Wheel retaining tool, a manufacturing method thereof and knife flywheel retaining mechanism using wheel retaining tool

A manufacturing method and wheel holding technology, which can be used in manufacturing tools, glass manufacturing equipment, stone processing tools, etc., can solve the problem that the cutter wheel cannot form high-precision scribe lines, etc., to suppress wear resistance or load resistance. Deterioration, load resistance improvement, and wear suppression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, details of the present invention will be described in detail based on drawings showing its embodiment, wherein:

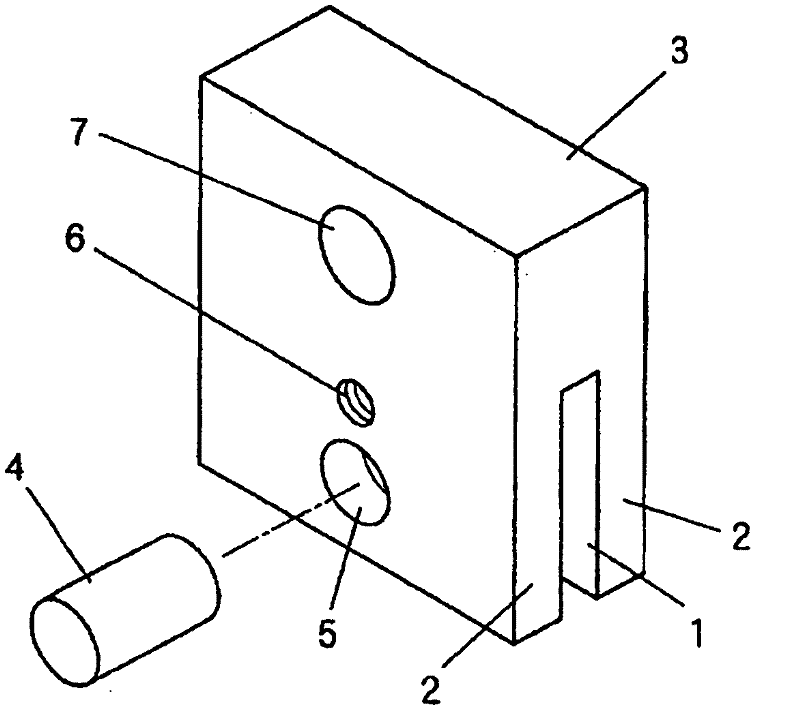

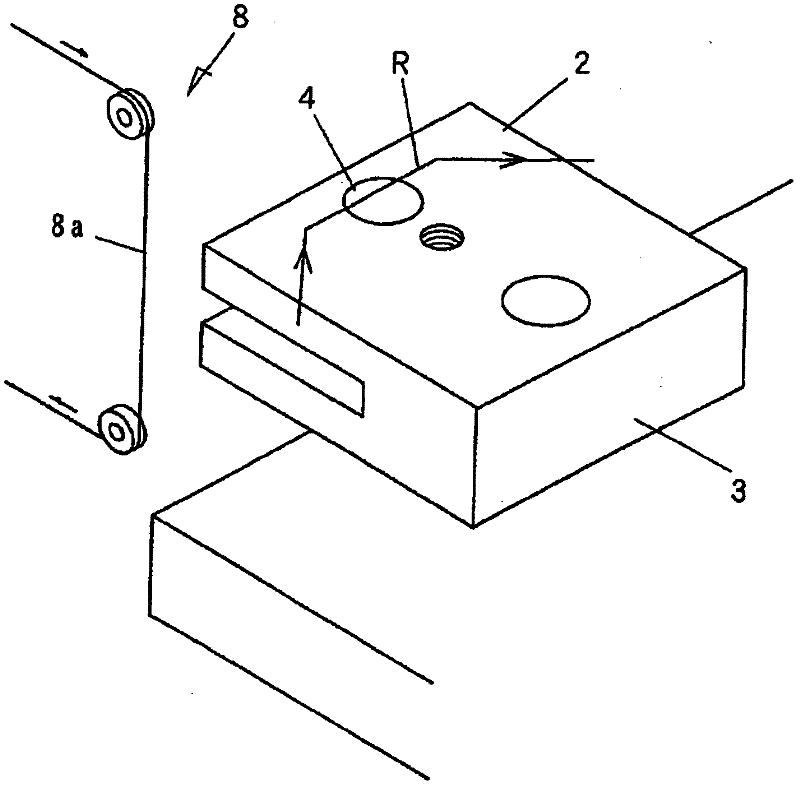

[0057] figure 1 In order to show a perspective view of the wheel holder W manufactured by the manufacturing method of the present invention, the following Figure 7 (d) shows its profile. This wheel holder W is provided with a downwardly opening groove 1 which accommodates a cutter wheel A which will be described later, and a holder main body 3 provided with left and right supporting parts 2 facing each other across the groove 1 . A cylindrical body 4 made of a superhard material (sintered diamond or cemented carbide) is attached to the support part 2 so as to penetrate the support part 2 (partially cut off). In addition, a pin insertion hole 9 is formed in the axial center portion of the cylindrical body 4 by wire electric discharge machining.

[0058] The following is based on Figure 2-Figure 7 The steps of the production method of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com