Improvement of feeding efficiency by laser heating of metal in riser head

A laser heating and riser technology, applied in the field of casting technology, can solve problems such as unfavorable automation, sand particles entering the cavity, and casting sand sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

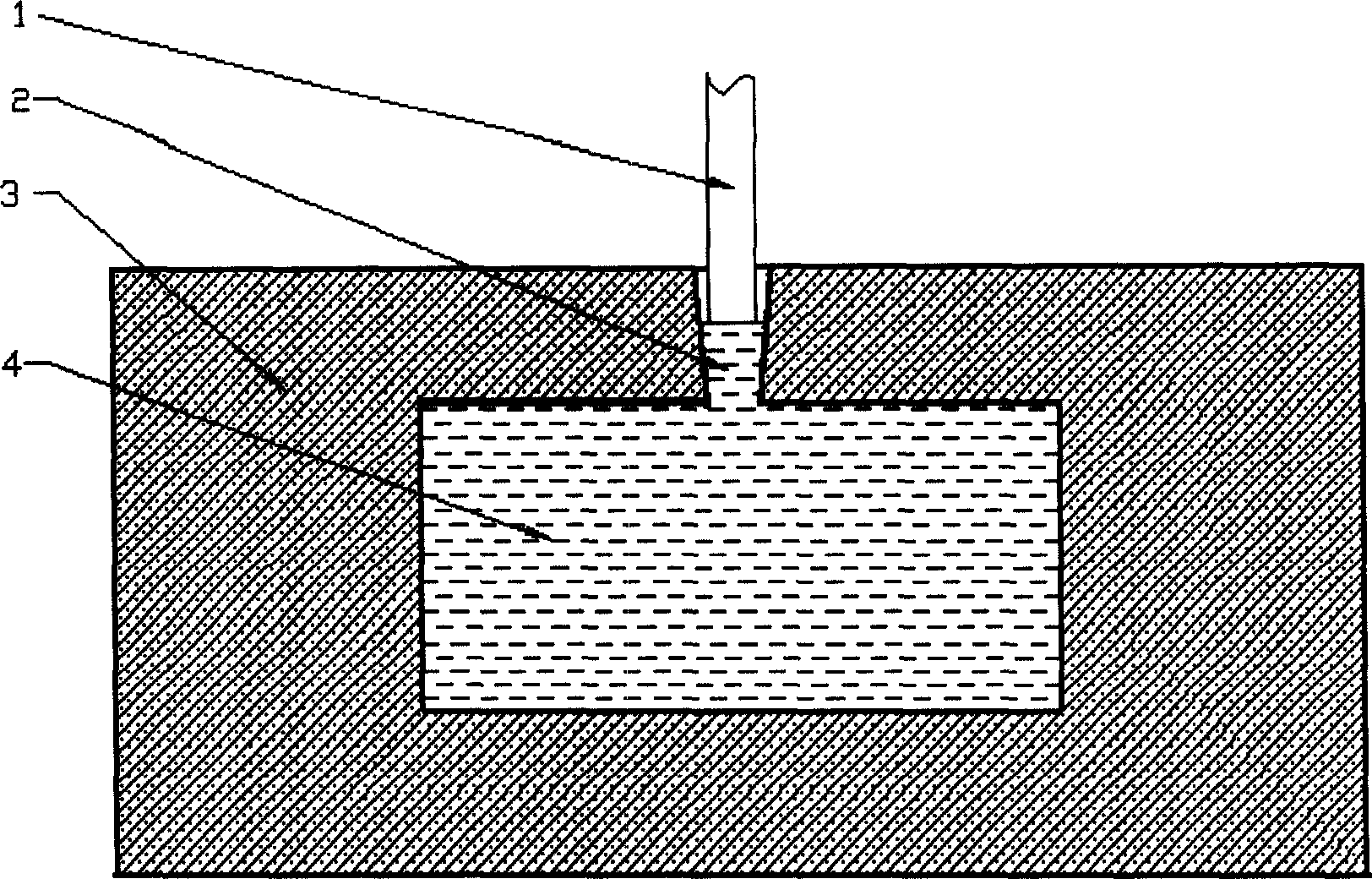

Image

Examples

Embodiment Construction

[0009] Before implementing the present invention, the relevant process parameters must be calculated first, and the calculation results are set as the initial values of the process parameters. First, calculate the solidification time of the casting, the parts of the casting that need to be fed and the volume of the supplementary metal according to the pouring process parameters, the structure of the casting and its material thermophysical characteristics, and the characteristics of the mold, so as to determine the shape, size and position of the riser and the feeding channel The maintenance time; then calculate the heat P radiated by the surface of the metal in the riser per unit time r and the heat lost by conduction through the mold P c , because the absorption rate α of the liquid metal to the laser can be determined, and the formula αP l =P r +P c Calculate the laser power P l (The actual power also needs to be determined by P l multiplied by an empirical coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com