Patents

Literature

259results about How to "Strong load bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compression spring processing process

InactiveCN102248097AShorten the lengthGuaranteed straightnessFurnace typesWire springsSand blastingMechanical property

The invention relates to a compression spring processing process. The compression spring processing process is characterized by comprising the following process steps of: rolling, cutting into rings, reducing diameters, quenching, performing primary tempering, inspecting mechanical properties, setting, grinding end faces, correcting the length and the concentricity of springs, performing secondary tempering, setting, performing primary heating and loading aging treatment, grinding the end faces, detecting, performing sand blasting, performing magnetic powder inspection, performing sand blasting, performing surface treatment, performing secondary heating and loading aging treatment, and detecting finished products. By the process, the deformation of the springs in the processing process can be reduced, the geometric dimension of the springs is ensured, and production efficiency is greatly improved.

Owner:SHENYANG AIRCRAFT CORP

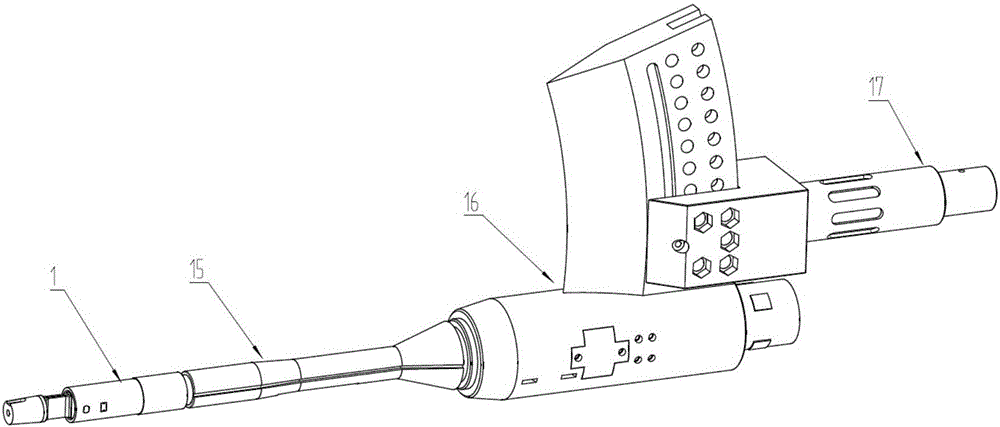

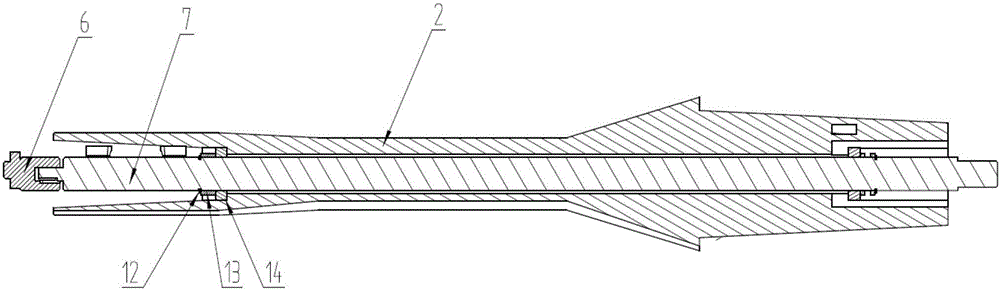

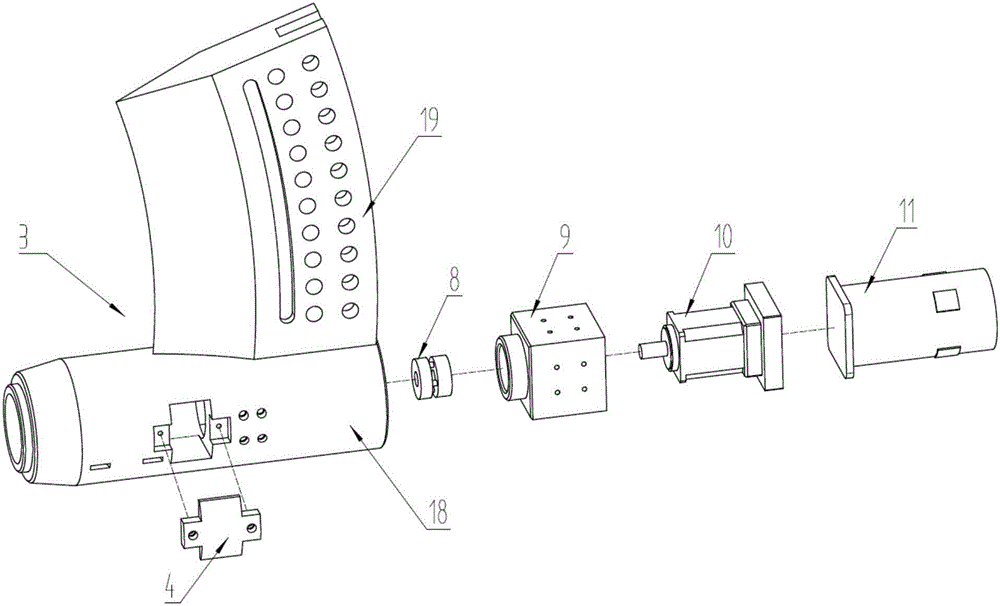

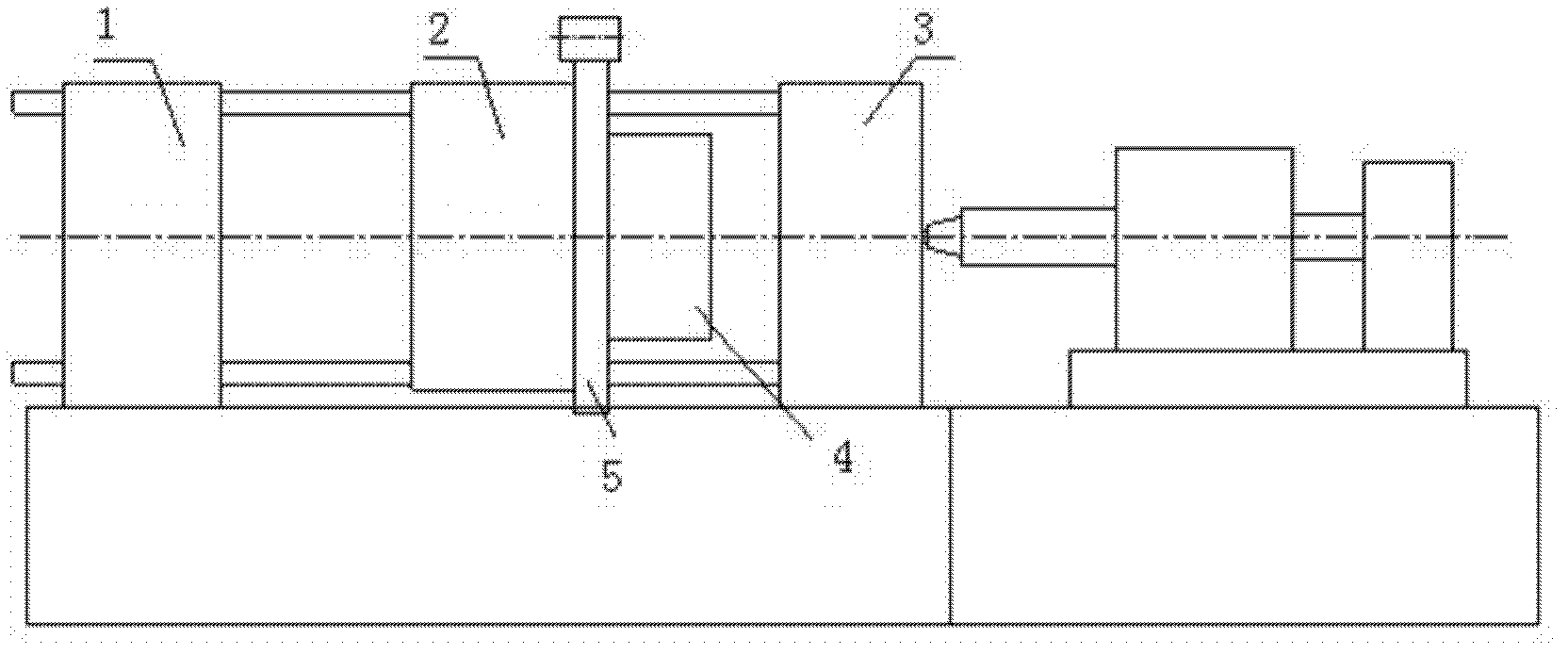

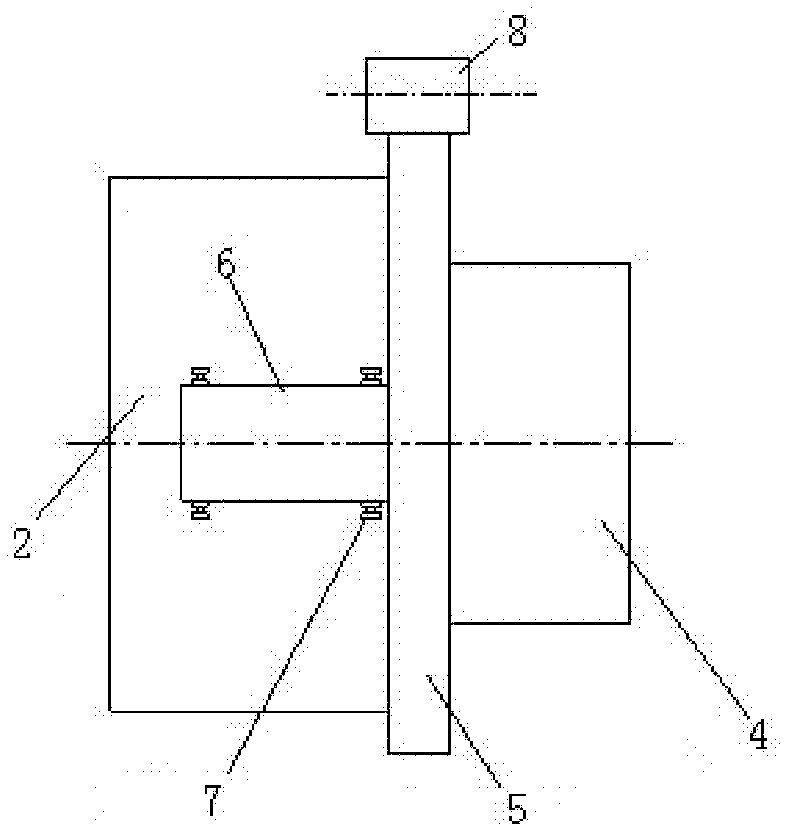

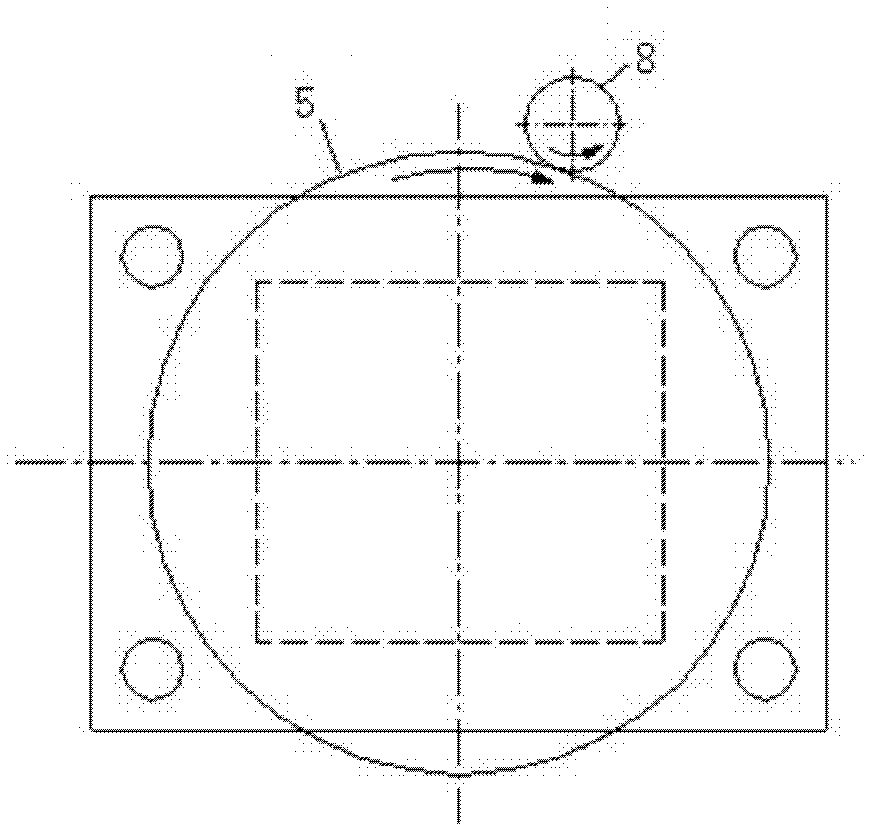

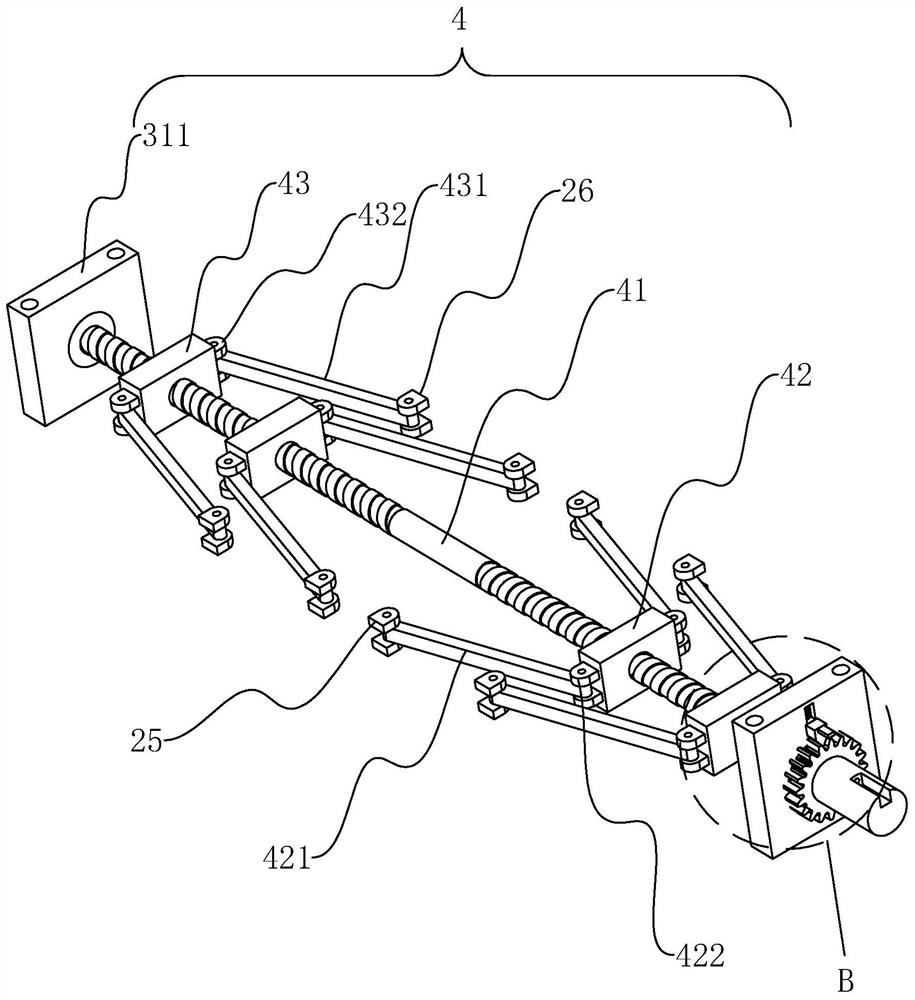

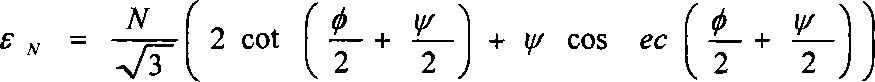

Device for forced vibration test of dynamic derivative in wind tunnel

ActiveCN106840574AStrong load bearing capacityEffectively fixedAerodynamic testingAviationDrive shaft

The invention discloses a device for forced vibration test of dynamic derivative in wind tunnel. The device comprises a dynamic balance, a supporting mechanism, a side-slip angle mechanism and a rolling angle mechanism. The dynamic balance is connected to the side-slip angle mechanism through the supporting mechanism. The rolling angle mechanism is connected to the side-slip angle mechanism, and a relative position and angle between the side-slip angle mechanism and the rolling angle mechanism are adjusted through the coordination between the side-slip angle mechanism and the rolling angle mechanism so as to meet the test requirements under the condition of different attack angles, side-slip angles and rolling angles. According to the device, an output torque of a servo motor can drive a transmission shaft to continuously perform rotational motion in a fixed-frequency or a sweep-frequency mode, and an eccentric cam cooperates with a groove of the dynamic balance to complete the motion form conversion and realize the harmonic forced vibration. The device has the advantages of reasonable and compact structure, large normal-direction bearing capacity and high precision, and has great application value in the field of aviation and aerospace.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

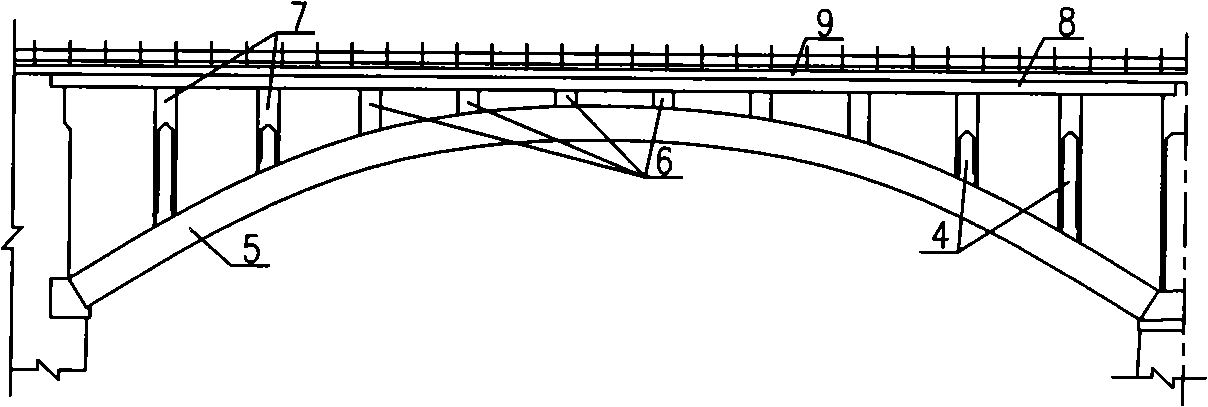

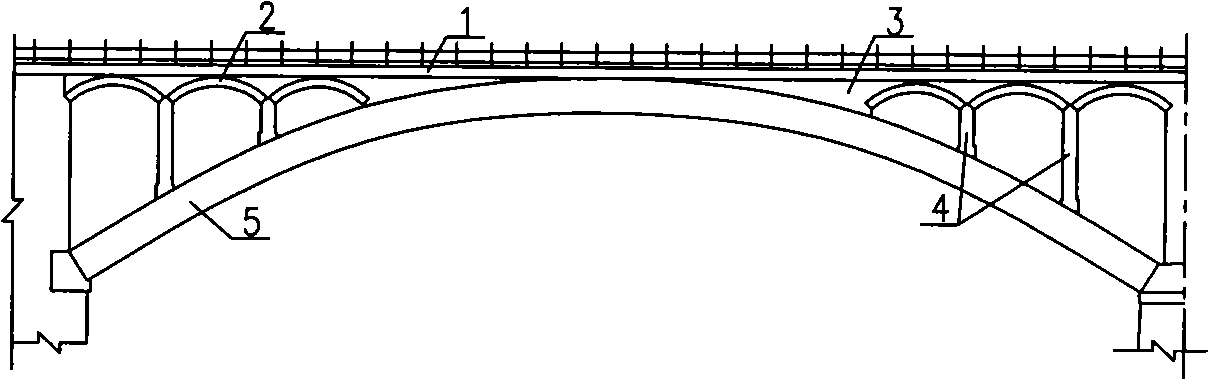

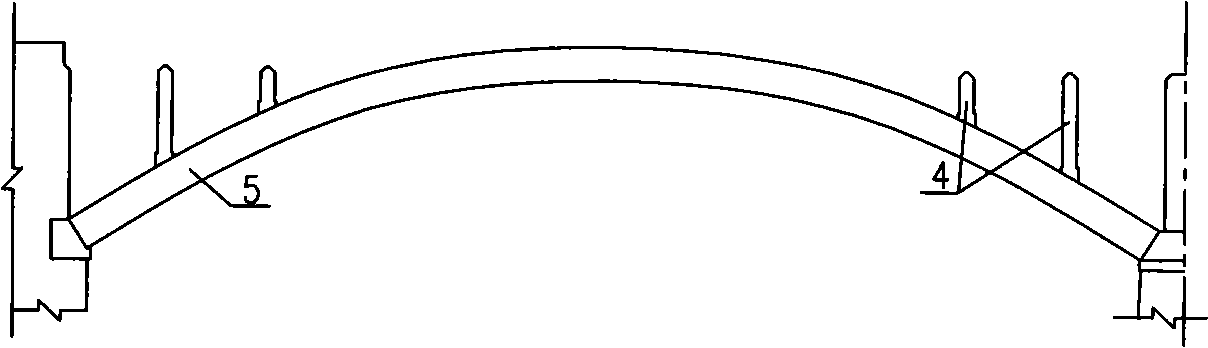

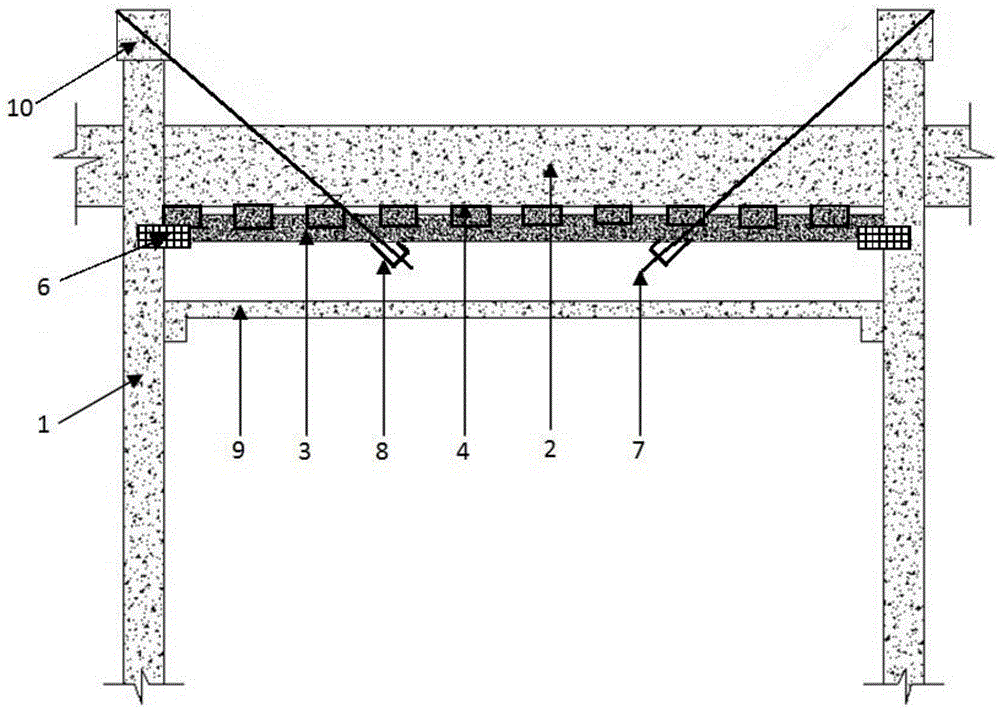

Process for rebuilding double arch bridge by replacing arch style construction on arch with continuous slabs

InactiveCN101289835AImprove the state of stressReasonable forceBuilding repairsBridge erection/assemblyNatural resourceBridge deck

The invention relates to a reforming method of replacing double arch bridges in arched spandrel structure with continuous slabs. The method comprises the following steps that: a bridge floor system, a spandrel arch ring and a solid web section of a double arch bridge in arched spandrel structure are dismantled first; a plate girder pier is arranged on a ribbed main arch ring, and a former spandrel arch pier is heightened to form another plate girder pier, ensuring that the plate girder piers are identical in interval and horizontal height; bridge piers are heightened to ensure that the horizontal height of the bridge piers is equal to the plate girder piers; continuous slabs are cast on the plate girder piers and the bridge piers, and then the continuous slabs are paved with a bridge deck. The method improves the stress state of the ribbed main arch ring and ensures that the stress of the ribbed main arch ring tends to be more reasonable; as the arched spandrel structure is replaced with the continuous slabs, the dead load weight of an arch is reduced, and the bearing capacity of the bridge is improved correspondingly; the method saves the occupancy of natural resources and economic resources, which is caused by abandonment, old bridge demolishment and reconstruction, has the reinforcement cost which is 50 percent of new construction cost, and avoids the pollution on the natural environment caused by abandonment and old bridge demolishment.

Owner:江西中煤建设集团有限公司

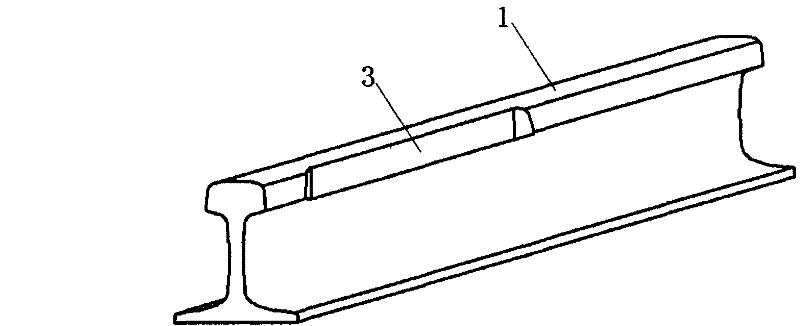

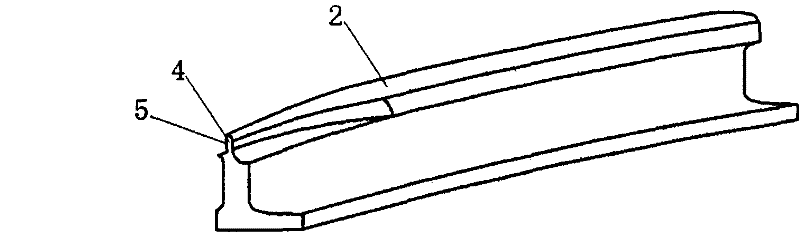

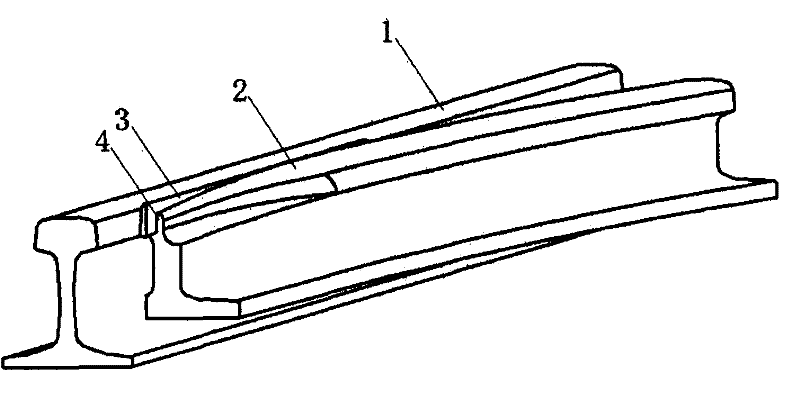

High-strength turnout switch

The invention discloses a high-strength turnout switch, and belongs to the technical field of railway assembly manufacture. The turnout switch comprises a straight basic rail and a curved point rail. The turnout switch is characterized in that: the surface, attached to the curved point rail, of the straight basic rail is a sunken vertical abutted surface; the surface, attached to the straight basic rail, of the curved point rail is a vertical abutted surface; and the rail head of the curved point rail is a flat rail head capable of being concealed in the sunken abutted surface of the straight basic rail. The turnout switch has the advantages that: the point end of the original curved point rail is widened to improve the strength of the point end of the curved point rail; and correspondingly the abutted surface of the straight basic rail is changed into the vertical abutted surface capable of accommodating the widened point end of the curved point rail, so that the transition distance from the point end of the curved point rail to the width of the complete rail head is shortened at the same time of ensuring abutting, namely the length of the weak section of the curved point rail is reduced, the load bearing capacity and the abrasion resistance of the curved point rail are improved, and the service life of the curved point rail is greatly prolonged. The turnout switch is particularly suitable to be used in heavy-duty line turnouts.

Owner:王萍 +5

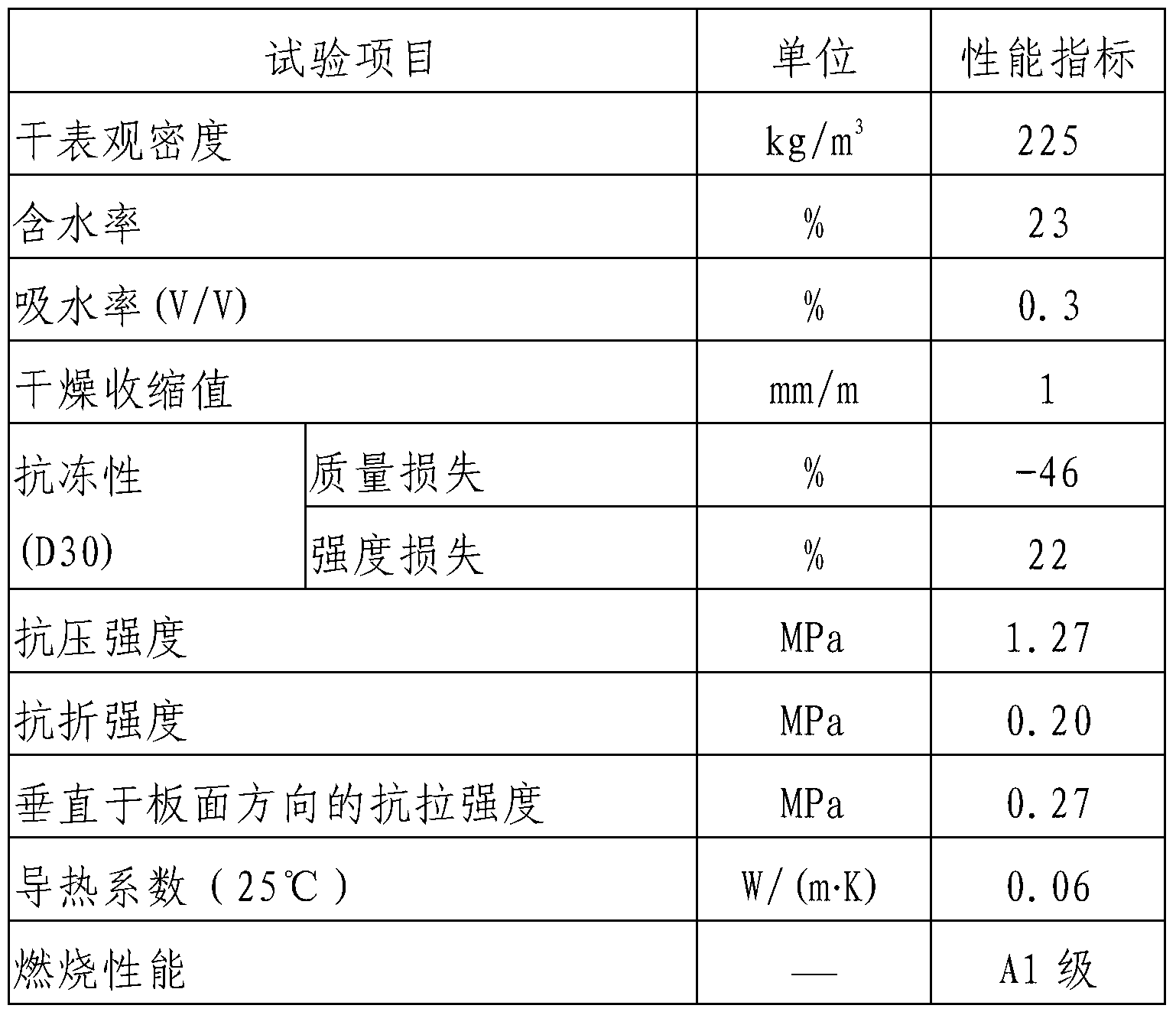

Foamed concrete heat preservation plate and preparation method thereof

The invention belongs to the field of heat preservation materials, and in particular relates to a foamed concrete heat preservation plate and a preparation method thereof. The foamed concrete heat preservation plate comprises the following raw materials in parts by weight: 380-430 parts of a binding material, 135-160 parts of an admixture, 8-12 parts of calcium stearate, 3-6 parts of polymer gelatine powder, 0.5-3 parts of anti-cracking fibers, 1-4 parts of moisture repellent, 25-35 parts of hydrogen peroxide and 270-310 parts of water. The foamed concrete heat preservation plate is obtained by adding the raw materials into a gravity-free mixing stirrer to mix for 2-5 minutes, pouring the mixtures into a die and forming and maintaining the product. The bonding material consists of portland cement and high-alumina cement; the weight ratio of the portland cement to the high-alumina cement is (1-4):1. The foamed concrete heat preservation plate is high in tensile strength, small in density, light in weight, high in fire retardant effect and low in absorption rate; the combustion performance of the foamed concrete heat preservation plate is up to grade A1; the cost of the raw materials is low; the heat preservation plate is high in safety, and therefore, toxic gas cannot be produced even under the condition of high temperature or fire.

Owner:上海宝冶工程技术有限公司

Method for preparing special lubricating grease and thickening agent for cylinder of electric tool

The invention relates to a method for preparing special lubricating grease and thickening agent for a cylinder of an electric tool. The lubricating grease and thickening agent mainly comprise the following components: a) base oil; b) at least one thickening agent of compound lithium, compound lithium calcium or carbamido grease, or composite thickening agent of any two of the three substances; c) silicon-containing anti-foaming agent; d) one or more extreme-pressure antiwear agents of borates or vulcanized whale oil substitute; e) one or more anilines antioxygens or dialkyldithiophosphates antioxygens; and f) tripolycyanamide urate; wherein the amount of the base oil in use accounts for 70-95% of the total weight of the lubricating grease, the thickening agent accounts for 5-30% of the total weight of the lubricating grease, the amount of the silicon-containing anti-foaming agent accounts for 5-10% of the total weight of the lubricating grease, the amount of the extreme-pressure antiwear agents accounts for 2-5% of the total weight of the lubricating grease, the amount of the antioxygens accounts for 1-5% of the total weight of the lubricating grease, and the amount of the tripolycyanamide urate accounts for 3-15% of the total weight of the lubricating grease. The lubricating grease, rubber and thermoplastic elastomer which are prepared using the components have good compatibility, excellent extreme-pressure wearability, foaming resistance, lubrication, flame resistance and noise lowering, and the like. The lubricating grease is suitable for the lubrication of the cylinders of various electric hammers and electric picks and in particular suitable for the lubrication and sealing of the cylinders of the electric hammers and electric picks which keeps on operating for a long time at a high speed.

Owner:杭州得润宝油脂股份有限公司

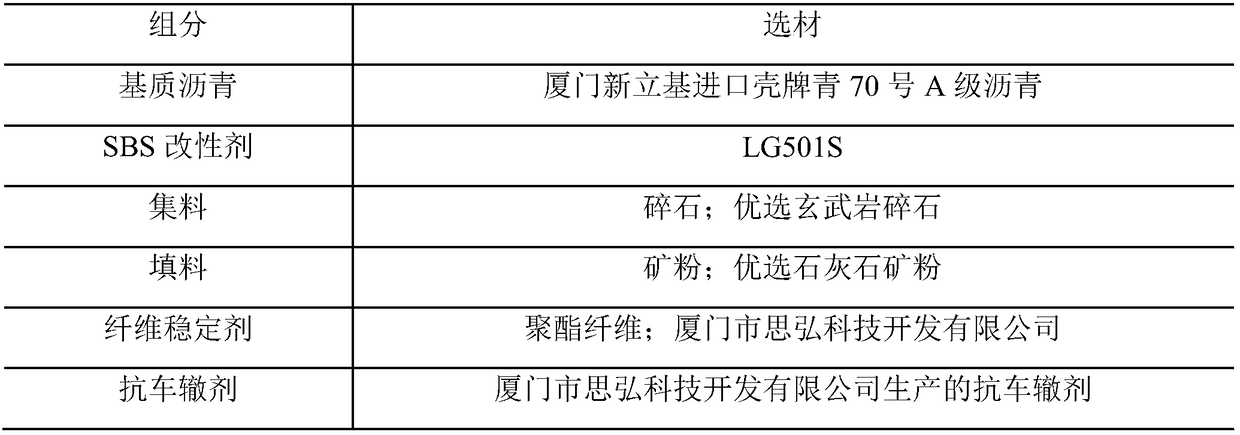

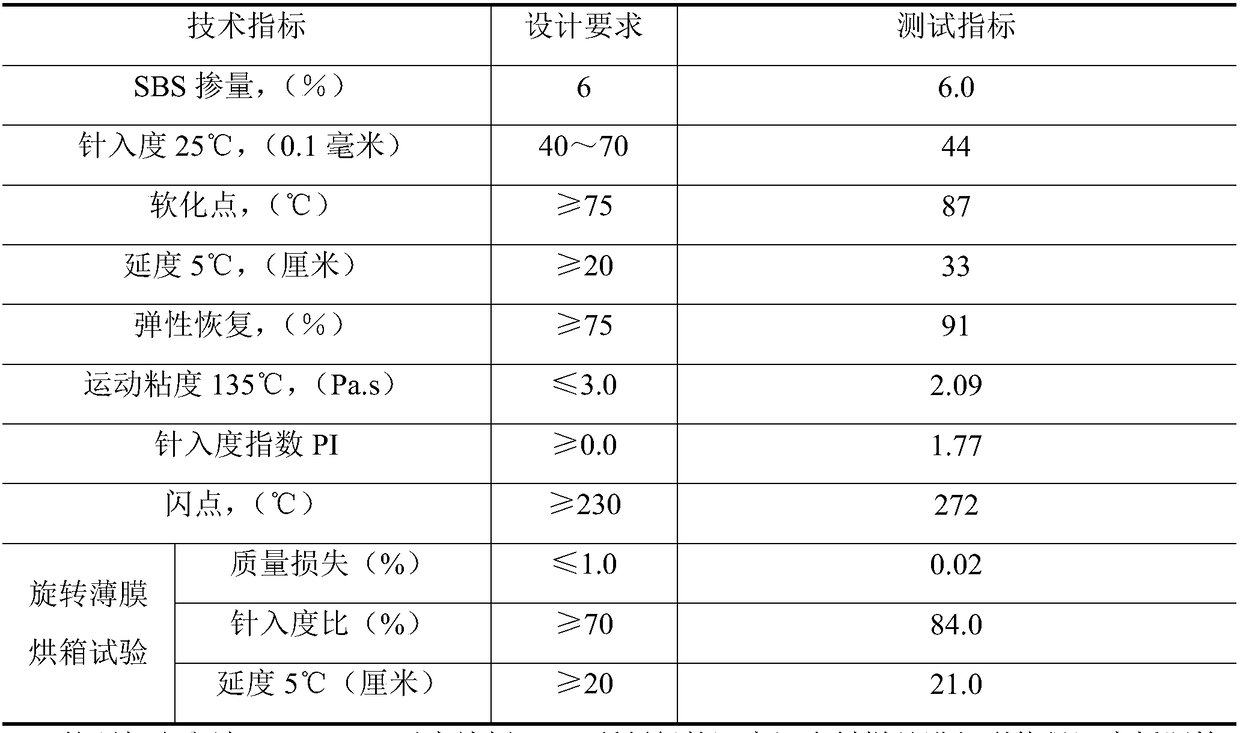

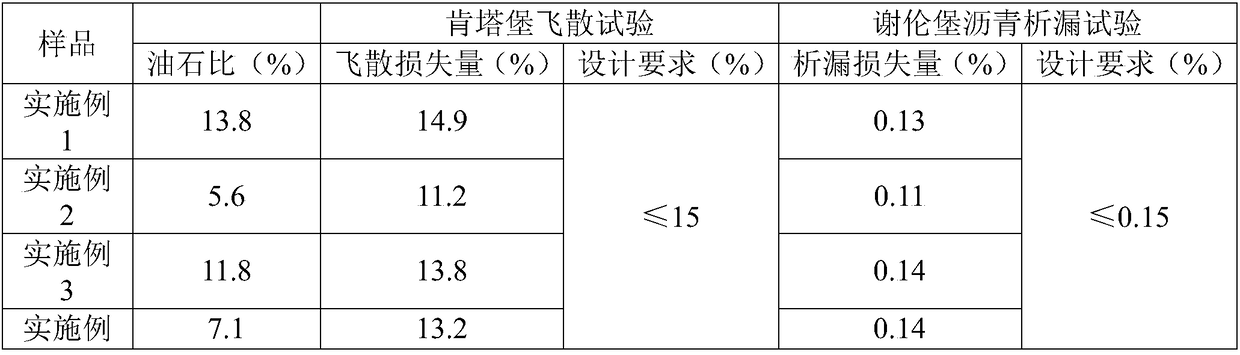

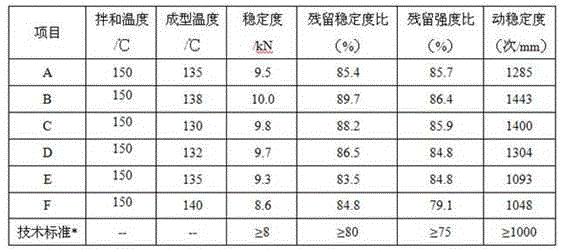

Asphalt mixture and production method thereof

ActiveCN109180077AImproves rutting resistanceImprove stress resistanceBuilding insulationsAsphaltPolymer chemistry

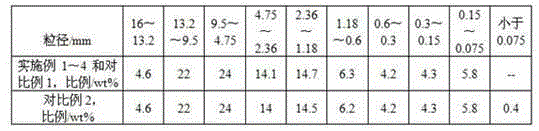

The invention discloses an asphalt mixture and a production method thereof and relates to the field of building materials. The asphalt mixture solves the problem that the existing asphalt mixture forthe airport runway has poor stability and anti-rutting ability, and comprises 4 to 12 wt% of modified asphalt, 72 to 88 wt% of aggregate, 5 to 10 wt% of a filler, 0.5 to 3 wt% of a fiber stabilizer and 0.5 to 3 wt% of an anti-rutting agent and has an asphalt-aggregate ratio of 5.6 to 14%. The modified asphalt comprises matrix asphalt and SBS and the weight of the SBS is 5-8 wt% that of the matrixasphalt. The asphalt mixture has the advantages of high dynamic stability, high temperature stability, strong rutting resistance and good water stability, and is suitable for airport runways.

Owner:厦门市政沥青工程有限公司 +2

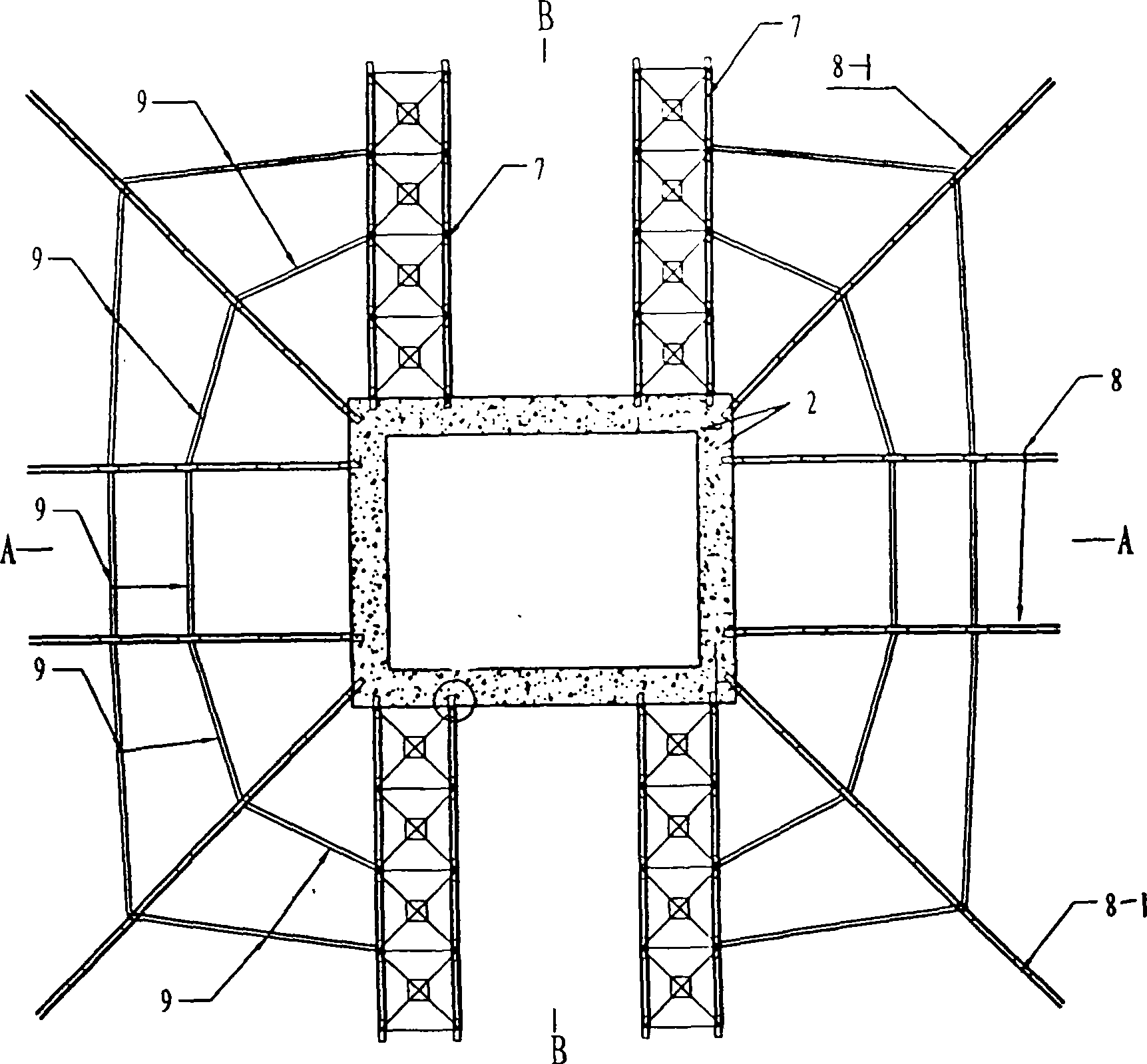

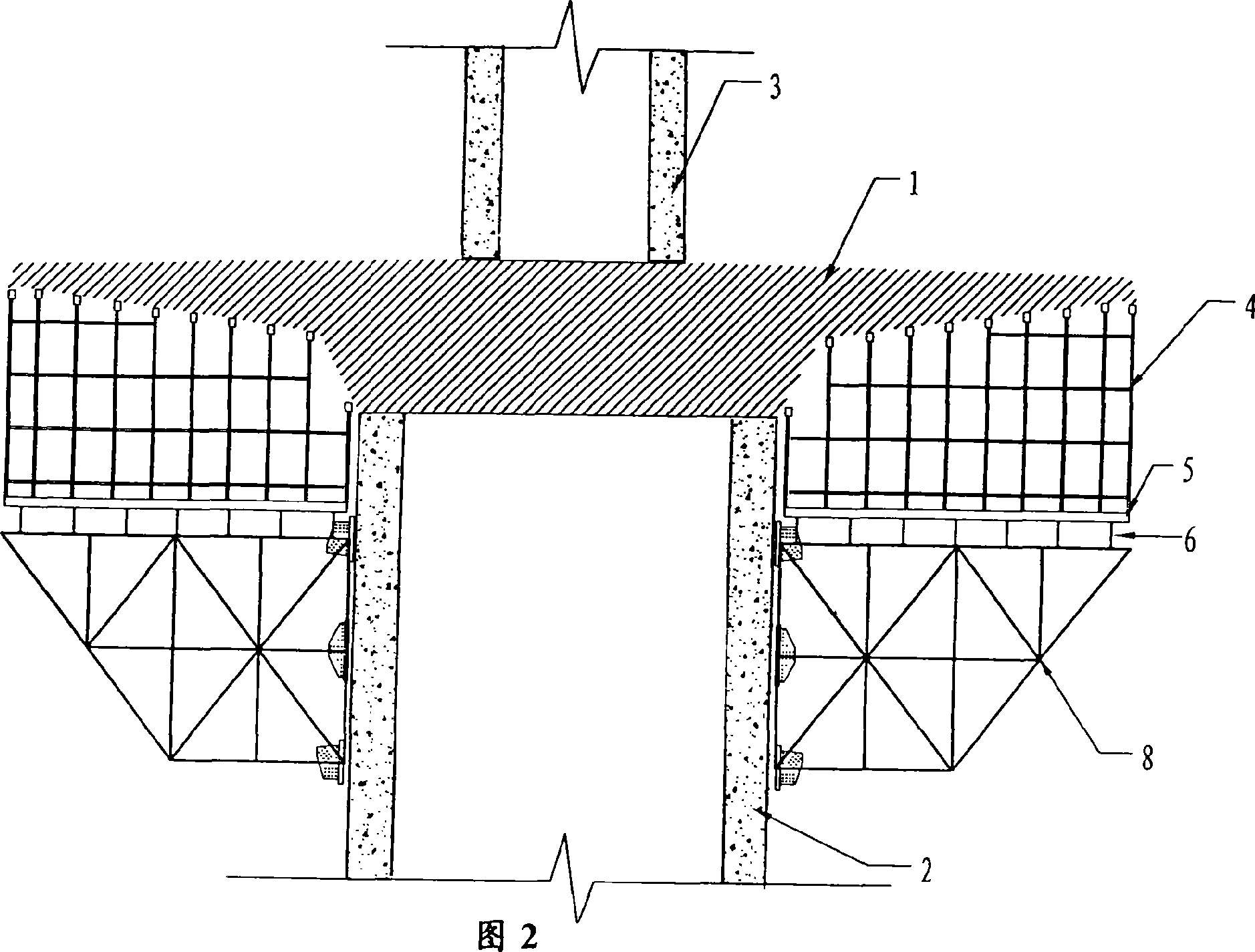

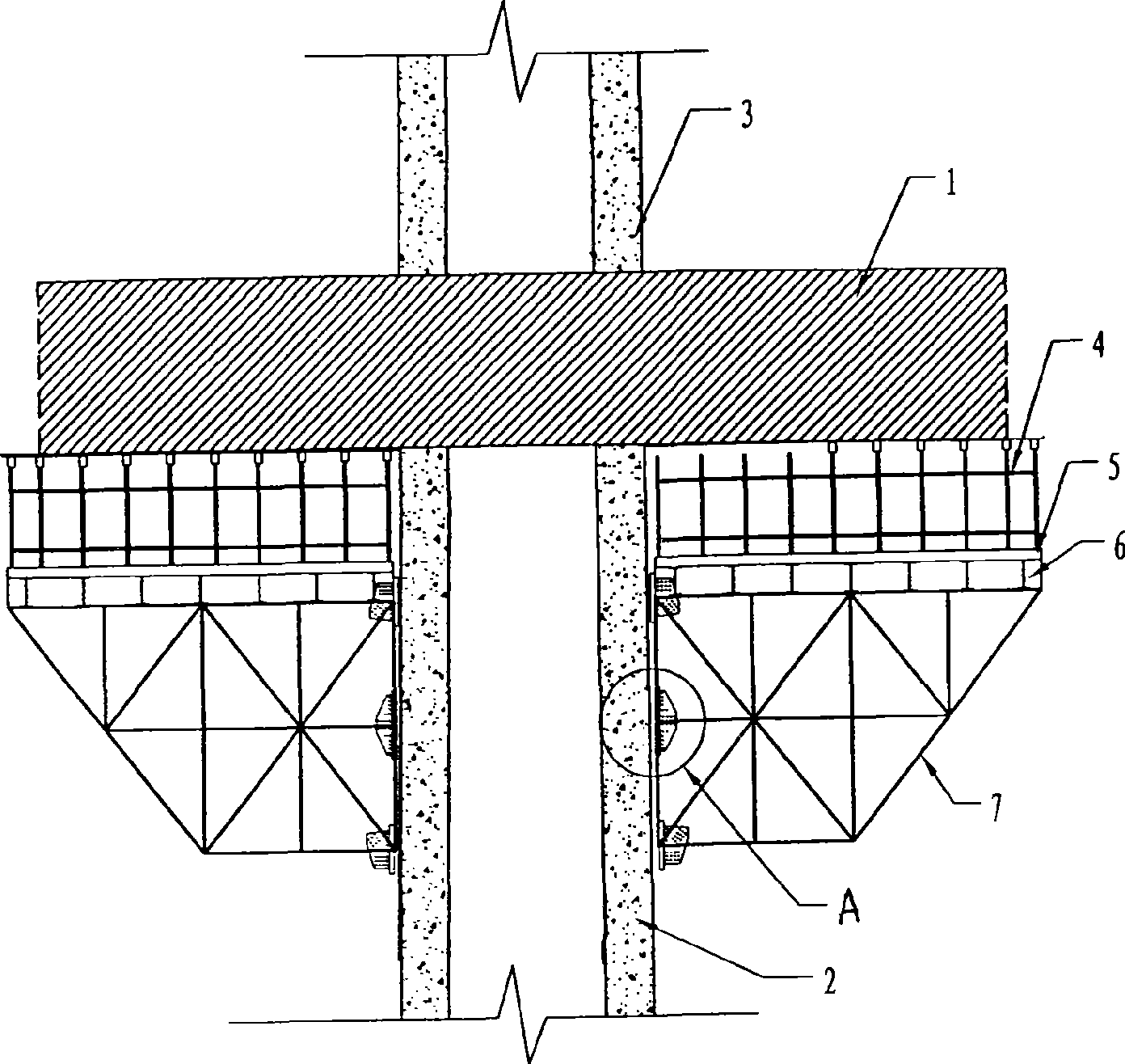

Cast-in-place support for long cantilever No. 0 block of cable-stayed bridge with tower beam consolidation and putting up method

InactiveCN101446076AClear forceSimple and fast operationBridge erection/assemblyFalseworkGusset plate

The invention relates to a cast-in-place support for the long cantilever No. 0 block of a cable-stayed bridge with tower beam consolidation, which comprises a reassembling type truss girder falsework, an I-shaped steel distributive girder, a sleeper and a bowl-fastening piece support, wherein the reassembling type truss girder falsework is connected at the upper part of the a lower pylon column; the I-shaped steel distributive girder is laid on the reassembling type truss girder falsework; the sleeper is laid on the I-shaped steel distributive girder, and the bowl-fastening piece support is built on the sleeper. The cast-in-place support is characterized in that reassembling type truss girder falsework is formed to be an inverted trapezoid through the connection of four groups of double-beam truss group, four single-beam trusses and four oblique angled single-beam trusses. The method for putting up the cast-in-place support comprises the following steps: pre-burying a bolt sleeve; mounting a special angle iron and a special gusset plate; putting up the reassembling type truss girder falsework; laying the I-shaped steel distributive girder; laying the sleeper and putting up the bowl-fastening piece support. The invention has the advantages of long cantilever, strong load bearing capability, big stiffness, clear stress and simple and easy operation, and safety risks caused by welding defects are avoided.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

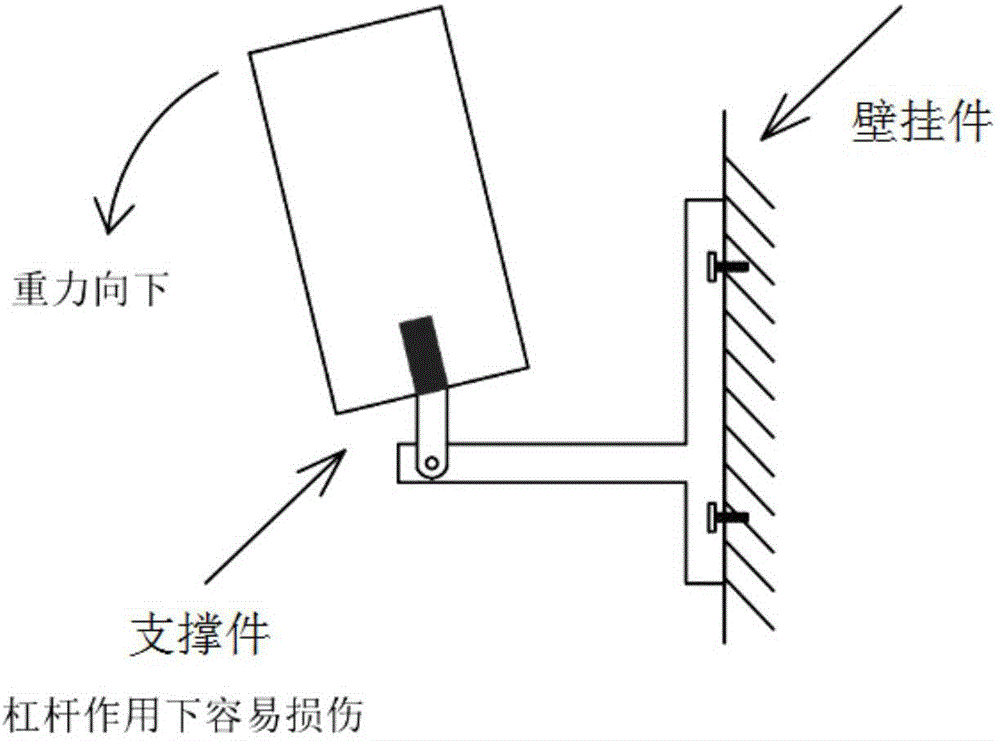

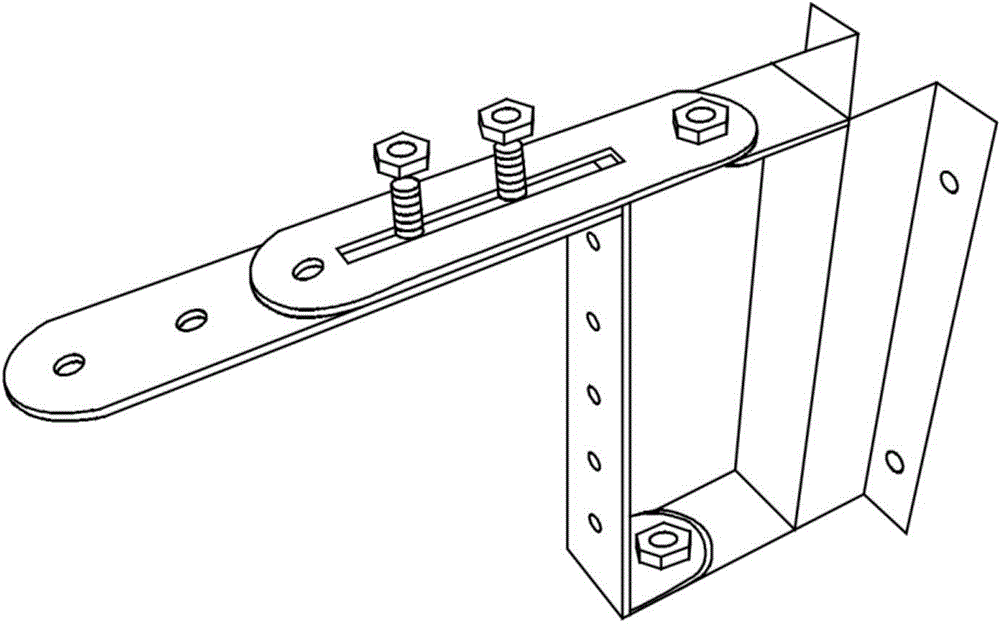

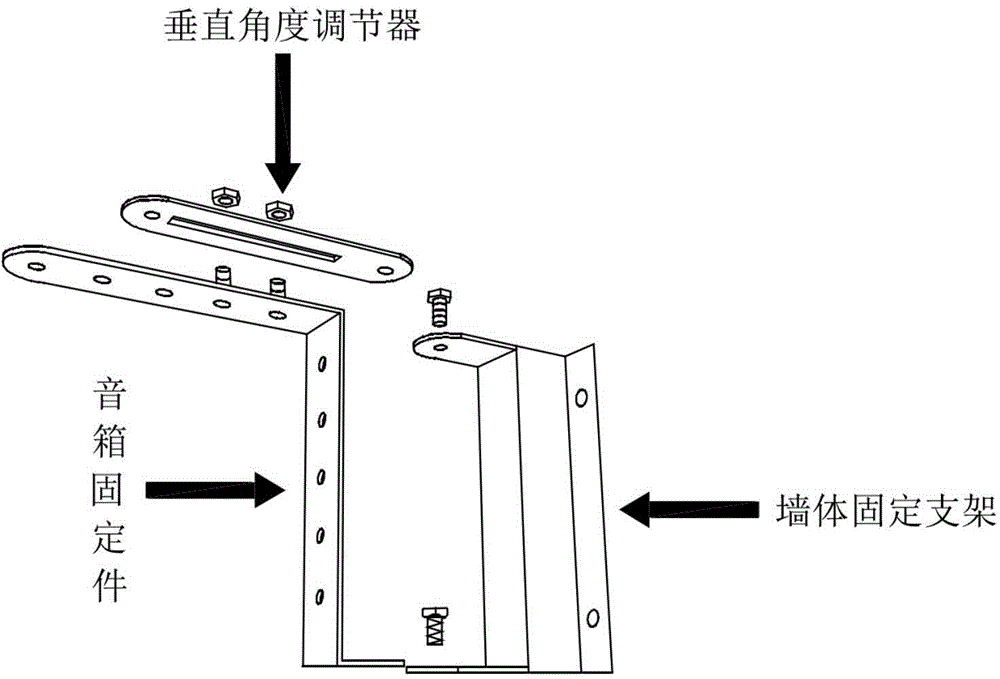

Sound box wall hanger

InactiveCN104918150ASolve the problem of poor load-bearing capacityStrong load-bearing capacityTransducer casings/cabinets/supportsCarrying capacityLoad carrying

The invention discloses a sound box wall hanger which comprises a sound box fixing member, a wall body fixing bracket and a vertical angle adjuster. The sound box fixing member is a Z-shaped fixing plate. One end of a horizontal section on the upper end of the sound box fixing member is fixedly connected with the top of a sound box through a screw. The other end of the horizontal section on the upper end of the sound box fixing member is connected with a long hole in the vertical angle adjuster through a screw. A vertical section of the sound box fixing member is fixedly connected with the back of the sound box through a screw. The wall body fixing bracket comprises a suspension end and a fixation end. The fixation end is fixedly connected with a wall body through a screw. Upper and lower ends of the suspension end are respectively provided with a screw hole, and screws are arranged in the screw holes. A screw hole in the vertical angle adjuster is connected with the wall body fixing bracket through the upper screw. A screw hole in a horizontal section on the lower end of the sound box fixing member is connected with the wall body fixing bracket through the lower screw. According to the invention, a support nest is changed; the problem of poor load carrying capacity, which is caused by the damaged support nest, is solved; and the sound box wall hanger has the characteristics of good force-bearing point, strong carrying capacity and easy installation.

Owner:NANJING PIONE HIGH TECH

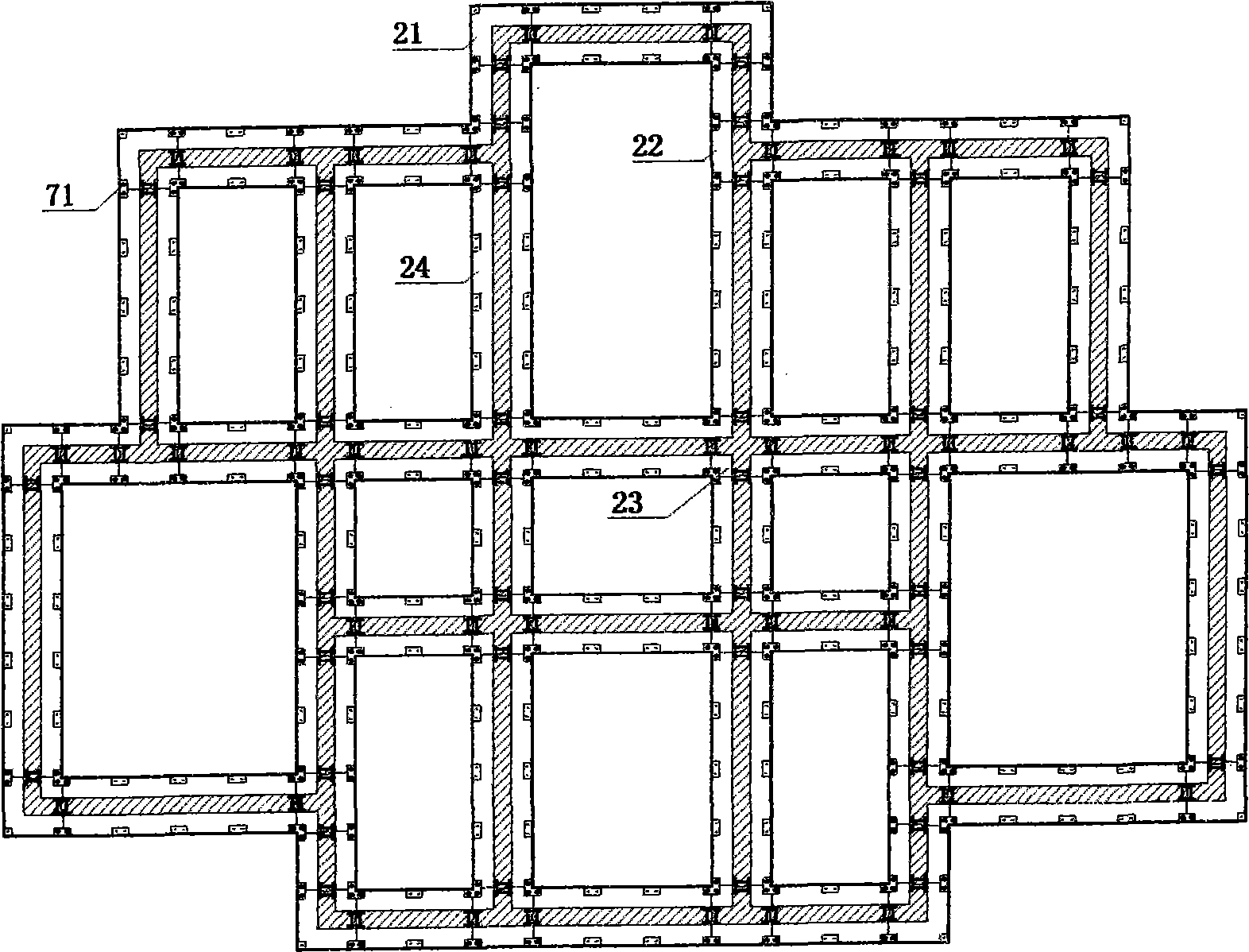

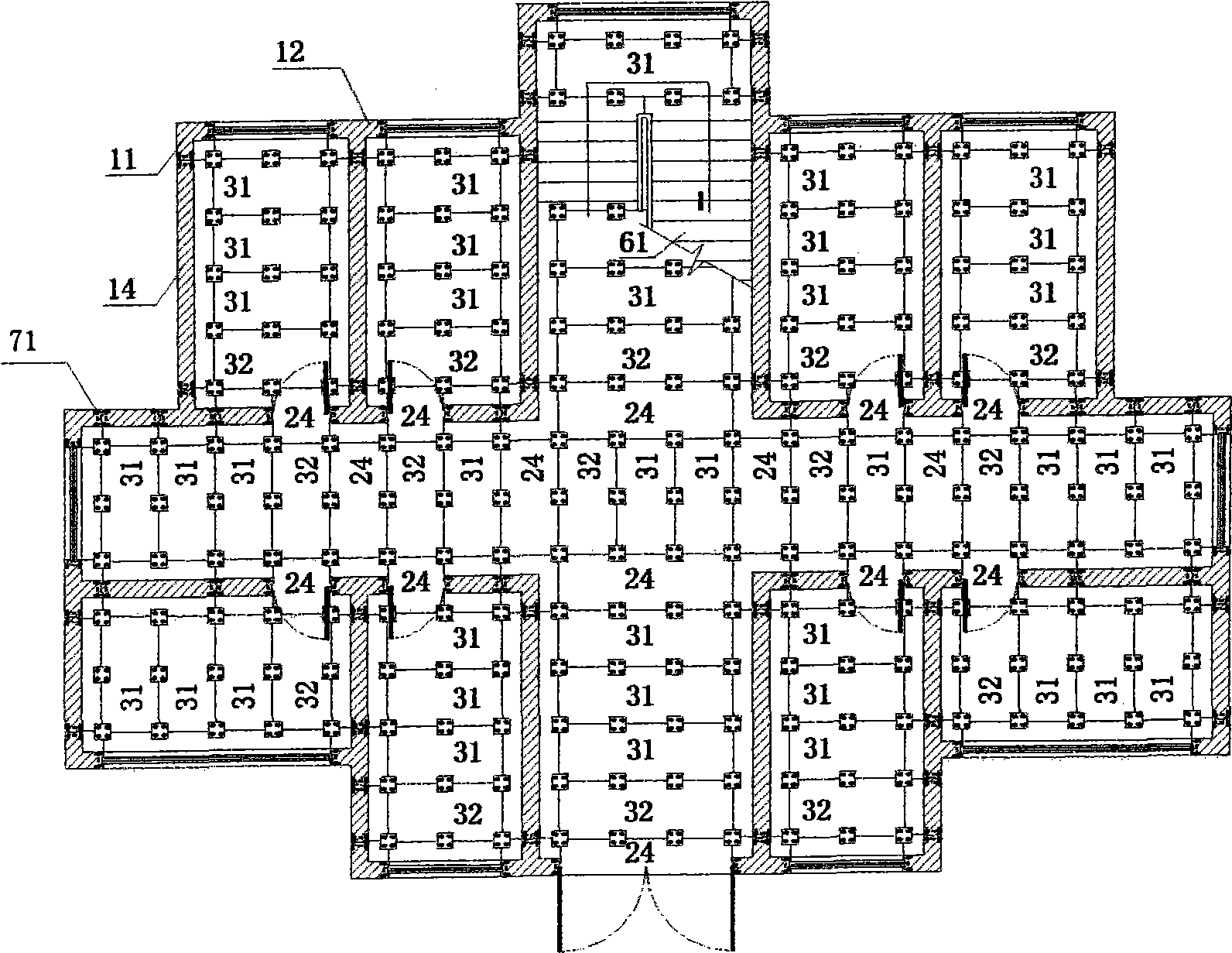

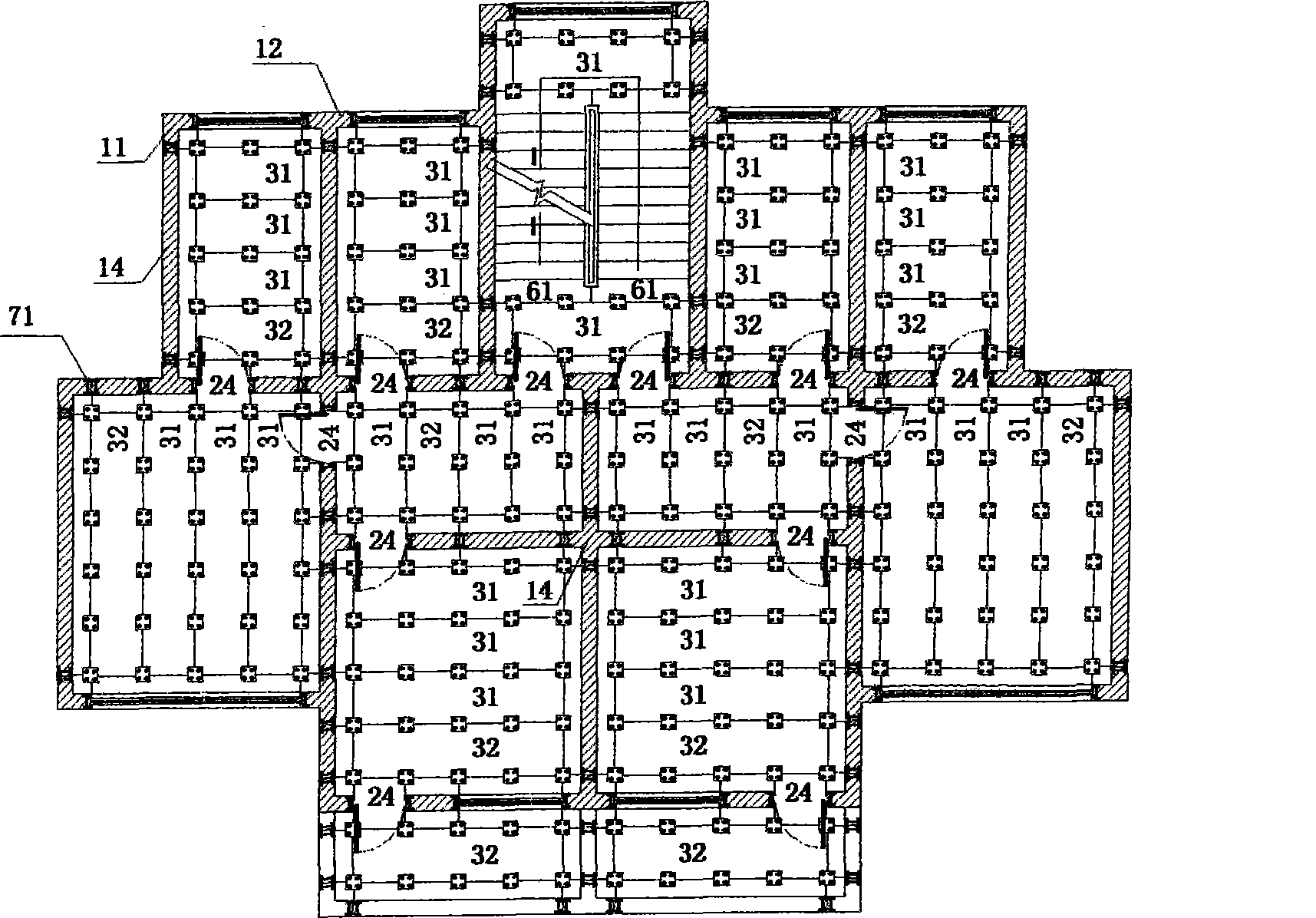

Prefabricated house

InactiveCN101476350AStrong load bearing capacityAvoid disadvantagesBuilding constructionsHouse buildingEngineering

The invention relates to a house assembled by prefabricated members, which comprises metope (column) slab prefabricated members, beam prefabricated members, floor (foundation) slab prefabricated members, roof slab prefabricated members, valley prefabricated members, staircase prefabricated members and connecting mechanisms. The overall dimension of the prefabricated members adopts a unified building module, and the prefabricated members can be assembled into various types of houses with different storey heights and can be prefabricated into standard members in advance for storage in batch. Due to the tensioning function of the connecting mechanisms, the overall stress of the assembled house is more reasonable, and simultaneously the tightening and sealing effect between the connected prefabricated members can be achieved by treating the prefabricated members through dry process. The invention shortens the construction period of building construction, and reduces the integrated cost of social construction because the prefabricated members can be disassembled and recycled. The house assembled by the prefabricated members has actual significance in the aspects of promoting resource intensification and building industrialization.

Owner:华玉武

Method for reinforcing existing municipal pipe gallery within deep foundation pit excavation range

ActiveCN104674863APlay a supporting roleAvoid deformationFoundation repairBulkheads/pilesSupport pointBuilding construction

The invention relates to a method for reinforcing an existing municipal pipe gallery within a deep foundation pit excavation range, and is particularly applied to the condition of excavating a large-sized foundation pit when a municipal pipe gallery exists in a thick alluvial formation. The method comprises the following steps: constructing ordinary precast piles and pipe gallery reinforcement precast piles, wherein reserved connection devices are arranged on the pipe gallery reinforcement precast piles; excavating a foundation pit soil body from top to bottom until the reserved connection devices on the pile bodies are exposed; simultaneously pouring a pipe gallery support structure taking a soil model as a template below the pipe gallery and beams on two sides of the pipe gallery by taking the reserved connection devices of the pipe gallery reinforcement precast piles as support points; constructing anchor ropes, wherein one end of each anchor rope is anchored onto the corresponding beam, and the other end of each anchor rope is connected with a top beam on the corresponding pipe gallery reinforcement precast pile; continuing excavating the residual foundation pit soil body to a baseline of the foundation pit, constructing air duct structures, and integrally pouring waist beams of the foundation pit and air duct top plates to finish the construction. According to the method, the stability of the soil body around air ducts during the excavation of the air ducts is ensured, and the influence of excavation of the soil body on the lower part on the pipe gallery is reduced, and the pipe gallery is supported in advance.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

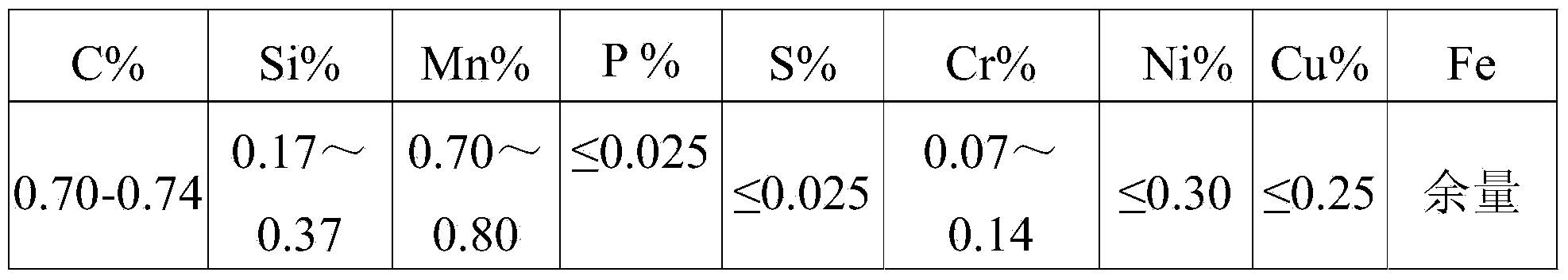

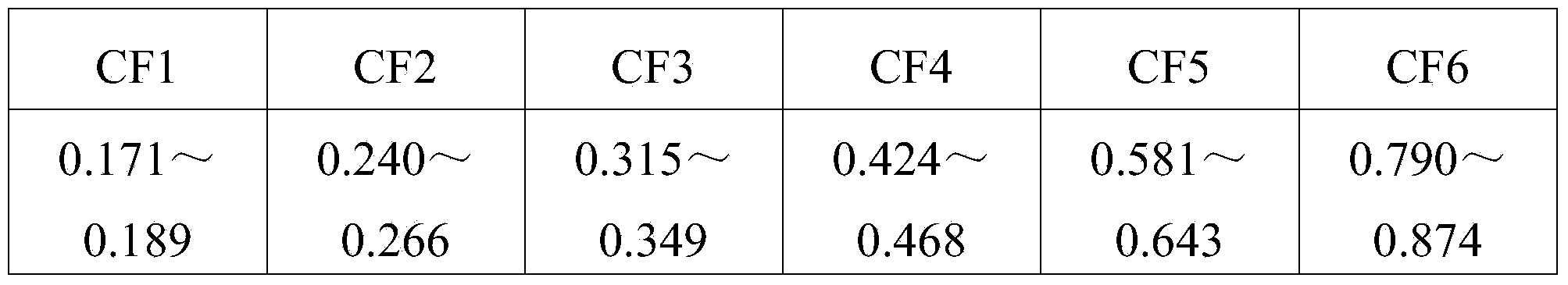

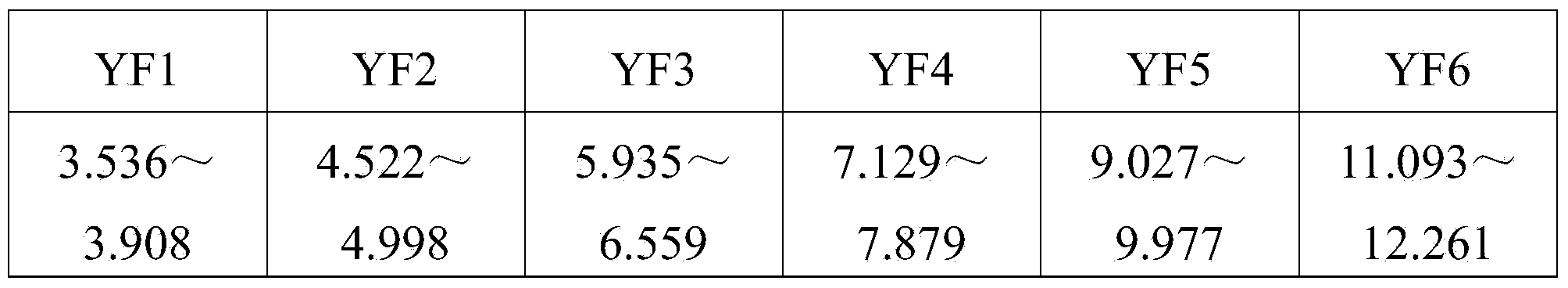

Hot-rolled wire rod for manufacturing high-strength steel strand of strong and smart grid and production method of hot-rolled wire rod

ActiveCN104233097ACompact configurationReasonable configurationMetal rolling arrangementsWire rodChemical composition

The invention discloses a hot-rolled wire rod for manufacturing a high-strength steel strand of a strong and smart grid and a production method of the hot-rolled wire rod, and relates to a hot-rolled wire rod for manufacturing a high-strength steel strand of a grid. Chemical composition of the hot-rolled wire rod is composed of the following substances in percentage by weight (%): 0.70-0.74% of C, 0.17-0.37% of Si, 0.70-0.80% of Mn, 0.07-0.14% of Cr, less than or equal to 0.025% of P, less than or equal to 0.025% of S, less than or equal to 0.30% of Ni, less than or equal to 0.25% of Cu and the balance of Fe. According to the phi6.5mm hot-rolled wire rod produced by the method disclosed by the invention, tensile strength is 1120-1200Mpa, area reduction is 40-50% and percentage of elongation is more than or equal to 18%. The hot-rolled wire rod disclosed by the invention has the advantages that process equipment and parameter setting are reasonable, longstanding problems are solved and product quality is improved; the wire rod is drawn into a steel wire to enhance strength, and a loading bearing capacity of a steel strand processed from the steel wire is greatly improved; and the hot-rolled wire rod is easy to draw, and capable of avoiding an intermediate heat treatment process and saving energy.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

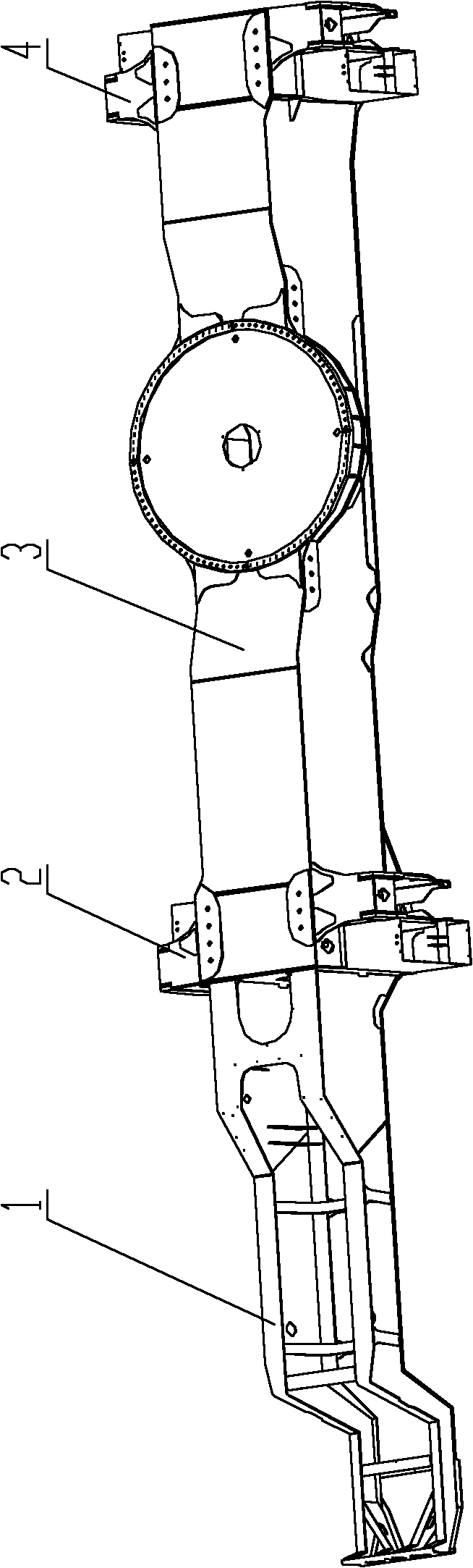

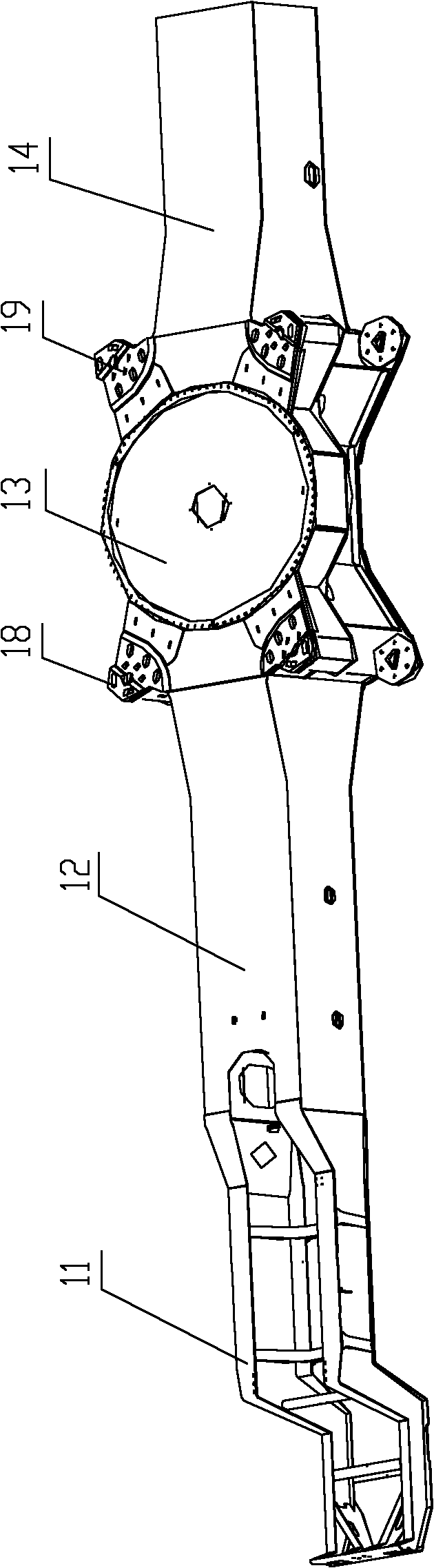

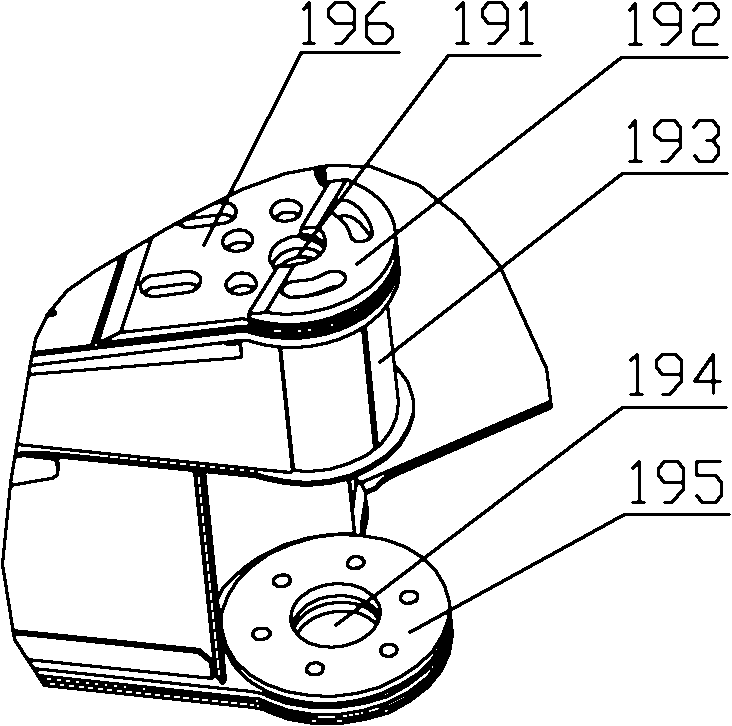

Crane and frame thereof

InactiveCN102001585AReduce horizontal sizeReduce vertical sizeBase supporting structuresBraking devices for hoisting equipmentsVehicle frameEngineering

The invention provides a frame which comprises a frame front section (11) and a frame rear section, wherein the frame rear section comprises a first rear section (12), a washer (13) for mounting a rotating platform and a second rear section (14) which are connected in sequence; the first rear section (12) is connected with the frame front section (11); the outer sides of both end parts of the connecting position of the washer (13) and the first rear section (12) are oppositely provided with two front hinging points (18) for connecting a front support leg device; and the outer sides of both end parts of the connecting position of the washer (13) and the second rear section (14) are oppositely provided with two rear hinging points (19) for connecting a rear support leg device. The frame provided by the invention has the advantages of small rear section box-shaped structure of the frame and light integral weight. In addition, the invention also provides a crane with the frame.

Owner:XUZHOU HEAVY MASCH CO LTD

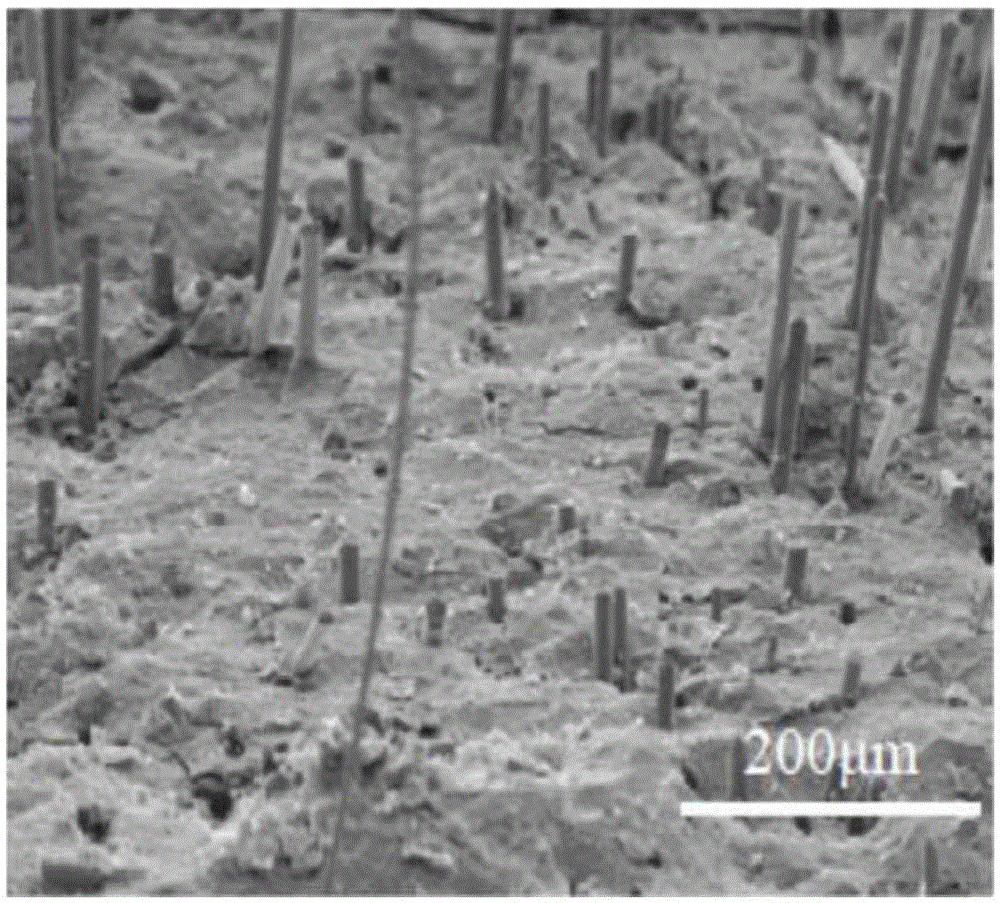

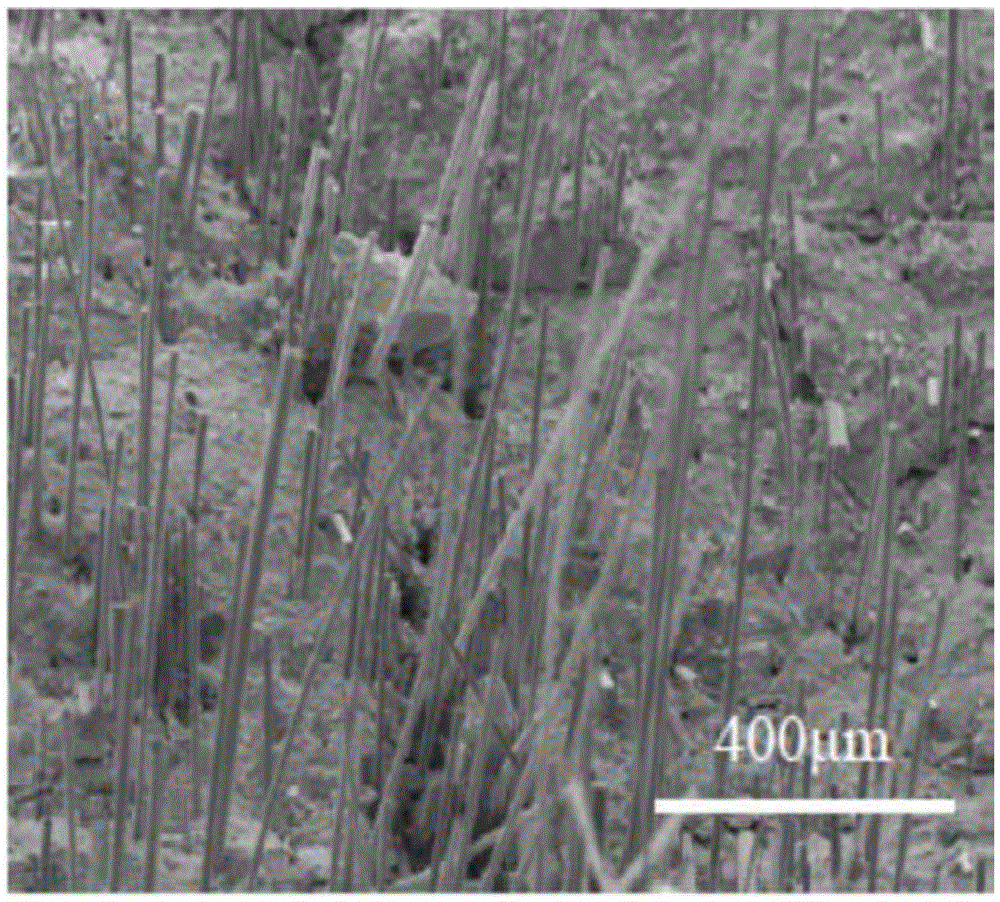

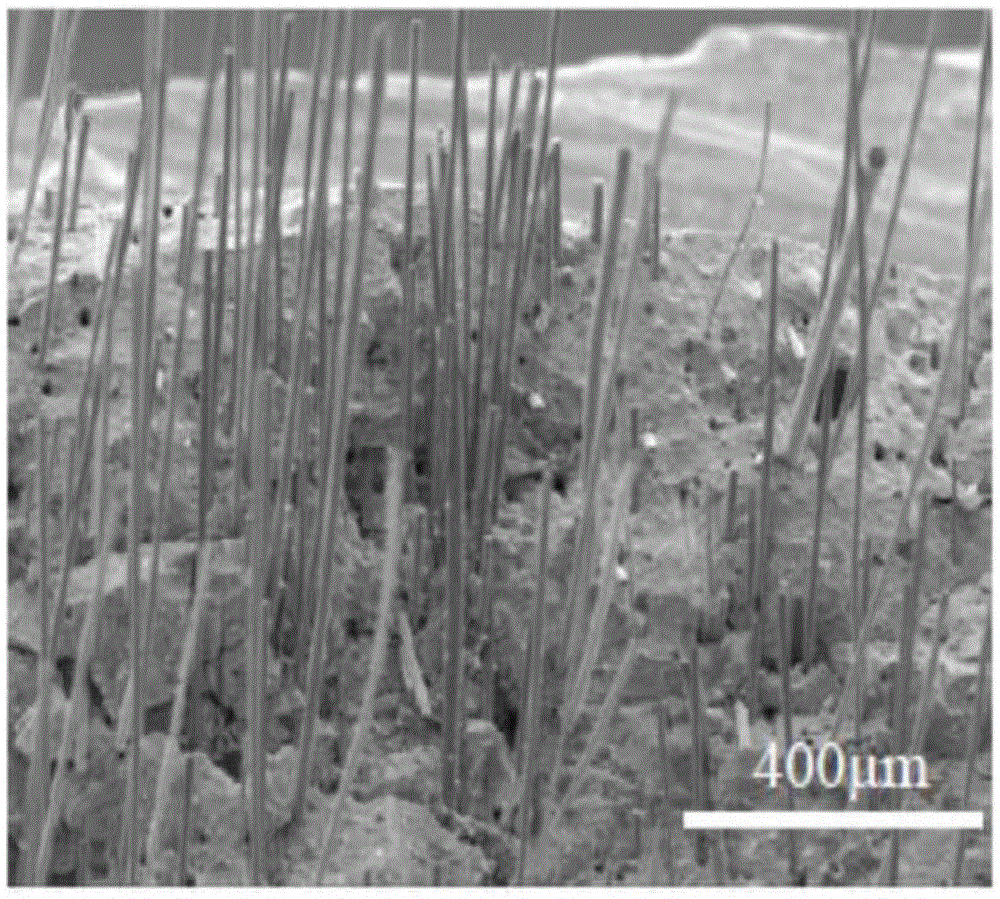

Preparation method for chopped silicon carbide fiber reinforced aluminosilicate polymer composite material

InactiveCN105541197AMaintain thermophysical propertiesStrong load bearing capacityPolymer scienceSlurry

The invention provides a preparation method for a chopped silicon carbide fiber reinforced aluminosilicate polymer composite material, and relates to the preparation method for composite materials. The preparation method provided by the invention is to solve the problem of severe limitation of a conventional aluminosilicate polymer material extensively applied in the field of high-tech materials demanding a certain loading capacity and high reliability due to inherent brittleness and low mechanical strength and toughness of the conventional aluminosilicate polymer material. The preparation method for the chopped silicon carbide fiber reinforced aluminosilicate polymer composite material is realized through the following steps: 1, preparation of a raw material, i.e., active aluminosilicate; 2, preparation of a ball-milled mixture; 3, preparation of an alkali-activation solution; 4, preparation of an aluminosilicate polymer material slurry; and 5, curing. The preparation method provided by the invention is used for preparation of the chopped silicon carbide fiber reinforced aluminosilicate polymer composite material.

Owner:HARBIN INST OF TECH

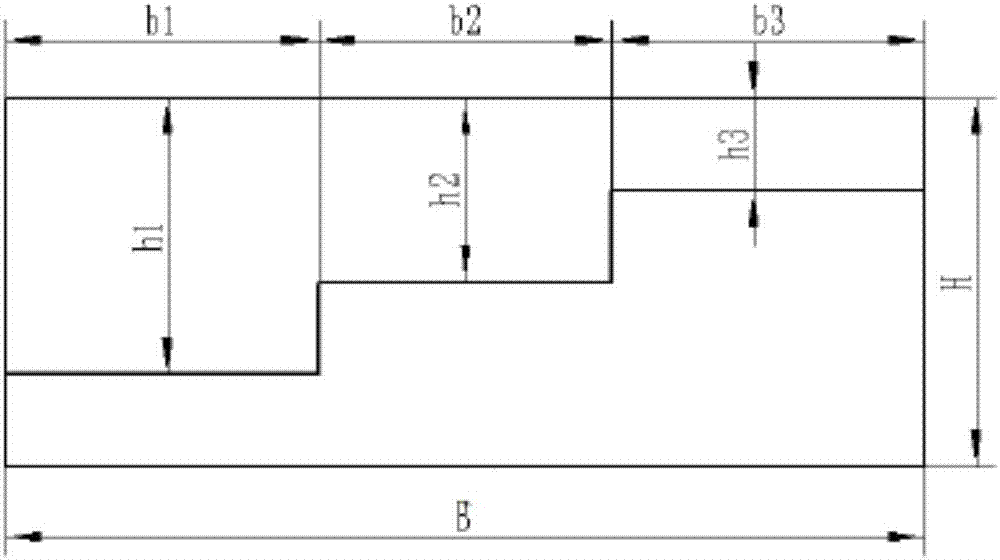

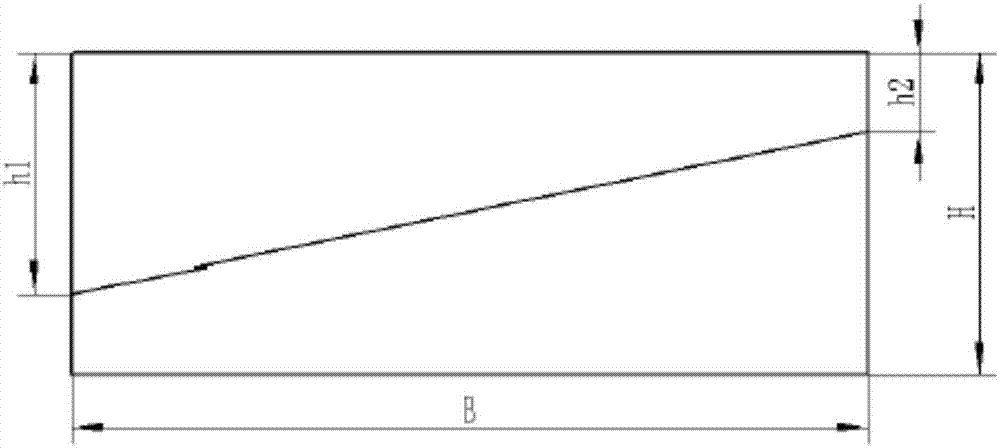

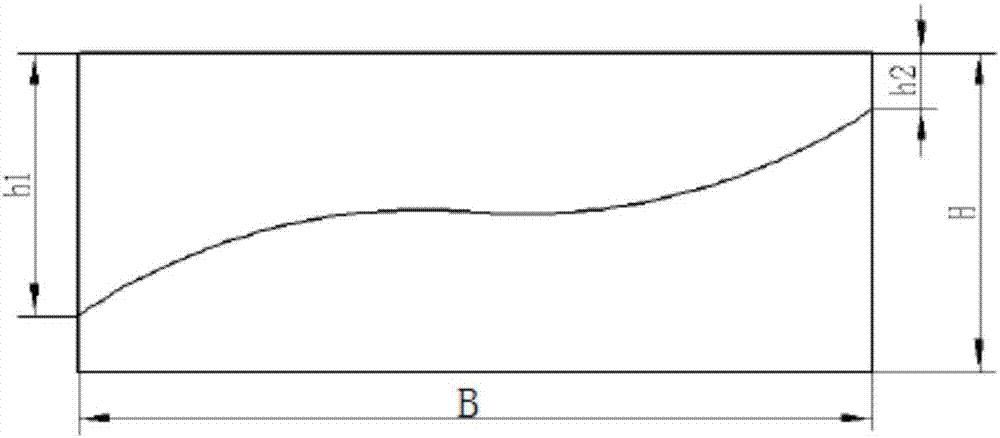

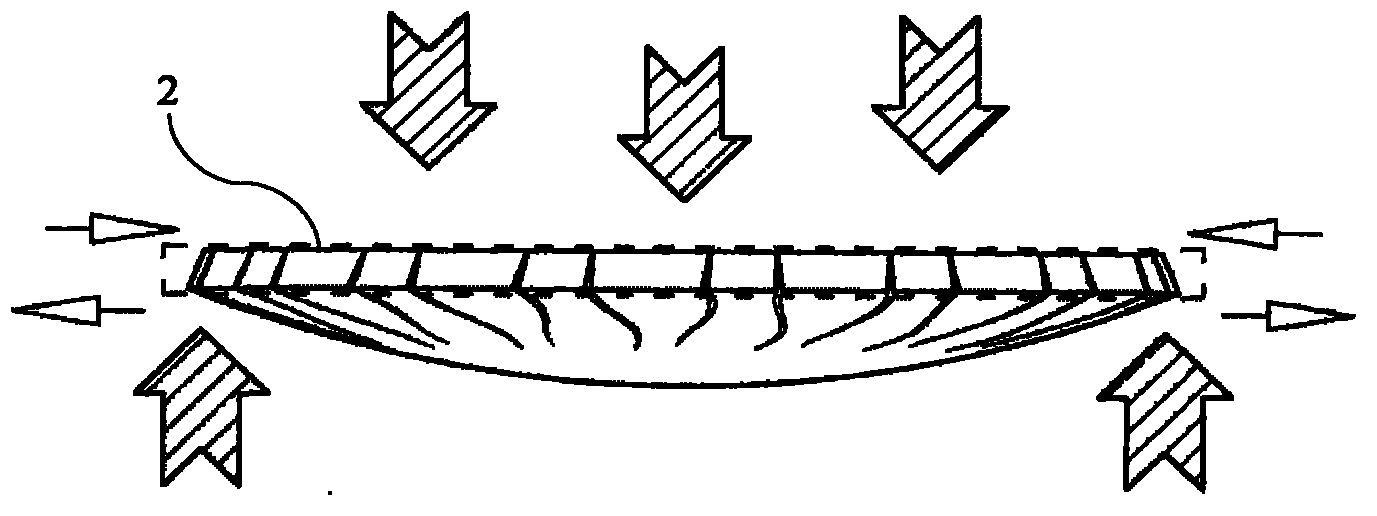

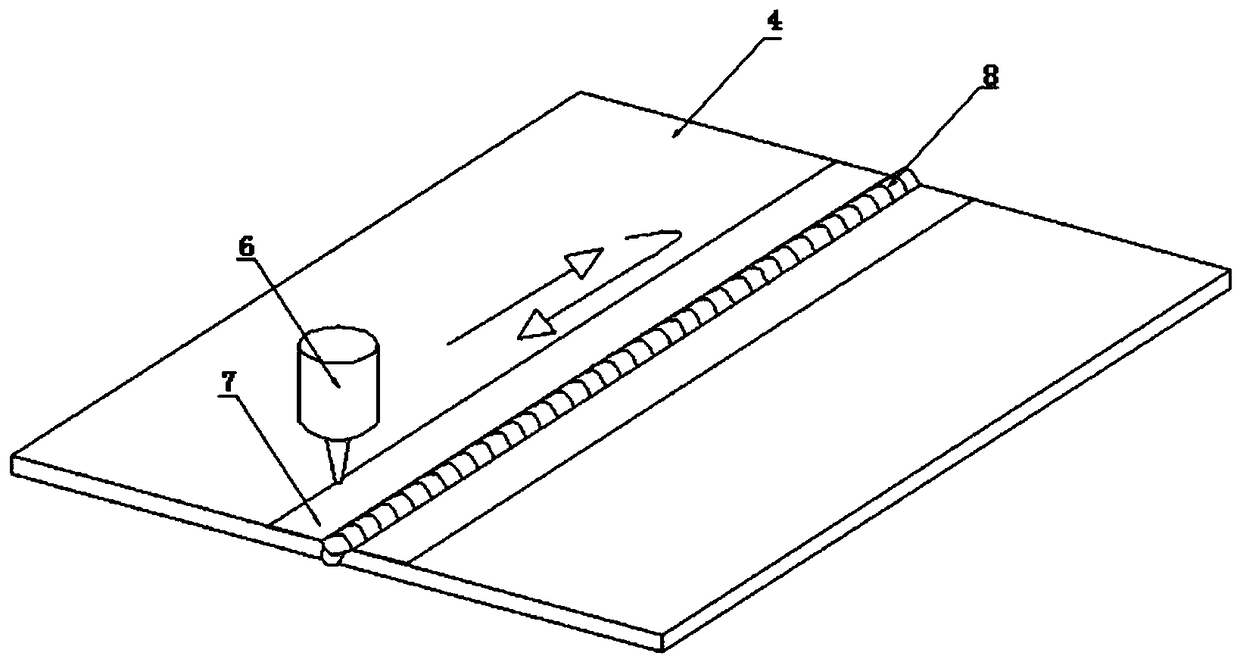

Ply rolling method for utilizing point symmetry to prepare transverse variable thickness plate strips

InactiveCN107999536AMeet different needsGood for weight lossAuxillary arrangementsMetal rolling arrangementsVariable thicknessMetallic materials

The invention belongs to the technical field of metal material deep processing and particularly relates to a ply rolling method for utilizing point symmetry to prepare transverse variable thickness plate strips. According to the method, the point symmetry is utilized for preparing the transverse variable thickness plate strips, the defects of waves, curve, torsion and the like caused by uneven andasymmetrical deformation in the variable thickness plate strip rolling process can be overcome, and the method can be used for preparing the various metal material transverse variable thickness platestrips. The method has the beneficial effects that adaptability to raw material texture and shape size is high, the flexibility of thickness changing of products is improved remarkably, flat rollerscan be used for carrying out rolling, the expense generated by using milling roller types is saved, the defects of waves, curve, torsion and the like caused by uneven deformation of variable thicknessrolling can be avoided, whether transition areas between thick areas and thin areas exist on the transverse variable thickness plate strips or not can be selected and designed, the shape and the position of the transition areas can selected and designed, and the best weight reducing and load bearing effects are achieved.

Owner:NORTHEASTERN UNIV

Multi-color injection molding machine

The invention relates to a multi-color injection molding machine. The multi-color injection molding machine comprises an adjusting mold plate, a moving mold plate and a fixed mold plate, wherein a mold and a rotating disc are fixedly arranged on the moving mold plate, the rotating disc is connected to the moving mold plate through a rotating shaft and a bearing, and a driving part is matched with the rotating disc for rotation. The multi-color injection molding machine disclosed by the invention has the advantages of reliable performances, convenience in installation and good transmission effect.

Owner:无锡市长嵘塑料机械有限公司

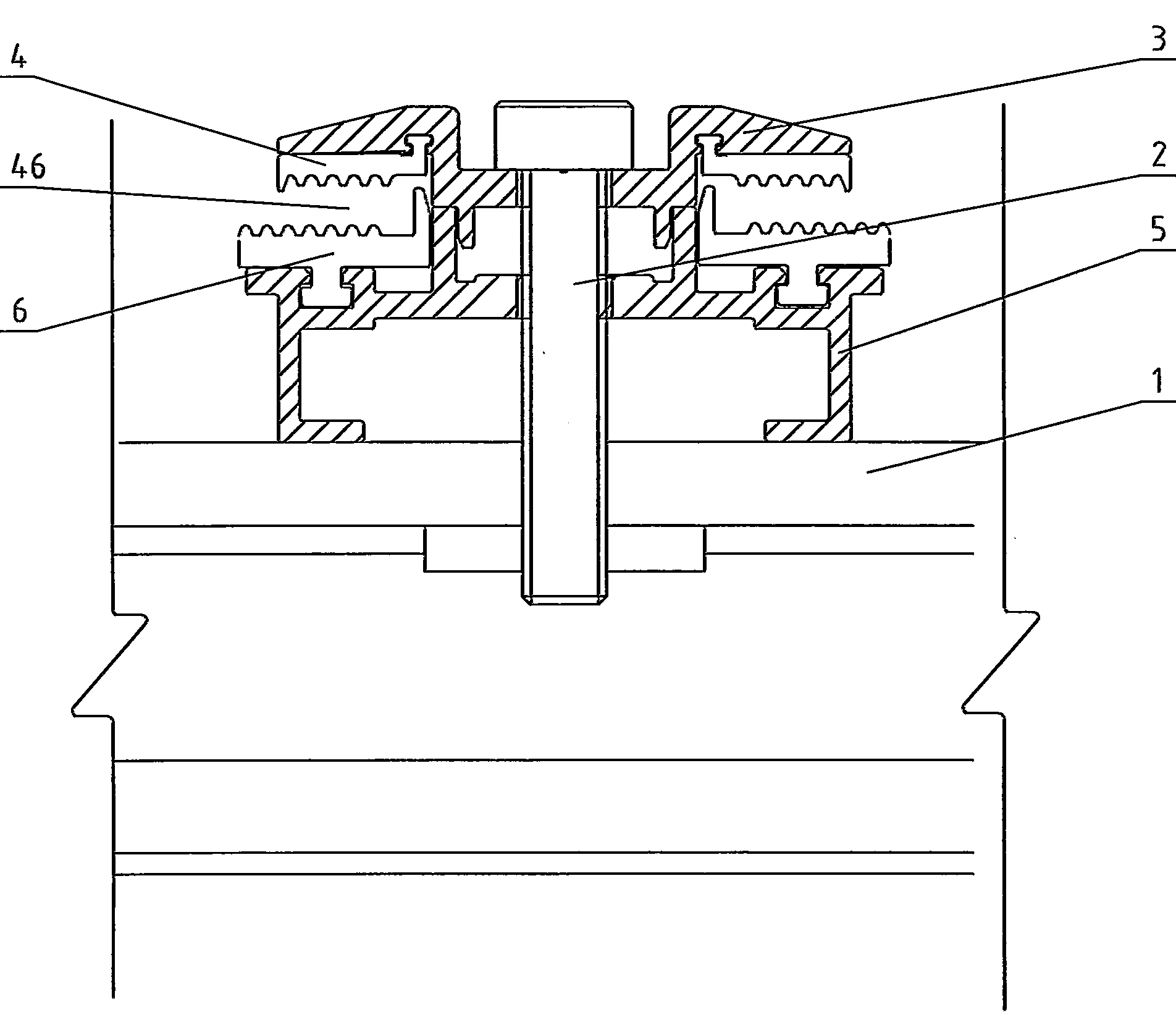

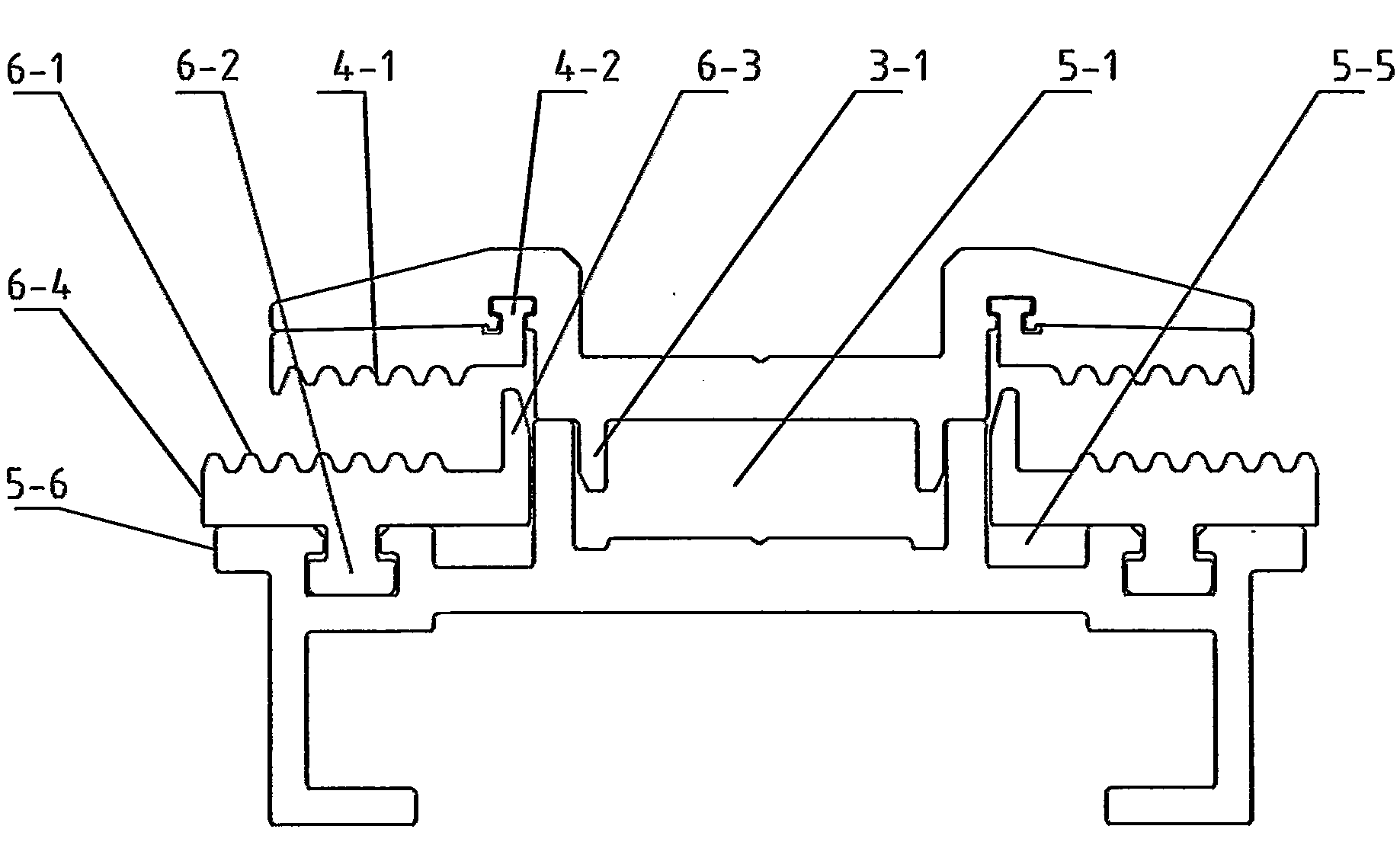

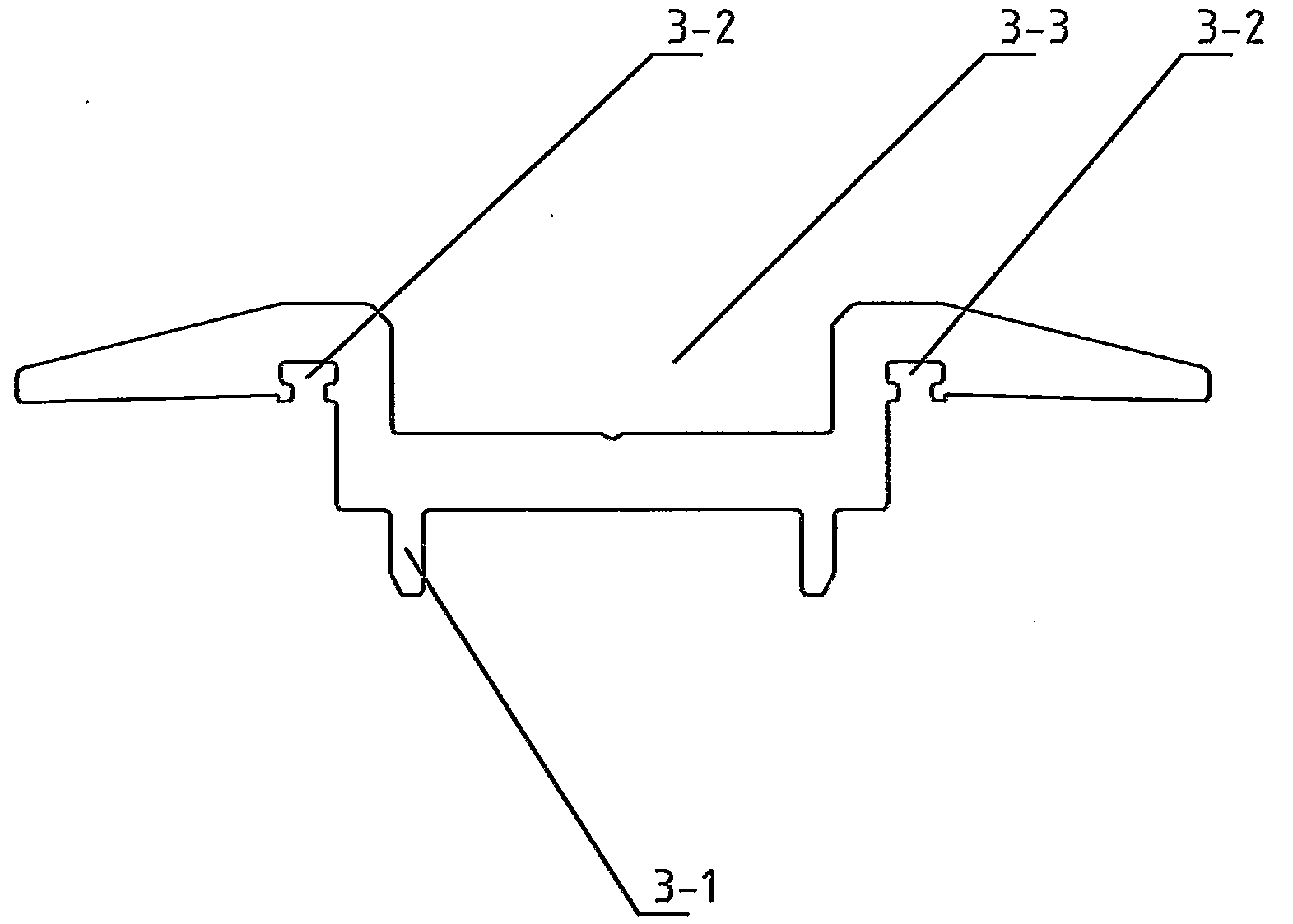

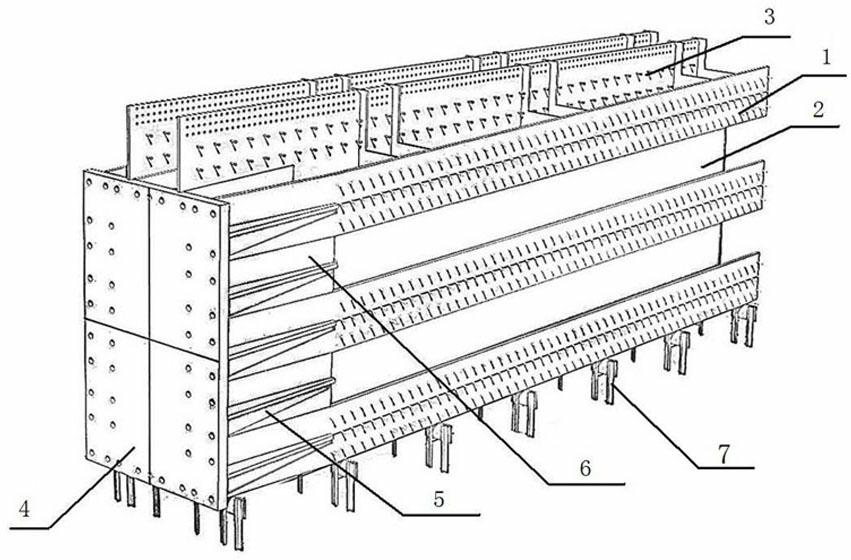

Solar module mounting clamping device

ActiveCN103258882AStrong load bearing capacityAvoid hard contactPhotovoltaic supportsPhotovoltaic energy generationEngineeringLarge size

The invention discloses a solar module mounting clamping device which comprises a support, a connecting screw rod, an upper pressing block, an upper rubber pad, a pressing block seat and a lower rubber pad. The connecting screw rod penetrates through the upper pressing block and the pressing block seat and then is fixedly connected with the support, the upper rubber pad is mounted on the upper pressing block in a clamping mode, the lower rubber pad is mounted on the pressing block seat in a clamping mode, the upper rubber pad is provided with a clamping face, the lower rubber pad is provided with a bearing face, and a clamping groove used for clamping a solar module is formed between the clamping face and the bearing face. A positioning groove is formed in the pressing block seat, a positioning rib set is arranged at the bottom end of the upper pressing block, and the positioning rib set is inserted in the positioning groove and matched with the positioning groove to achieve guiding and positioning. By means of the solar module mounting clamping device, the load bearing ability for mounting the solar module can be improved, and the solar module mounting clamping device is suitable for large-size solar modules.

Owner:TRINA SOLAR CO LTD

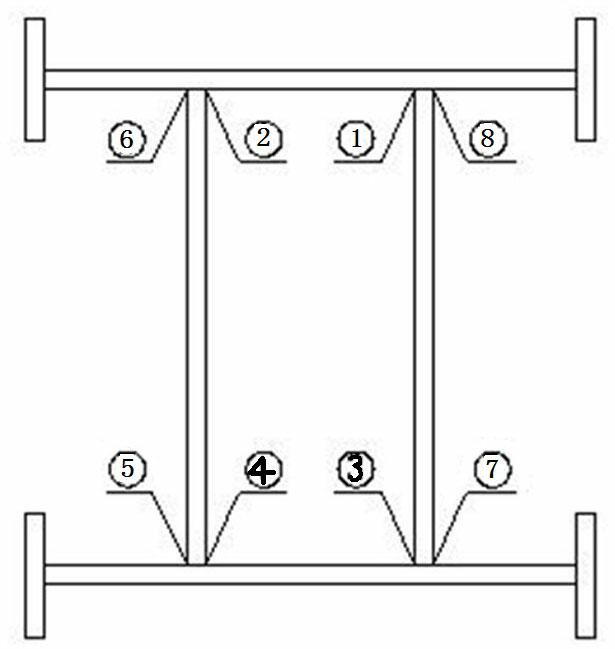

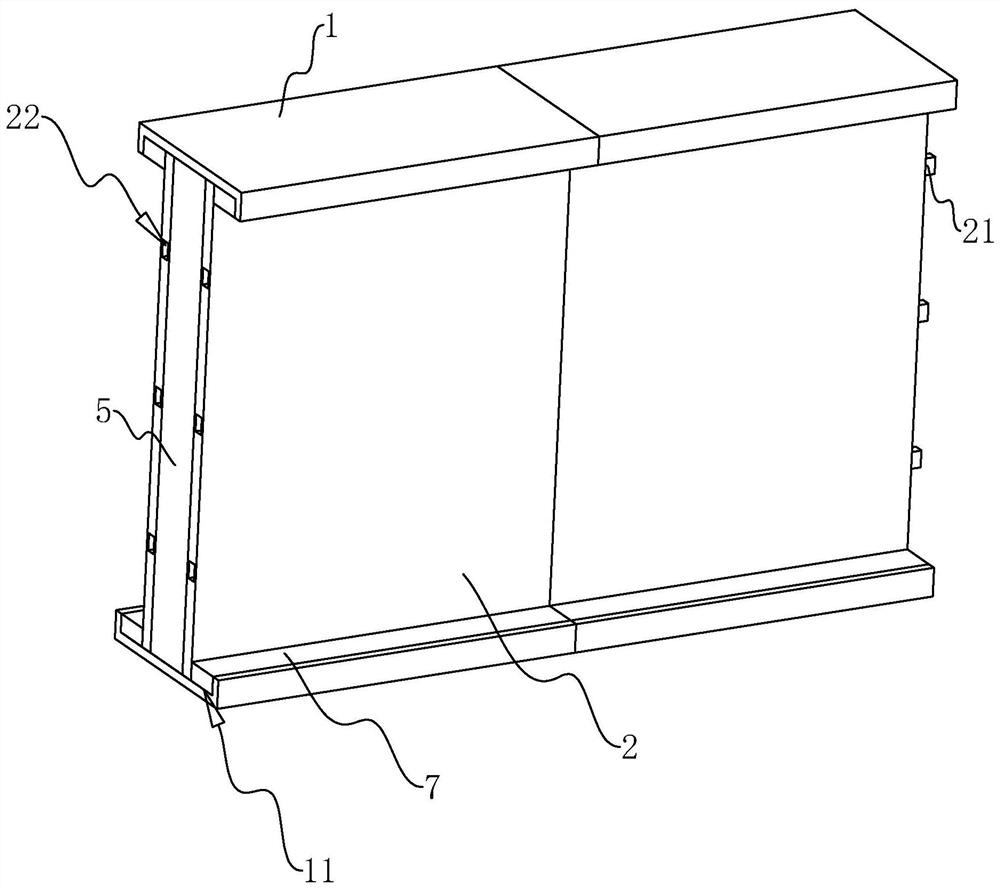

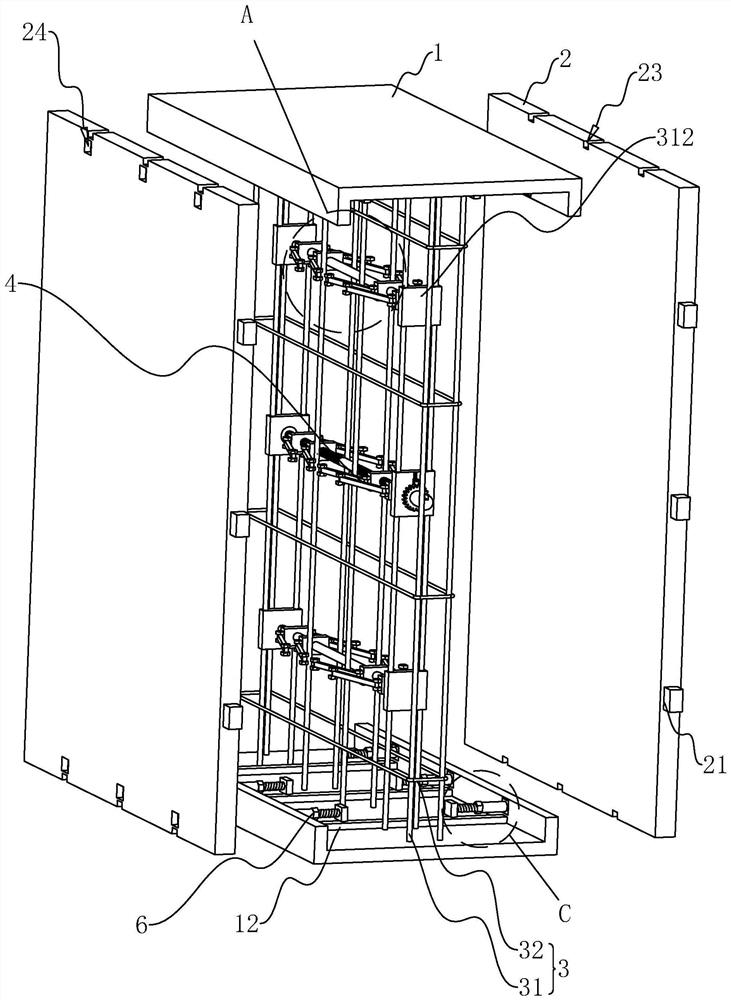

Mega column in shape of double Chinese characters ya and manufacturing method thereof

ActiveCN102182276AIngenious structural designStrong load-bearing capacityStrutsBuilding material handlingEngineeringH shaped

The invention discloses a mega column in the shape of double Chinese characters ya, which comprises H-shaped members, a partition plate, connecting plates and column baseplates, wherein the partition plate is positioned between the H-shaped members; the connecting plates are positioned at the top ends of the H-shaped members; and the column baseplate is positioned on one side of each H-shaped member. The invention further discloses a manufacturing method of the mega column in the shape of the double Chinese characters ya. The mega column in the shape of the double Chinese characters ya is ingenious in structural design and very strong in bearing capacity; in the method, the manufactured mega column in the shape of the double Chinese characters ya can be firm in structure by adjusting the welding sequence and the welding way, the factory production of the mega columns in the shape of the double Chinese characters ya is further realized, and the production efficiency is improved.

Owner:JIANGSU HUNING STEEL MECHANISM

Fabricated environment-friendly building wall body and construction method thereof

InactiveCN113175151AGood stitchingChange thicknessWallsBuilding material handlingArchitectural engineeringMechanical engineering

The invention relates to a fabricated environment-friendly building wall body and a construction method thereof, and relates to the field of fabricated buildings. The fabricated environment-friendly building wall body comprises a plurality of wall body units, wherein each wall body unit comprises two oppositely arranged bases and two oppositely arranged wallboards; a plurality of inserting and connecting blocks are fixed to the side walls of the wallboards; inserting and connecting grooves matched with the inserting and connecting blocks in an inserting and connecting mode are formed in the side walls, far away from the inserting and connecting blocks, of the wallboards; steel bar planting assemblies positioned between the two wallboards are arranged between the bottom walls of two installing grooves; installing grooves are formed in the opposite side walls of the two bases; the two ends of the wallboards respectively slide on the bottom walls of the two installing grooves; a transmission mechanism used for driving the two wallboards to approach to or leave far away from each other is arranged between the two wallboards; and the space between the two wallboards is filled with a first grouting layer. The fabricated environment-friendly building wall body and the construction method have the advantages that the effect of high installing precision is achieved, the construction efficiency is favorably improved, the construction cost is reduced, the application range is wide, the field storage and management cost is reduced, and the overall bearing capacity is high.

Owner:慈溪市庵东建筑安装工程有限公司

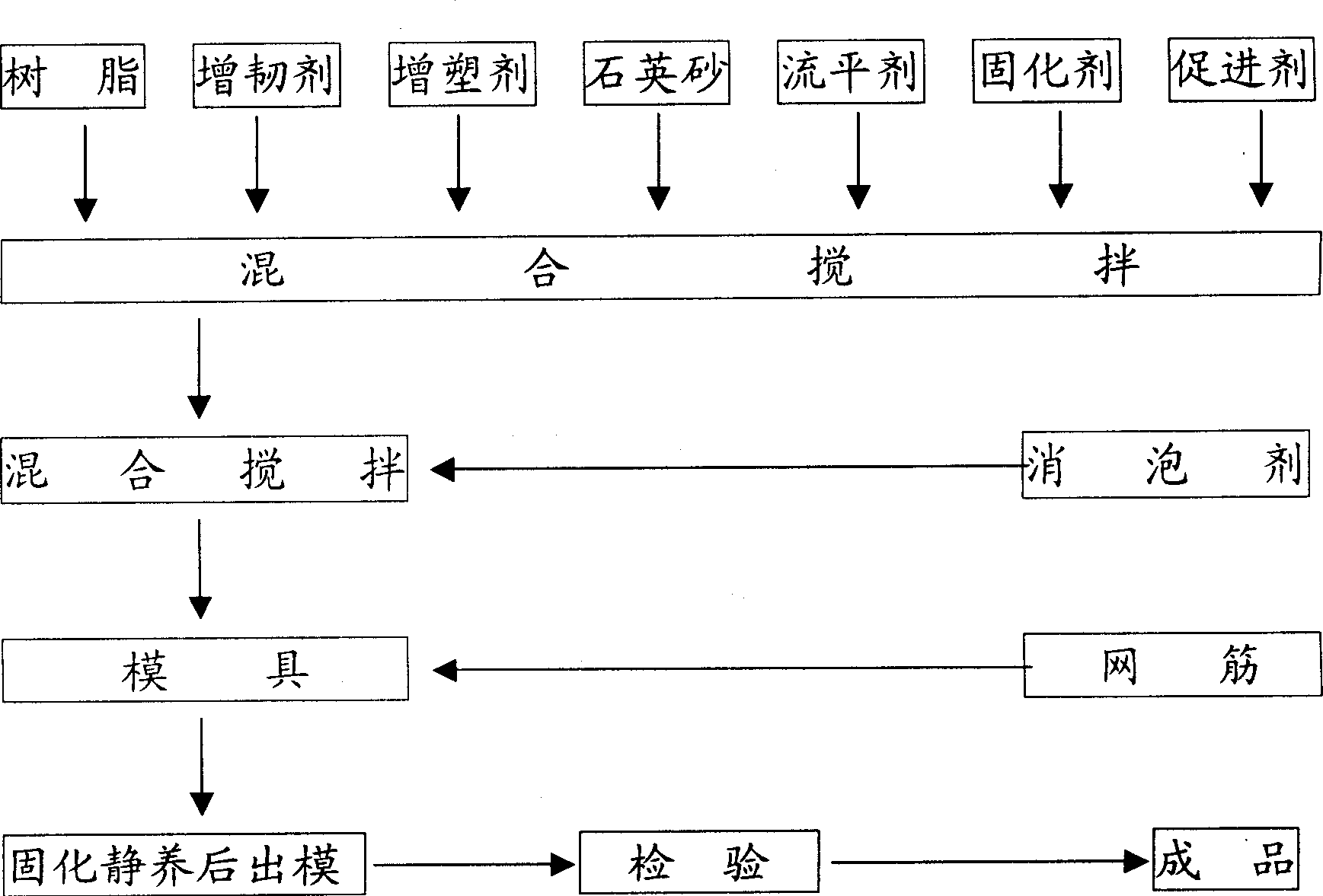

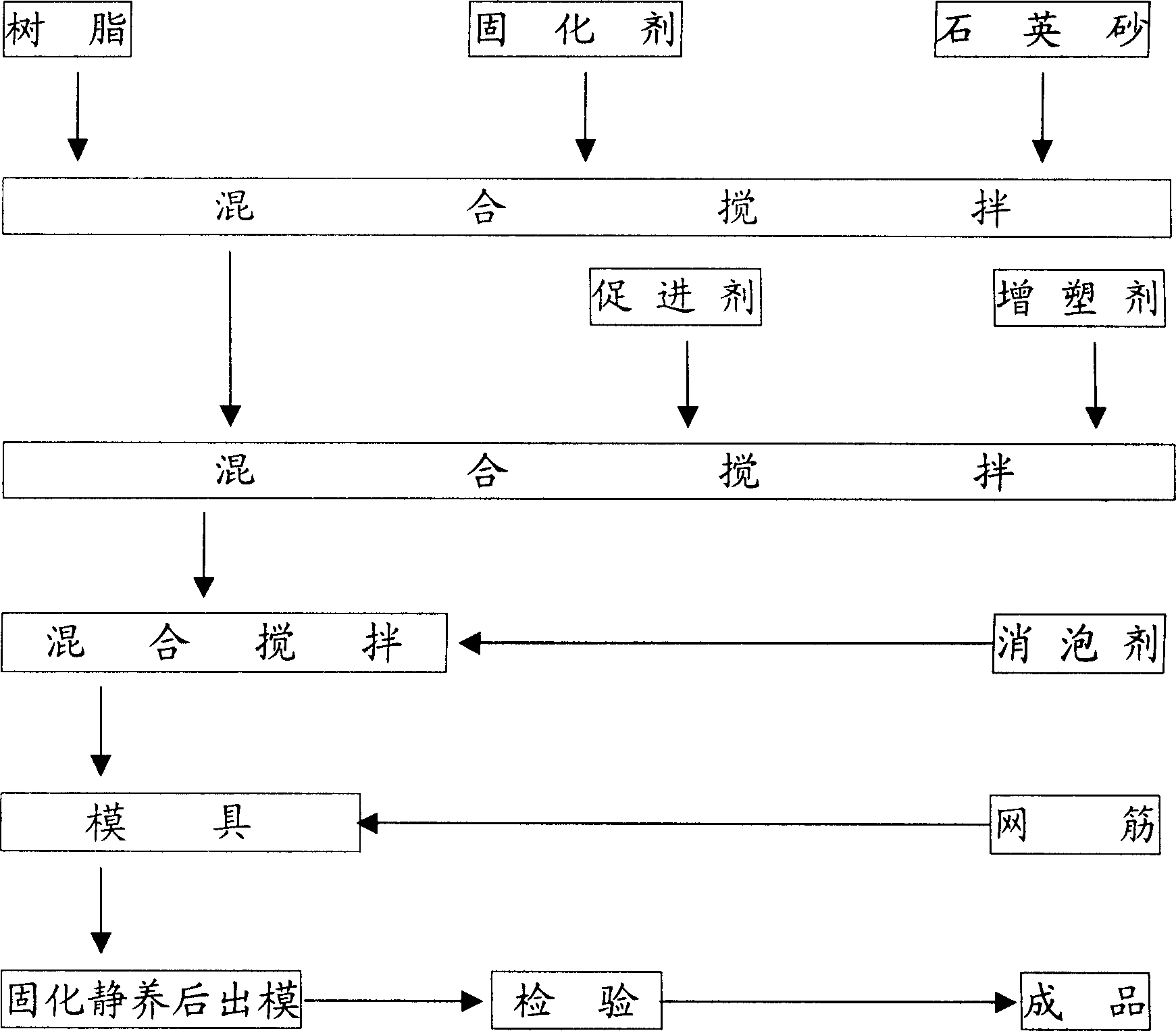

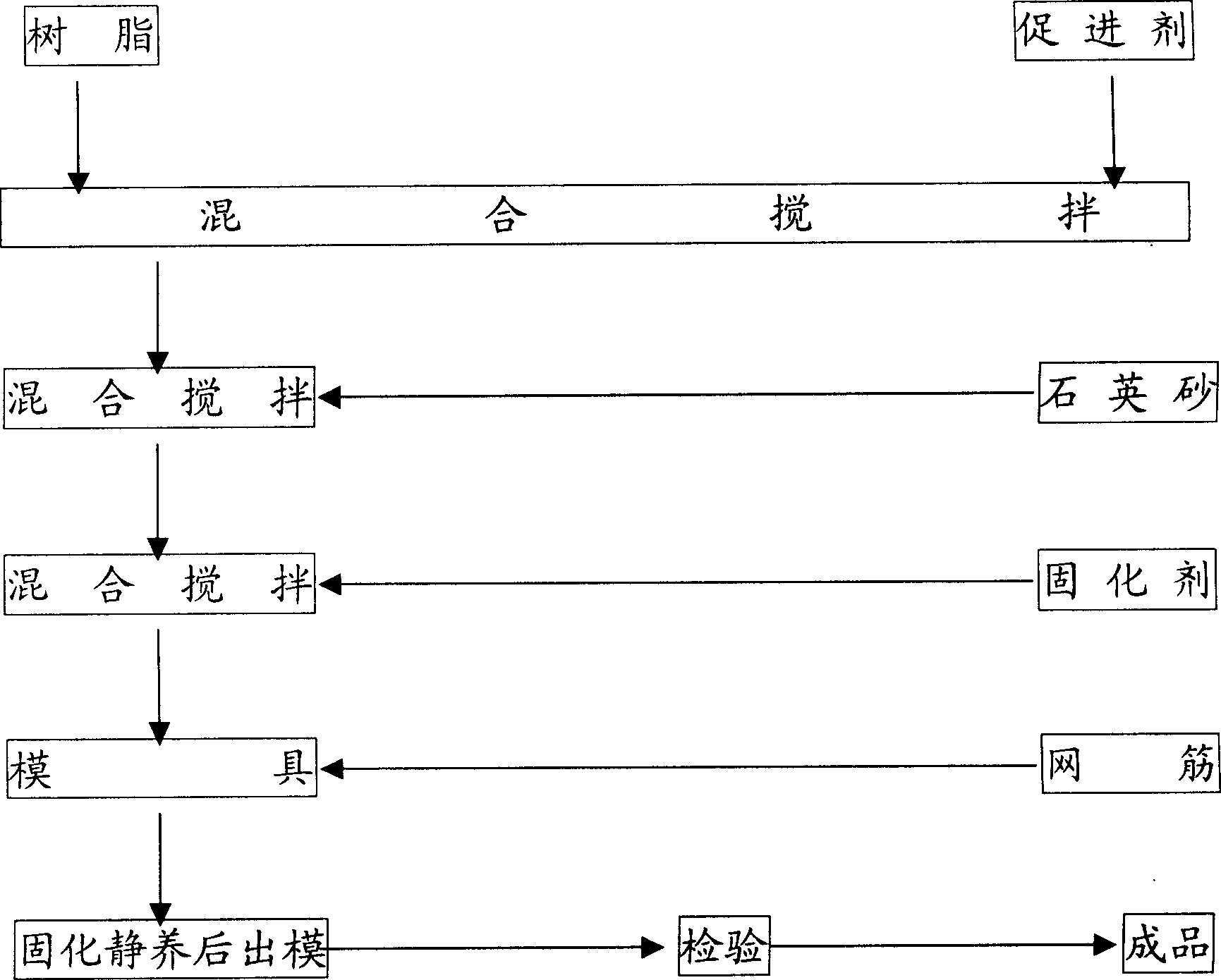

Reinforced concrete resin slurry casting pipe and method for manufacturing the same

InactiveCN1807051ALow priceExtended service lifeMixing operation control apparatusShaping reinforcementsReinforced concreteSlurry

The invention discloses the reinforcement coagulate resin mortar casting tube and preparing method. The method comprises the following steps: 1 10-60% resin, 3.497-15% toughening agent, 1.5-6% plasticizing agent, 5- 80% quartz sand, 0.5-5% levelling agent, 40-3% curing agent, 0.5-5% accelerating agent, 0.003-5% defoaming agent; 2 mixing resin, plasticizing agent, quartz sand, levelling agent, curing agent and accelerating agent; 3 adding defoaming agent; 4 adding them into die with web tendon; 5 curing, stewing and mould unloading; 6 checking; 7 getting the reinforcement coagulate resin mortar casting tube. The tube is used as tube building material. The invention has the advantages of high strength, light weight, good sealing, corrosion prevention, long lifetime and low cost.

Owner:泊谊文化传播(北京)有限公司

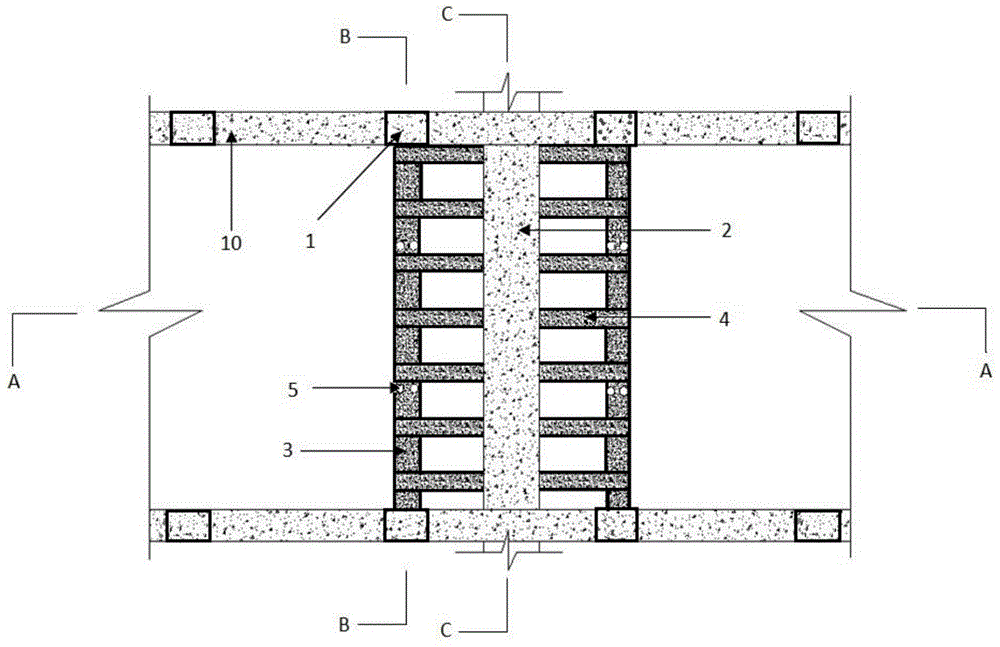

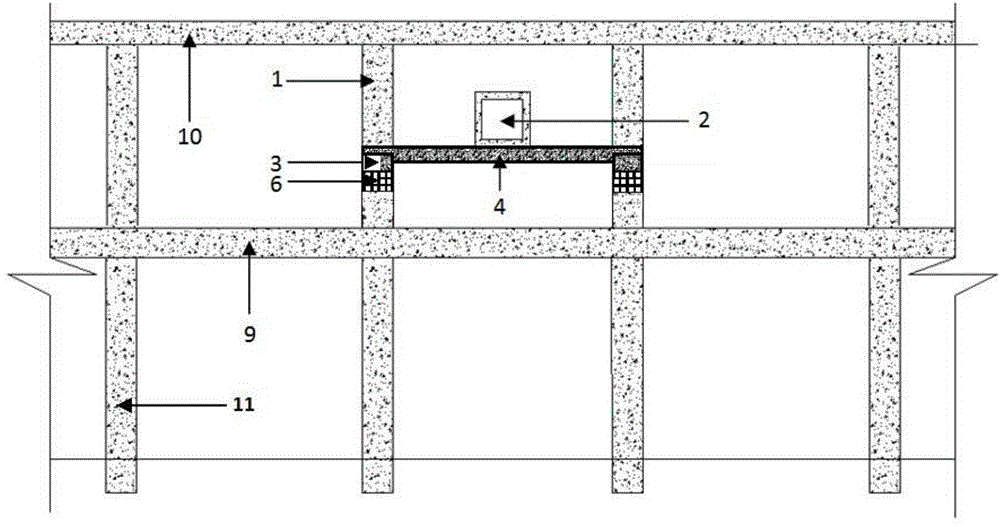

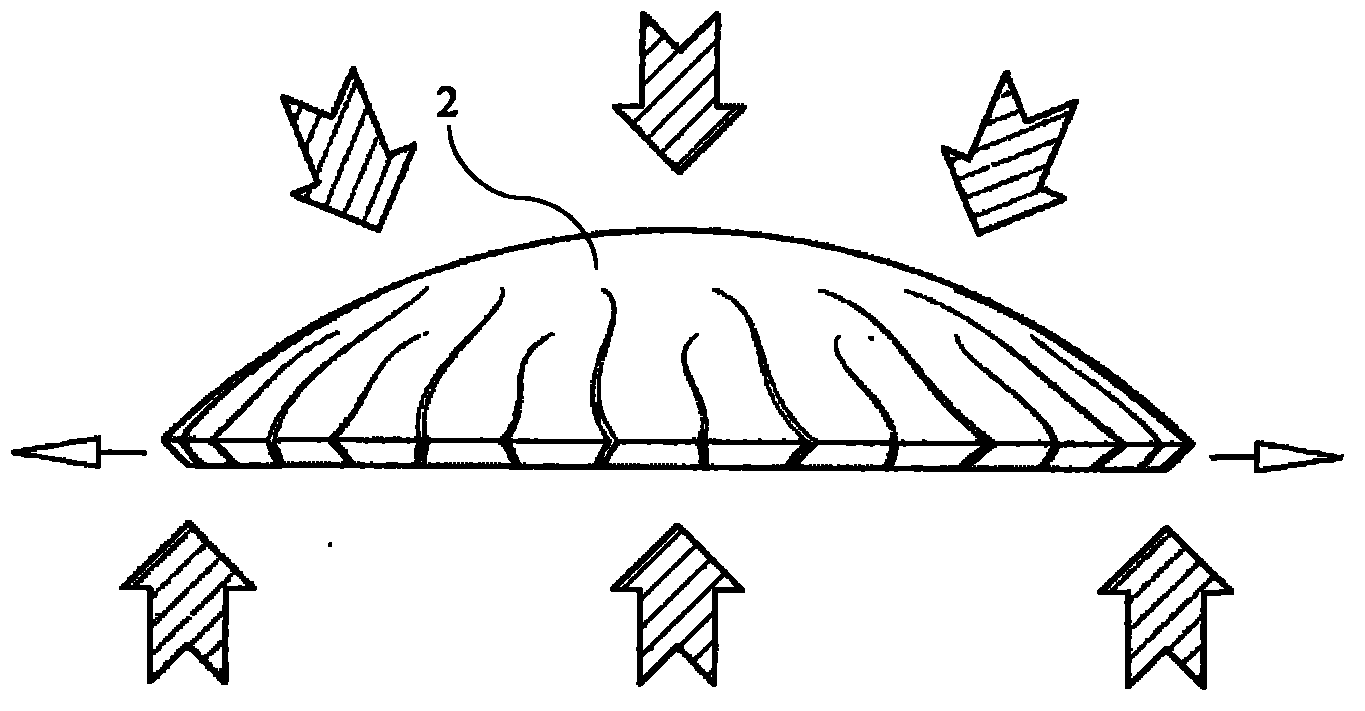

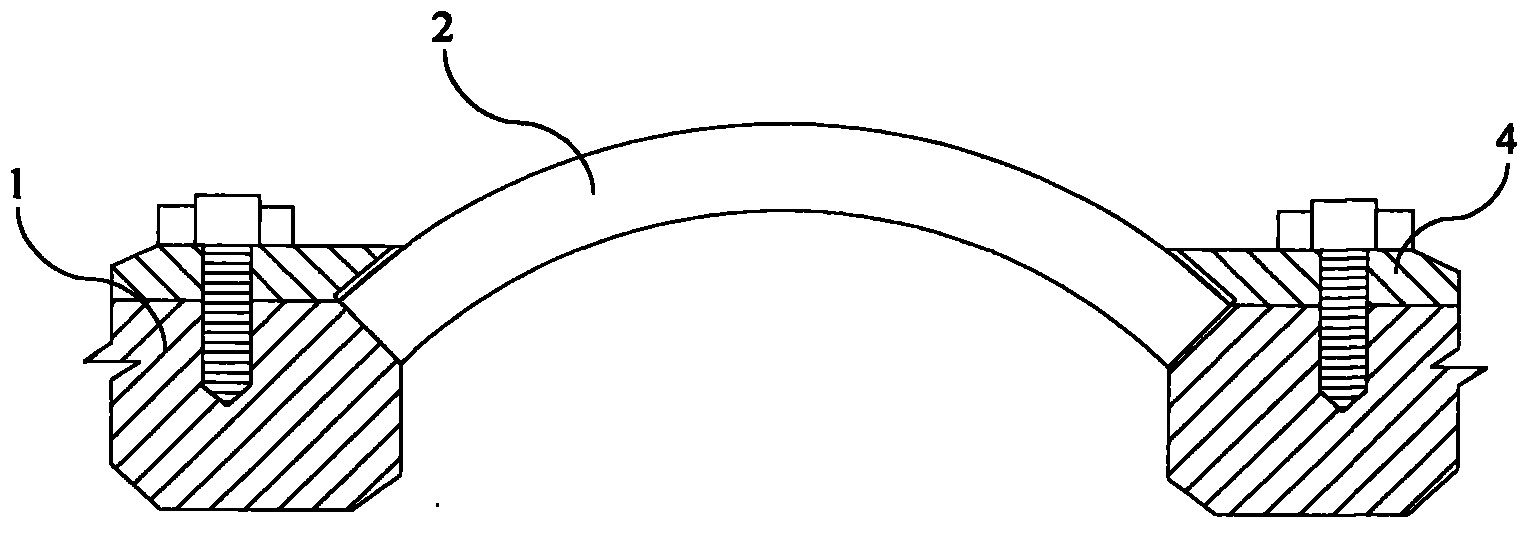

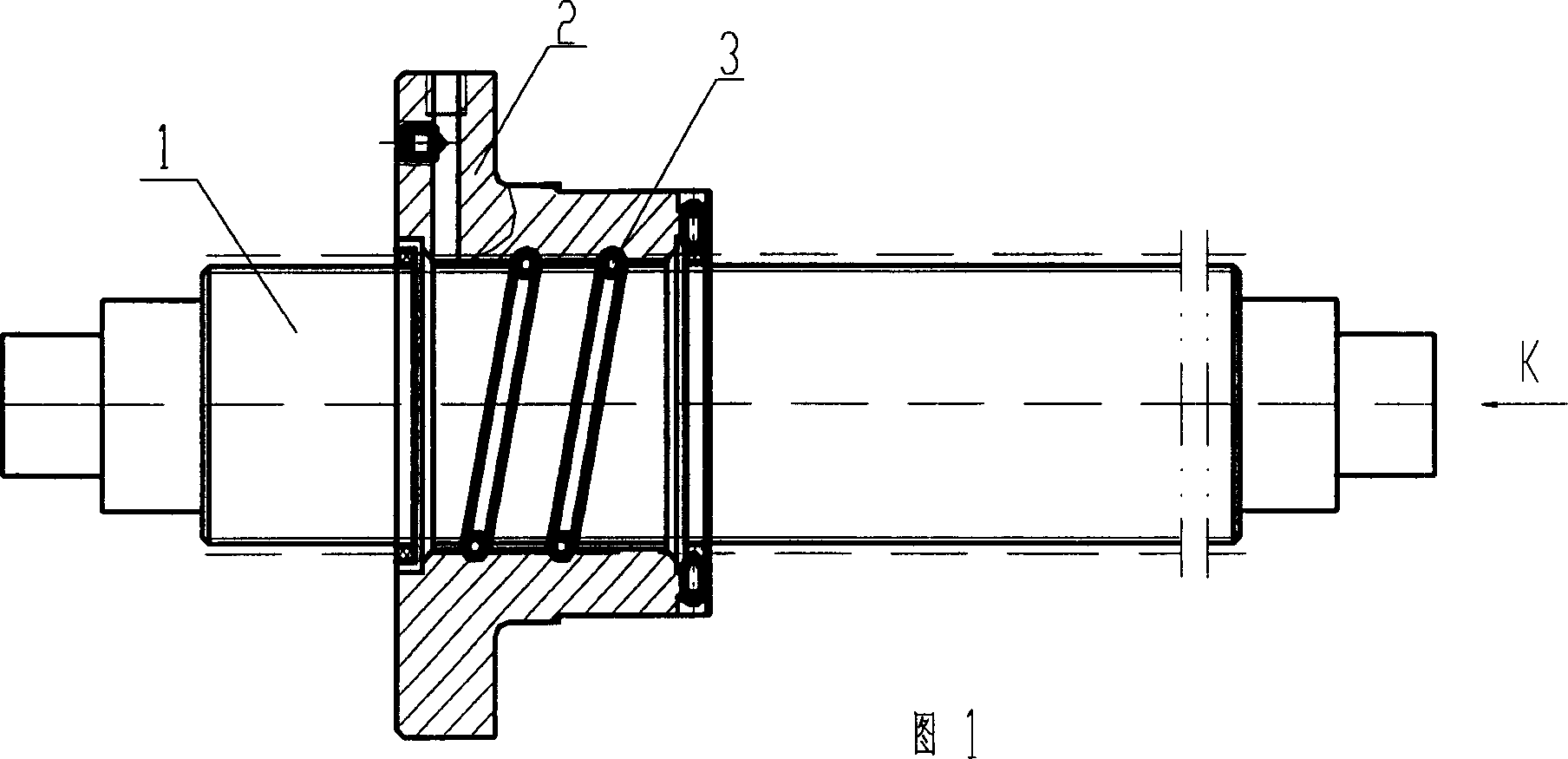

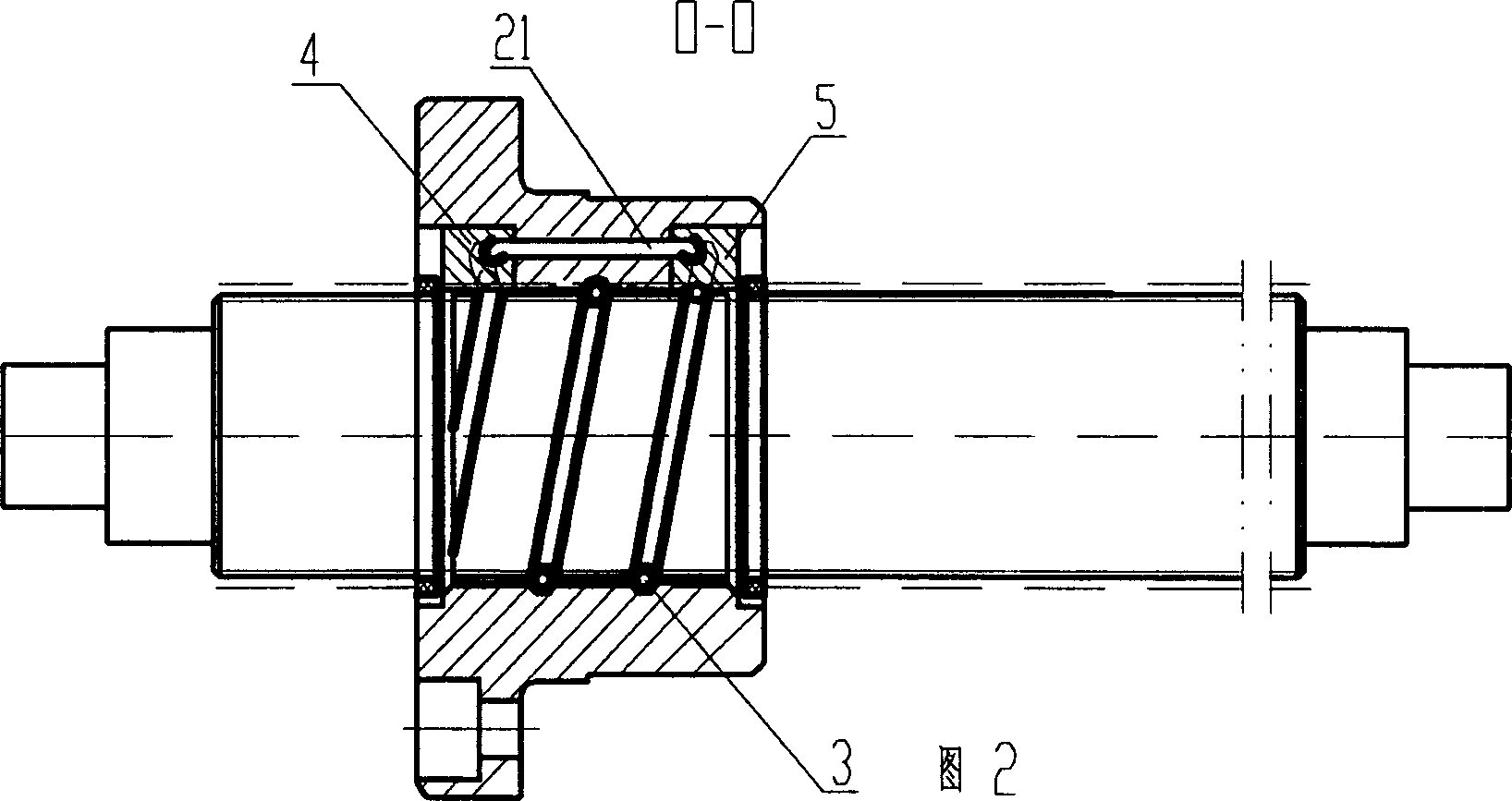

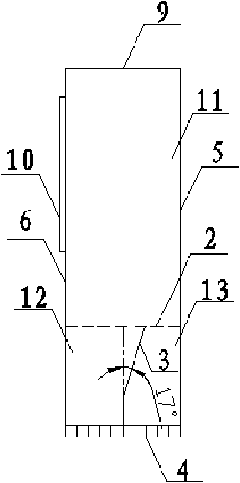

Manned submersible device observation window transparent piece fastening structure and method

InactiveCN104165019AHigh strengthStrong load bearing capacityBuilding braking devicesClear-view screensPre stressPre stressing

A fastening structure and fastening method for the transparent part of an observation window on a manned submersible, comprising an external shell (1) and an observation window transparent part (2) arranged on the external shell (1), the peripheral edges of the observation window transparent part (2) being incorporated into a frame (3); the frame (3) comprises a compression component (31) and a fastening component (32); a pre-stressing force is generated by means of the compression component (31) fitting to the observation window transparent part (2) and compressing the fastening component (32), thereby fastening the observation window transparent part (2). The present fastening structure is very strong, and has a wide range of application.

Owner:YIHE TECH DEV SHANGHAI

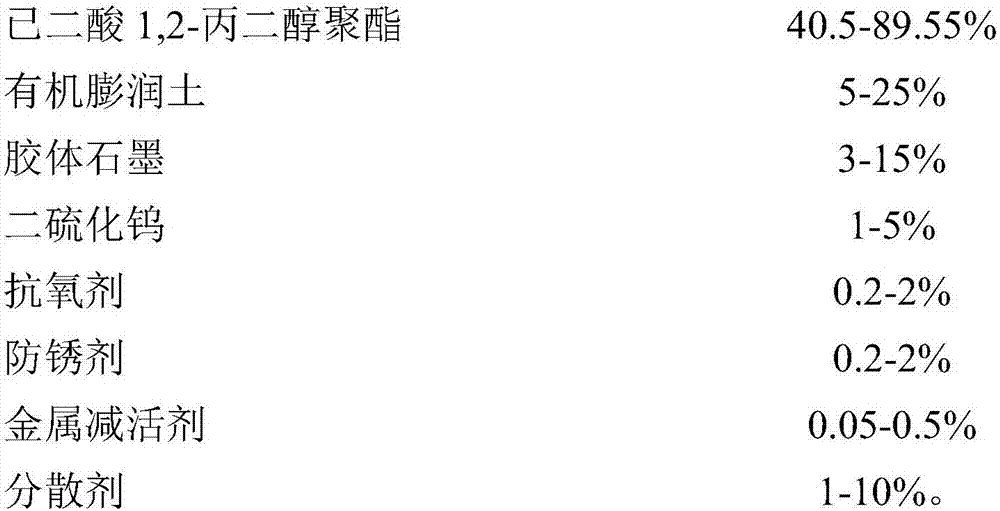

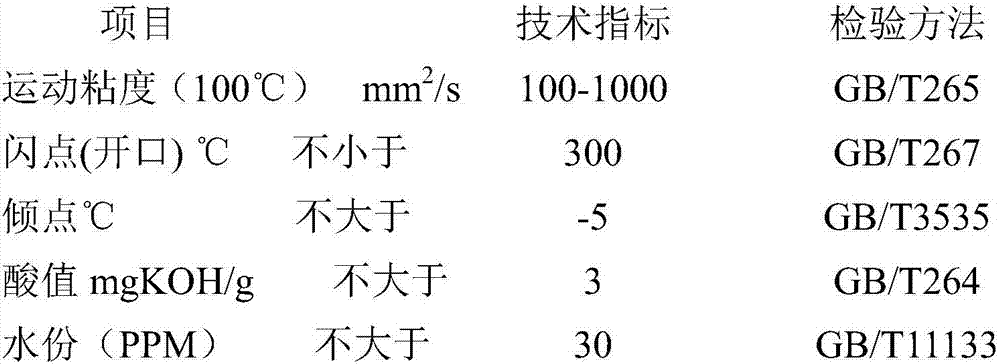

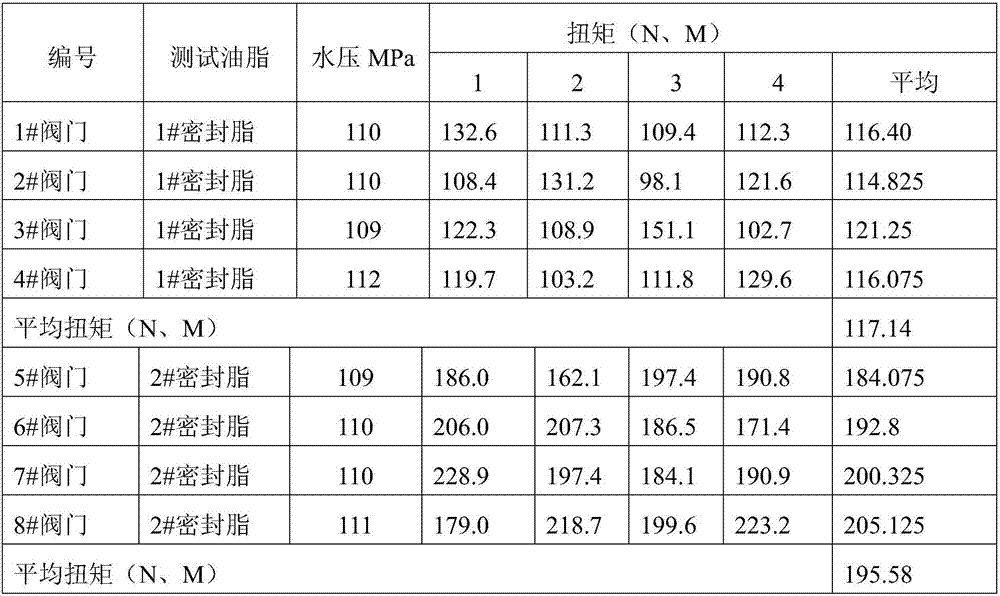

Christmas tree oil-resistant sealing grease composition and preparation method thereof

The invention provides a Christmas tree oil-resistant sealing grease composition. The Christmas tree oil-resistant sealing grease composition is prepared from the following components in percentage by mass: 40.5 to 89.55 percent of hexanedioic acid 1,2-propylene glycol polyester, 5 to 25 parts of organic bentonite, 3 to 15 parts of colloid black lead, 1 to 5 percent of tungsten disulfide, 0.2 to 2 percent of antioxidant, 0.2 to 2 percent of antirust agent, 0.05 to 0.5 percent of metal deactivator, and 1 to 10 percent of dispersing agent. The invention further provides a preparation method for the Christmas tree oil-resistant sealing grease composition. The Christmas tree oil-resistant sealing grease composition provided by the invention is prepared by refining high-viscosity hexanedioic acid 1,2-propylene glycol polyester base oil, an organo-bentonite thickening agent and a plurality of additives, and has superior viscosity, leak tightness, oil resistance and friction resistance. An oilfield Christmas tree valve adopting the Christmas tree oil-resistant sealing grease composition has low starting torque, is convenient to operate, and has superior high temperature performance, superior thermal stability and extremely-long service life.

Owner:武汉博达特种润滑技术有限公司

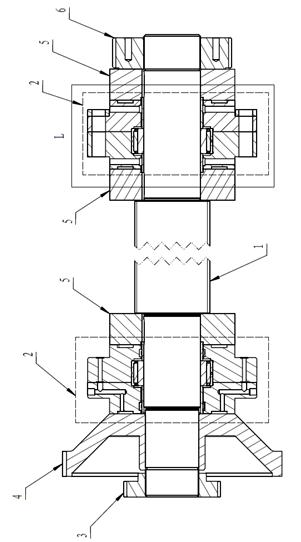

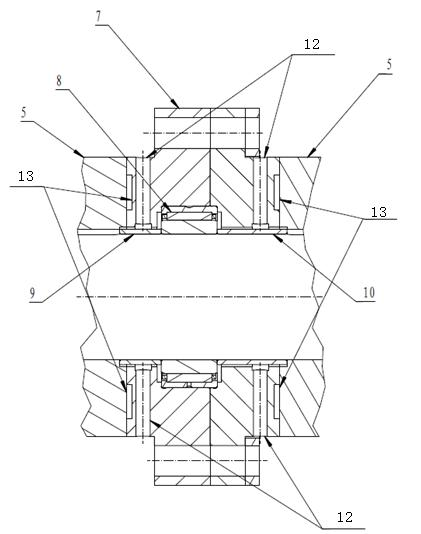

Inner loop end block type ball screw pair

InactiveCN1654852ALarge load effective circleCarrying more effective circlesGearingBall bearingBall screw

This invention discloses a ball bearing thread rod pair and especially relates to inner recycling end ball bearing pair composed of thread rod, screw and steel ball. The invention separately locates rolling groove on the thread rod and screw and the steel ball is located in the channel formed by thread rod and rolling grove of the screw. The screw is opened with holes and reverse groove on both ends. Each reverse device groove is located with reverse device as one reverse block. The reverse block is located with reverse rolling channel and block plate. The reverse rolling channel end is connected to the steel channel. The other end of reverse channel is connected to the screw hole and the block of the reverse block is located inside the steel channel.

Owner:NANJING TECHN EQUIP MFG

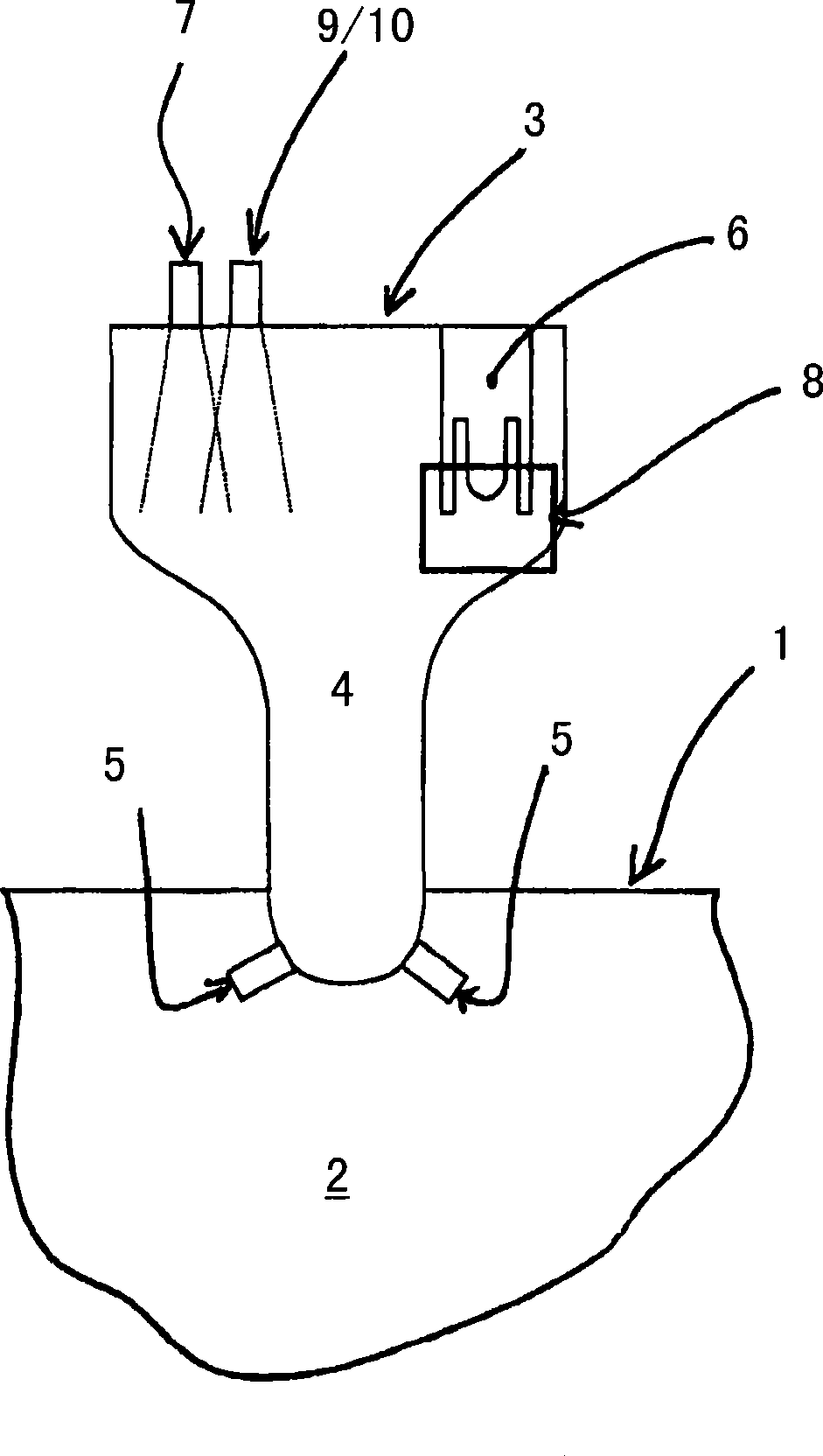

Internal-combustion engine and method for operating internal-combustion engine

InactiveCN101545397AAvoid misfirePrevent misfireInternal combustion piston enginesFuel supply apparatusFlammable gasCombustion chamber

The invention relates to an internal-combustion engine and a method for operating internal-combustion engine, comprising a main combustion chamber (2) and a precombustion chamber (4) connected with the main combustion chamber through at least an opening (5). A gas nozzle (7) connected on a high pressure gas pipeline is disposed in the precombustion chamber, and the gas nozzle is used for injecting gas into the precombustion chamber in high pressure and mixing the gas with the thin gas-air mixture in the precombustion chamber. The internal-combustion engine also comprises an ignition unit (6) stretched into the precombustion chamber to fire the thick gas-air mixture. At least one nozzle (9, 10) is arranged in the precombustion chamber for leading air and / or waste gas into the precombustion chamber and mixing the gas with the thin gas-air mixture in the precombustion chamber before the gas nozzle leads the gas, thereby the limited non-flammable gas-air mixture exists before the gas nozzle leads the gas, and the limited ignitable gas-air mixture exists after the gas nozzle leads the gas.

Owner:MAN B & W DIESEL AS

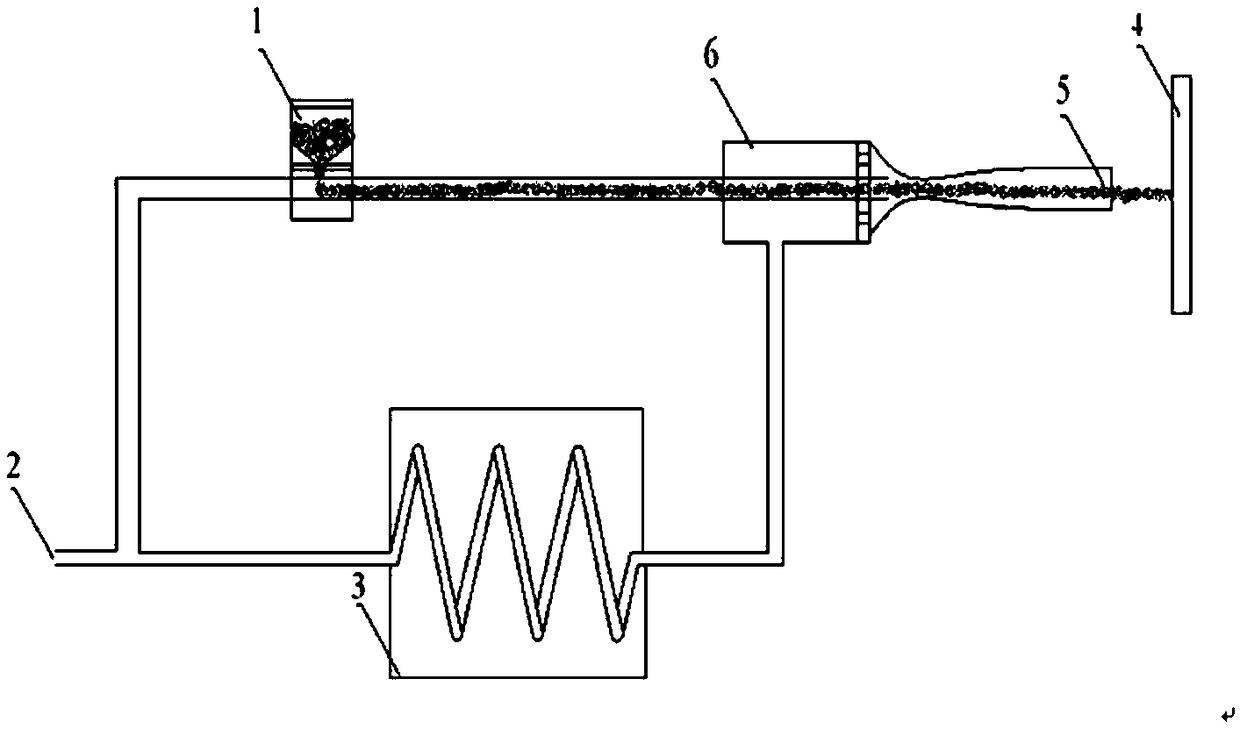

Method for reducing residual stress of metal structure material fusion welding joint

InactiveCN108838904AReduce or eliminate residual tensile stressStrong load bearing capacityEdge grinding machinesBlast gunsHigh pressureNitrogen gas

The invention provides a method for reducing residual stress of a metal structure material fusion welding joint. According to the method, heated gas and high-speed particle flows are utilized to simultaneously impact a weld joint area and the part near the weld joint area, the pressure stress is generated on the surface of the joint, so that the stress distribution is improved, the fatigue strength of the joint is improved, and the service life of the joint is prolonged; the size of the impact particles mostly ranges between 10 microns and 100 microns, the acceleration of the particles can berealized through high-pressure compressed gas (helium, nitrogen or compressed air), the gas pressure generally ranges from 1.5 MPa to 3.5 MPa, and the particle speed can reach the speed ranging from 400 m / s to 1000 m / s; in addition, the gas can be preheated according to requirements, and the preheating temperature generally ranges from 200 DEG C to 600 DEG C; in the method, the high-speed particleimpact effect and the hot gas impact effect are combined so that the residual tension of a component can be effectively reduced or eliminated, the mechanical property of the joint can be improved, and the service life of the component can be prolonged; and the method can be used for regulating and controlling the residual stress of the metal structure material fusion welding joint, and can also be used for improving the residual stress distribution of various welding joints of other materials, so that the safety and reliability of the joint are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Overhead wall adherent low diffusion ladder flow air supply system for displacement ventilation

InactiveCN101825330AJet stream is conducive to the formation ofAdhesive jetDucting arrangementsLighting and heating apparatusVena contracta diameterInlet channel

The invention discloses an overhead wall adherent low diffusion ladder flow air supply system for displacement ventilation, which comprises a box body (1) containing an air inlet channel, and an air inlet (10) and an air outlet shutter (4) which are arranged on a box body (1). The invention is characterized in that a current sharing orifice plate (2) is horizontally arranged at the lower part of the box body (1) and between the air inlet (10) and the air outlet shutter (4). The current sharing orifice plate (2) divides the box body (1) into an upper plenum box cavity (11) and a lower air supply box cavity in which a drainage folded plate (3) is arranged vertically between the current sharing orifice plate (2) and the air outlet shutter (4). The air supply system can effectively solve the problems of the displacement ventilation under installed air port arrangement form, realize the high ventilation efficiency of the air conditioner manner when a side wall overhead air port is arranged and give consideration to both traditional displacement ventilation and mixed ventilation.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

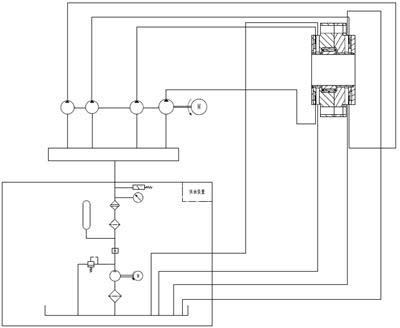

Static combined bearing for screw rod

InactiveCN102490065AReduce the influence of rotation accuracyIncrease stiffnessFeeding apparatusNeedle roller bearingEngineering

The invention relates to the field of a bearing, in particular to a static combined bearing for a screw rod. The static combined bearing comprises an oil supply device used for supplying oil through a throttler and is characterized in that the static combined bearing is provided with a static bearing, a rolling needle bearing, a locking screw nut, a front separation sleeve, a back separation sleeve and regulating pads, a step groove is arranged in the inner circumferential direction of the static bearing, an outer ring of the rolling needle bearing is fixedly arranged in the step groove, the outer ring of the rolling needle bearing is tightly pressed in the axial direction and the radial direction through the static bearing surrounded at the outer side, the front end of an inner circle of the rolling needle bearing is tightly pressed through the front separation sleeve, the back end of the inner circle of the rolling needle bearing is tightly pressed through the back separation sleeve, positions of the side surface of the static bearing, corresponding to the front separation sleeve and the back separation sleeve, are provided with oil discharge openings, annular oil grooves are respectively arranged on two end surfaces of the static bearing, two ends of the static bearing are respectively and tightly pressed with the regulating pads through the locking screw nut, and the annular oil grooves form annular oil cavities through the regulating pads and are communicated with the throttler and the oil supply device through oil supply openings arranged on the static bearing. Therefore, lubricating oil films with sufficient pressure are respectively formed at two sides of the static combined bearing, simultaneously, the static bearing and the front and back regulating pad form liquid friction, the influence caused by terminal deformation on the rotation precision of the screw rod is reduced, the axial load bearing capability is greatly enhanced, and the service life is greatly prolonged.

Owner:威海华东重工有限公司

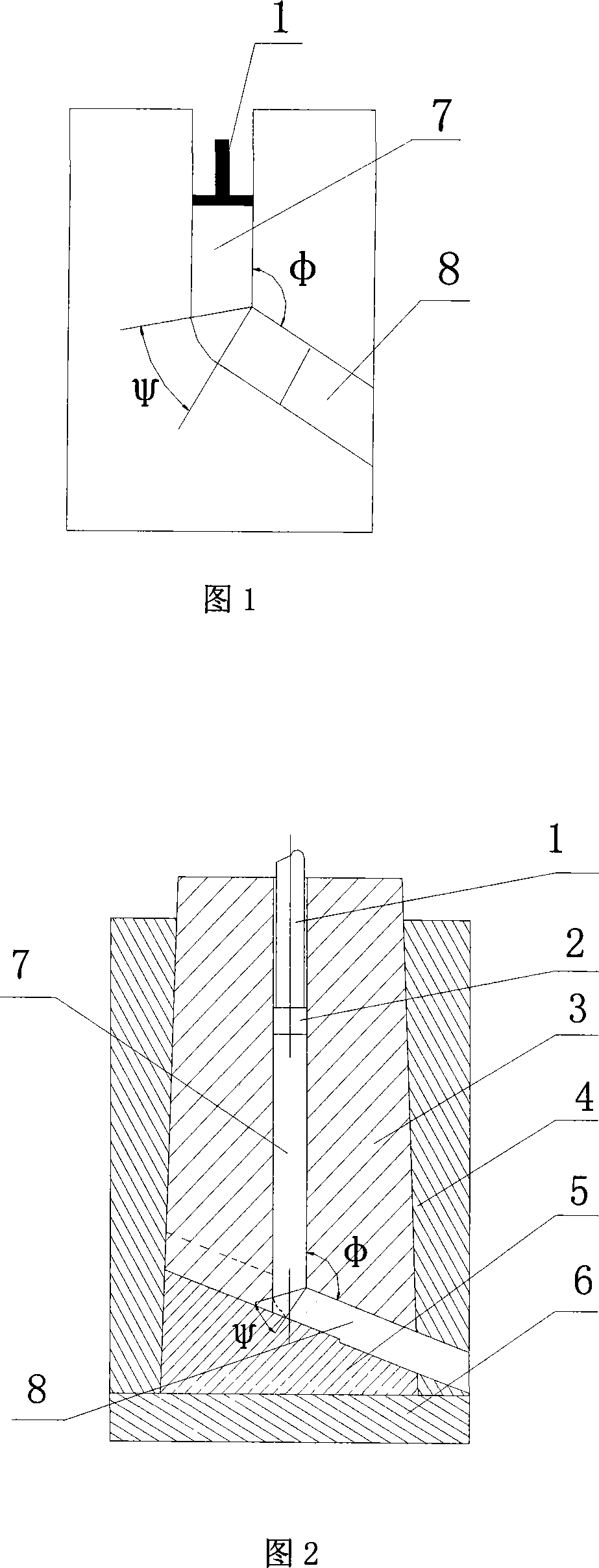

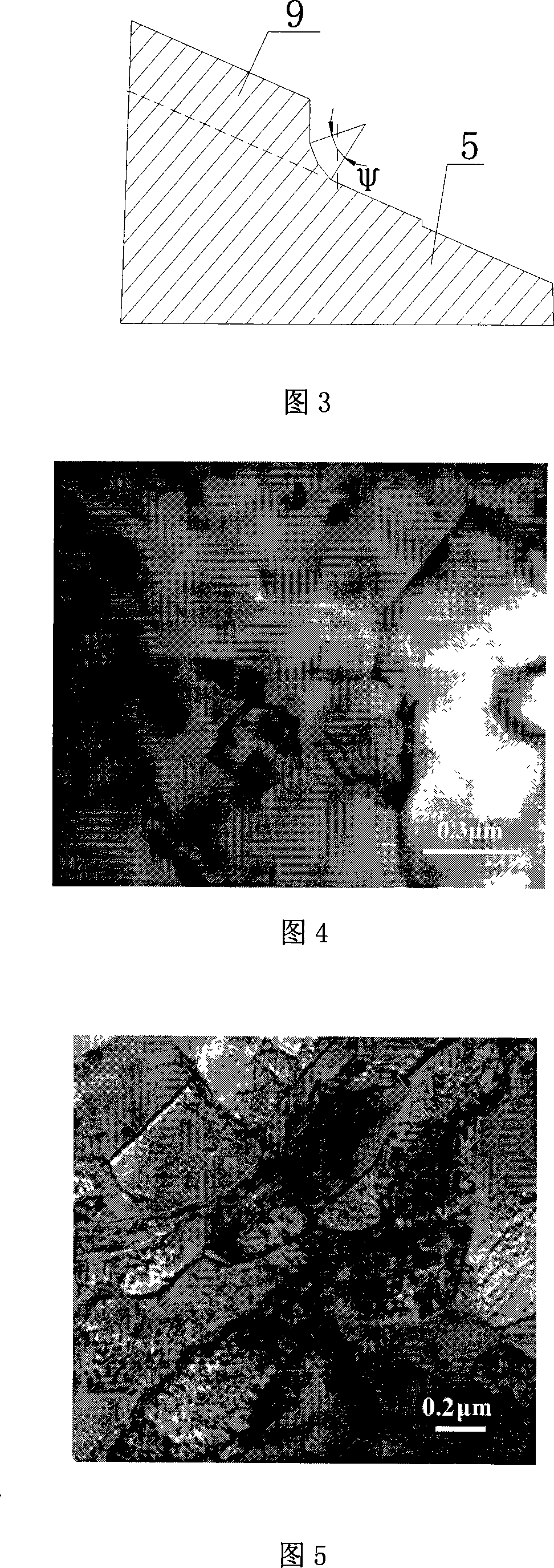

Equal channel deformation mould for preparing block body ultrafine grain metal

ActiveCN101147927AImprove load bearing capacityImprove securityExtrusion diesUltra fineMaterials science

The present invention discloses an equal-channel deformation mould for preparing block-body ultra fine grain metal. Said equal-channel deformation mould includes the following several portions: pressure rod, upper mould, fastening sleeve, lower mould and base seat, in the upper mould interior and lower mould interior are respectively cut two crossed equal-diameter channels. Besides, said invention also provides the concrete structure of above-mentioned every portion, and also provides the concrete application method of said equal-channel deformation mould.

Owner:溧阳常大技术转移中心有限公司

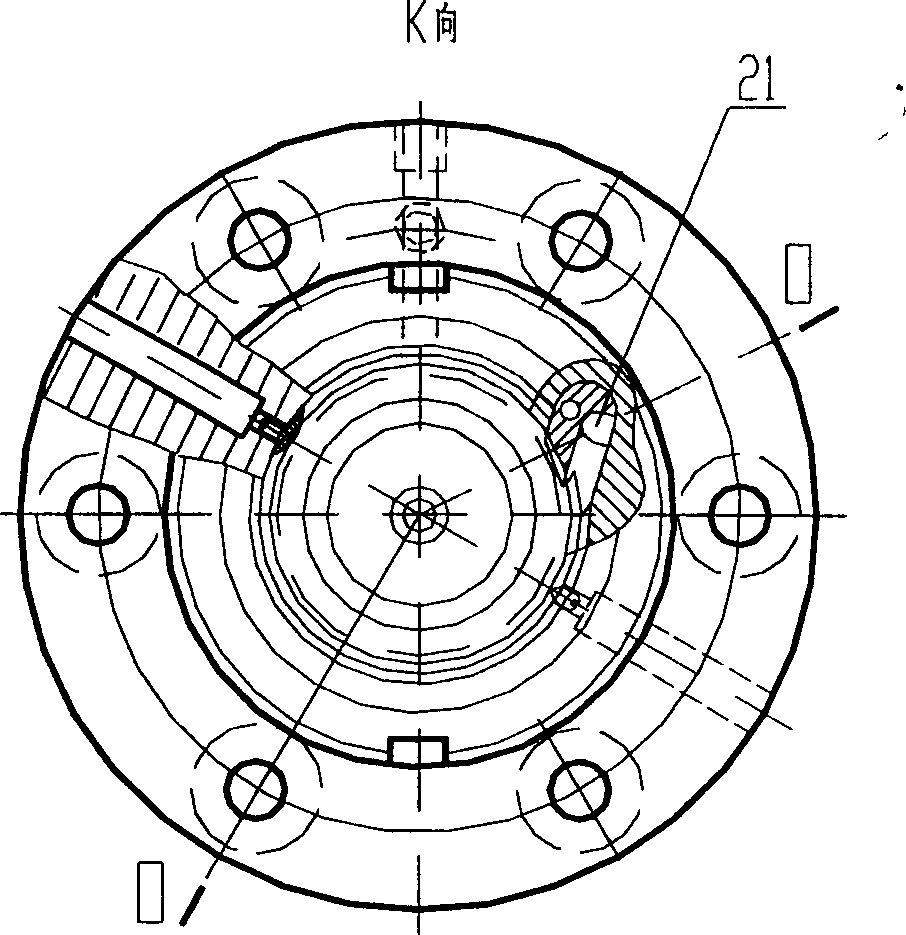

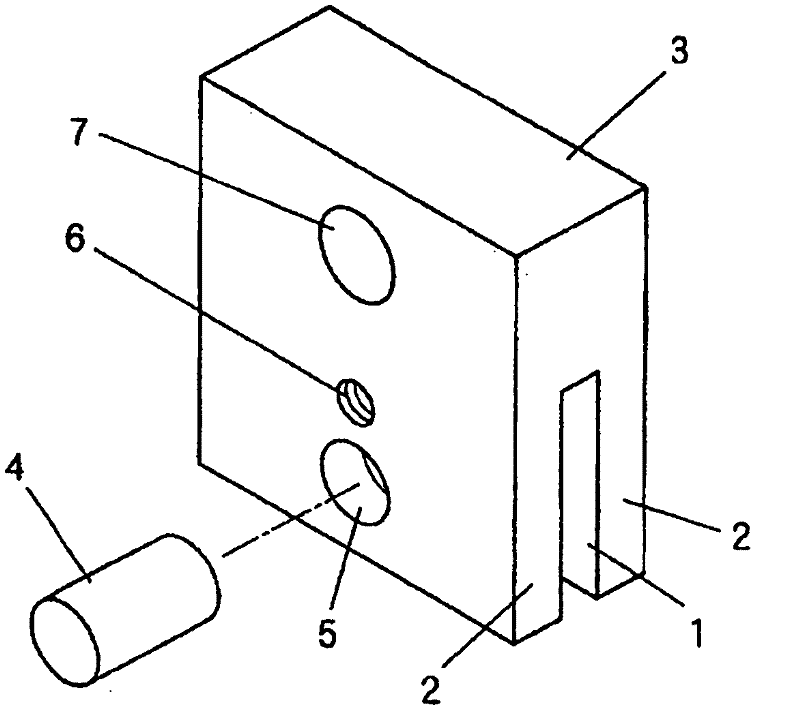

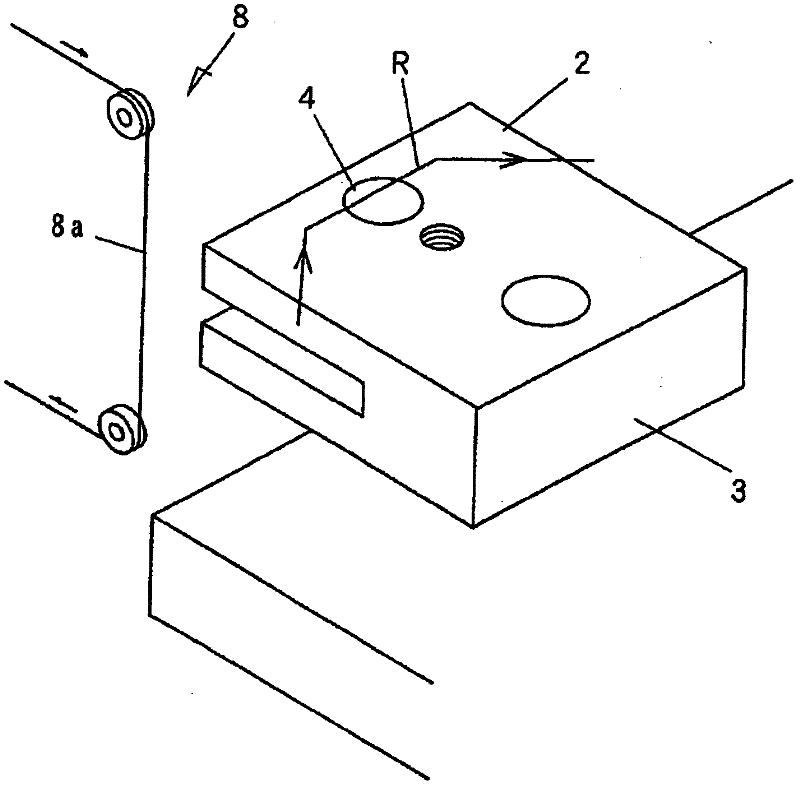

Wheel retaining tool, a manufacturing method thereof and knife flywheel retaining mechanism using wheel retaining tool

ActiveCN102248613AImprove straightnessHigh rotation accuracyWorking accessoriesFine working devicesSuperhard materialFlywheel

The invention provides a wheel retaining tool having a high rotation precision and an elongated life and a manufacturing method thereof. The method for manufacturing the retaining tool includes steps of: processing the supporting parts 2 which are opposite leftward and rightward with a groove 1 as an interval, a cylindrical installing hole 5 formed by running through the left and right supporting parts 2 and a metallic retaining tool body 3 of a shield installing hole 6 in parallel with the cylindrical installing hole 5; installing a cylinder 4 made of the superhard material in the cylindrical installing hole 5 of the retaining tool body 3; enabling a wire 8a of a wire discharge processing machine 8 to pass through the shield installing hole 6 and moving from the shield installing hole 6 to the cylinder 4 and processing a pin insertion hole 9 at an axle center part of the cylinder 4 in a discharge processing way; and cutting off a middle part of the cylinder 4 in the groove 1 to process a gap 10 placing the knife flywheel A.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Preparation method of environment-friendly asphalt mixture additive

ActiveCN106147252AImprove the ability to resist rutting deformationReduce pollutionSludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeGlycoside formation

The invention discloses an environment-friendly asphalt mixture additive and a preparation method thereof. The environment-friendly asphalt mixture additive is prepared from, by weight, 55%-90% of powdery solids, 7%-20% of polyethylene, 1%-5% of a fluorocarbon surfactant, 1%-10% of Kaloamine and 1%-10% of alkyl glycoside. The preparation method comprises the following steps that the powdery materials, polyethylene, the fluorocarbon surfactant, Kaloamine and alkyl glycoside are put into a screw extruder in proportion, mixed to be uniform and extruded to obtain a finished product, and then the asphalt mixture additive is obtained. According to the asphalt mixture additive, the powdery solids generated after thermal extraction treatment of oily sludge can be fully reused and can be put into asphalt mixture production by replacing ore powder, environmental pollution is reduced, the cost is reduced, the rutting deformation resistance of the asphalt mixture is improved, and the service life of a pavement can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com