Patents

Literature

41results about How to "Reduce residual tensile stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass laminate substrate having enhanced impact and static loading resistance

ActiveUS20060127679A1Increased resistance to impactIncrease static loadLiquid crystal compositionsGas-filled discharge tubesDisplay deviceThermal expansion

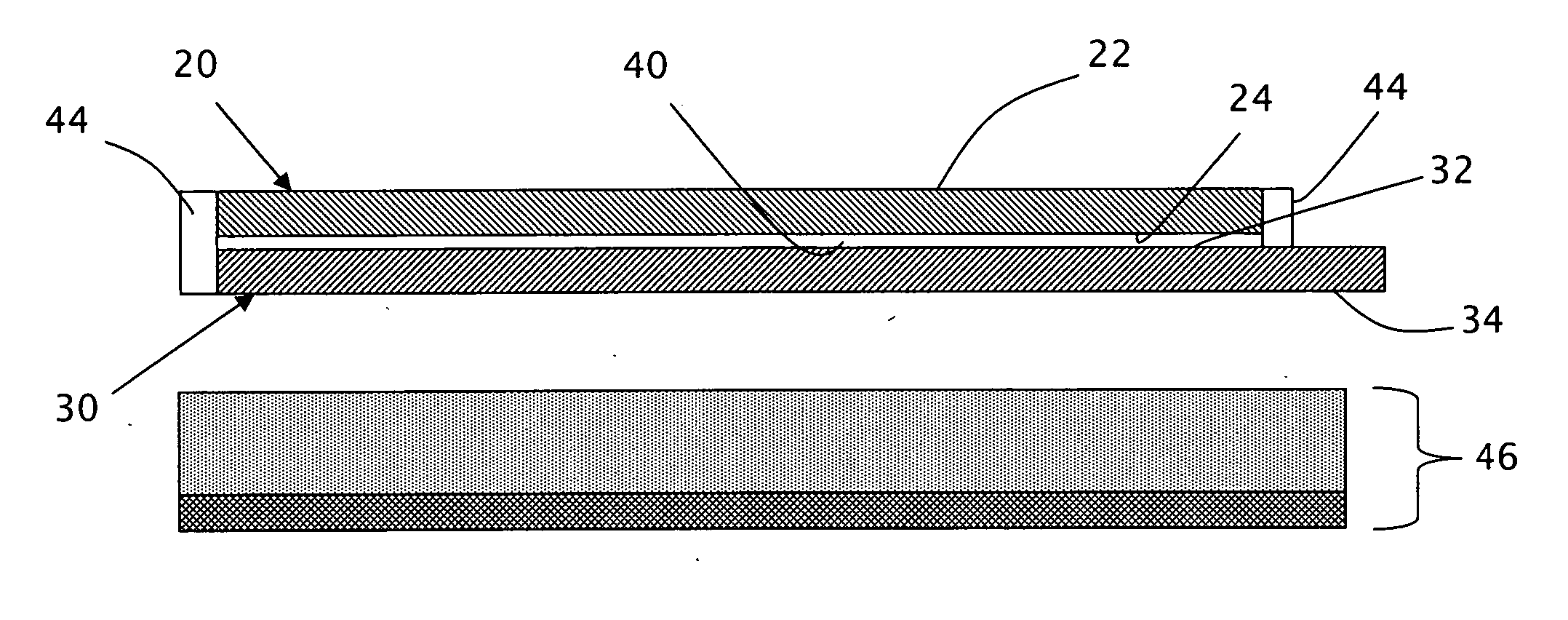

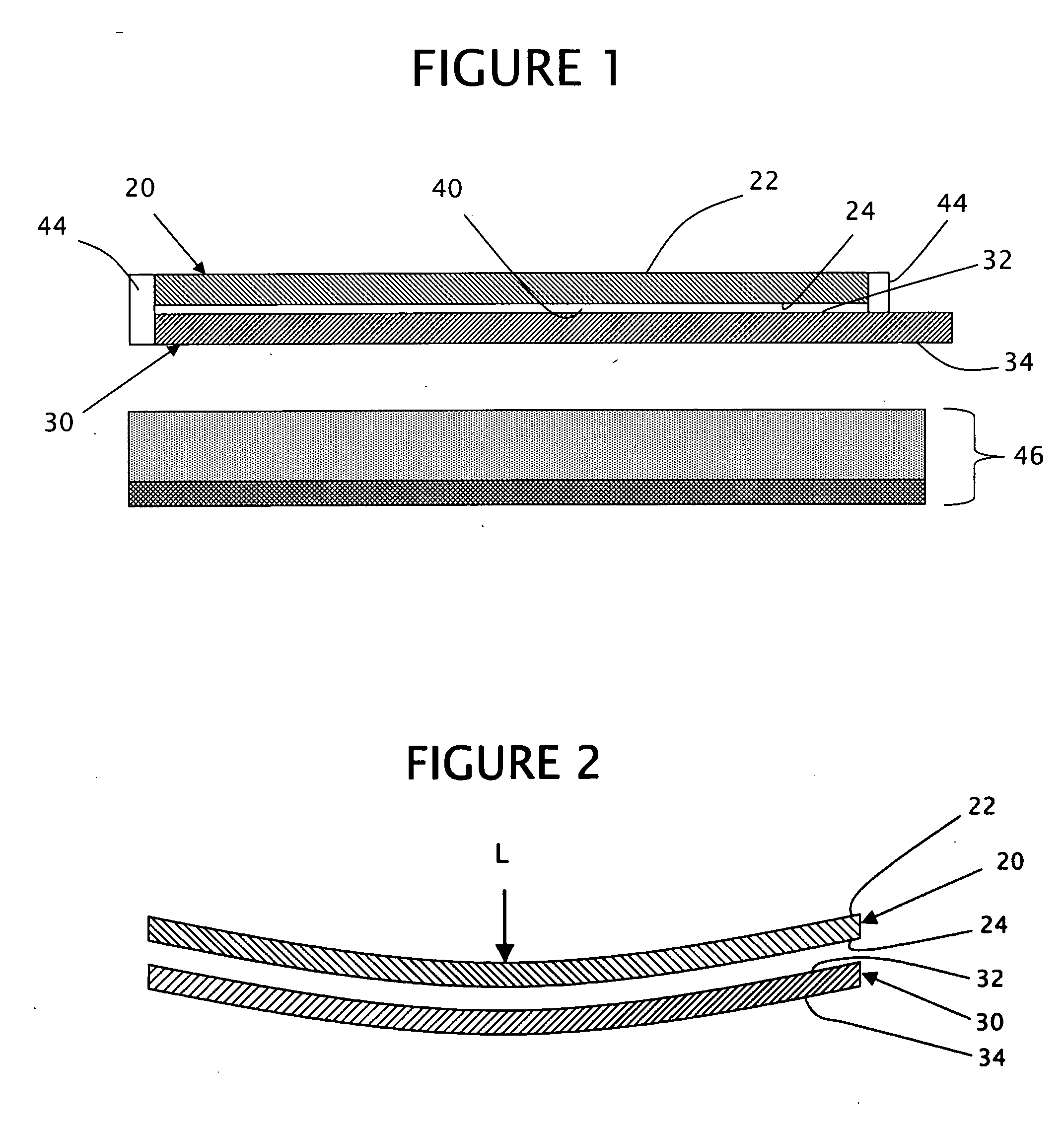

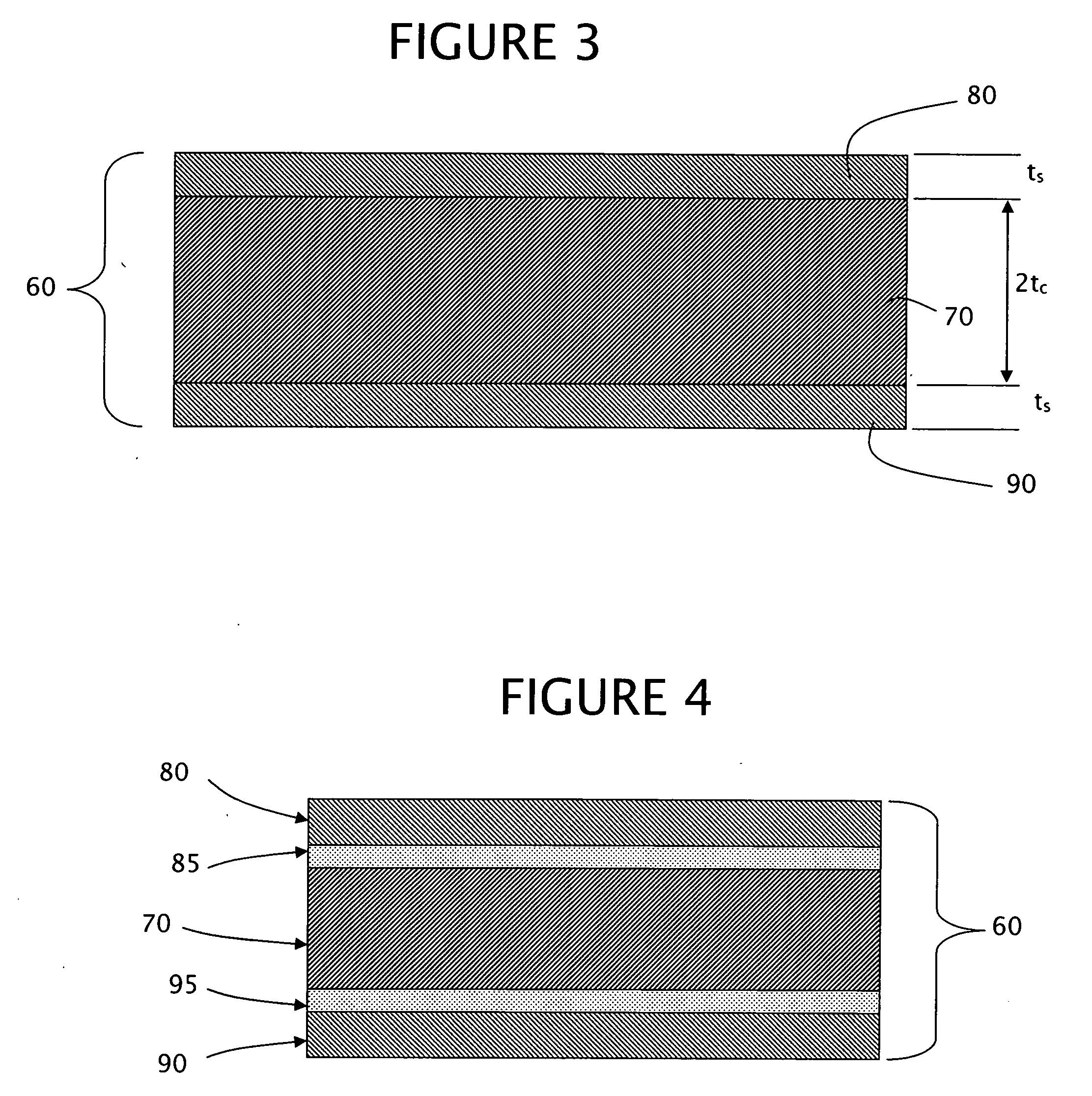

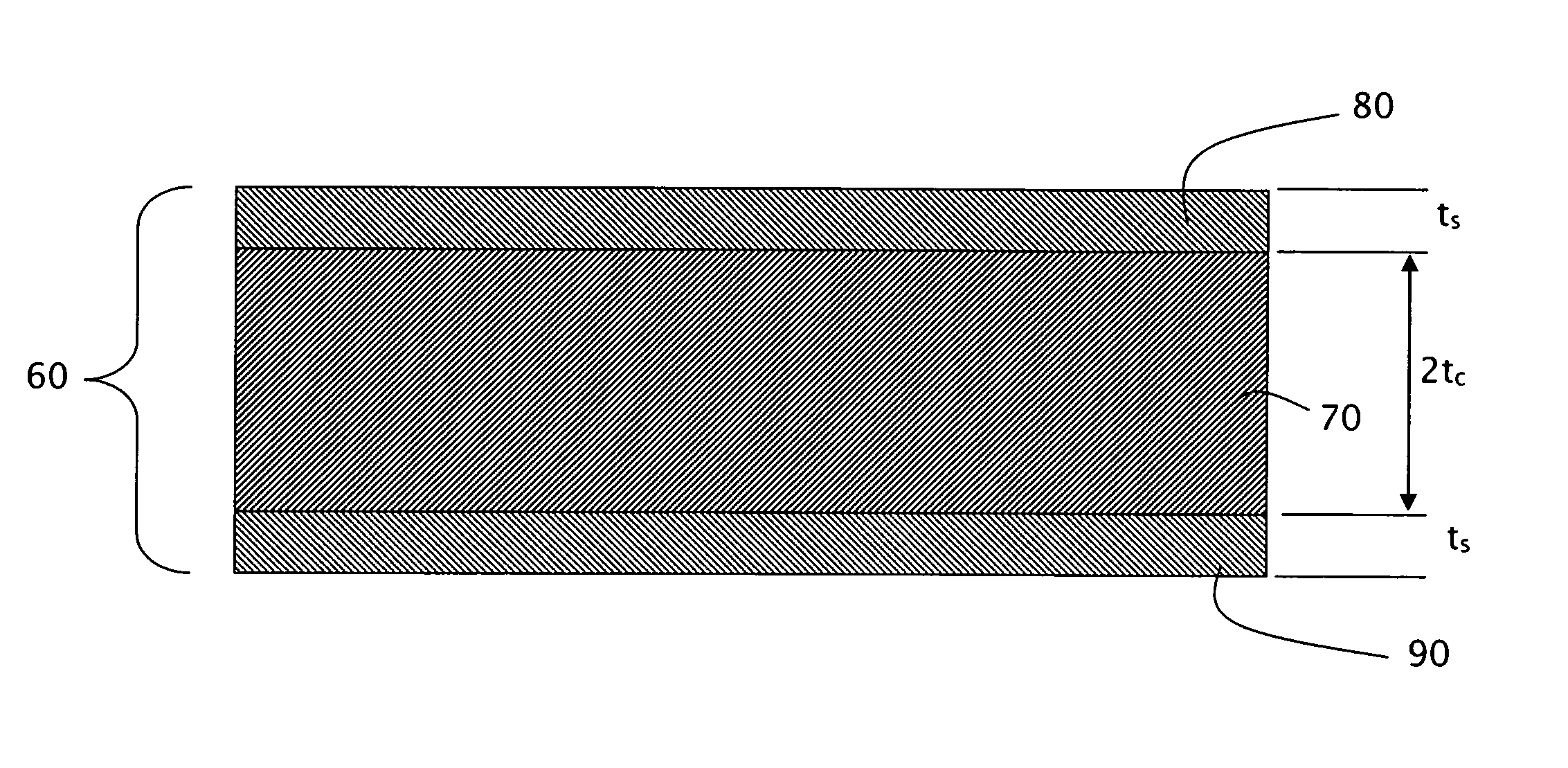

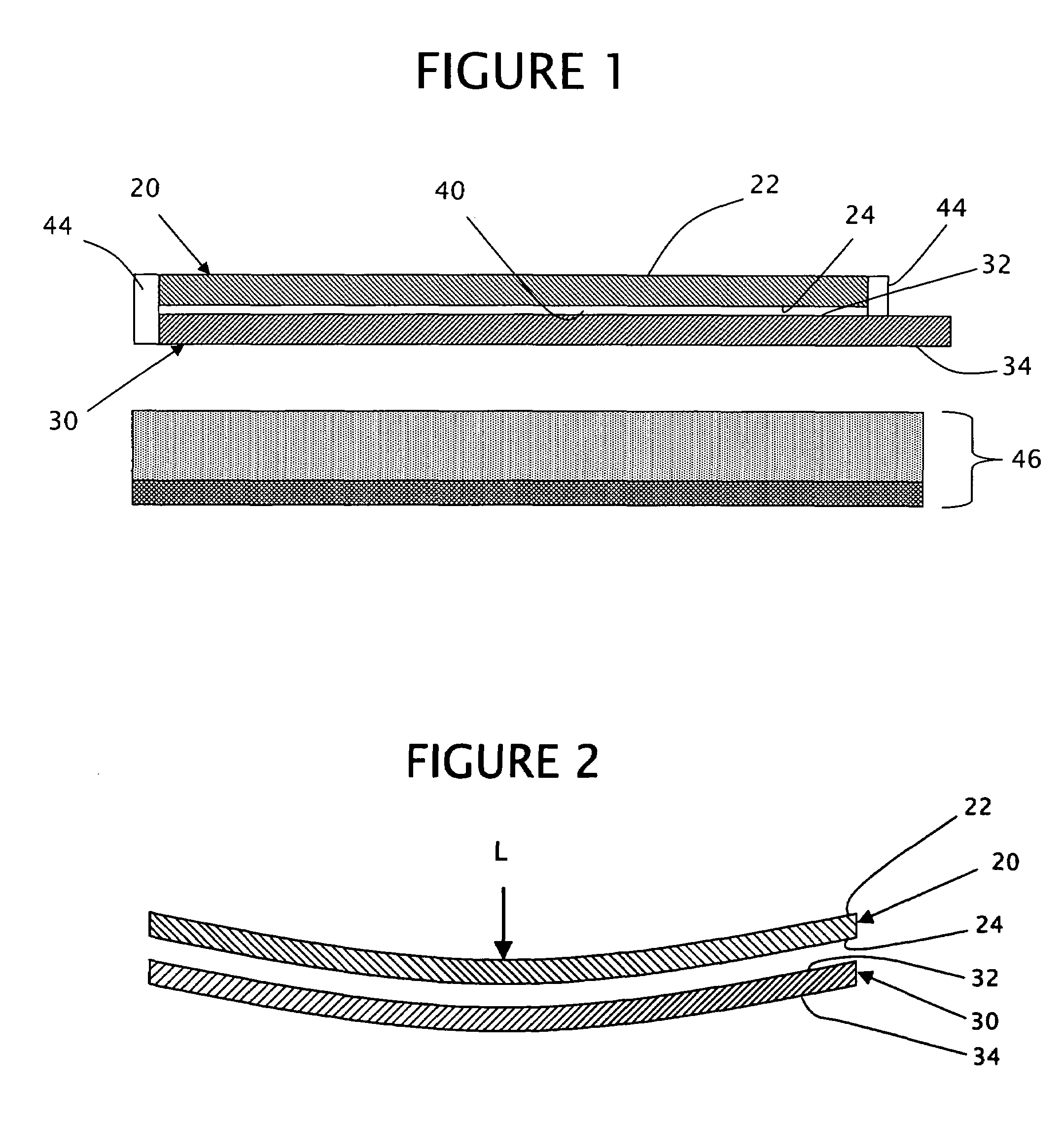

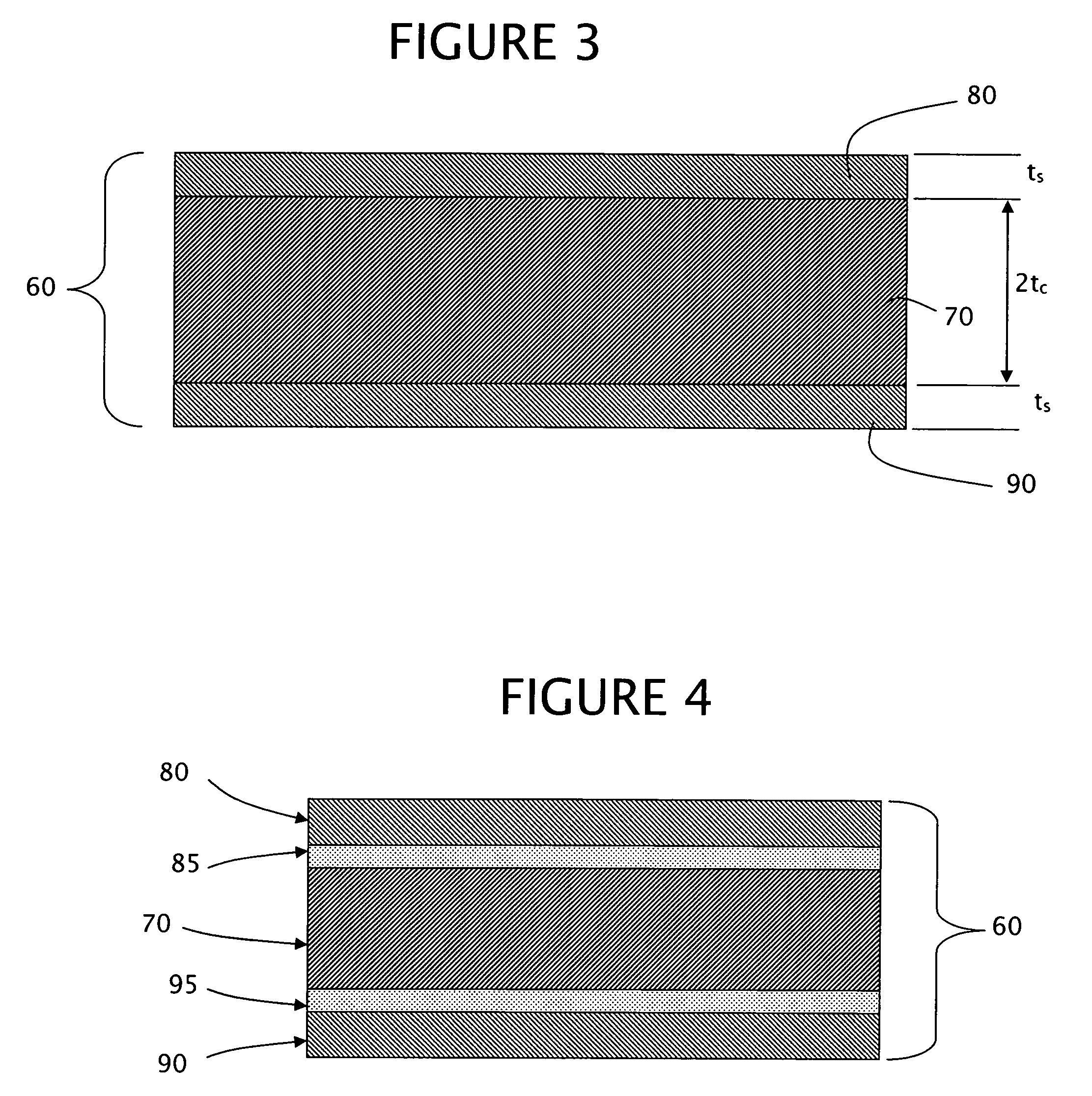

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

Glass laminate substrate having enhanced impact and static loading resistance

ActiveUS7201965B2Increased resistance to impact and static loadingImprove load resistanceLiquid crystal compositionsGas-filled discharge tubesThermal expansionFlat panel display

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

Weldable aluminum product and welded structure comprising such a product

InactiveUS6337147B1Smooth transitionReduce the amount requiredElectric discharge heatingArc welding apparatusUltimate tensile strengthAluminium alloy

Improved shape and strength of the weld in a welded structure are obtained by use of a weldable aluminum product comprising a structural component which is a sheet, a plate or an extruded body and is made of an aluminum alloy containing not more than 1.5 wt % Zn. This component has, adhered on at least one side, a cladding layer made of an AA7xxx-series alloy having a corrosion potential lower than that of the alloy of the structural component. The alloy of the structural component is preferably an AA5xxx-series alloy containing Mg in the range 2 to 6 wt %.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

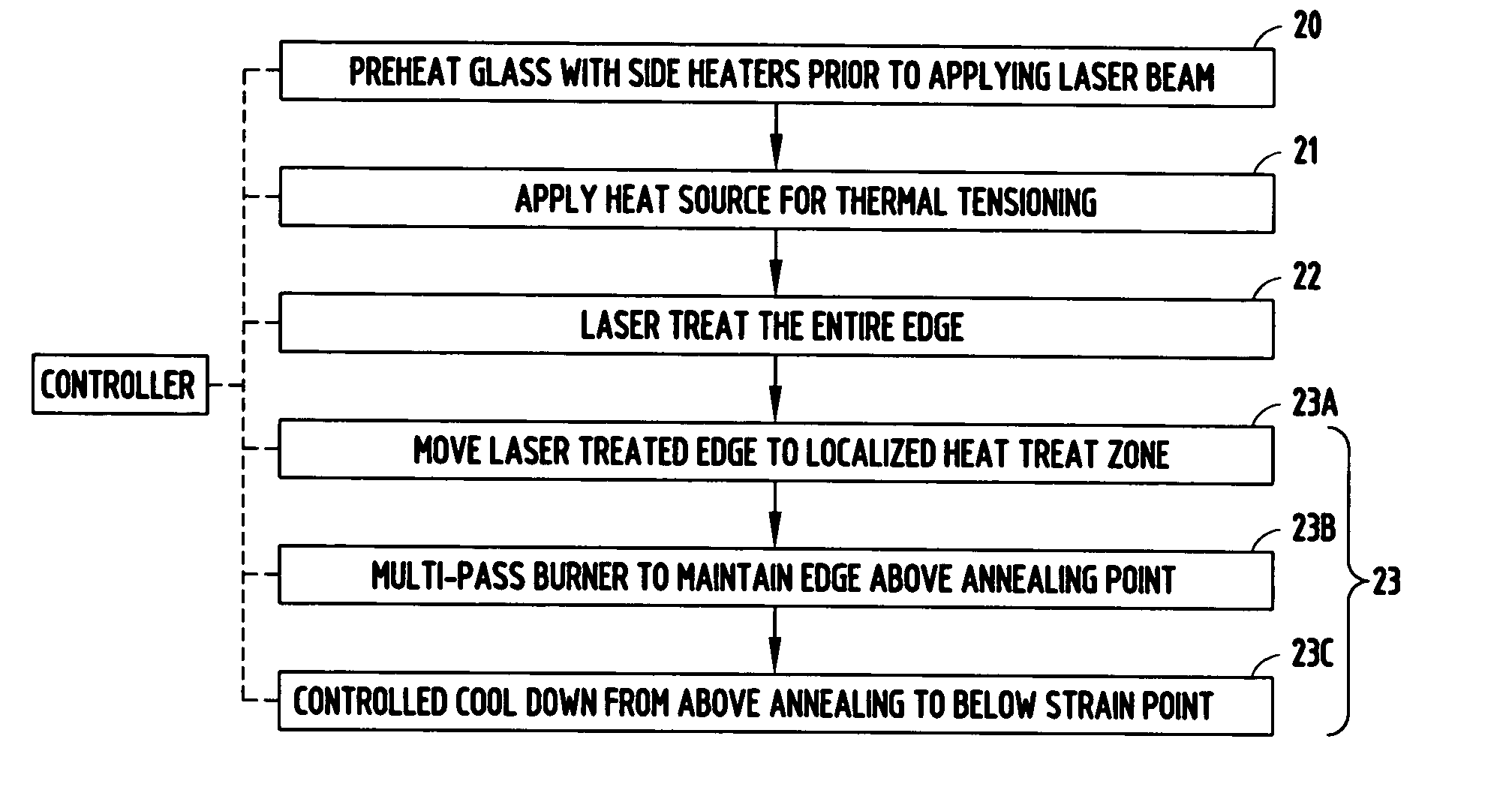

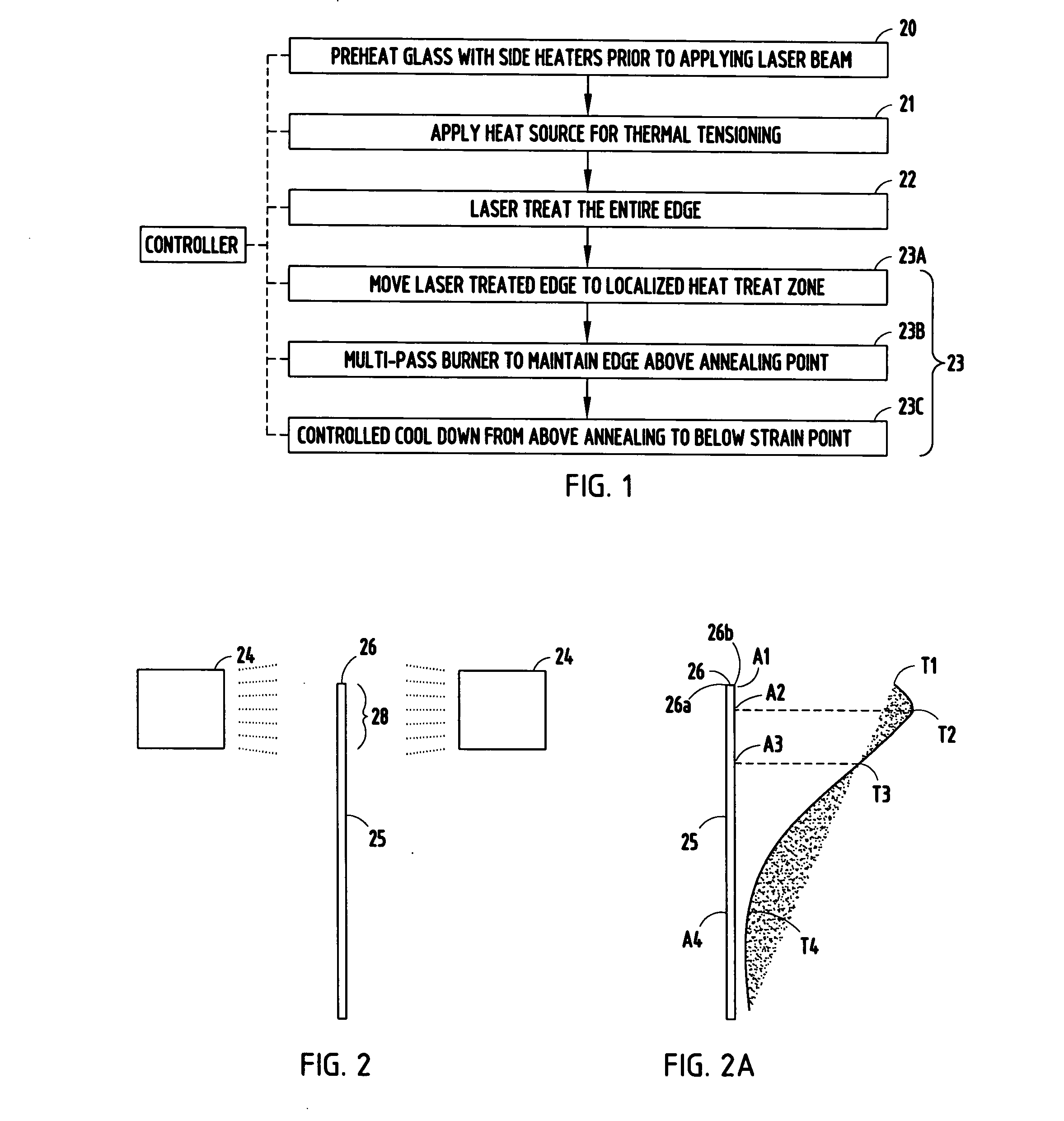

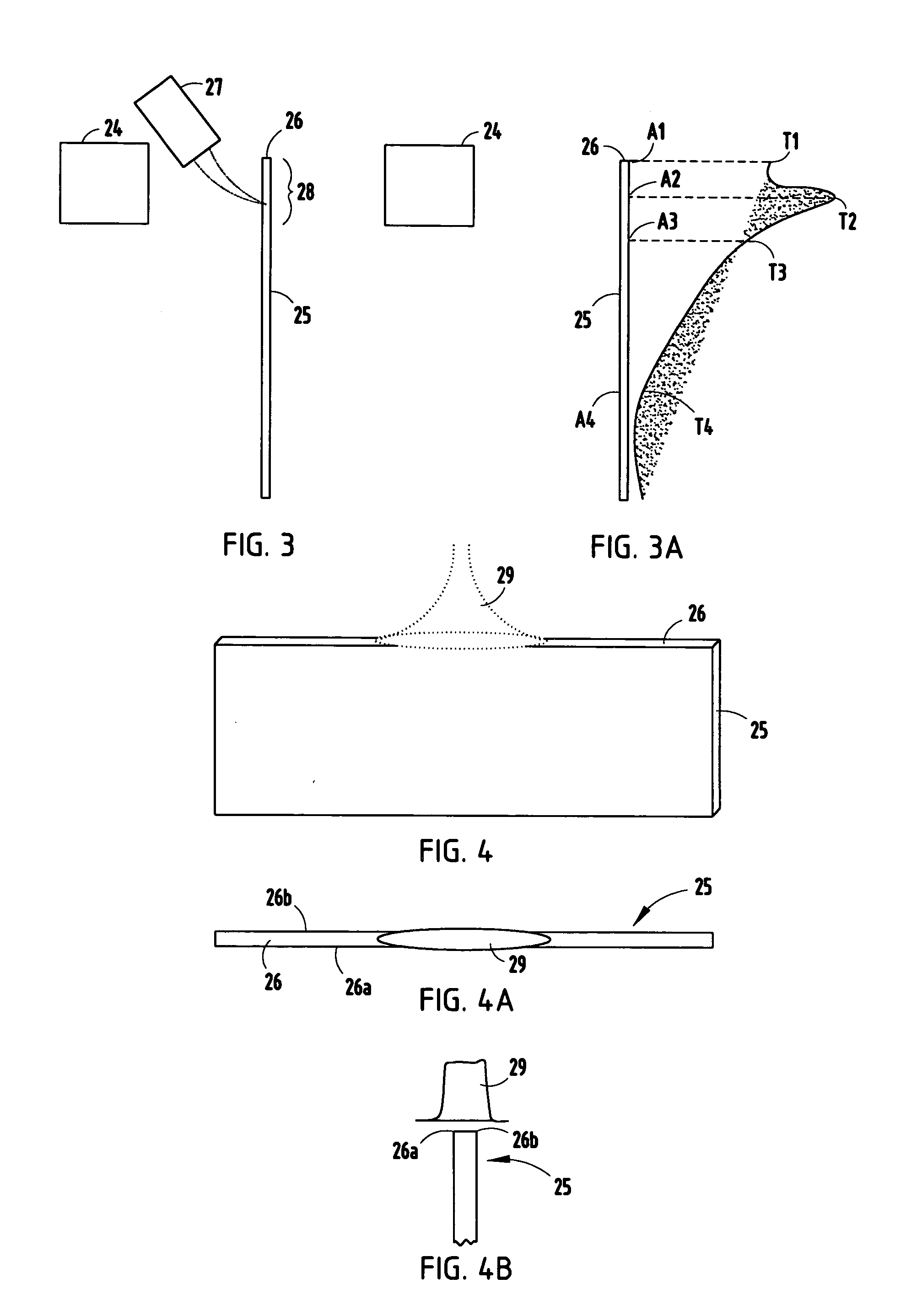

Thermal tensioning during thermal edge finishing

InactiveUS20080041833A1Reduce residual tensile stressRelieve stressGlass reforming apparatusGlass severing apparatusThermal energyThermal expansion

A thermal edge-finishing process includes pre-heating an edge of a glass sheet, focused heating inboard of the edge to cause thermal tensioning, laser finishing the edge, and localized annealing of the edge. By stress cancellation, the thermal energy added by a laser edge-finishing operation does not result in as much residual stress. By the present process, residual stress is reduced to below 3000 psi, and more preferably to about 1000 psi, and as low as 600 psi in the first 1 mm along the treated edge.

Owner:CORNING INC

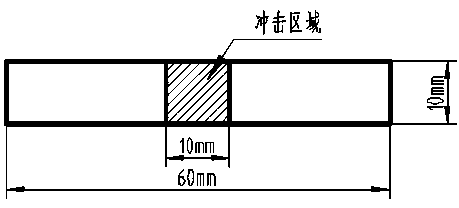

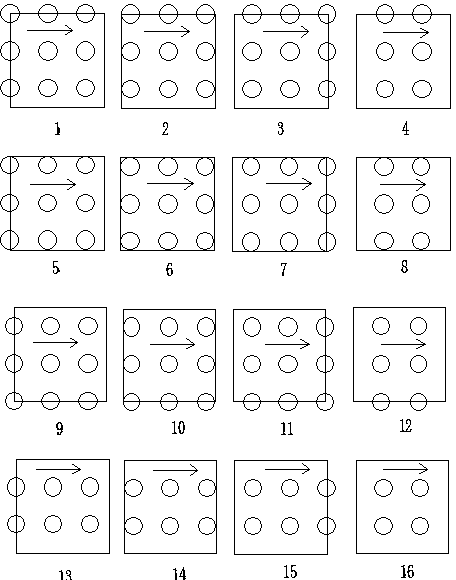

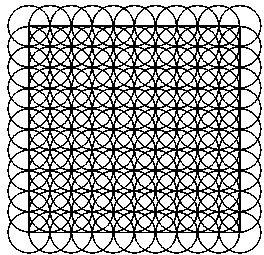

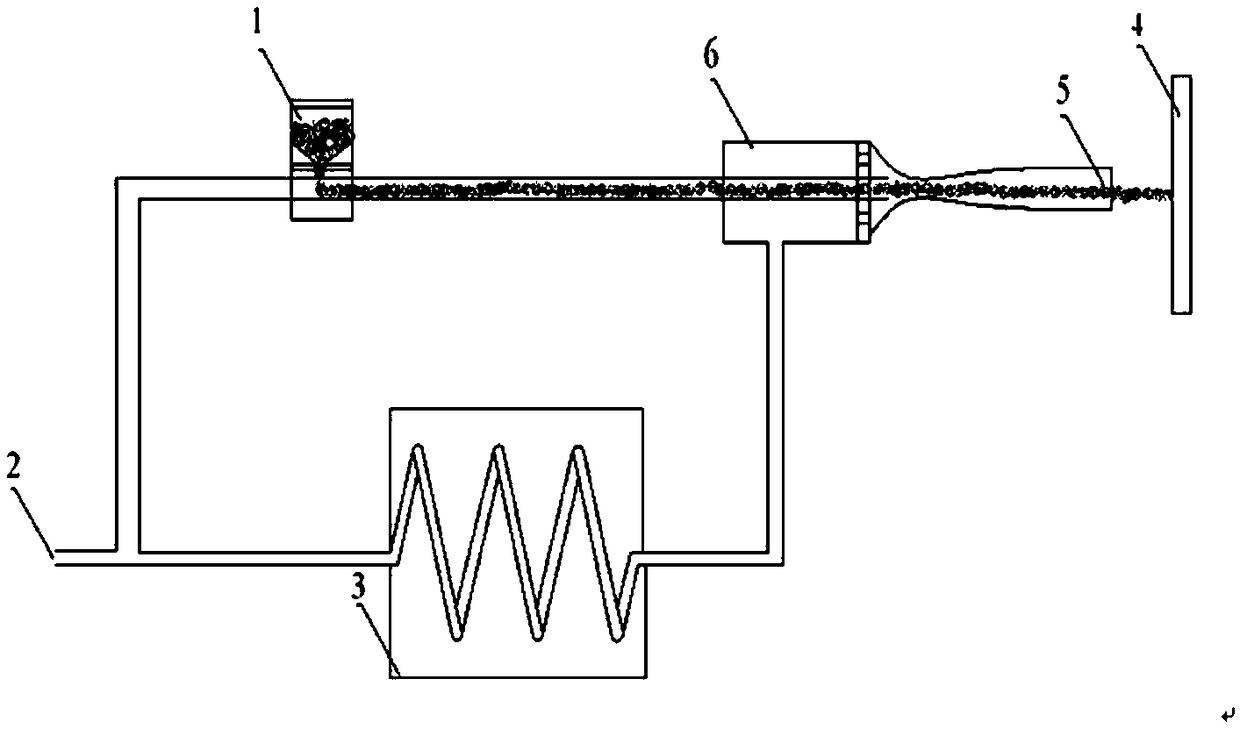

Method for reinforcement of metal surface by large area laser shock

InactiveCN104164554AReduce residual tensile stressHigh bending fatigue strengthLaser processingMetal

The invention relates to the field of laser processing, and in particular relates to a method for reinforcement of metal surfaces by large area laser shock. The invention adopts laser shock reinforcement for interval shocks on the surface of a workpiece according to a certain trajectory, and large area lap connection shock on the workpiece can be achieved by multilayer stacking. The method can effectively reduce the residual tensile stress generated in the shock region boundary during the laser shock reinforcement, meanwhile avoids the absorption layer destruction and workpiece warpage, and can obtain a uniformly distributed shock reinforcement effect.

Owner:JIANGSU UNIV

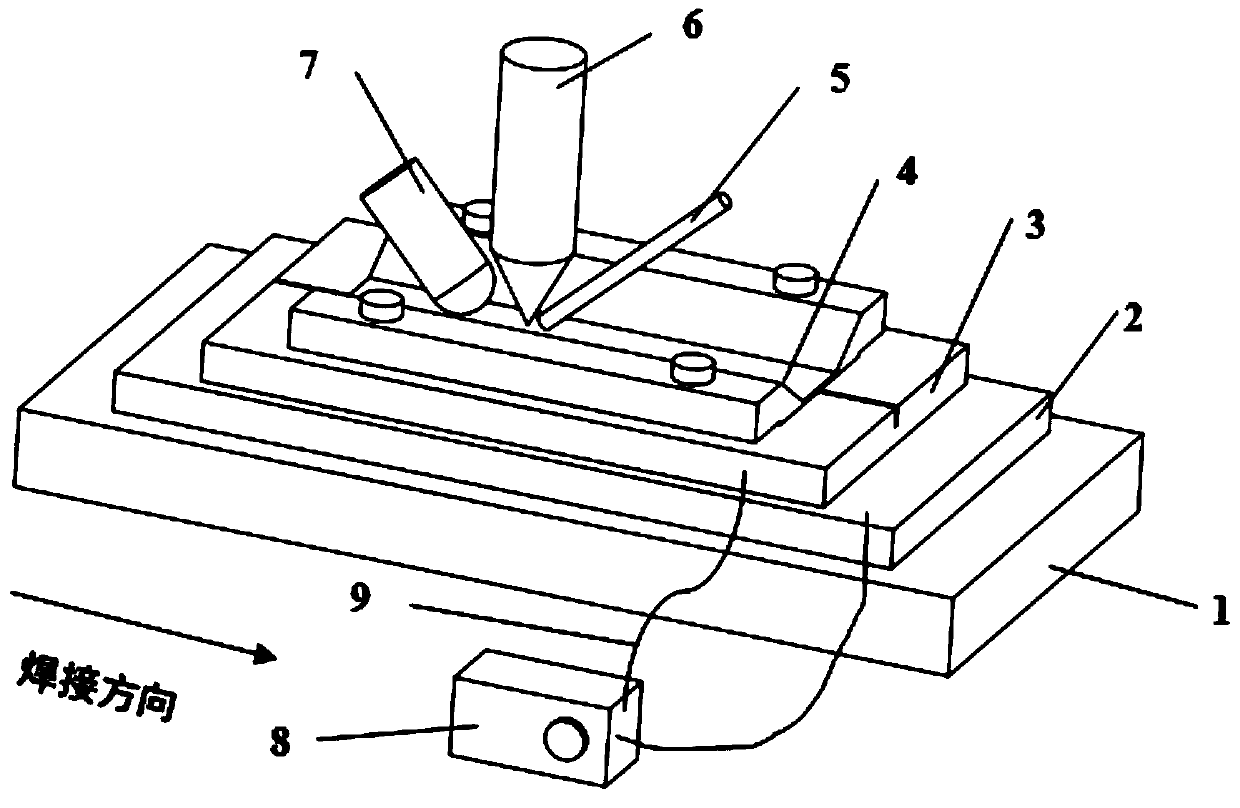

Laser welding method for ultrasonic vibration along with welding

ActiveCN109759700AReduce residual stressReduce stress concentrationLaser beam welding apparatusMetalWelding joint

The invention relates to a laser welding method for ultrasonic vibration along with welding, and belongs to the field of welding. According to the method, preheating is applied in the welding process,and ultrasonic vibration is applied to the front side of a weld joint at a certain distance behind a molten pool; a corresponding relation exists between the preheating temperature T and the distanced from the top end of an ultrasonic head to the welding position, wherein the relation expression is as follows: T is equal to 30d-40, the unit T is DEG C, and the unit d is mm; and the position, thepower and the force of ultrasonic application are adjusted according to the mechanical property of materials under the preheating temperature. According to the laser welding method, the welding residual stress can be effectively reduced, pores and cracks are reduced, and thus the fatigue performance of the weld joint is improved, and the welding deformation is reduced. By adopting the method, thetemperature gradient in the cooling process can be effectively reduced, and the residual stress is reduced; and the plasticity of the ultrasonic application area can be improved, and the ultrasonic effect is better. The ultrasonic impact can effectively reduce residual stress, refine crystal grains and reduce pores and cracks, and thus the fatigue performance of the weld joint is improved; and the metal plastic extension of the weld joint can effectively reduce the welding deformation.

Owner:DALIAN UNIV OF TECH

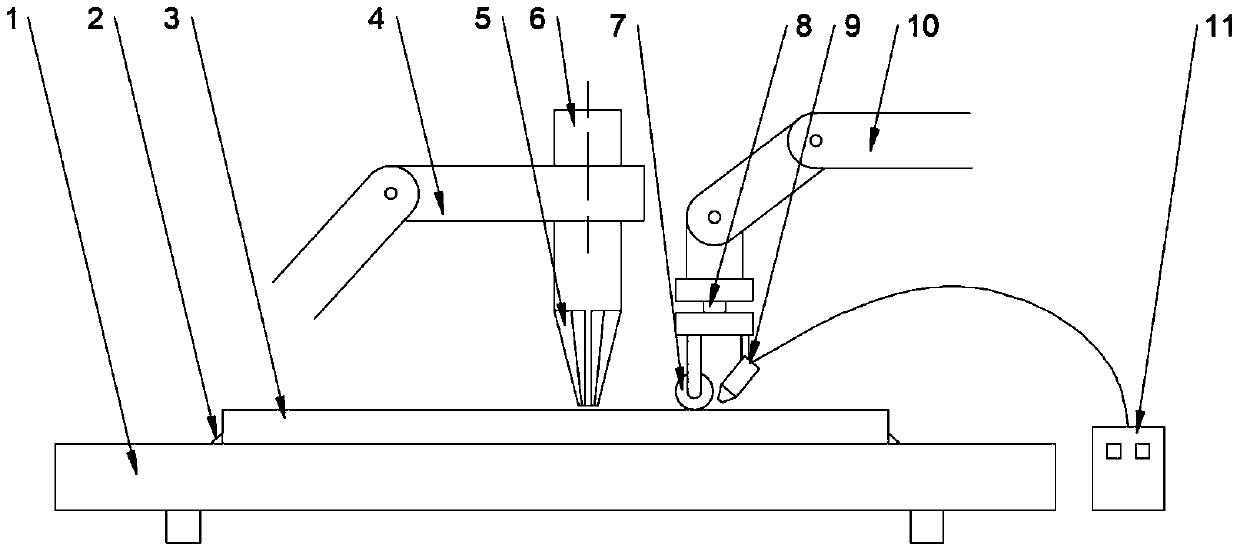

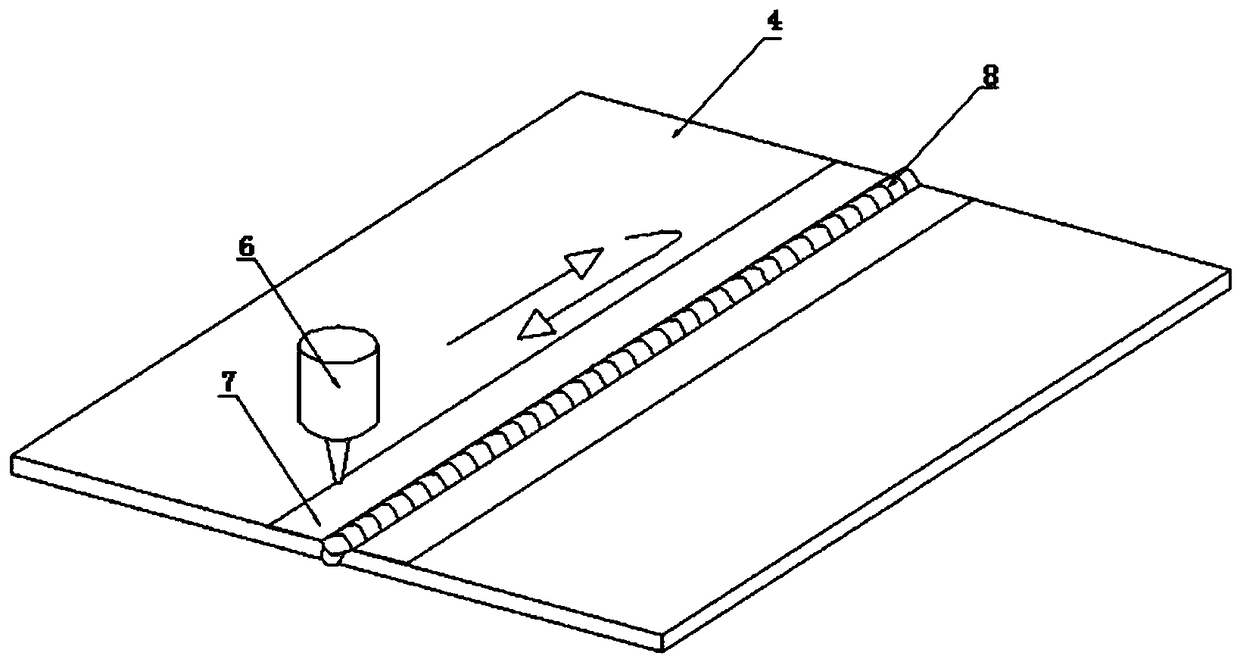

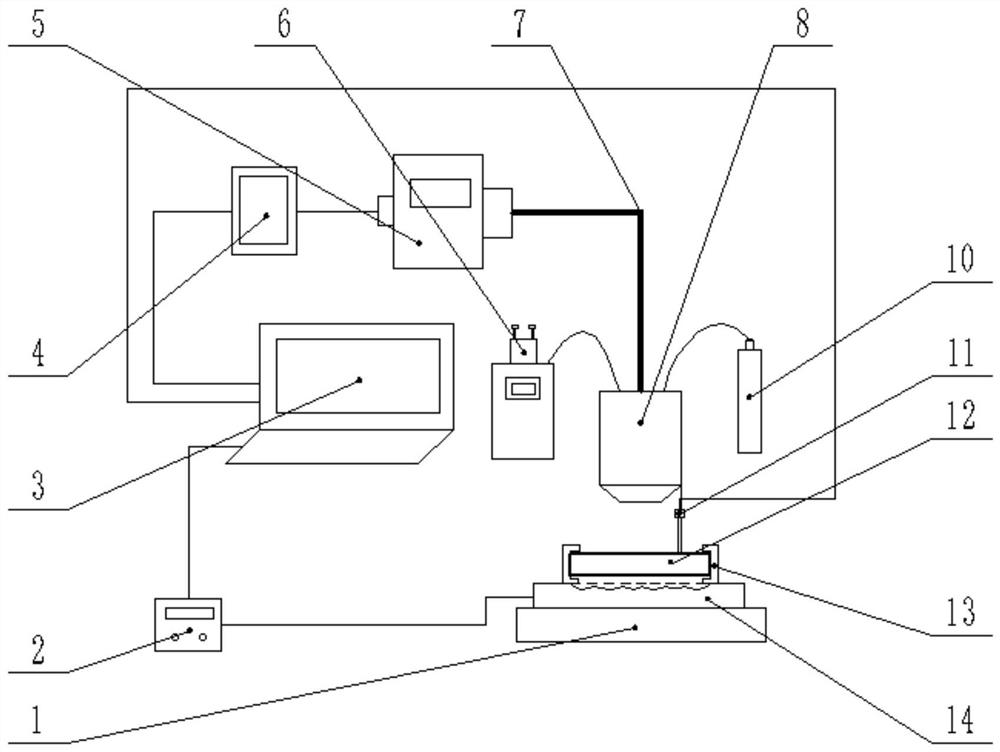

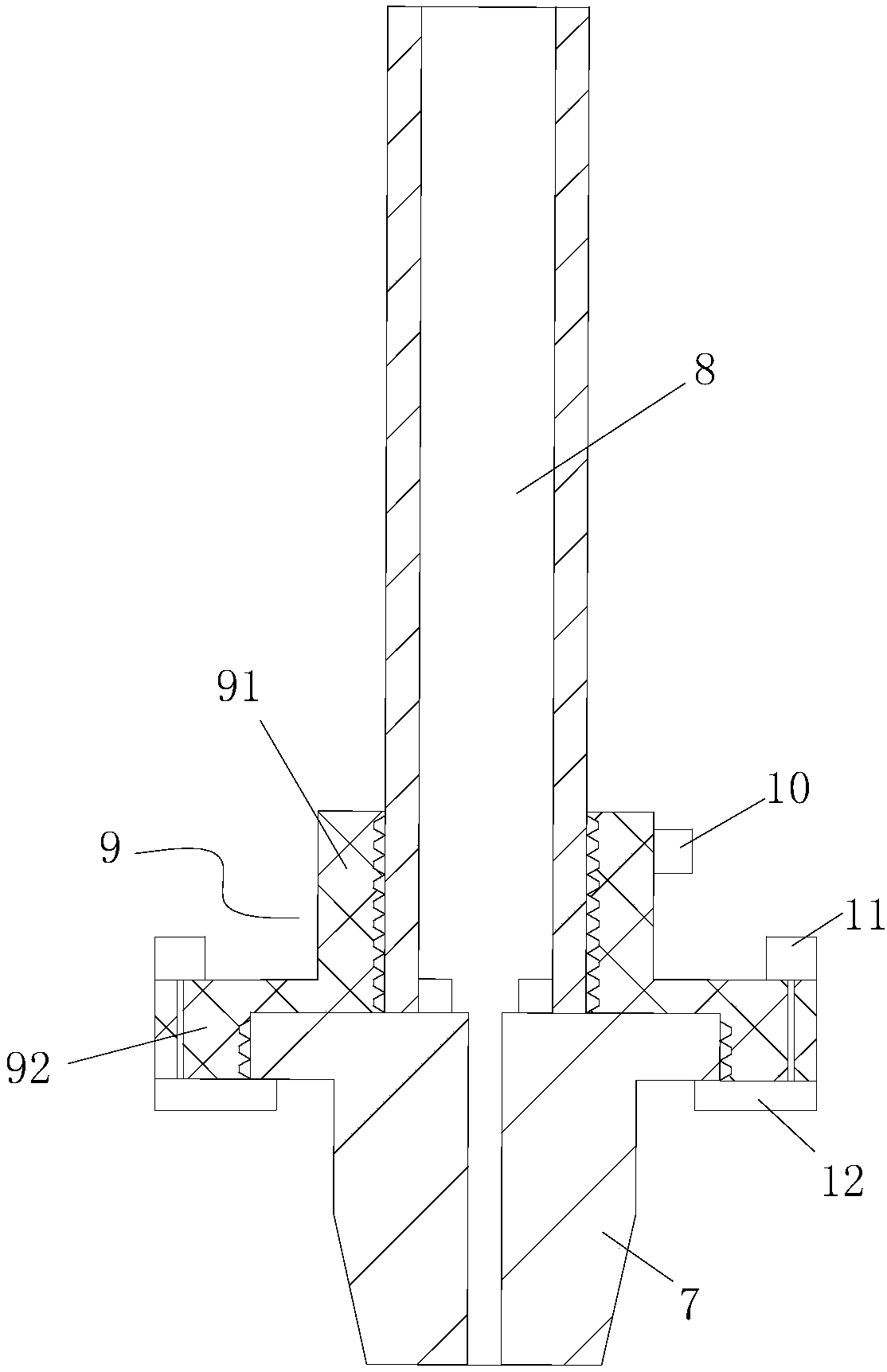

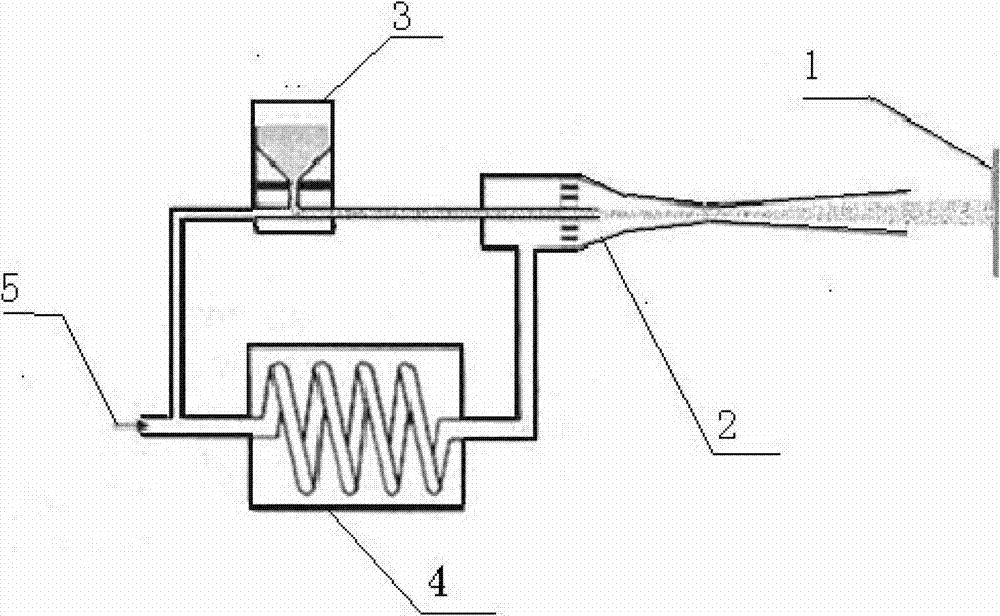

Micro rolling and ultrasonic-assisted laser cladding device

PendingCN110643996AEliminate residual tensile stressReduce residual tensile stressMetallic material coating processesLaser scanningEngineering

The invention relates to a micro rolling and ultrasonic-assisted laser cladding device, in particular to strengthening to the surface of a cladding layer. The device comprises a workbench, a fixed check block, a workpiece, a first mechanical arm, a synchronous powder feeder, a laser device, a micro roller, a rotating device, an amplitude-change pole, a second mechanical arm and an ultrasonic generator. During laser cladding, the micro rolling technology and the ultrasonic technology are used for assistance, and adverse effects left during pure laser scanning can be eliminated to the largest degree by means of the combination. By means of micro rolling, dendritic crystalline lenses generated during cooling of the cladding layer are ground through the micro roller, the crystal structure is refined, and air pores are effectively suppressed. By means of the ultrasonic technology, residual tension generated during temperature decrease of the cladding layer is eliminated, and cracks are effectively reduced. The micro rolling technology and the ultrasonic technology are applied to the laser cladding layer, and compactness, isotropy and other properties of the cladding layer are further improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for reducing residual stress of metal structure material fusion welding joint

InactiveCN108838904AReduce or eliminate residual tensile stressStrong load bearing capacityEdge grinding machinesBlast gunsHigh pressureNitrogen gas

The invention provides a method for reducing residual stress of a metal structure material fusion welding joint. According to the method, heated gas and high-speed particle flows are utilized to simultaneously impact a weld joint area and the part near the weld joint area, the pressure stress is generated on the surface of the joint, so that the stress distribution is improved, the fatigue strength of the joint is improved, and the service life of the joint is prolonged; the size of the impact particles mostly ranges between 10 microns and 100 microns, the acceleration of the particles can berealized through high-pressure compressed gas (helium, nitrogen or compressed air), the gas pressure generally ranges from 1.5 MPa to 3.5 MPa, and the particle speed can reach the speed ranging from 400 m / s to 1000 m / s; in addition, the gas can be preheated according to requirements, and the preheating temperature generally ranges from 200 DEG C to 600 DEG C; in the method, the high-speed particleimpact effect and the hot gas impact effect are combined so that the residual tension of a component can be effectively reduced or eliminated, the mechanical property of the joint can be improved, and the service life of the component can be prolonged; and the method can be used for regulating and controlling the residual stress of the metal structure material fusion welding joint, and can also be used for improving the residual stress distribution of various welding joints of other materials, so that the safety and reliability of the joint are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

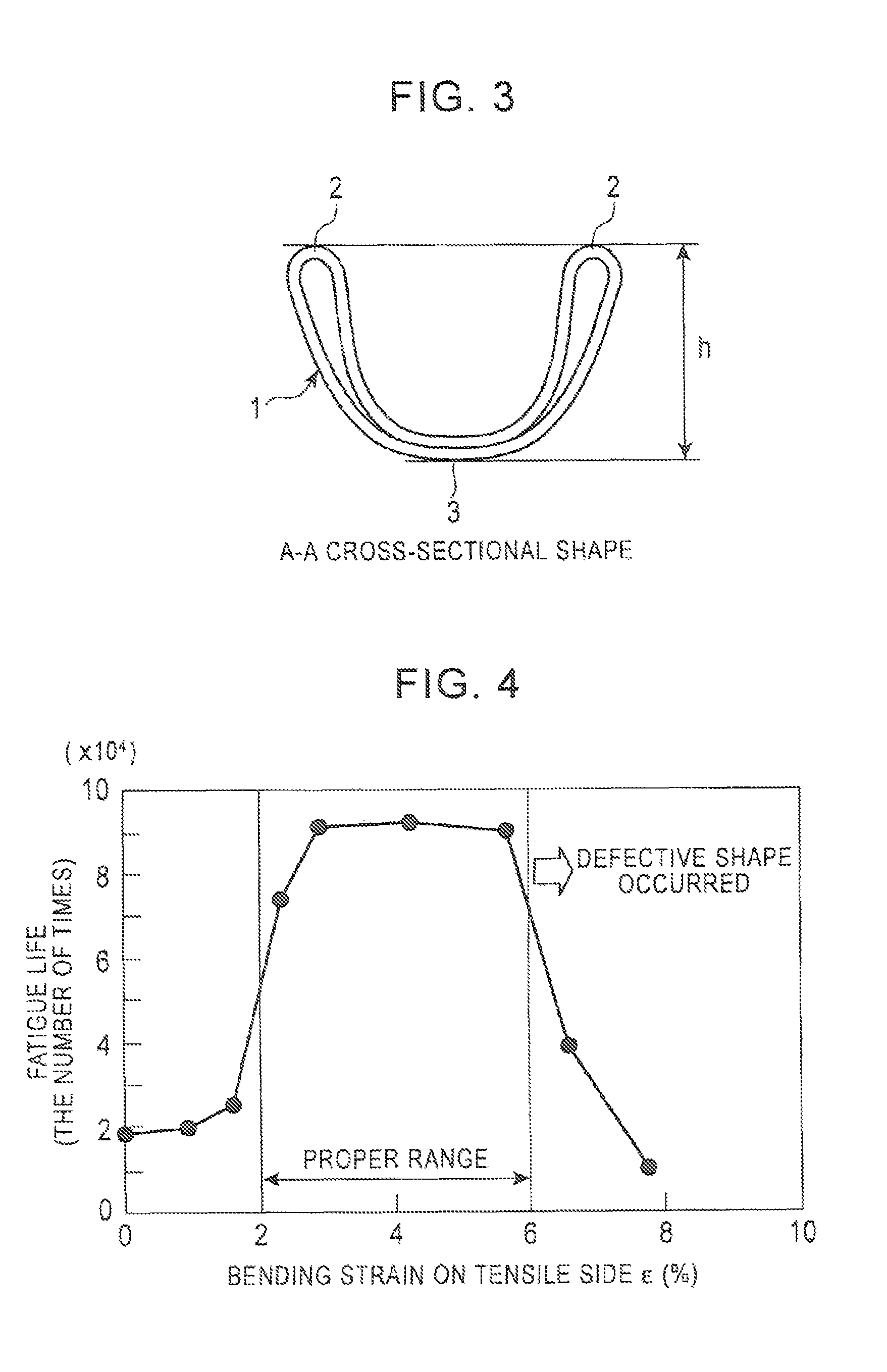

Torsion beam manufacturing method and torsion beam

ActiveUS8505941B2Improve fatigue strengthHigh riskMetal-working apparatusInterconnection systemsProduction rateEngineering

A method enhances fatigue strength of ear portions which are high fatigue risk parts in a torsion beam almost without bringing about disadvantages in terms of productivity and cost. A torsion beam is formed with a portion of the tubular body into an approximately U-shape in cross section by crushing the portion of the tubular body in the radial direction and, thereafter, due to bending with a bottom line set as a belly side of bending, a bending strain of 2 to 6% in the tube longitudinal direction on a tensile side is imparted to the ear portions.

Owner:JFE STEEL CORP

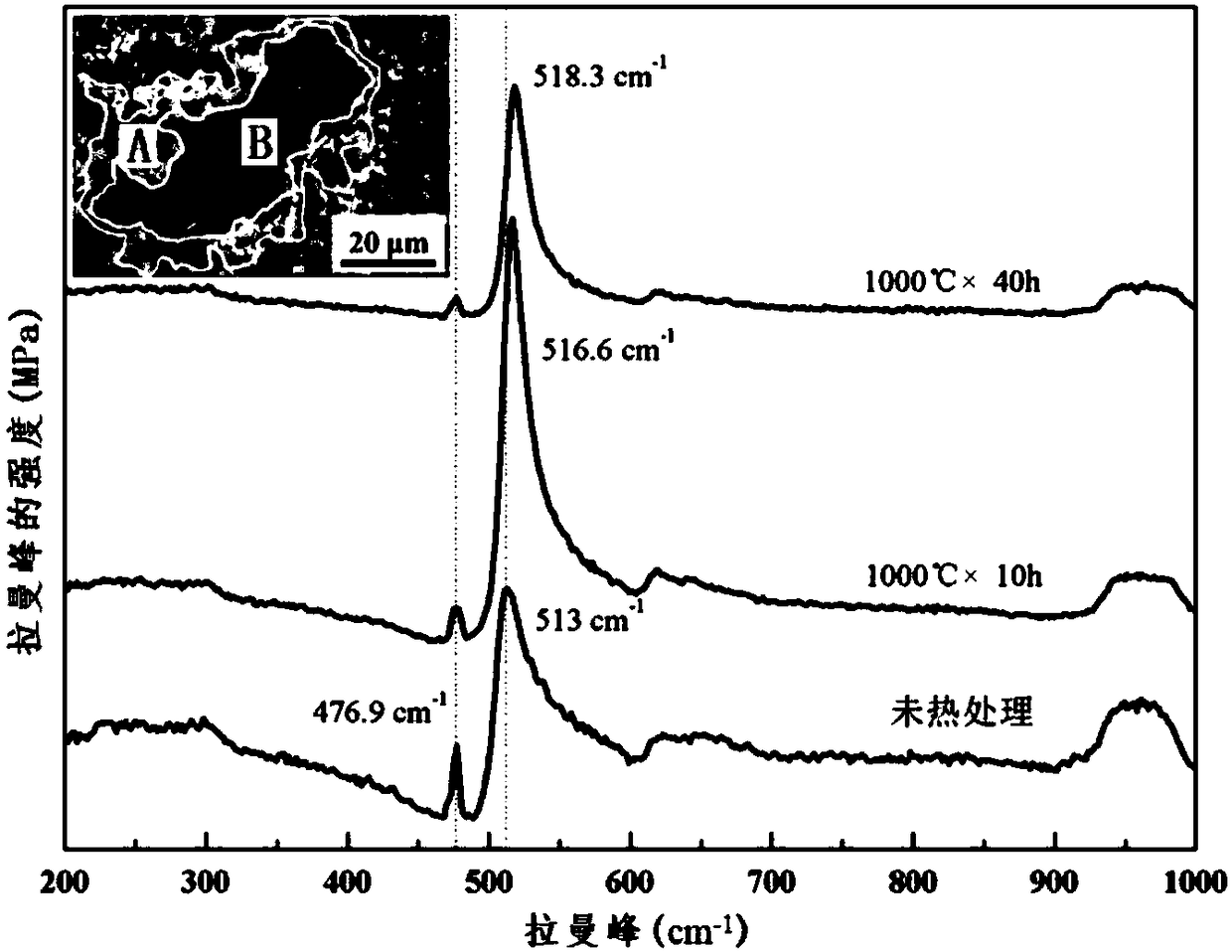

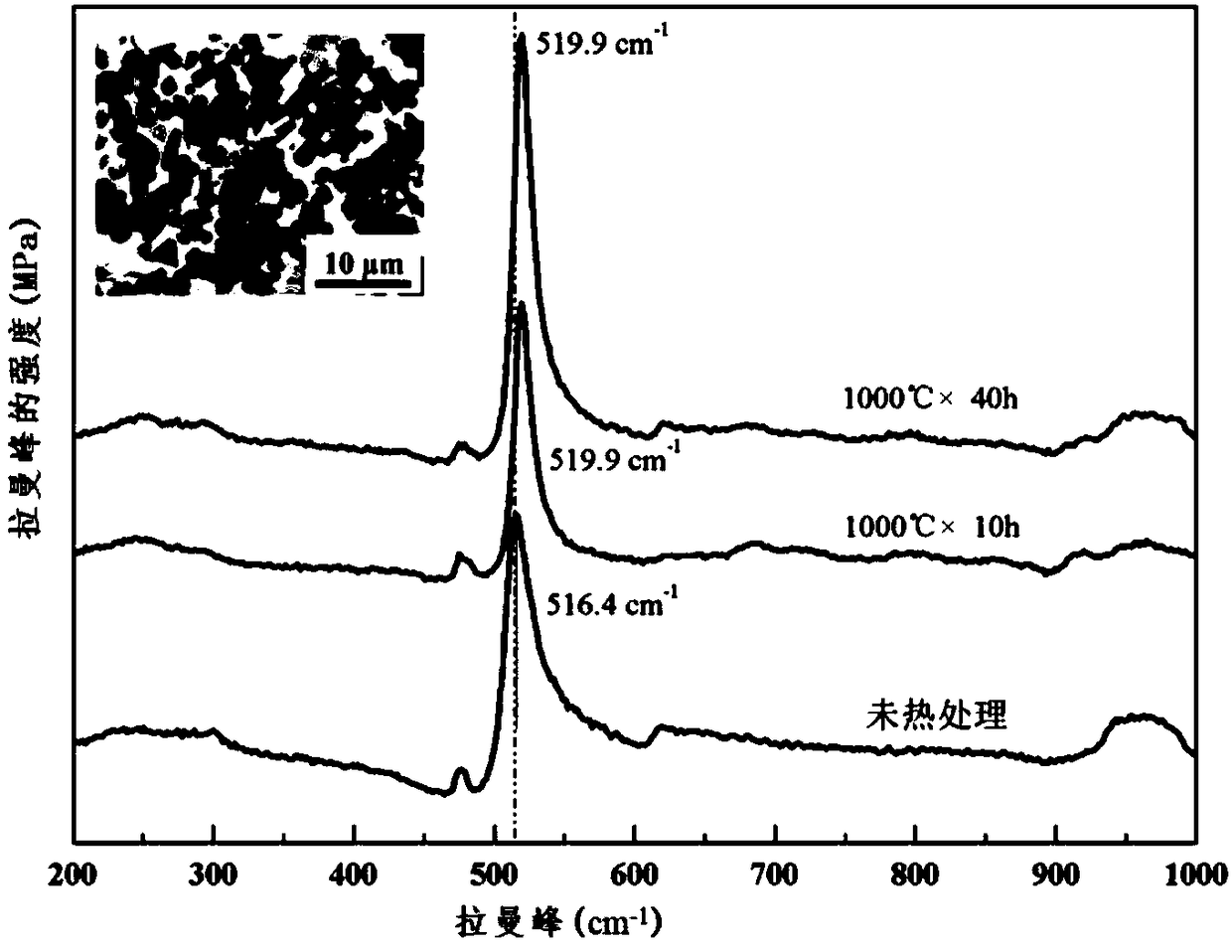

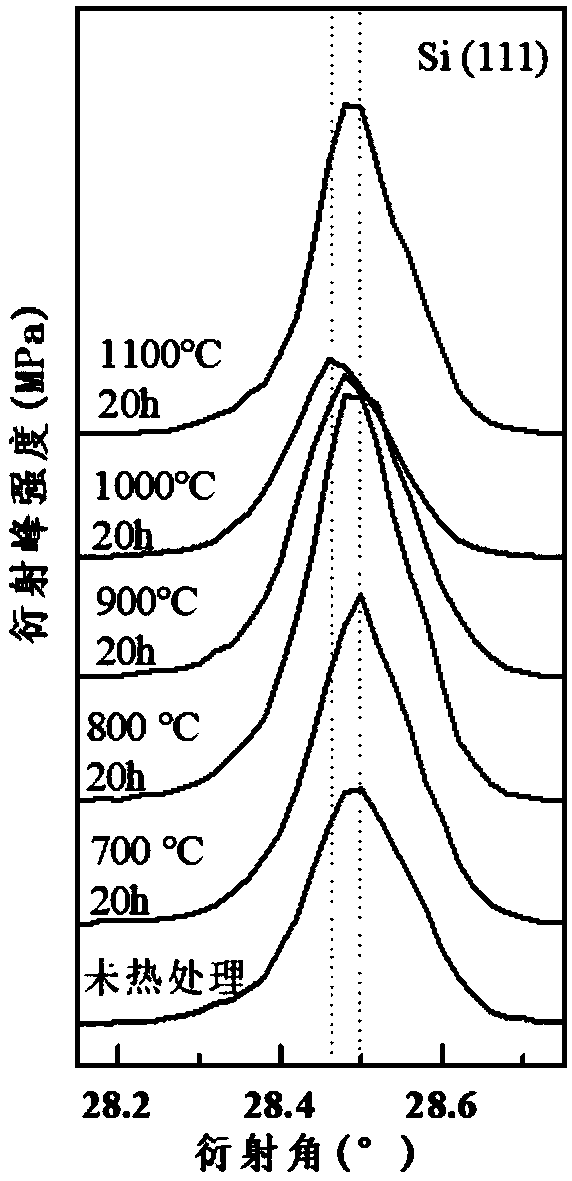

Preparation method of boron carbide ceramic composite material

The invention relates to a preparation method of a boron carbide ceramic composite material. The method includes the steps of S1, performing wet mixing on boron carbide powder, a carbon source and a mixing medium to obtain a mixed material, drying, grinding, and sieving to obtain a material for mould pressing; S2, performing compression molding on the material for mould pressing, and drying to obtain a ceramic green body; S3, placing a silicon block on the ceramic green body to perform vacuum infiltration reaction sintering so as to obtain a boron carbide ceramic composite material precursor;S4, removing the residual silicon on the surface of the boron carbide ceramic composite material precursor, performing thermal treatment on the precursor in heating equipment, and cooling to room temperature to obtain the boron carbide ceramic composite material. The preparation method can lower sintering temperature, increase the compactness of the boron carbide ceramic composite material and increase the mechanical performance of the boron carbide ceramic composite material.

Owner:NORTHEASTERN UNIV

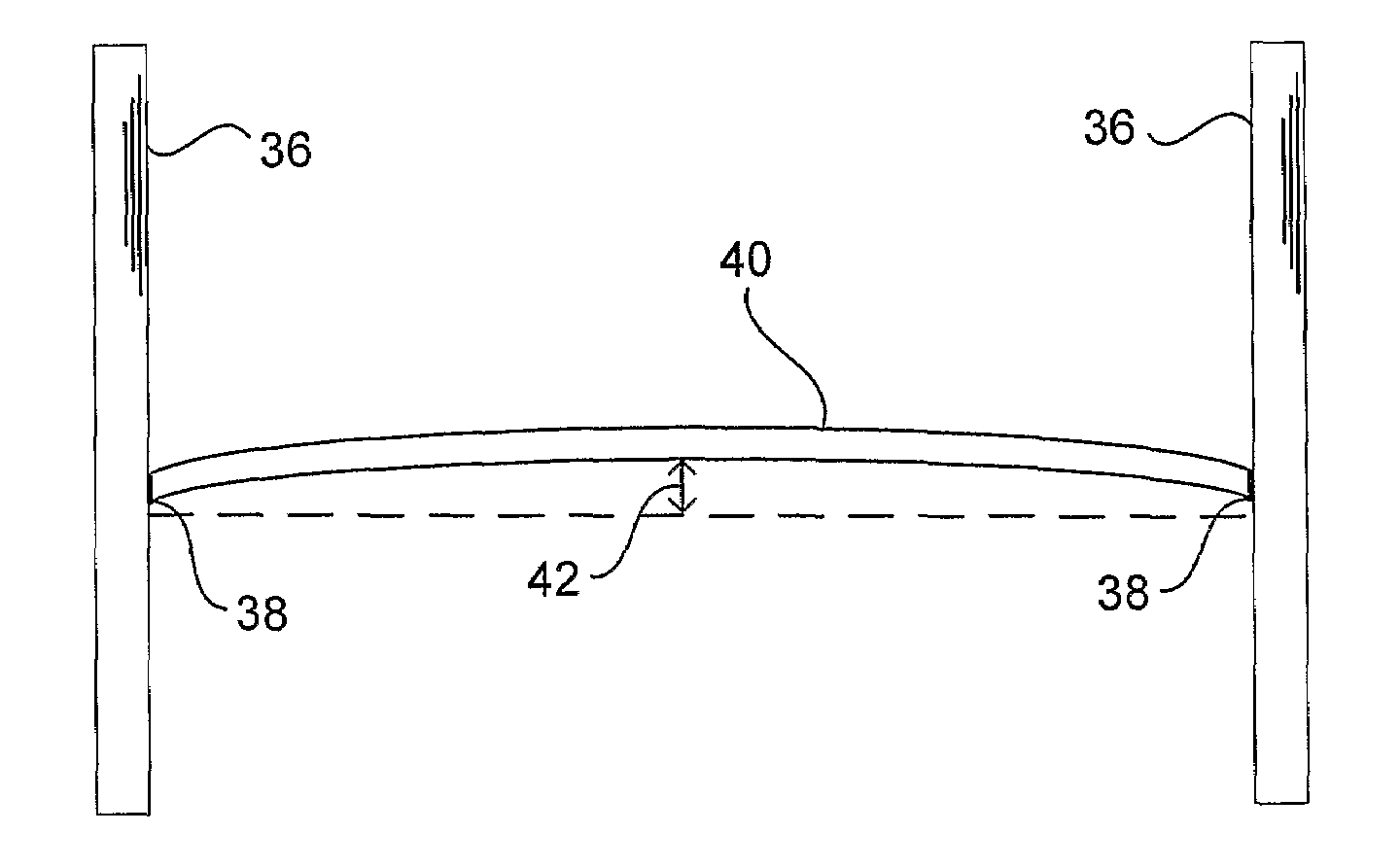

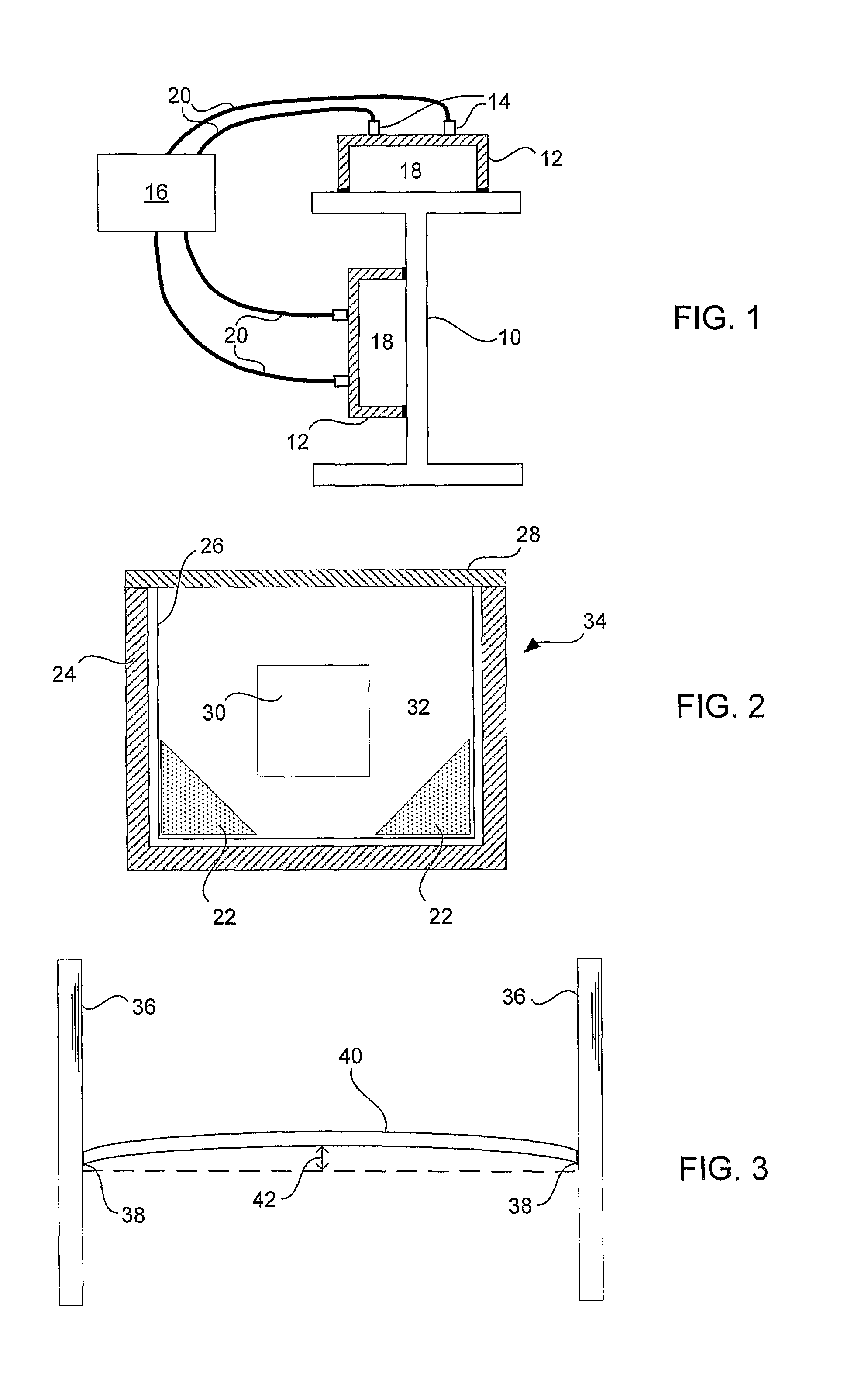

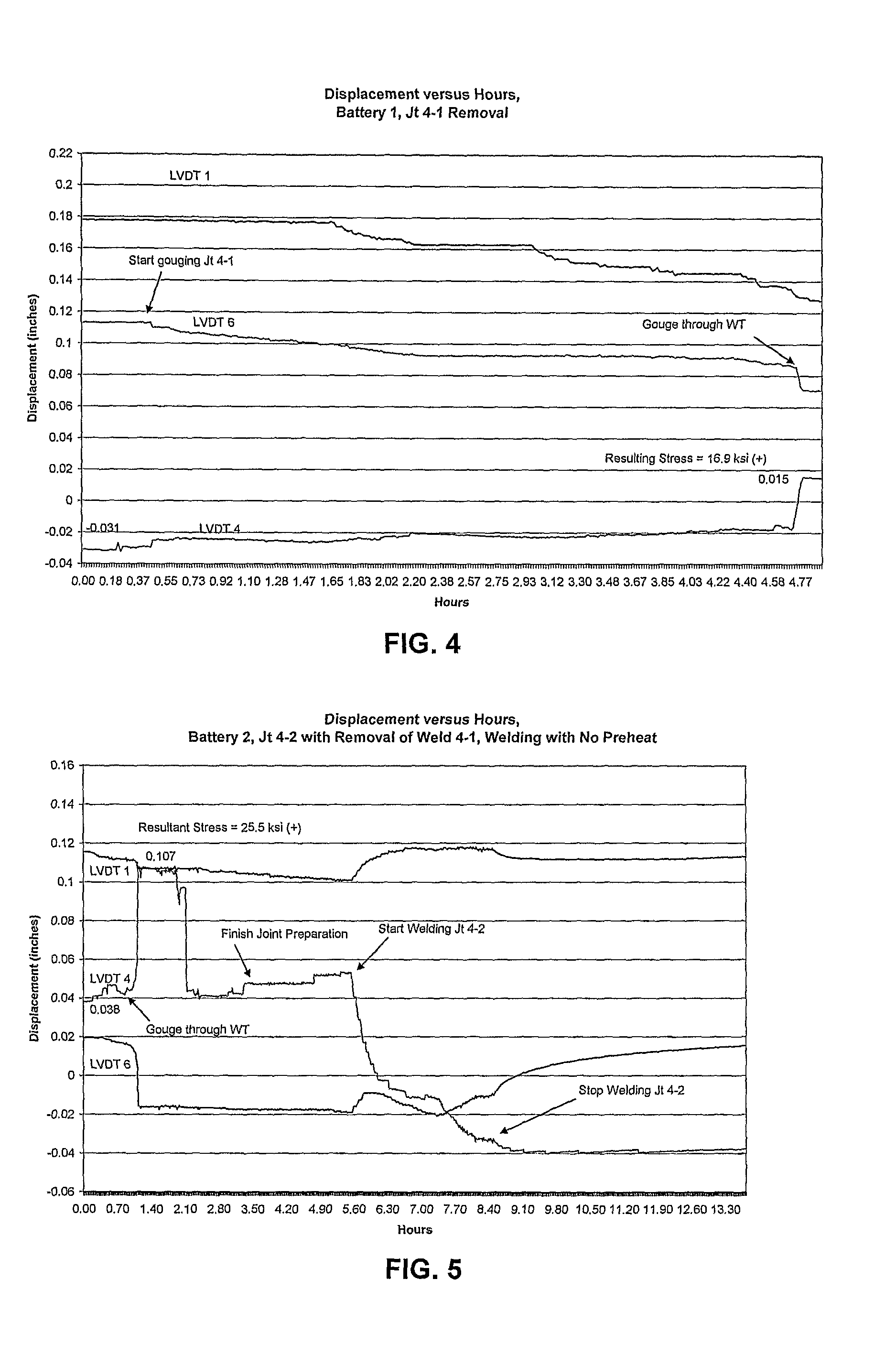

Methods and systems for mitigating residual tensile stresses

ActiveUS7690553B2Reduce residual tensile stressReduce residual stressExhaust apparatusWelding/cutting auxillary devicesStructural deformationEngineering

Residual tensile stresses can be mitigated through methods and systems provided by the present invention. Such a method can include securing a metal member (10) to a substrate and at least partially surrounding a portion of the metal member (10) with a cooling fluid (18). As a result, the cooled portion of the metal member (10) contracts a predetermined amount. Once cooled, the metal member may be fixed, preferably welded, to another metal member in a constrained relationship. As the portion of the metal member is returned to its original temperature, expansion of the metal member acts to mitigate residual tensile stresses in the metal assembly. Tensile stress in restrained members, cambering, and structural deformation can be readily controlled in an assembled structure.

Owner:UNIV OF UTAH RES FOUND

Gradient material design process for guiding ruler liner plate used before hot-rolled strip steel coiling through laser manufacturing

ActiveCN106756251AGuaranteed binding stabilityExtended service lifeMetallic material coating processesGradient materialStrip steel

The invention discloses a gradient material design process for a guiding ruler liner plate used before hot-rolled strip steel coiling through laser manufacturing. The process is characterized in that the guiding ruler liner plate comprises a priming layer, a transition layer and a functional layer through gradient design, wherein a priming layer cladding material comprises 3.6-18% of Cr, 5-16% of Mn, 0.2-0.7% of Si, 3-8% of N, 4-18% of W, 8-19% of B and the balance Ni; a transition layer cladding material comprises 3-18% of Cr, 4-15% of Mn, 0.1-0.6% of Si, 3-8% of N, 6-16% of W, 8-15% of B and the balance Ni; and a functional layer cladding material comprises 3-16% of Cr, 5-15% of Mn, 0.1-0.5% of Si, 3-6% of N, 8-18% of W, 8-12% of B and the balance Ni. The service life of the guiding ruler liner plate is prolonged to 5-6 times that of original guiding ruler liner plates.

Owner:沈阳大陆激光工程技术有限公司

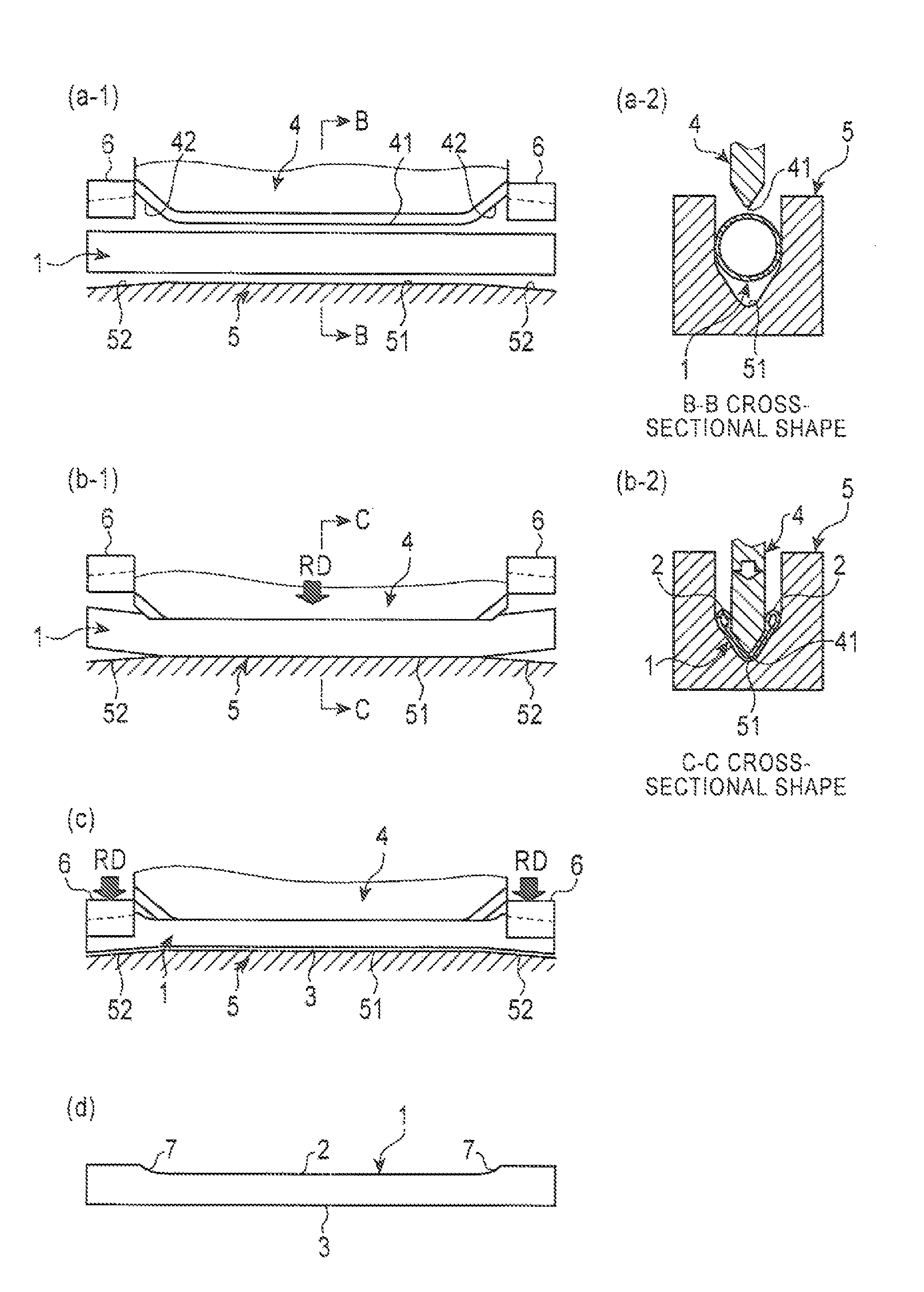

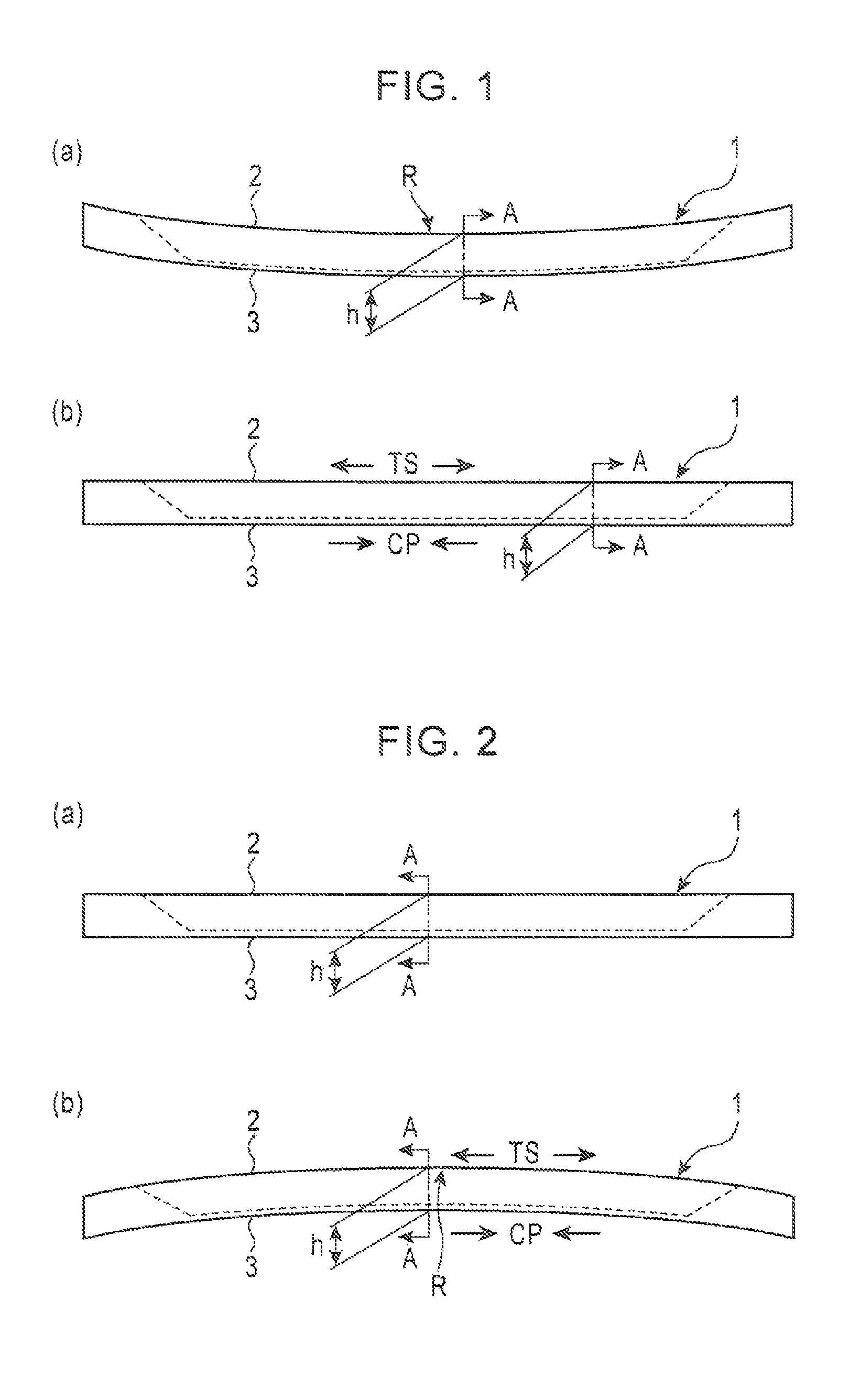

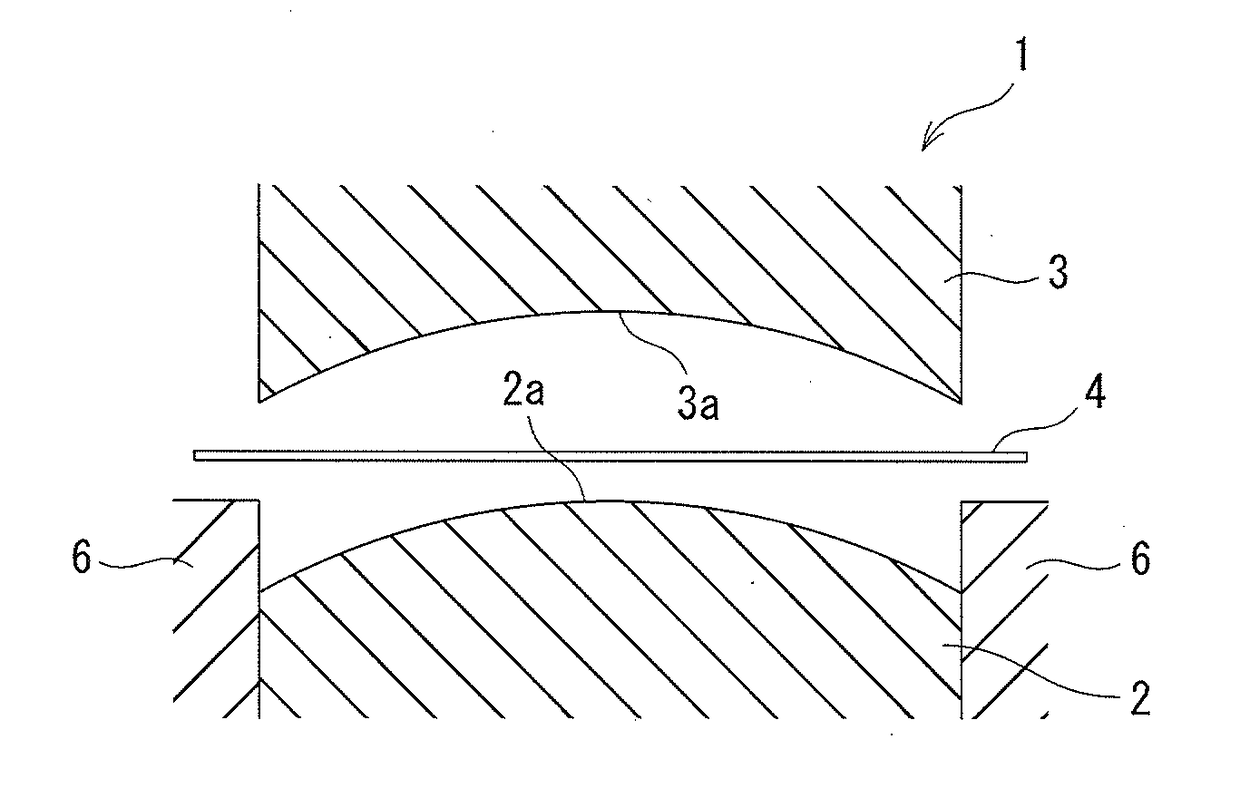

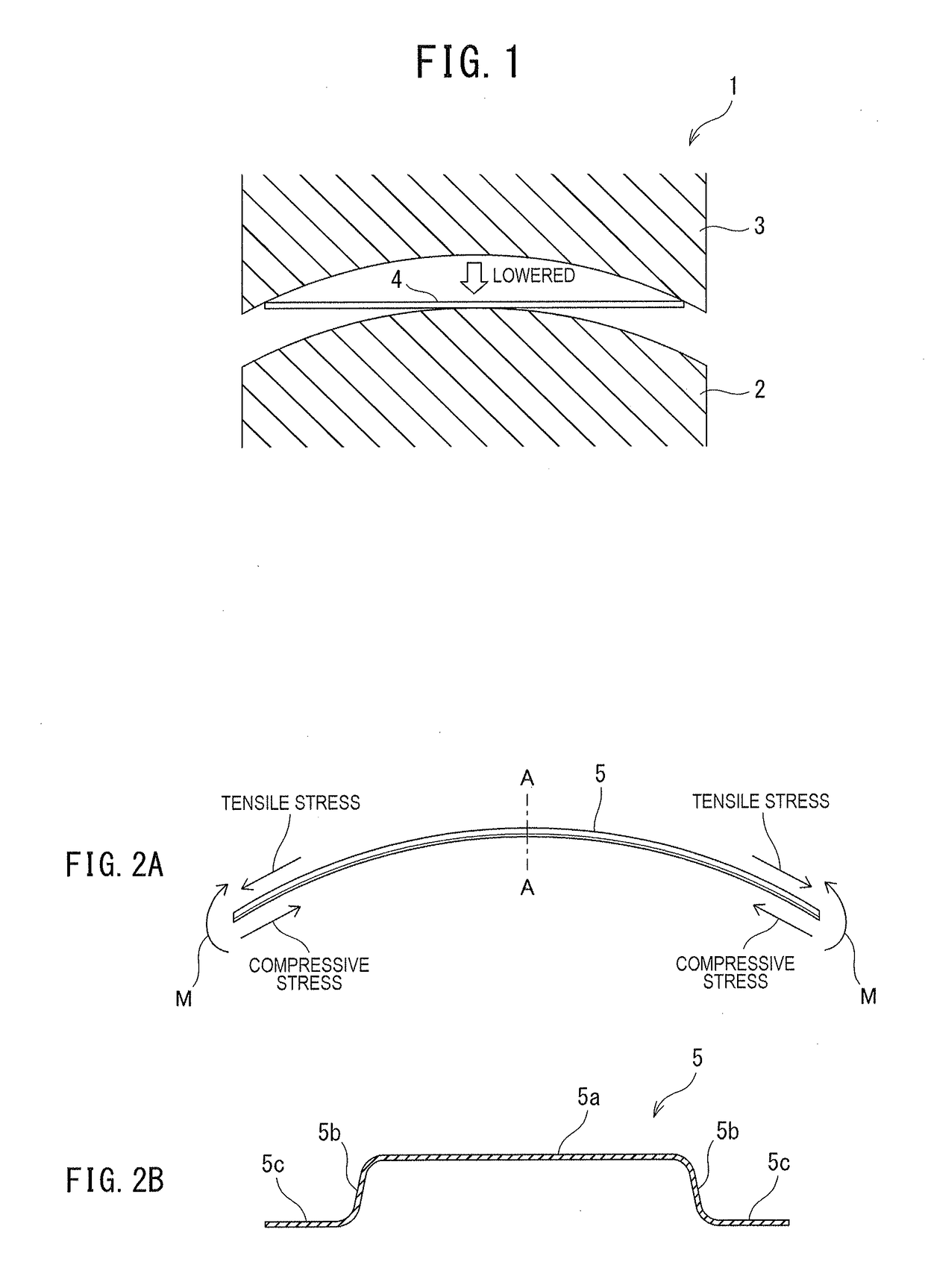

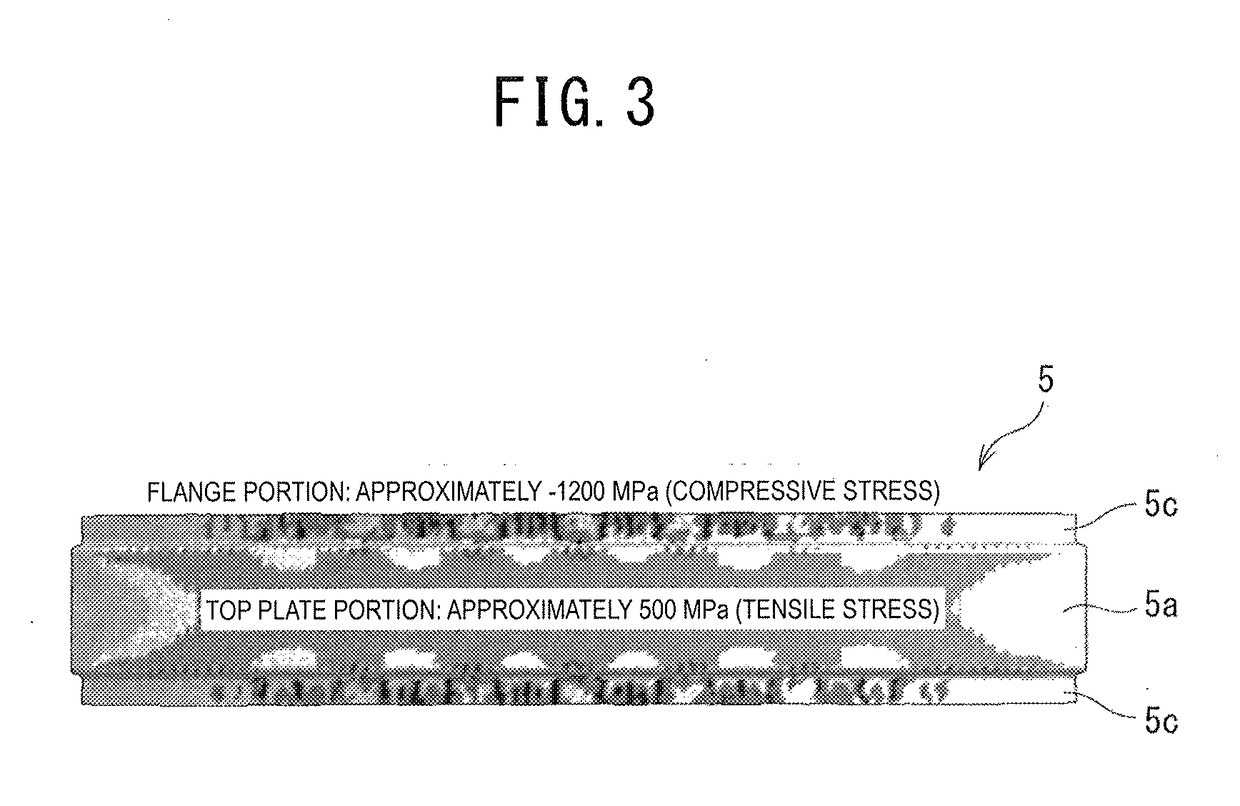

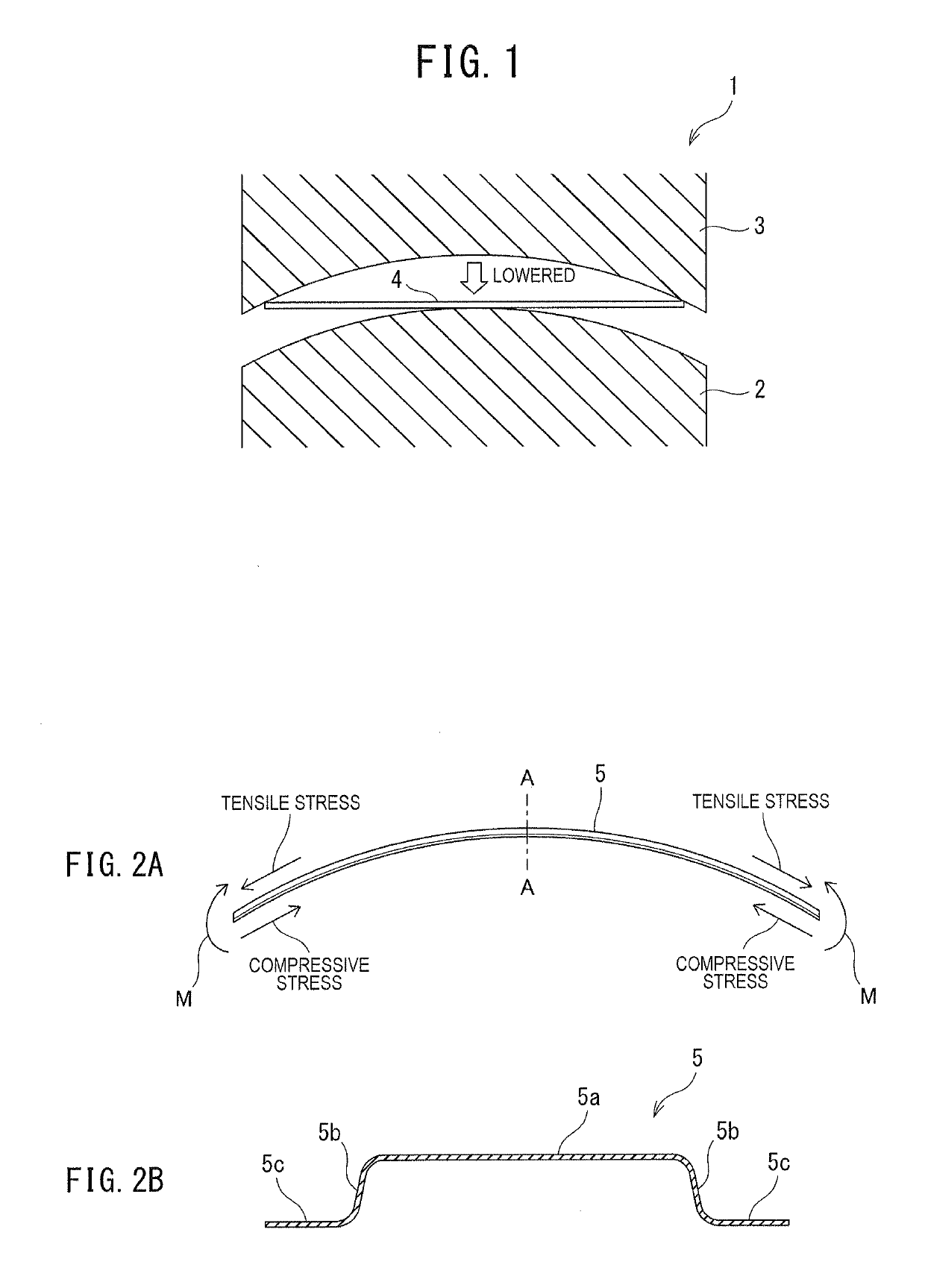

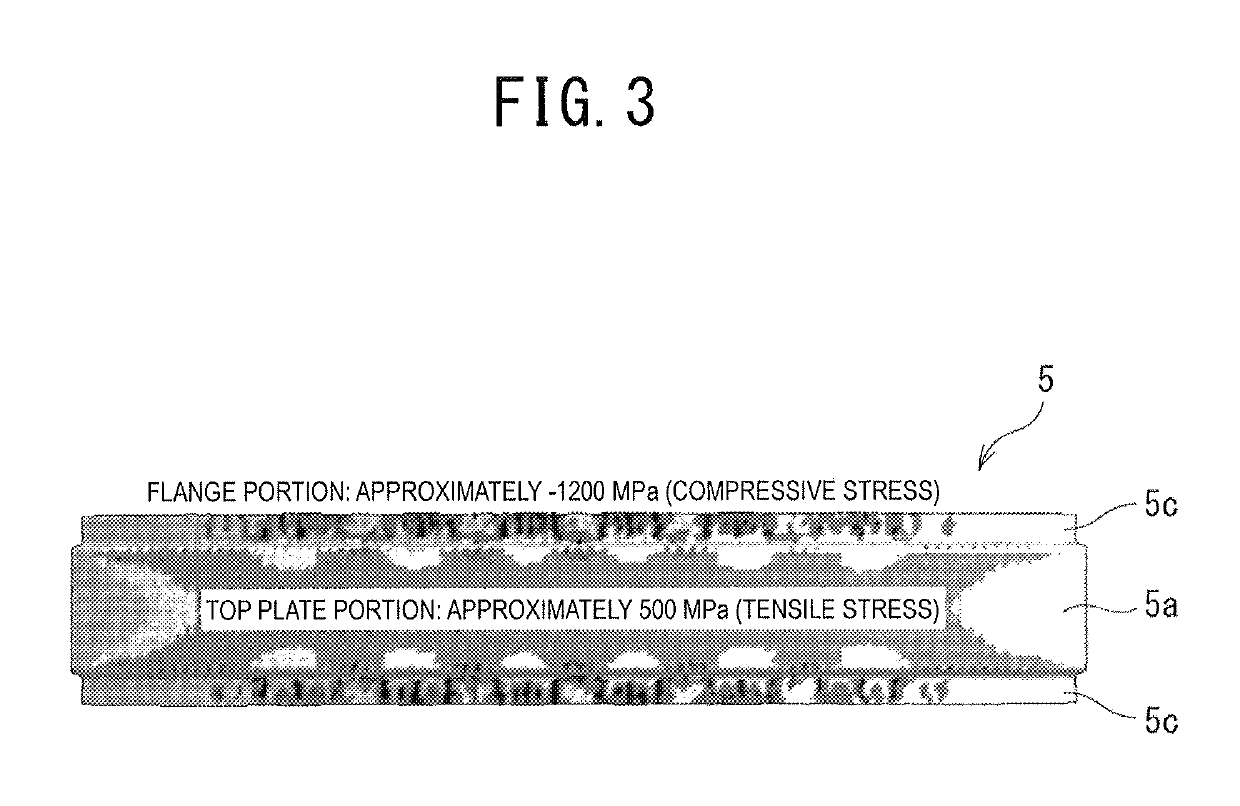

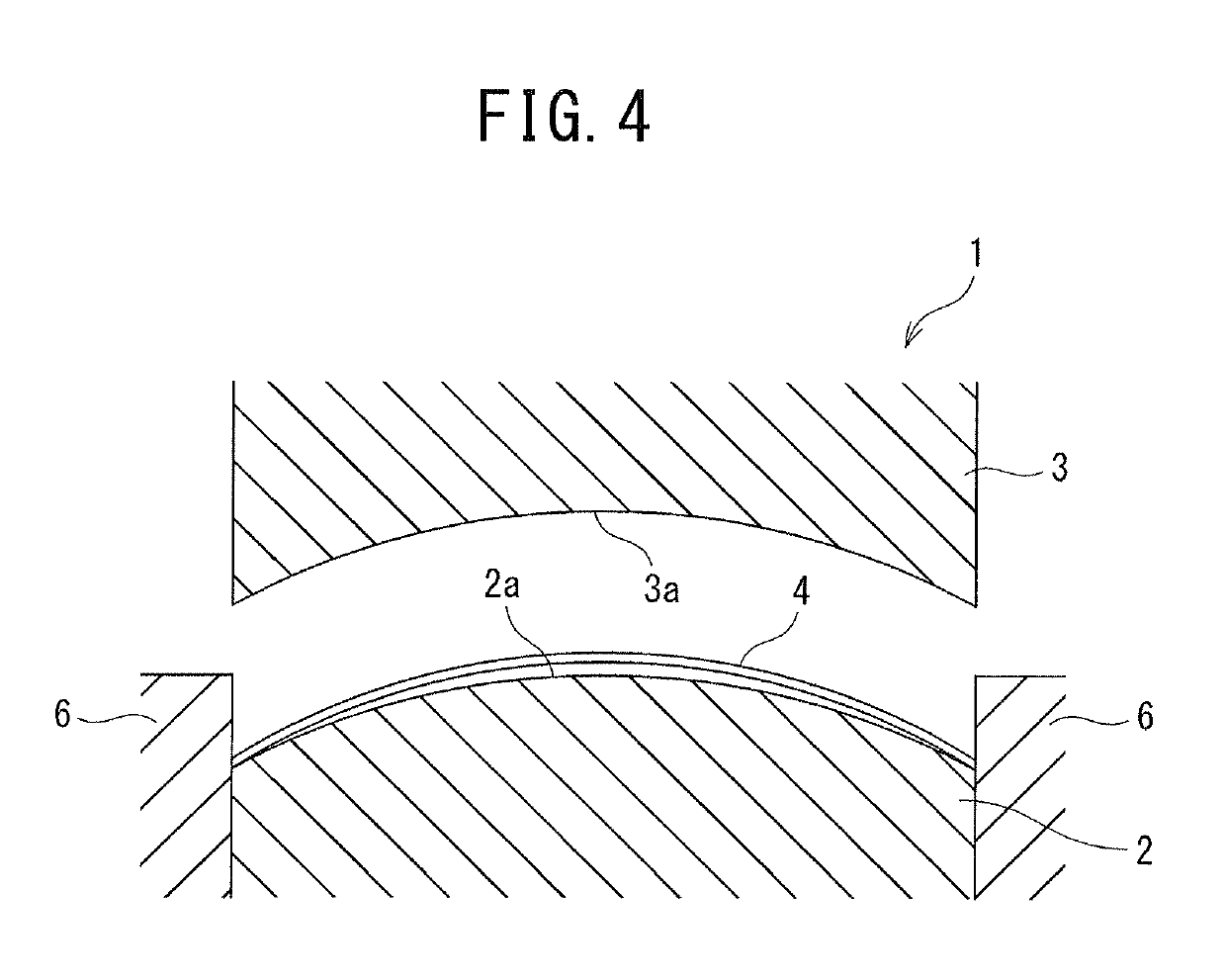

Press forming method and method of manufacturing press formed product

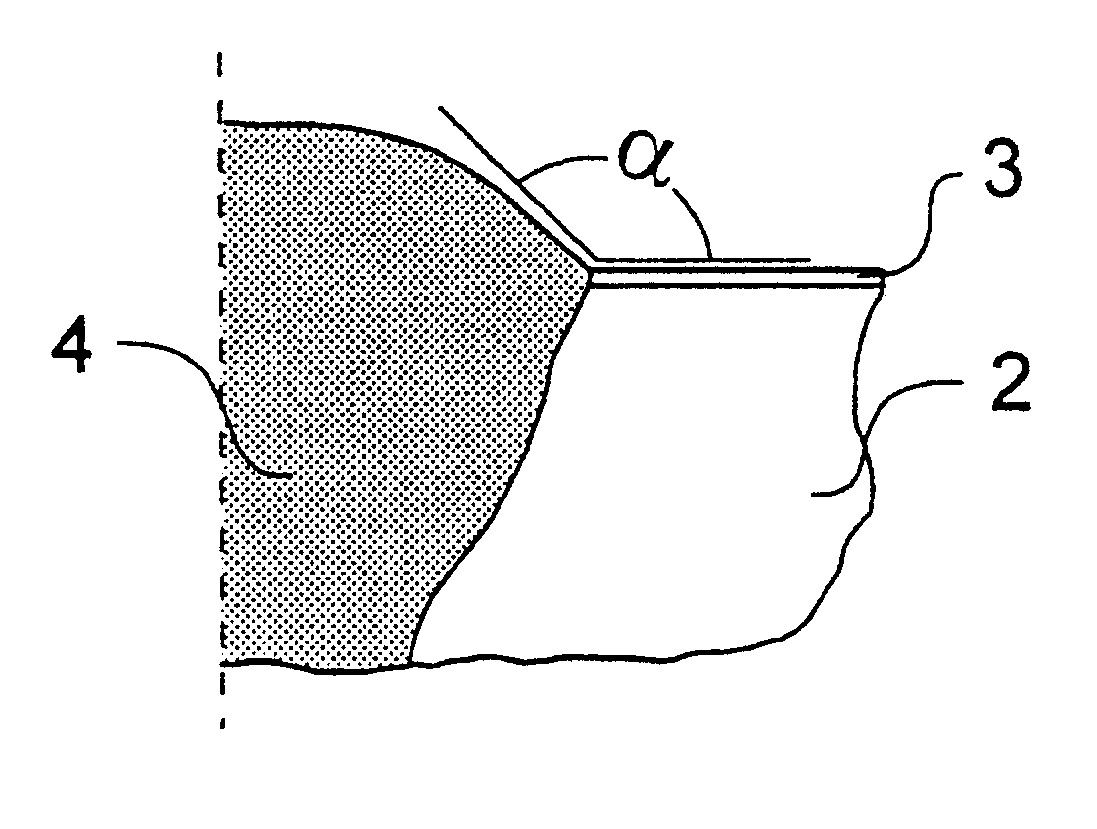

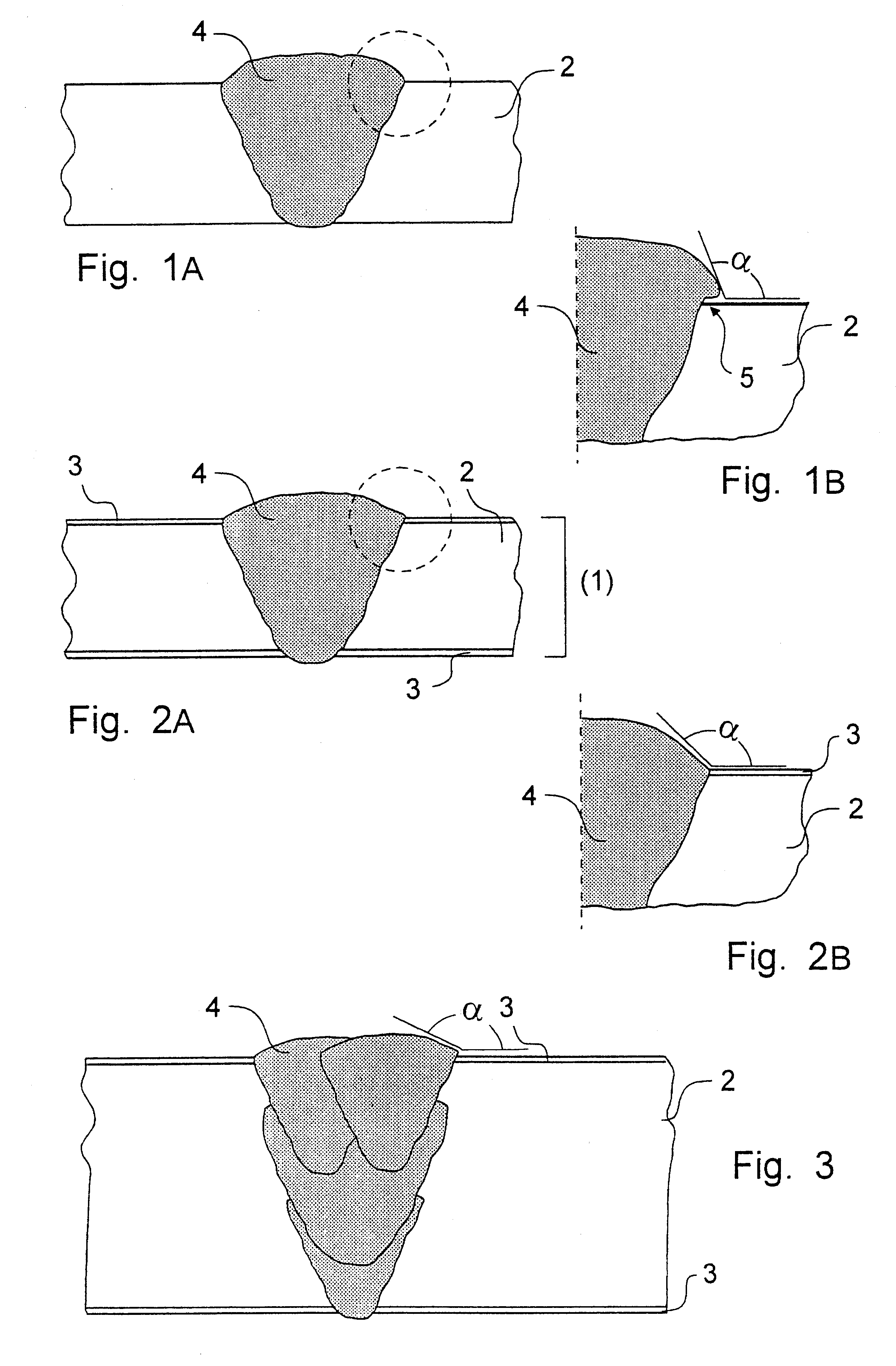

ActiveUS20170165735A1Reduce restrictionsReduce residual tensile stressVehicle componentsEngineeringMechanical engineering

There is provided a press forming method capable of suppressing a camber back, which occurs in a hat-shaped member while reducing a restriction on a shape of the hat-shaped member. At a time of the press forming, a blank material (4) in which a longitudinal line length is at least longer than a longitudinal line length of a top plate portion of a hat-shaped member (5) is fixed between a pair of press dies (lower die (2), upper die (3)), which have bent surfaces (convex surface (2a), concave surface (3a)), while being warped upward, that is, in a bending direction of the lower die (2) and the upper die (3). Subsequently, for the fixed blank material (4), a bent portion of the hat-shaped member (5) is press formed by using the convex surface (2a) and the concave surface (3a).

Owner:JFE STEEL CORP

Laser cladding process and laser cladding repair processing system based on thermal aging treatment

PendingCN112760641ARealize dynamic temperature controlSmall temperature differenceMetallic material coating processesTemperature controlRoom temperature

The invention provides a laser cladding process based on thermal aging treatment. The laser cladding process comprises the following steps of (1) pretreating a cladding part and a flat sample; (2) clamping the flat sample, and arranging a heating device below a chuck clamp; (3) arranging a temperature sensor near a to-be-cladded area of the flat sample for detecting the cladding temperature; (4) carrying out a single-pass laser cladding test on the flat sample, and recording the temperature range achieved by the cladding surface under corresponding cladding process parameters; (5) clamping the cladding part on the chuck clamp, enabling a temperature control system to control the heating temperature of the heating device according to the recorded temperature range, performing dynamic temperature control on the cladding part, and maintaining the overall temperature of the cladding part within the temperature interval achieved by laser cladding; (6) setting the corresponding laser cladding process parameters, and carrying out laser cladding on the surface of the cladding part; and (7) after the cladding is finished, controlling to stop heating by the temperature control system, and slowly cooling to room temperature. According to the process, the generation of cladding cracks can be reduced, and the cladding quality and effect can be improved.

Owner:NANJING ZHONGKE RAYCHAM TECH

Method for repairing size of casing spigot by supersonically spraying NiCrFeMn coating

InactiveCN108220864AHigh bonding strengthImprove stabilityMolten spray coatingKeroseneMaterials science

The invention relates to a method for repairing the size of a part, in particular to a method for repairing the size of a casing spigot by supersonically spraying a NiCrFeMn coating. The method comprises the following steps of 1, carrying out sand blowing treatment on the casing spigot; 2, performing oil removal treatment on the casing spigot; 3, carrying out protection on the part, which does notneed to be subjected to spraying repair, of the casing spigot before sand blowing; 4, carrying out sand blowing treatment on the area, which needs to be repaired in size, of the casing spigot, wherein 50-60 mesh magnesia sand is adopted, and sand blowing pressure is 0.2-0.5 MPa; and 5, supersonically spraying the NiCrFeMn coating on the area, which needs to be repaired, of the casing spigot, wherein the specific parameters are as follows that a kerosene flow rate is 2.5-5.5 L / min, an oxygen flow rate is 800-1200 L / min, a powder feeding rate is 75-80 g / min, spraying distance ranges from 120 mmto 240 mm and a spraying angle ranges from 60 degrees to 65 degrees. According to the method, a repaired part meets the assembling requirements, part reproduction cost is saved, and the production cost is reduced.

Owner:新锐咨询(辽宁)有限公司

Press forming method and method of manufacturing press formed product

InactiveUS10413956B2Reducing the camber backControl shapeVehicle componentsMechanical engineeringLine length

There is provided a press forming method capable of suppressing a camber back, which occurs in a hat-shaped member while reducing a restriction on a shape of the hat-shaped member. At a time of the press forming, a blank material (4) in which a longitudinal line length is at least longer than a longitudinal line length of a top plate portion of a hat-shaped member (5) is fixed between a pair of press dies (lower die (2), upper die (3)), which have bent surfaces (convex surface (2a), concave surface (3a)), while being warped upward, that is, in a bending direction of the lower die (2) and the upper die (3). Subsequently, for the fixed blank material (4), a bent portion of the hat-shaped member (5) is press formed by using the convex surface (2a) and the concave surface (3a).

Owner:JFE STEEL CORP

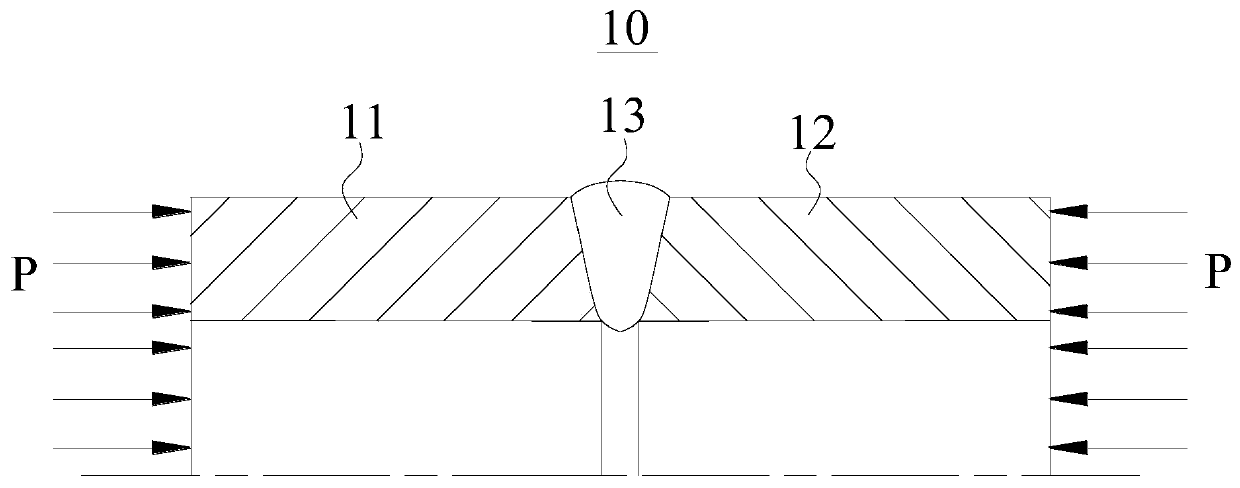

Process for reducing residual stress of butt-welding seam of dissimilar metal thick-wall barrel body

InactiveCN111187892AReduce residual tensile stressProcess efficiency improvementButt weldingWelding residual stress

The invention discloses a process for reducing the residual stress of a butt-welding seam of a dissimilar metal thick-wall barrel body, and belongs to the technical field of control over welding residual stress. The process for reducing the residual stress of the butt-welding seam of the dissimilar metal thick-wall barrel body comprises the following step: a pressing step of applying an axial pressure on the butt-welding seam between dissimilar metal workpieces, and enabling metal in a welding seam area to generate the plastic strain of transversal compression and radial extension, so that thewelding residual tensile stress of the welding seam and areas at the two sides of the welding seam is released. According to the process for reducing the residual stress of the butt-welding seam of the dissimilar metal thick-wall barrel body, by applying the axial pressure on the butt-welding seam of the dissimilar metal thick-wall barrel body, the residual tensile stress at the butt-welding seamof the dissimilar metal thick-wall barrel body can be effectively reduced.

Owner:CENT OF EXCELLENCE FOR ADVANCED MATERIALS +1

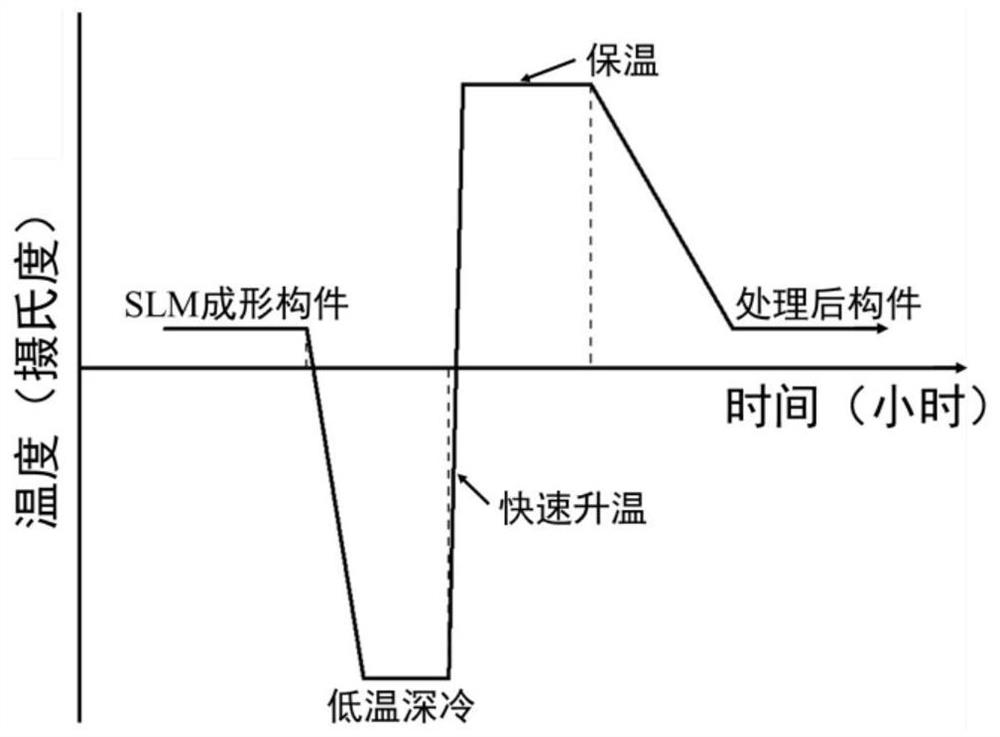

Method for eliminating residual stress of aluminum alloy component formed by selective laser melting

PendingCN113523303AReduce residual tensile stressGuaranteed mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh heat

The invention relates to a method for eliminating residual stress of an aluminum alloy component formed by selective laser melting. The method specifically comprises the following steps of (S1), immersing the aluminum alloy component formed by selective laser melting into a low-temperature medium, and fully cooling the aluminum alloy component; (S2), rapidly transferring the component into a high-temperature medium, rapidly increasing the temperature of the component, and carrying out heat preservation for a period of time; (S3), taking out the component and cooling to the room temperature in air; and (S4), cyclically repeating the operations from S1 to S3. The method is suitable for the aluminum alloy component which is formed by selective laser melting and has a complex shape, the treated component has low residual stress, and the dimensional stability of the component can be improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Gradient material design process for laser-manufactured hot-rolled strip coil leading guide liner

ActiveCN106756251BGuaranteed binding stabilityExtended service lifeMetallic material coating processesGradient materialStrip steel

The invention discloses a gradient material design process for a guiding ruler liner plate used before hot-rolled strip steel coiling through laser manufacturing. The process is characterized in that the guiding ruler liner plate comprises a priming layer, a transition layer and a functional layer through gradient design, wherein a priming layer cladding material comprises 3.6-18% of Cr, 5-16% of Mn, 0.2-0.7% of Si, 3-8% of N, 4-18% of W, 8-19% of B and the balance Ni; a transition layer cladding material comprises 3-18% of Cr, 4-15% of Mn, 0.1-0.6% of Si, 3-8% of N, 6-16% of W, 8-15% of B and the balance Ni; and a functional layer cladding material comprises 3-16% of Cr, 5-15% of Mn, 0.1-0.5% of Si, 3-6% of N, 8-18% of W, 8-12% of B and the balance Ni. The service life of the guiding ruler liner plate is prolonged to 5-6 times that of original guiding ruler liner plates.

Owner:沈阳大陆激光工程技术有限公司

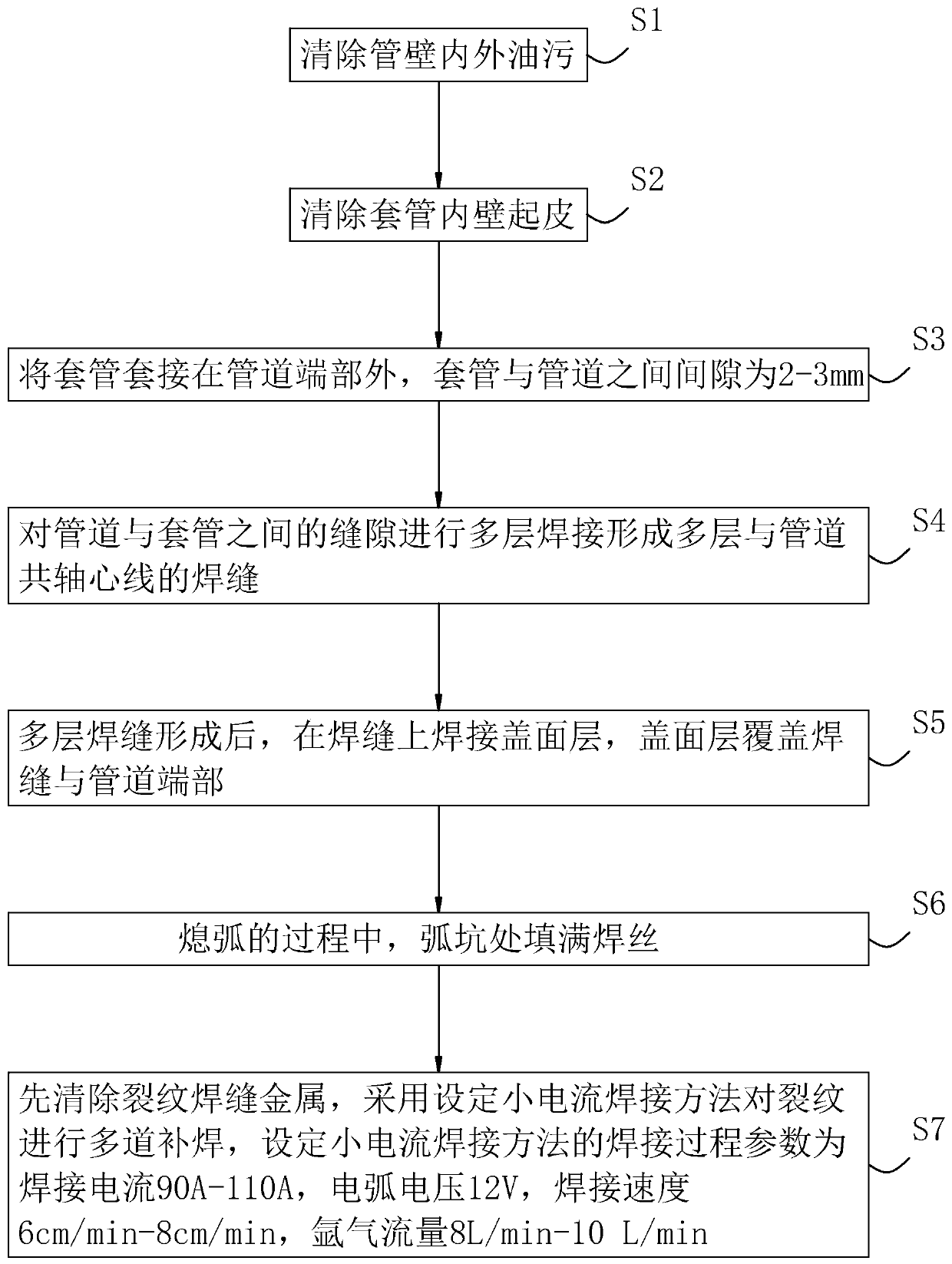

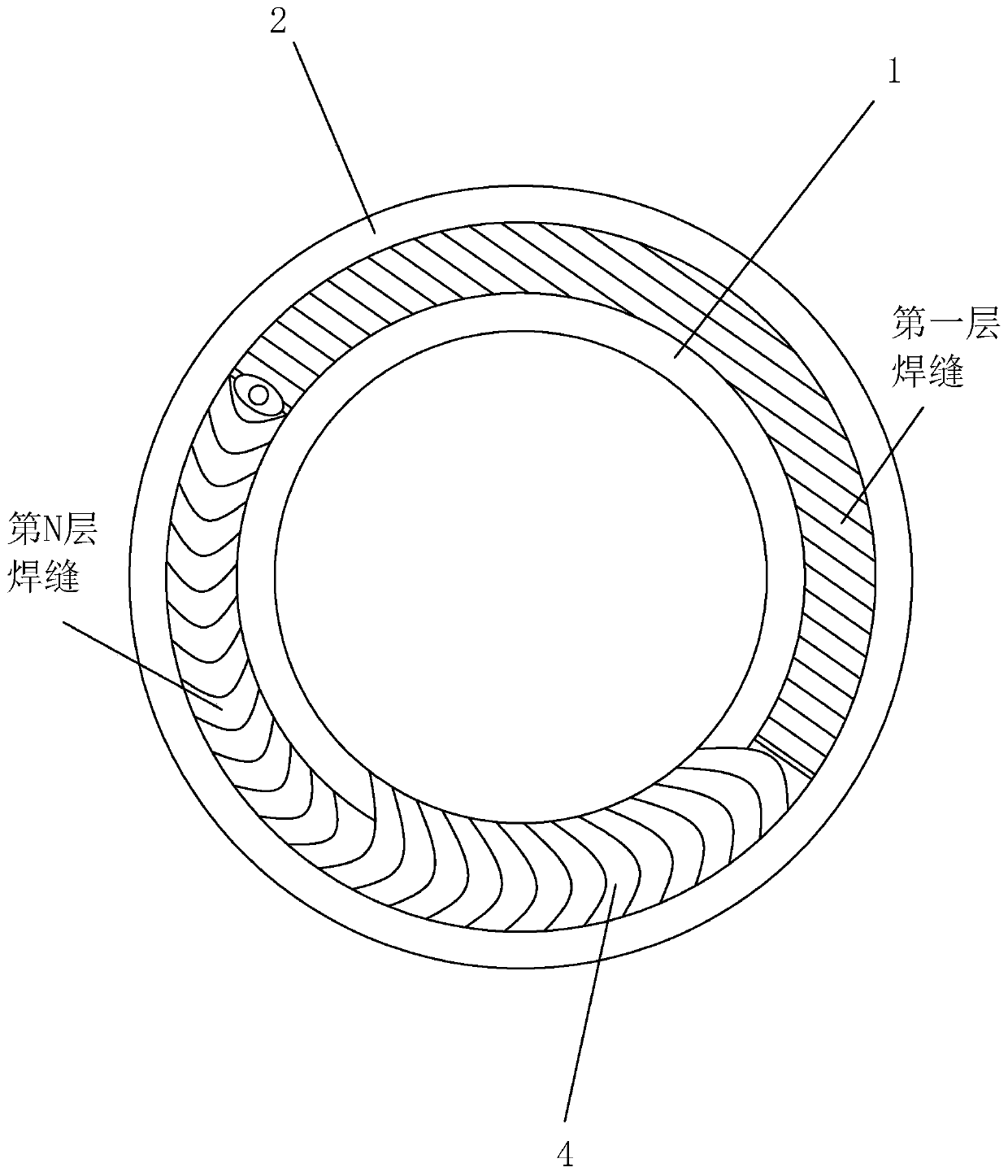

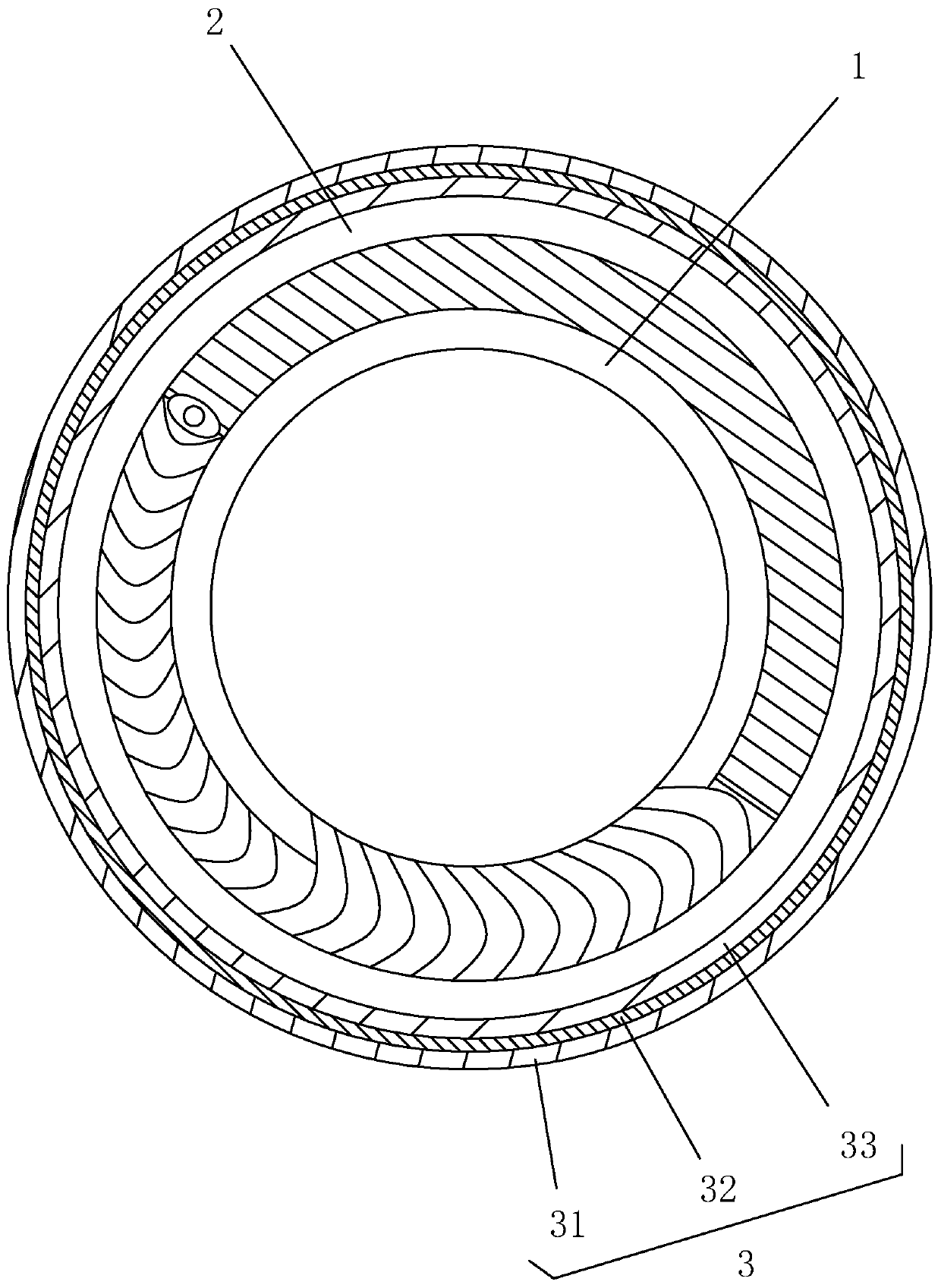

Pipeline sleeve joint welding process

ActiveCN111037045AReduce welding tensile stressAttenuation of residual tensile stressArc welding apparatusWeld seamPipe welding

The invention relates to the technical field of pipeline welding, and discloses a pipeline sleeve joint welding process. The process comprises the steps that S1, oil stains inside and outside the pipewall are removed; S2, peeling of the inner wall of the sleeve is removed; S3, the end of the pipeline is sleeved with a sleeve, and the gap between the sleeve and the pipeline is 2-3mm; S4, multi-layer welding is conducted on the gap between the pipeline and the sleeve to form multiple layers of welding seams coaxial with the pipeline; S5, after the multiple layers of welding seams are formed, acover surface layer is welded to the welding seams, and the cover surface layer covers the welding seams and the end of the pipeline; and S6, arc pits are filled with welding wires in the arc extinguishing process. The generation of a low-melting-point liquid film is prevented, the welding tensile stress is reduced, the permeation of harmful substances is controlled, the residual tensile stress after welding can be effectively attenuated through multiple layers of welding, the cooling speed is reduced, the generation of hot cracks is prevented, slow arc extinguishing is realized, and the arc pits are filled with the welding wires to further prevent the generation of the hot cracks.

Owner:上海江南船舶管业有限公司

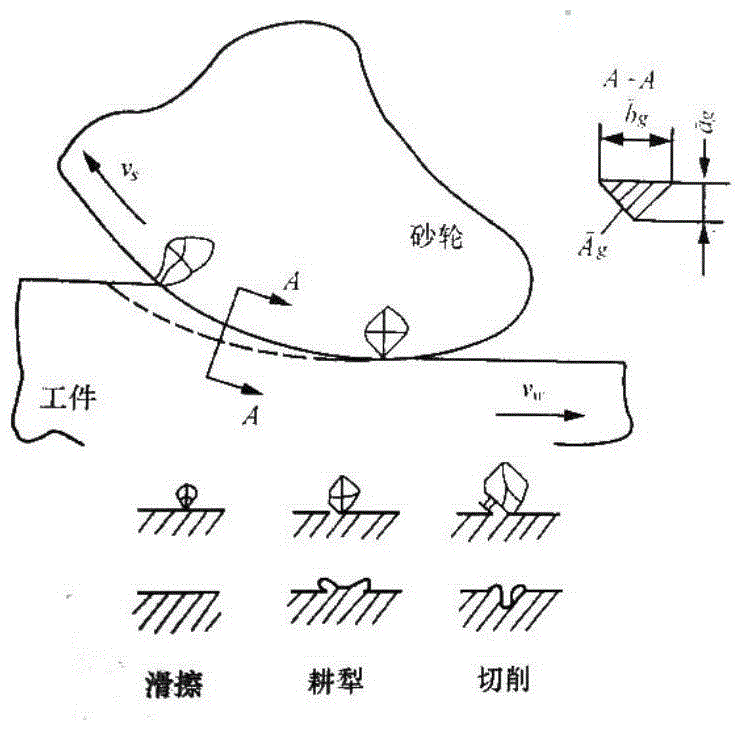

A Prestressed Grinding Method for Revolving Workpieces

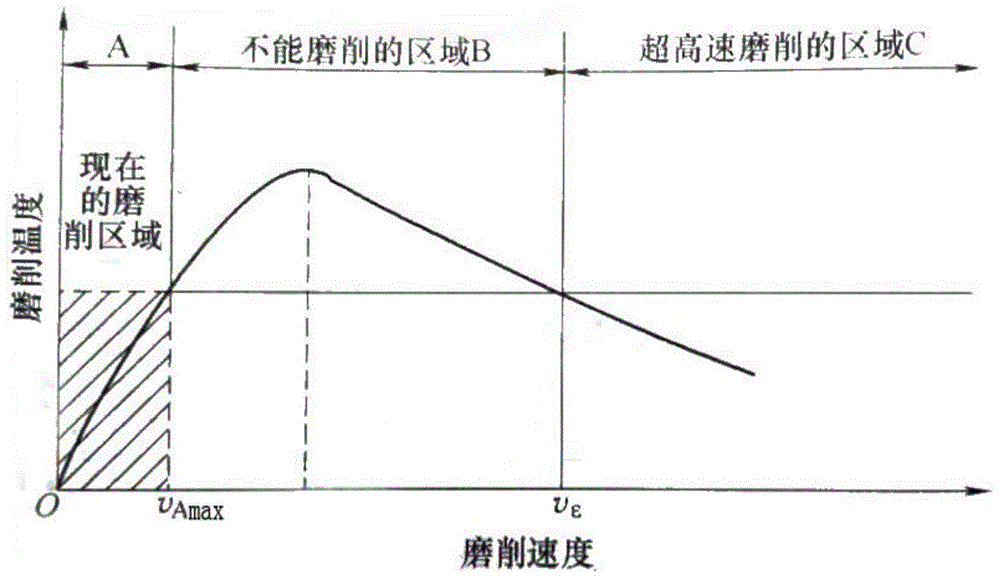

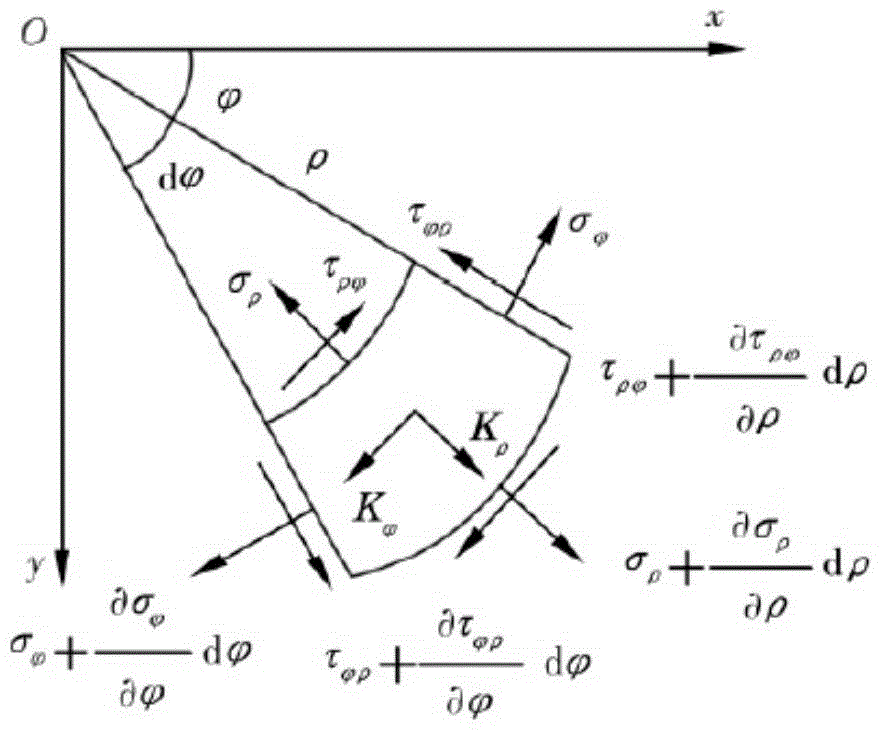

ActiveCN104759954BSimple structureStability is not affectedRevolution surface grinding machinesUltra high speedMachine

The invention discloses a prestress grinding method for a revolved body workpiece. The method includes the following steps that (1) the workpiece to be machined is well clamped on a grinding machine; (2) tool setting operation is conducted, a grinding wheel and the workpiece are made to be in a low speed state first, the position of the grinding wheel is adjusted step by step, the linear speed of the grinding wheel is adjusted to be in an ultra high speed state of vs>=150 m / s after sparks just appear on the surface of the workpiece, and the rotating speed of the workpiece is adjusted to be in an ultra high speed centrifugal state; (3) abrasive machining is carried out according to a certain radial amount of feed; after machining is completed, the grinding wheel and the workpiece are separated first, and then the grinding wheel and the workpiece are decelerated to be zero. According to the prestress grinding method for the revolved body workpiece, there is no need to use a special force application mechanism to apply prestress to the workpiece, only the rotating speed of the workpiece in the machining process needs to be controlled, and residual compressive stress can be obtained on the surface of the workpiece after machining is completed; due to the fact that the rotating speed of the workpiece can be adjusted flexibly, different magnitudes of residual compressive stress can be obtained by controlling the rotating speed of the workpiece, so that the using requirements of different parts are met.

Owner:GUANGZHOU UNIVERSITY

A device for reducing weld residual stress by using high-pressure water jet

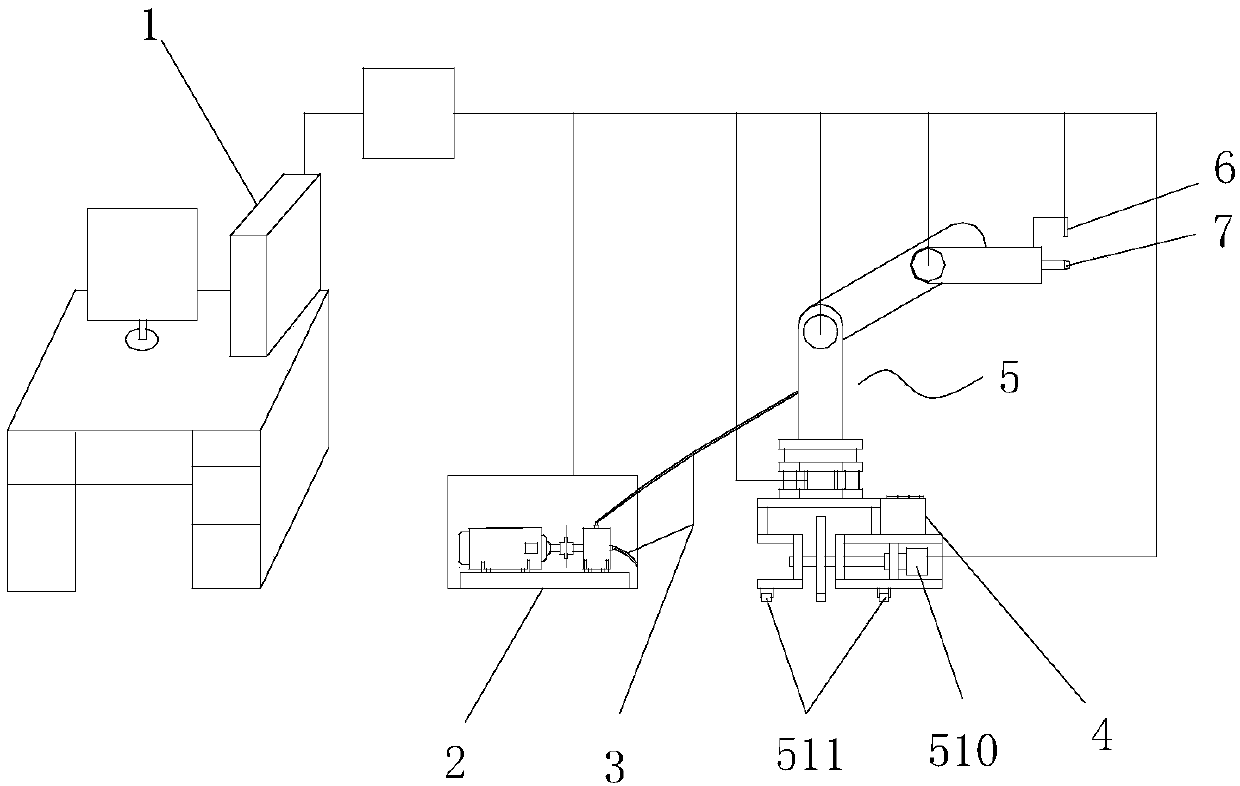

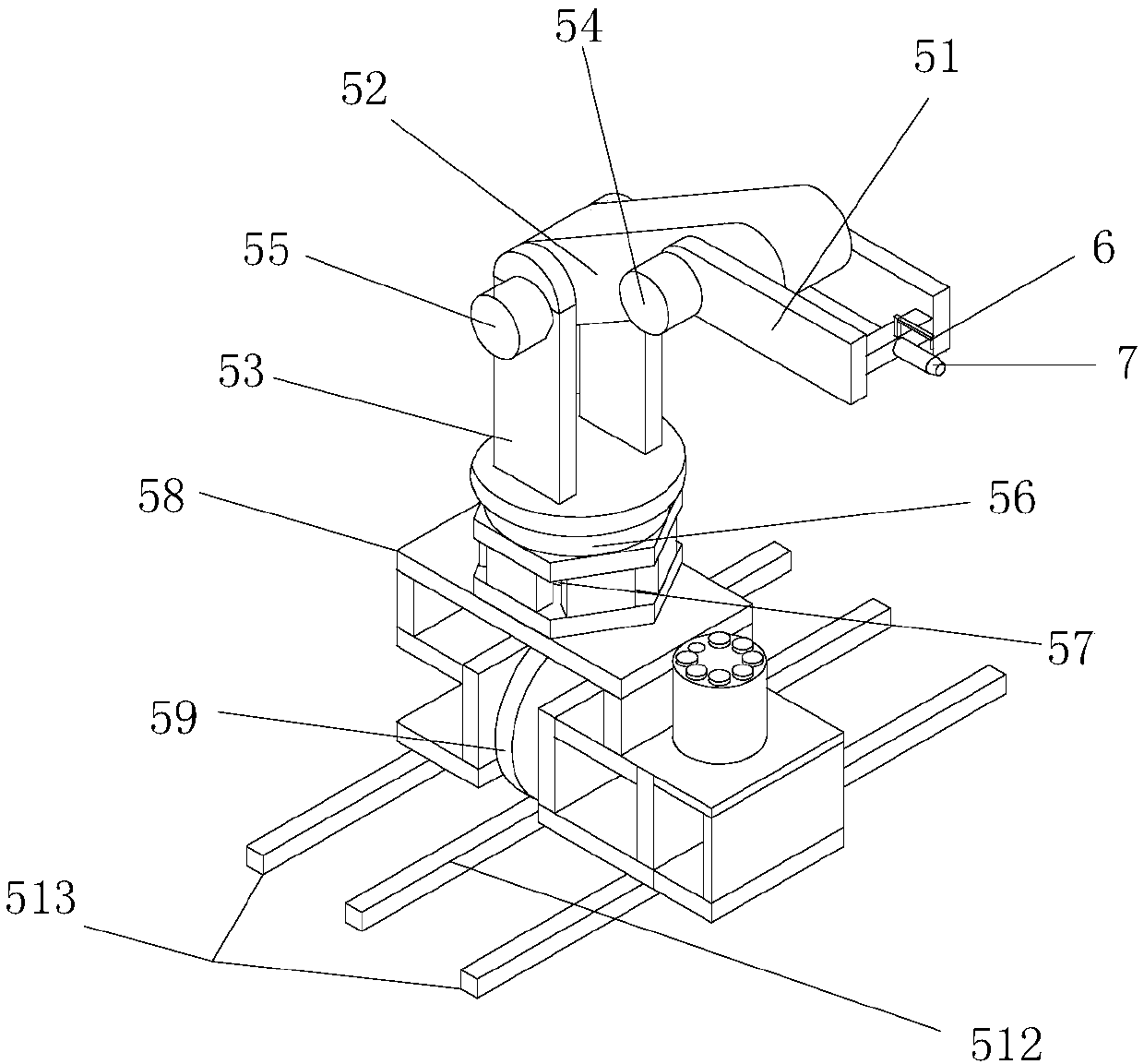

ActiveCN107354289BAchieve regulationHigh degree of automationProcess efficiency improvementControl systemEngineering

The invention discloses a device for reducing weld residual stress by using high-pressure water jet, which includes a control system, a high-pressure water jet delivery pump, a mechanical arm system and a nozzle system; the nozzle system includes a nozzle, the nozzle is connected with the high-pressure water jet delivery pump, and The water jet delivery pump supplies the nozzle with high-pressure water jet; the mechanical arm system includes the first mechanical arm and the driving device that drives the first mechanical arm to complete the rotation, pitching, and lifting movements. The nozzle is set in front of the first mechanical arm; the control system It includes a controller and an image collector. The image collector is arranged in front of the first mechanical arm. The image collector is connected with the controller and transmits the collected image information to the controller in real time. The invention is flexible and has high degree of automation, and can be used to reduce the residual stress of welding seams of different types and widths.

Owner:SHANDONG UNIV OF SCI & TECH

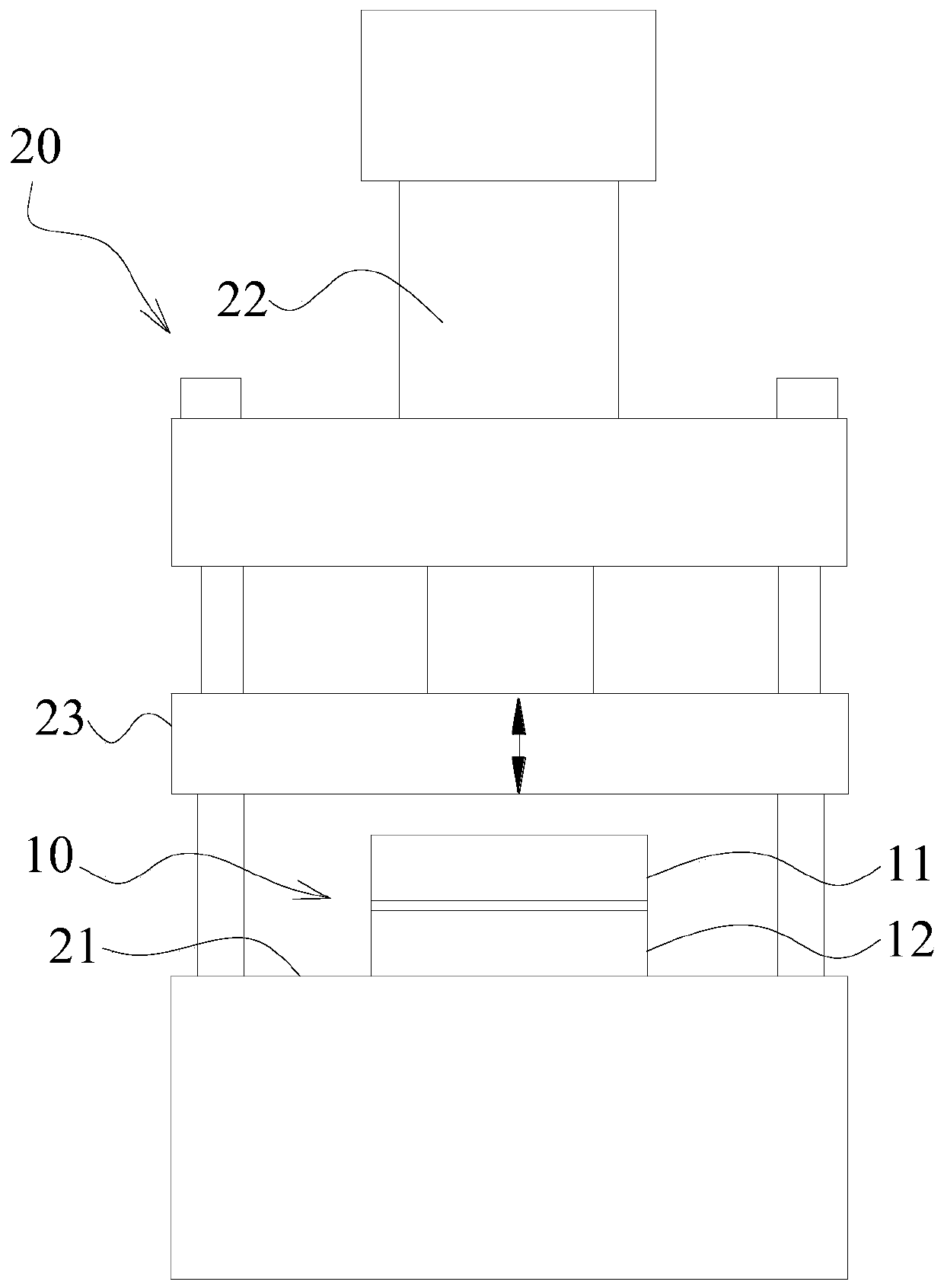

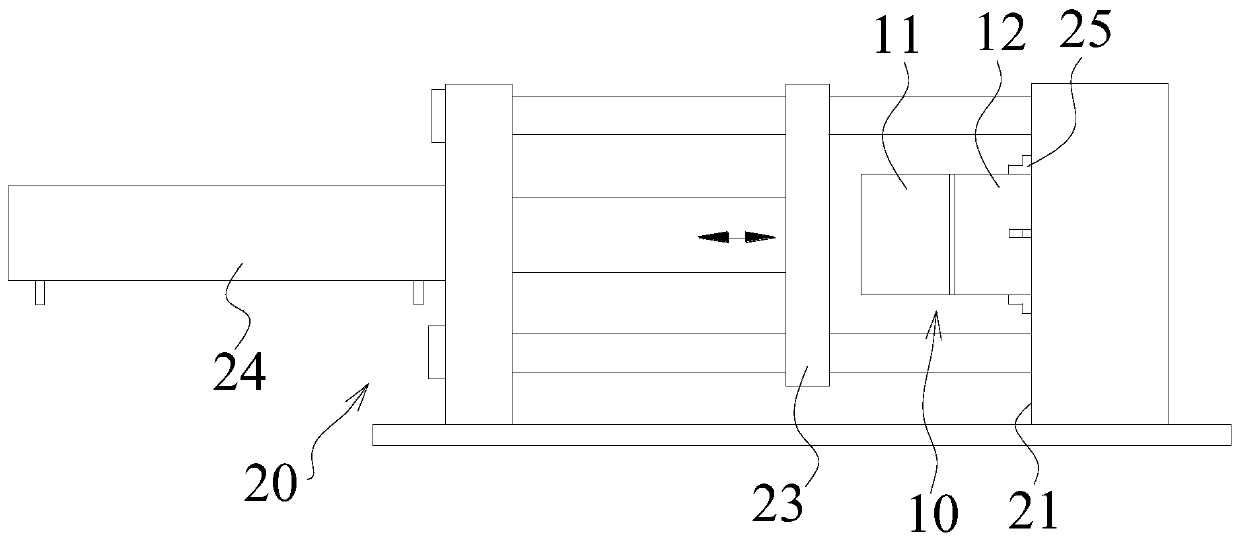

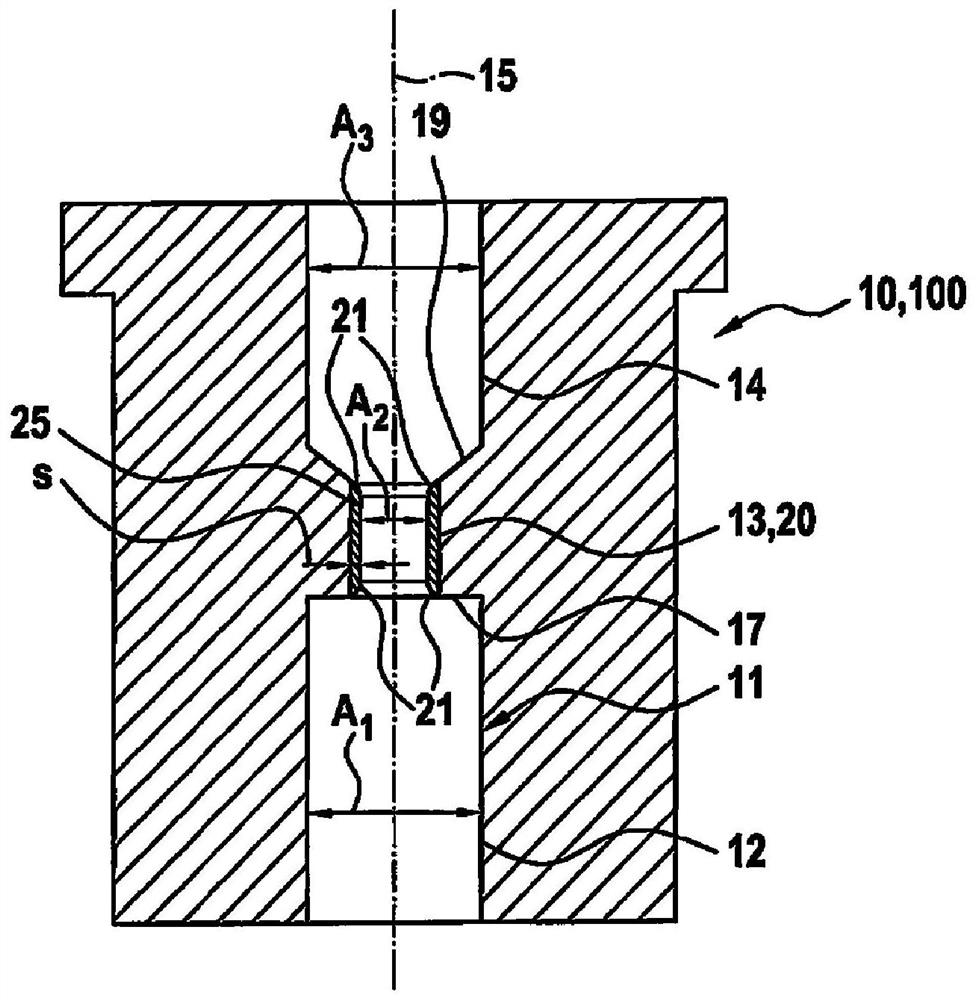

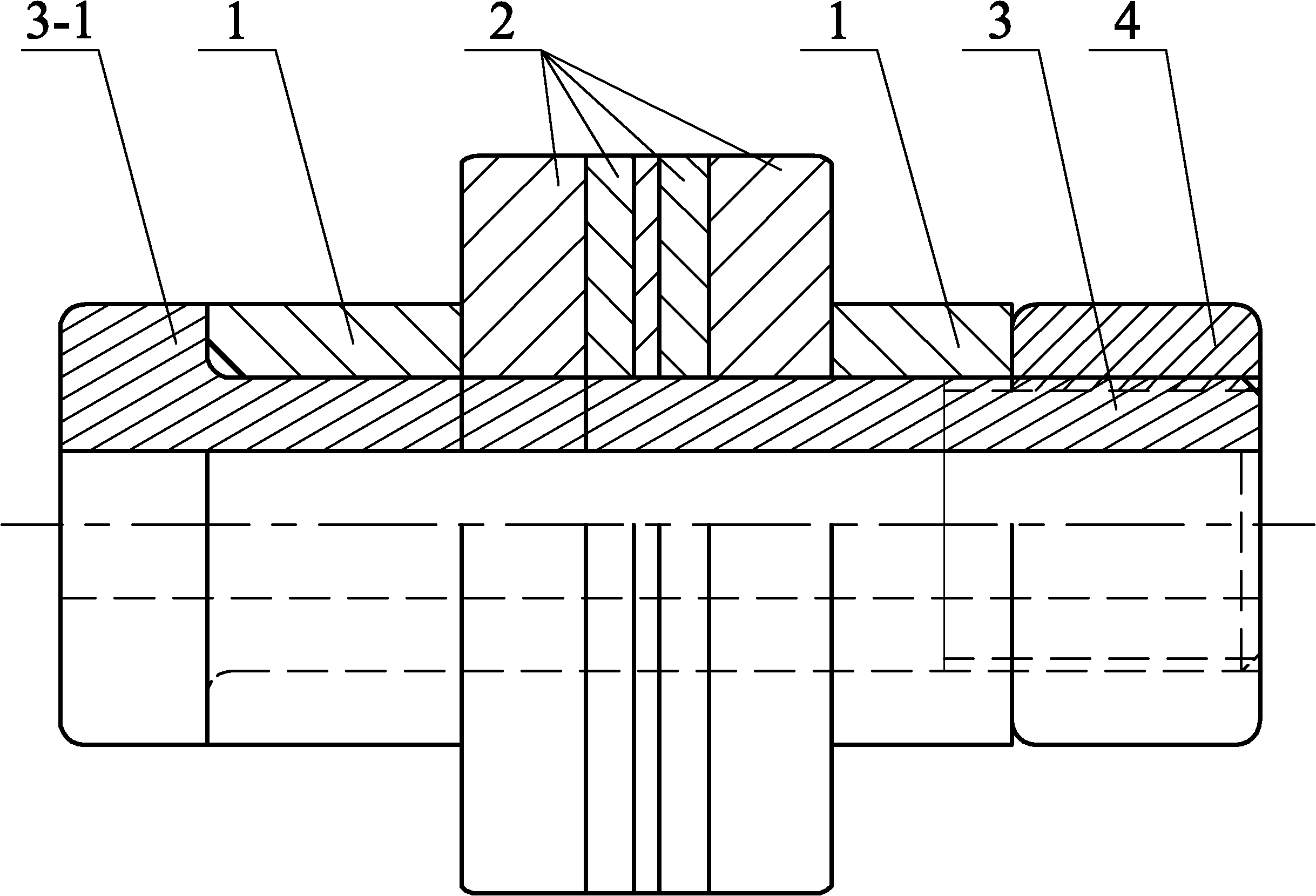

Method for manufacturing boreholes, components and fuel injectors

ActiveCN107130096BReduce residual tensile stressIncrease manufacturing costFurnace typesHeat treatment furnacesEngineeringHeat treated

The invention relates to a method for producing a borehole (11) in a component (10) of a fuel injector (100), in particular for a pressure medium under high pressure, wherein the borehole (11) has a A section (13) produced by erosion, wherein the component (10) consisting of steel is subjected to a heat treatment for hardening the component (10).

Owner:ROBERT BOSCH GMBH

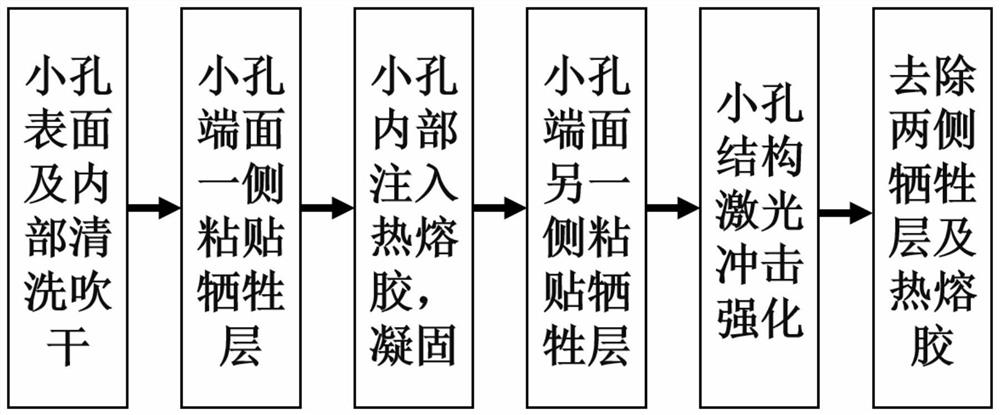

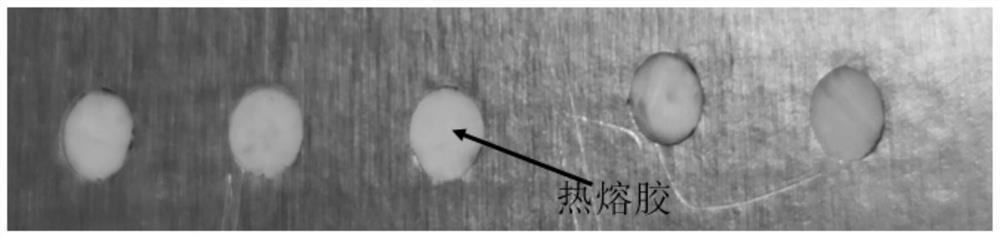

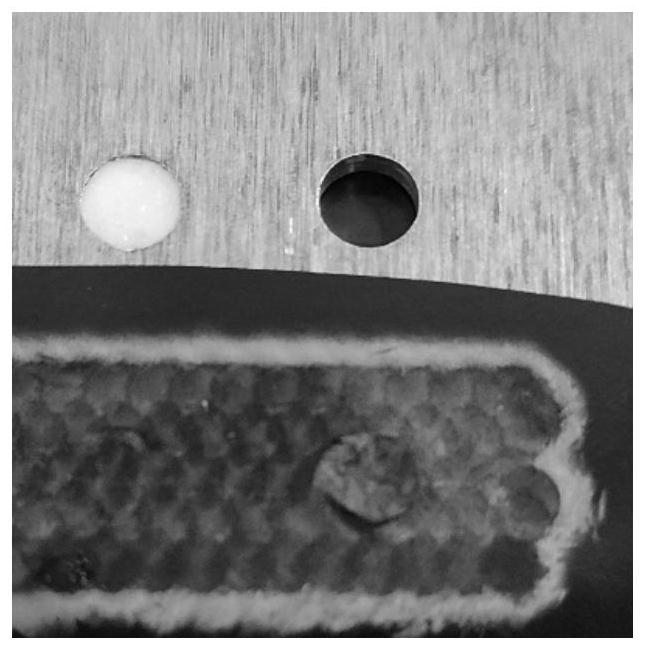

Hot melt adhesive assisted laser shock peening method for small hole of airplane structural part

The invention discloses a hot melt adhesive assisted laser shock peening method for a small hole of an aircraft structural part, and belongs to the technical field of laser shock peening. The method comprises the following steps: (1) mounting a workpiece with a small hole structure on a clamp, and pasting a sacrificial layer on one end surface; (2) the other end face faces upwards, liquid hot melt adhesive is injected, and after the hot melt adhesive is solidified, a sacrificial layer is pasted; (3) a restraint layer water film is applied to the to-be-strengthened area, laser shock strengthening is conducted on the two end faces of the small hole, and strengthening parameters are as follows: the laser energy is 5-10 J, the light spot diameter is 2-3 mm, the pulse width is 15-20 ns, the frequency is 1-5 Hz, the water film thickness is 1-2 mm, the lap joint rate is 25%-75%, and the shock frequency is 1-4 times; and (4) removing the sacrificial layer after the workpiece is subjected to laser shock peening, and removing the hot melt adhesive in the small hole by using a metal tool of which the diameter is smaller than that of the small hole. The method can ensure the strengthening effect of the laser shock peening small hole.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

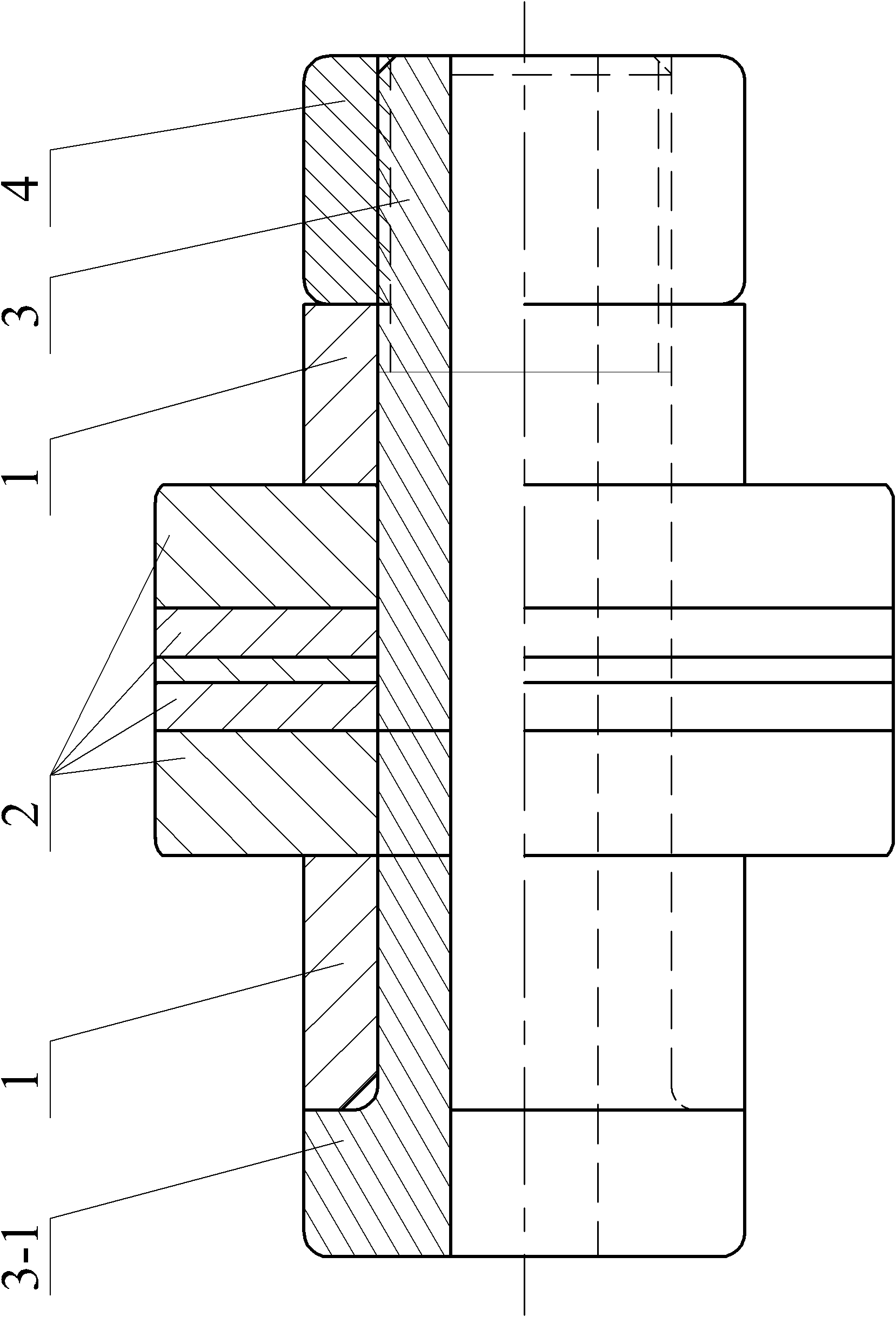

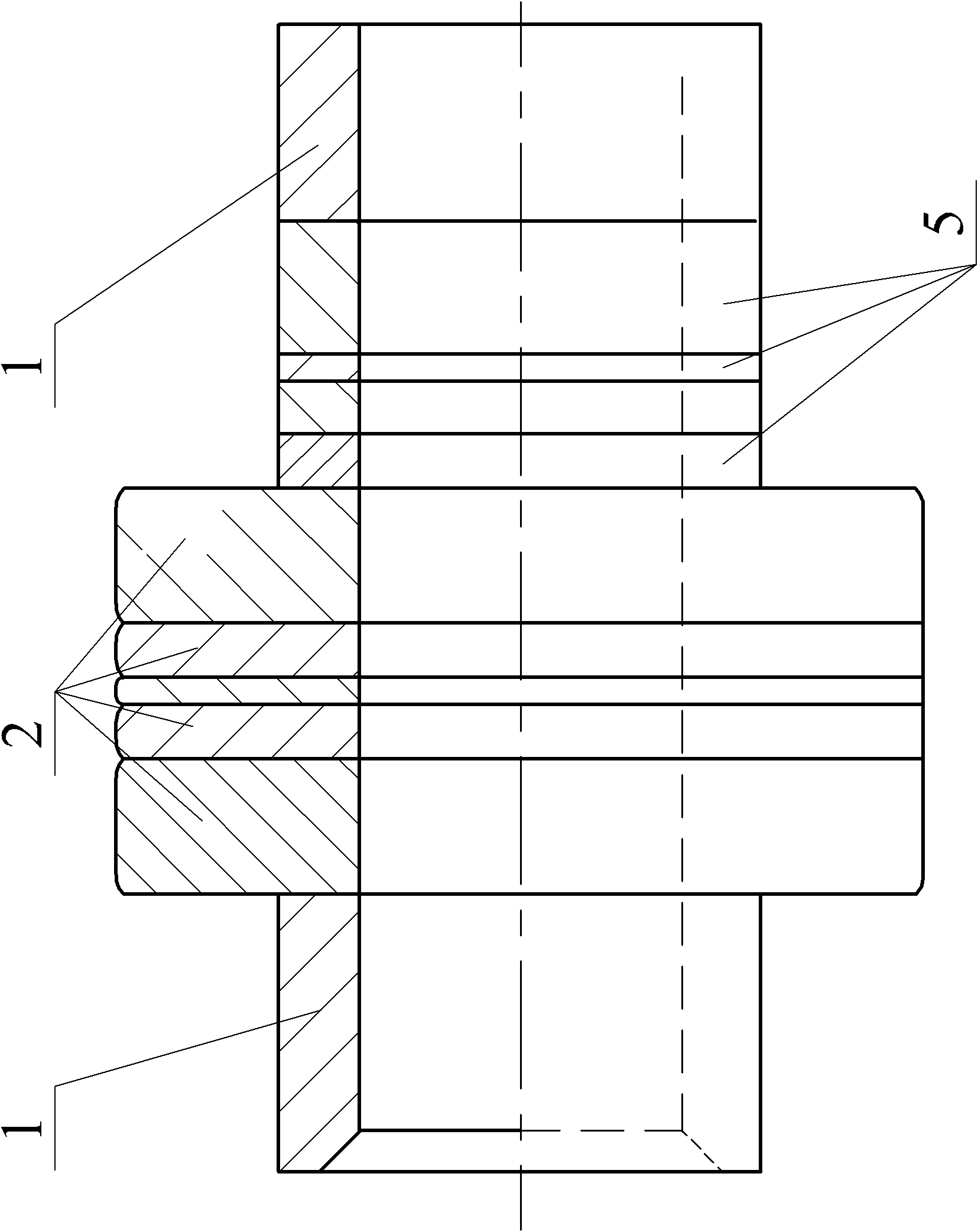

Narrow-gap adjustable device and cosmetic welding adjustable device for improving bearing capacity of butt joints

InactiveCN102091892AImprove carrying capacityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesButt jointWelding residual stress

The invention improves a narrow-gap adjustable device and a cosmetic welding adjustable device for improving the bearing capacity of butt joints, which belong to the field of a welding technique and can acquire high-quality butt joints with good bearing capacity. A fastener is used for axially pressing and fixedly mounting a group of annular sheets with different thicknesses and two wheel rim bodies on a shaft sleeve; and the two wheel rim bodies and the group of annular sheets with different thicknesses between the two wheel rim bodies are arranged coaxially, and the surface profile of the integration of the wheel rim bodies and the annular sheets is matched with the surface shape of the weld reinforcement of the butt joints. The narrow-gap adjustable device is convenient in operation, and has the advantages of high efficiency, high adaptability and the like; and the device with the adjustability can shape the butt joints which have different thicknesses and are made of different materials during welding. Under the sequential action of the narrow-gap adjustable device and the cosmetic welding adjustable device, butt joints with less weld defects, fine grains, low welding residual stress, desired shape and size, and high bearing capacity can be manufactured.

Owner:HARBIN INST OF TECH

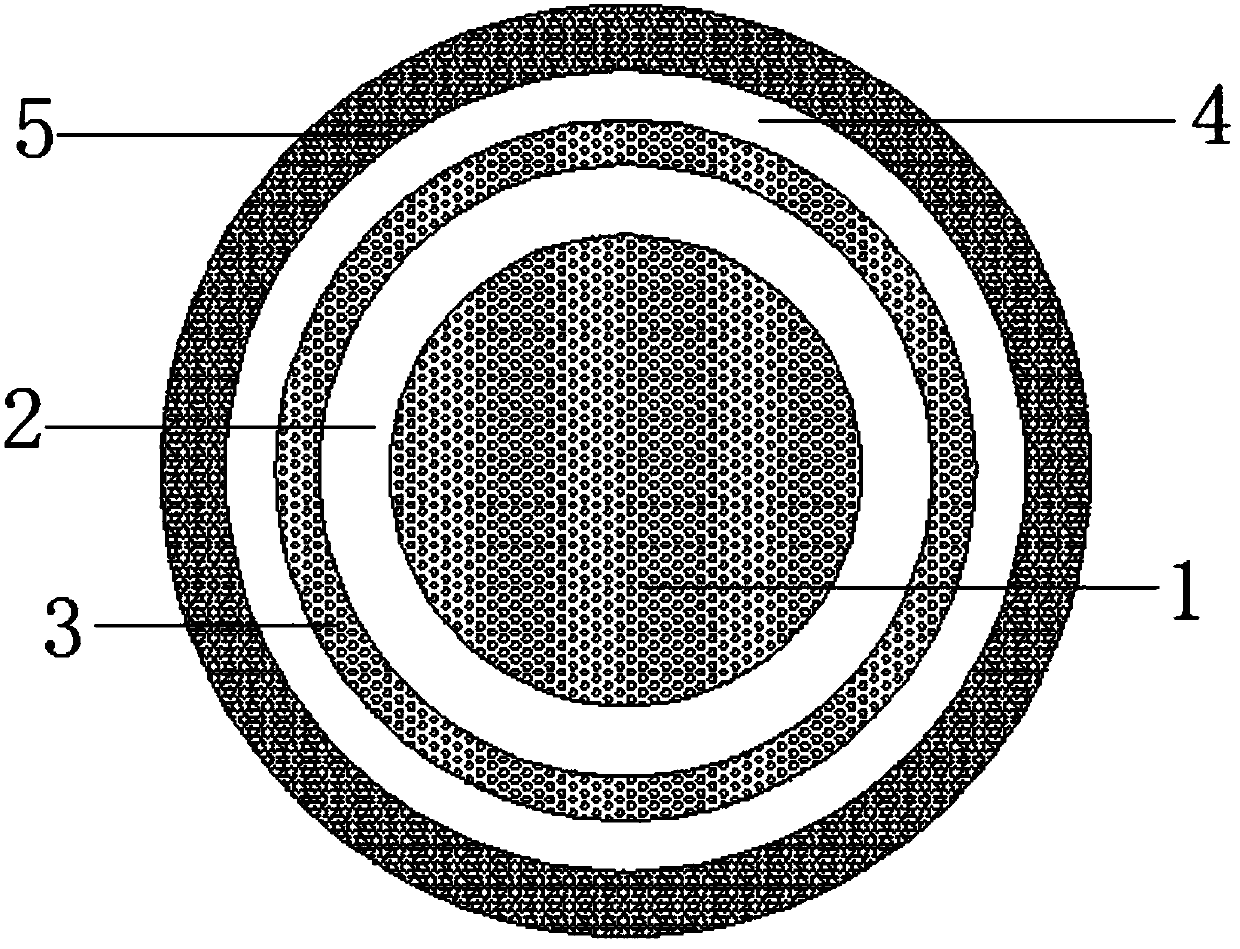

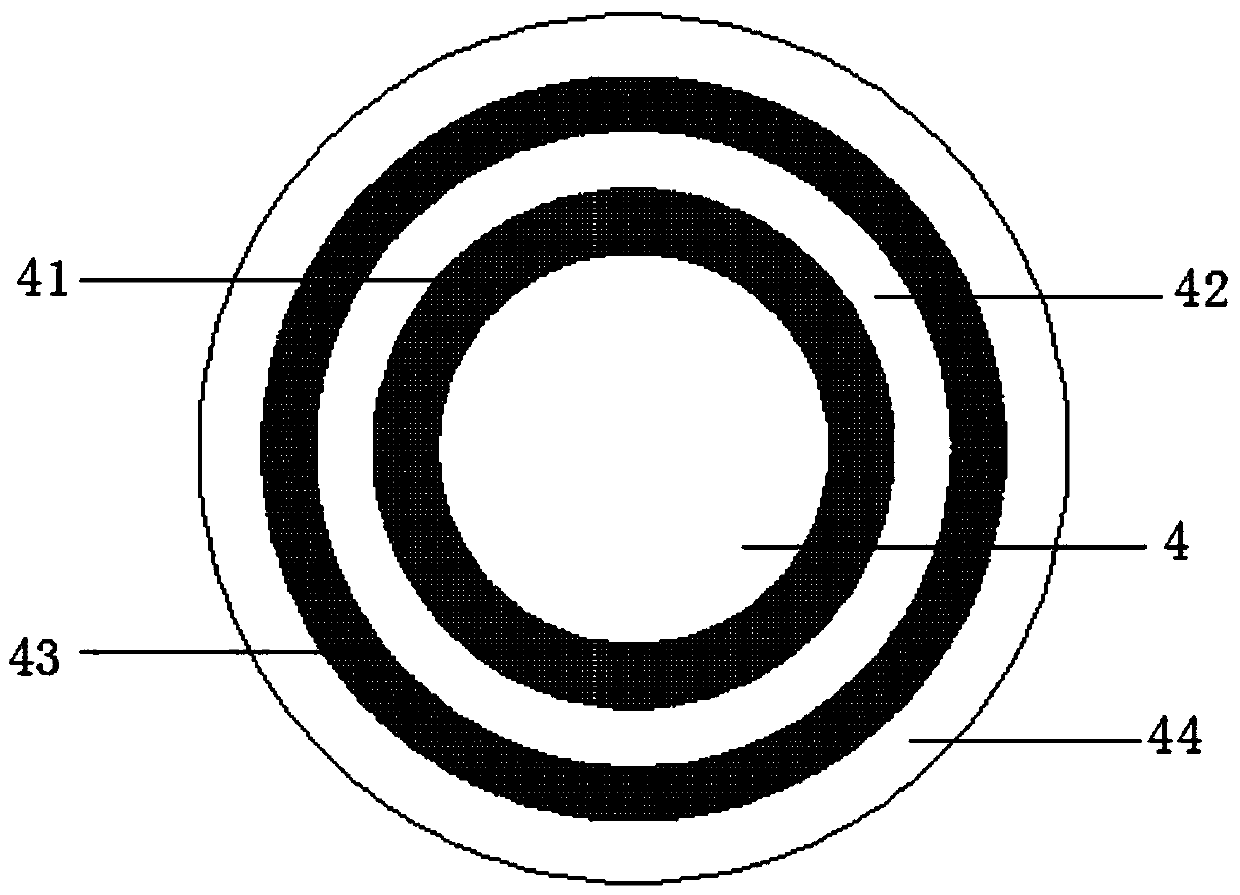

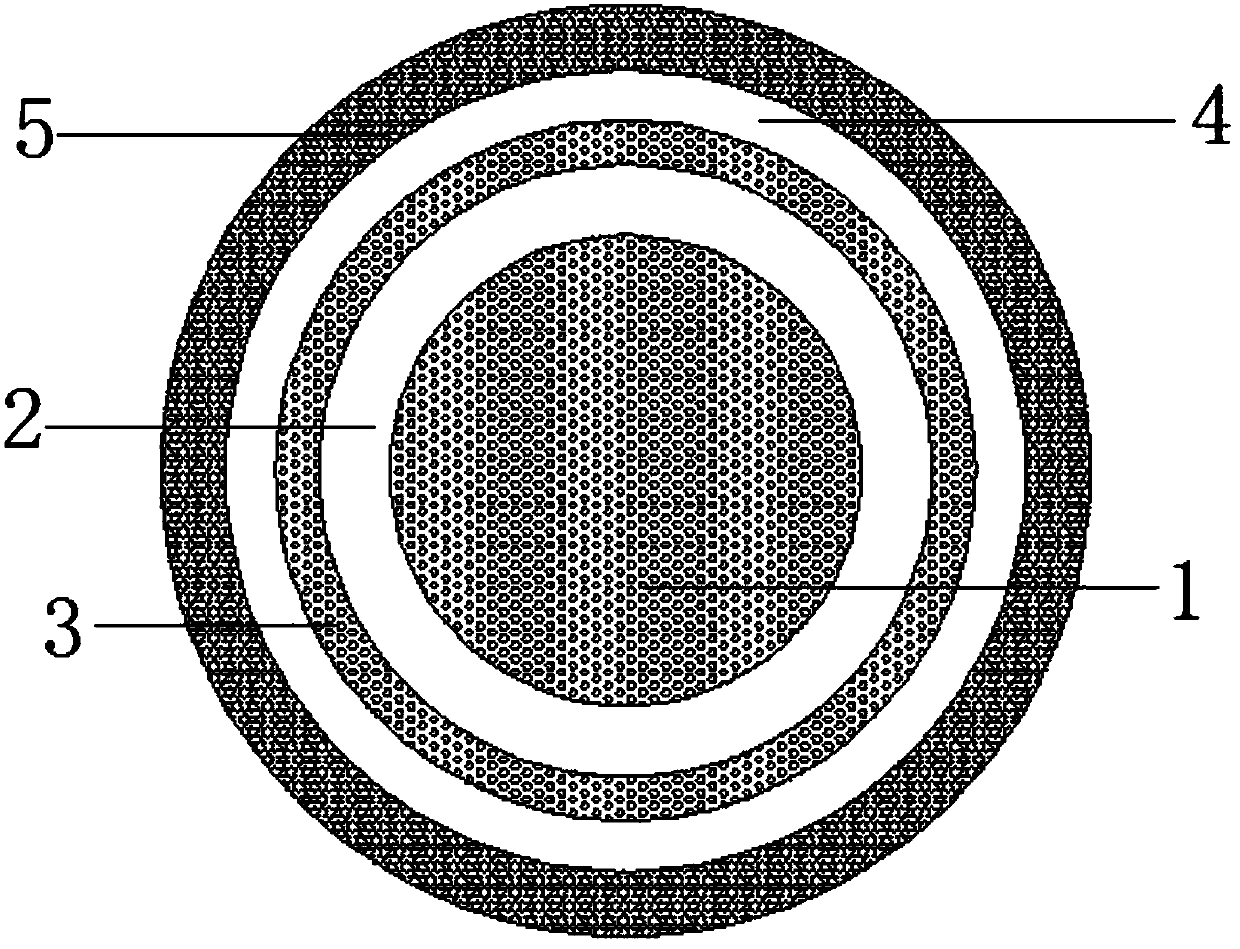

Laser cladding layer titanium alloy treatment device

InactiveCN109957799AWell formedNo crackMetallic material coating processesOrganic matterTitanium alloy

The invention discloses a laser cladding layer titanium alloy treatment device which belongs to the technical field of laser. The laser cladding layer titanium alloy treatment device comprises a titanium alloy body, the outer wall of the titanium alloy body is connected with an elastic layer in a sleeved manner, the outer wall of the elastic layer is connected with a transition layer in a sleevedmanner, the outer wall of the transition layer is connected with a plasticity layer in a sleeved manner, the plasticity layer comprises an iron base alloy layer, the outer wall of the iron base alloylayer is connected with a cobalt base alloy layer in a sleeved manner, the outer wall of the cobalt base alloy layer is connected with a nickel base alloy layer in a sleeved manner, and the outer wallof the nickel base alloy layer is connected with a magnesium alloy layer in a sleeved manner. The laser cladding layer titanium alloy treatment device is simple in structure and convenient to use, the cladding surface is good in molding, free of cracks, compact in tissue, high in strength, good in heat dissipation performance and vibration reducing performance, high in load impact bearing capacity and good in corrosion resistance to organic matters and alkali, the residual tensile stress of the cladding surface can be reduced, the service life of the cladding surface is prolonged, and the cladding surface has the effects of buffering, the corrosion resistance and wear resistance.

Owner:天津万世达激光技术有限公司

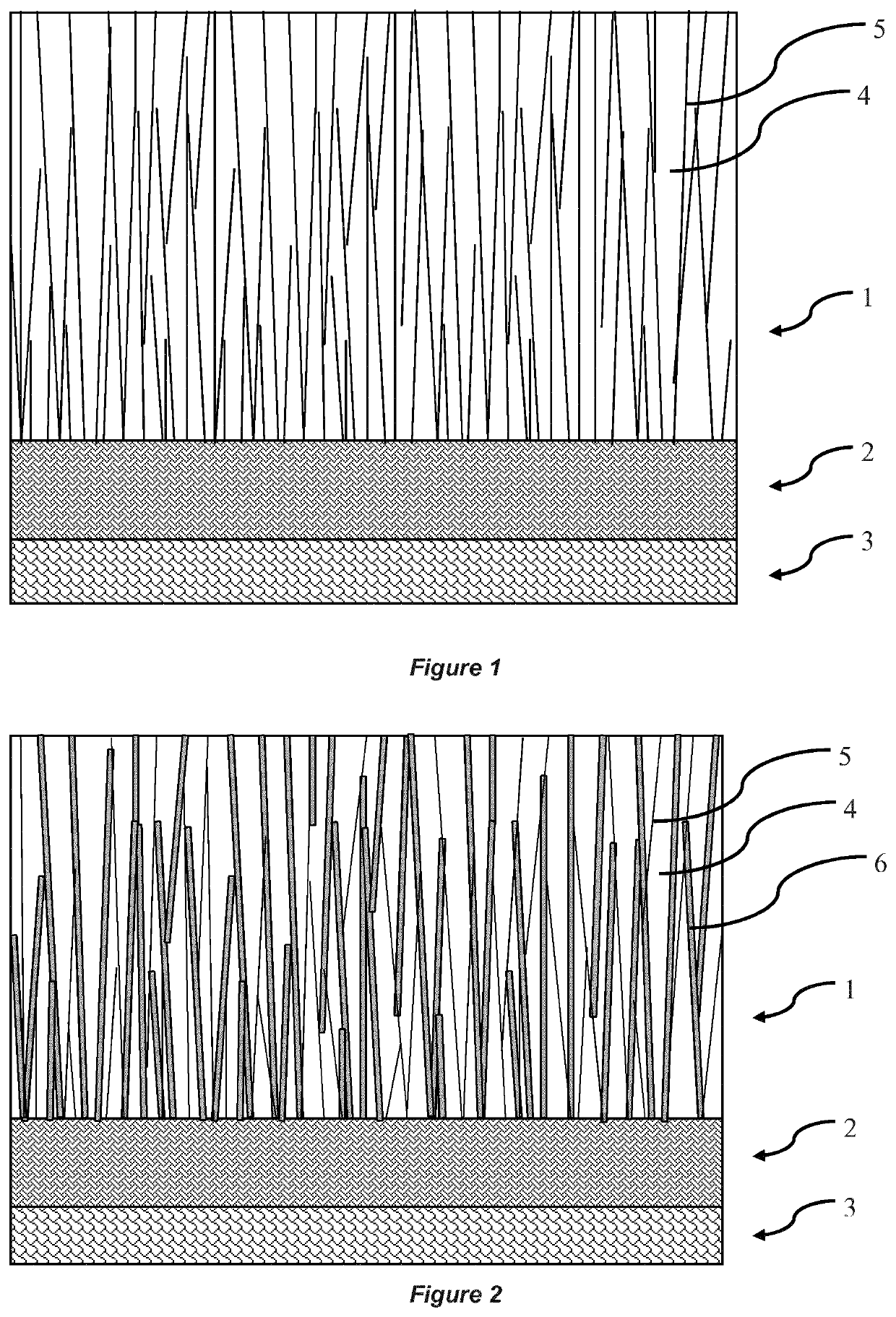

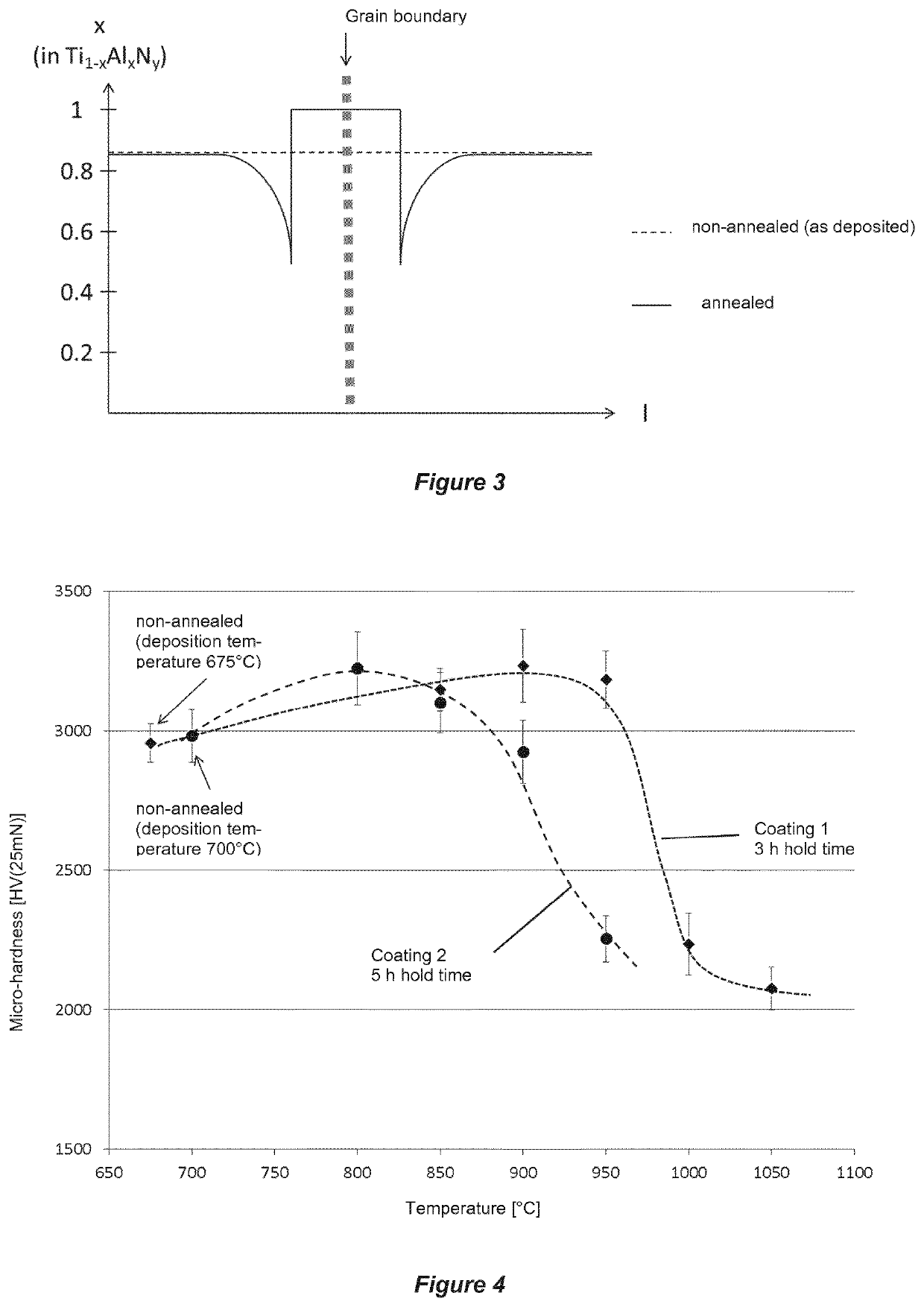

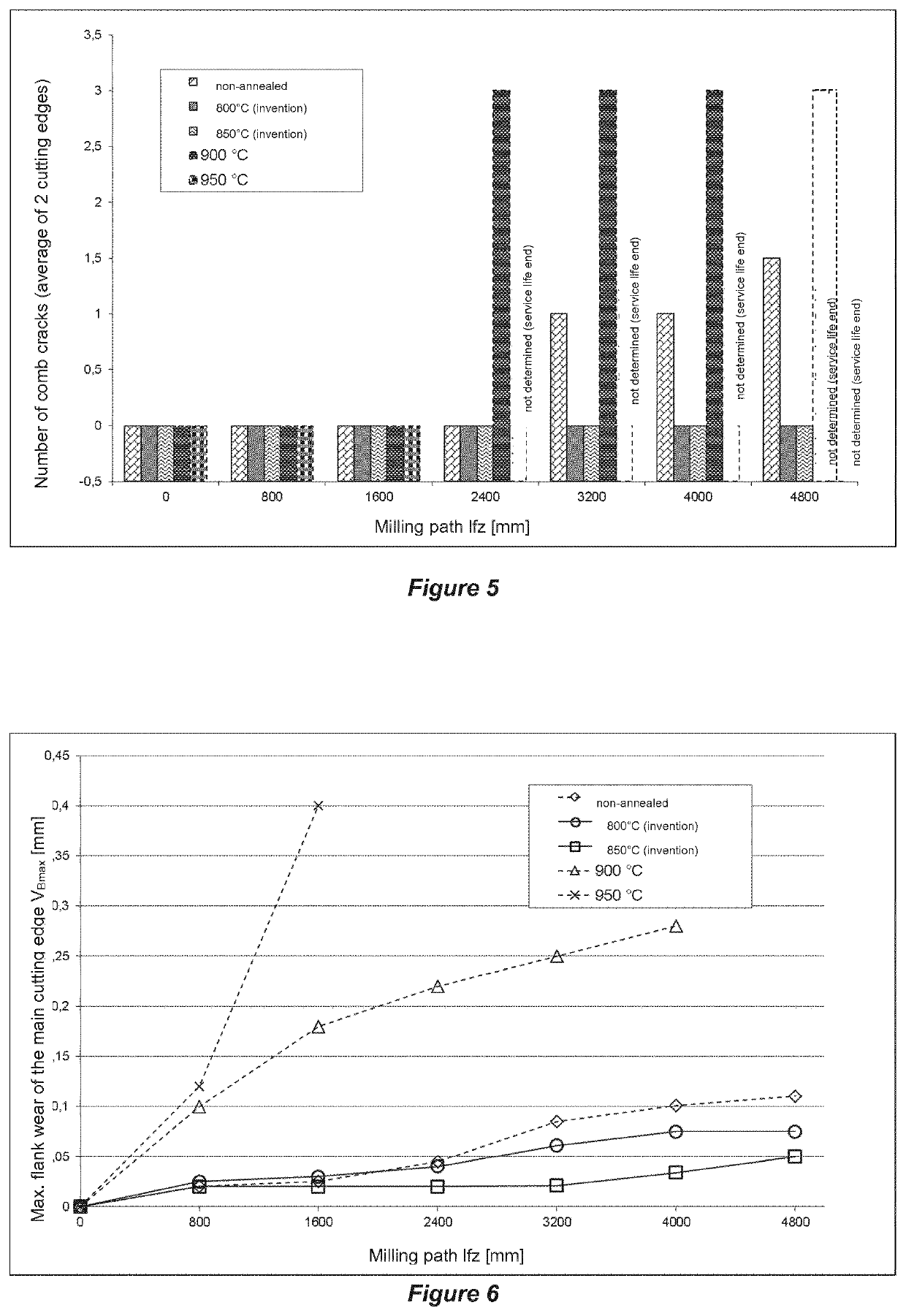

Tool with TiAIN coating

ActiveUS10662524B2Improve fatigue performanceIncrease the residual compressive stressWorkpiecesTurning toolsCrystal structureCemented carbide

A tool having includes a base body of cemented carbide, cermet, ceramics, steel or high-speed steel and a single-layer or multi-layer wear protection coating deposited thereon by CVD process and having a thickness within the range of from 2 μm to 25 μm. The wear protection coating has at least a Ti1-xAlxCyNz layer with 0.40≤x≤0.95, 0≤y≤0.10 and 0.85≤z≤1.15 having a thickness in the range of from 1 μm to 16 μm and having >85 vol-% face-centered cubic (fcc) crystal structure. The Ti1-xAlxCyNz layer includes precipitations of Ti1-oAloCpNq at the grain boundaries of the Ti1-xAlxCyNz crystallites have a higher Al content than inside the crystallites, wherein 0.95≤o≤1.00, 0≤p≤0.10, 0.85≤q≤1.15 and (0−x)≥0.05.

Owner:WALTER AG

Method for preparing tungsten coating by using cold air dynamic spraying technology

InactiveCN102260869BReduce the temperatureLittle thermal impactPressure inorganic powder coatingSurface engineeringCold air

The invention provides a method for preparing a tungsten coating by using a cold air dynamic spraying technology, belonging to metal surface engineering. The method specifically comprises: preparing the tungsten coating on a copper alloy or stainless steel substrate from fine tungsten powder used as a raw material by using the cold air dynamic spraying technology. During the preparation of the tungsten coating by cold air dynamic spraying, the particle size of the tungsten powder is controlled at 0.4-10 mu m, nitrogen gas or helium gas can be used as a carrier gas and accelerating gas, and the spraying distance is controlled at 10-50 mm. When nitrogen as is used as the carrier gas and accelerating gas, the temperature of cold air dynamic spraying is controlled at 500-800 DEG C, the air flow pressure is controlled at 20-50bar, and the powder feeding amount is controlled at 10-50 g / min. When helium gas is used as the carrier gas and accelerating gas, the temperature of cold air dynamic spraying is controlled at 200-500 DEG C, the air flow pressure is controlled at 10-30bar, and the powder feeding amount is controlled at 10-20 g / min. The method provided by the invention has the advantages that: the tungsten coating can be prepared on a copper alloy and stainless steel; the prepared tungsten coating is dense, has no oxidation phenomenon existence, intact coating interface bonding and no pores, cracks and other defects; and the tungsten coating with the thickness less than 10 microns can be prepared.

Owner:UNIV OF SCI & TECH BEIJING

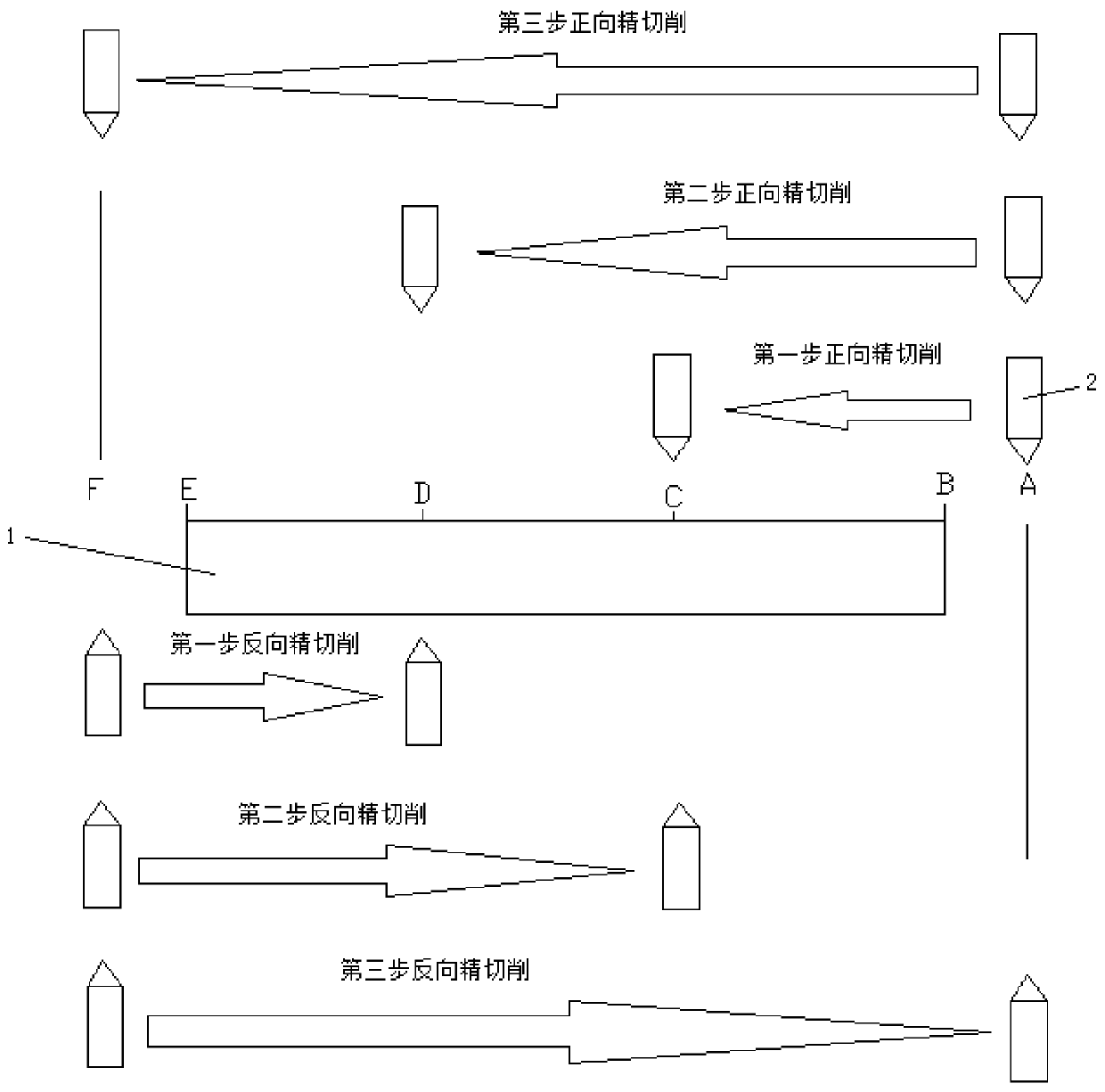

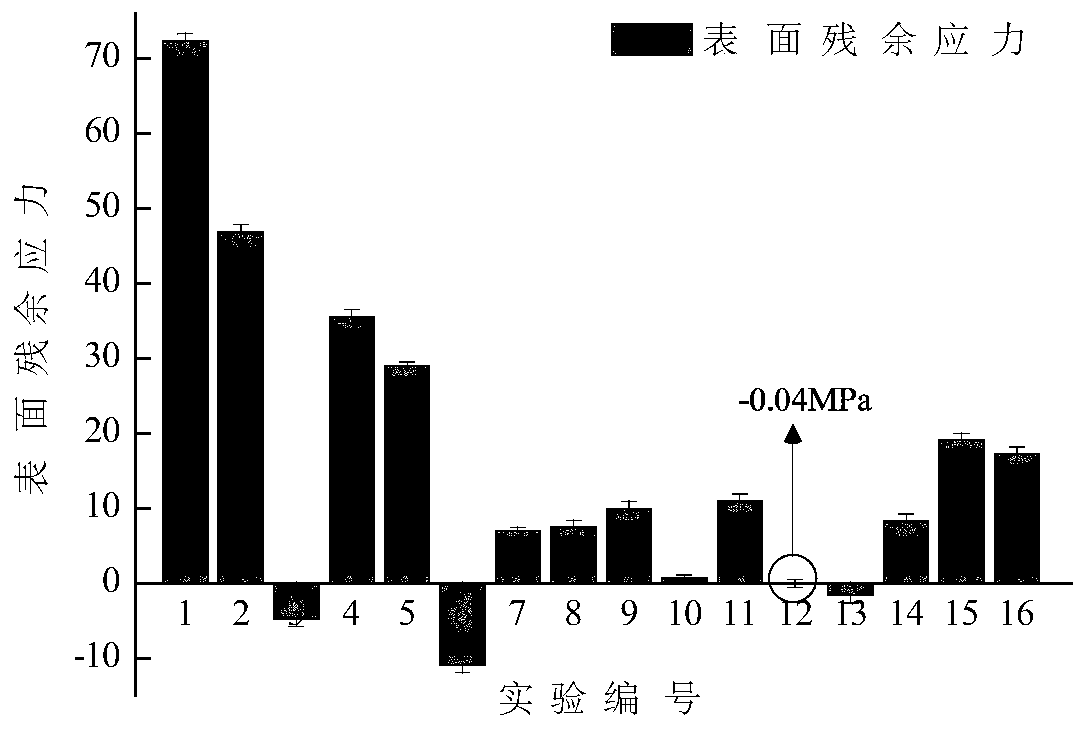

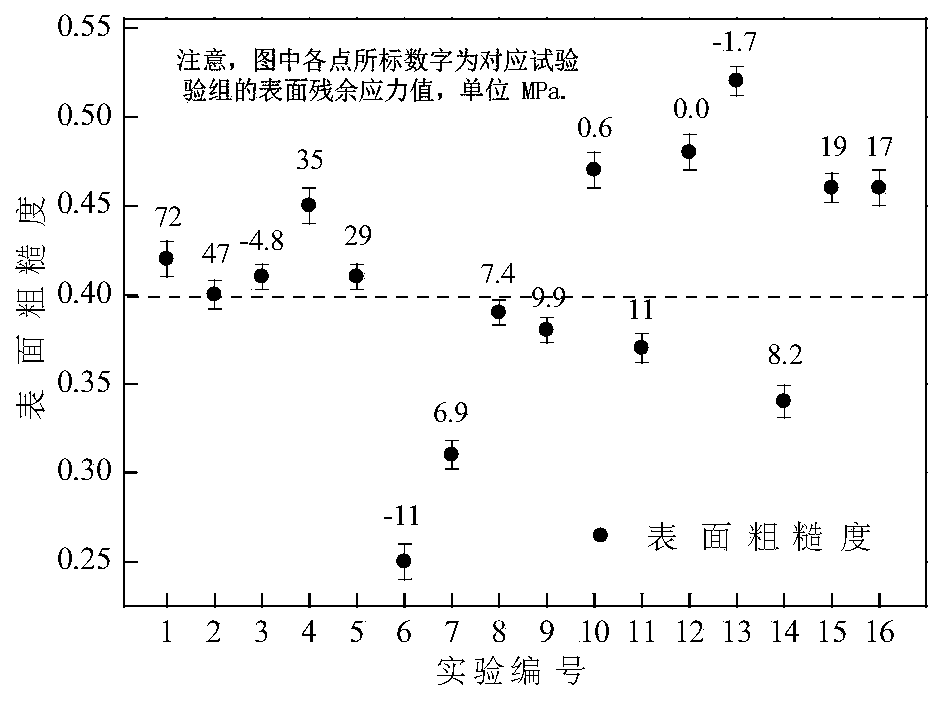

A workpiece cutting method for obtaining high-integrity surface

ActiveCN110539005BReduce surface roughnessStable hardeningAutomatic control devicesPrecision positioning equipmentMachined surfaceEngineering

The invention relates to a workpiece cutting method for obtaining a high-integrity surface. The workpiece is subjected to at least one forward finish cutting and at least one reverse finish cut after rough cutting, and each forward finish cut and reverse finish cut uses It is carried out in multiple steps. In two adjacent steps, the cutting of the latter step passes through the machined surface of the cutting step of the previous step. The cutting method of the present invention reduces the residual tensile stress on the surface of the workpiece, reduces the surface roughness, and stabilizes the hardness at a reasonable level. within range.

Owner:SHANDONG UNIV

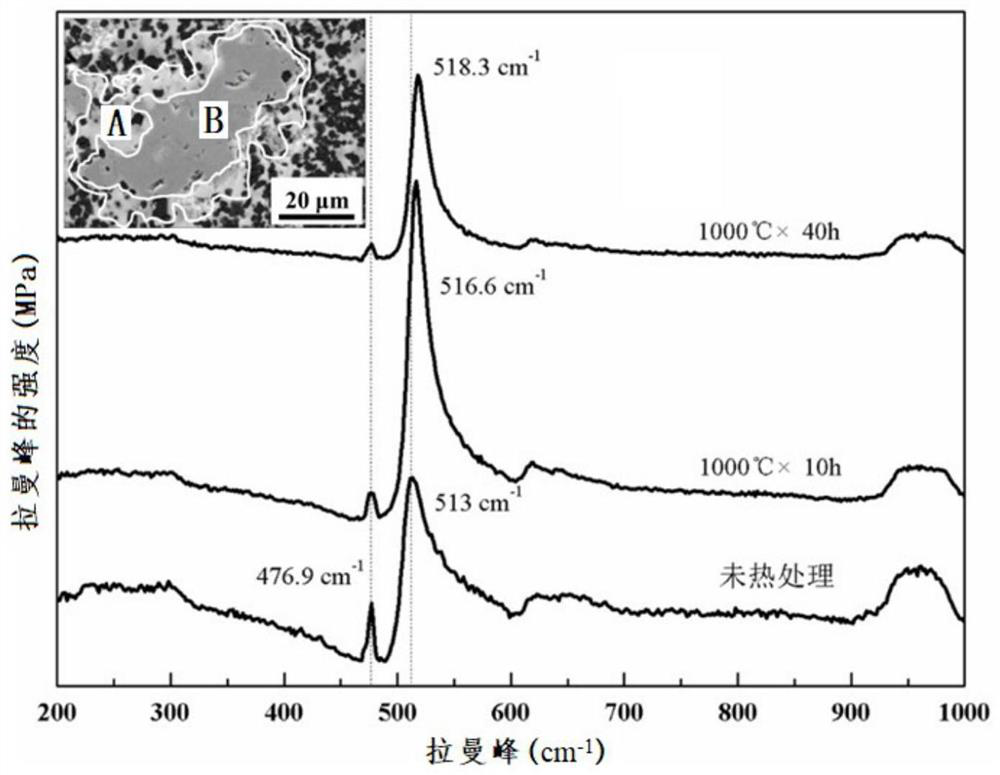

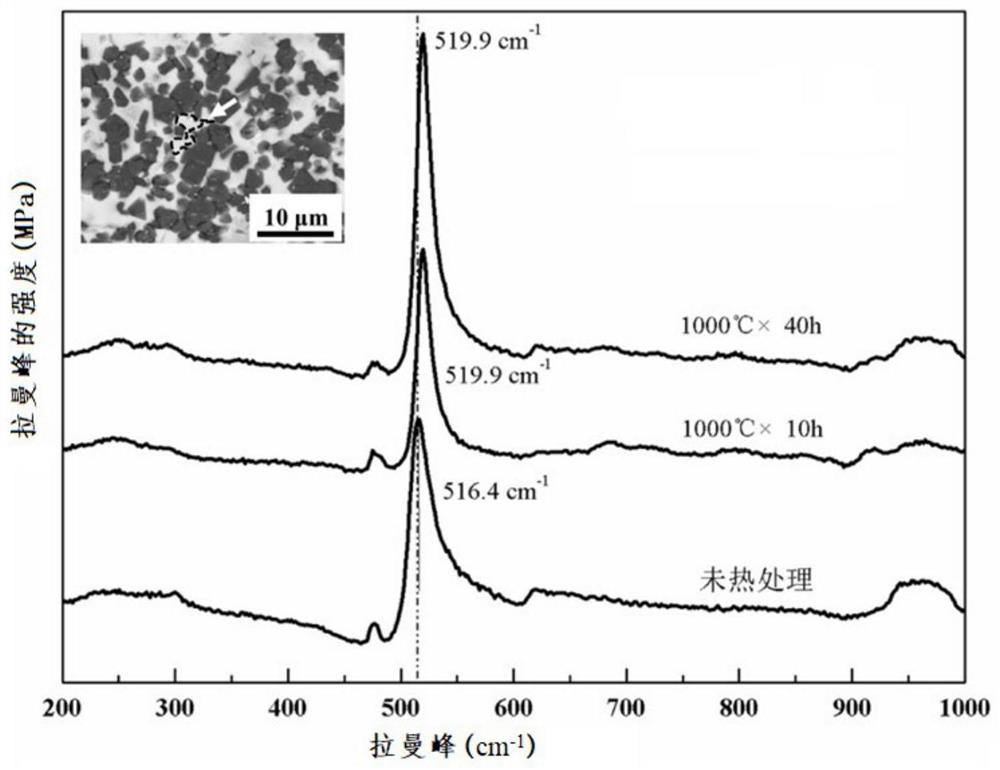

A kind of preparation method of boron carbide ceramic composite material

The invention relates to a method for preparing boron carbide ceramic composite materials, which includes the following steps: S1. Wet-mix boron carbide powder, carbon source and mixing medium to form a mixed material, which is dried, ground and sieved to form a mixture to be prepared. Molding materials; S2. Press and shape the materials to be molded, and obtain a ceramic body after drying; S3. Place the silicon block on the ceramic body for vacuum infiltration reaction sintering to obtain a boron carbide ceramic composite precursor; S4. After removing the residual silicon on the surface of the boron carbide ceramic composite precursor, it is placed in a heating device for heat treatment, and then cooled to room temperature to obtain the boron carbide ceramic composite material. The preparation method of the boron carbide ceramic composite material of the present invention can reduce the sintering temperature, improve the density of the boron carbide ceramic composite material, and at the same time improve the mechanical properties of the boron carbide ceramic composite material.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com