Patents

Literature

56results about How to "Improve flow behavior" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

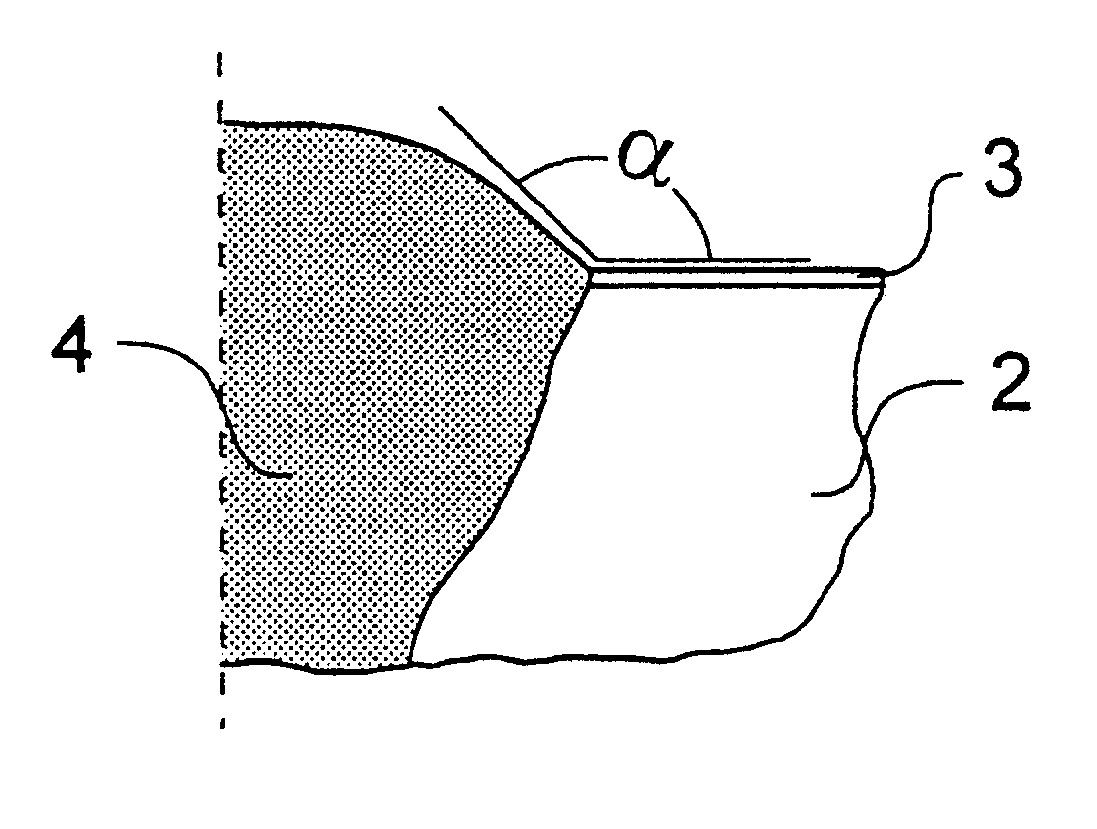

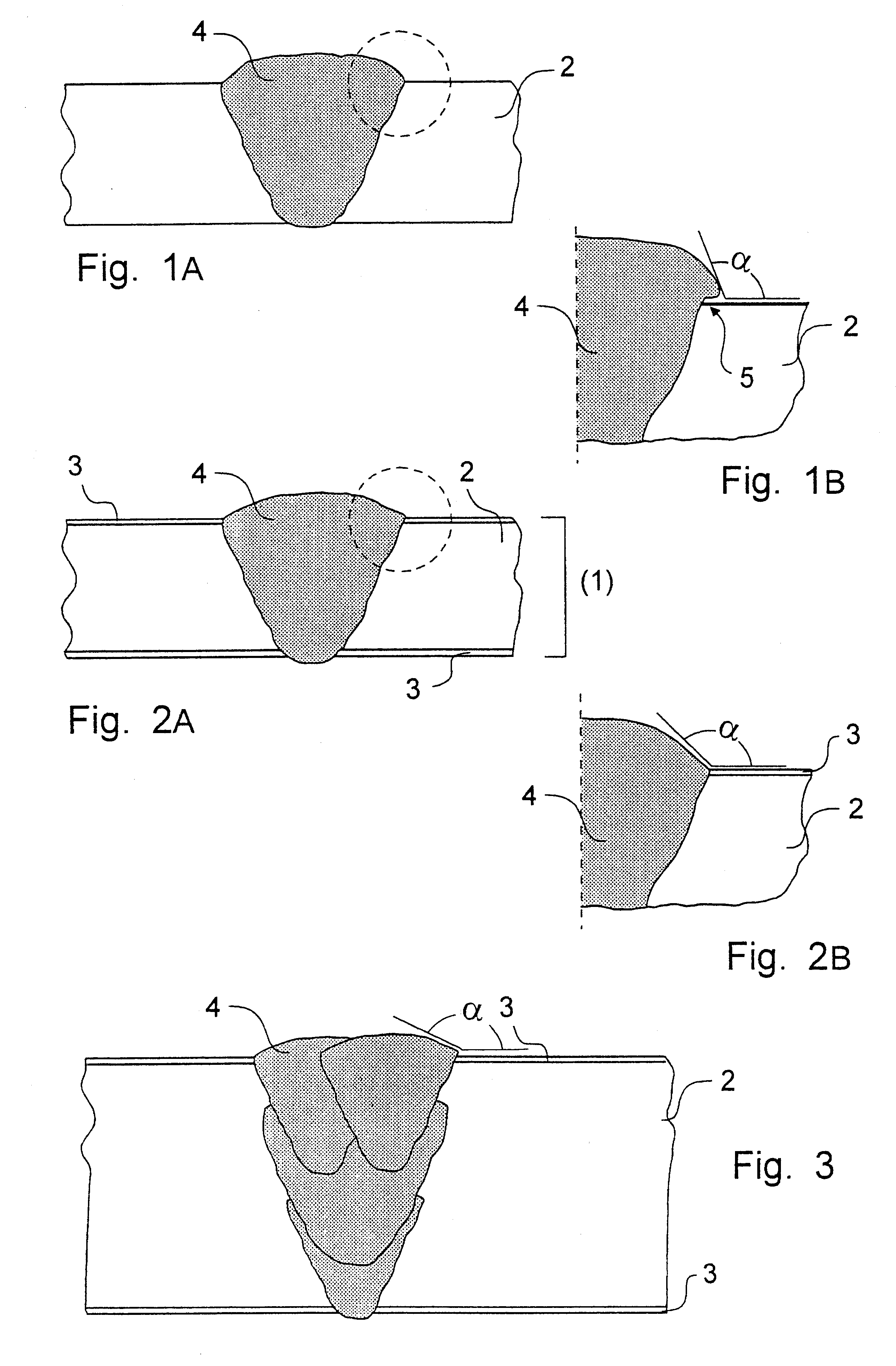

Weldable aluminum product and welded structure comprising such a product

InactiveUS6337147B1Smooth transitionReduce the amount requiredElectric discharge heatingArc welding apparatusUltimate tensile strengthAluminium alloy

Improved shape and strength of the weld in a welded structure are obtained by use of a weldable aluminum product comprising a structural component which is a sheet, a plate or an extruded body and is made of an aluminum alloy containing not more than 1.5 wt % Zn. This component has, adhered on at least one side, a cladding layer made of an AA7xxx-series alloy having a corrosion potential lower than that of the alloy of the structural component. The alloy of the structural component is preferably an AA5xxx-series alloy containing Mg in the range 2 to 6 wt %.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

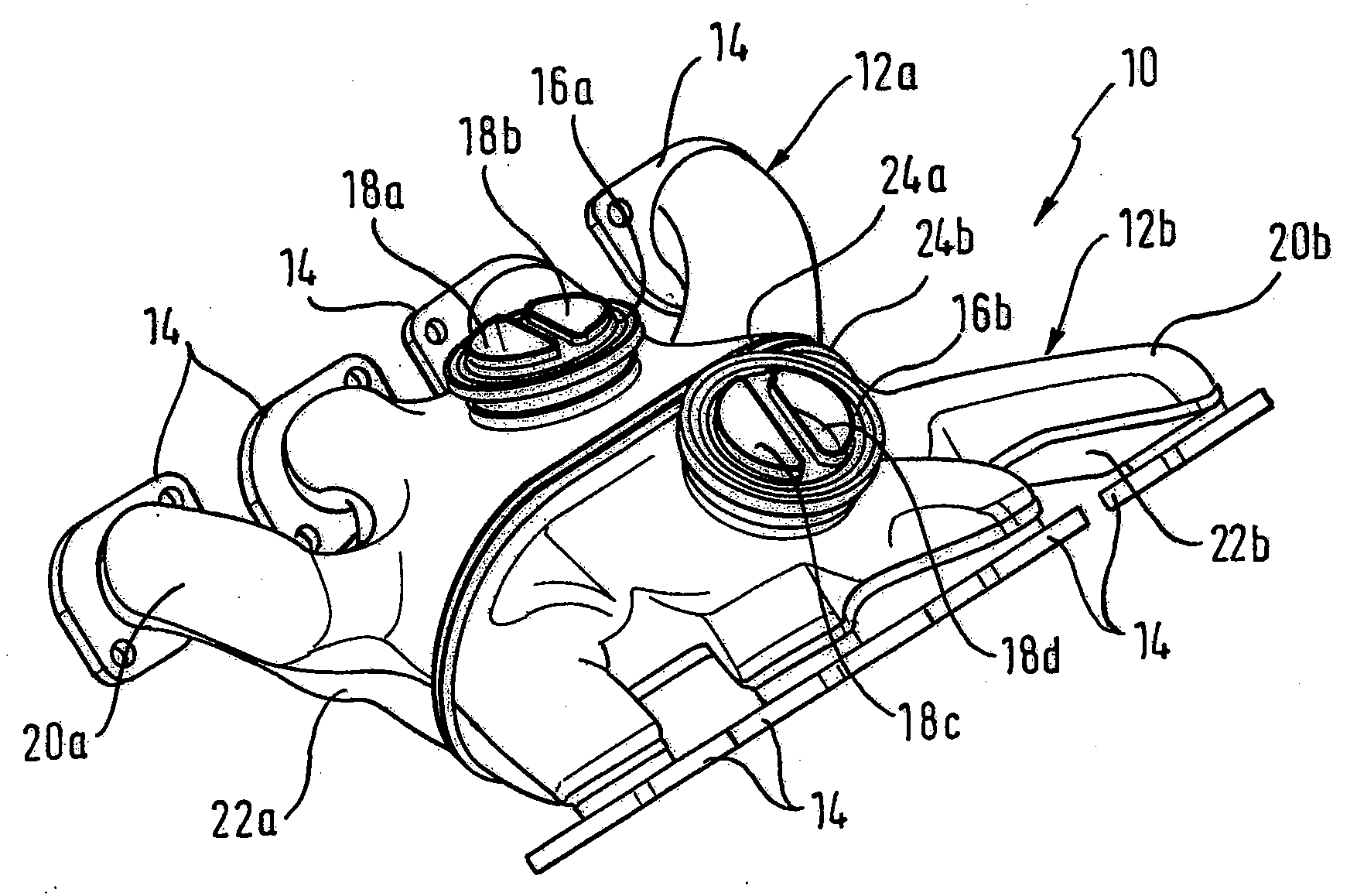

Method for the production of a sandwich component having a honeycomb core and the sandwich component obtained in this way

InactiveUS20090252921A1Improve adhesionEnhance layeringLamination ancillary operationsSynthetic resin layered productsShell moldingAdhesive

The invention relates to a method for the production of a fiber reinforced sandwich component (10) having a honeycomb core (12), the honeycombs of which are closed on both sides. The honeycomb core is closed at least on one side by a cover layer (14) made of fiber material, which is embedded in matrix material. The method comprises the following steps: —Producing a fabric comprising the honeycomb core and at least on one side of the honeycomb core, disposed from the inside to the outside, a curable adhesive layer (20), a barrier layer (16) and a fiber layer (14); —Locking the fabric on a one-sided molding tool (30) in a gastight chamber, which is formed up by a vacuum foil (48) on the one-sided molding tool; —Creating a vacuum in this gastight chamber, —After creating the vacuum, hardening or partial hardening of the adhesive layer between the honeycomb core and barrier layer in this vacuum such that the honeycomb cells (18) are evacuated at least partially before they are closed off by the barrier layer; —After hardening or partially hardening of the adhesive layer, infusion of the fiber layer in a vacuum with a matrix material; and —Hardening of the matrix material in a vacuum.

Owner:EURO COMPOSITES

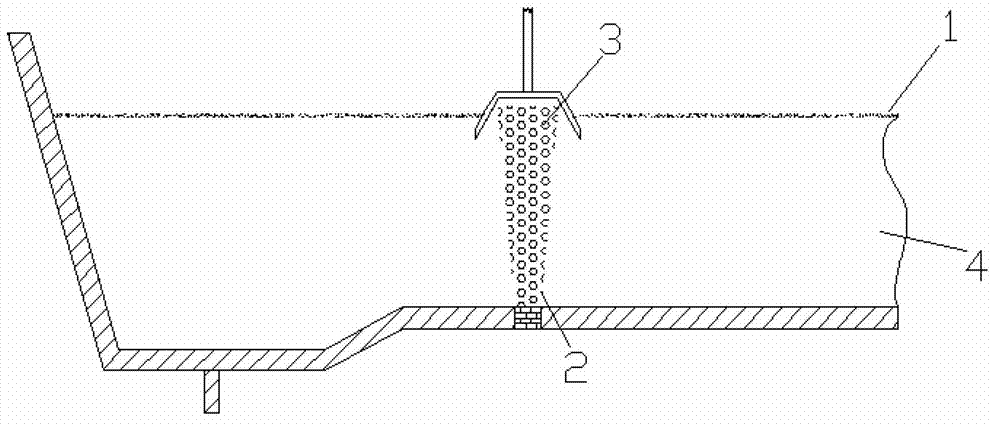

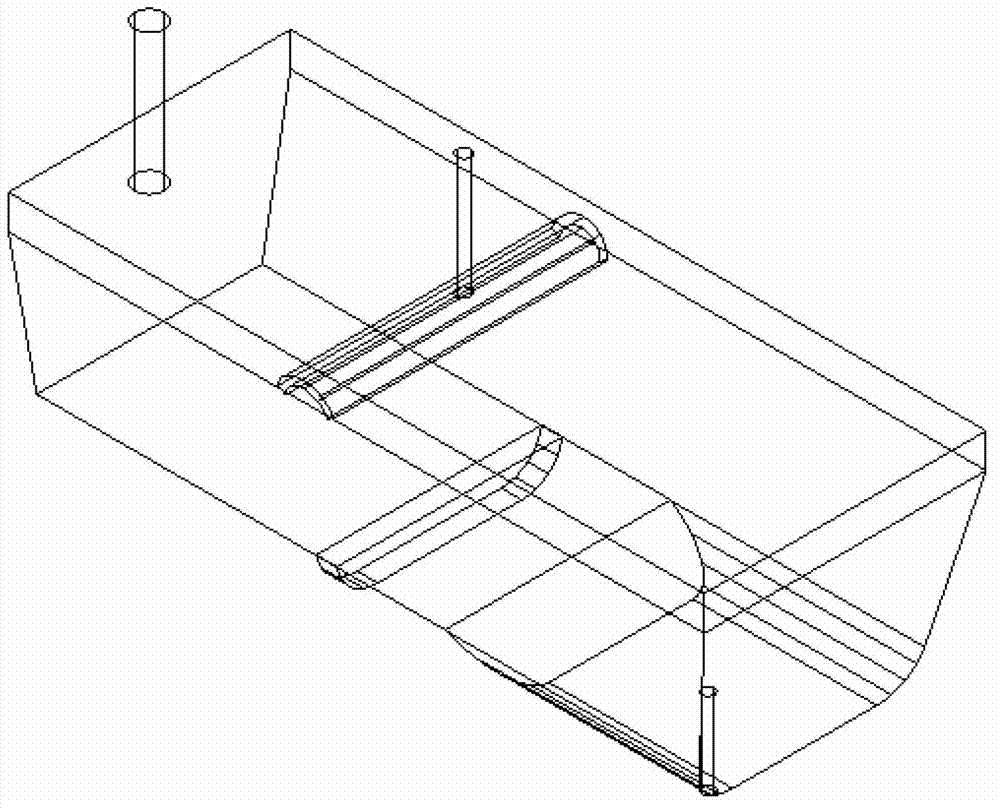

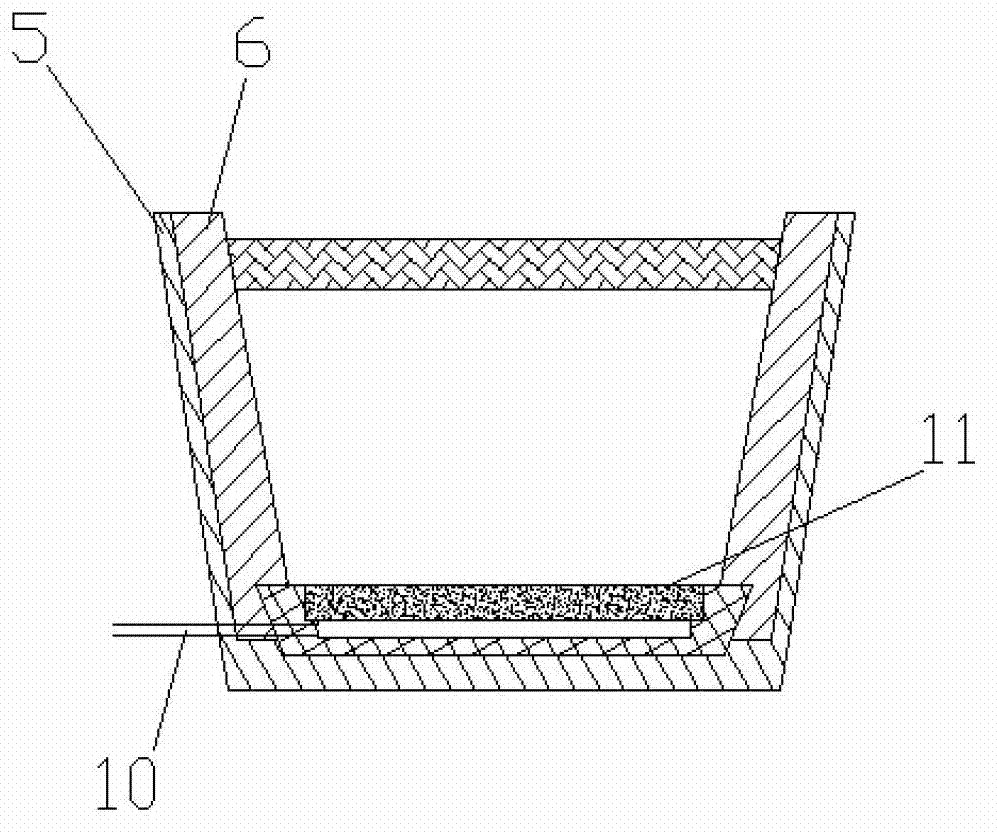

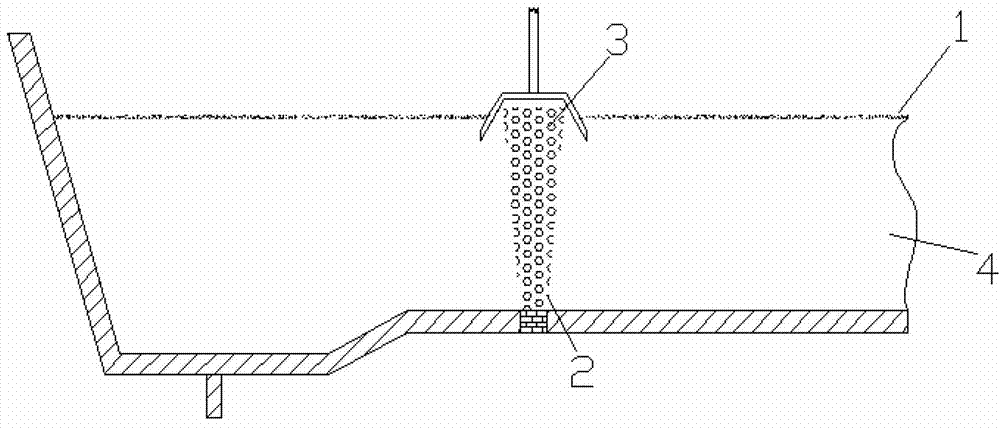

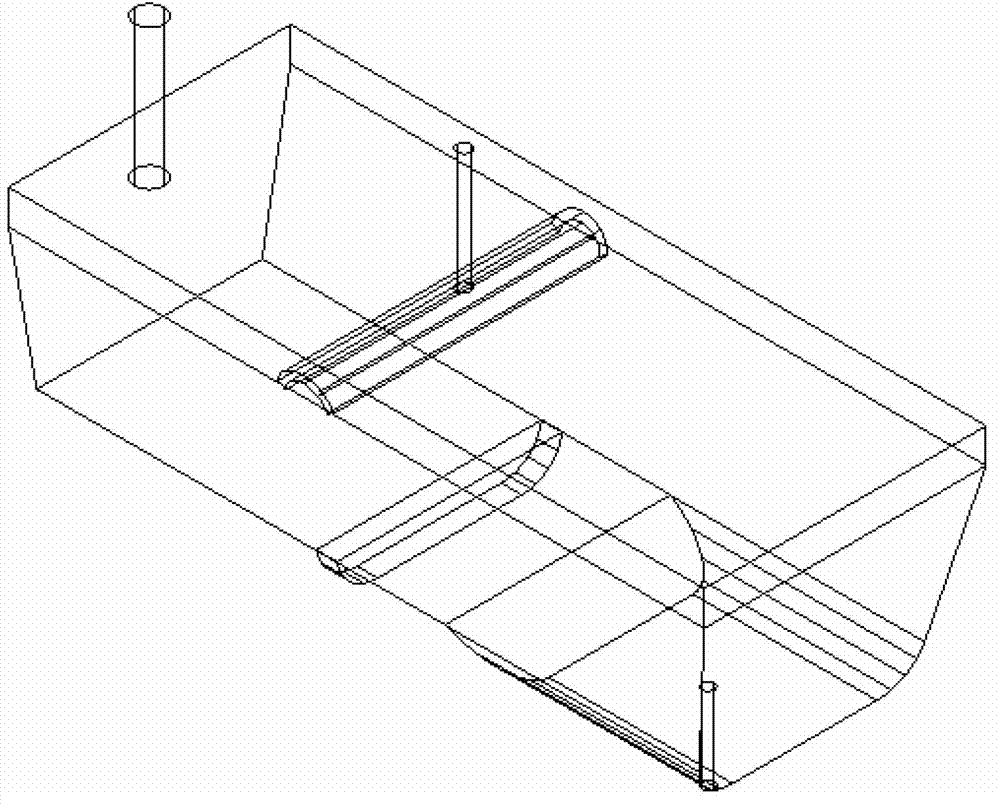

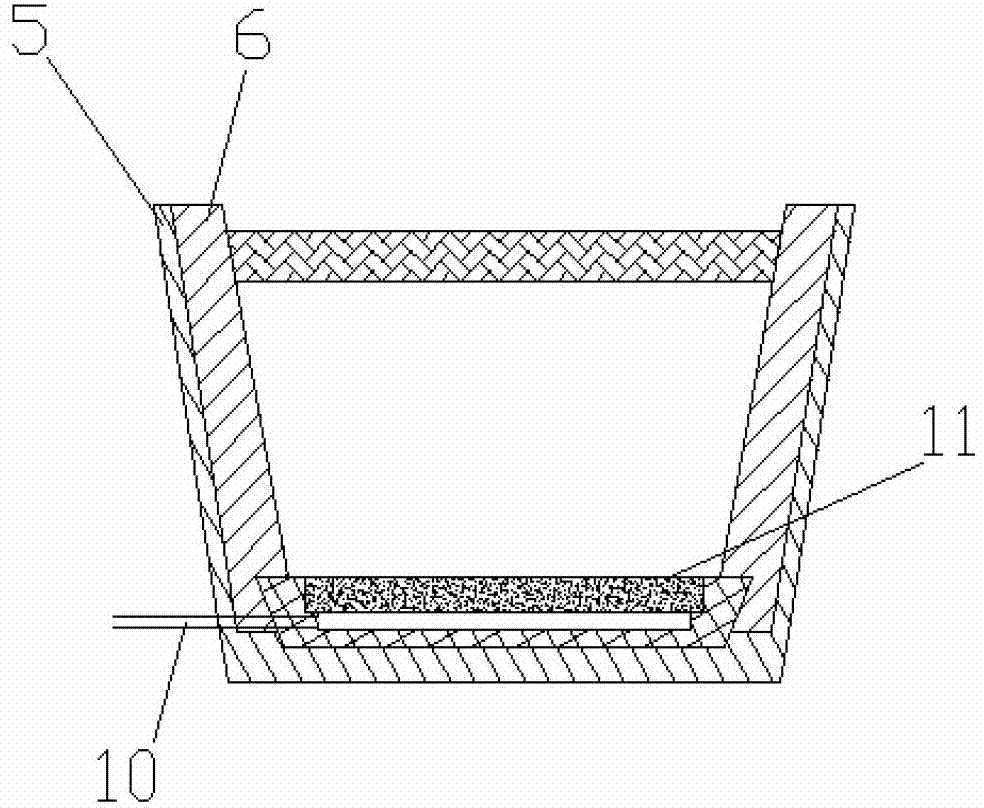

Blowing and refining device and method used for removing tundish molten steel inclusion

The invention discloses a blowing and refining device and method used for removing the tundish molten steel inclusion. The blowing and refining device is characterized by comprising a tundish 1, a blowing device 2 and a dipping cover 3, wherein the tundish comprises a permanent layer and a working layer arranged on the inner surface of the permanent layer; the bottom of the permanent layer is provided with the blowing device; the blowing device comprises an air brick and a ventilating pipe; the air brick comprises a dense layer and a ventilating layer; the middle of the ventilating layer is provided with an air chamber; and the dipping cover is a refractory material cover supported by a steel plate, is connected with an automatic lifting system and is arranged above the blowing device. According to the blowing and refining device, an air curtain retaining wall with a big air flow can be introduced in to form continuous and tight bubble columns, the average residence time of molten steel in the tundish is obviously prolonged, the molten steel flowing behavior is obviously improved, the molten steel can be stirred by a great quantity of tiny bubbles, inclusions with a smaller size can be adsorbed, and meanwhile, steel slag rolling and mixing and the secondary oxidation of the molten steel due to big blowing amount can be avoided.

Owner:UNIV OF SCI & TECH BEIJING

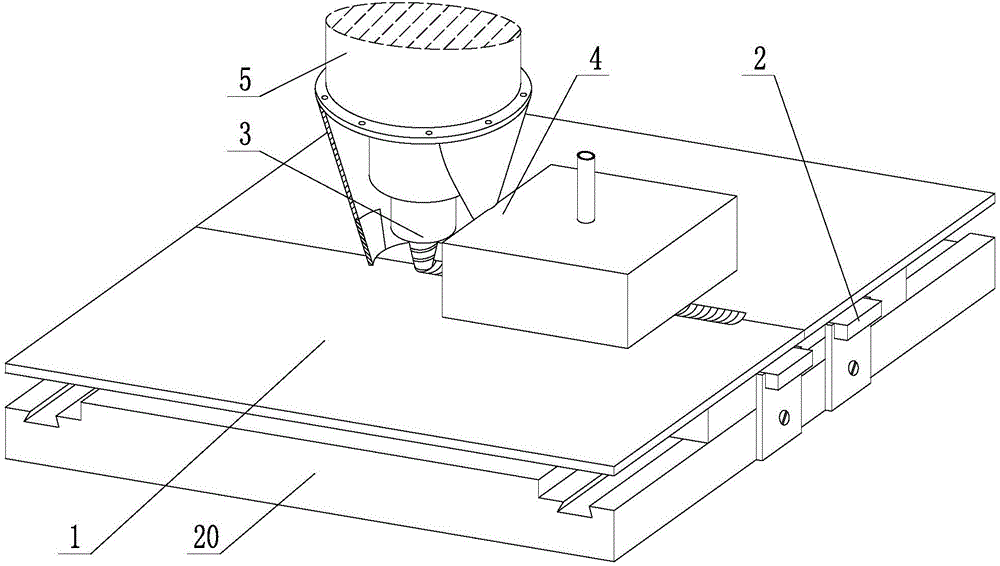

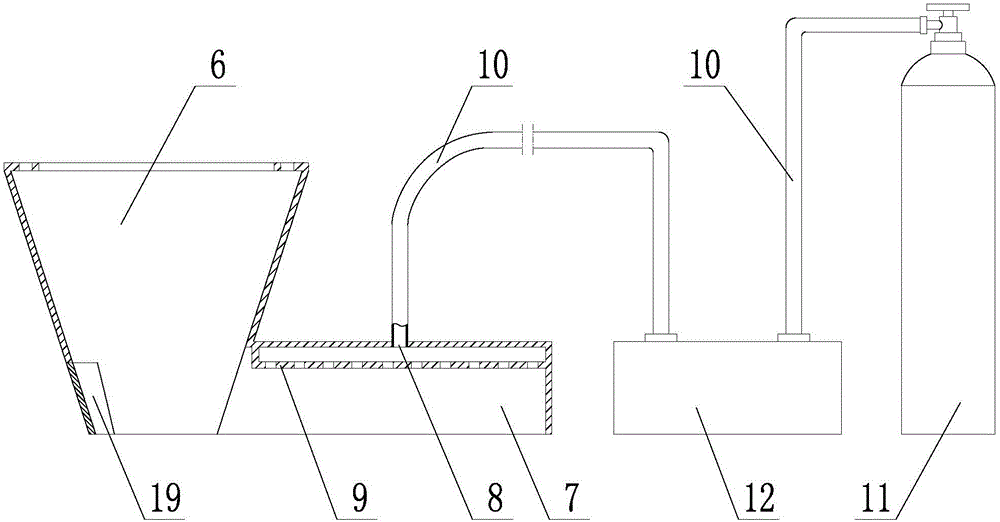

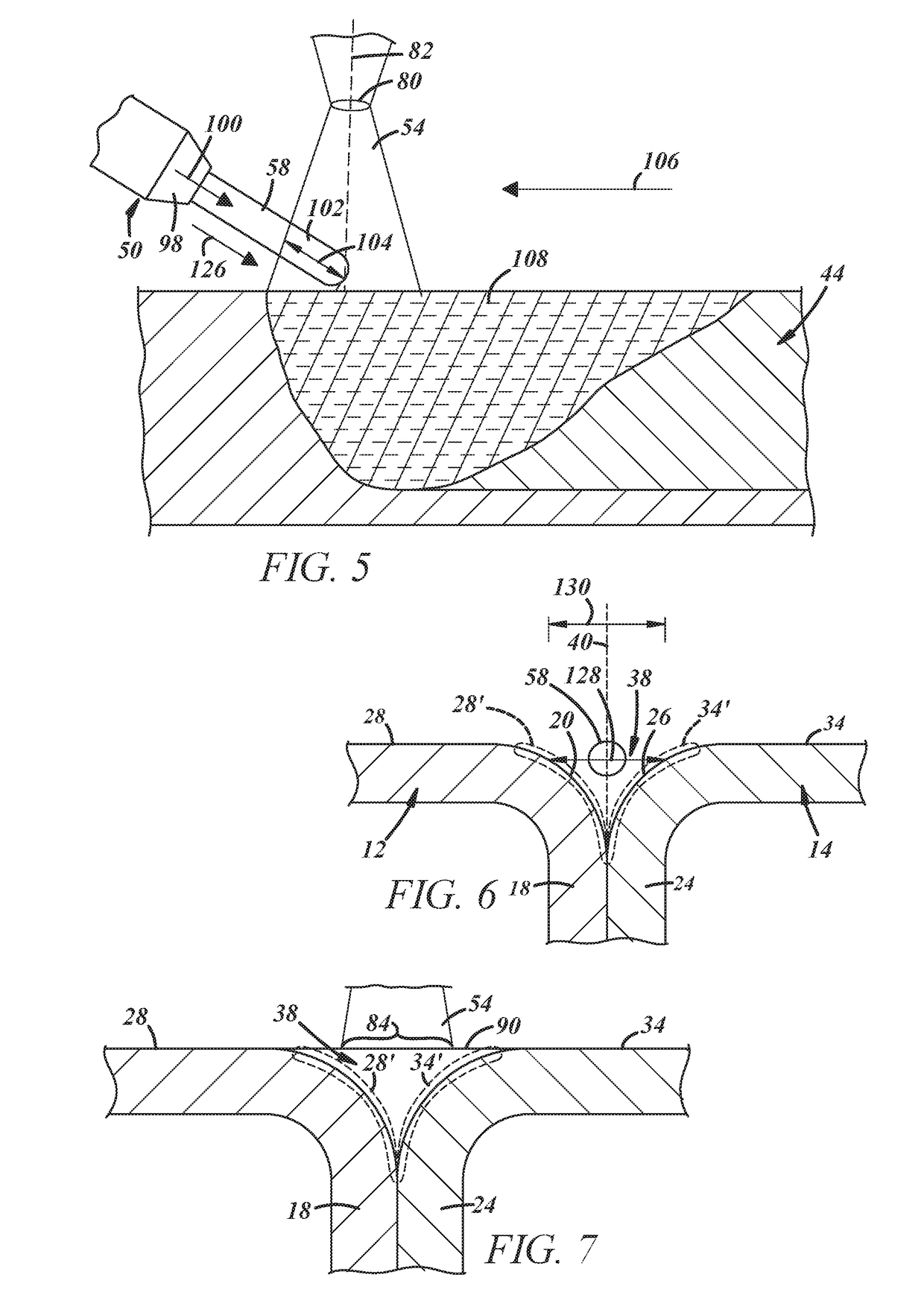

Friction stir welding process for combining back surface heating with frontal surface chilling

ActiveCN106271025AReduce temperature gradientImprove unevennessNon-electric welding apparatusCarbon Dioxide / HeliumShielding gas

The invention discloses a friction stir welding process for combining back surface heating with frontal surface chilling. The friction stir welding process comprises the following steps: a workpiece to be welded is fixedly clamped; heaters are arranged on two sides of a welding line area; a chilling shielding gas protective cover for moving along with a stirring head is arranged on the outer side of the stirring head; the heaters are started to heat the back surface of the workpiece to be welded, so that the temperature of the upper surface of the workpiece to be welded is not higher than 250 DEG C; the chilling shielding gas protective cover is filled with the chilling shielding gas, and the covering range includes the welding line area and the upper surface area of the workpiece to be welded rightly above the heaters; friction stir welding equipment is started, and the rotating stirring head is controlled to insert in the workpiece to be welded; the shaft shoulder end surface of the stirring head is continuously pressed down by a section of distance, and the stirring head is stopped until a set inserting depth is reached; the stirring head is controlled to continuously rotate by a period of time under the set inserting depth, so that the welding line area of the workpiece to be welded is fully preheated to reach an excellent plastic state; and the stirring head is controlled to finish the welding work of the welding line area at a set welding speed.

Owner:SHENYANG AEROSPACE UNIVERSITY

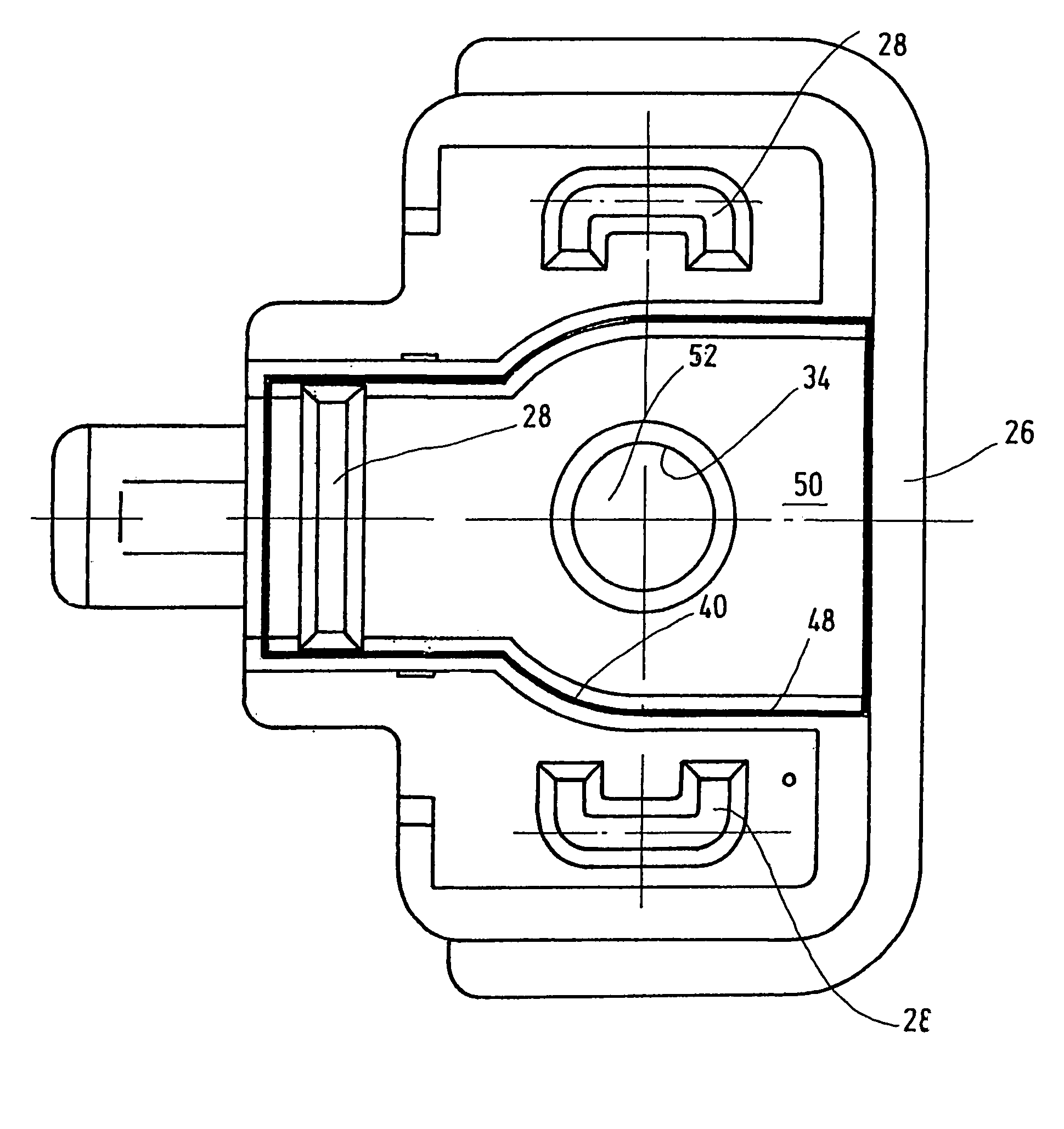

Two-For-One Twisting Spindle Having a Pneumatically Actuated Threading Device

InactiveUS20100018178A1Easy to produceReduce weightPiercing arrangementsDrafting machinesRotational axisEngineering

Two-for-one twisting spindle having a pneumatically actuated threading device, with a spindle shaft rotatable about a vertical axis partially configured as a hollow shaft with a lower feed bore extending coaxially to the rotational axis, and with an injector element opening into a thread guide channel of a thread guide ring temporarily connectable during threading to a compressed air source. Part of the compressed air feed to the injector element is formed by the feed bore. The compressed air feed comprises a connection element (27) with a curved air channel (26), which connects the feed bore (24) to the injector element (16). The connection element (27) is configured as a separate component and the air channel (26) is adapted to the flow requirements.

Owner:SAURER TECH GMBH & CO KG

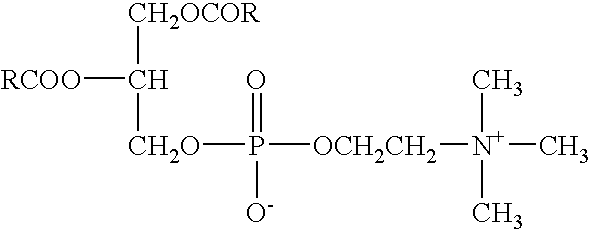

Emulsifier concentrate for a cosmetic composition

InactiveUS20070166270A1Improve cold flow behaviorImprove flow behaviorCosmetic preparationsOrganic compound preparationEmulsionPolyethylene glycol

The invention relates to emulsifier concentrates which are pourable at 20° C. and contain (a) up to 90 percent by weight of a polyethylene glycol fatty acid diester based on a C16-C22 fatty acid, C16-C22 hydroxy fatty acid, polyhydroxy stearic acid, or poly-(C16-C22 hydroxy fatty acid), (b) up to 80 percent by weight of an oil or oil mixture that is liquid at 25° C., and (c) 2 to 8 percent by weight of water. Also disclosed are the use in emulsions and a method for producing emulsions based on the inventive emulsifier concentrates.

Owner:COGNIS IP MANAGEMENT GMBH

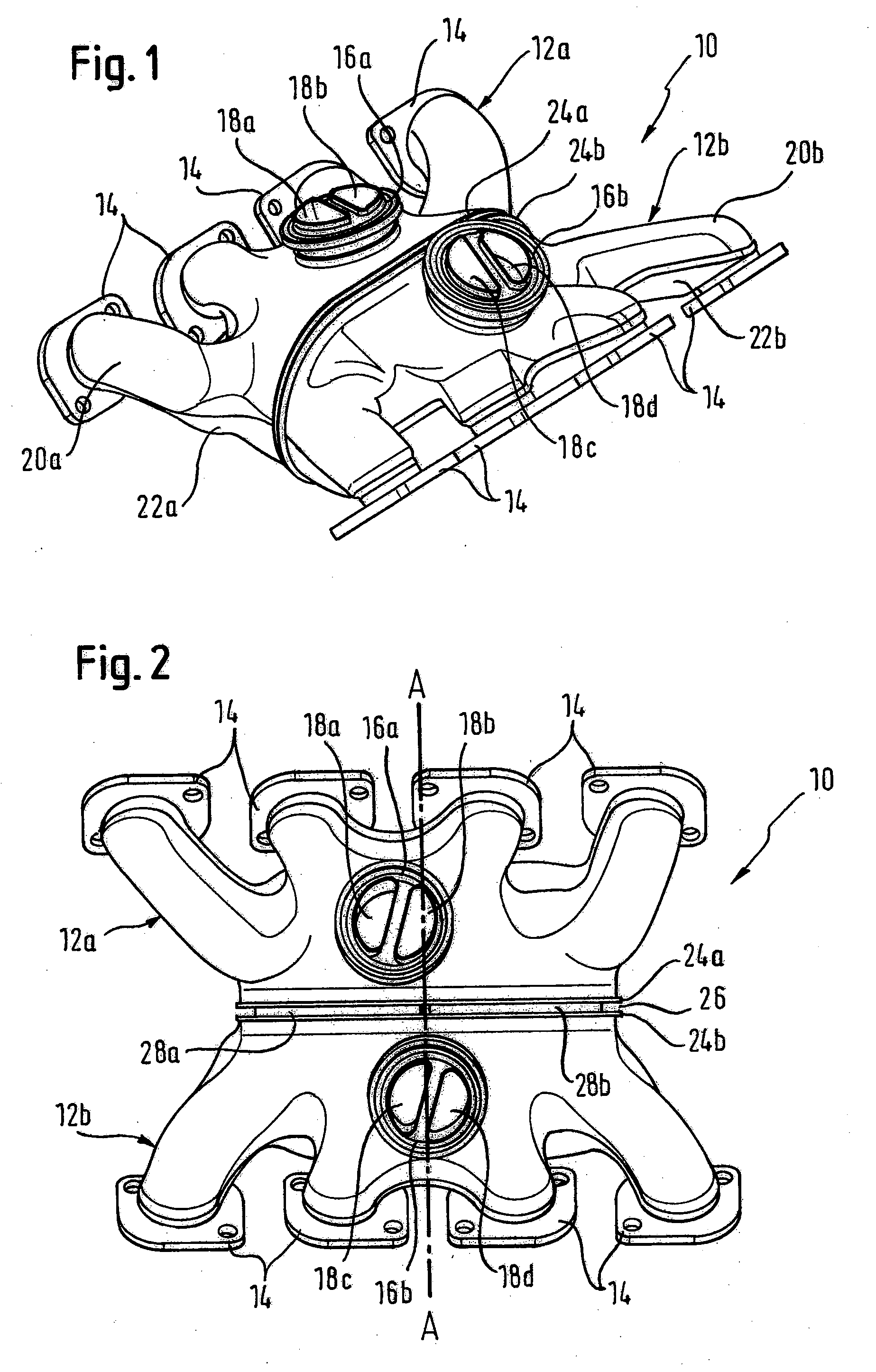

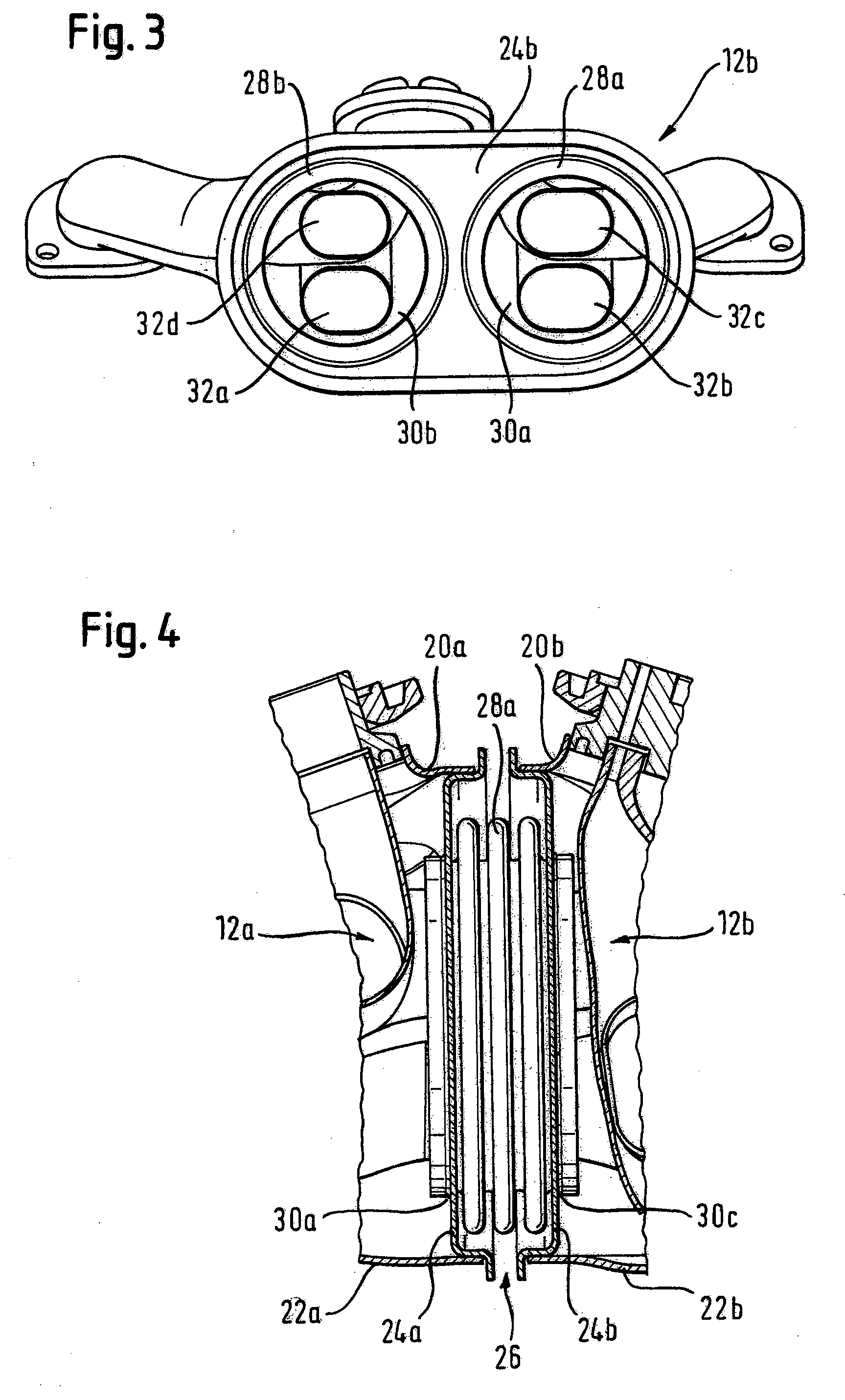

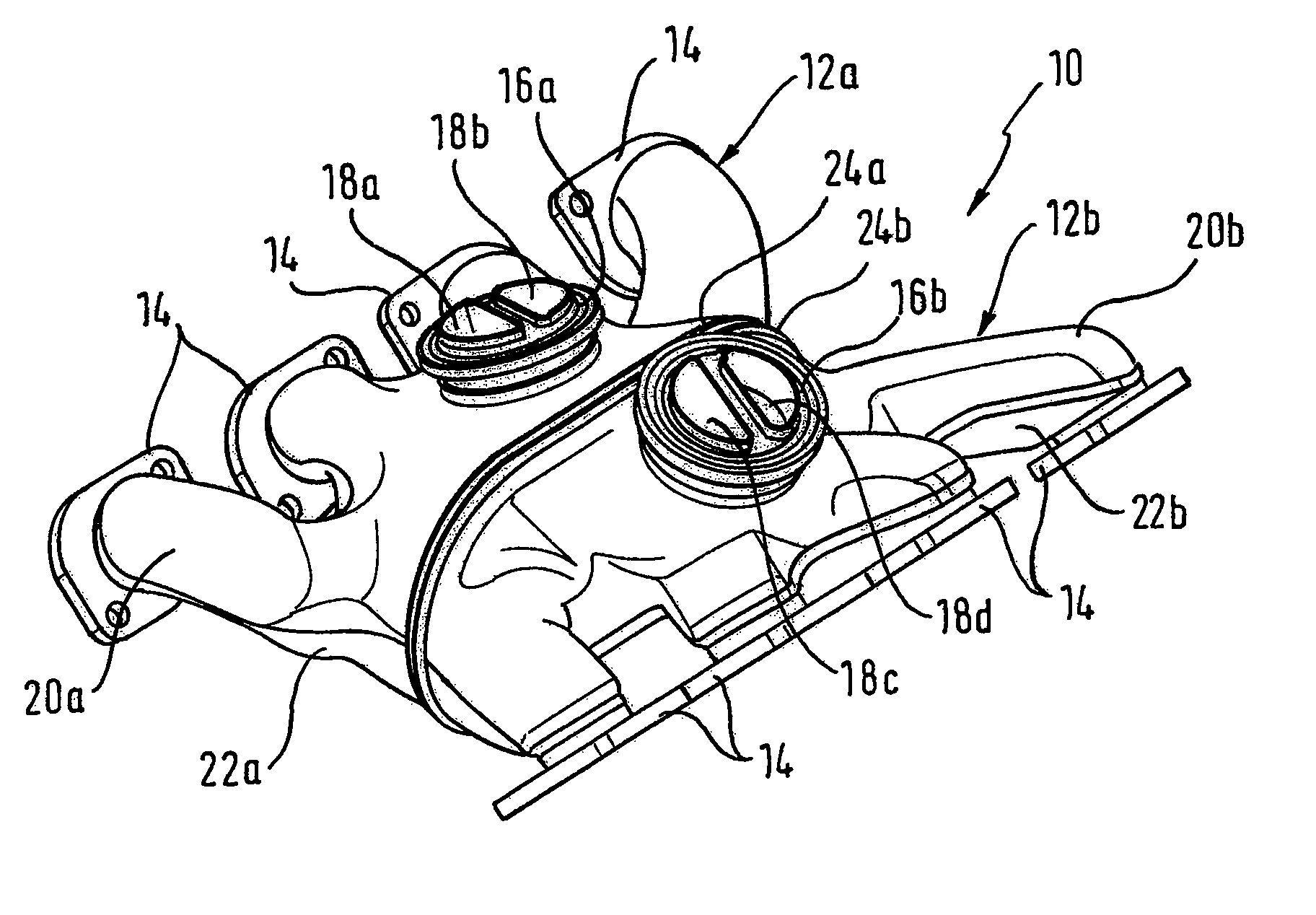

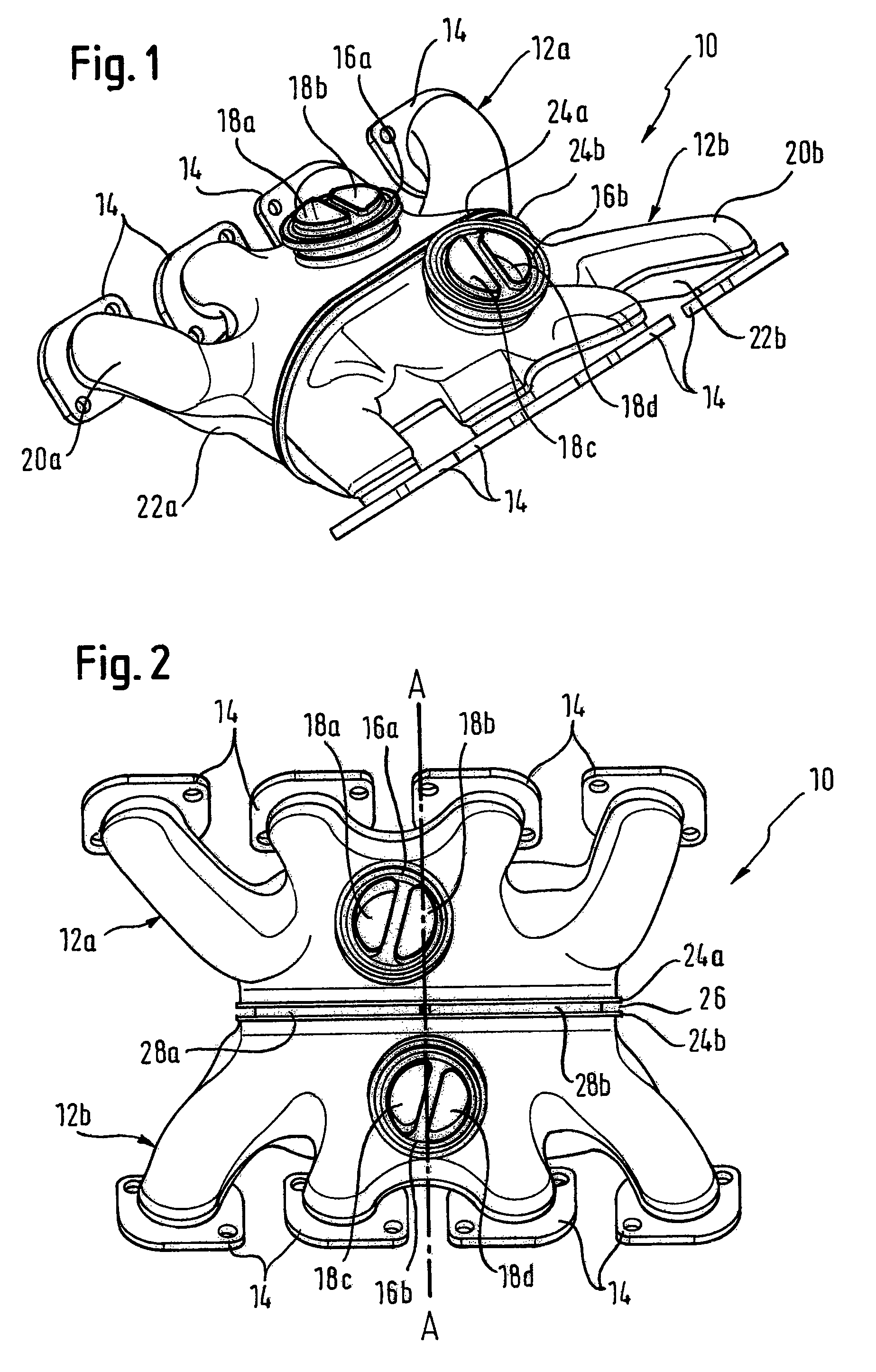

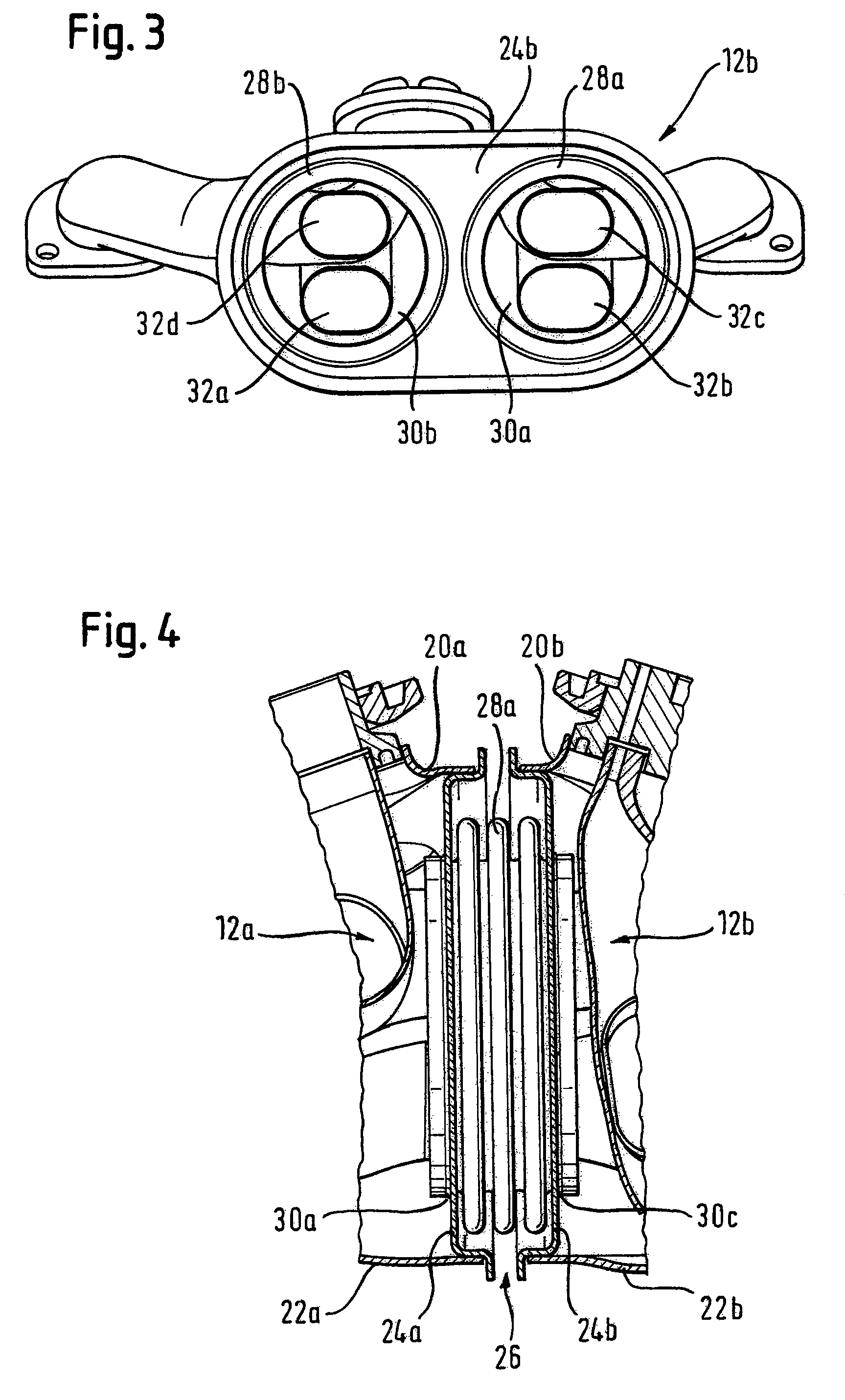

Exhaust Gas System

ActiveUS20080289323A1Improve flowing behaviorImprove deformation abilityExhaust apparatusSilencing apparatusExhaust gasExhaust fumes

An exhaust gas system for an internal combustion engine, in particular a motor vehicle engine, is provided having, in one form, two cylinder banks arranged at an acute angle to one anther and each having at least one exhaust gas outlet, a so-called V-engine, having exhaust gas guide elements arranged in the region of the inner angle, including a housing surrounding the exhaust gas outlets of both cylinder banks in a gas tight manner and having at least one exhaust gas outlet opening is characterized in that the housing is made in two parts, with a first part which is connected to the one cylinder bank and surrounds its exhaust gas outlets and with a second part which is connected to the other cylinder bank and surrounds its exhaust gas outlets; in that the two parts each have a side facing the other part and having at least one housing opening via which the two parts communicate with one another; and in that an expansion compensation element is arranged between the two parts and surrounds the housing opening of the two parts in a gas tight manner.

Owner:FRIEDRICH BOYSEN +1

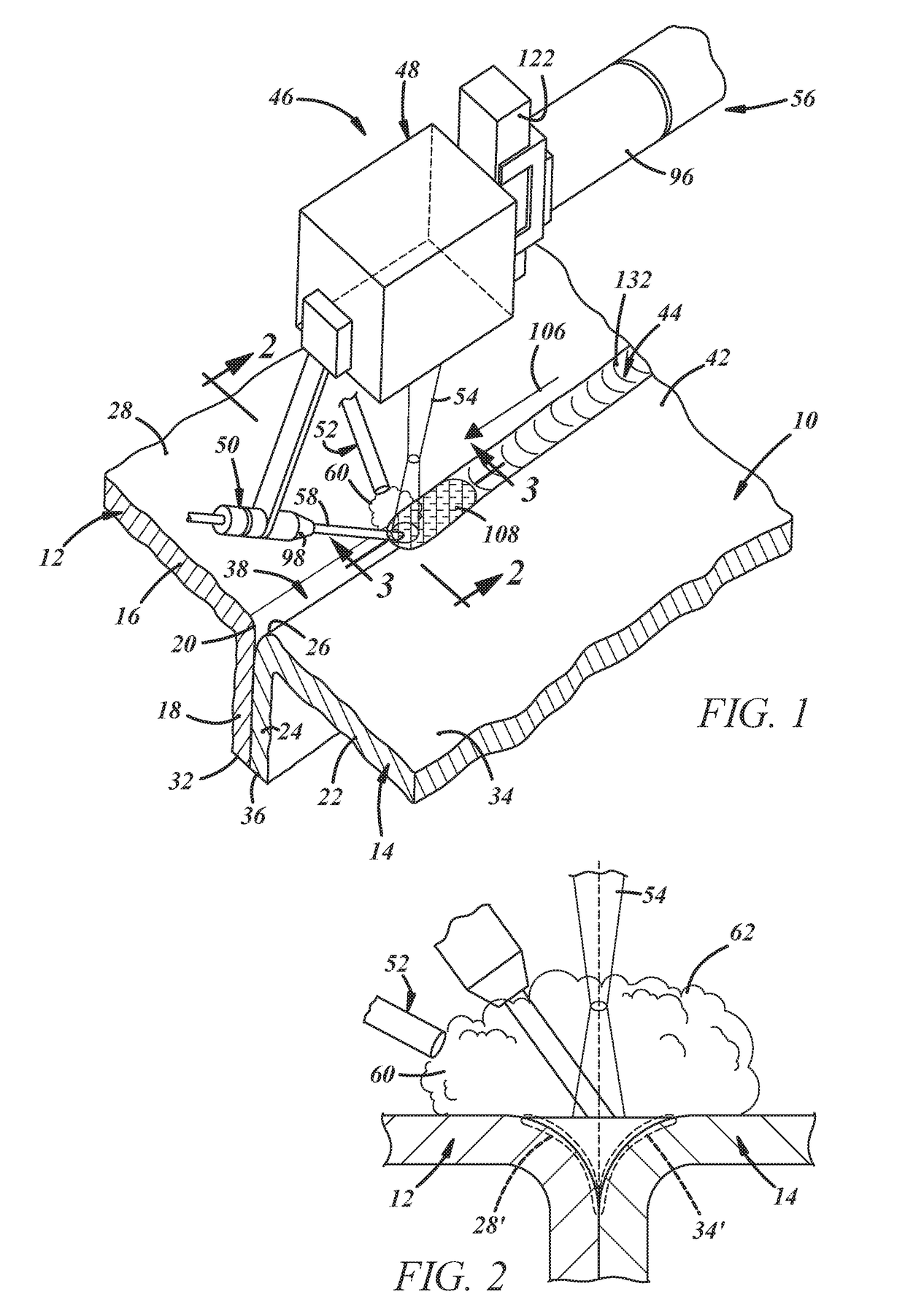

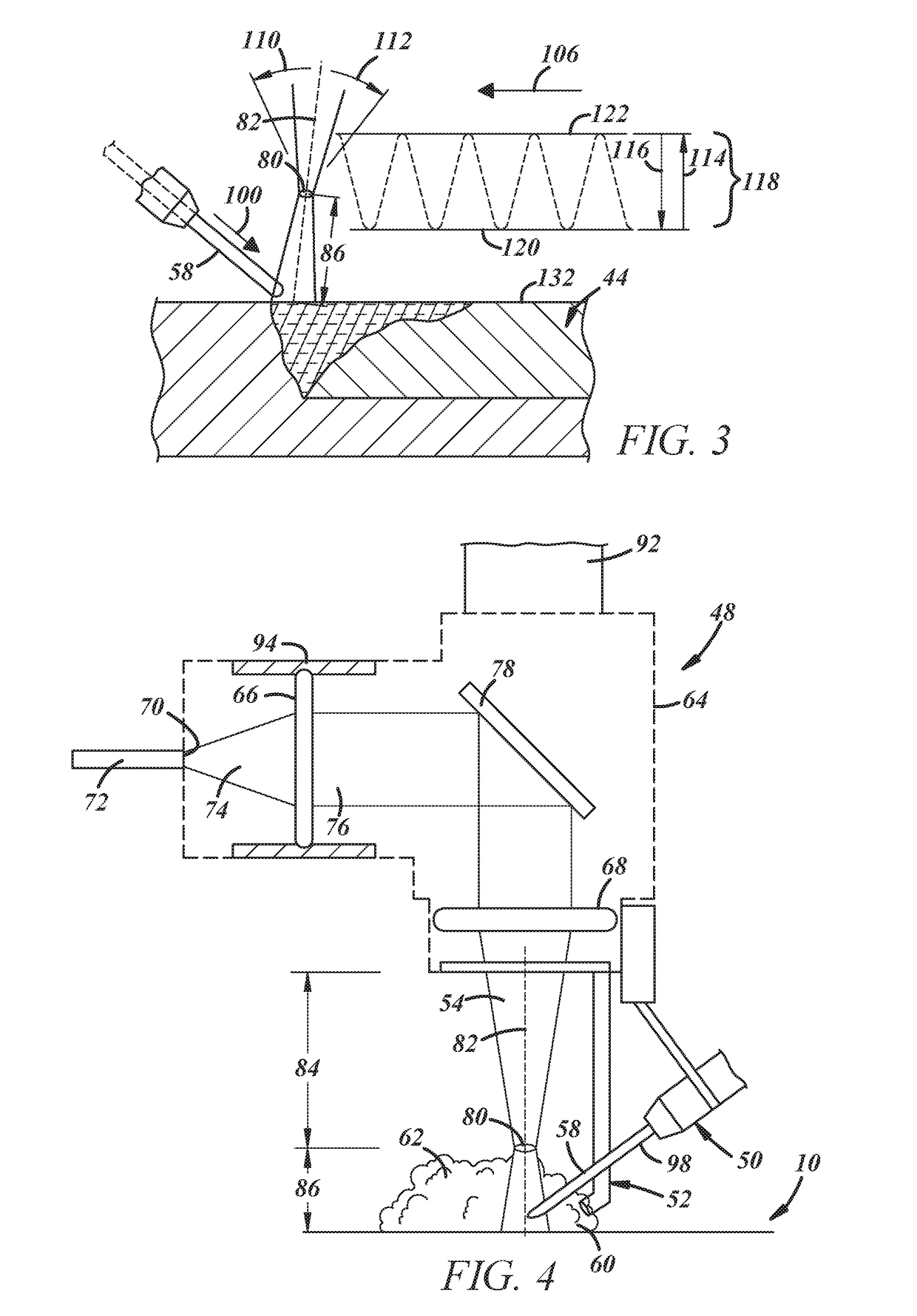

Laser brazing of metal workpieces with relative movement between laser beam and filler wire

InactiveUS20190061053A1Increase and decrease focal distanceImprove the heating effectSoldering apparatusVehicle componentsOptoelectronicsMetal

A method of laser brazing a metal workpiece assembly along a joint seam established between a first metal workpiece and a second metal workpiece involves advancing a laser beam along the joint seam while feeding a filler wire into the laser beam to melt a leading end of the filler wire, which is impinged by the laser beam, to produce and dispense molten filler material within and along the joint seam. The dispensed molten filler material solidifies behind the laser beam into a braze joint. Additionally, as part of the method, a position of a focal point of the laser beam relative to the leading end of the filler wire is repeatedly fluctuated during advancement of the laser beam along at least part of the joint seam.

Owner:GM GLOBAL TECH OPERATIONS LLC

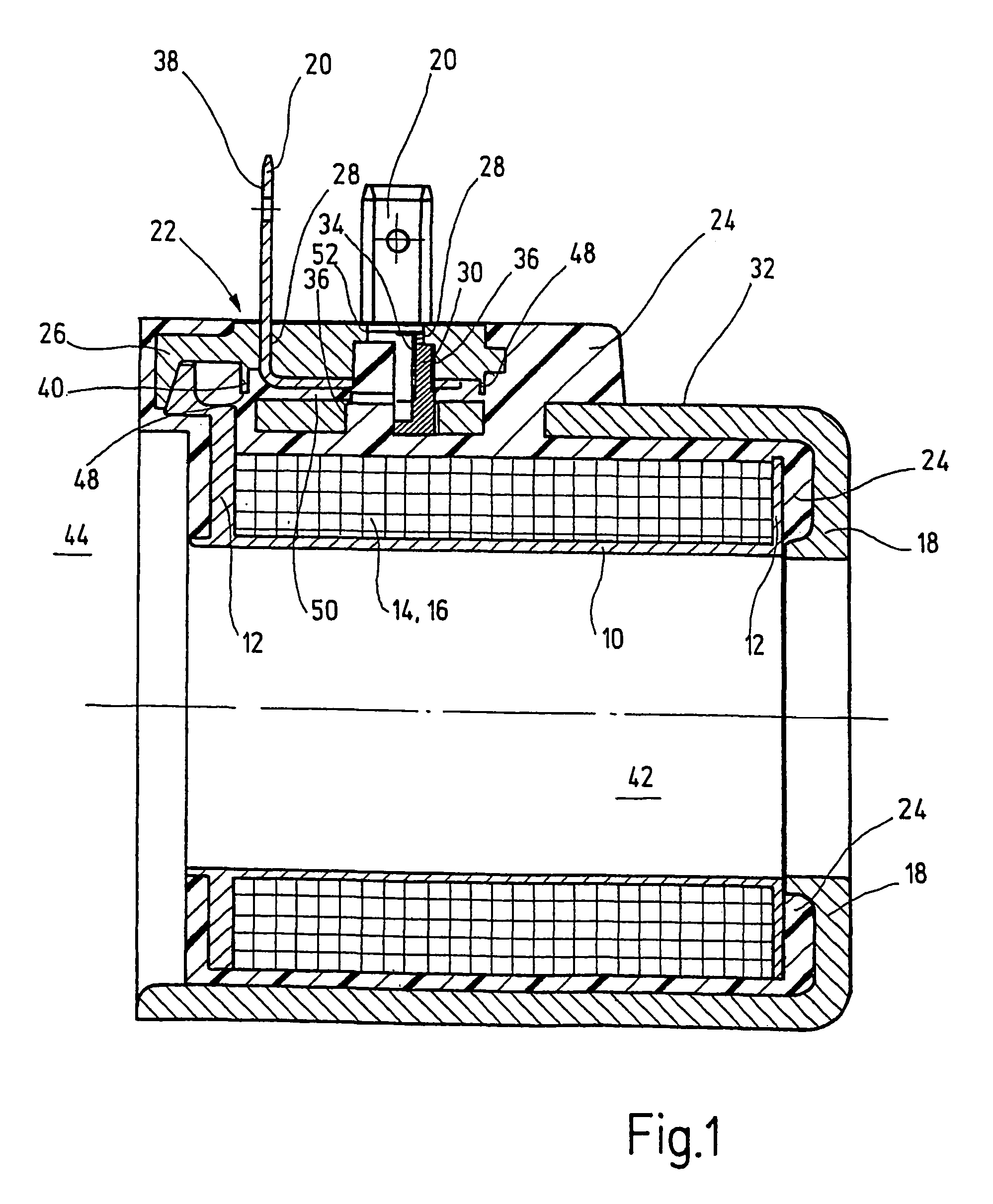

Sealed-off switchgear

InactiveUS7151427B2Reliable operationGuaranteed uptimeOperating means/releasing devices for valvesTransformers/inductances casingsEngineeringElectrical conductor

A switchgear, especially for actuating valves, includes a housing (18) and a coil body (10) disposed in the housing. A switch element is guided in the coil body. The coil body is provided with a winding (14) of a conductor (16) that is connected to a plug connector (22) via contact elements (20). At least some sections of the housing (18) and of the plug connector (22) are enclosed by a plastic compound (24). Sealing devices (40) seal off the interior (42) of the switchgear from the surroundings (44). At least one of the sealing devices (40) is configured as a sealing web (48) of a meltable material. The sealing web (48) is disposed on the bottom face (50) of a plug plate (26) of the plug connector (22) which faces the housing (18). The sealing web (48), in the molten connection state, seals off at least the engaging parts of the plug connector (22) that are connected to the housing (18) from the surroundings (44) in a fluid-tight manner by the plastic compound (24), thereby eliminating the need for conventional rubber packing rings (O rings) in the area of the plug connector that are prone to failures.

Owner:HYDAC ELECTRONICS GMBH +1

Cosmetic and/or pharmaceutical agents

InactiveUS20040067213A1Good emulsifying effectGood foaming effectCosmetic preparationsHair cosmeticsEmulsionAmino acid

Preparations comprising at least one acylated amino acid in an amount of from 40 to 80% by weight and at least one protein condensate in an amount of from 20 to 60% by weight, based on the total weight of the combined at least one acylated amino acid and the at least one protein condensate, are described. Cosmetic and / or pharmaceutical compositions containing said preparations are also described along with methods of preparing emulsions, producing foam and stabilizing foam produced by surfactant compositions.

Owner:COGNIS DEUT GMBH & CO KG

Valve with connection on the pressure side

ActiveUS20120298903A1Stop movingSmall flow resistancePlug valvesOperating means/releasing devices for valvesEngineeringVALVE PORT

The invention refers to a valve, in particular a pressure valve, comprising a feed area provided in front of a globe valve in flow direction of the medium, wherein the globe valve can be sealed by a loose closing element provided in the feed area, and wherein an activation rod angles the closing element against the flow direction of the medium with reference to the globe valve. The invention is characterized in that in the feed area a flow guiding device is provided, wherein the flow guiding device has several channel areas, so that the medium flowing through the channel areas is set in a helical twist.

Owner:SVM SCHULTZ VERW +1

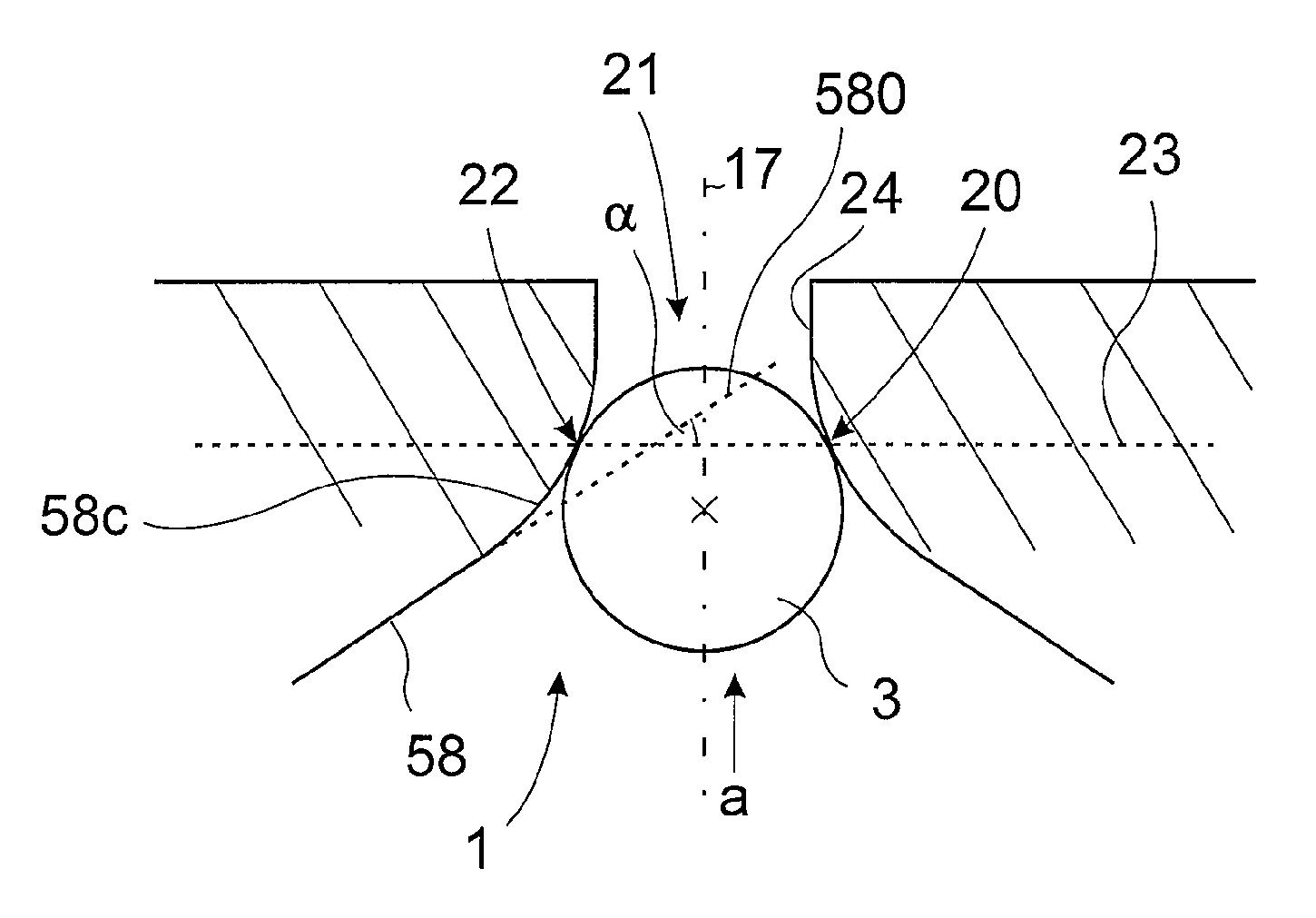

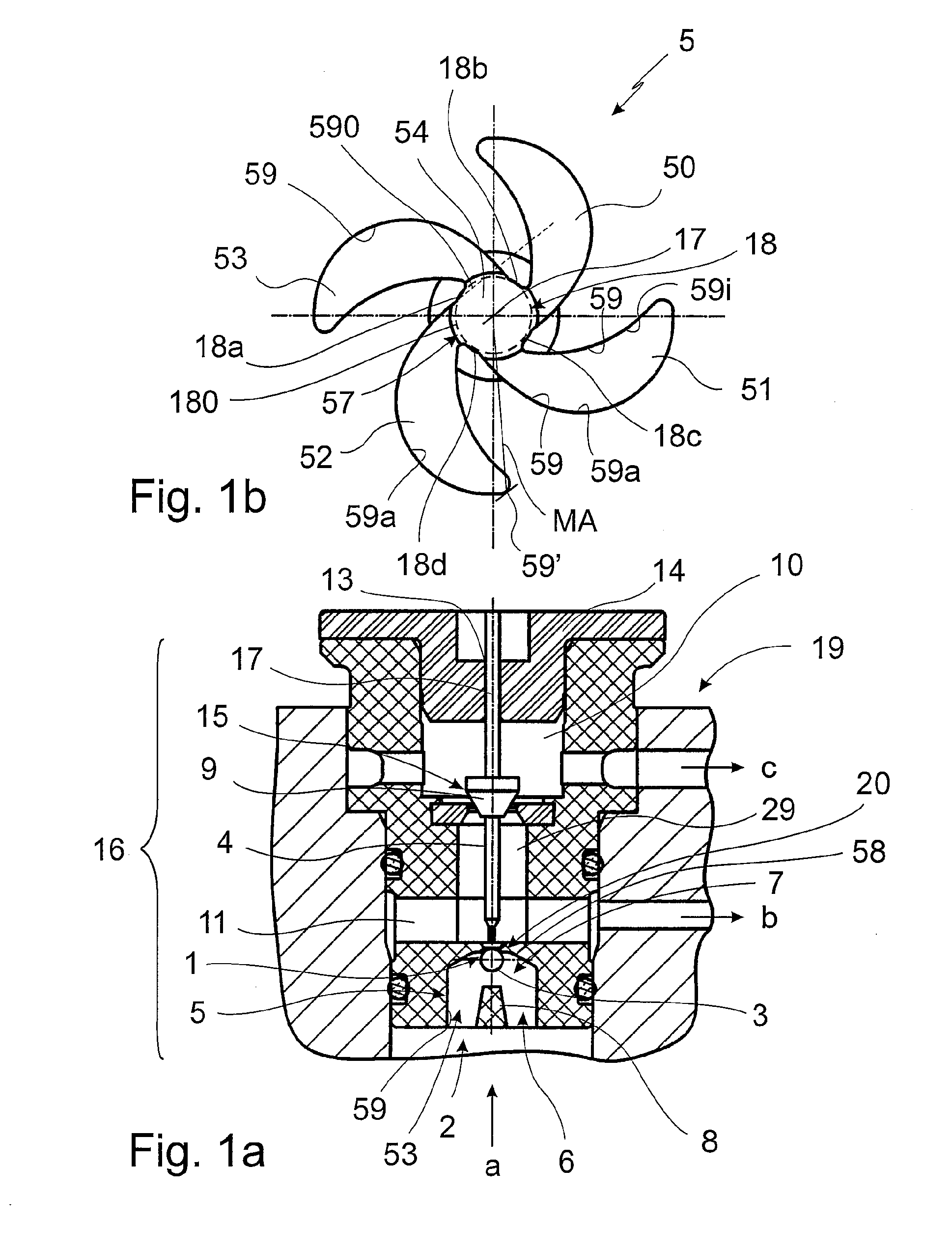

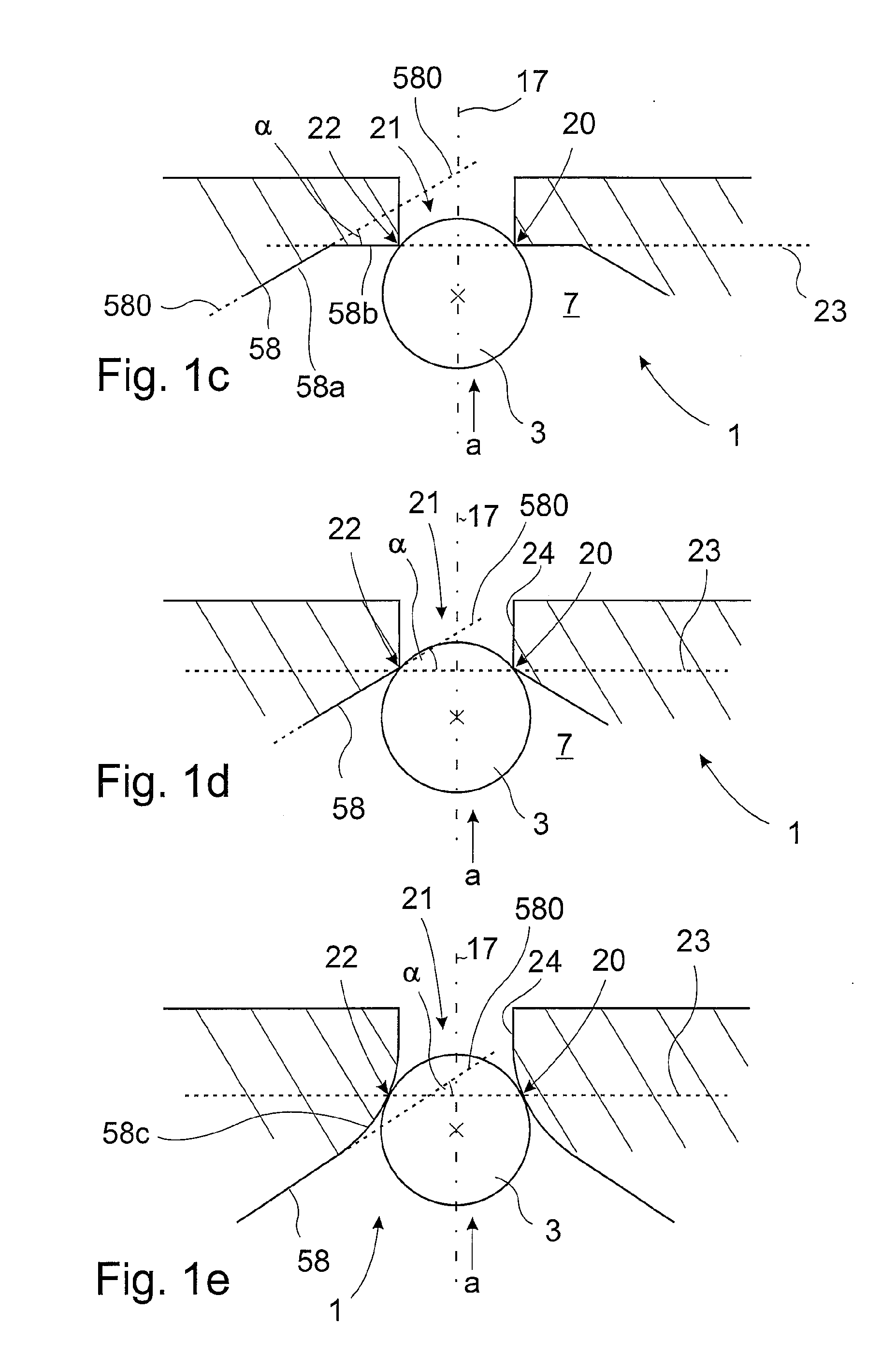

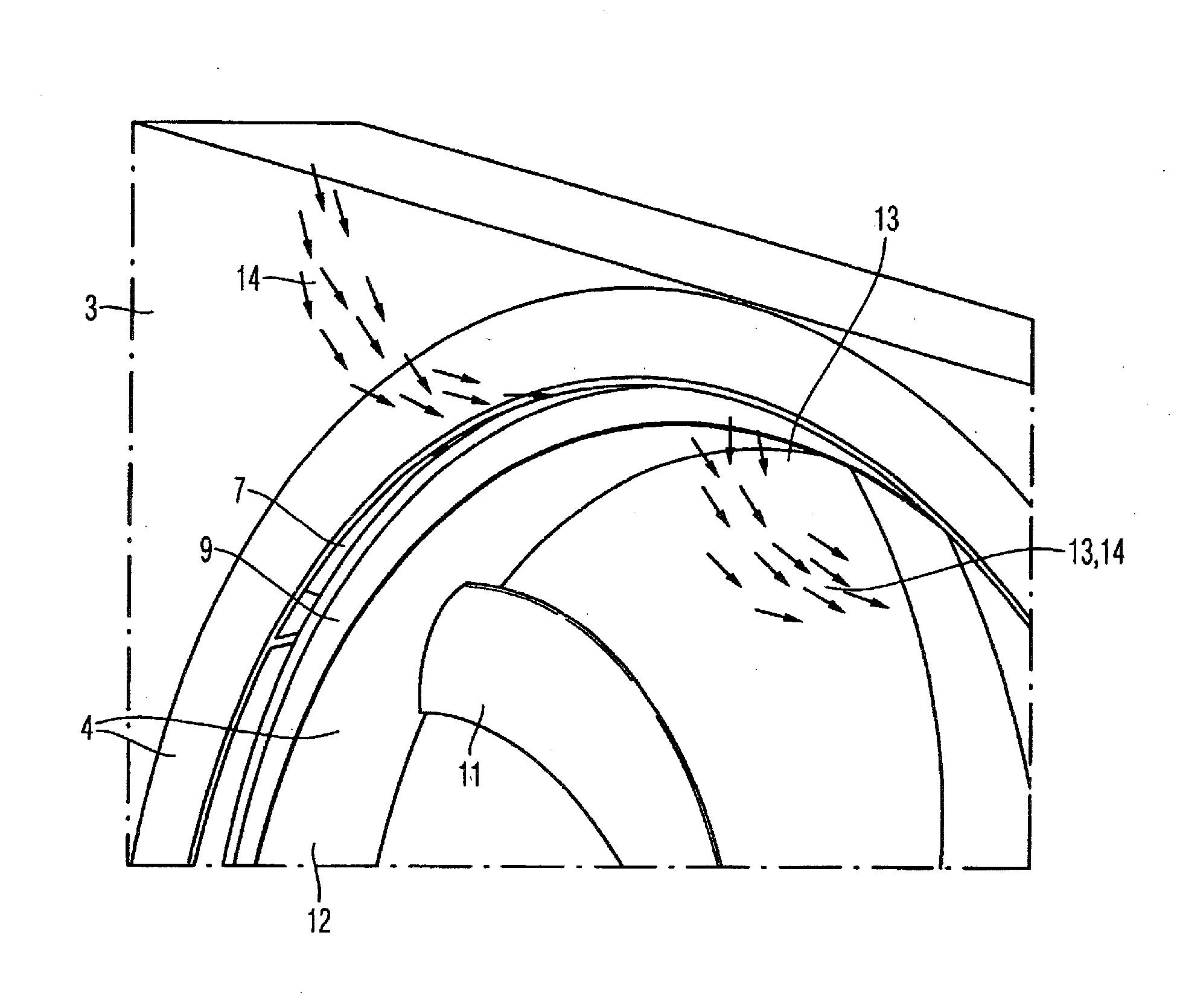

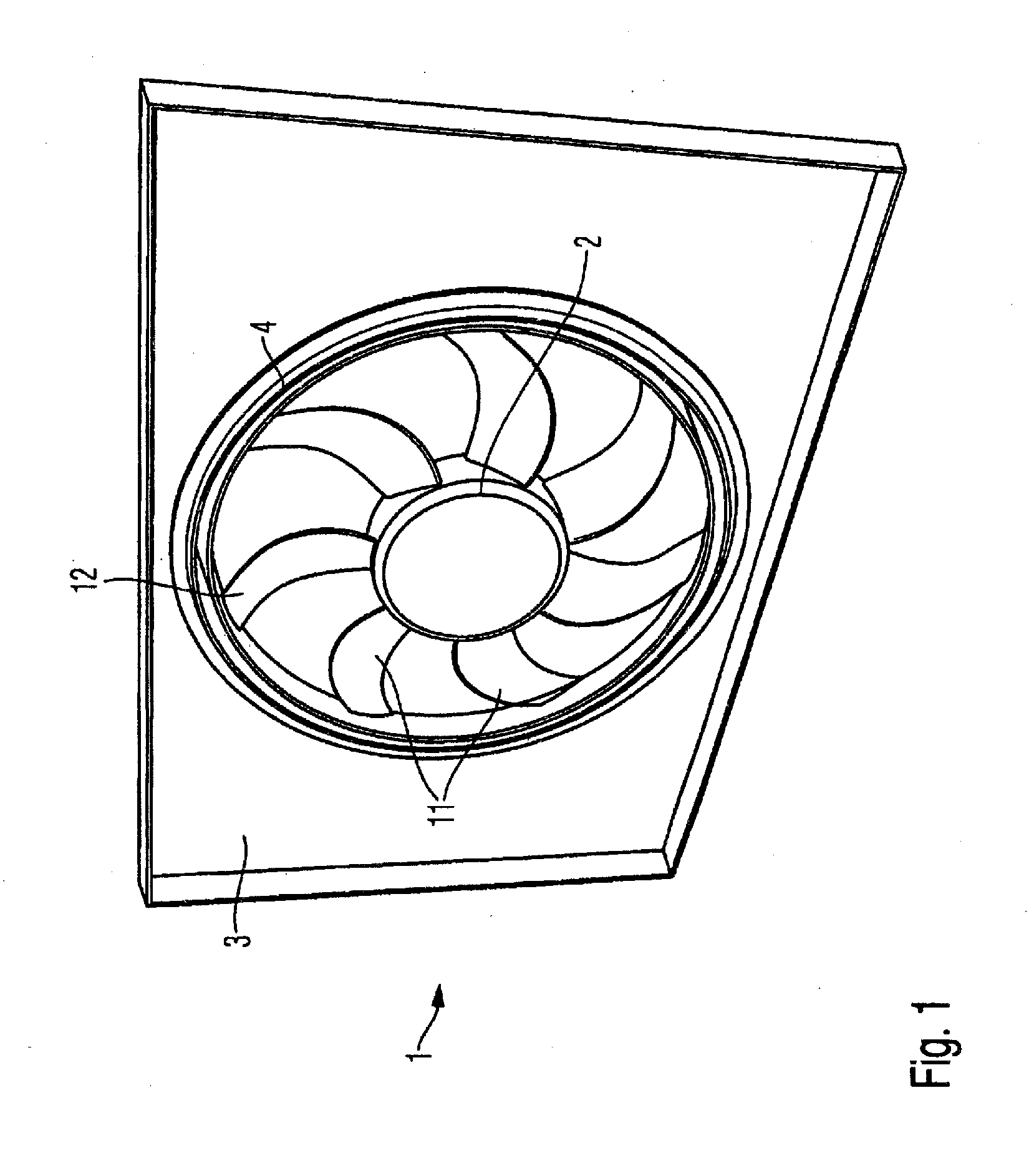

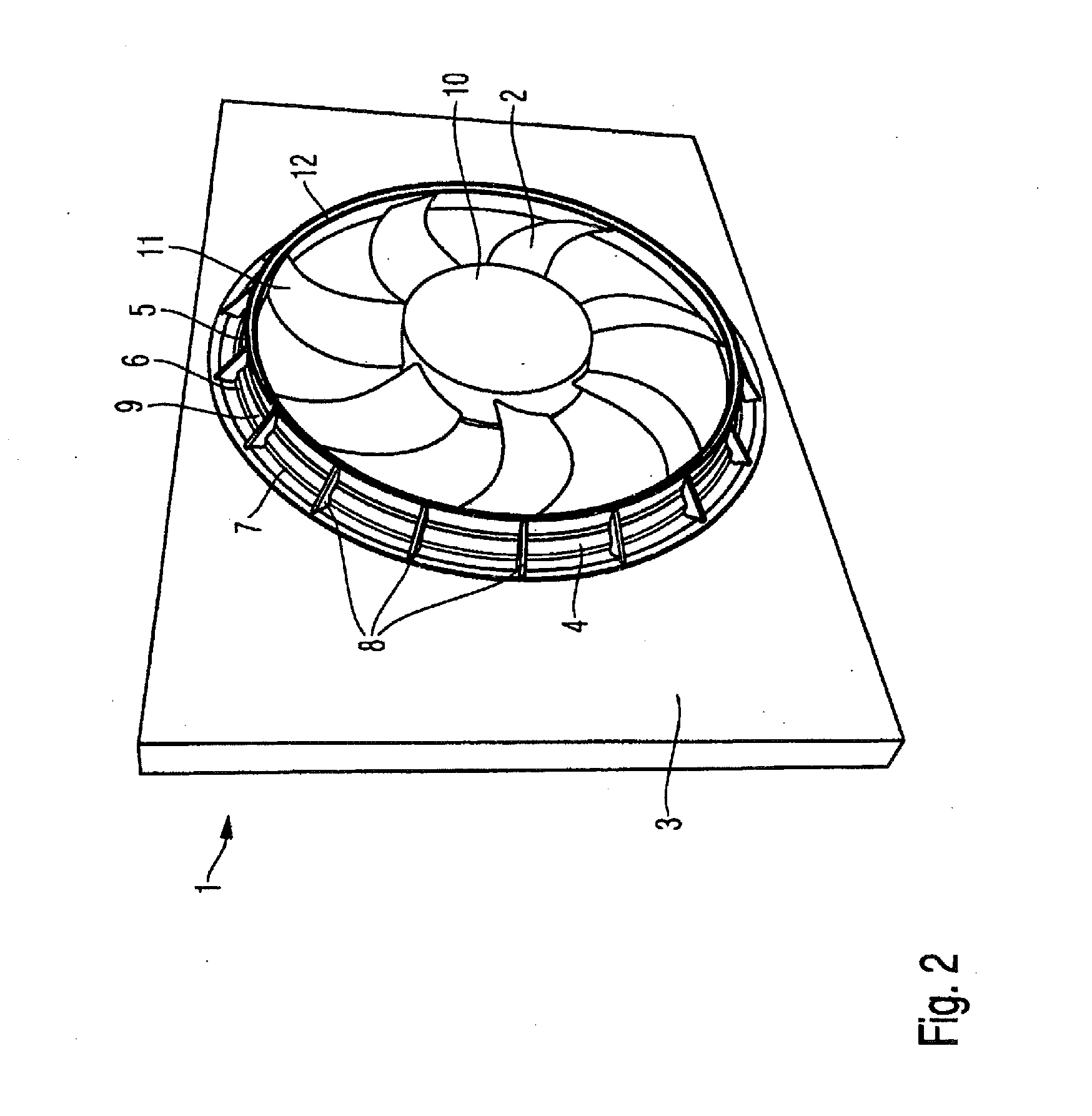

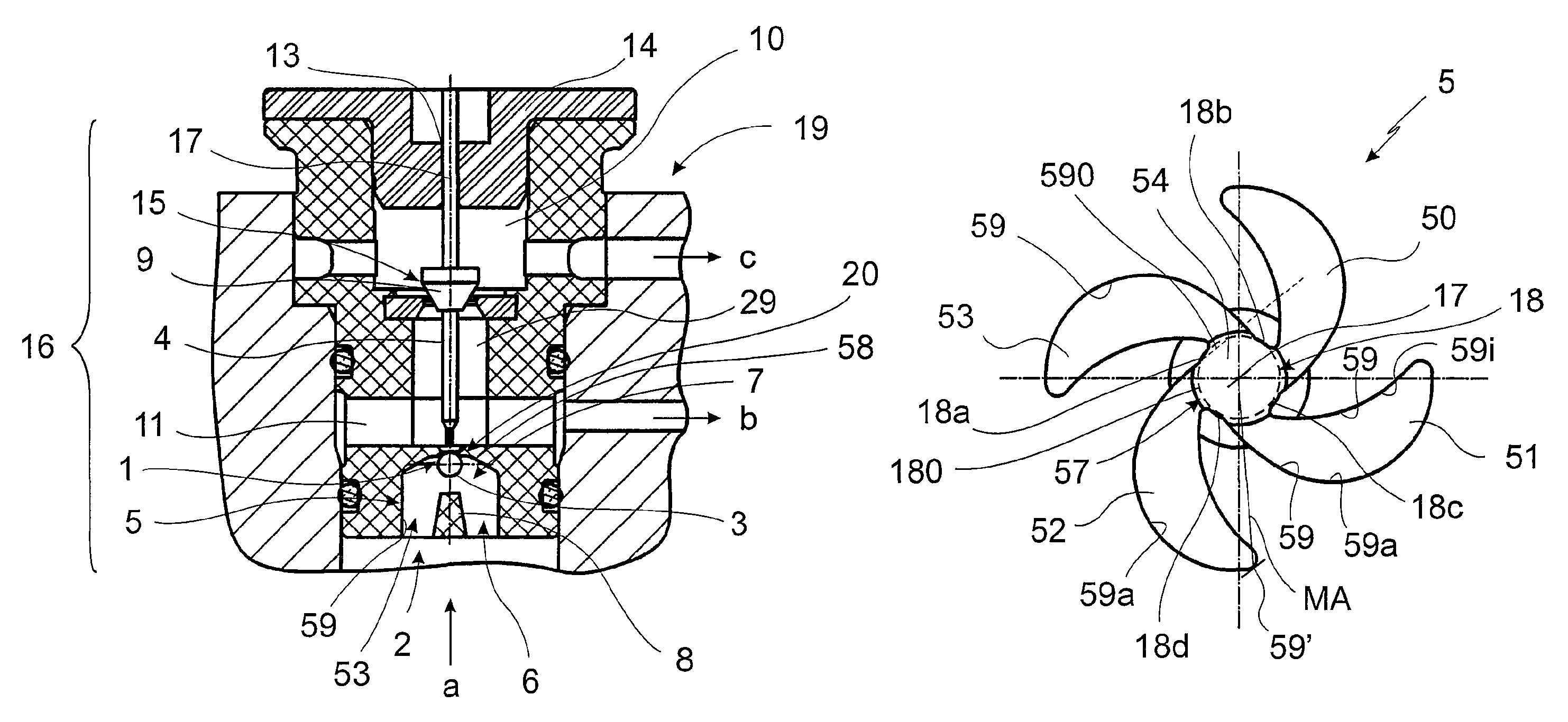

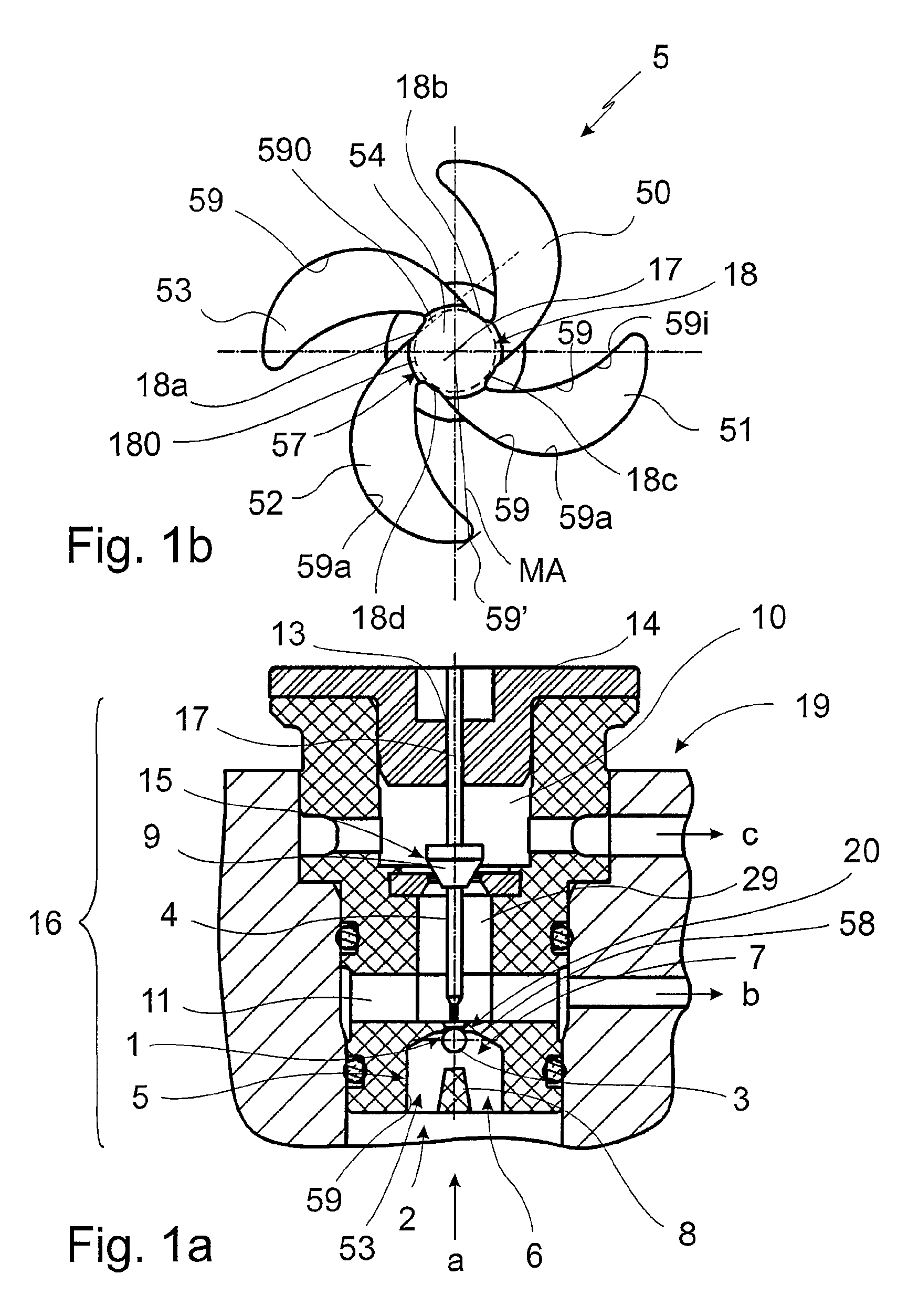

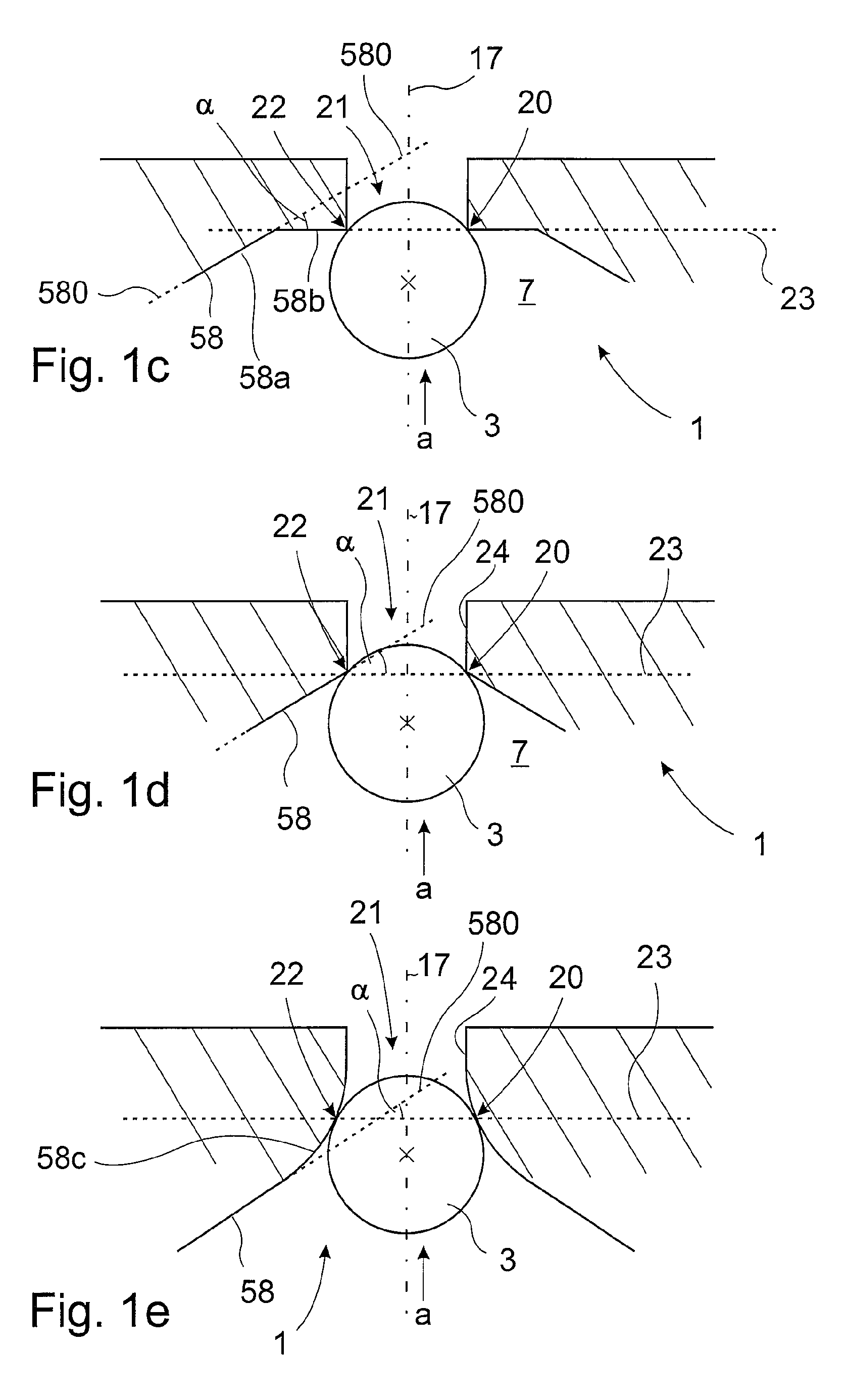

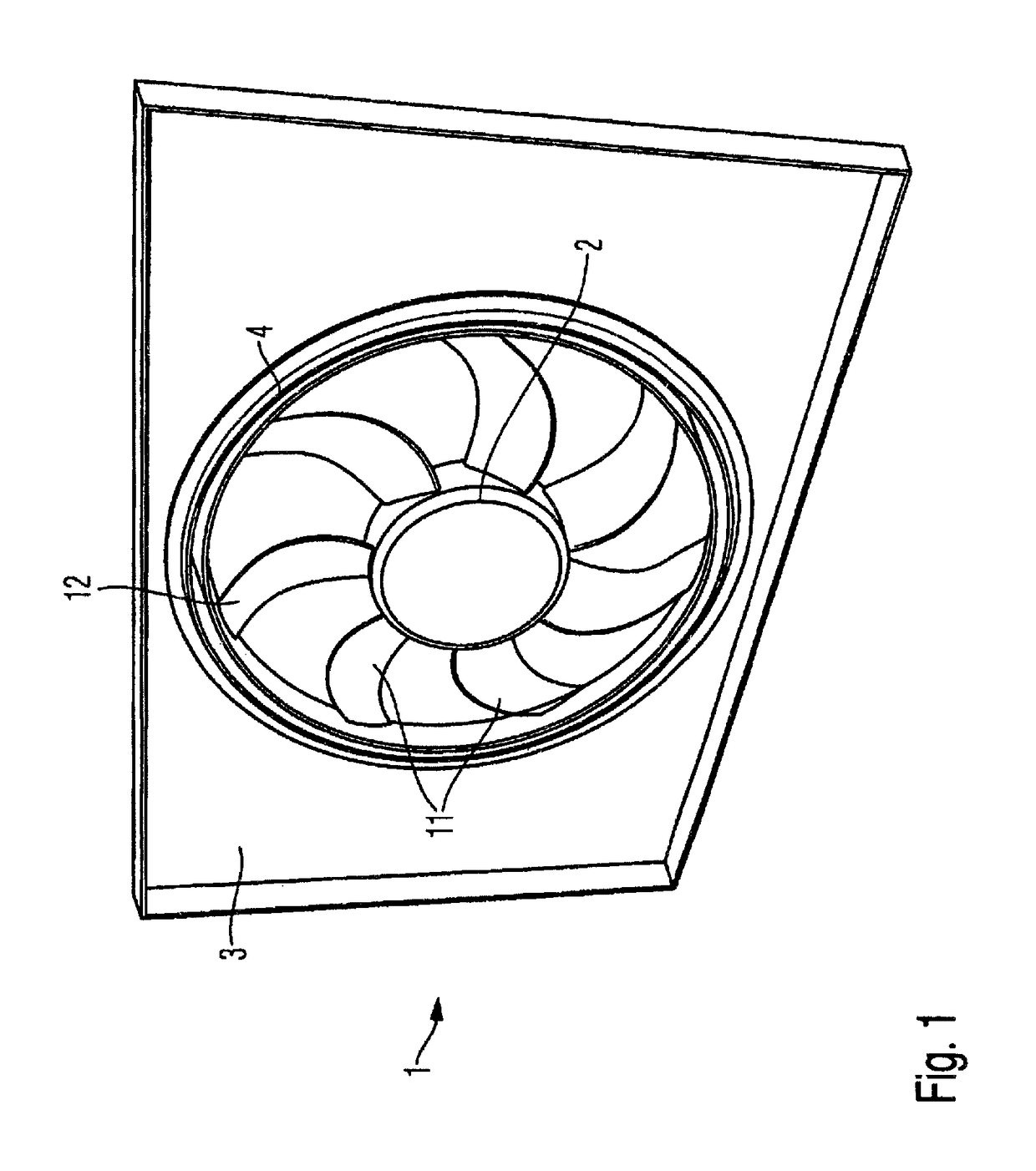

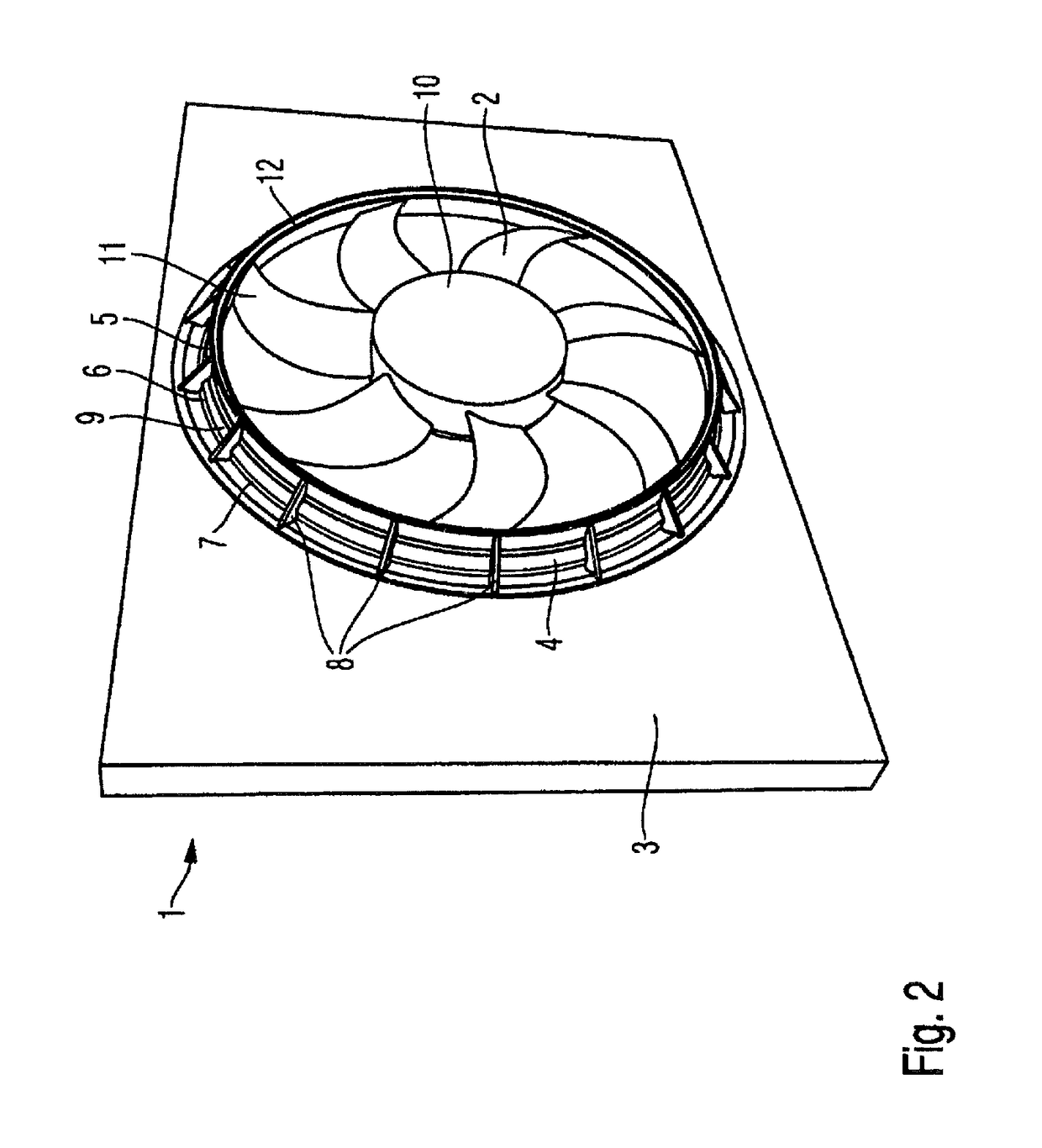

Cooling fan module

The invention relates to a cooling fan module for a motor vehicle, having a fan impeller which has a multiplicity of fan impeller blades which are connected to one another via a fan impeller outer ring, having a frame, on which the fan impeller is mounted, having an annular reverse flow guide device, which has an inner ring and an outer ring and which is designed to de-spin a reverse flow between the inner ring and the outer ring and to mix said reverse flow with the slot flow between inner ring and fan impeller outer ring.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

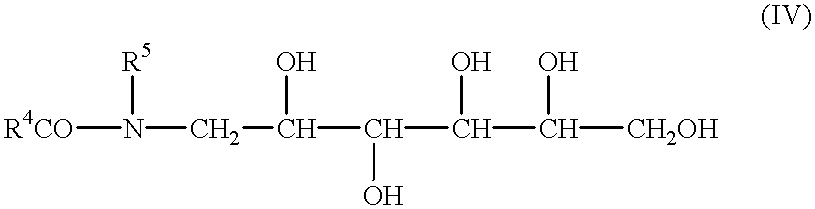

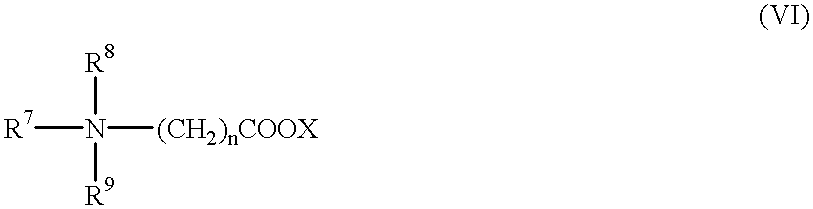

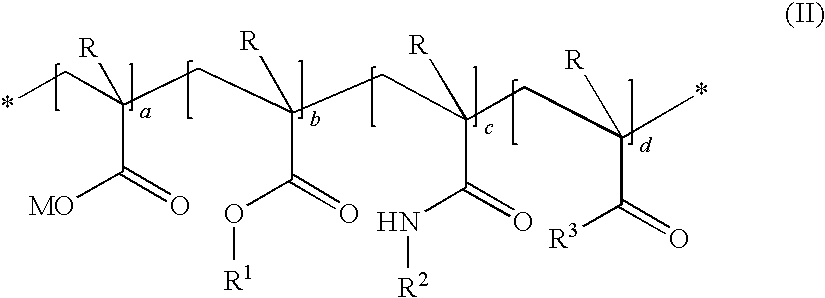

Cosmetic formulations

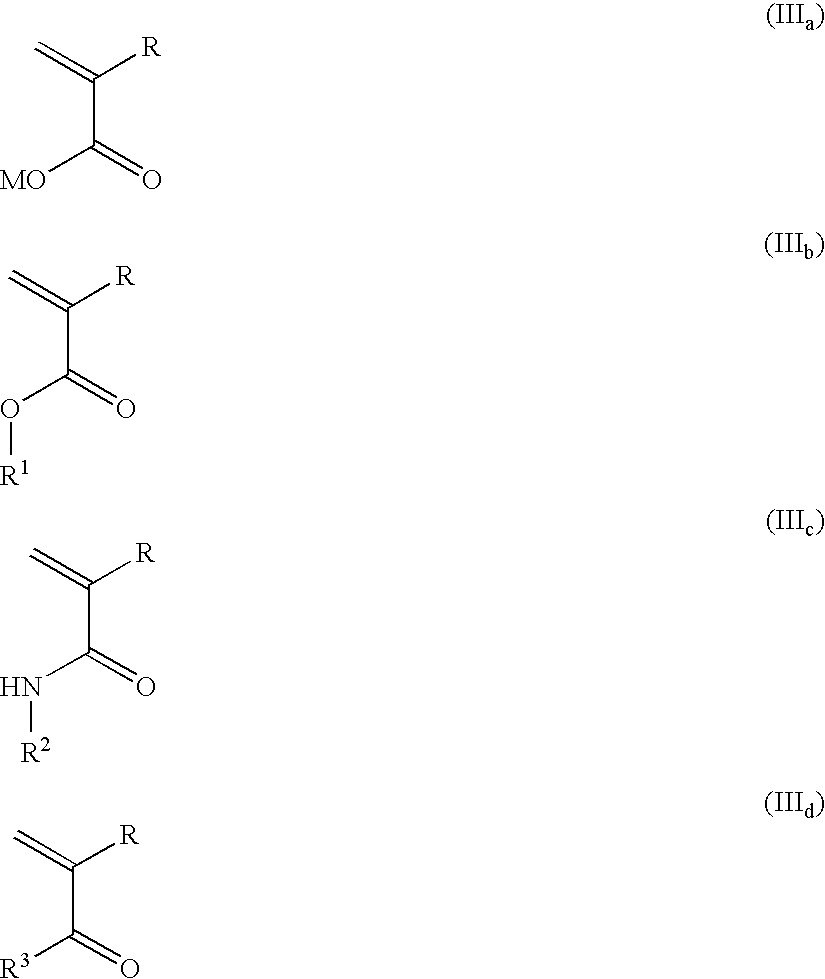

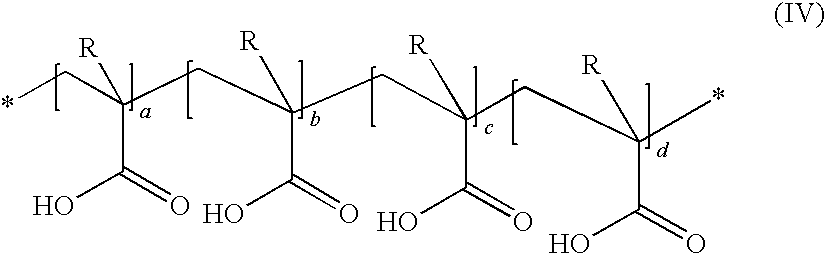

InactiveUS20020012686A1Improve flow behaviorCosmetic preparationsOrganic active ingredientsBetaineAlkenyl-GP

A pearlescent composition containing: (a) a dialkyl ether corresponding to formula (I): <paragraph lvl="0"><in-line-formula>R1-O-R2(I) < / in-line-formula>wherein R1 and R2 independently of one another represent linear or branched alkyl and / or alkenyl groups having from 12 to 22 carbon atoms; (b) a cationic polymer; and (c) an emulsifier selected from the group consisting of a fatty acid-N-alkyl polyhydroxyalkyl amide, an alkyl ether sulfate, a betaine, and mixtures thereof.

Owner:COGNIS DEUT GMBH & CO KG

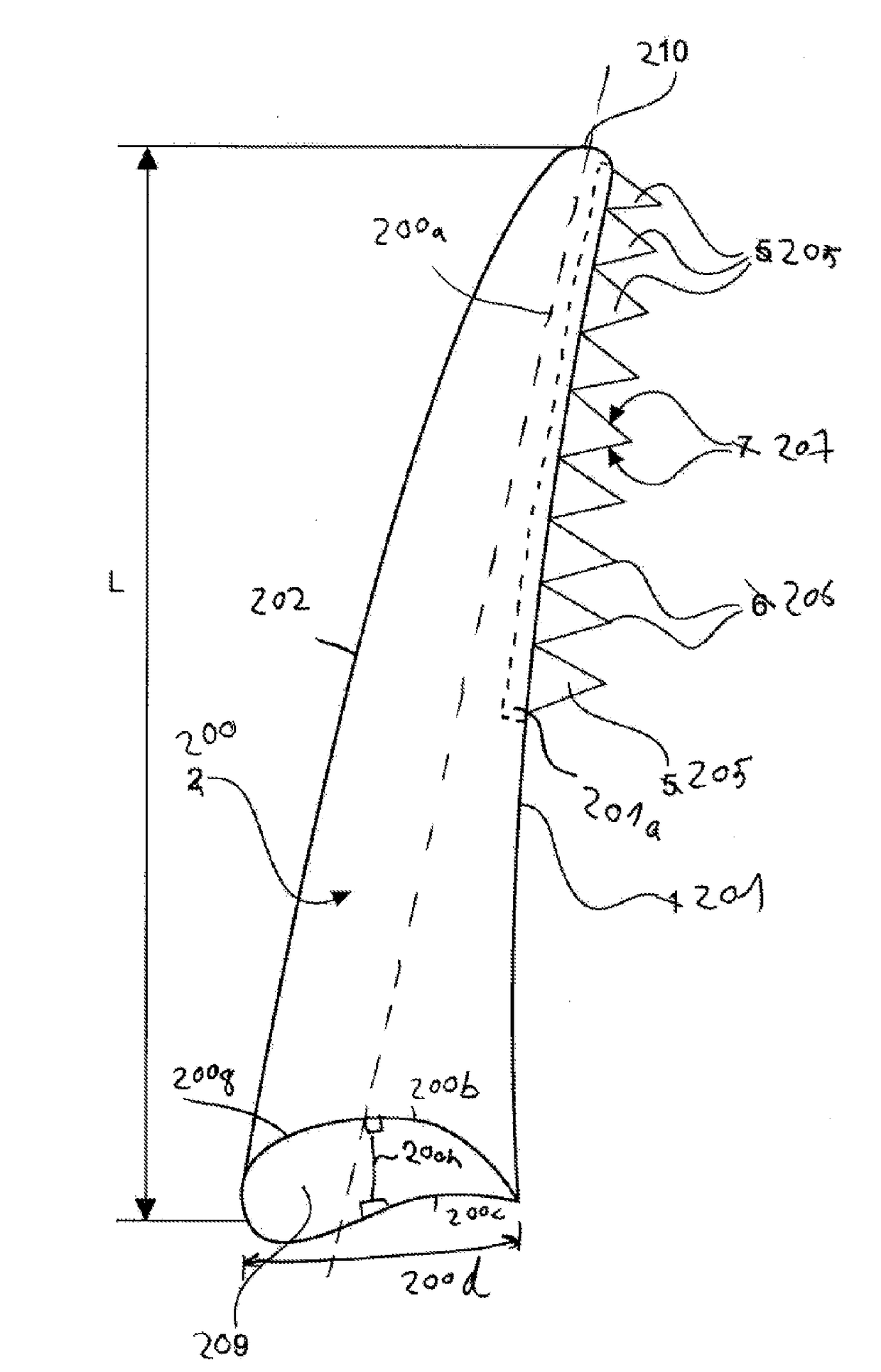

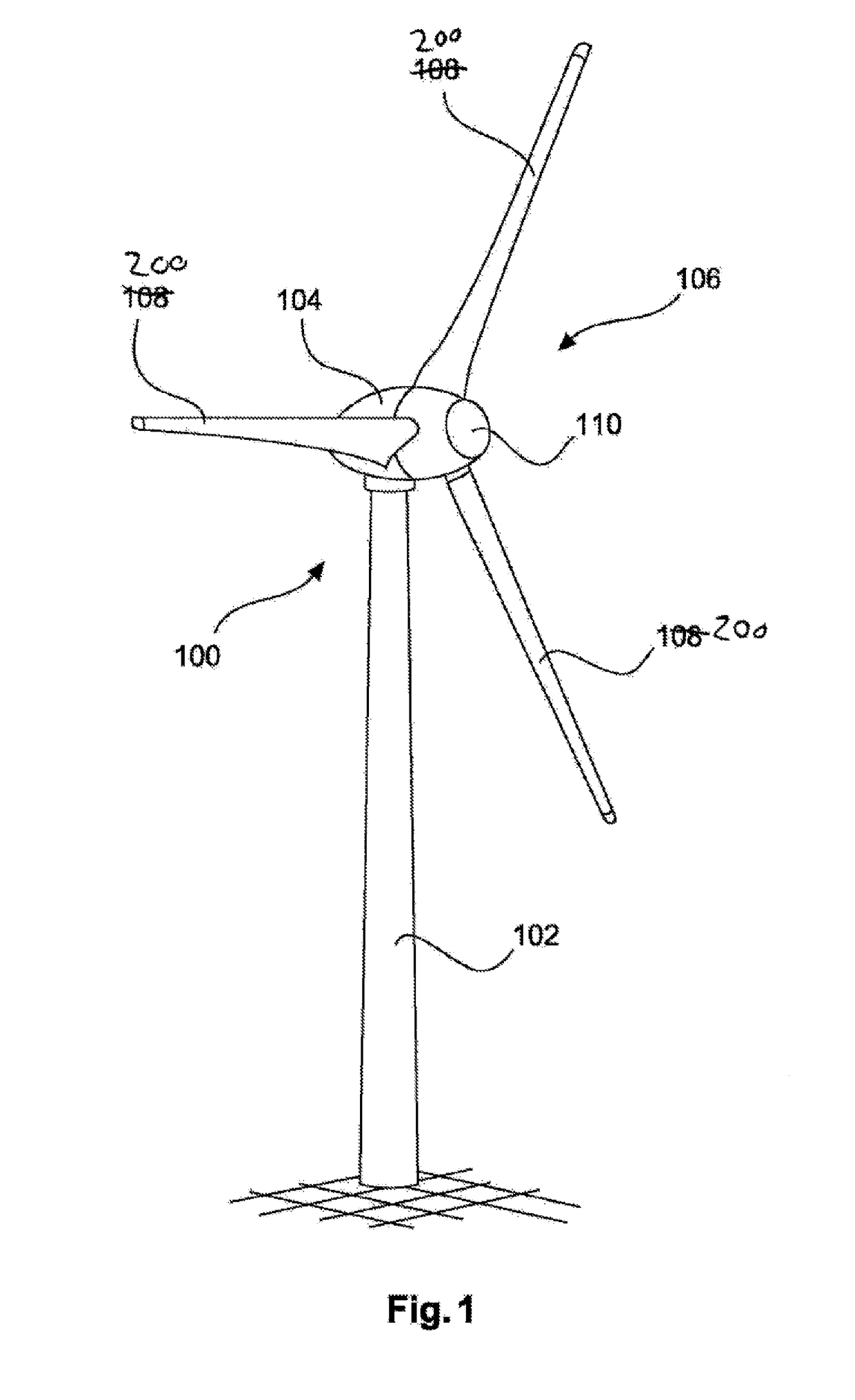

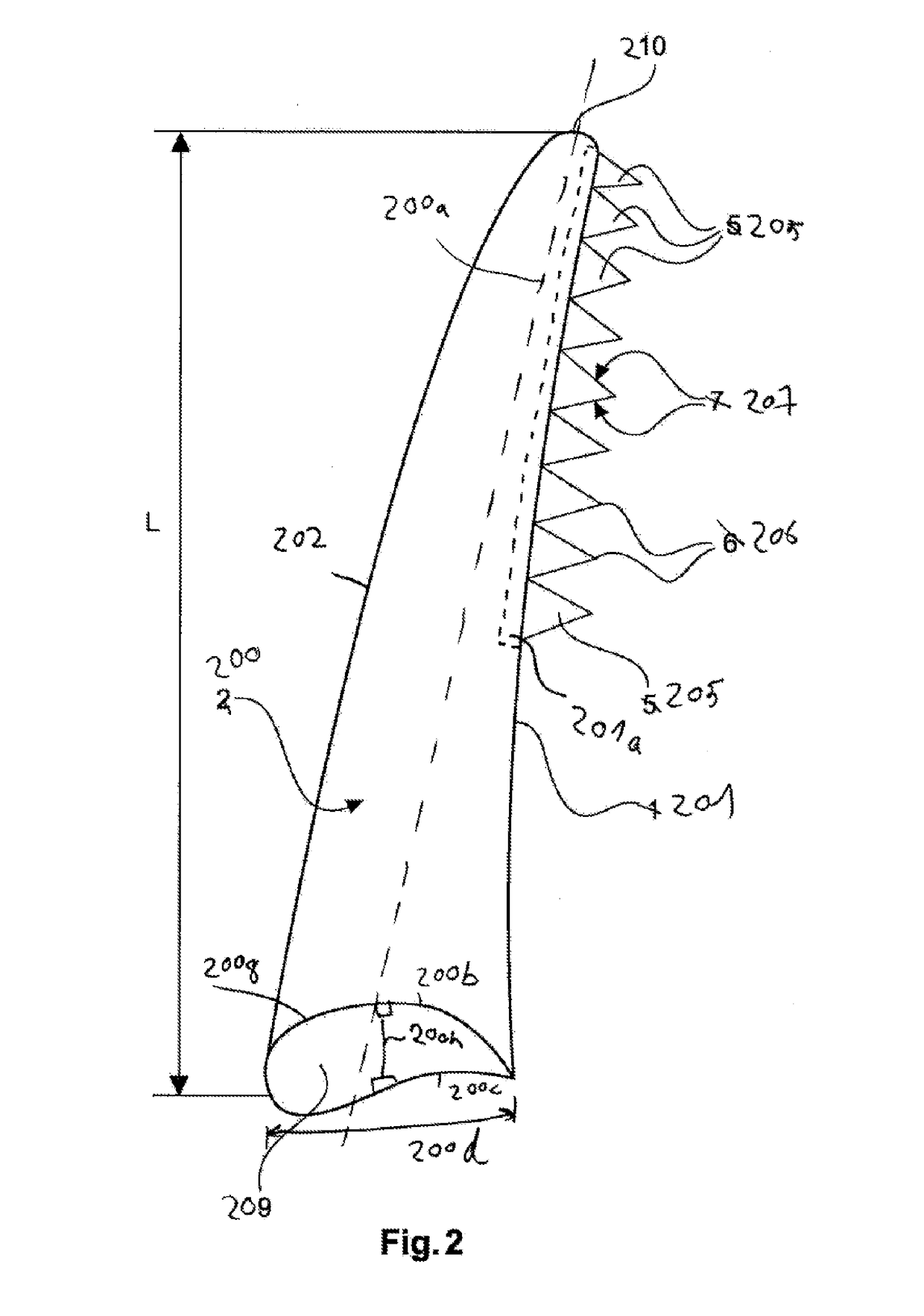

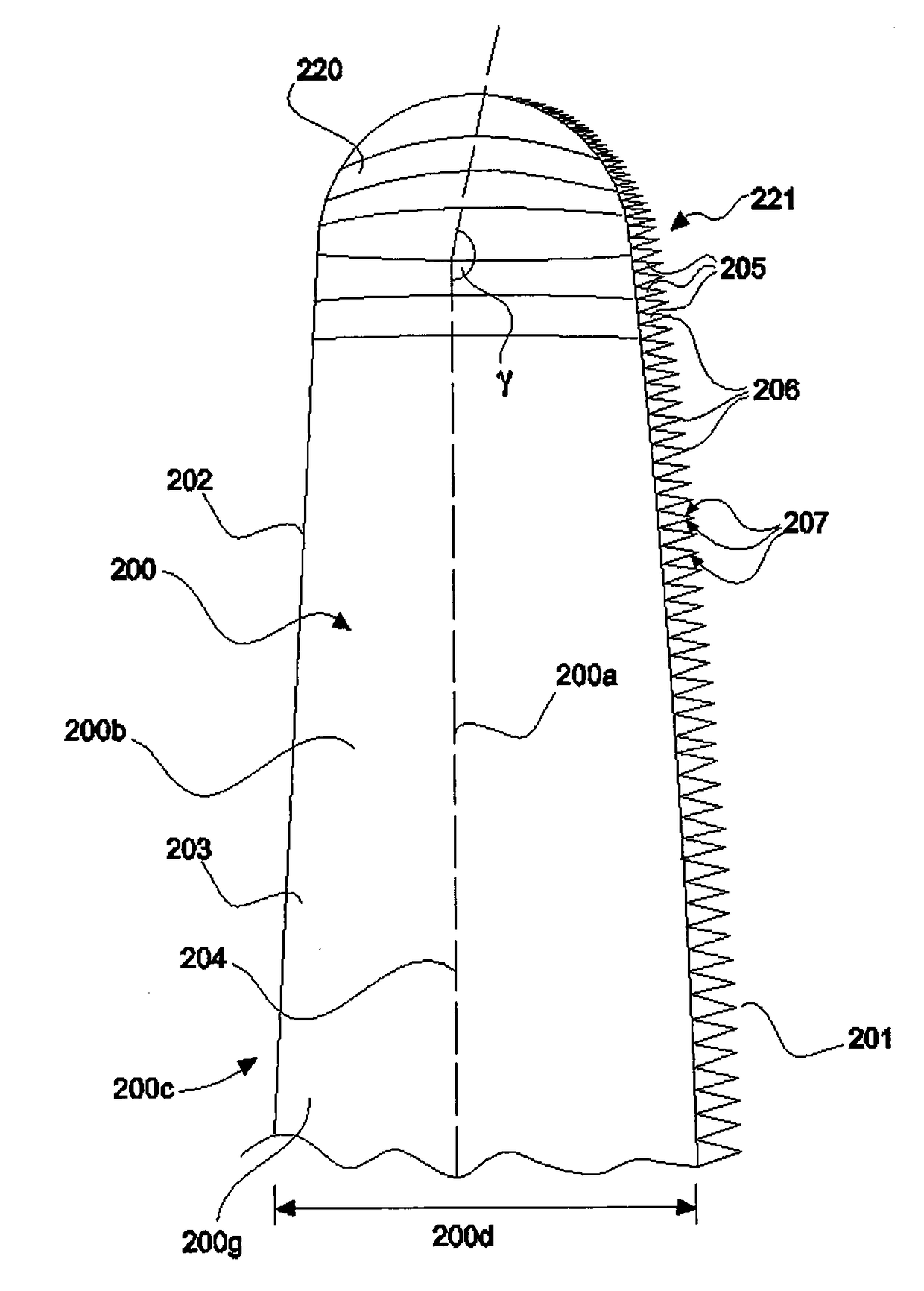

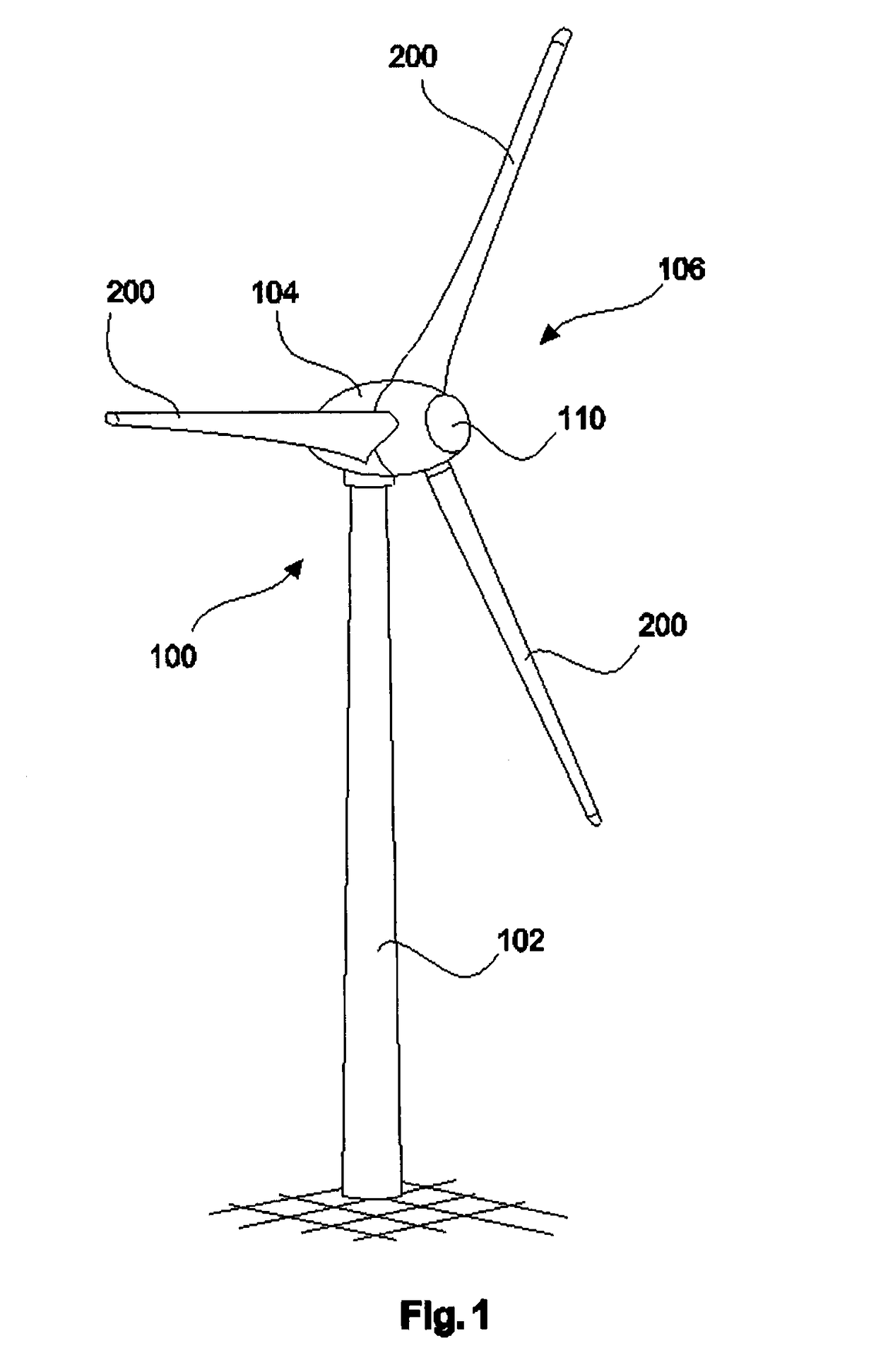

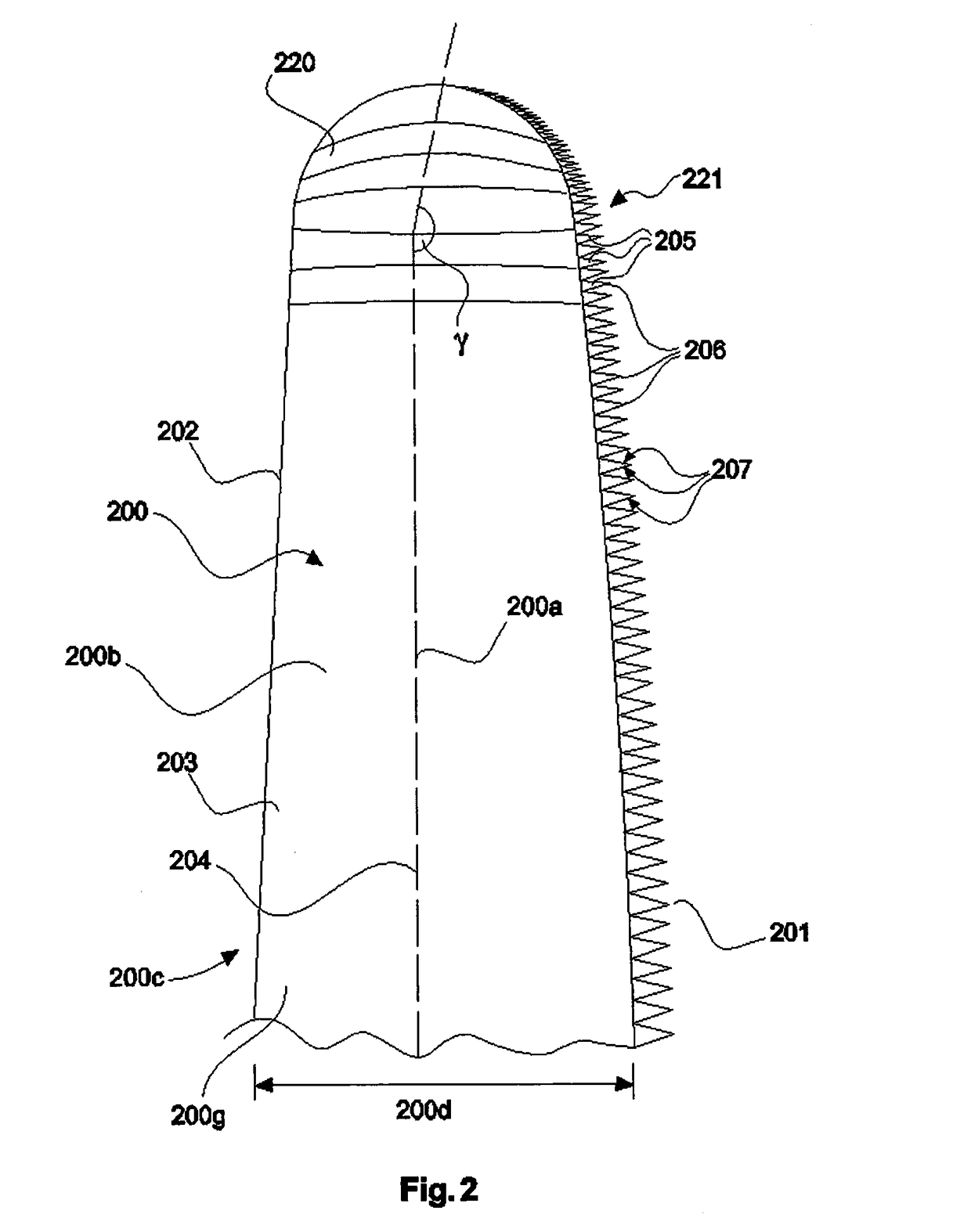

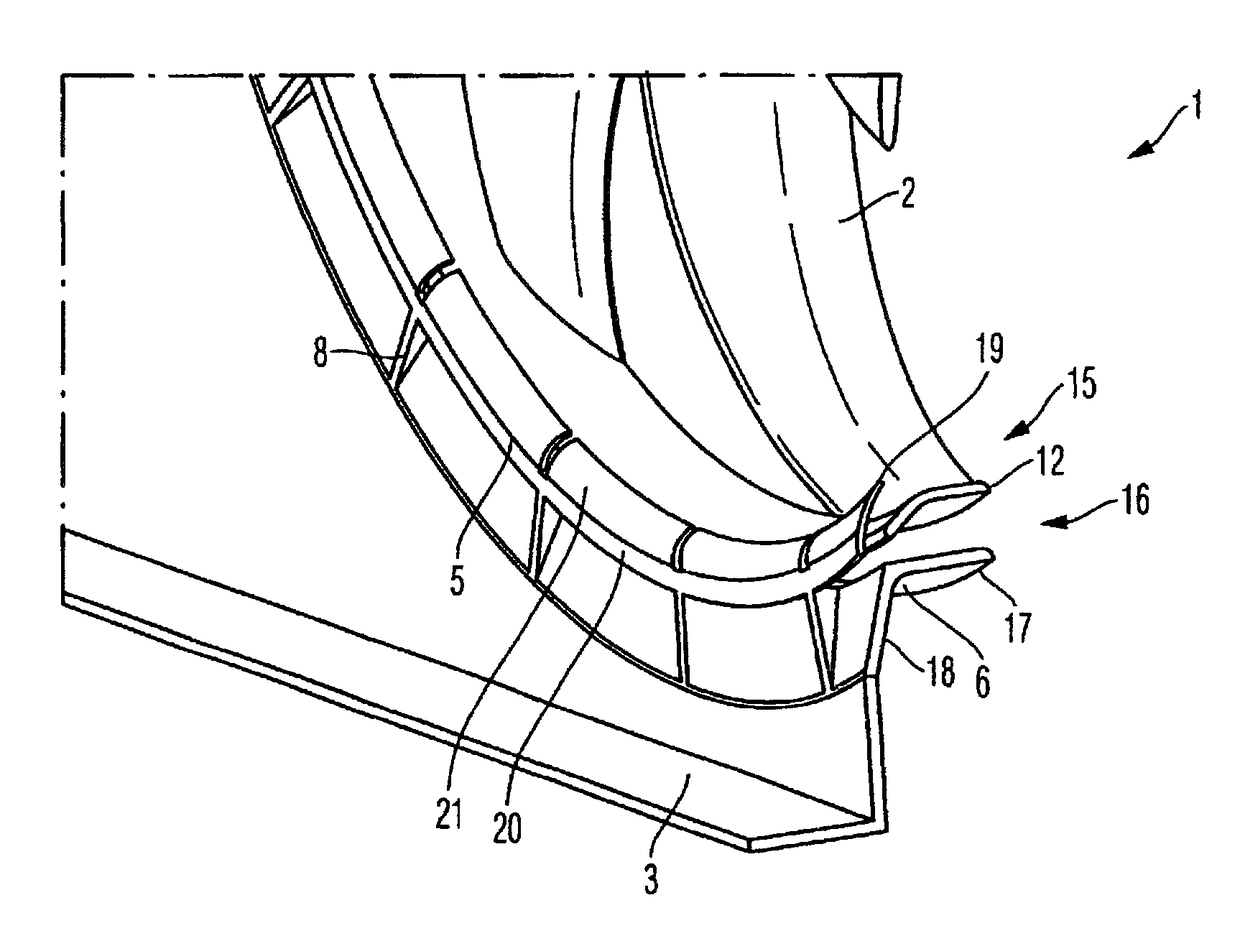

Wind-turbine rotor blade, rotor blade trailing edge, method for producing a wind-turbine rotor blade, and wind turbine

ActiveUS20170204832A1Improve efficiencyReduce noiseEngine fuctionsMachines/enginesTurbine bladeTrailing edge

A wind turbine rotor blade that has a rotor blade tip, a rotor blade root, a suction side, a pressure side, a rotor blade length, a profile depth and a pitch axis of rotation. The profile depth decreases along the rotor blade length from the rotor blade root to the rotor blade tip. The trailing edge has a trailing edge delimiting line, which replicates the contour of the trailing edge. The trailing edge has a plurality of serrations to improve flow behaviour behavior at the trailing edge. The serrations respectively have a serration tip, two serration edges and an angle bisector. The serration edges are provided non-parallel to a direction of incident flow that is perpendicular to the pitch axis of rotation. The serration edges are non-perpendicular to a tangent to the trailing edge delimiting line. The trailing edge delimiting line has a plurality of portions, at least one of the portions extending non-parallel to the pitch axis of rotation.

Owner:WOBBEN PROPERTIES GMBH

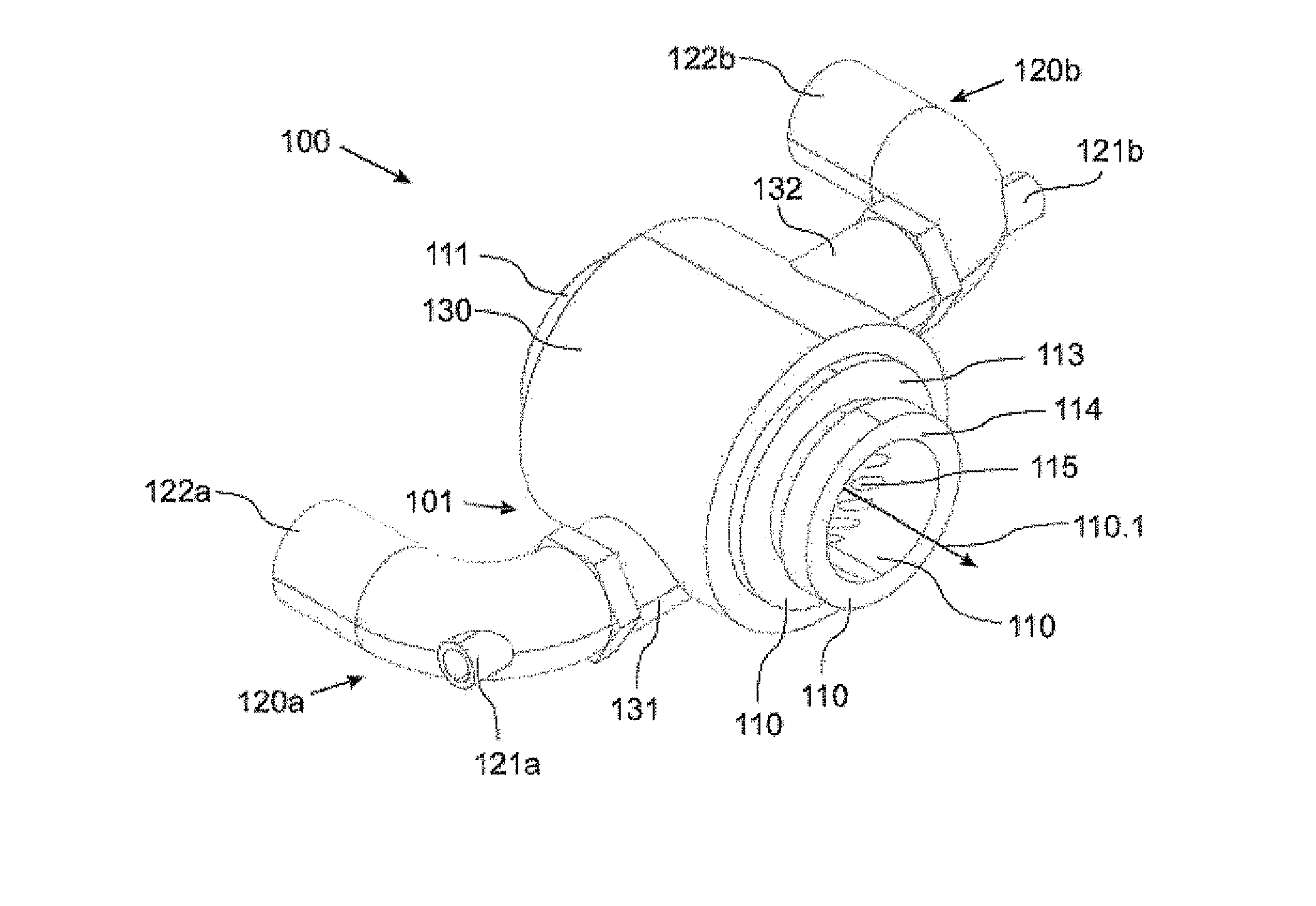

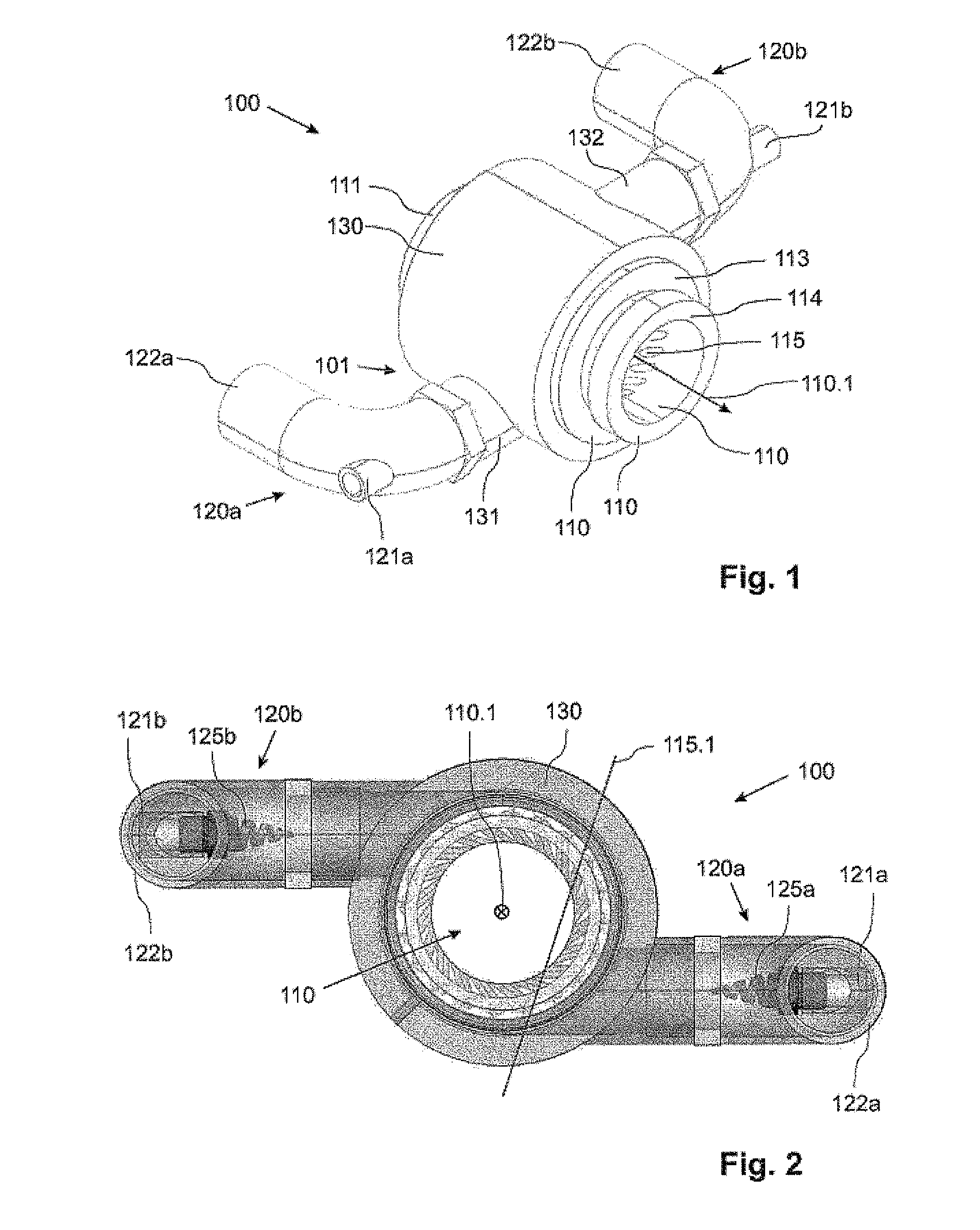

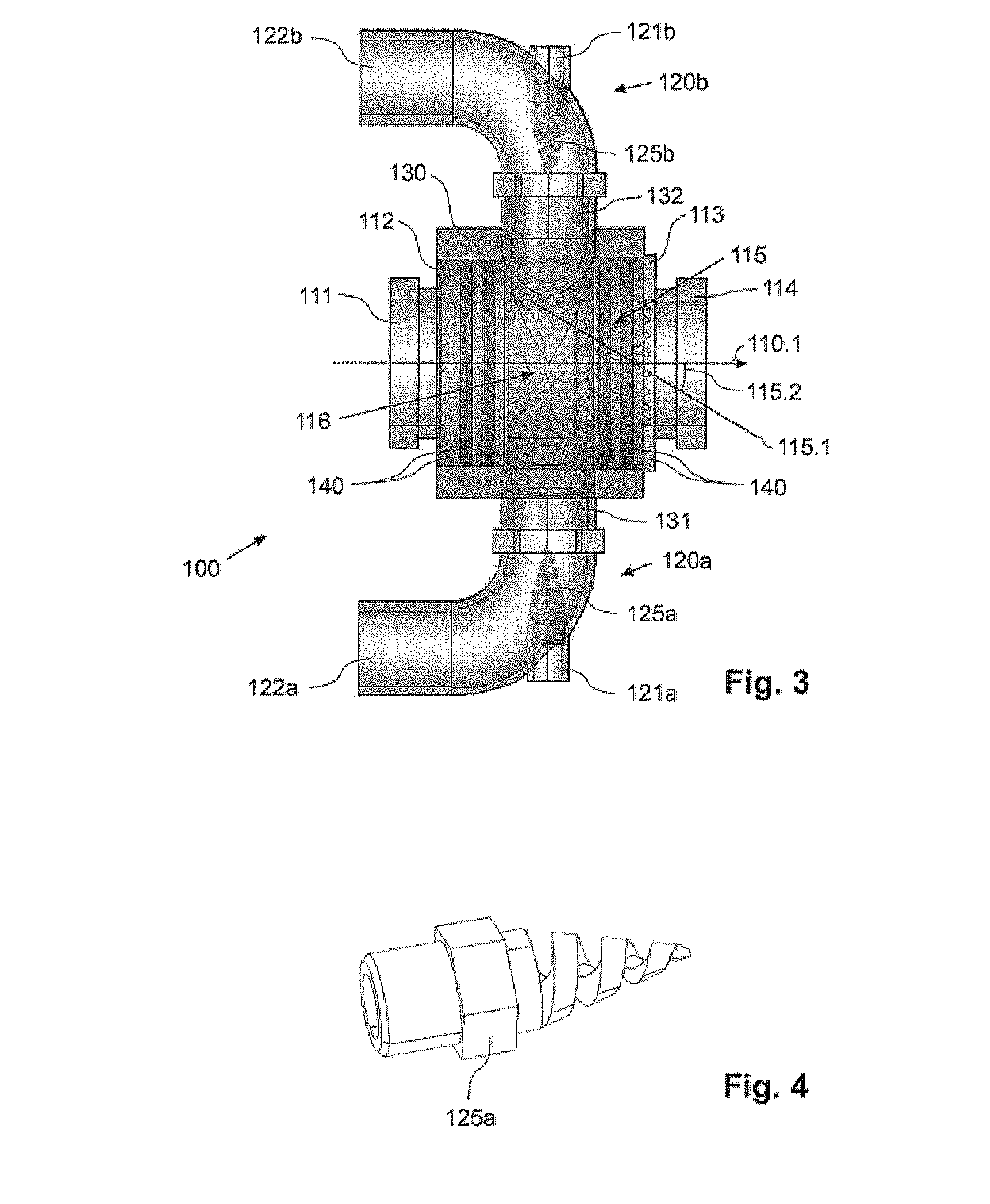

Mixing apparatus for pumpable mixtures and method related thereto

ActiveUS20130170314A1Improve the mixing effectDistribution moreFlow mixersMixing operation control apparatusShotcreteBiomedical engineering

The invention relates to a mixing apparatus for the metered addition of an additive to a pumpable mixture, in particular a pumpable hydraulically setting mixture, in particular a liquid shotcrete composition, wherein the mixing apparatus includes a delivery line for delivering the mixture through the mixing apparatus, and a metering device communicating with the deliver line for introducing the additive into the mixture is provided, wherein the mixing apparatus is including in that the metering device has a device for dispersing the additive in a carrier method such that the additive can be introduced into the mixture in a state in which the additive is finely distributed in the carrier medium.

Owner:SIKA TECH AG

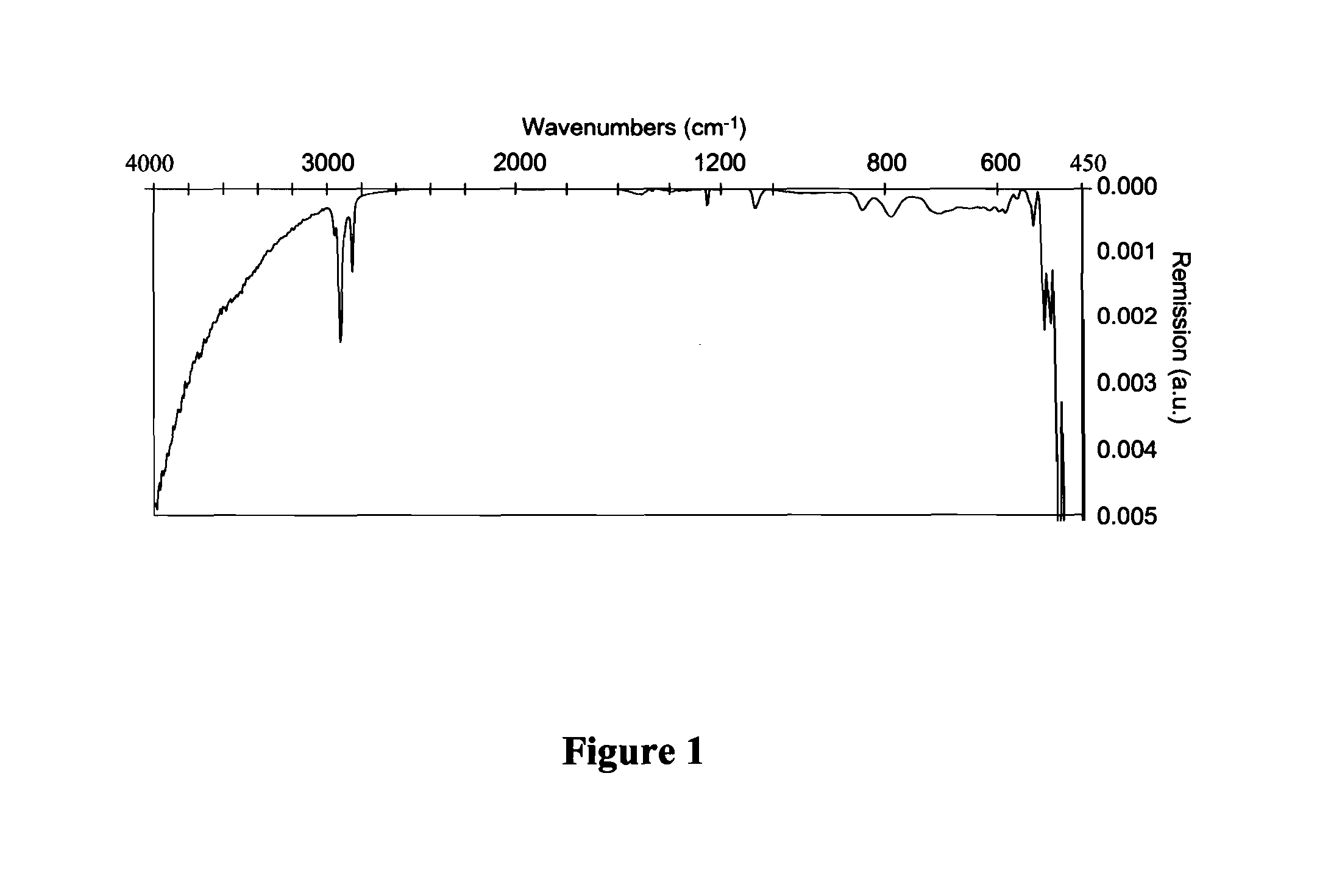

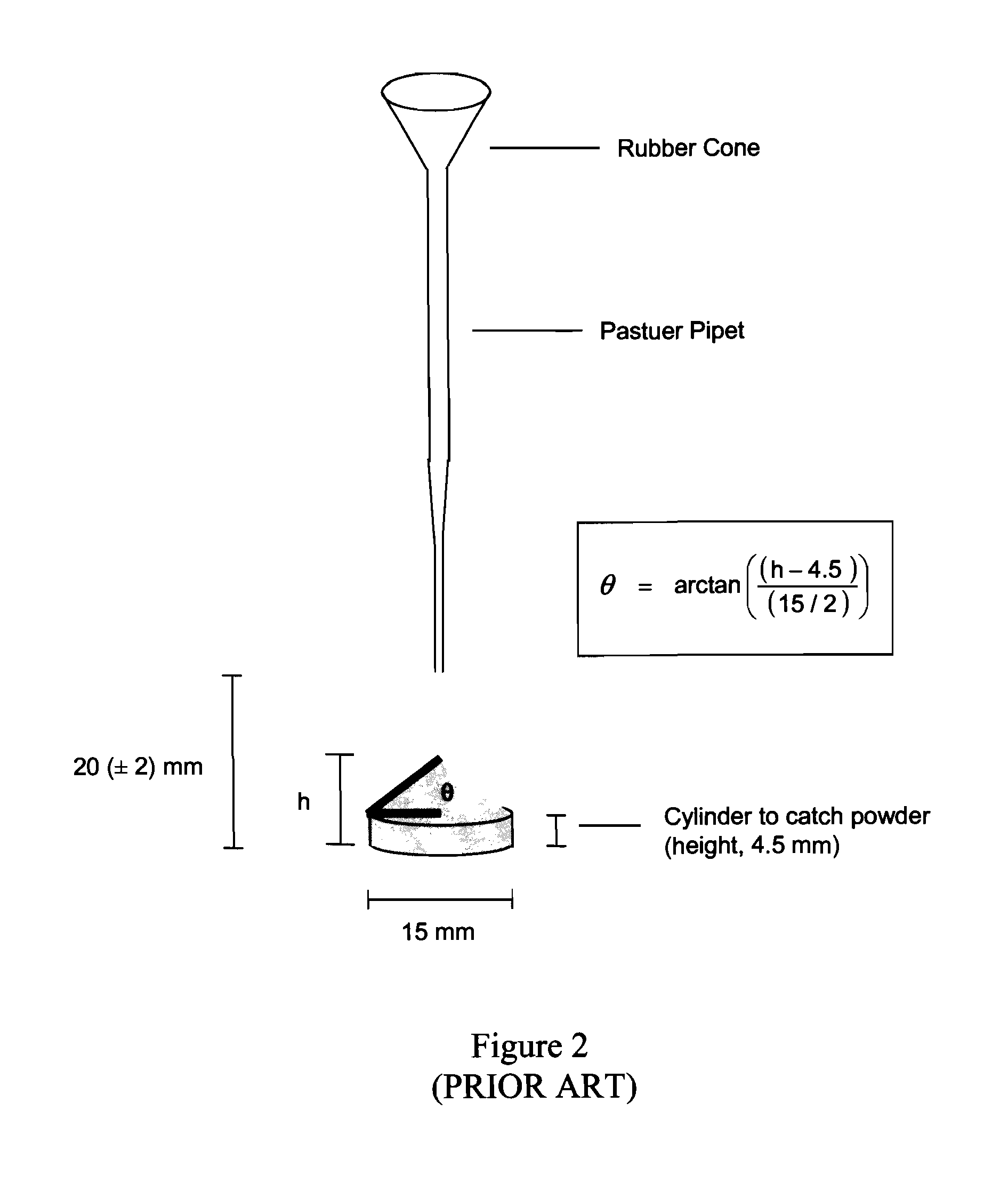

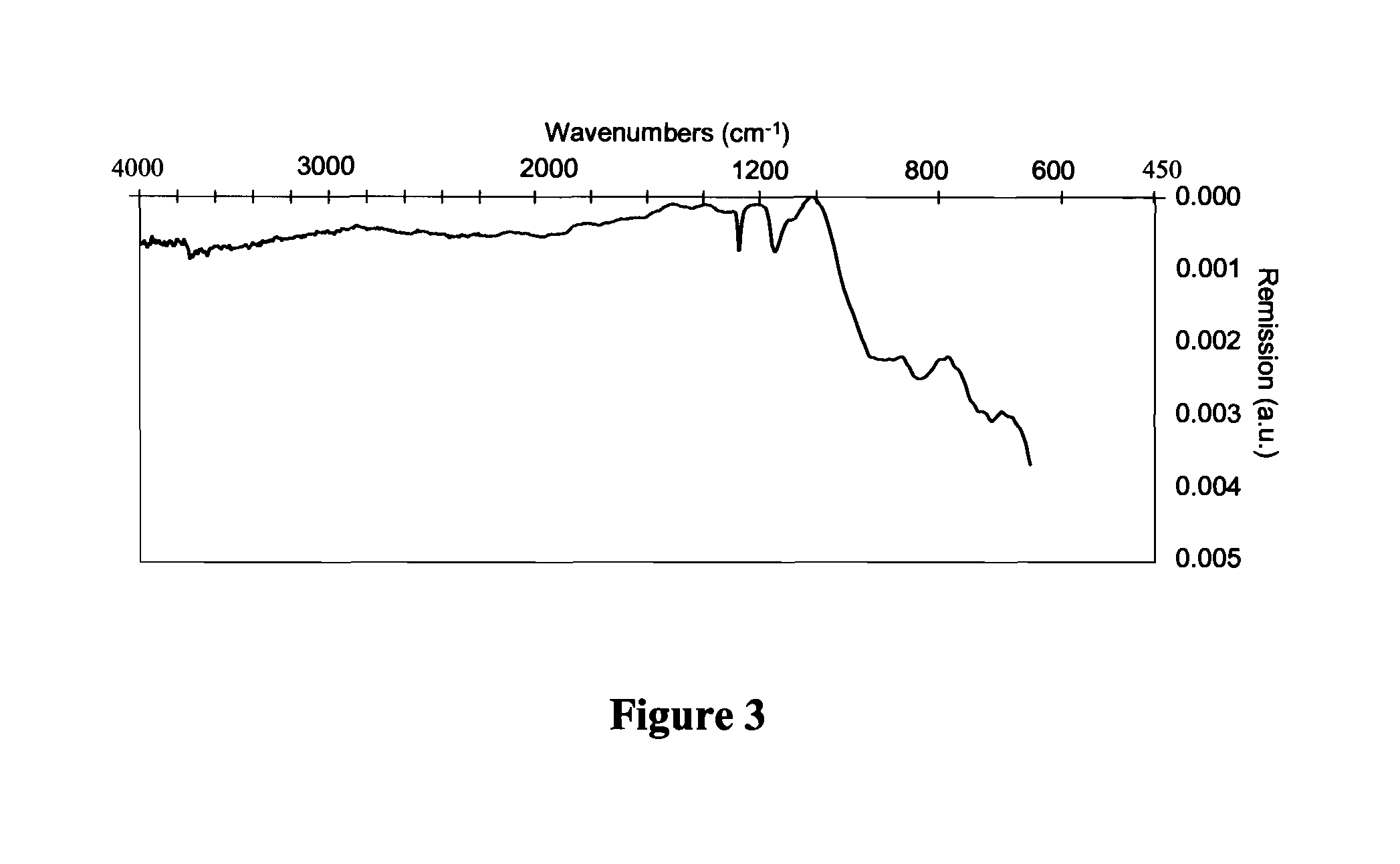

Metal powders with improved flowability

ActiveUS8894739B1Improve liquidityImprove flow behaviorSynthetic resin layered productsMetal-working apparatusMean diameterMethyltrichlorosilane

A process to increase the fluidity of metal powders by surface modification with alkylsilane reagents. This invention generally discloses that the most efficient process results from treatment with methyltrichlorosilane in hexane. In particular, the fluidity of aluminum powders having mean diameters smaller than 10 micrometers was considerably improved by the process of embodiments of the invention.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

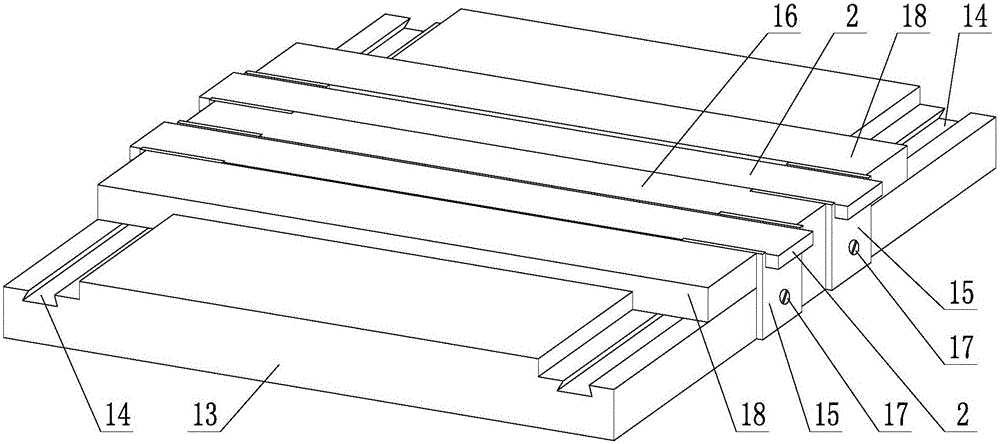

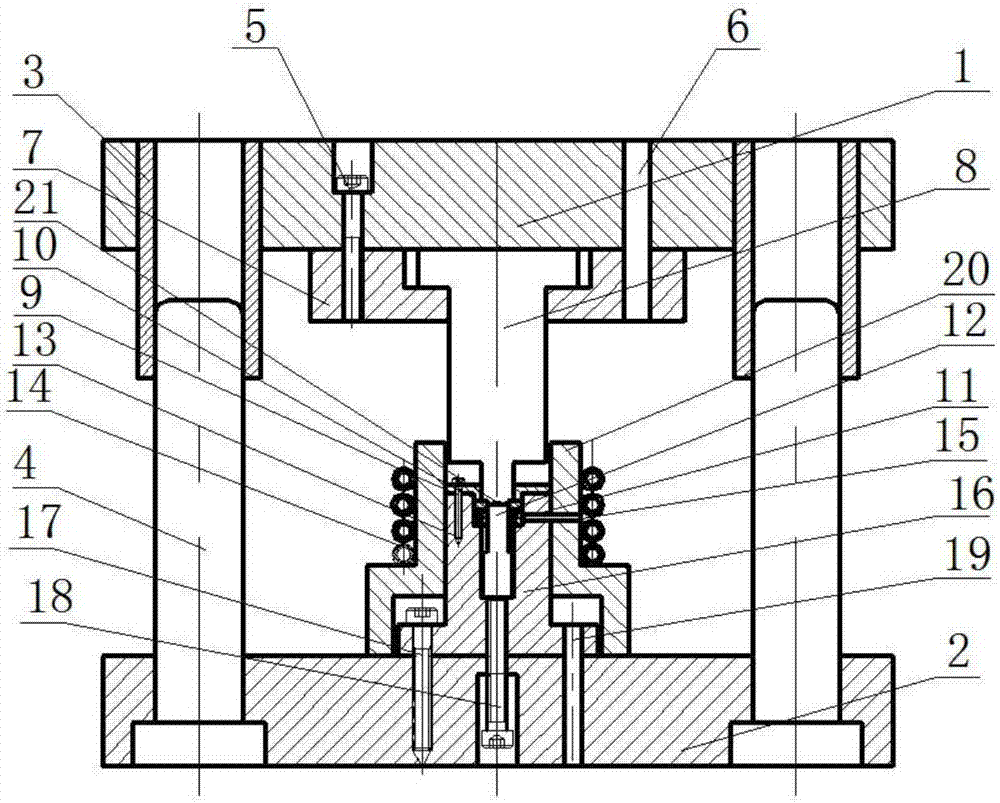

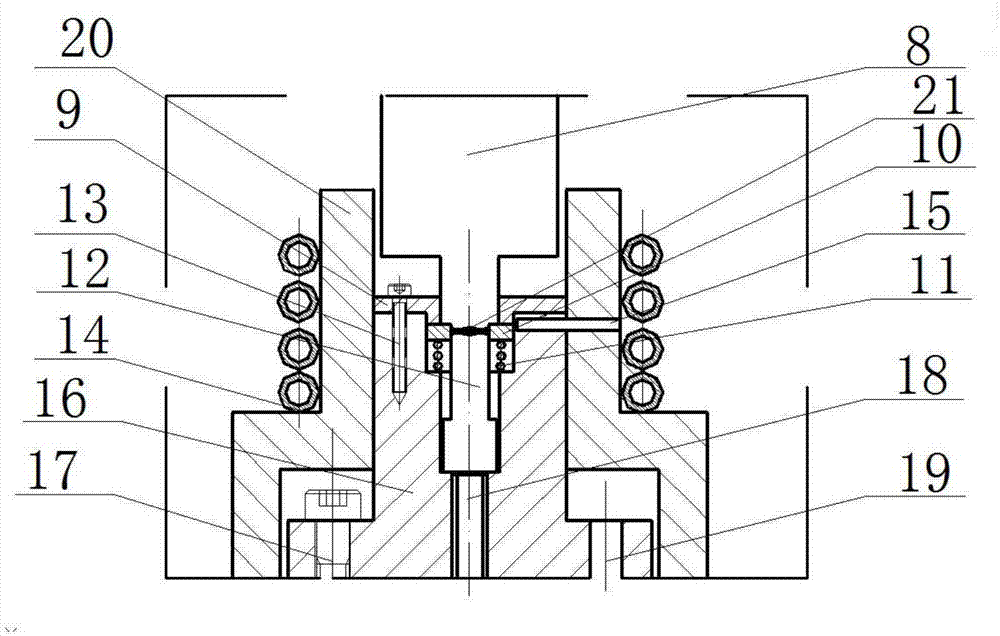

Micro-turbine disc forming device and method

InactiveCN106903247AAvoid exposure to high temperaturesIncrease profitForging/hammering/pressing machinesWheelsEngineeringTurbine

The invention relates to the field of micro-turbine disc precise manufacturing, in particular to a micro-turbine disc forming device and method. The device is characterized in that an upper mold plate (1) and a lower mold plate (2) are arranged; guide sleeves (3) are arranged on the upper mold plate (1); guide columns (4) matched with the guide sleeves (3) are arranged on the lower mold plate (2); a closed frame is formed by the upper mold plate (1) and the lower mold plate (2) through the guide sleeves (3) and the guide columns (4); and a mold auxiliary mechanism is arranged in the closed frame and comprises an upper puncher pin fixing plate (7), an upper puncher pin (8), a concave mold fixing plate (9), a floating concave mold (10), a spring (11), a lower puncher pin (12), an induction coil (14), a concave mold containing cavity (16), an ejection bolt (18) and a ceramic sleeve (20). Compared with the prior art, the device has the beneficial effects of being simple in structure, short in technological process, high in efficiency, low in cost and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

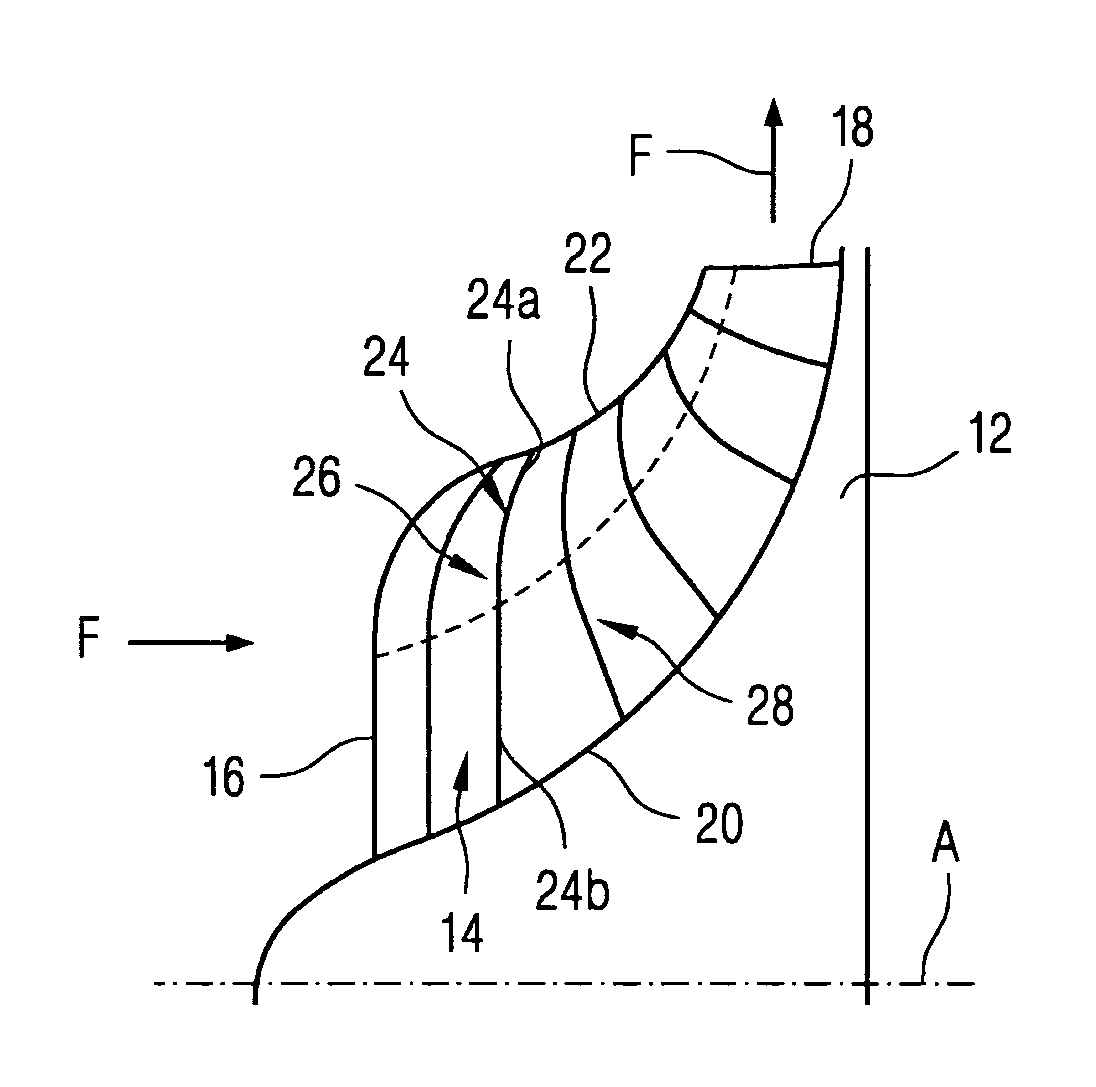

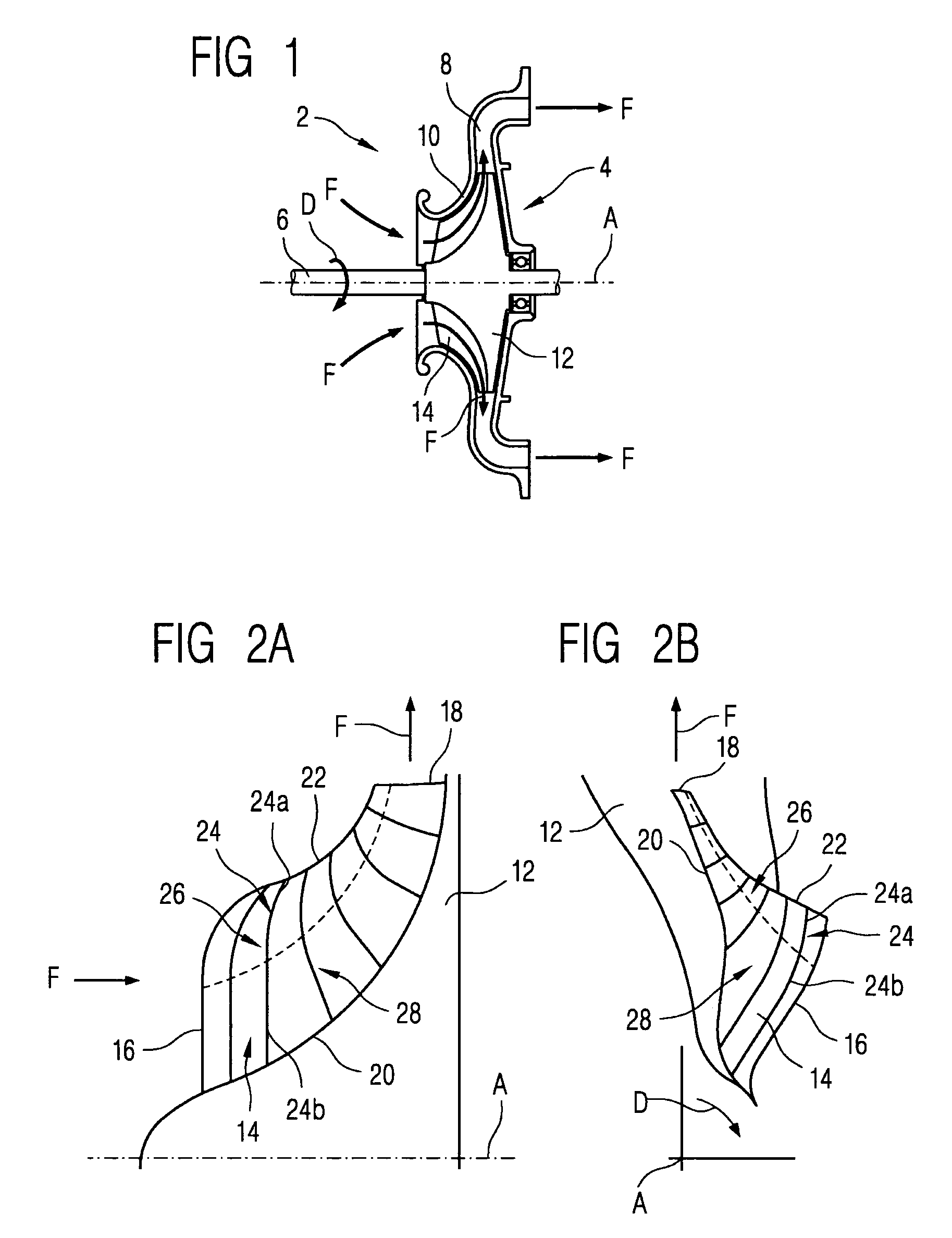

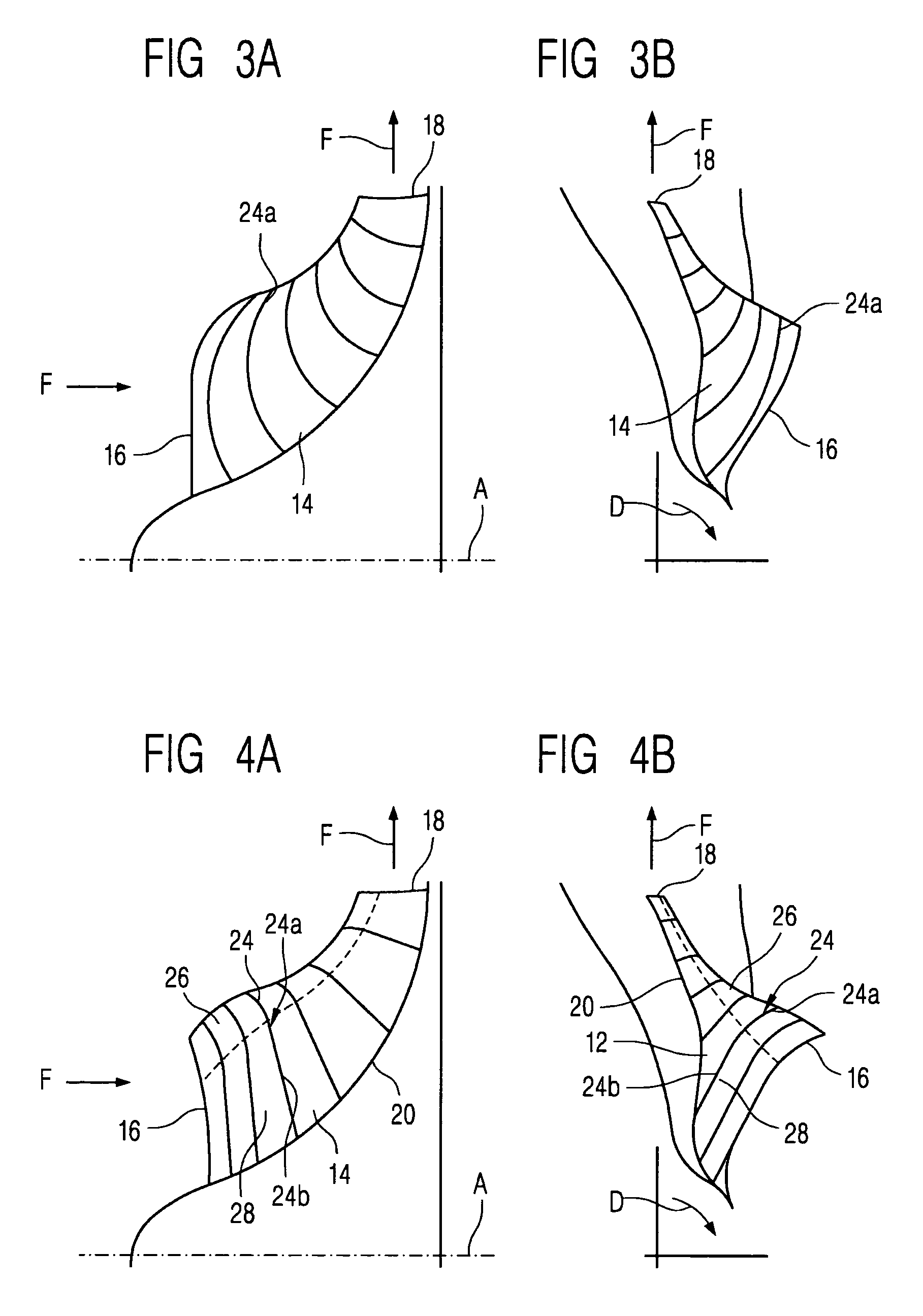

Radial compressor rotor

ActiveUS8277187B2Improve efficiencyImprove flow behaviorPropellersRotary propellersEngineeringMechanical engineering

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

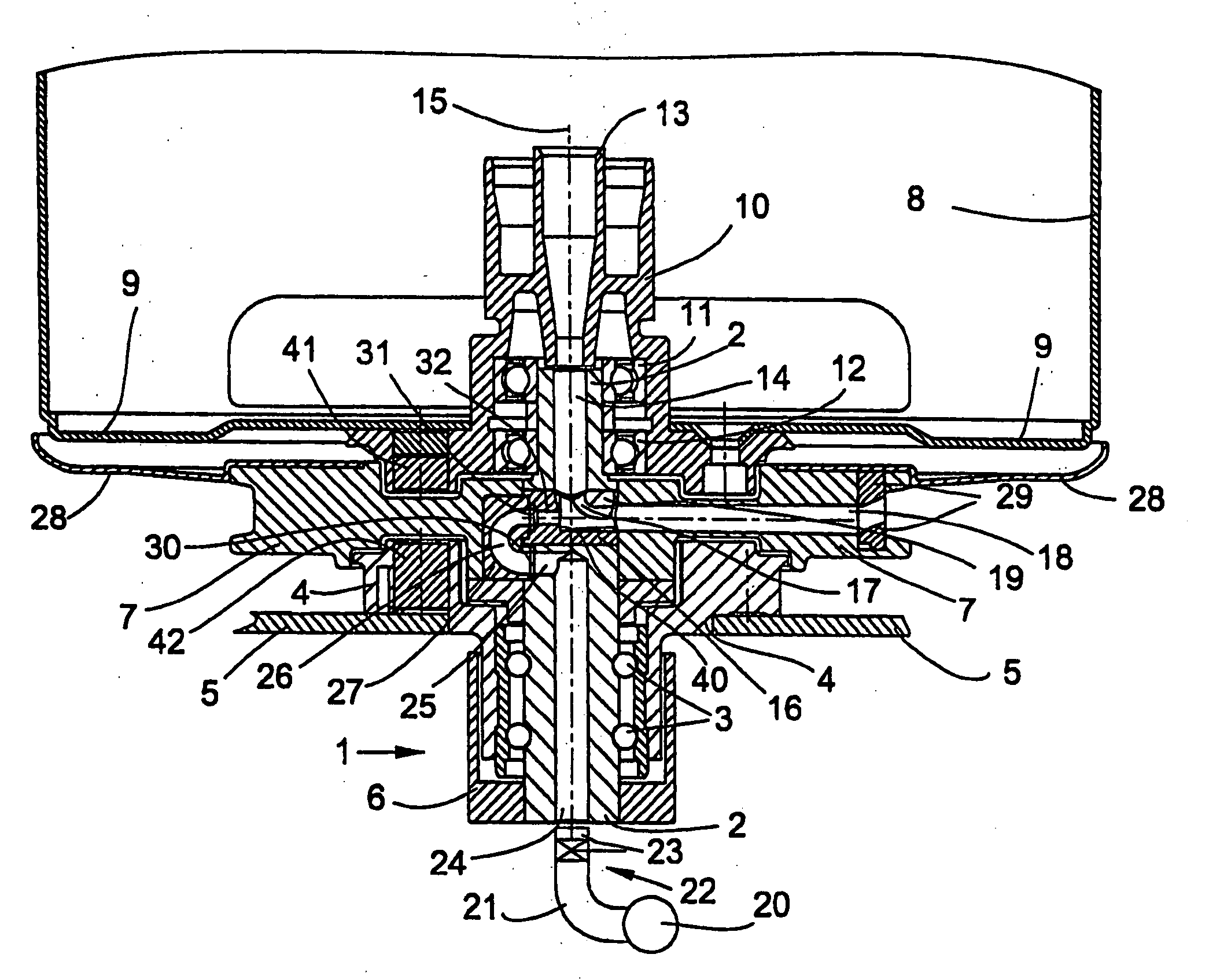

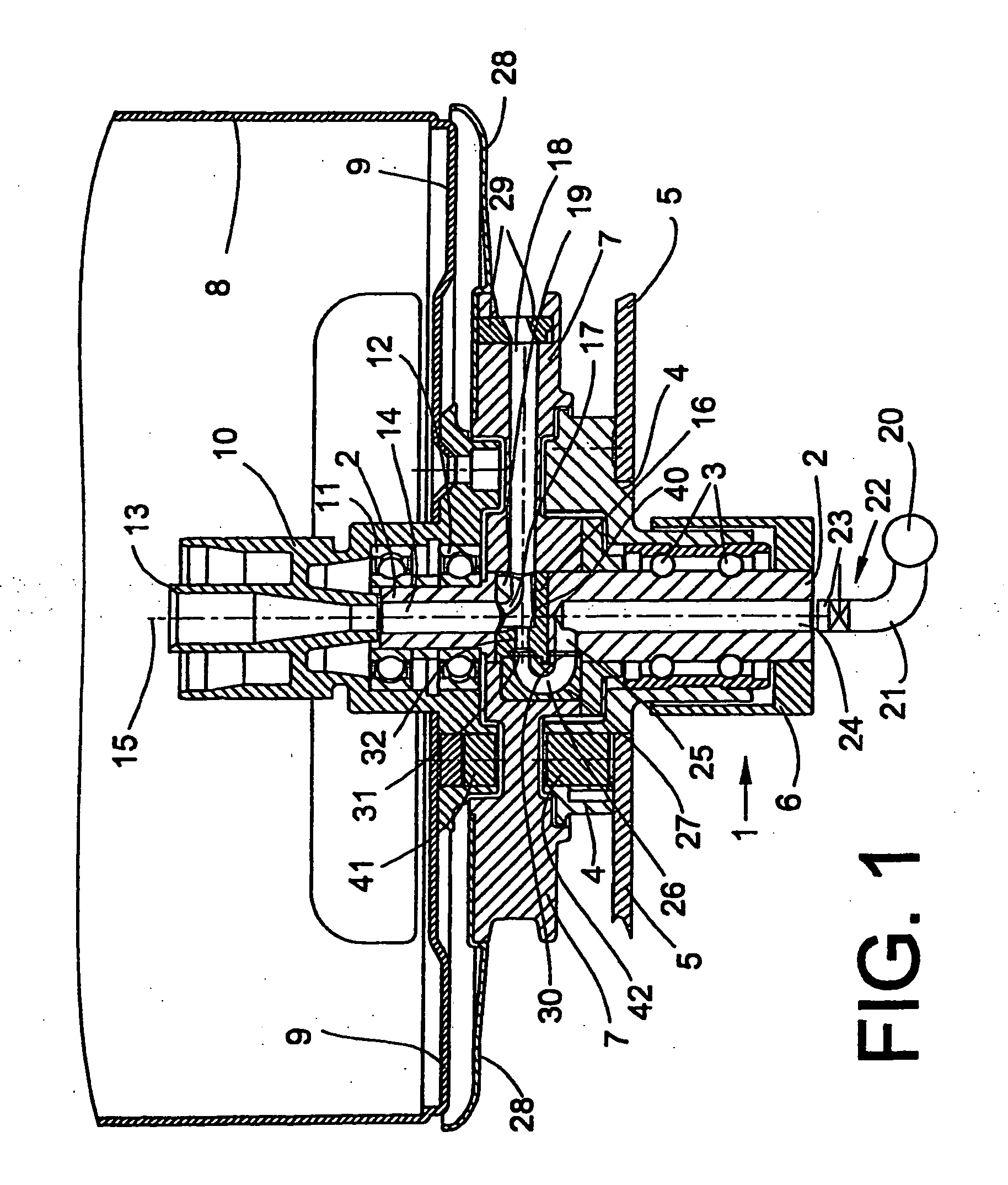

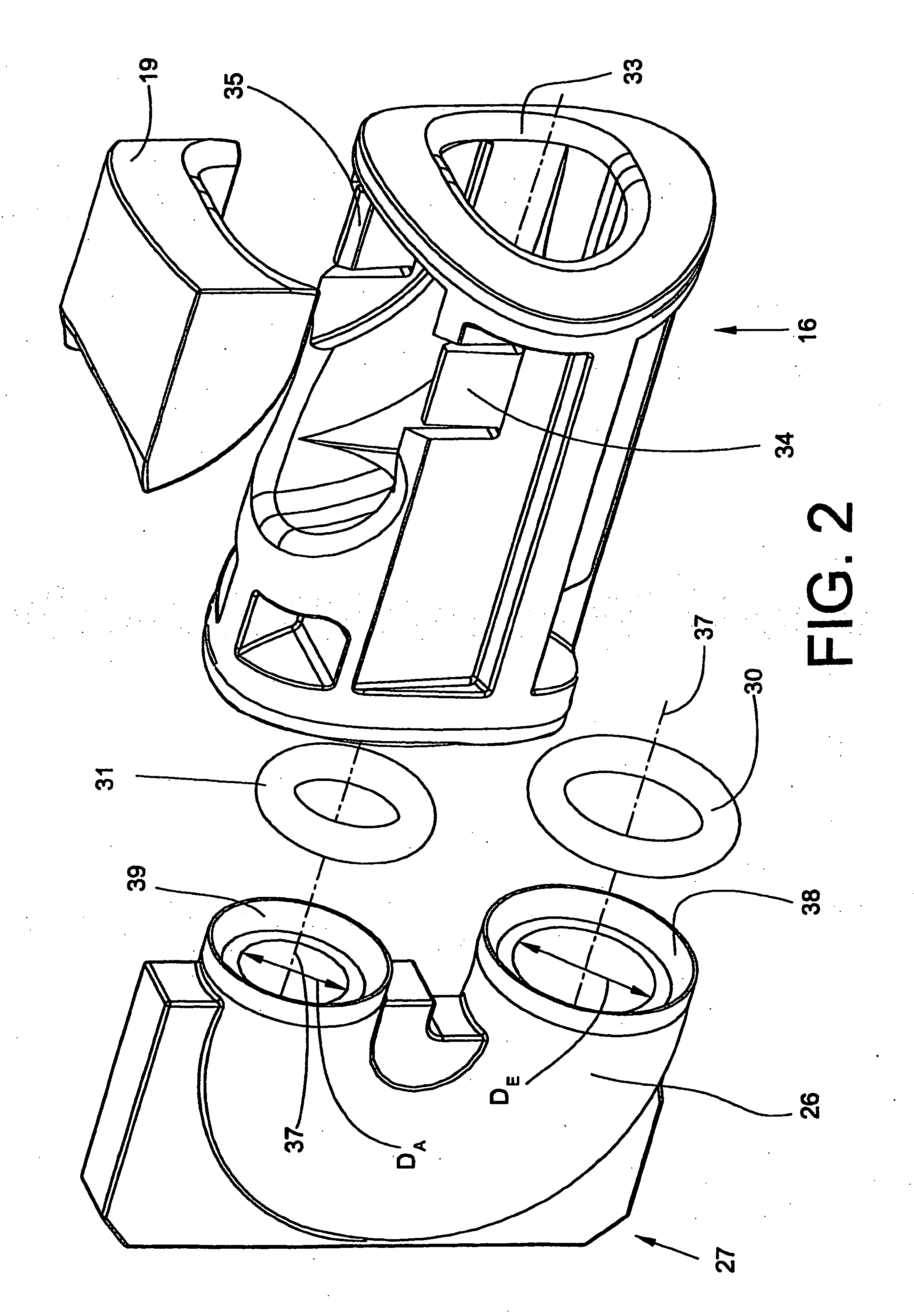

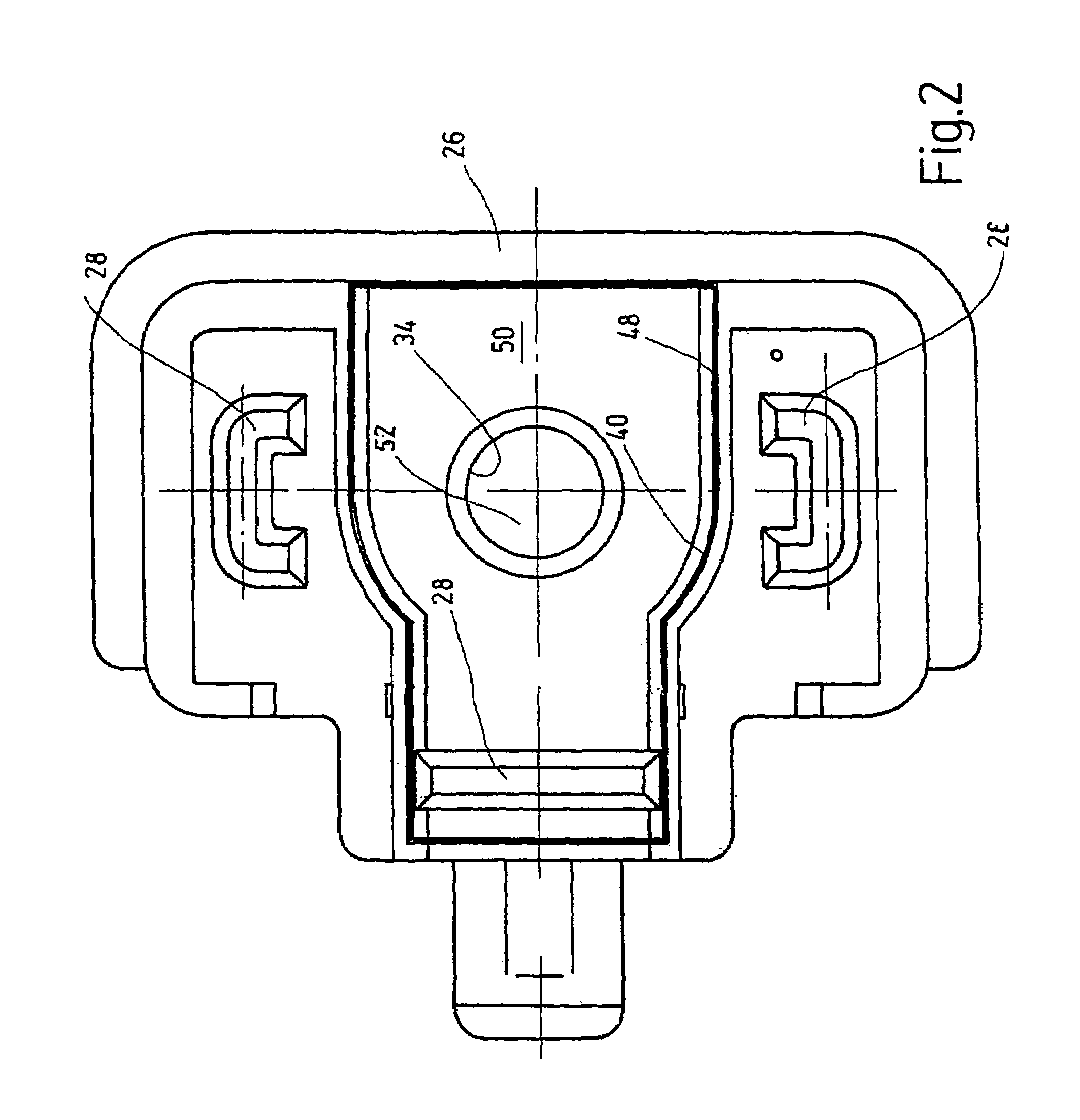

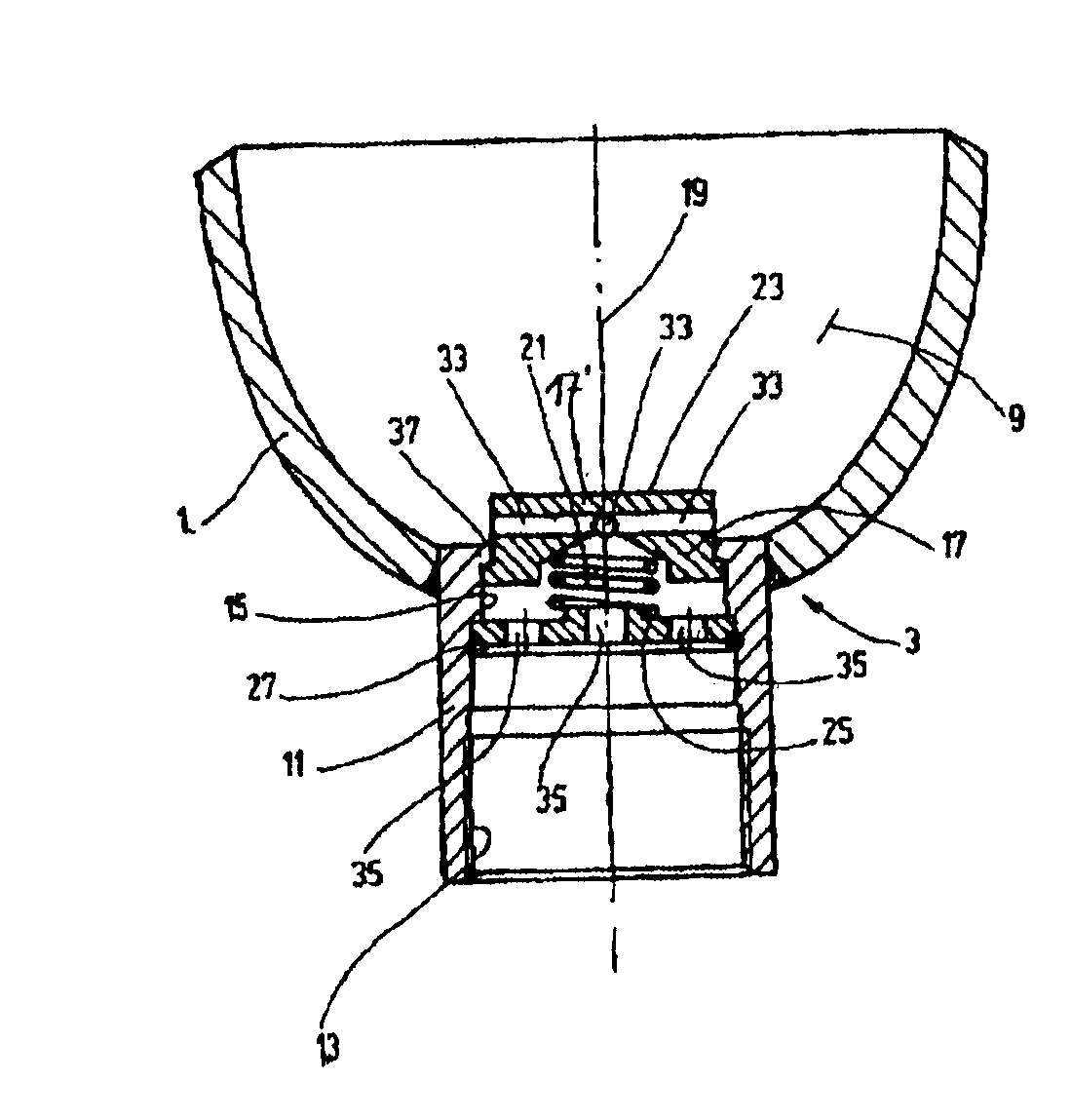

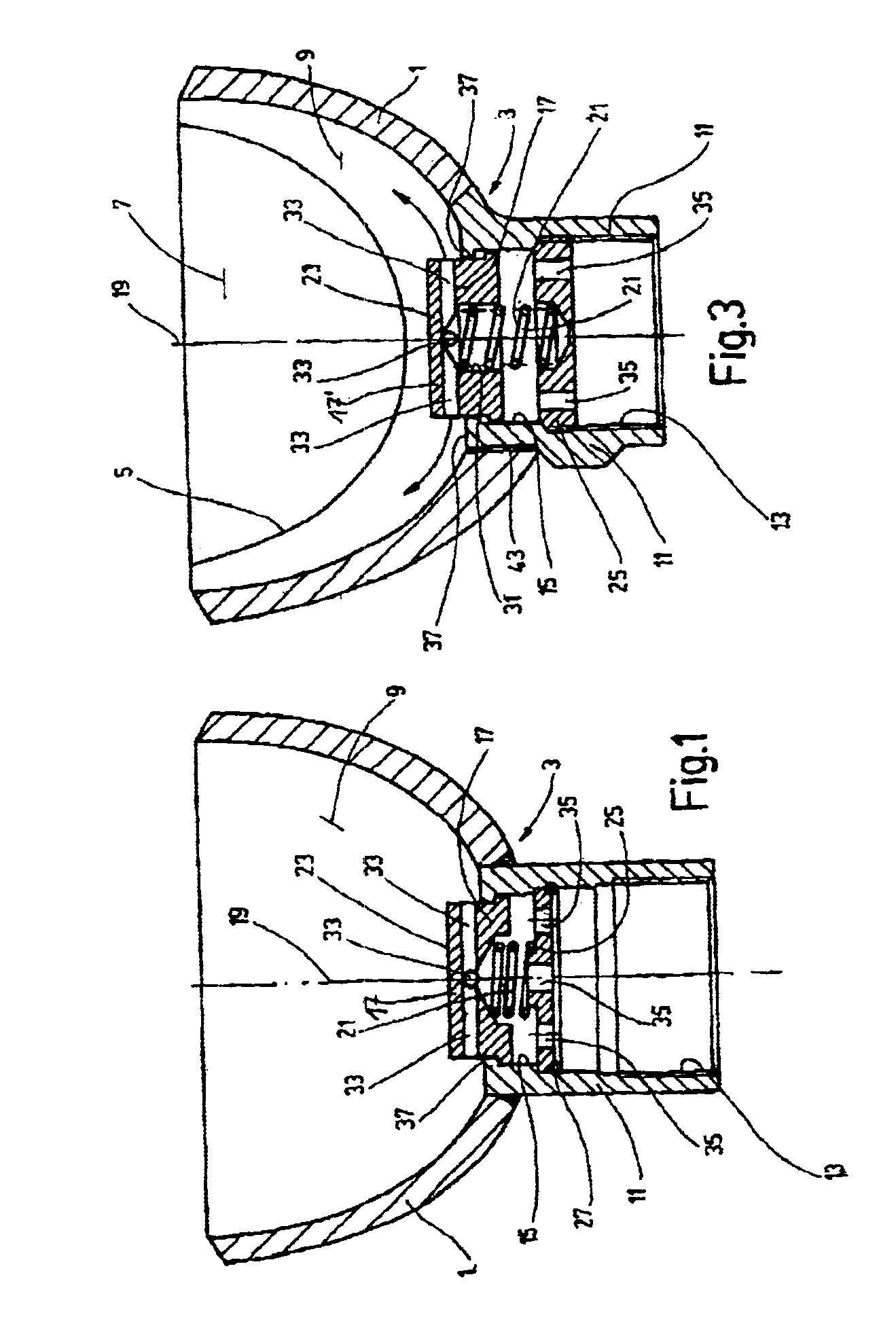

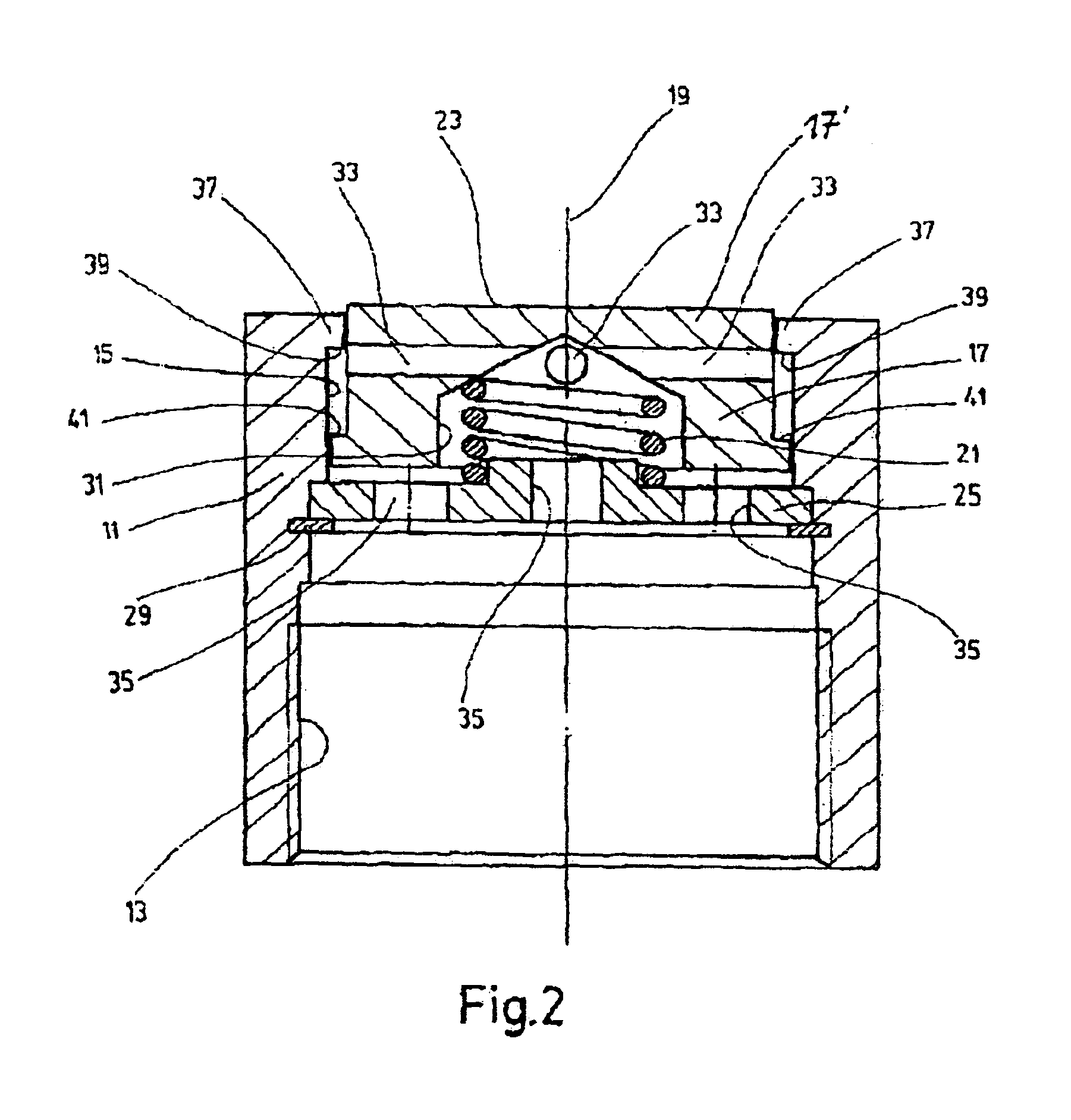

Hydroaccumulator, in a particular a bladder accumulator

InactiveUS6988514B2Simple structureEconomically implementedOperating means/releasing devices for valvesAccumulator installationsEngineeringGas chamber

A hydroaccumulator, in particular a bladder accumulator, includes a pressurized container (1) and a separation element (5) located in the container to separate a gas chamber (7) lying adjacent to an inlet on the gas side from a fluid chamber (9) lying adjacent to an inlet on the fluid side inlet (3), having a fluid connecting sleeve (11) and a valve arrangement located in the connecting sleeve (11). The valve body (17) has a transversal bore (33). The valve body is pretensioned in an open position which allows the passage of fluid and can be displaced into a closed position by a displacement of the separation element (5). The interior surface (15) of the connecting sleeve (11) lies directly against the valve body (17) and guides the displacement of the body between the open and closed positions. The side of the valve body (17′) that faces the separation element (5) is configured as a planar plate extending partially into the fluid chamber (9). The diameter of the valve body (17) is greater than its height, measured in the direction of displacement of the valve body (17). The valve arrangement has a plate-valve construction of small proportions and can be cost-effectively produced.

Owner:HYDAC TECH GMBH

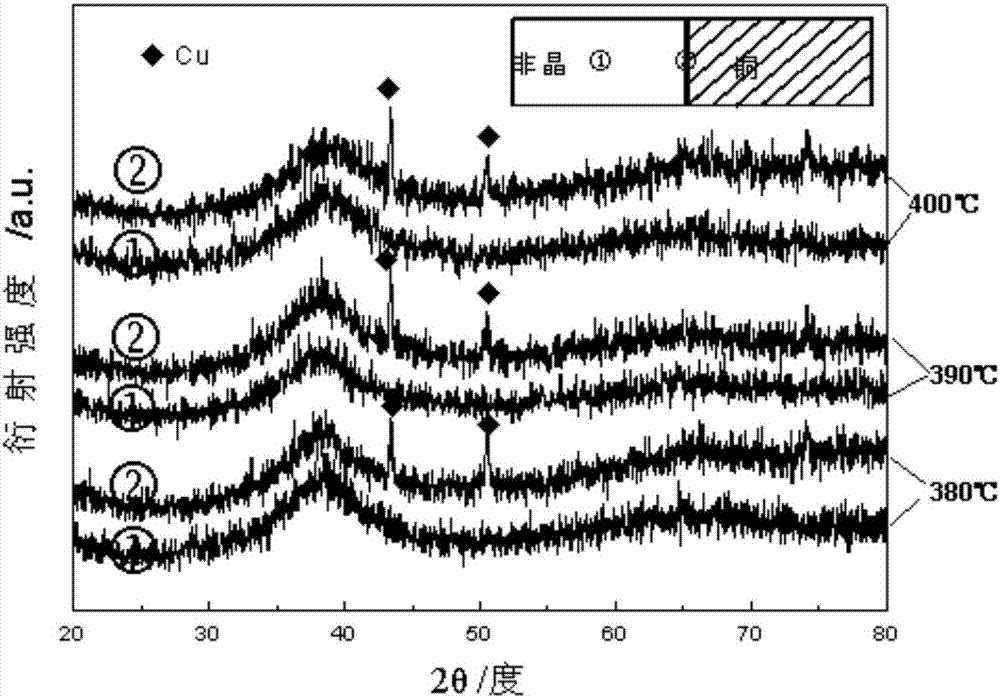

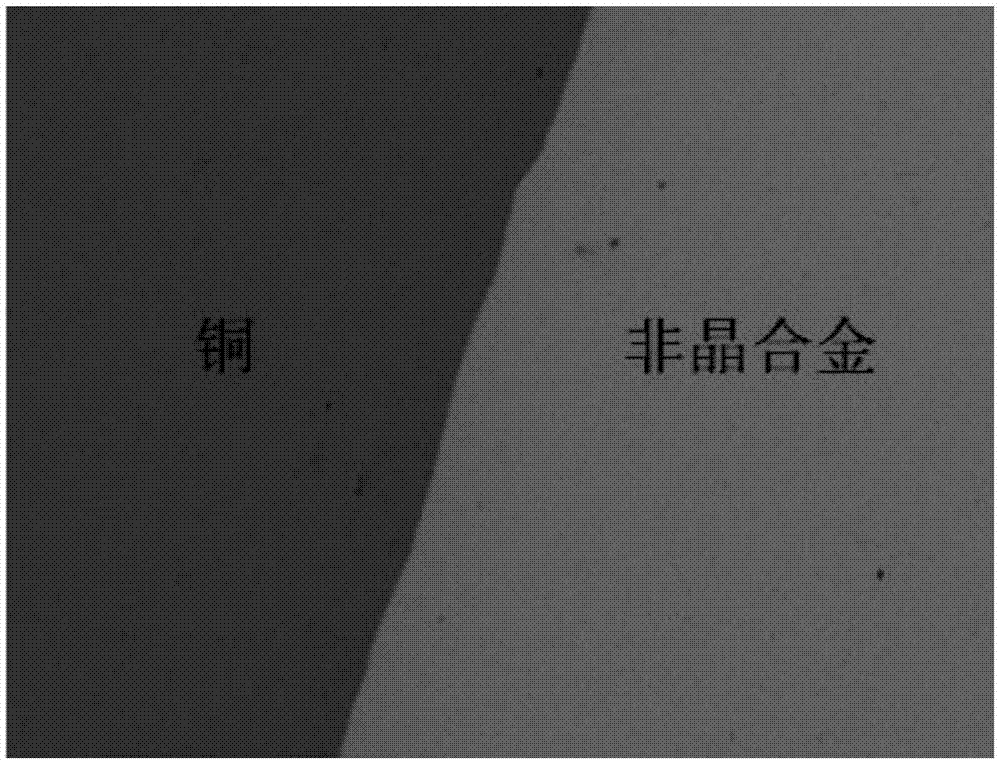

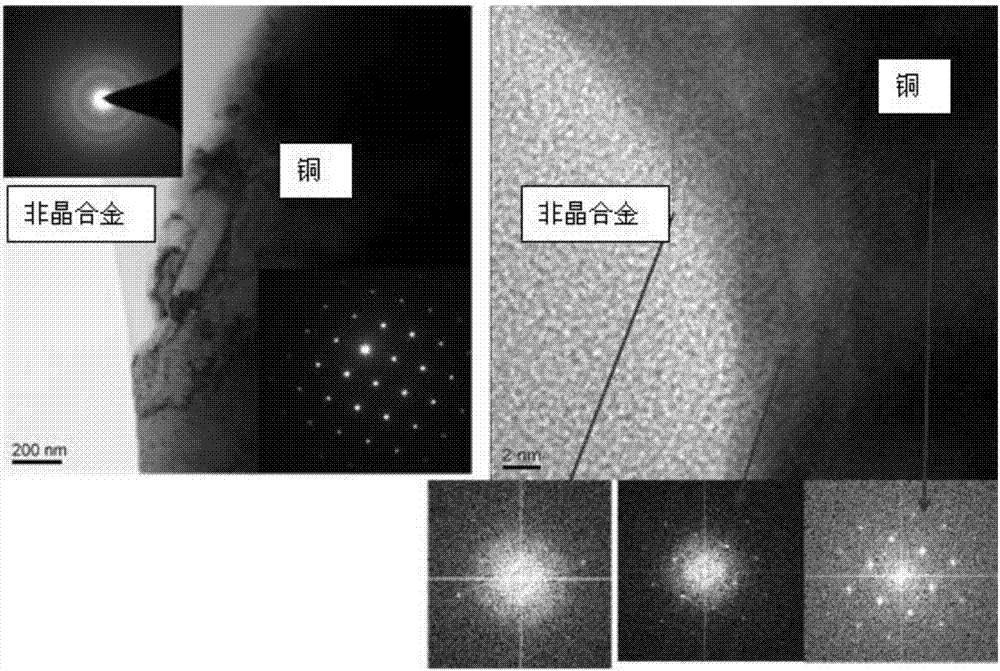

Preparation method for amorphous alloy/pure copper layered composite material

InactiveCN106939378AImprove flow behaviorImprove thermal stabilitySolid state diffusion coatingCopperUltimate tensile strength

The invention discloses a preparation method for an amorphous alloy / pure copper layered composite material. The preparation method comprises the following steps of: performing rheological behavior processing on an amorphous alloy through a cold-liquid-phase region temperature, enabling a micro bulge part of an amorphous alloy connecting surface to generate plastic deformation to increase a close contact area, and activating diffusion among atoms to change metal key connection into firm metallurgical connection; connecting the amorphous alloy treated in step to fine copper under control of connecting technological parameters, preserving the heat and diffusing, diffusing atoms in an interface region on which the amorphous alloy is in contact with the pure copper, improving diffusion connection reliability of dissimilar materials, reducing formation of defects, improving connecting strength of the layered material, and finally obtaining the amorphous alloy / pure copper layered composite material. The preparation method has the characteristics of adopting matrix and keeping an amorphous state and being wide in scope of application.

Owner:XIJING UNIV

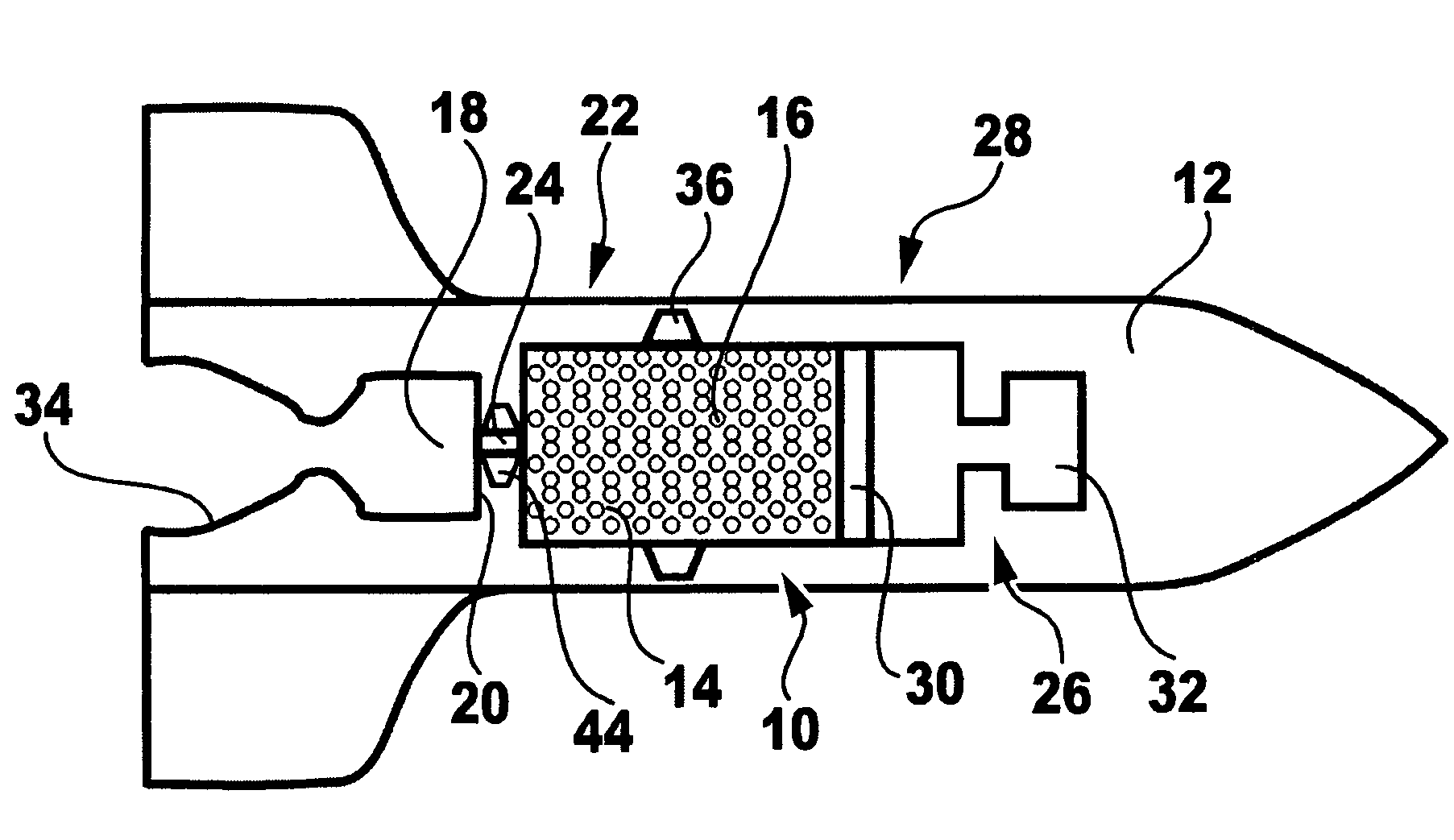

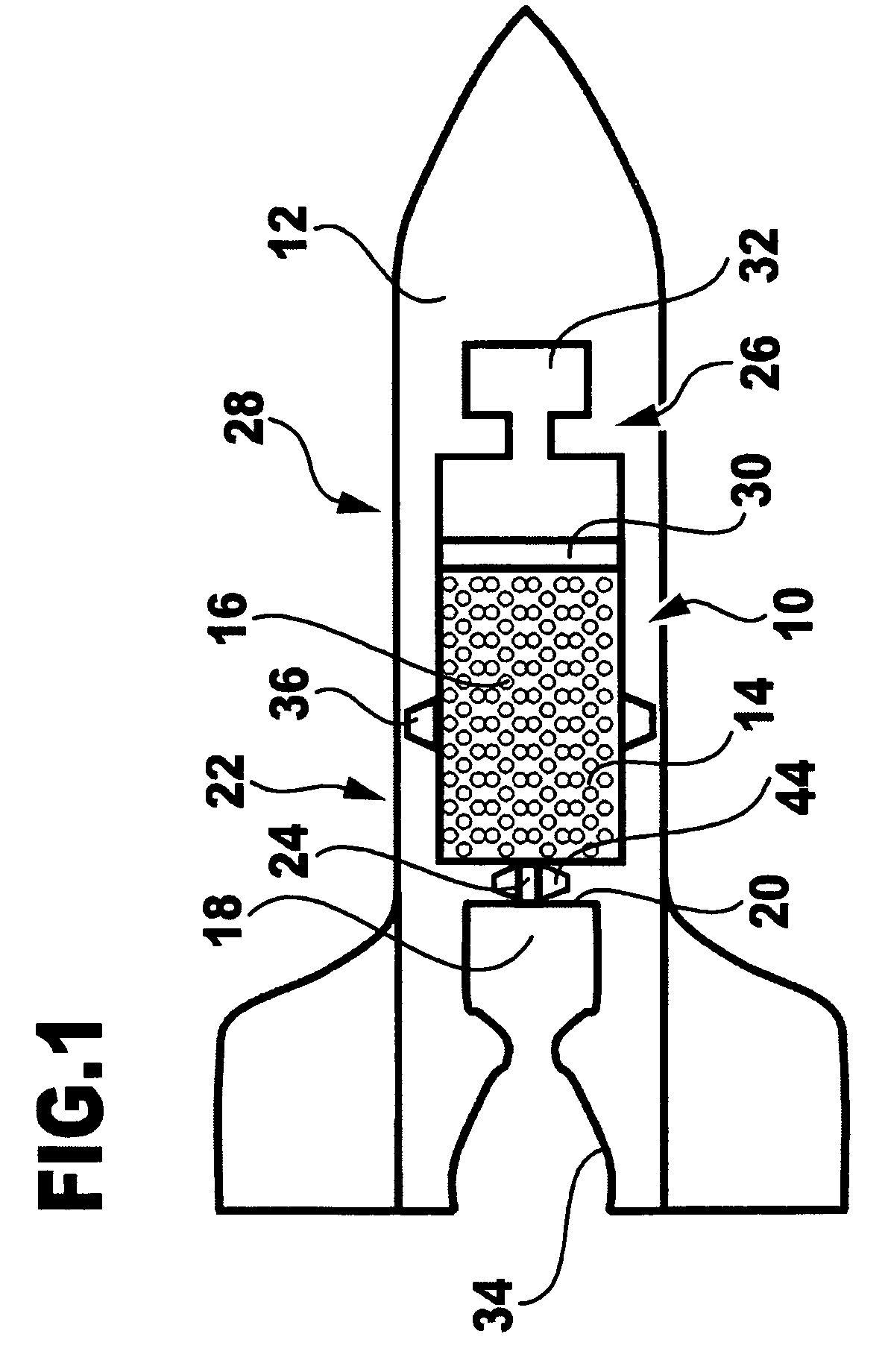

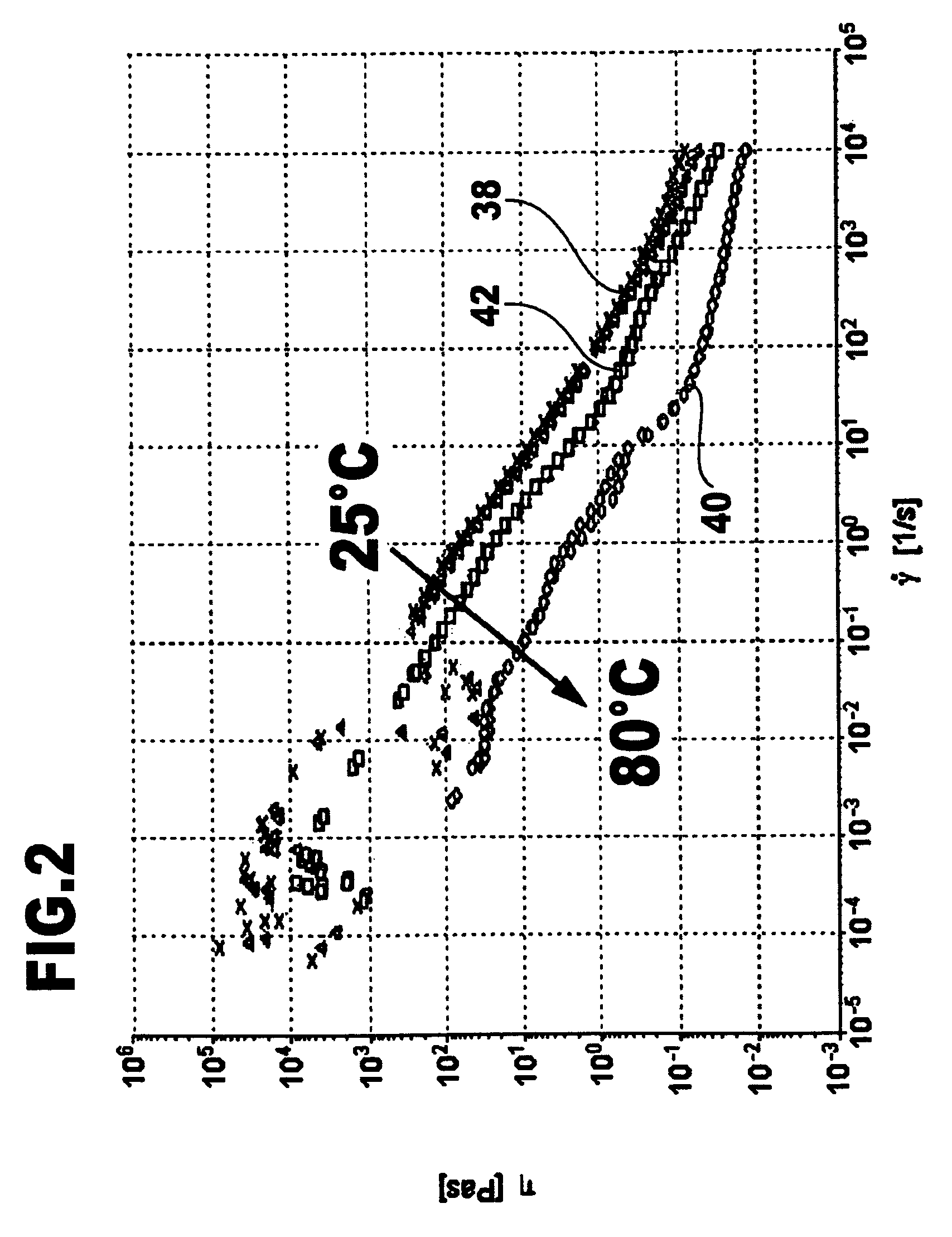

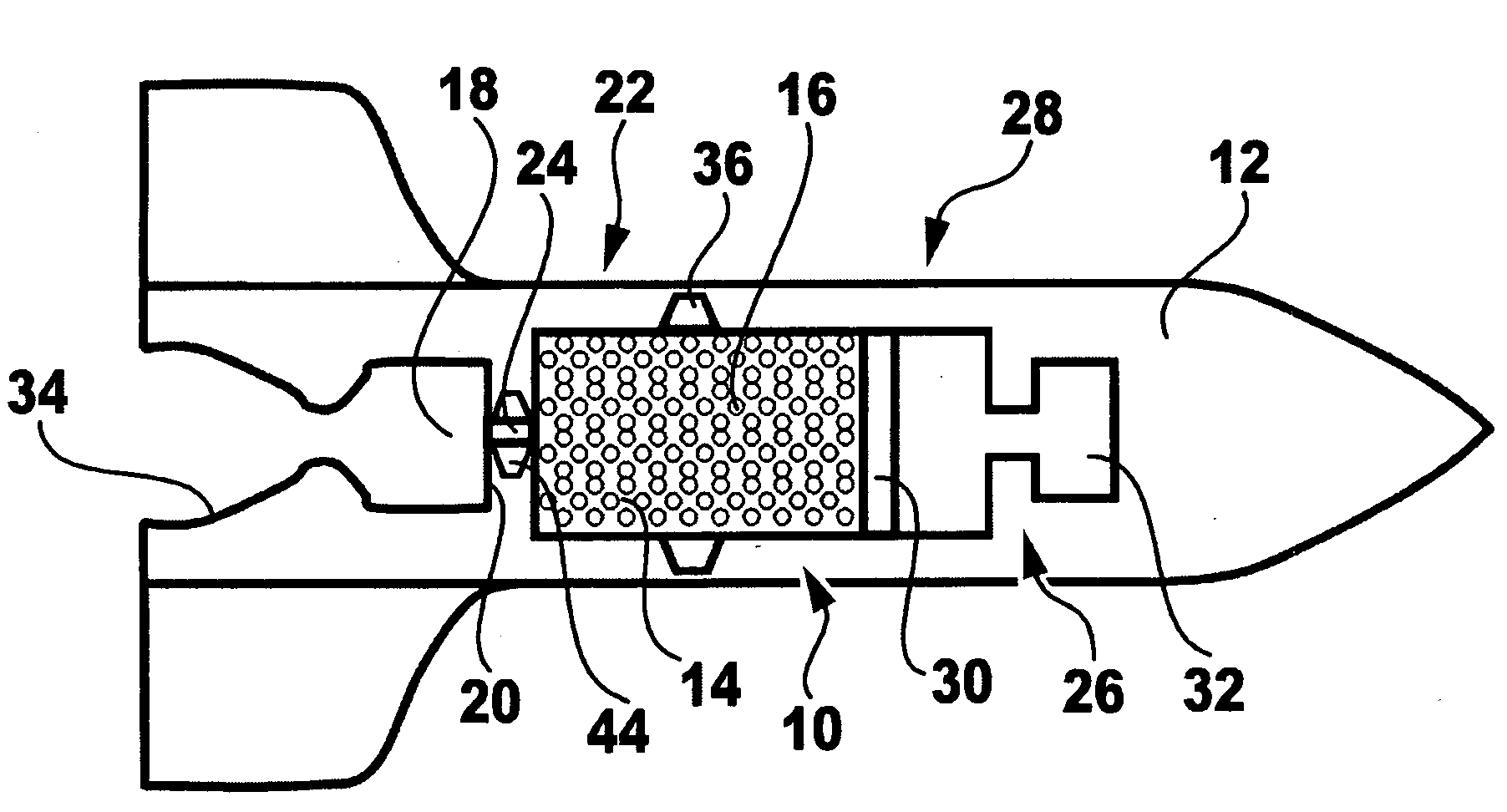

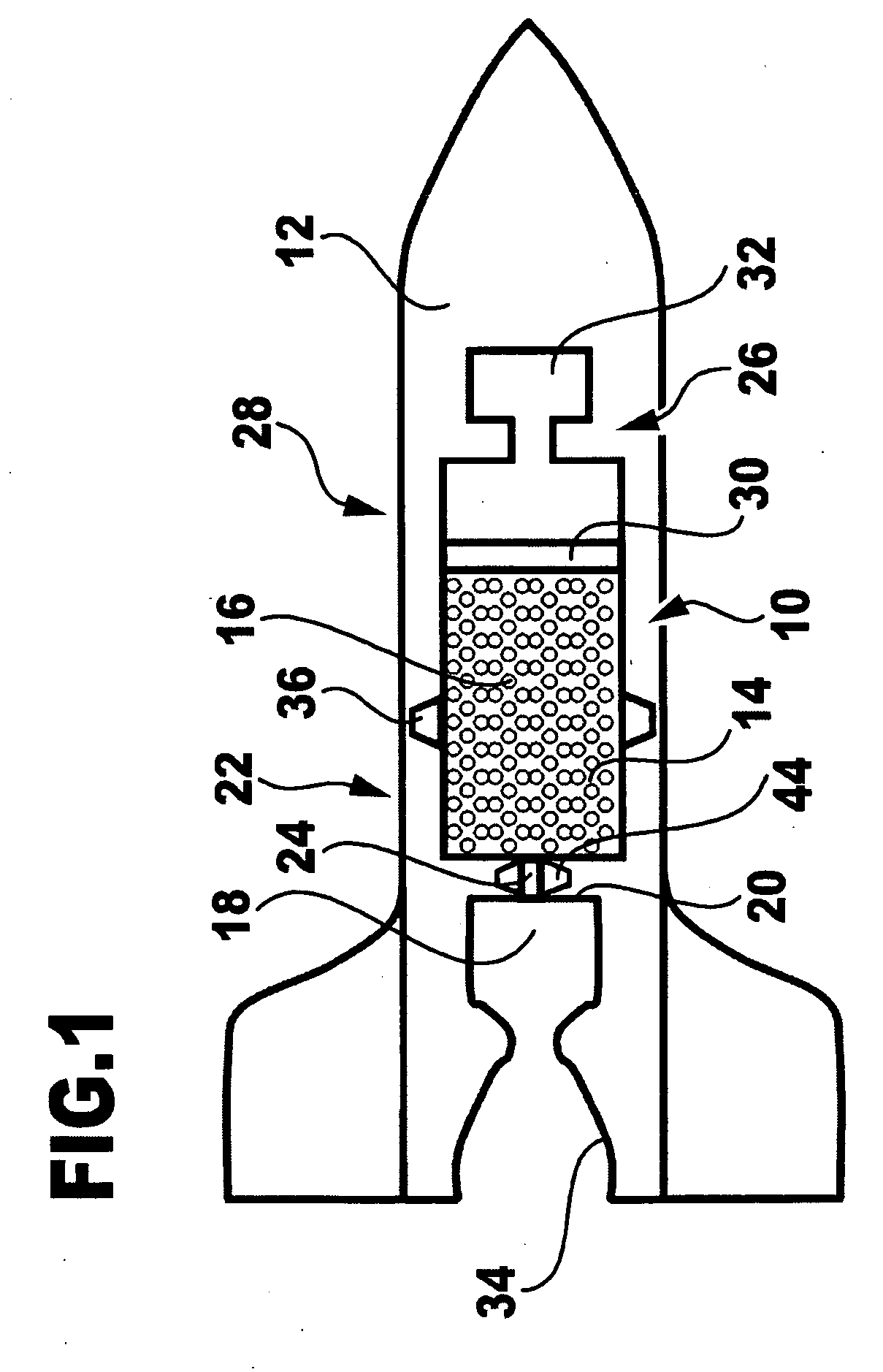

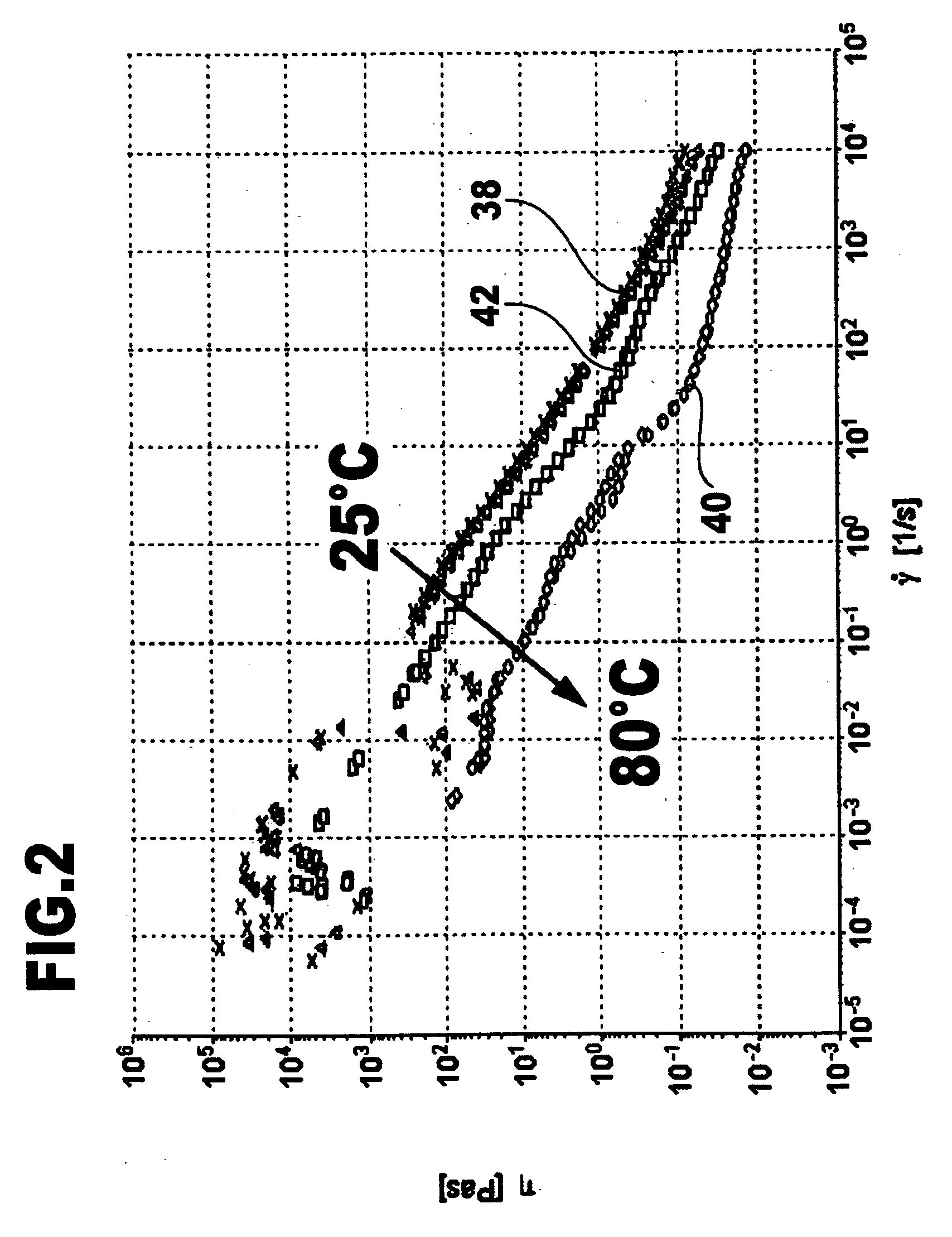

Drive device on the basis of a gel-type propellant and method for conveying propellant

InactiveUS8033095B2Easy constructionImprove flow behaviorEngine fuctionsWorking fluid for enginesCombustion chamberElectromagnetic radiation

In order to make a drive device available on the basis of a gel-type propellant, in particular, for a flying object, comprising at least one tank for gel-type propellant, a combustion chamber and a device for supplying propellant to the combustion chamber, which is of a simple construction it is suggested that at least one radiation impinging device be provided for acting on gel-type propellant with electromagnetic radiation and / or at least one heating device for heating gel-type propellant in order to improve the flow behavior.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

Composition and its use for improving the processibility of hydraulically setting compositions

The invention relates to a composition comprising at least one plasticizer for a hydraulically setting composition and at least one polyalkylene glycol. The invention also relates to a process that uses the composition for improving the processibility, in particular for extending the processing time, of hydraulically setting compositions.

Owner:SIKA TECH AG

Wind-turbine rotor blade, trailing edge for wind-turbine rotor blade tip, method for producing a wind-turbine rotor blade, and wind turbine

ActiveUS20170152834A1Improve efficiencyImprove Noise PerformanceEngine fuctionsMachines/enginesTurbine bladeTrailing edge

A trailing edge for a rotor blade tip of an aerodynamic rotor of a wind turbine. The trailing edge comprises a trailing edge delimiting line, which replicates the contour of the trailing edge, and multiple serrations to improve flow behavior at the trailing edge. The serrations are provided at the trailing edge in dependence on the trailing edge delimiting line, and consequently on geometrical and operating parameters.

Owner:WOBBEN PROPERTIES GMBH

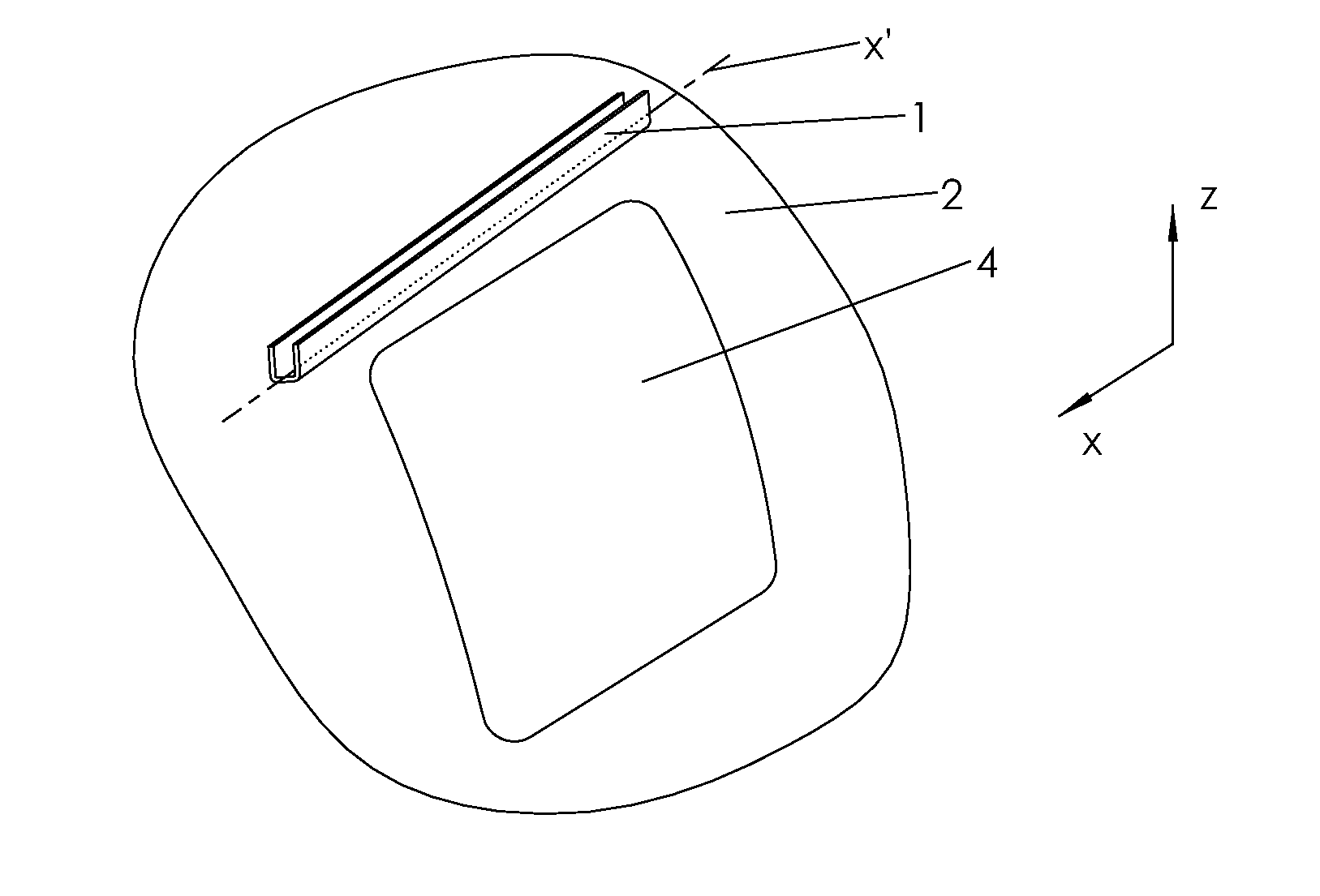

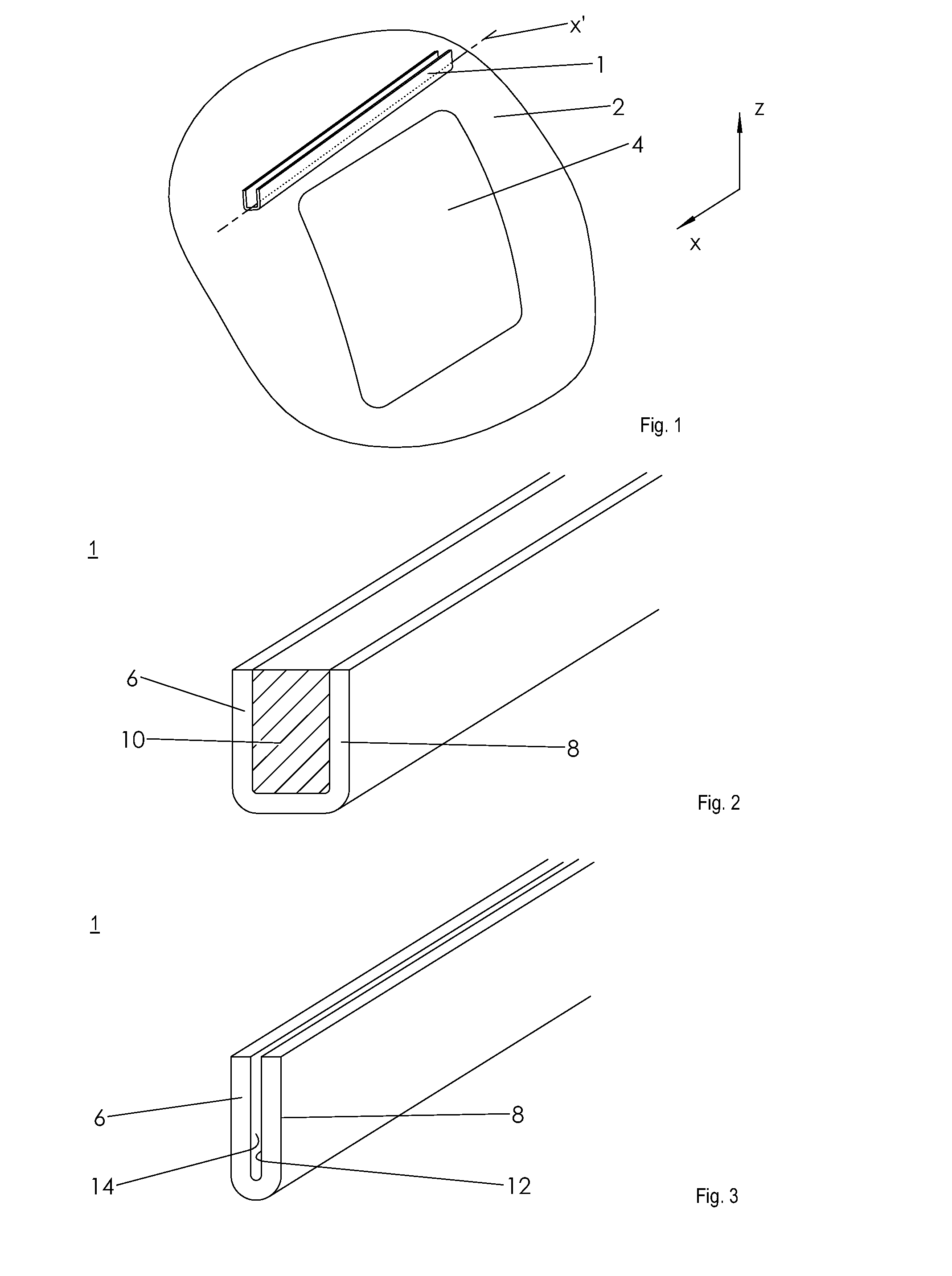

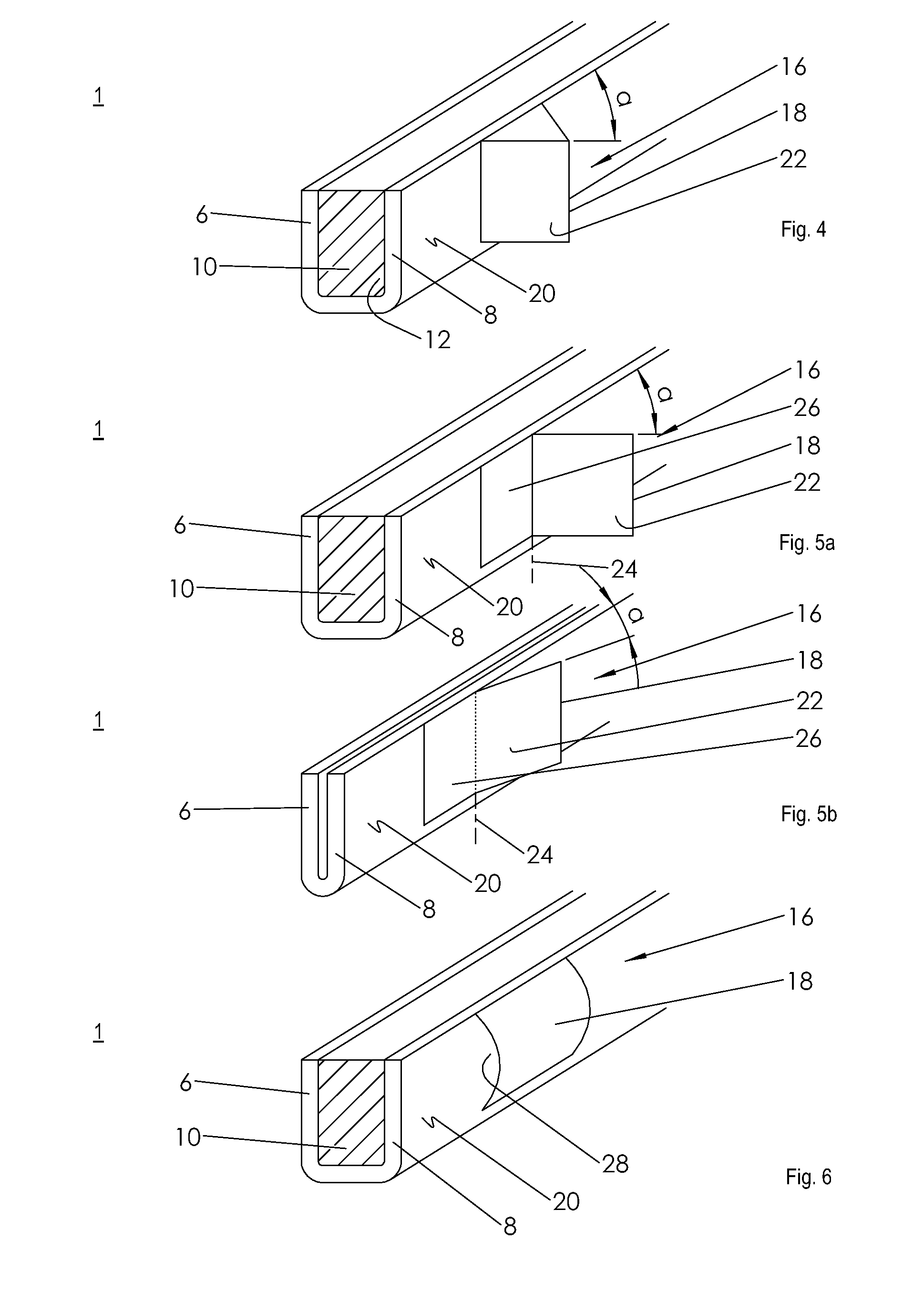

Gutter profile and aircraft

ActiveUS20140077035A1Improve flow behaviorReduces its drain cross-section in flightFuselagesAircraft floorsAirplane

A gutter profile for draining liquids on an aircraft, comprising a connecting section for connecting the gutter profile to an outer skin of the aircraft and comprising a drain section for forming a drain cross-section of the gutter profile. The drain section is pre-tensioned into a ground position which opens the drain cross-section and has a flow guiding device for transferring the drain section into a flight position which closes the drain cross-section. An aircraft having such a gutter profile is also disclosed.

Owner:AIRBUS OPERATIONS GMBH

Valve with connection on the pressure side

ActiveUS9285052B2Improve flow behaviorIncrease chanceOperating means/releasing devices for valvesCheck valvesEngineeringVALVE PORT

The invention refers to a valve, in particular a pressure valve, comprising a feed area provided in front of a globe valve in flow direction of the medium, wherein the globe valve can be sealed by a loose closing element provided in the feed area, and wherein an activation rod angles the closing element against the flow direction of the medium with reference to the globe valve. The invention is characterized in that in the feed area a flow guiding device is provided, wherein the flow guiding device has several channel areas, so that the medium flowing through the channel areas is set in a helical twist.

Owner:SVM SCHULTZ VERW +1

Drive device on the basis of a gel-type propellant and method for conveying propellant

InactiveUS20090165437A1Easy constructionImprove flow behaviorEngine fuctionsWorking fluid for enginesGel basedCombustion chamber

In order to make a drive device available on the basis of a gel-type propellant, in particular, for a flying object, comprising at least one tank for gel-type propellant, a combustion chamber and a device for supplying propellant to the combustion chamber, which is of a simple construction it is suggested that at least one radiation impinging device be provided for acting on gel-type propellant with electromagnetic radiation and / or at least one heating device for heating gel-type propellant in order to improve the flow behavior

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

Composition and Its Use for Improving the Processibility of Hydraulically Setting Compositions

The invention relates to a composition comprising at least one plasticizer for a hydraulically setting composition and at least one polyalkylene glycol. The invention also relates to a process that uses the composition for improving the processibility, in particular for extending the processing time, of hydraulically setting compositions.

Owner:SIKA TECH AG

Exhaust gas system

ActiveUS7971431B2Improve deformation abilitySimple designExhaust apparatusSilencing apparatusAcute angleExhaust fumes

An exhaust gas system for an internal combustion engine, in particular a motor vehicle engine, is provided having, in one form, two cylinder banks arranged at an acute angle to one anther and each having at least one exhaust gas outlet, a so-called V-engine, having exhaust gas guide elements arranged in the region of the inner angle, including a housing surrounding the exhaust gas outlets of both cylinder banks in a gas tight manner and having at least one exhaust gas outlet opening is characterized in that the housing is made in two parts, with a first part which is connected to the one cylinder bank and surrounds its exhaust gas outlets and with a second part which is connected to the other cylinder bank and surrounds its exhaust gas outlets; in that the two parts each have a side facing the other part and having at least one housing opening via which the two parts communicate with one another; and in that an expansion compensation element is arranged between the two parts and surrounds the housing opening of the two parts in a gas tight manner.

Owner:FRIEDRICH BOYSEN +1

Cooling fan module

The invention relates to a cooling fan module for a motor vehicle, having a fan impeller which has a multiplicity of fan impeller blades which are connected to one another via a fan impeller outer ring, having a frame, on which the fan impeller is mounted, having an annular reverse flow guide device, which has an inner ring and an outer ring and which is designed to de-spin a reverse flow between the inner ring and the outer ring and to mix said reverse flow with the slot flow between inner ring and fan impeller outer ring.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

Blowing and refining device and method used for removing tundish molten steel inclusion

The invention discloses a blowing and refining device and method used for removing the tundish molten steel inclusion. The blowing and refining device is characterized by comprising a tundish 1, a blowing device 2 and a dipping cover 3, wherein the tundish comprises a permanent layer and a working layer arranged on the inner surface of the permanent layer; the bottom of the permanent layer is provided with the blowing device; the blowing device comprises an air brick and a ventilating pipe; the air brick comprises a dense layer and a ventilating layer; the middle of the ventilating layer is provided with an air chamber; and the dipping cover is a refractory material cover supported by a steel plate, is connected with an automatic lifting system and is arranged above the blowing device. According to the blowing and refining device, an air curtain retaining wall with a big air flow can be introduced in to form continuous and tight bubble columns, the average residence time of molten steel in the tundish is obviously prolonged, the molten steel flowing behavior is obviously improved, the molten steel can be stirred by a great quantity of tiny bubbles, inclusions with a smaller size can be adsorbed, and meanwhile, steel slag rolling and mixing and the secondary oxidation of the molten steel due to big blowing amount can be avoided.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com