Method for reinforcing existing municipal pipe gallery within deep foundation pit excavation range

A deep foundation pit and pipe gallery technology, applied in the repair of foundation structure, foundation structure engineering, sheet pile wall, etc., can solve the problem that Bailey beam occupies a large area, unfavorable earthwork backfill, and it is difficult to detect the displacement of the pipe gallery and adjust the pipe Corridor and other problems, to avoid the deformation of the pipe gallery, improve the stability, the effect of early support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, implementation method of the present invention is described in detail:

[0036] One of embodiment:

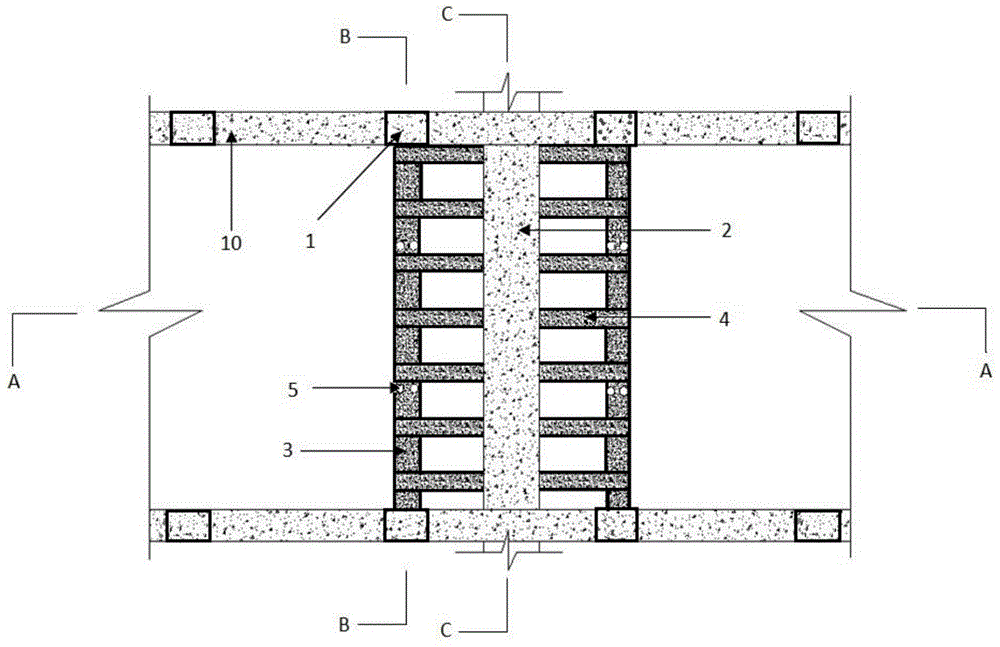

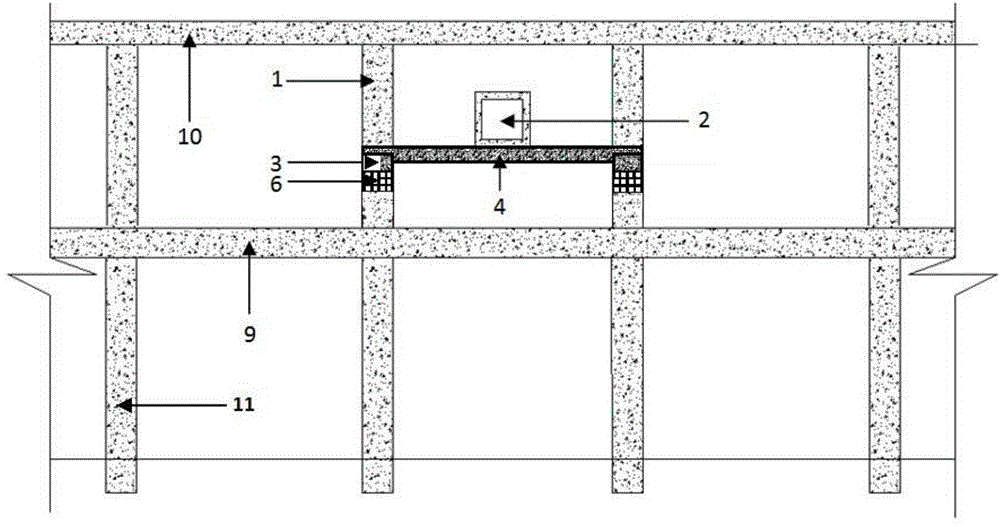

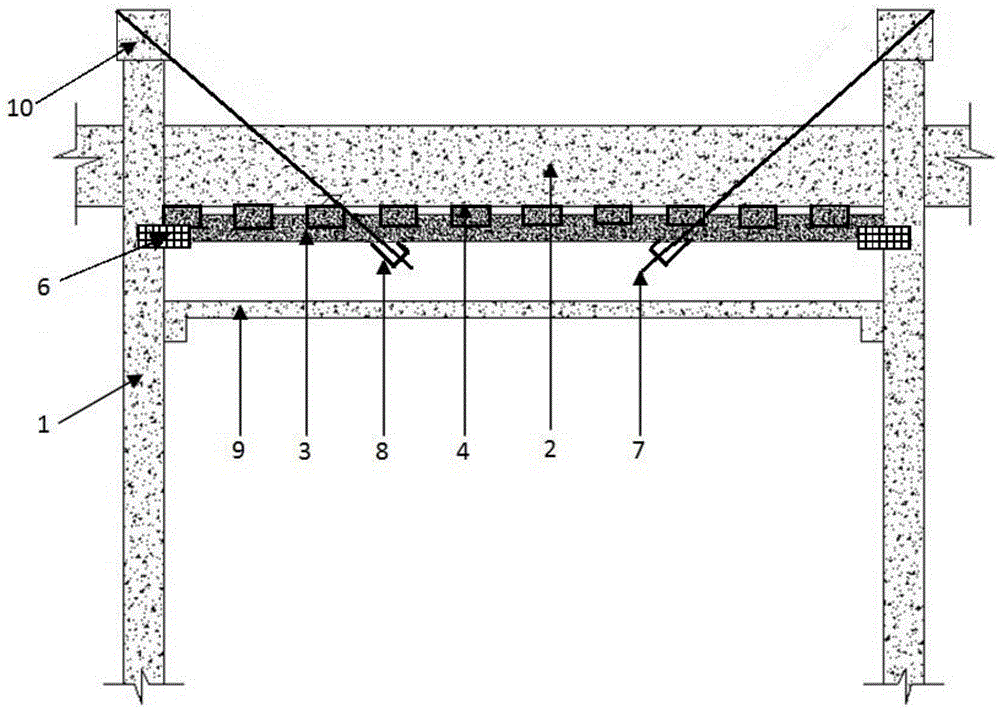

[0037] A reinforcement method for the existing municipal pipe gallery within the excavation range of a deep foundation pit, including laying general prefabricated piles 11 and pipe gallery reinforcement prefabricated piles 1 at the design boundary of the foundation pit, and excavating the soil layer of the foundation pit to the pipe gallery 2 At the bottom position, the reserved connection device 6 for reinforcing the prefabricated piles of the pipe gallery is used as the support point, and the pipe gallery support structure 4 with the soil mold as the template under the pipe gallery and the beams 3 on both sides of the pipe gallery are poured at the same time. The beam passes through the anchor cable 7 and The top crown beams 10 of the prefabricated piles are connected.

[0038] Generally, the prefabricated piles 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com