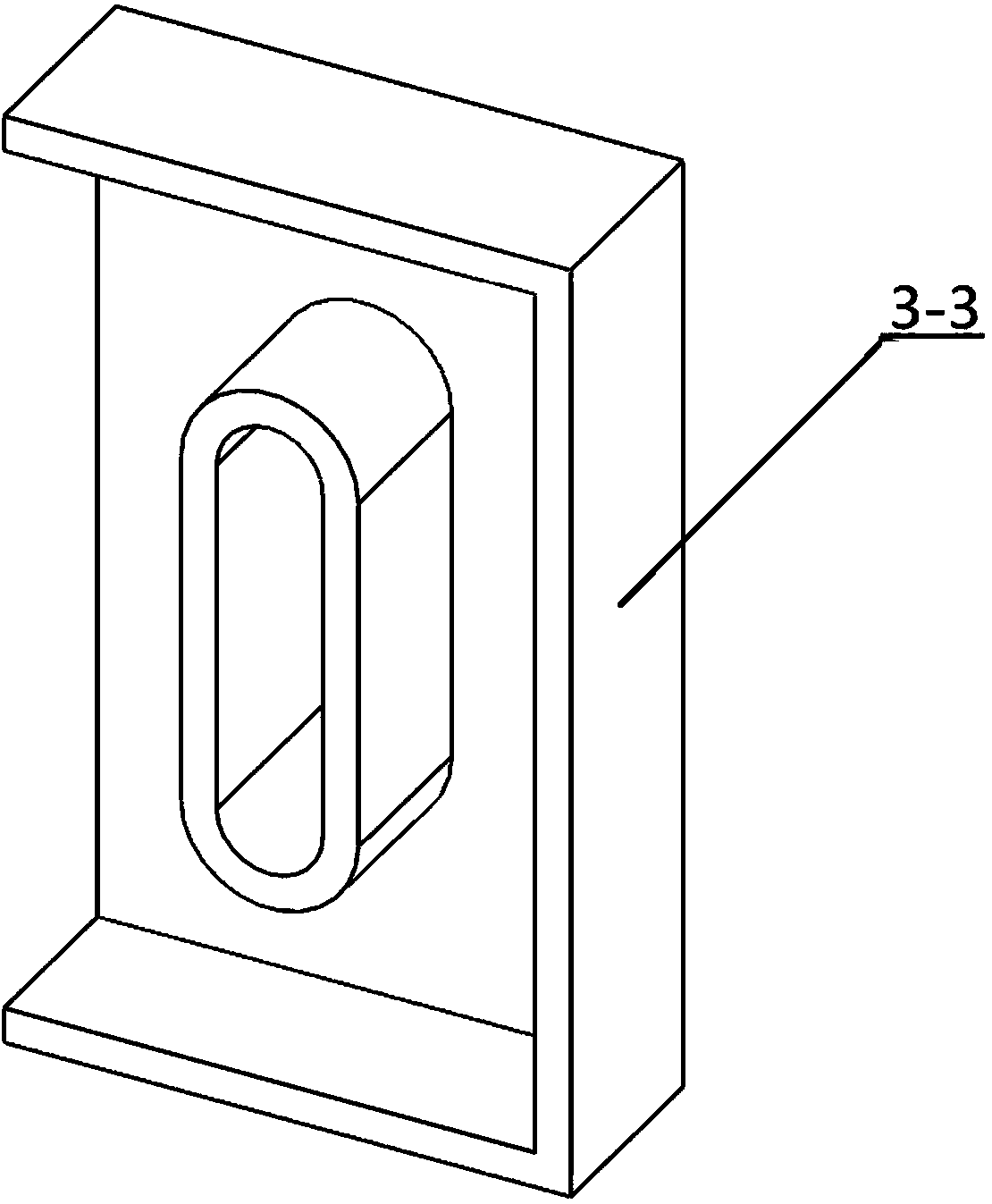

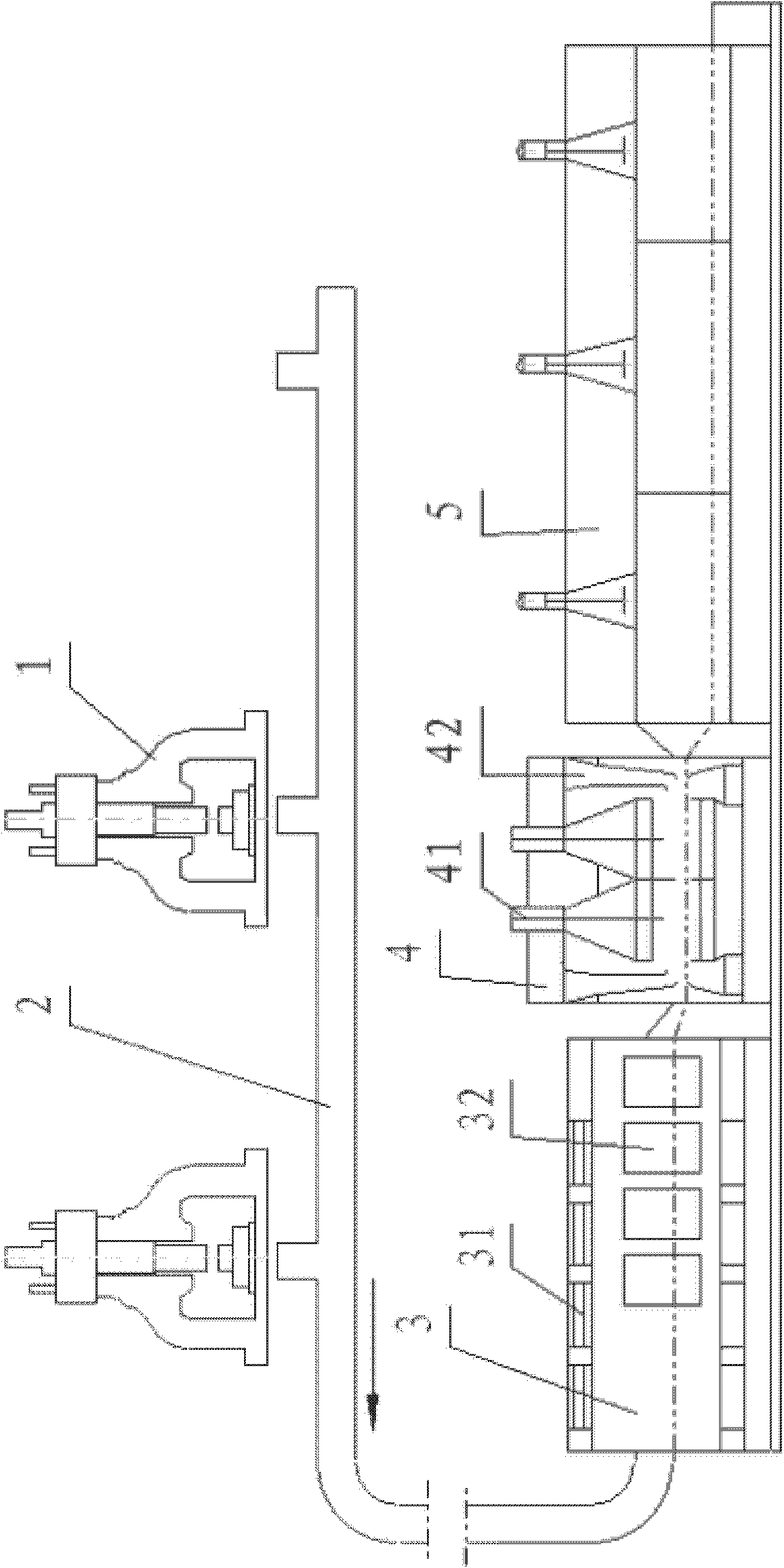

Electroplastic equal-diameter rolling mill

ActiveCN103846278AImprove working conditionsIncreased Equal Angle Rolling EfficiencyMetal rolling stand detailsMetal rolling arrangementsMetallic materialsSuperalloy

The invention discloses an electroplastic equal-diameter rolling mill. The electroplastic equal-diameter rolling mill is mainly characterized in that on the basis of a two-high rolling mill, an equal-diameter angular rolling mechanism consisting of a guiding plate and an equal-diameter angle mold and an electroplastic processing mechanism consisting of an electrical pulse interface and a power supply are added. The electroplastic equal-diameter rolling mill disclosed by the invention has the beneficial effects that the necessary preheating and hot-rolling equipment in the conventional equal-diameter angular rolling process is omitted, annealing treatment does not need to be carried out on plates after rolling, the rolling process can be carried out under the normal temperature, so that the procedure and the processing cost are greatly reduced; and continuous rolling also can be carried out, the processing process is simple and high-efficiency, not only can the effect of greatly improving the comprehensive mechanical performance of the plates after conventional equal-diameter angular rolling be obtained, but also the fussy procedure and the heavy equipment in the conventional equal-diameter angular rolling process are greatly simplified. The electroplastic equal-diameter rolling mill is suitable for carrying out rolling and performance improvement on metal materials such as magnesium alloy with low plasticity and difficult rolling and metal materials such as high-temperature alloy and high-strength steel with high strength and difficult deformation.

Owner:安徽华驰动能科技有限公司

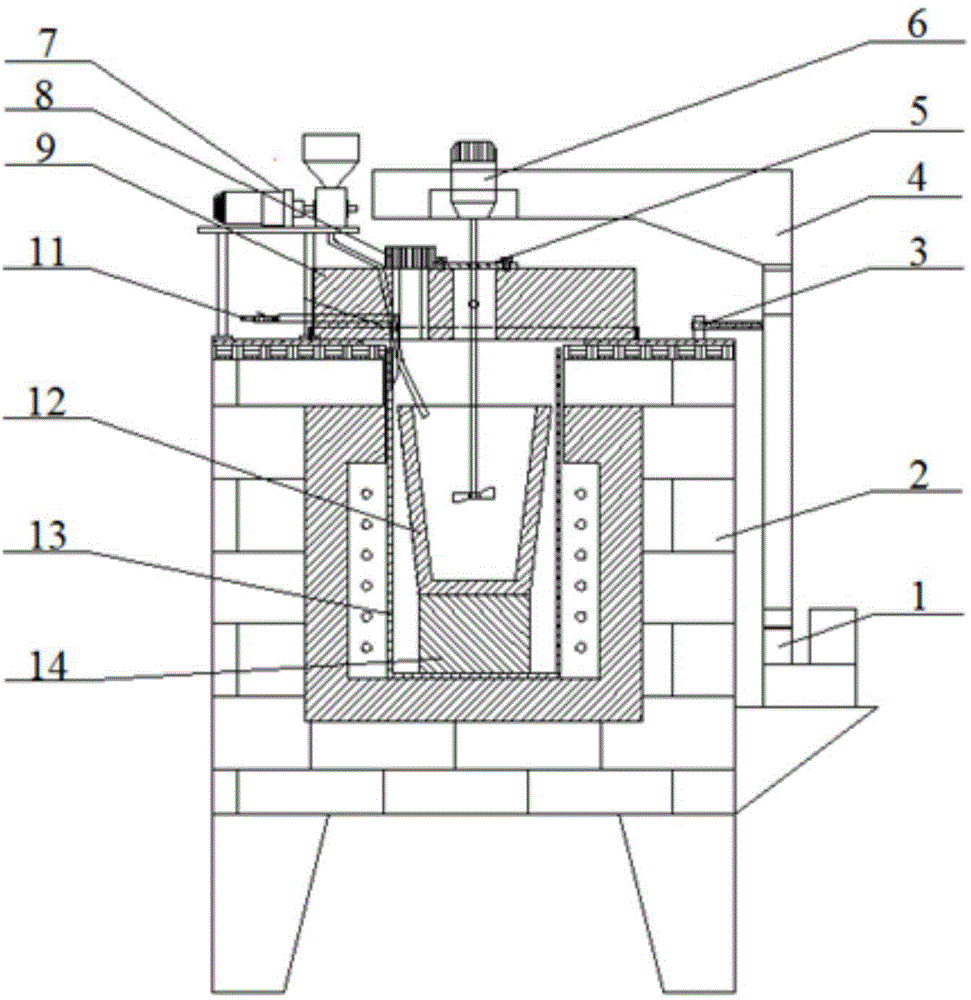

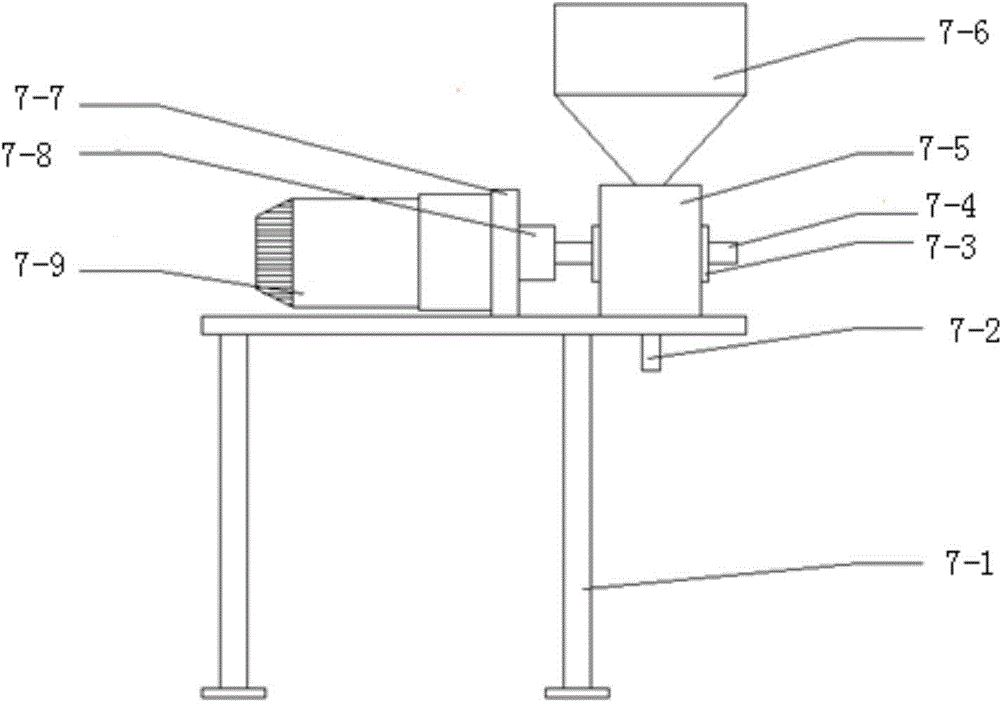

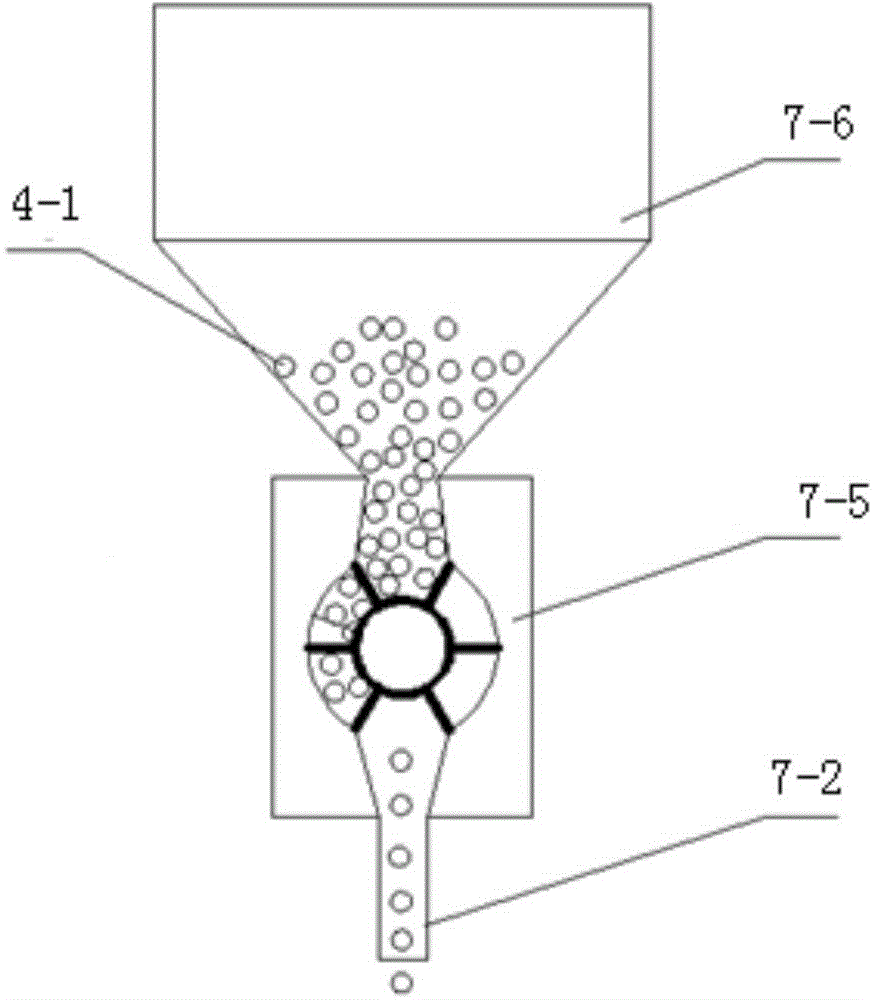

Device and method for preparing particulate-reinforced aluminum matrix composites by stirring and casting

ActiveCN104152727AImprove efficiency and stabilityGood for even distributionAluminum matrix compositesGas protection

The invention discloses a device and a method for preparing particulate-reinforced aluminum matrix composites by stirring and casting. The device comprises a lifting mechanism, a resistance furnace, a fixed column, a supporting mechanism, a stirring device, a particulate conveying device, a furnace lid, a feeding hole, a gas inlet tube, a graphite crucible and a stainless steel crucible. The device for preparing particulate-reinforced aluminum matrix composites by stirring and casting can be used for quantitatively conveying and adding reinforced particulates, and realizing gas protection and automatic preparation. The device is delicate in structural design, simple and convenient to operate, high in automation degree and good in stability. By virtue of the gas protection, gas absorption and surface oxidization of a melt in a preparation process based on stirring and casting are reduced; the quantitative conveying and adding of the reinforced particulates are realized by virtue of the particulate conveying device; the quantitative control on a stirring position and a stirring speed is realized by virtue of the lifting device and the stirring device, and thus, the performance and preparation efficiency of a composite material are well improved.

Owner:SOUTH CHINA UNIV OF TECH

Production method of steel plate warm formed parts with high efficiency, low energy consumption and high quality

The invention relates to steel plate warm formed parts with high efficiency, low energy consumption and high quality and a production method thereof, belonging to the technical field of part forming. The steel plate for producing parts comprises the following components in percent by weight: 0.02-0.45% of C, 3.50-9.0% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. On the basis of these components, one or more of the following components (in percent by weight) are additionally added: 0.1-3.0% of Ni, 0.2-3.0% of Cr,0.1-0.8% of Mo, 0.3-2.3% of Si, 0.5-2.0% of Cu, 0.0005-0.0050 of B, 0.02-0.30% of Nb, 0.002-0.250% of [N], 0.05-0.25% of Ti, 0.02-0.25% of V, 0.015-3.0% of Al, 0.002-0.005% of RE, and 0.005-0.03% of Ca. The production method comprises the following steps: steel plate heating, steel plate transferring, steel plate precooling, part forming, part cooling, and part temperature control treatment. The production method provided by the invention has the advantages of low cost and high efficiency, and improves the forming rate and final mechanical properties of workpieces.

Owner:CENT IRON & STEEL RES INST

Laser inducement nano-surface preparation method for iron based amorphous nanocrystalline soft magnetic material

InactiveCN101509053ALow crystallization brittlenessIncreasing the thicknessAmorphous phaseNano crystalline

The invention relates to a nano-preparation method of laser-induced surface of iron-based amorphous and nano-crystalline soft magnetic material, belonging to the field of material technology. The method comprises the following steps: a solid pulsing laser is adopted to scan by different overlapping rate along the length direction or width direction of an amorphous belt, and the total thickness of a laser surface nano-layer is controlled to be 2-10mum. When the thickness of the surface nano-layer is 2-7mum, single-side laser-induced treatment is carried out on the amorphous belt; when the thickness of the nano-layer is 7-10mum, double-side laser-induced treatment is carried out on the amorphous belt; finally, alpha-Fe (Si) nano-crystalline phase having the nano-crystalline size at 5-40 nm and the relative quantity at 5-20% as well as rest amorphous phase biphase organization material structure are formed. The amorphous nano-crystalline belt prepared by the invention has the characteristic that the amorphous nano-crystalline belt does not have brittle failure when being wound into a round due to good toughness, thus having important application value.

Owner:XINGKE MEDIUM & SMALL ENTERPRISES SERVICE CENT OF NORTHEASTERN UNIV

Improved process for producing copper alloy powder by water atomization method

The invention discloses an improved process for producing copper alloy powder by a water atomization method. The process includes the steps: (1) smelting by an intermediate frequency furnace: adding nonmetallic ore elements and salt in the smelting process; (2) performing water atomization pulverization; (3) performing vacuum suction filtering: adding composite antioxidants when suction filtering is performed; (4) treating the atomized water obtained by vacuum suction filtering, then recycling the treated atomized water, and drying, screening and packing the obtained copper alloy powder. The nonmetallic ore elements account for 0.5-0.7% of the weight of a copper block, the salt accounts for 0.3-0.5% of the weight of the copper block, an ejecting angle ranges from 40 degrees to 45 degrees, a spray nozzle is made of No.45 steel, the diameter of a package leaking hole ranges from 5mm to 8mm, atomization pressure ranges from 18Mpa to 25Mpa, the height of an atomization barrel is 3m, cooling water level ranges from 0.3m to 0.5m, and the composite antioxidants account for 0.05-0.15% of the weight of the copper block. By the aid of the improved process for producing the copper alloy powder by the water atomization method, the produced spherical copper alloy powder has the advantages of fine sphericity and formability, uniform components, excellent sintering property, less surface oxidation, low production cost, high production efficiency and stable product quality.

Owner:安徽旭晶粉体新材料科技有限公司

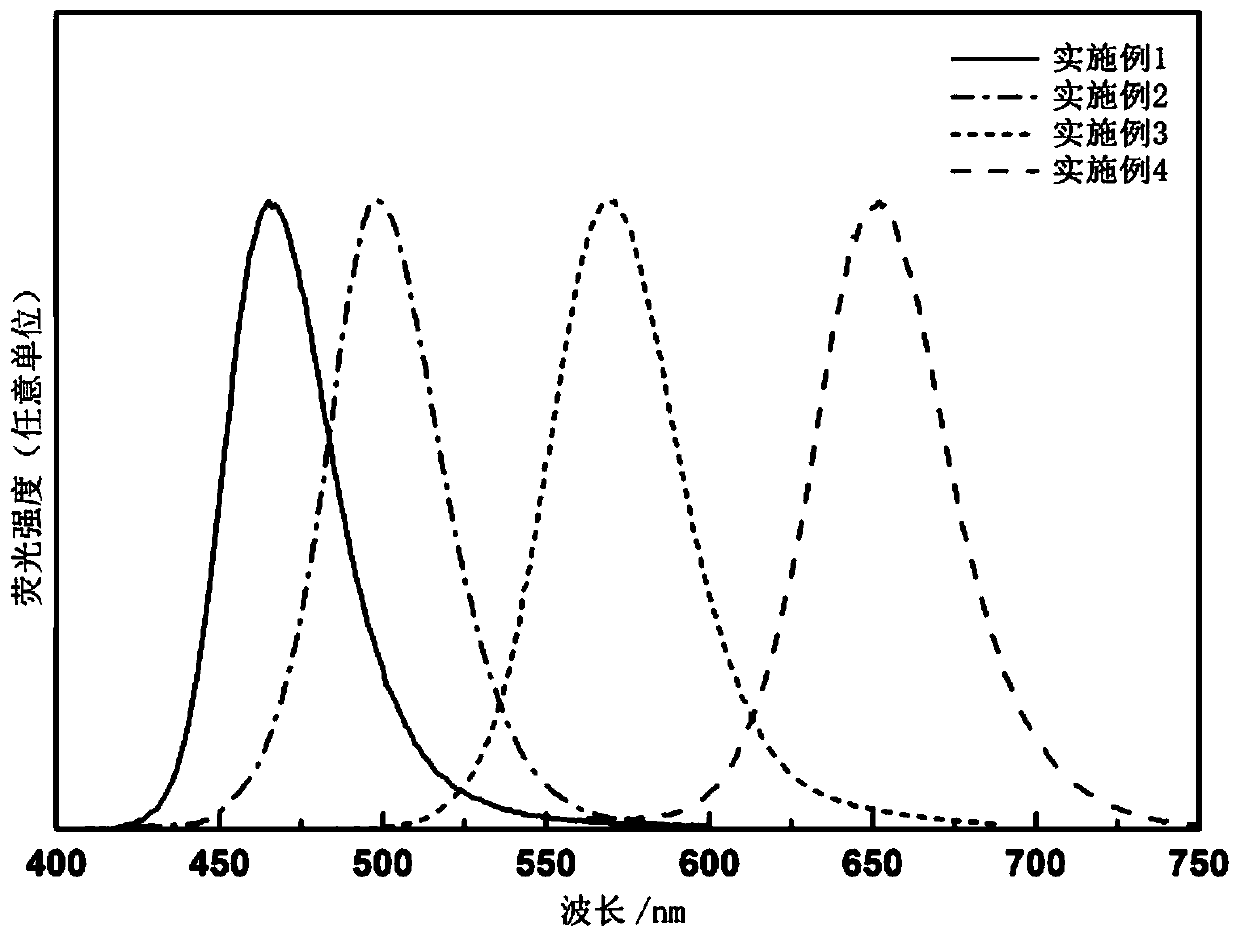

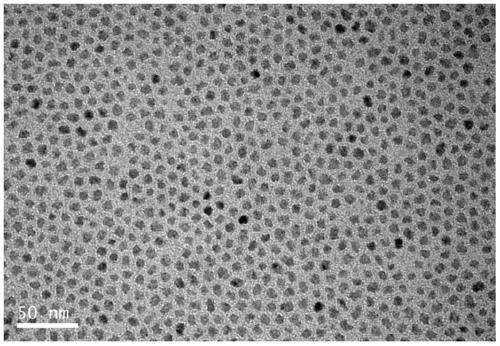

InP quantum dot and preparation method thereof

The invention discloses a preparation method of an InP quantum dot, relates to the field of quantum dot materials, comprising the following steps: firstly, water and oxygen are removed from a reactionvessel, then a homogeneous precursor solution of indium and zinc is prepared, a phosphorus precursor is added, a synthetic shell material is added, and then, an InP quantum dot structure with a shellstructure is prepared by increasing the shell thickness while raising the temperature. The InP crystal nucleus of the InP quantum dot prepared by the invention are nano-structures, and the shell layer composition comprises one or several of ZnS, ZnSe and ZnSeS; the fluorescence emission peaks range from 450 nm to 700 nm, and the half maximum width is less than 55 nm. The invention can effectivelycontrol crystal nucleus growth and fluorescence emission wavelength, and obtain InP quantum dots with small and uniform crystal nucleus diameter, wide luminous color gamut and narrow half-maximum width. At the same time, it can reduce the surface oxidation of the crystal nucleus, promote the thickness of the shell layer with high quality and low defects, and improve the luminescence efficiency ofInP quantum dot.

Owner:SHANGHAI JIAO TONG UNIV

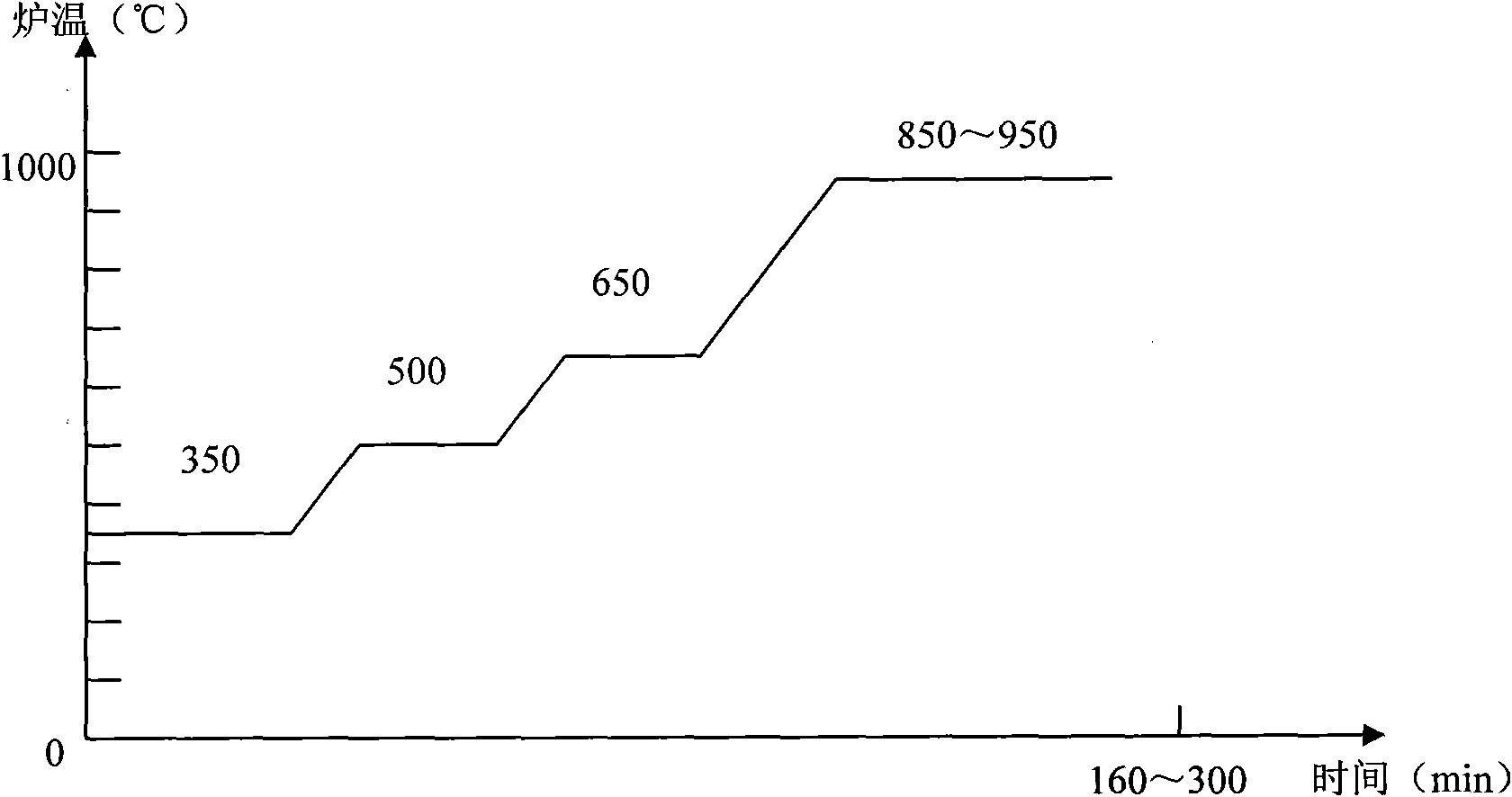

Method for heating titanium blank by using continuous heating furnace

InactiveCN101812652AReduce surface oxidationReduce hydrogen absorptionFurnace typesHeat treatment furnacesBeta phaseSurface oxidation

The invention discloses a method for heating a titanium blank by using a continuous heating furnace. The heating temperature of the titanium blank is about 880 DEG C and is far lower than the heating temperature of about 1,200 DEG C of a steel blank; and if the titanium blank is heated by using a continuous heating furnace for heating the steel blank, over-high temperature or non-uniform heating is caused, and the over-high heating temperature causes the defects of rolling in a beta-phase area, thick and large tissue, serious surface oxidation and the like. The invention provides the method for heating the titanium blank by using the continuous heating furnace for heating the steel blank, wherein the thickness of the blank is 150 to 250 millimeters, and the titanium blank avoids a high-temperature flame area in a mode of furnace body radiation and furnace gas convection so as to achieve the effects of uniform heating temperature and good heating quality.

Owner:SHANDONG IRON & STEEL CO LTD

Post rolling fast cooling-production technology of high strength ribbed reinforced bar

An ultrahigh-speed cooling technology for the rolled high-strength ribbed steel bar includes hot rolling and afterheat treating. For said afterheat treating, the rolled steel bar is quickly cooled to 480-720 deg.C within 1 second to quickly convert its austenite structure to the ferrite / pearlite structure with the grain fineness of class 11-12. It is suitable for rolling high-quality steel bar.

Owner:NORTHEASTERN UNIV

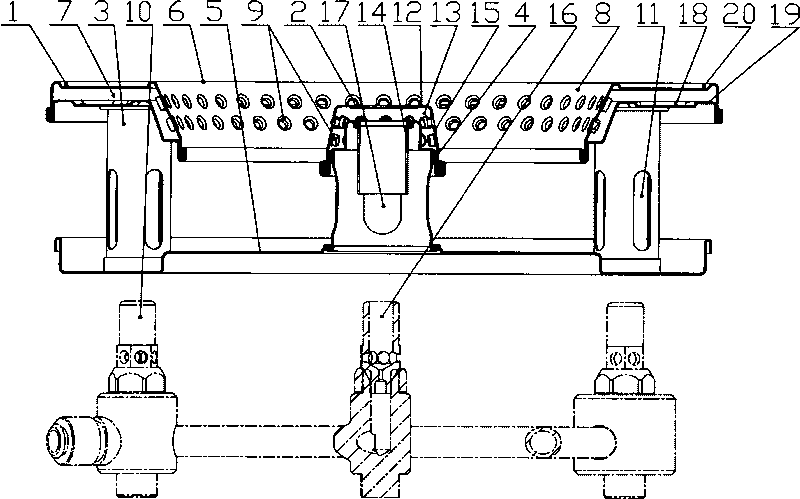

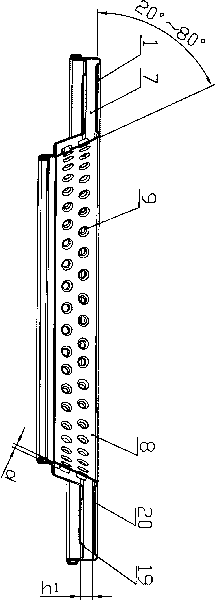

Inner flame energy-concentrating riser pipe type gas burner

ActiveCN101725987AGood energy gathering effectIncrease heat loadGaseous fuel burnerMultiple burner assemblyGas burnerThermal efficiency

The invention discloses an inner flame energy-concentrating riser pipe type gas burner, which comprises a big fire burner, a small fire burner, a mixing tube of the big fire burner, a positioning tube of the small fire burner, and a water collector. An inner ring of an annular shell of the big fire burner is an inverted frustum which forms an angle between 20 and 80 DEG with a horizontal plane, and 1 to 5 fire exhaust holes are formed on the inner ring. One end of the mixing tube of the big fire burner is connected with the annular shell and communicated with an inner cavity of the annular shell, while the other end is communicated with a big fire nozzle which is arranged on the lower part of the water collector. The small fire burner comprises a frustum cap shell and an inner cavity of the frustum cap shell, wherein 1 to 5 fire exhaust holes are formed on external side face of the frustum cap shell, and the inner cavity of the frustum cap shell is communicated with a small fire nozzle which is positioned on the lower part of the water collector by a mixing tube of the small fire burner. The inner flame energy-concentrating riser pipe type gas burner has the advantages of reasonable structure, high thermal efficiency, material conservation, convenient processing, excellent energy-saving effect, less exhaust emission and the like.

Owner:三峰实业有限公司

Forging waste heat isothermal normalizing device and method

ActiveCN102286655AReduce energy consumptionExcellent forging billet qualityHeat treatment process controlCooling chamberAlloy

The invention provides a method and a device for carrying out isothermal normalizing heat treatment on alloy cemented steel parts utilizing forging waste heat. The method comprises the following steps: after finish forging of a forged steel blank, slowly cooling the forged steel blank from the final forging temperature to a pre-cooling temperature T1 at a pre-cooling rate V1, insulating heat for t1, then rapidly cooling to a forced cooling temperature T2 at a forced cooling rate V2, carrying out isothermic transition at the isothermic temperature of Tiso for isothermic time tiso, and then cooling to room temperature in a random cooling mode. The invention also provides a device for isothermal normalizing of cemented steel parts utilizing forging waste heat, and the device is composed of atransmission mechanism, a slow cooling chamber, a rapid cooling chamber, an isothermal furnace, a control system, a transmission system and process parameter calculation and correction software. The calculated process parameters can be used for precise control and operation of the device, thereby guaranteeing that the normalizing quality of steel parts is superior or at least equal to the heat treatment quality using conventional normalizing and isothermal normalizing.

Owner:浙江万能达炉业有限公司

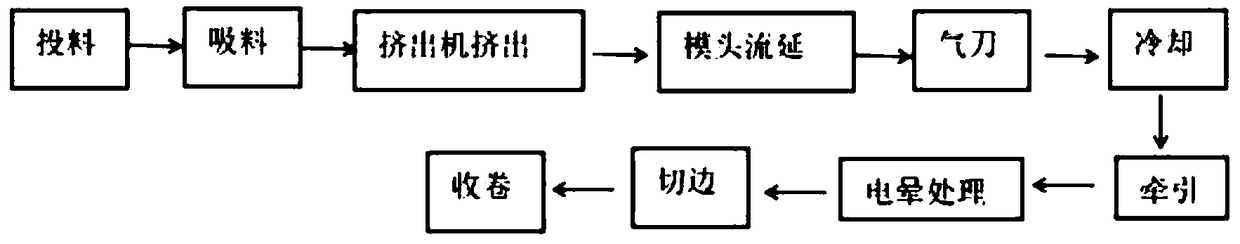

Two-way linear easy-to-tear polyethylene film and production process thereof

ActiveCN109263200ALow hazeHigh light transmittanceSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a two-way linear easy-to-tear polyethylene film and a production process thereof. The polyethylene film is obtained through the processing by a tape casting process; the polyethylene film comprises a hot sealing layer, a middle layer and a corona layer; the hot sealing layer is prepared from the following ingredients by weight: 80 to 84 percent of low density polyethylene,15 to 18 percent of polybutylene, 0.5 to 1.0 percent of smoothening agent and 0.5 to 1.0 percent of opening master batch; the middle layer is prepared from the following ingredients by weight: 65 to70 percent of low density polyethylene, 20 to 25 percent of high density polyethylene, 0.1 to 0.5 percent of processing auxiliary agent and 8 to 12 percent of polybutylene; the corona layer is prepared from the following ingredients by weight: 99.5 to 99.9 percent of low density polyethylene and 0.1 to 0.5 percent of processing auxiliary agent. The polyethylene film has the advantages that the mist degree is low; the light transmission rate is high; the mechanical performance is good; the linear easy-to-tear performance is excellent; the processing cost is low.

Owner:HUANGSHAN NOVEL

Magnesium-lithium alloy foil and preparation method and application thereof

ActiveCN111004951AShort preparation processImprove efficiencyTemperature control deviceMetal rolling arrangementsIngotAluminum foil

The invention belongs to the technical field of magnesium-lithium alloy materials, and particularly relates to a magnesium-lithium alloy foil and a preparation method and application thereof. A magnesium-lithium alloy cast ingot is coiled into an alloy coiled tape with the thickness of 1.5-3.5 mm through large-deformation hot extrusion cogging, then, multi-pass coiling type cooling rolling is conducted through a four-roller aluminum foil rolling mill provided with a tension roller set and a coiling machine, and thus the magnesium-lithium alloy foil is obtained, wherein the minimum thickness ofthe magnesium-lithium alloy foil can be rolled to 0.014 mm. The foil is short in preparation process, high in efficiency, small in residual stress, fine in grain, smooth, free of burrs and high in yield, and the yield can reach 80% or above. The magnesium-lithium alloy foil is used for preparing a vibrating diaphragm or a vibrating diaphragm dome base material, and has good shock absorption performance and high fidelity.

Owner:郑州轻研合金科技有限公司

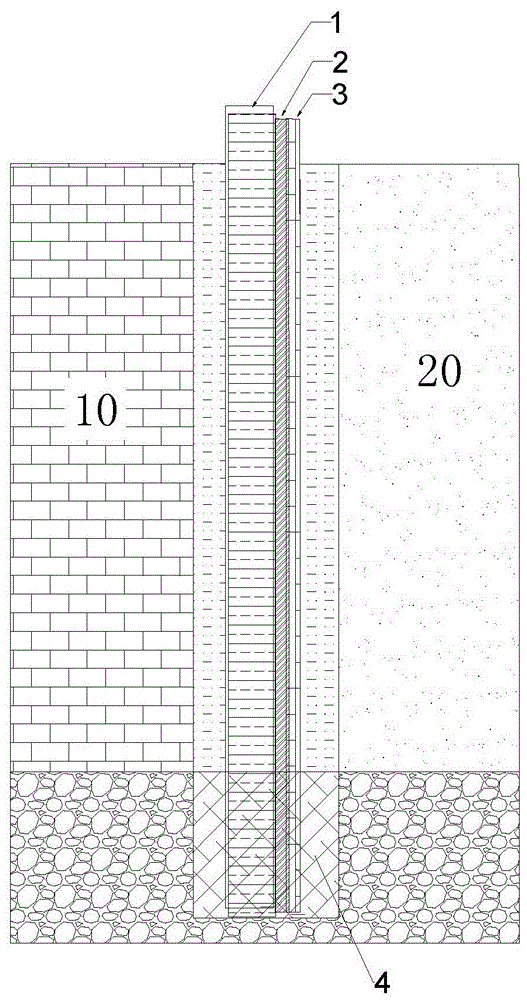

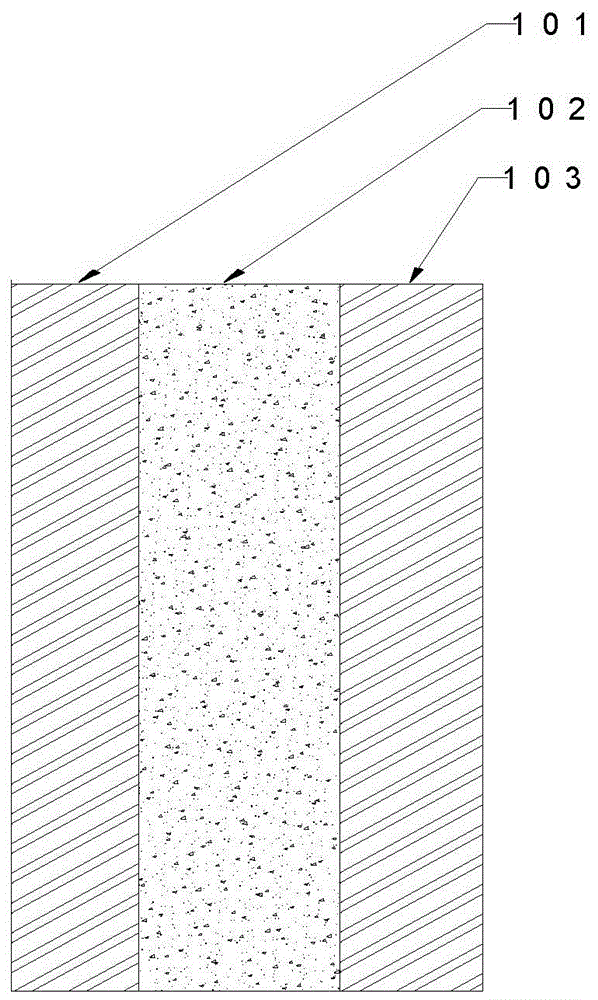

Flexible barrier having restoration and vertical obstruction functions and preparation and application thereof

The invention discloses a flexible barrier having restoration and vertical obstruction functions. The flexible barrier having the restoration and vertical obstruction functions comprises a restoration functional portion and a vertical obstruction portion. The restoration functional portion comprises two layers of nonwoven geotextile and a restoration functional material layer placed between the two layers of nonwoven geotextile. The vertical obstruction portion is composed of HDPE geomembrane. The vertical obstruction portion is fixed to the outer side of one of the two layers of nonwoven geotextile of the restoration functional portion. The flexible barrier having the restoration and vertical obstruction functions is established in the manner that the restoration functional portion and the HDPE geomembrane are combined, the problems that a traditional vertical anti-seepage barrier do not have the restoration function, and a permeable reactive barrier do not have the vertical obstruction function are solved, and the flexible barrier having the restoration and vertical obstruction functions has the advantages of being simple in construction, good in anti-seepage effect, good in restoration function and the like.

Owner:BEIJING GEOENVIRON ENG & TECH

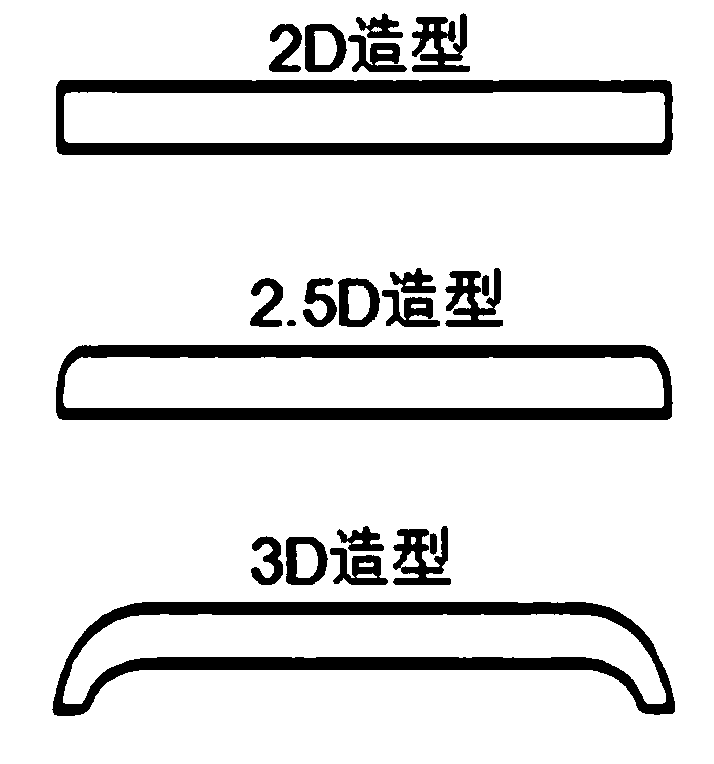

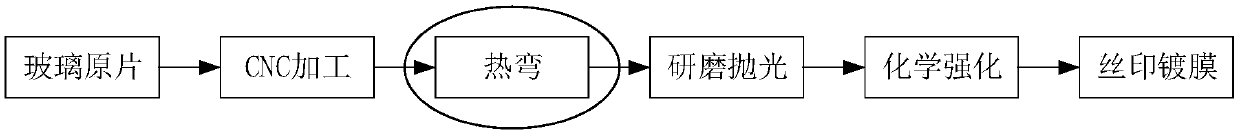

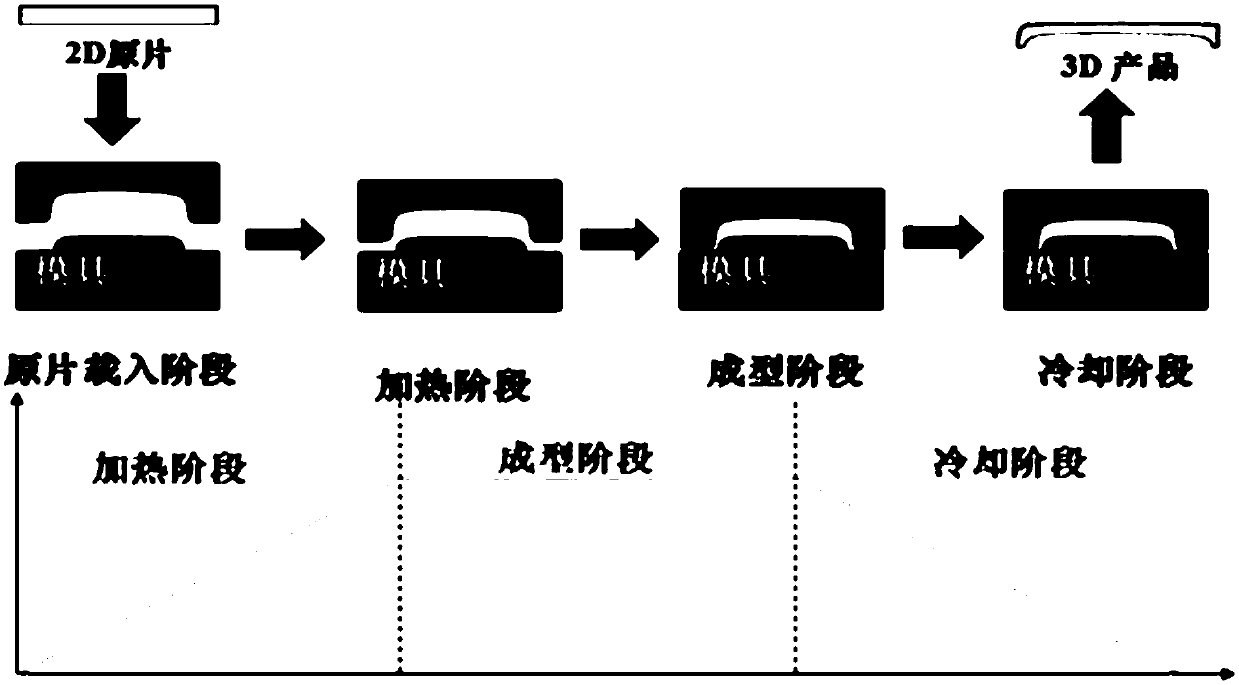

Mobile phone cover plate glass capable of meeting requirements of 5G communication and 3D compression molding and process method

ActiveCN109626816AReduce surface oxidationReduce lossGlass pressing apparatusGlass tempering apparatusDivalent metalProtective glasses

The invention discloses mobile phone cover plate glass capable of meeting requirements of 5G communication and 3D compression molding and a process method. The mobile phone cover plate glass is alkali-aluminum silicate glass, and comprises SiO2, B2O3, Al2O3, an alkali metal oxide R2O, an alkaline earth and divalent metal oxide RO, a clarifying agent and a surfactant. The process method comprises the steps of matching material melting, primary compression molding, three-step method chemical strengthening treatment, and obtaining of the mobile phone cover plate glass. The dielectric constant ofthe mobile phone cover plate glass is only 6.35-6.43 and is reduced by 10-20% compared with that of existing mobile phone cover glass so that the loss of 5G high-frequency transmission signals can bewell reduced; the softening point temperature of the glass is lower than 709 DEG C and is reduced by 175 DEG C or above compared with that of the existing mobile phone cover plate glass; therefore, surface oxidation and losses, caused by primary compression molding of the cover plate protective glass, of the surface of a mold can be reduced, the service life of the mold is prolonged, and the surface quality of the glass is improved.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD

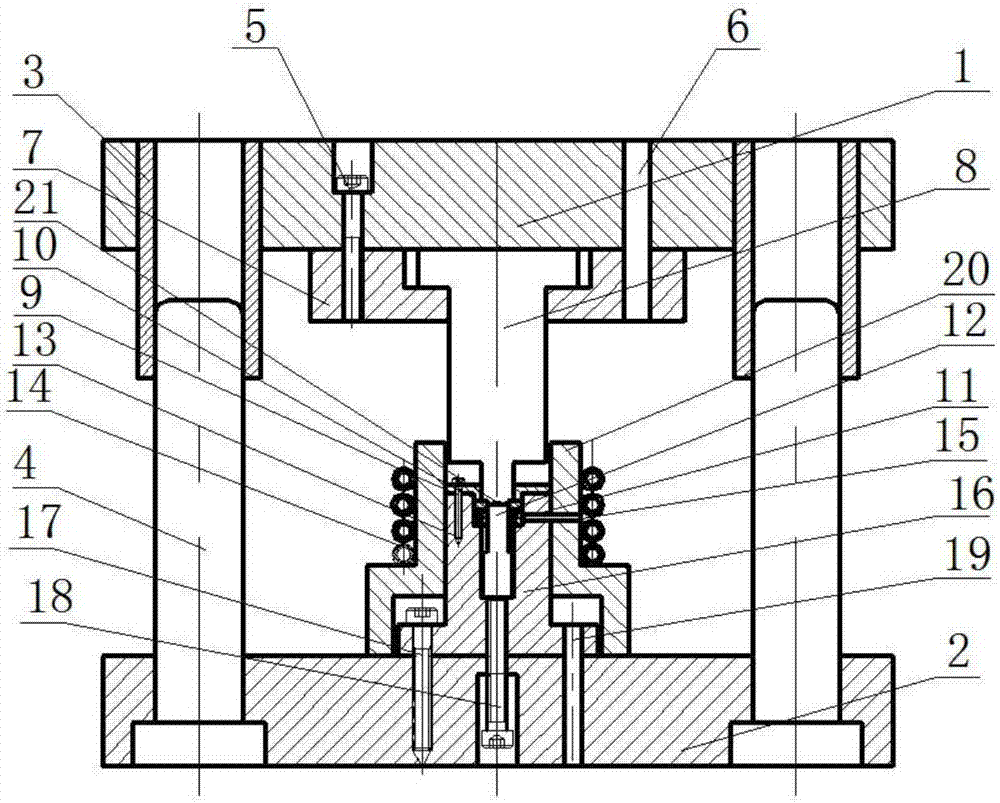

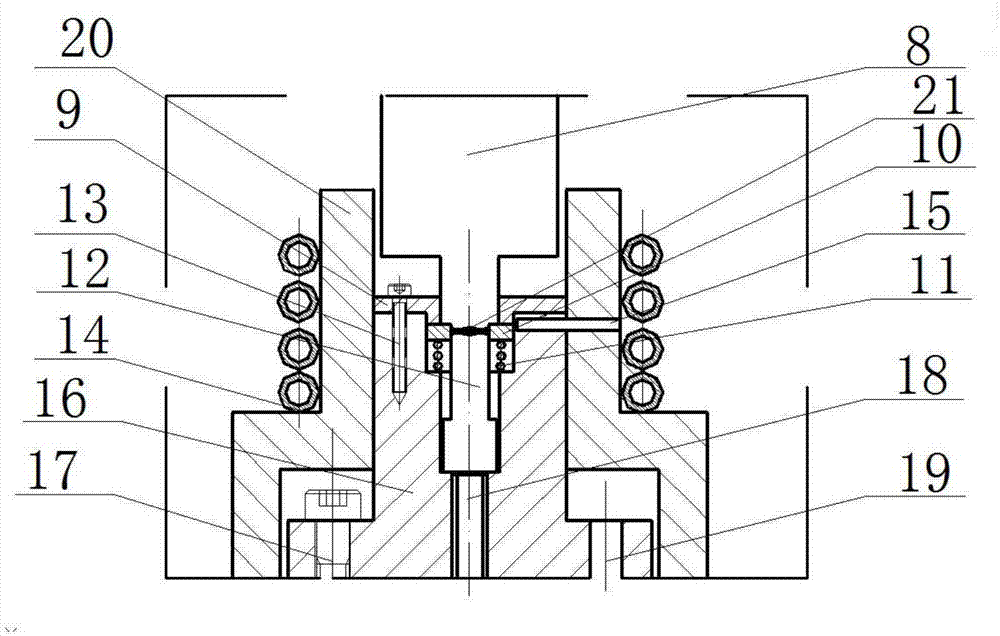

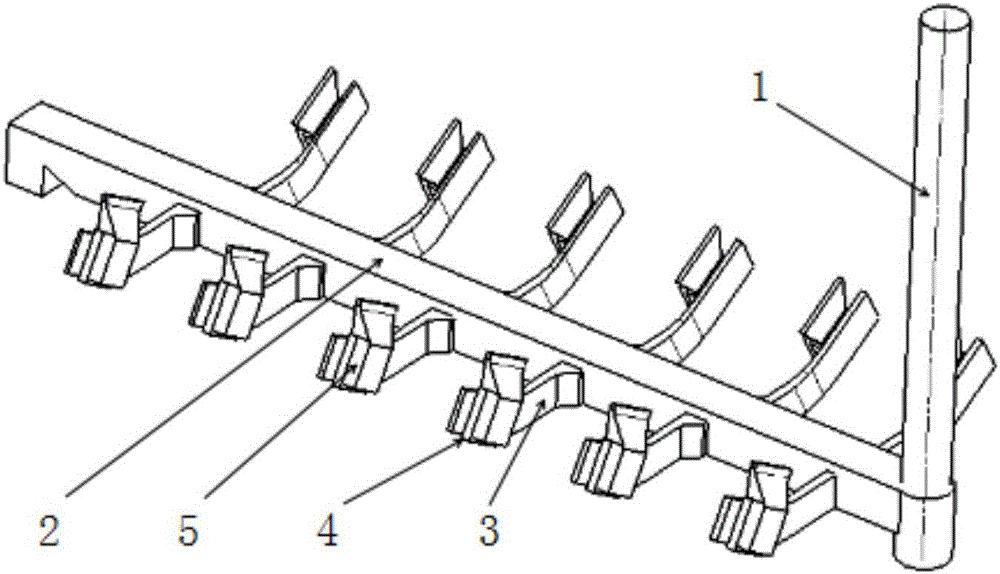

Micro-turbine disc forming device and method

InactiveCN106903247AAvoid exposure to high temperaturesIncrease profitForging/hammering/pressing machinesWheelsEngineeringTurbine

The invention relates to the field of micro-turbine disc precise manufacturing, in particular to a micro-turbine disc forming device and method. The device is characterized in that an upper mold plate (1) and a lower mold plate (2) are arranged; guide sleeves (3) are arranged on the upper mold plate (1); guide columns (4) matched with the guide sleeves (3) are arranged on the lower mold plate (2); a closed frame is formed by the upper mold plate (1) and the lower mold plate (2) through the guide sleeves (3) and the guide columns (4); and a mold auxiliary mechanism is arranged in the closed frame and comprises an upper puncher pin fixing plate (7), an upper puncher pin (8), a concave mold fixing plate (9), a floating concave mold (10), a spring (11), a lower puncher pin (12), an induction coil (14), a concave mold containing cavity (16), an ejection bolt (18) and a ceramic sleeve (20). Compared with the prior art, the device has the beneficial effects of being simple in structure, short in technological process, high in efficiency, low in cost and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

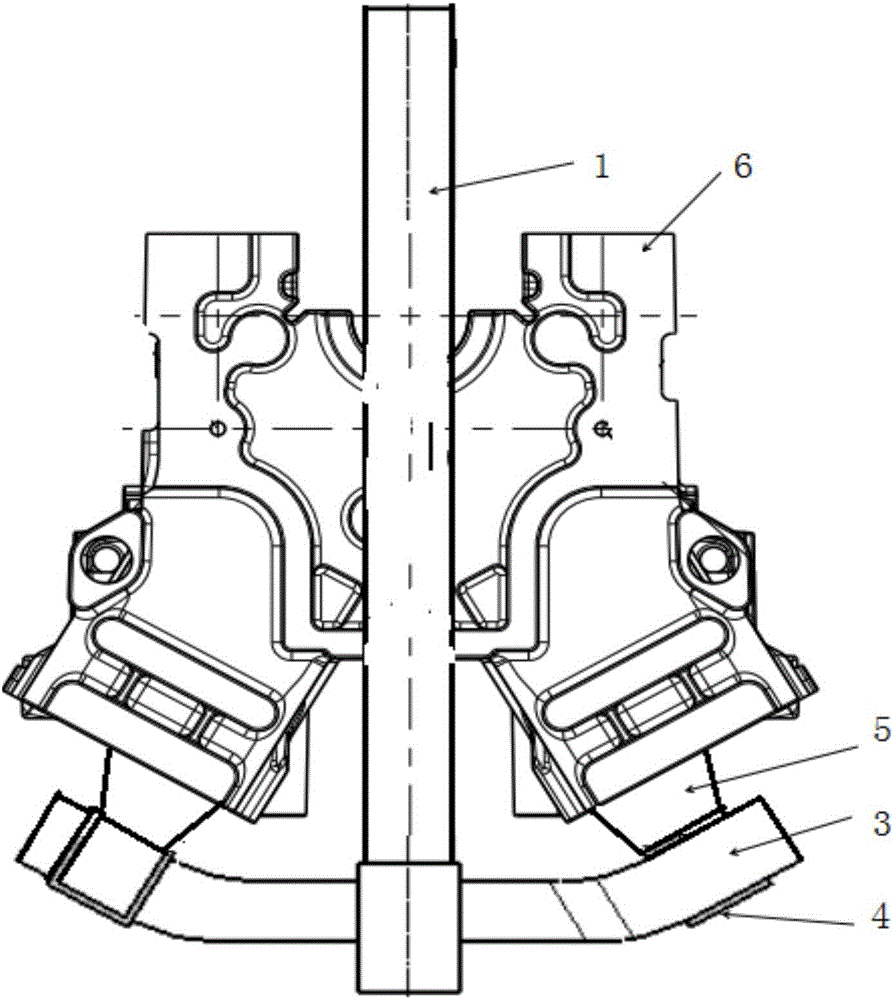

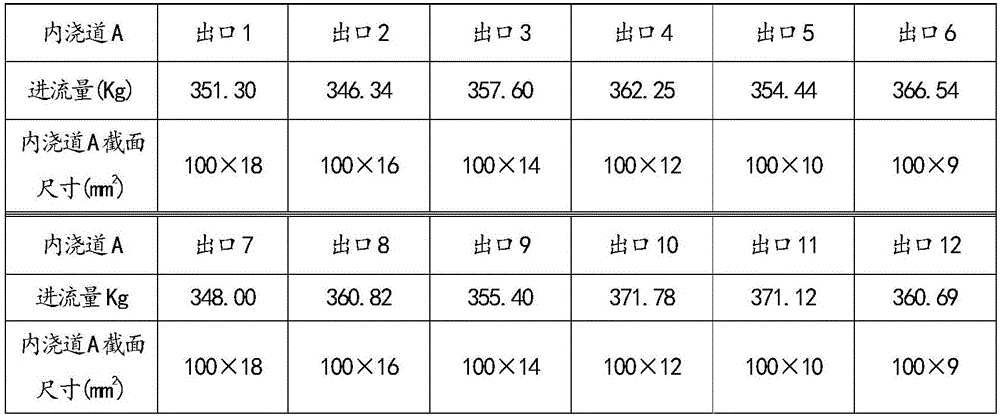

Pouring system for casting diesel engine block casting

InactiveCN106077493AReduce surface oxidationWon't touchFoundry mouldsFoundry coresEngineeringCasting mold

The invention discloses a pouring system for casting a diesel engine block casting. The pouring system comprises a sprue, a cross gate and a plurality of ingates A and ingates B, wherein an outlet of the sprue is perpendicularly connected with an inlet of the cross gate; the ingates A are symmetrically arranged on two sides of the cross gate in a spacing manner; outlets of the ingates A are connected with filtering devices; the filtering devices are connected with the ingates B; the heights of the pouring gates of the ingates B are greater than that of the cross gate; the sectional area of the sprue is smaller than that of the cross gate; the sectional area of the cross gate is smaller than the total of the sectional areas of the ingates A and the sectional areas of the ingates B; the sectional area of each of the ingates A is smaller than that of each ingate B; and the sectional areas of the ingates A are gradually decreased along the direction from the inlet and the outlet of the cross gate. The pouring system for casting the diesel engine block casting can effectively prevent oxidization of molten metal and relieve scouring to a casting mold; and the yield of the casting is greatly increased, and the pouring system is applicable to casting of large-size iron castings such as the diesel engine block casting.

Owner:四川共享铸造有限公司

Preparation of high impact resistance polystyrene from waste rubber fine rubber powder by in situ polymerization

The invention provides a high impact resistant polystyrene made of fine rubber powder of waste rubber by the method of in-situ polymerization. The high impact resistant polystyrene contains 67.5-40.5 percent of polystyrene by weight and 27.1-54.1 percent of modified waste rubber fine rubber powder. The invention has simple preparation technology, low cost, good impact resistant property of over 71.1J / m and good tensile property of over 21.2MPa..

Owner:CHINA NAT OFFSHORE OIL CORP +1

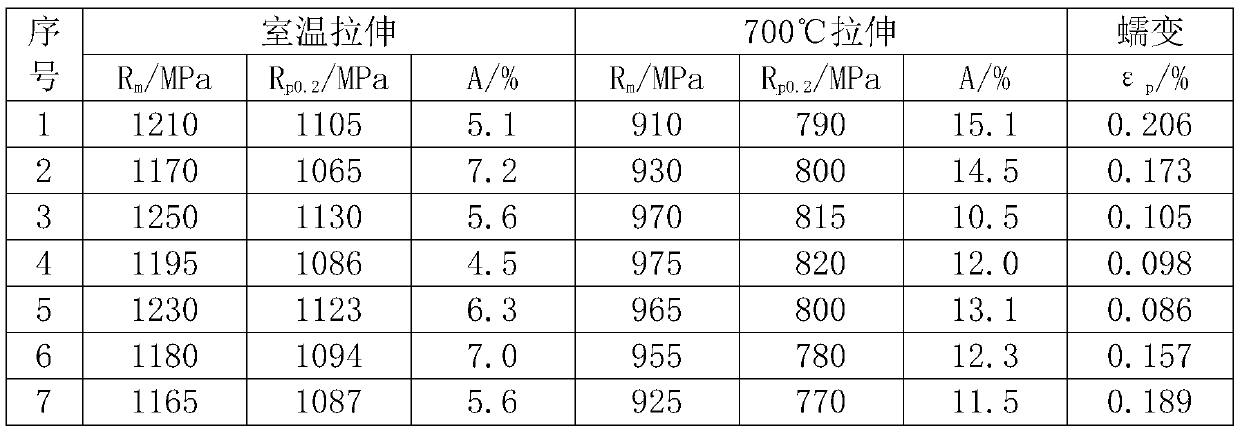

Ti2AlNb alloy and preparation method of Ti2AlNb alloy bar

ActiveCN111394637AImprove antioxidant capacityImprove the effect of solid solution strengtheningChemical compositionIngot

The invention relates to Ti2AlNb alloy and a preparation method of a Ti2AlNb alloy bar. The alloy comprises the following chemical components, in atomic percentage, of 22%-25% of Al, 20%-23% of Nb, 1%-8% of (Zr+Hf+W+Mo+Ta), greater than or equal to 0.5% of W, greater than or equal to 0.5% of Zr+Hf, and the balance Ti and inevitable impurities. A B2 single-phase region relatively-low-temperature upsetting and extrusion stretching composite process is adopted for ingot cogging, and a process of upsetting-stretching forging and stretching forming forging in two phase regions of (alpha2+B2) is further adopted to prepare the bar with the required specification. The provided Ti2AlNb alloy has good oxidation resistance, the tensile strength at 700 DEG C is 800 MPa or above, and the creep propertyat 700 DEG C is improved by 50%. The invention further provides a bar preparation method suitable for the Ti2AlNb alloy.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

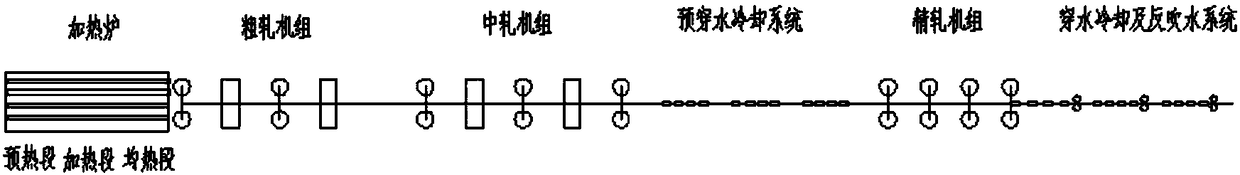

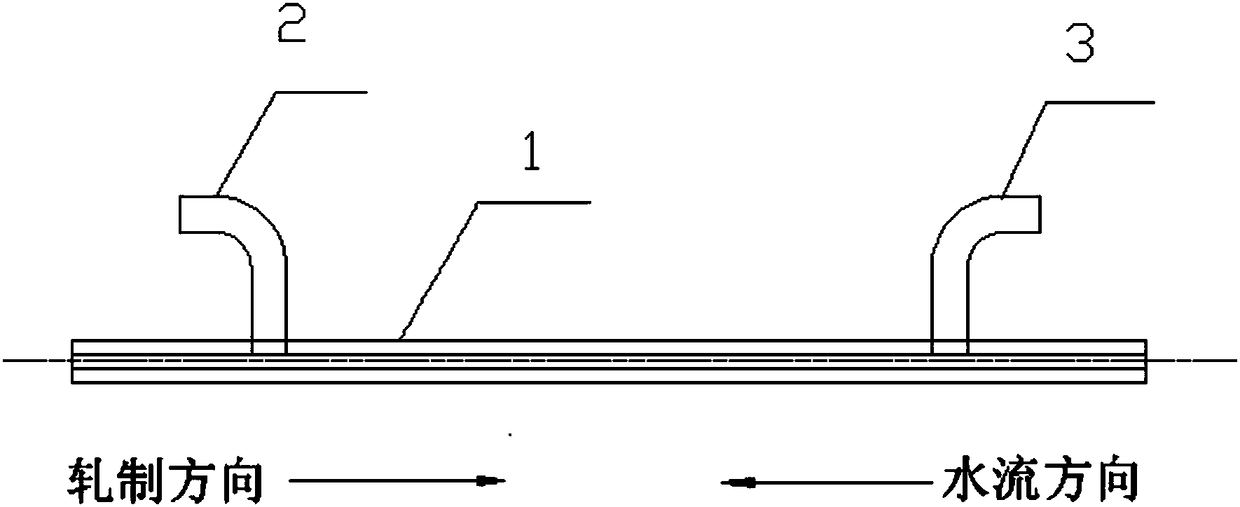

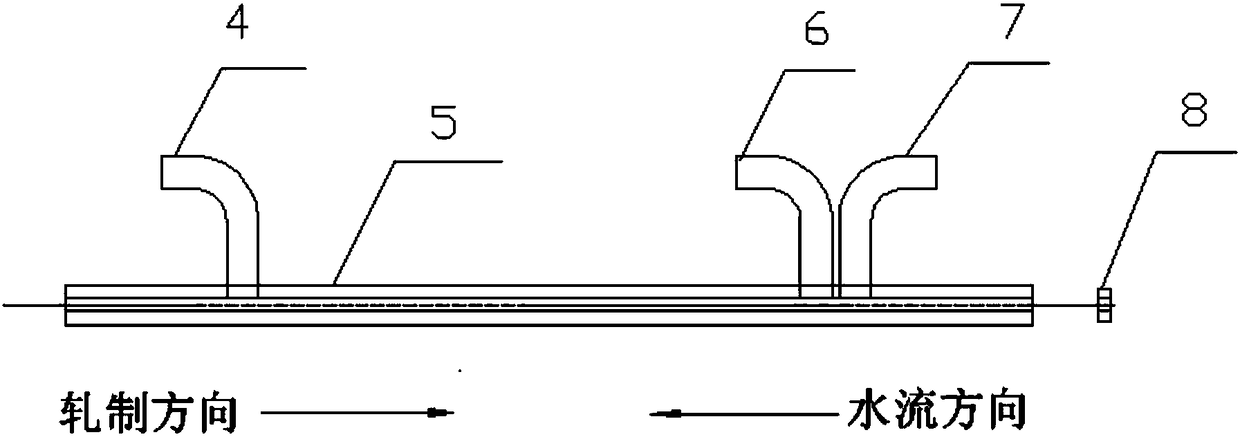

Technological method and equipment for improving corrosion resistance of surfaces of reinforced bars

InactiveCN108526217AImprove corrosion resistanceReduce thicknessTemperature control deviceWork treatment devicesTemperature controlAutomatic control

The invention relates to the field of steel rolling, in particular to a technological method and equipment for improving the corrosion resistance of the surfaces of reinforced bars. The technologicalmethod comprises the following steps of: step one. improving a heating technology, dividing a heating zone into a preheating segment, a heating segment and a soaking segment, automatically controllingthe temperature of each zone, and specially, controlling the temperature of the preheating segment to be less than 850 DEG C, the temperature of the heating segment to be in the range of 1060-1080 DEG C and the temperature of the soaking segment to be in the range of 1130-1180 DEG C; step two. controlling the initial rolling temperature, and controlling the rough rolling temperature to be in therange of 1030 DEG C-1050 DEG C; step three. entering an intermediate rolling system, carrying out intermediate rolling, and cooling by using a pre-through water system, and ensuring that the finish rolling temperature is controlled in the range of 930-950 DEG C; step four. entering a finish rolling system, and carrying out finish rolling; and step five. entering a through water cooling and back blow wash system, and carrying out through water cooling and back blow wash. The technological method and equipment can prevent air bubbles on the surfaces of the reinforced bars and improve the corrosion resistance and mechanical properties of the surfaces of the reinforced bar.

Owner:YANCHENG LIANXIN IRON & STEEL CO LTD

Improvement of feeding efficiency by laser heating of metal in riser head

The invention relates to a method that heating the metal inside the riser to improve the feeding efficiency in the process of cast molding. The method uses the liquid metal inside the riser to fill the slits left by shortened volume in the processes of cooling and solidifying liquid metal when in casting. The invention uses the laser to heat the metal liquid level inside the riser to keep the liquid condition; therefore, the feeding channel can keep free in the metal solidification process to improve the feeding efficiency. The invention can avoid sand into the die cavity to cause defect, and it uses the laser with higher electric-optical transformation efficiency to reduce the cost. The invention also provides the technique keys and parameters.

Owner:湖南嘉程增材制造有限公司

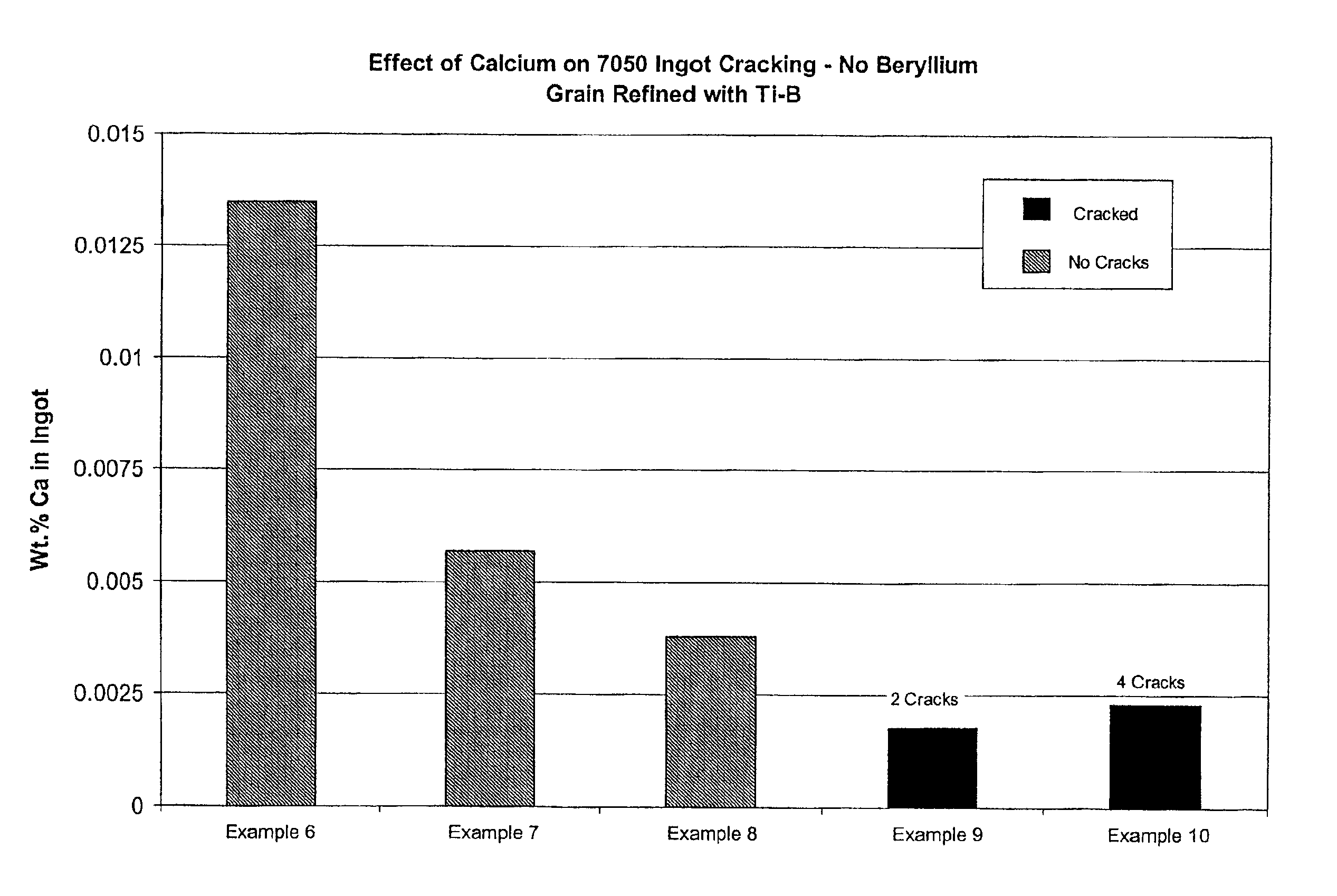

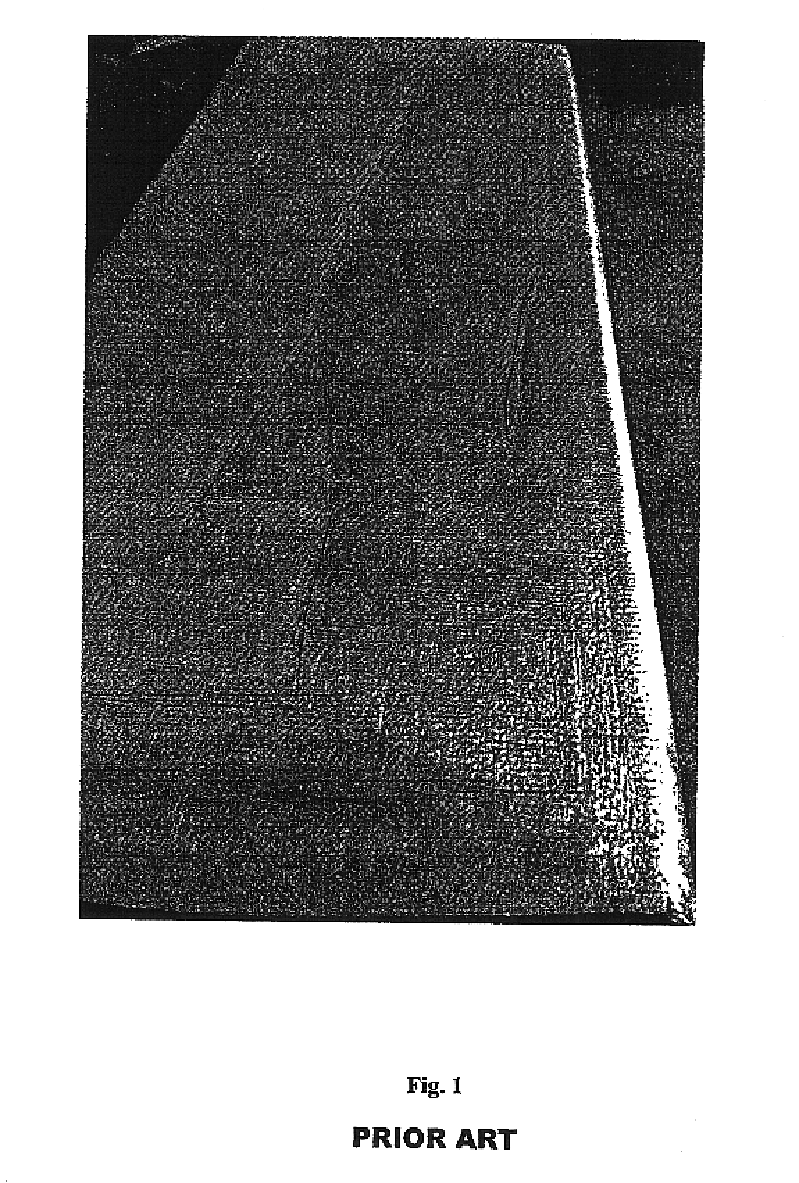

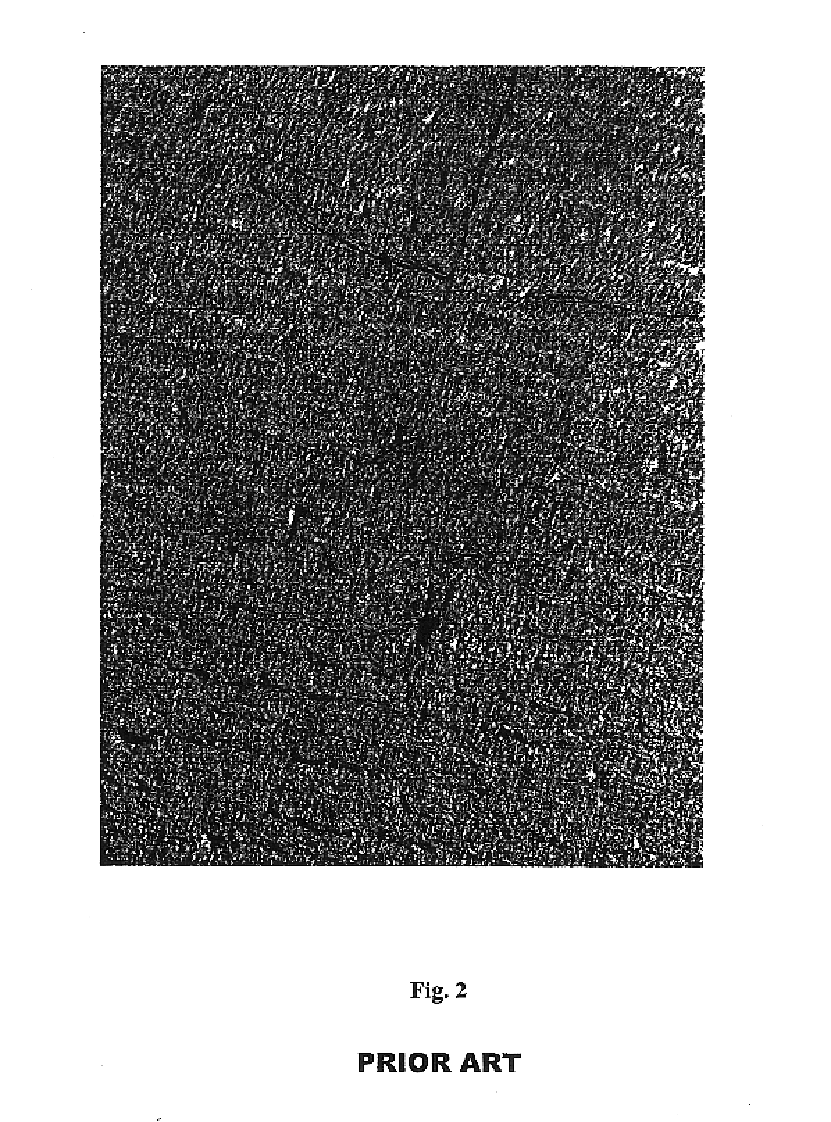

Aluminum alloys having improved cast surface quality

Aluminum alloy compositions are disclosed, which include small amounts of calcium that result in improved surface properties of the cast aluminum. The calcium, and up to 0.25% grain refiners, are added along with alkaline earth metals, transition metals and / or rare earth metals to the aluminum alloy as a melt. The addition results in improved appearance, substantially reduced surface imperfections and reduced surface oxidation in cast ingot aluminum and aluminum alloys. The addition of small amounts of these additives, surprisingly were found to substantially eliminate vertical folds, pits and ingot cracking in more than one ingot casting technique. The additions also improved the appearance of the ingots, including reflectance. As a result, the ingots could be reduced or worked essentially right out of the casting without first conditioning the surface by, for example, scalping. Also disclosed is a method of improving the surface properties and preventing surface imperfections and cracking of cast aluminum alloys. The method includes the steps of adding calcium to a molten aluminum alloy that is essentially free of Be and casting the aluminum alloy using any commonly used technique.

Owner:ARCONIC TECH LLC

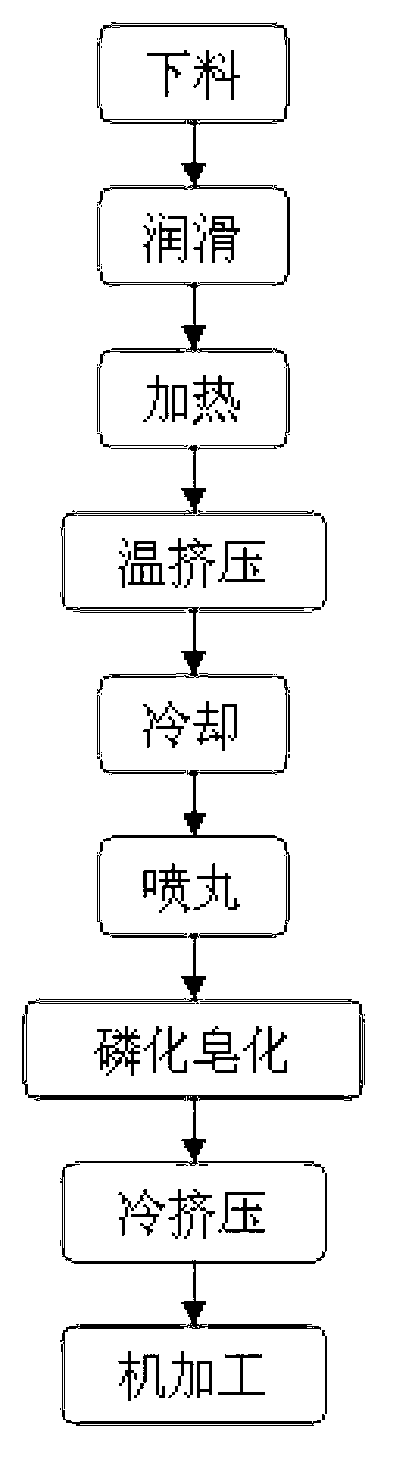

Cold and hot extrusion molding method of rotary thick-walled shell part for vehicle

The invention relates to a cold and hot extrusion molding method of a rotary thick-walled shell part for a vehicle. The method comprises the following steps of (1) blanking a round steel by sawing the round steel to obtain a blank material; (2) cleaning the surface of the blank material, removing impurities from the surface of the blank material, and lubricating the blank material; (3) heating the blank material; (4) performing hot extrusion on the heated blank material to form a cup-shaped part with large diameter; (5) cooling the cup-shaped part with large diameter; (6) performing shot blasting on the cup-shaped part with large diameter; (7) performing phosphorization and saponification on the cup-shaped part with large diameter; (8) performing cold extrusion on the cup-shaped part with large diameter, and molding and shaping the cup-shaped part with small diameter; and (9) machining the extruded cup-shaped part with small diameter to obtain the rotary thick-walled shell part for the vehicle. Compared with the prior art, the method has the advantages of compact production process, high material utilization rate, good part mechanical property, low production cost and the like.

Owner:SHANGHAI UNIV OF ENG SCI +1

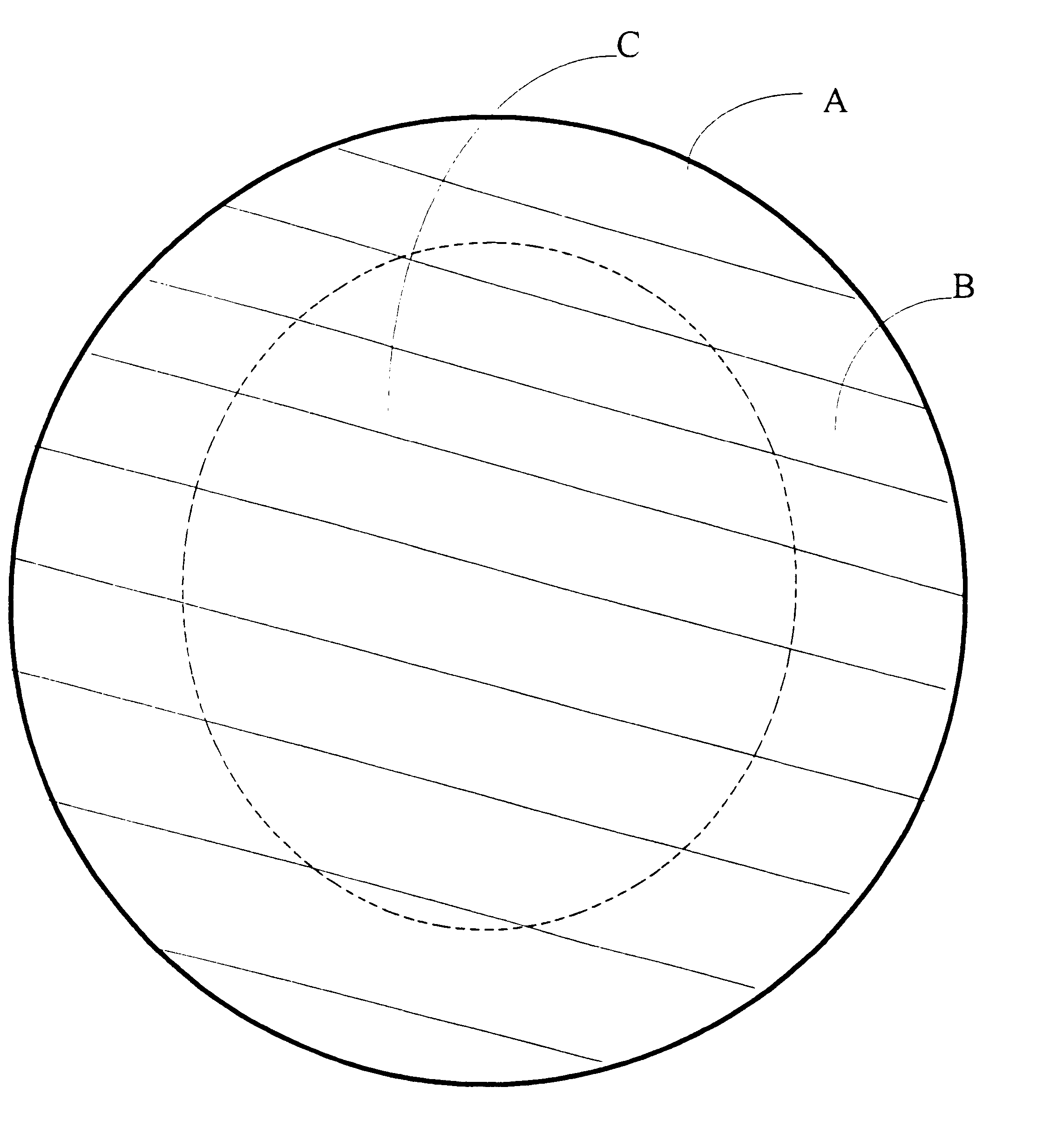

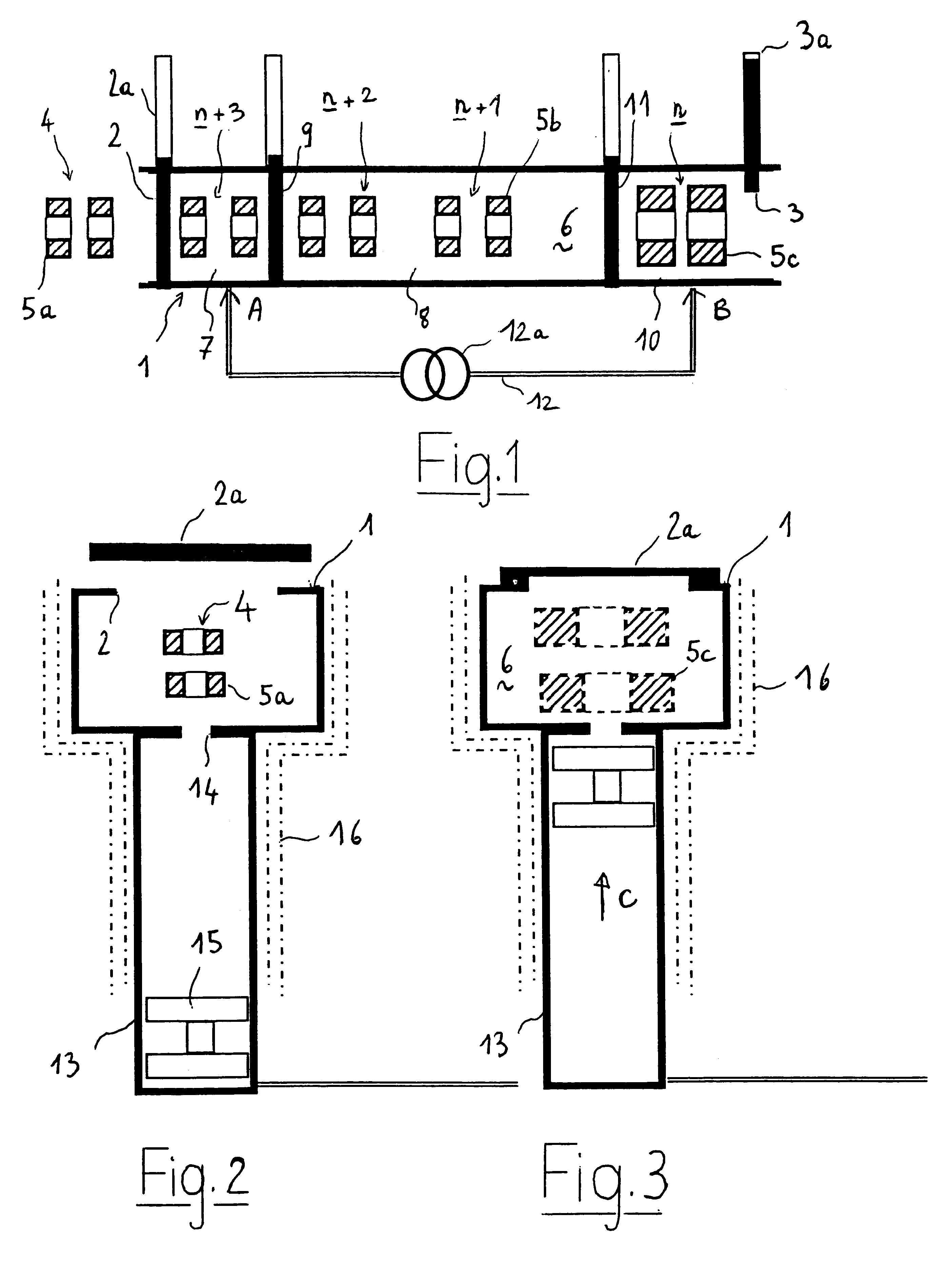

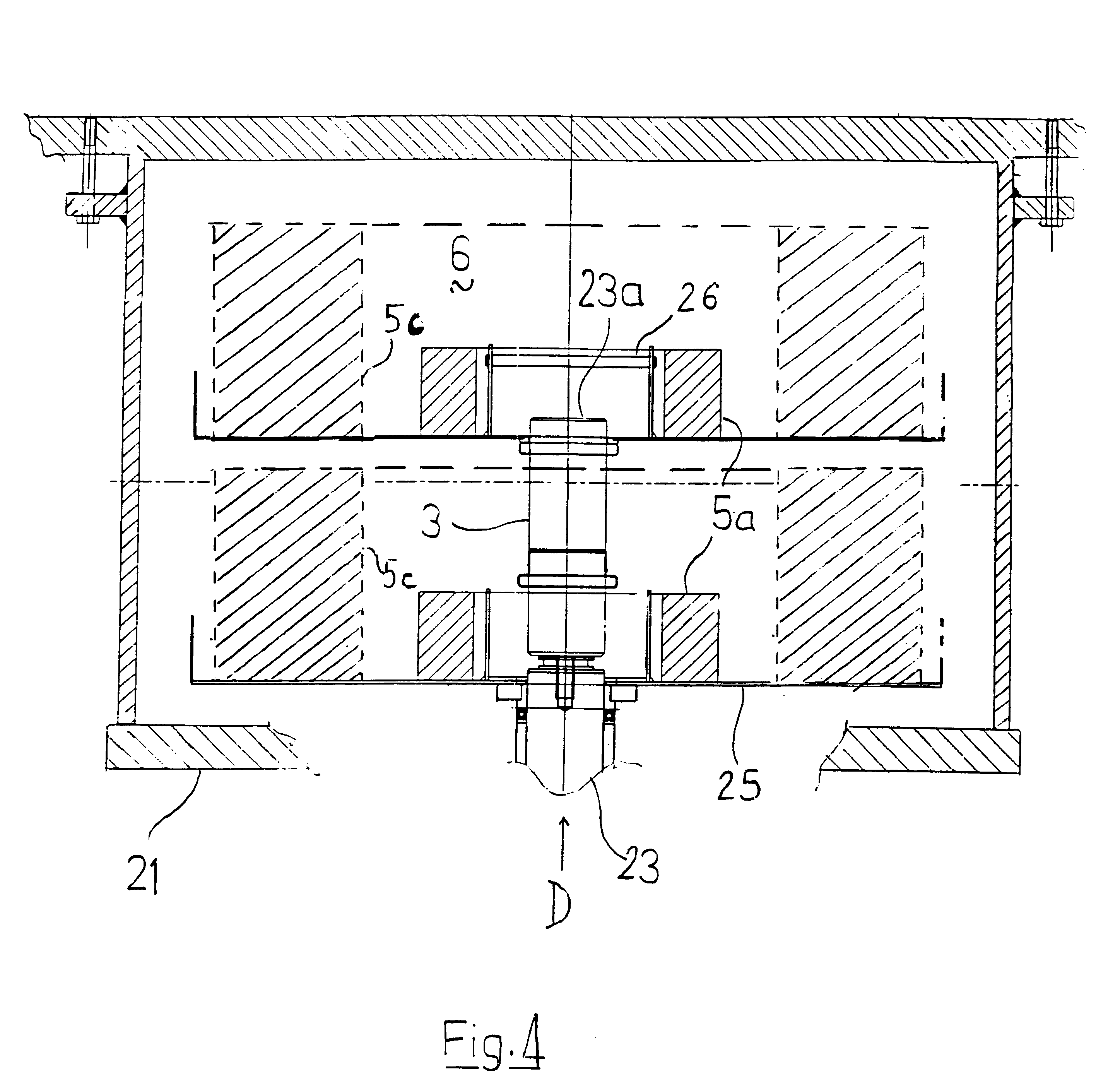

Process and device for cross-linking/expanding a blank for a safety support for a tire and support obtained by this process

A process for cross-linking / expanding at least one cross-linkable, expandable blank, which is intended to form all or part of an elastomeric safety support for a tire in which: the cross-linking consists of curing the expandable or expanded blank in a bath of fluid at excess pressure which is contained in an enclosure, such that the blank interacts with the bath independently of the enclosure, the temperature of the bath having a maximum value of between 110° C. and 210° C. and the absolute pressure of said bath having at least a value equal to or greater than 14 bar, and the expansion consists of curing the cross-linkable or cross-linked blank in the bath, the temperature of the bath having a maximum value of between 110° C. and 210° C., and the absolute pressure of the bath having at least a value equal to or greater than 5 bar and a final pressure-relief value substantially equal to 1 bar, for expanding the blank such that its increase in volume is unlimited with respect to the enclosure.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com