Cold and hot extrusion molding method of rotary thick-walled shell part for vehicle

A composite extrusion and parts technology, which is applied in the field of cold and warm composite extrusion forming of rotating thick-walled shell parts for vehicles, can solve problems such as difficult to form high-strength parts, and achieve low deformation resistance, good surface quality and high material utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

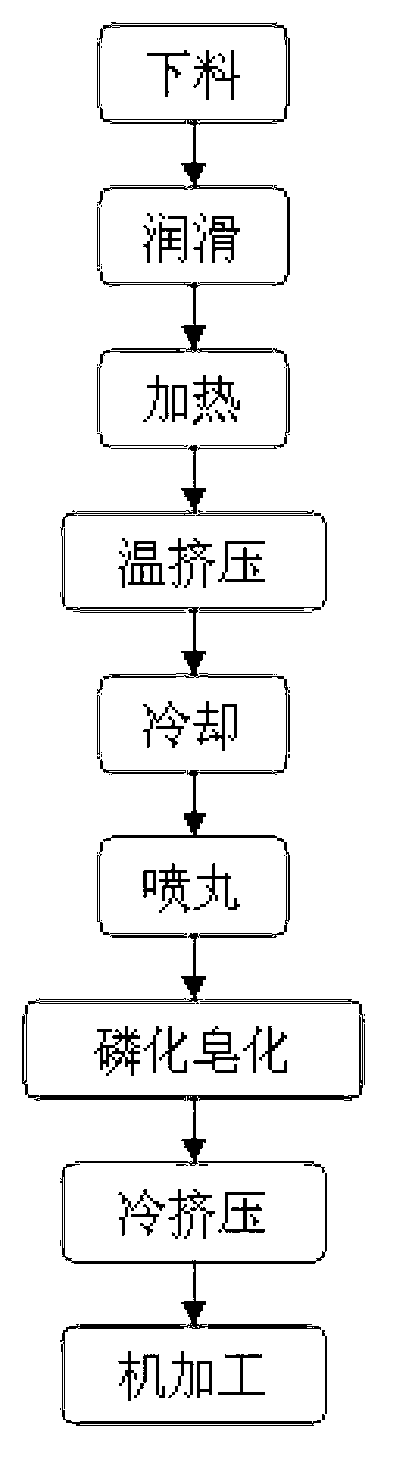

[0031] A cold-temperature compound extrusion forming method for a rotary thick-walled shell part for a vehicle, the process flow of which is as follows figure 1 As shown, the method comprises the following steps: (1) sawing round steel for blanking to obtain a billet; (2) cleaning the surface of the billet to remove impurities and lubricating the billet; (3) heating the billet; (4) ) Warm extrusion of the heated billet, so that the whole billet reaches the basic size of the part to form a large-diameter cup part; (5) cooling the large-diameter cup part; (6) shot blasting the large-diameter cup part (7) Carry out phosphating and saponification treatment to large-diameter cup parts; (8) Carry out cold extrusion to large-diameter cup parts, form small-diameter cup parts and shape them; (9) small-diameter cup parts after extrusion Machining is carried out to obtain rotary thick-walled shell parts for vehicles.

[0032] The method for heating the billet in step (3) is: heating the...

Embodiment 2

[0034] A cold-temperature compound extrusion forming method for a rotary thick-walled shell part for a vehicle, the process flow of which is as follows figure 1 As shown, the method comprises the following steps: (1) sawing round steel for blanking to obtain a billet; (2) cleaning the surface of the billet to remove impurities and lubricating the billet; (3) heating the billet; (4) ) Warm extrusion of the heated billet, so that the whole billet reaches the basic size of the part to form a large-diameter cup part; (5) cooling the large-diameter cup part; (6) shot blasting the large-diameter cup part (7) Carry out phosphating and saponification treatment to large-diameter cup parts; (8) Carry out cold extrusion to large-diameter cup parts, form small-diameter cup parts and shape them; (9) small-diameter cup parts after extrusion Machining is carried out to obtain rotary thick-walled shell parts for vehicles.

[0035] Wherein, the specific method of lubricating the billet in ste...

Embodiment 3

[0037] A cold-temperature compound extrusion forming method for a rotary thick-walled shell part for a vehicle, the process flow of which is as follows figure 1 As shown, the method comprises the following steps: (1) sawing round steel for blanking to obtain a billet; (2) cleaning the surface of the billet to remove impurities and lubricating the billet; (3) heating the billet; (4) ) Warm extrusion of the heated billet, so that the whole billet reaches the basic size of the part to form a large-diameter cup part; (5) cooling the large-diameter cup part; (6) shot blasting the large-diameter cup part (7) Carry out phosphating and saponification treatment to large-diameter cup parts; (8) Carry out cold extrusion to large-diameter cup parts, form small-diameter cup parts and shape them; (9) small-diameter cup parts after extrusion Machining is carried out to obtain rotary thick-walled shell parts for vehicles.

[0038] Wherein, the specific method of lubricating the billet in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com