Laser inducement nano-surface preparation method for iron based amorphous nanocrystalline soft magnetic material

A nanocrystalline soft magnetic, laser-induced technology, applied in the field of materials, can solve the problems of high crystalline brittleness, large particle size, complex process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

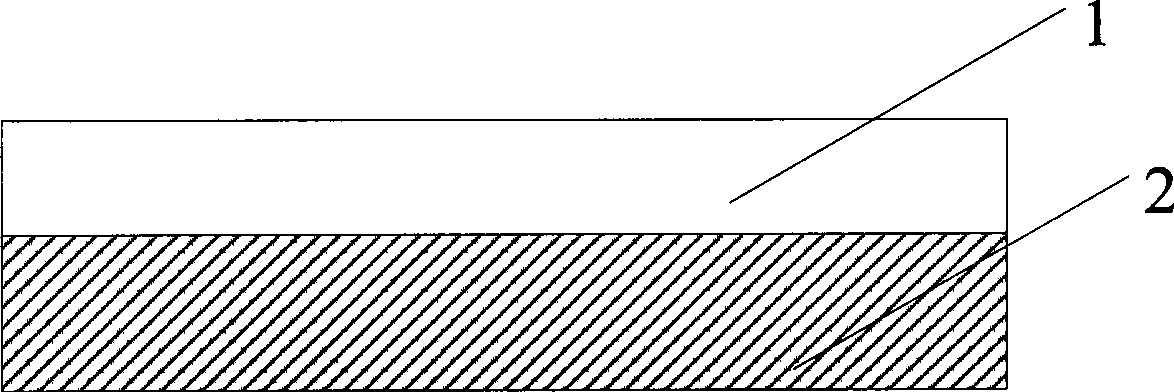

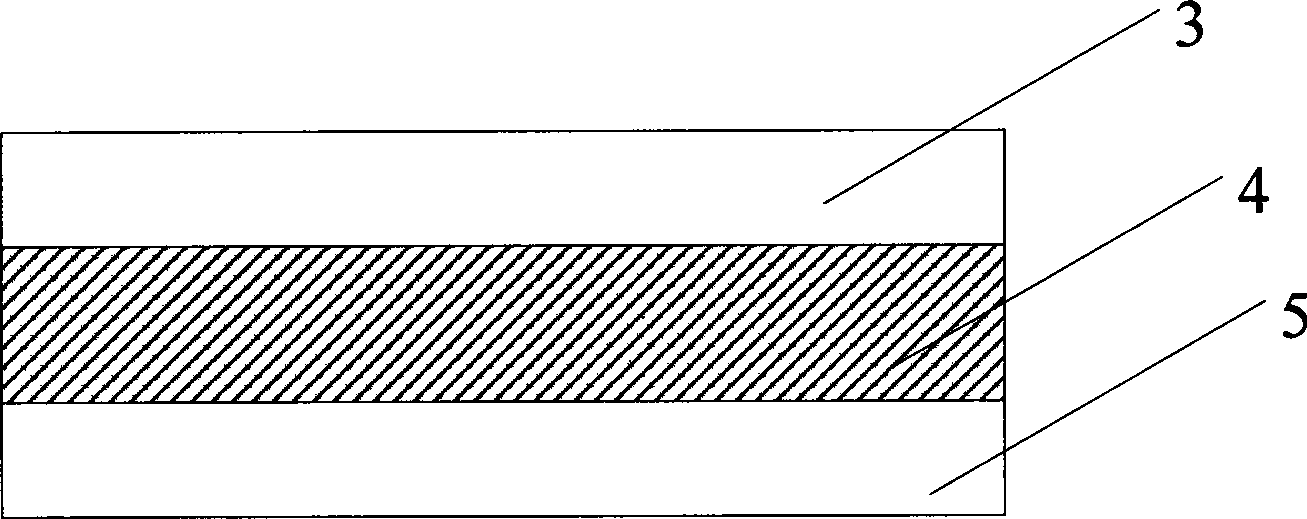

Method used

Image

Examples

Embodiment 1

[0037] Using amorphous band Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 Alloy, the width of the alloy is 20mm, the thickness is 30μm, and the length is 2000mm.

[0038] Clean the surface of the amorphous tape with absolute ethanol until the surface is clean, and blow dry or air-dry naturally until the surface is dry. Put the amorphous strip flat on the sample support platform, with the touch roller facing up so that the amorphous strip is in close contact with the support.

[0039] The laser is a YAG pulsed laser. The laser process parameters are selected as follows: the current intensity of the laser is 120A, the frequency is 30Hz, the spot size is 8mm, the scanning speed is 8mm / s, the overlap rate is 0%, the wavelength λ=1.064μm, and the scanning direction is along the length of the amorphous strip direction. When scanning the laser surface nanometerization, nitrogen blowing protection is carried out simultaneously.

[0040] Start the laser, select laser pulse widths of 0.4, 0.5, ...

Embodiment 2

[0042] Using amorphous band Fe 75 Si 2 B 16 Ni 4 Mo 3 Alloy, the width of the alloy is 20mm, the thickness is 30μm, and the length is 2000mm.

[0043] Clean the surface of the amorphous tape with absolute ethanol until the surface is clean, and blow dry or air-dry naturally until the surface is dry. Put the amorphous strip flat on the sample support platform, with the touch roller facing up so that the amorphous strip is in close contact with the support.

[0044] The laser is a YAG pulsed laser. The selected laser process parameters are: laser frequency f = 30HZ, wavelength λ = 1.064 μm, spot diameter d = 10mm, pulse width = 0.5ms, current I = 150A; laser scanning speed from 20mm / s, 17.5mm / s, 15mm / s, 12.5mm / s speed to scan once, the overlap rate is 1%, and the scanning direction is along the length direction of the amorphous strip. When scanning the laser surface nanometerization, nitrogen blowing protection is carried out simultaneously. After the surface nanometeriz...

Embodiment 3

[0046] Using amorphous band Fe 75 Si 2 B 16 Ni 4 Mo 3 Alloy, the width of the alloy is 20mm, the thickness is 30μm, and the length is 2000mm.

[0047] Clean the surface of the amorphous tape with absolute ethanol until the surface is clean, and blow dry or air-dry naturally until the surface is dry. Put the amorphous strip flat on the sample support platform, with the touch roller facing up and make the amorphous strip closely contact with the support.

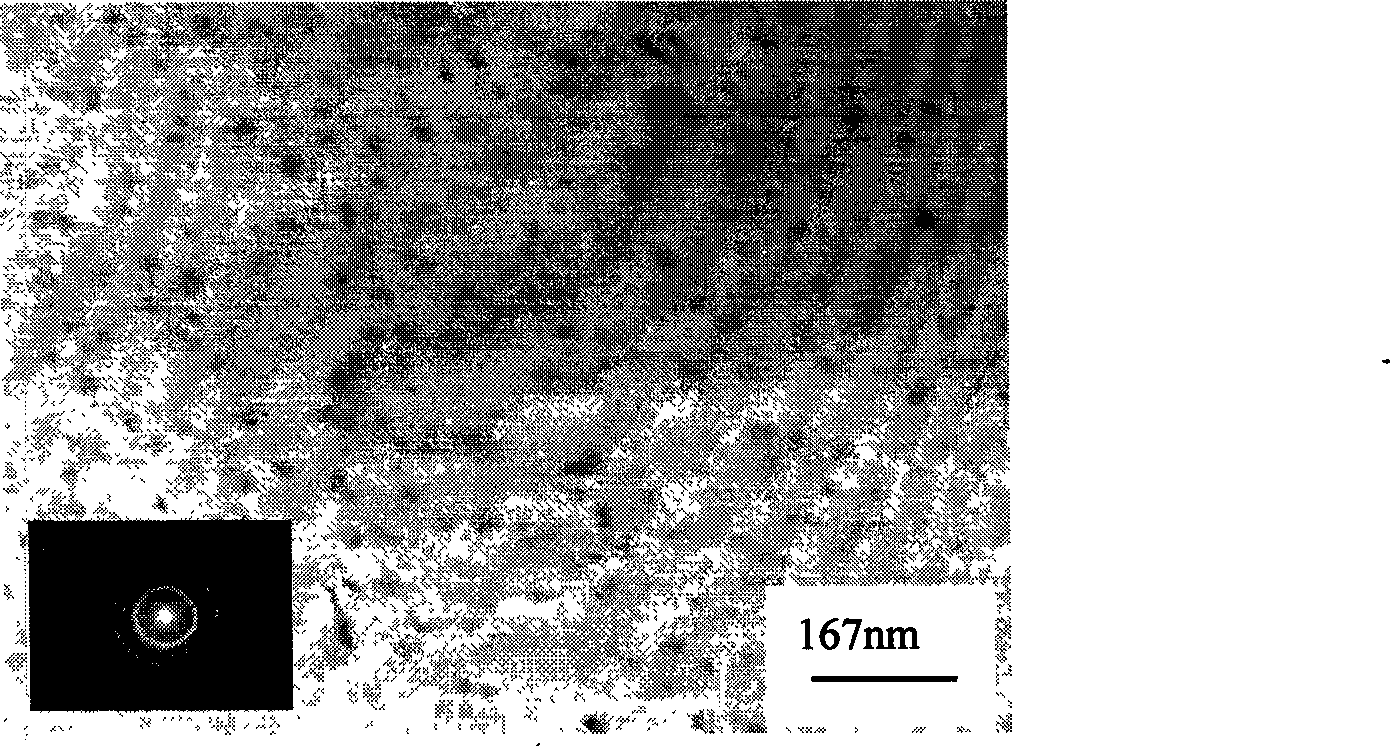

[0048]Nd:YAG pulsed laser is used, and the selected laser process parameters are: current I=105A, frequency f=30HZ, wavelength λ=1.064μm, spot diameter d=10mm, scanning speed v=10mm / s and other fixed parameters. Under the condition of a pulse width of 0.6 ms, when the laser surface is scanned for nanometerization, argon blowing protection is performed simultaneously, the laser overlap rate is 0.5%, and the scanning direction is along the length of the amorphous crystal. Amorphous band Fe after scanning 78 Si 9 B 13 α-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com