Micro-turbine disc forming device and method

A micro-turbine and cavity technology, applied in forging/pressing/hammer devices, wheels, transportation and packaging, etc., can solve the problems of micro-parts forging and forming difficulties, achieve improved material flow behavior, high dimensional accuracy, and reduce surface oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

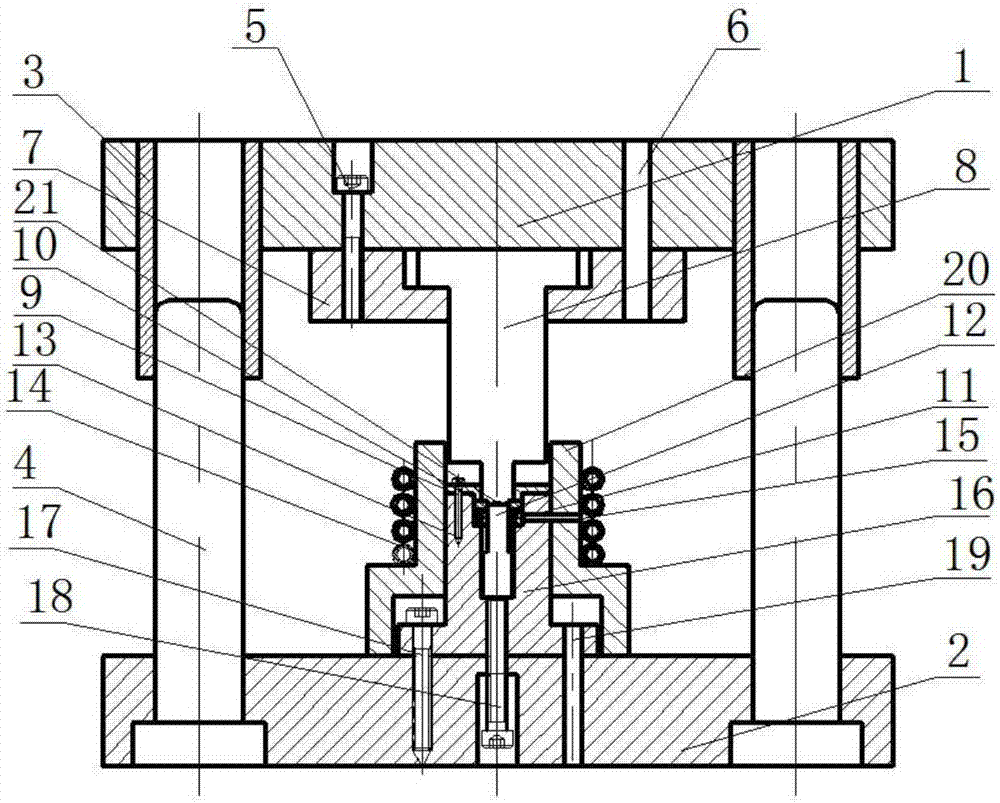

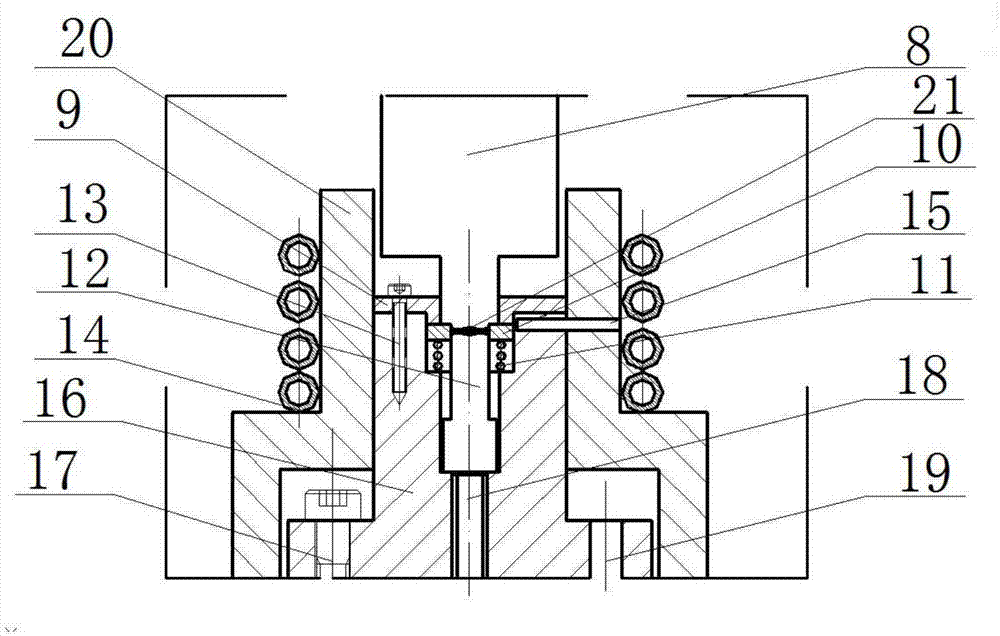

[0034] Specific implementation mode one: combine figure 1 with 2 Describe this embodiment, this embodiment takes GH4169 superalloy material as an example to introduce the method for manufacturing the micro-turbine disc structure, and the specific steps are:

[0035] Step 1: The upper template (1) drives the upper punch (8) up together under the drive of the press, and stops when the upper punch (8) is 5-10 mm away from the upper surface of the die fixing plate (12).

[0036] Step 2: placing the processed blank in the mold cavity formed by the floating die (10) and the lower punch (12);

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com