Method and system for rolling difficult-to-machine metal material by combining electro-plasticity with temperature plasticity

A metal material, electroplasticity technology, applied in temperature control, metal rolling, etc., can solve the problem of material deformation resistance drop, achieve the effect of deformation resistance drop, potential barrier increase, and reduce thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: The processed material is a cold-worked TiNiNb strip with a width of 10 mm and a thickness of 1.90 mm. The conventional warm rolling and the rolling method of the present invention are combined with electroplastic rolling and warm rolling for rolling comparison.

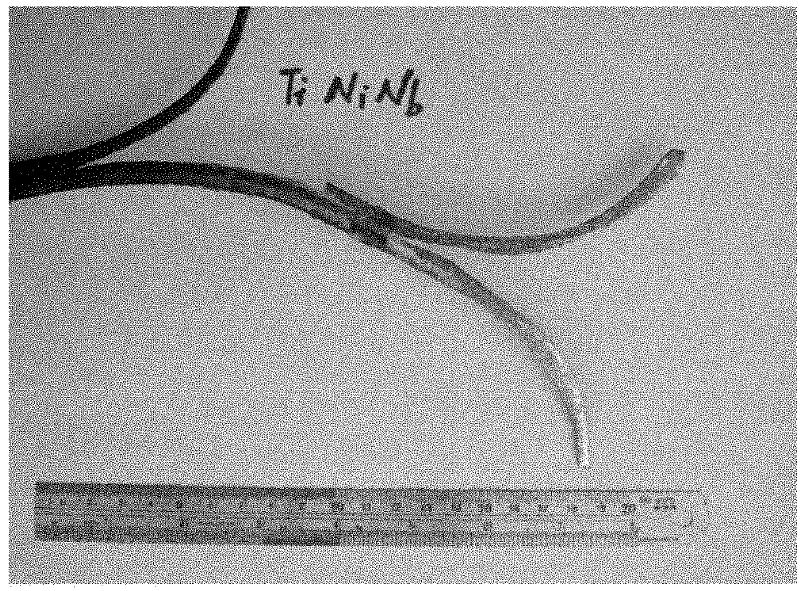

[0038] The above-mentioned TiNiNb strip was warm-rolled, the roll diameter of the rolling mill was 300mm, and the strip inlet speed was 0.1m / s. The roll was heated to 250°C, and the thickness of the TiNiNb strip was rolled from 1.90mm to 1.25mm in two passes. It was found that there were obvious cracks at the edge and center of the strip, such as figure 2 Shown.

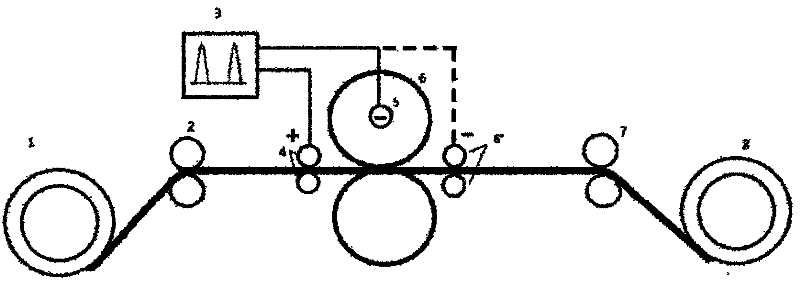

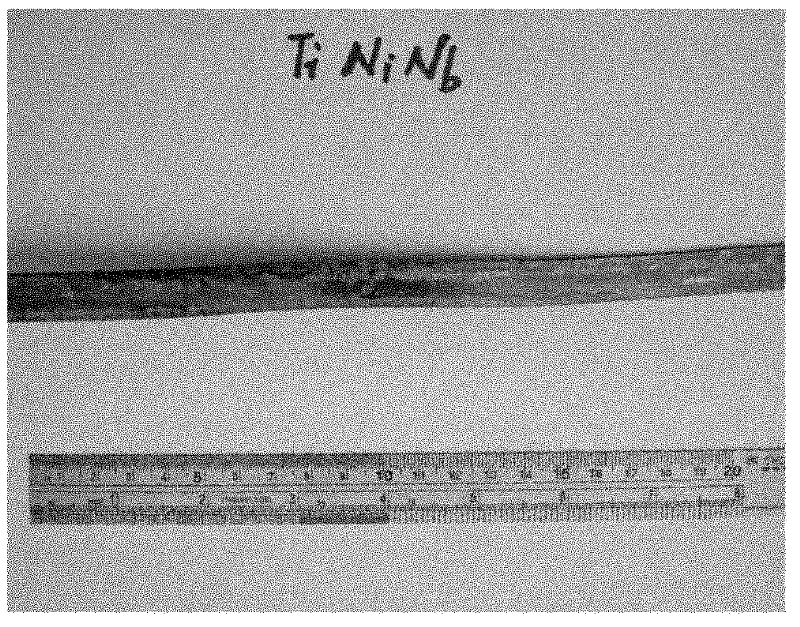

[0039] Reference figure 1 The method of the present invention is used for rolling, and the TiNiNb strip in the cold working state is still taken. The roll is also heated to 250℃ by electromagnetic induction heater, the unwinding and winding device drives the TiNiNb strip to be transported at a speed of 0.1m / s, the distance between the two elec...

Embodiment 2

[0040] Example 2: The processing material is a fully annealed AZ31 magnesium alloy strip with a width of 100mm and a thickness of 1.60mm. The rolling experiments were carried out by conventional rolling, warm rolling and the electroplastic warming rolling combined rolling method of the present invention. .

[0041] use figure 1 The rolling mill in China has a roll diameter of 300mm and a rolling speed of 0.2m / s. Cold rolling adopts conventional rolling at room temperature. As a result, the AZ31 magnesium alloy strip has obvious cracking when the deformation is about 15% (that is, from 1.60mm thick to 1.35mm thick). Figure 4 Shown.

[0042] During warm rolling, the roll 6 is heated to 160°C. When the AZ31 magnesium alloy strip approaches the roll, the heat is quickly transferred from the roll to the strip, and the roll applies rolling force at a rolling speed of 0.2m / s. After three passes of rolling, the strip is rolled from 1.60mm to 0.68mm (1.60→1.12→0.85→0.68mm; cumulative defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com