Foamed concrete heat preservation plate and preparation method thereof

A foamed concrete and thermal insulation board technology, applied in the field of thermal insulation materials, can solve the problems of shortening the service life of thermal insulation system, damage of foamed cement board, increasing raw material cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] By weight, the following raw materials were used: 300 parts of Portland cement (PO42.5), 100 parts of high alumina cement, 150 parts of fly ash (I grade), 10 parts of calcium stearate, 3 parts of polymer rubber powder, 2 parts of polypropylene fiber anti-crack fiber, 30 parts of hydrogen peroxide (27.5% by mass), 2 parts of water repellent, 290 parts of water, added to a gravity-free mixer and mixed for 3 minutes, poured into the mold, and formed after molding and curing Foamed concrete insulation board.

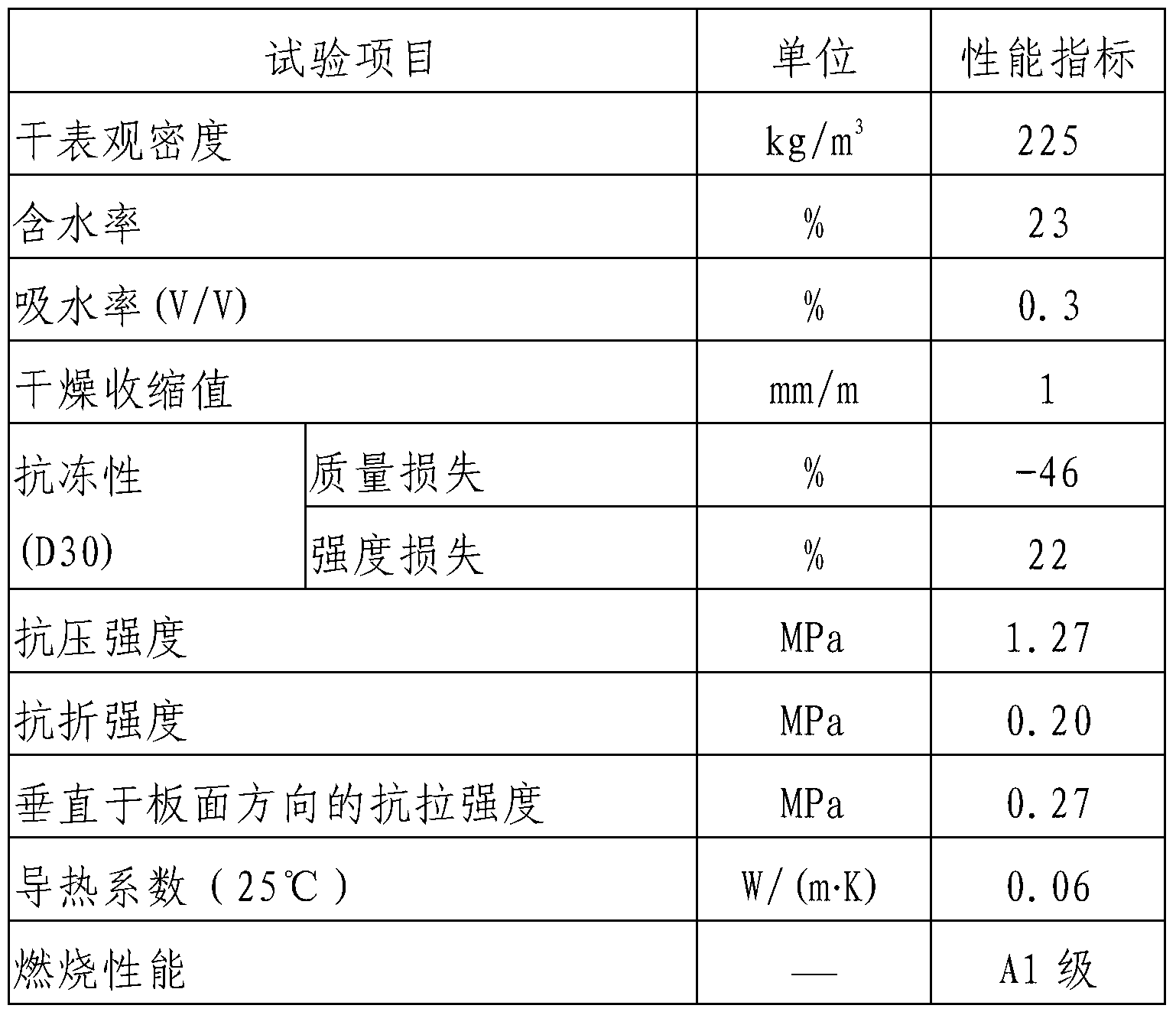

[0018] The foamed concrete insulation board in the present embodiment is cut into a size specification of 600mm*600mm for performance testing, and the test results are shown in Table 1:

[0019] Table 1

[0020]

[0021] As can be seen from the table, the compressive strength of the foamed concrete insulation board obtained in Example 1 reaches 1.27MPa, and the dry apparent density is 225kg / m 3 , the combustion performance reaches A1 level, which has a certain co...

Embodiment 2

[0023] By weight, the following raw materials were used: 290 parts of Portland cement (PO42.5), 100 parts of high alumina cement, 140 parts of fly ash (I grade), 9 parts of calcium stearate, 4 parts of polymer rubber powder, 2 parts of polypropylene fiber anti-crack fiber, 30 parts of hydrogen peroxide (27.5% by mass), 2 parts of water repellent, 290 parts of water, added to a gravity-free mixer and mixed for 3 minutes, poured into the mold, and formed after molding and curing Foamed concrete insulation board.

[0024] After testing, the compressive strength of the foamed concrete insulation board in this example reaches 1.30MPa, and the dry apparent density is 231kg / m 3 , the water absorption rate (V / V) is 0.31%, the thermal conductivity (25℃) is 0.05, the combustion performance reaches A1 level, and it has a certain compressive effect, which can be used as a thermal insulation board in the thermal insulation system.

Embodiment 3

[0026] By weight, the following raw materials: 300 parts of Portland cement (PO42.5), 120 parts of high alumina cement, 155 parts of fly ash (I grade), 10 parts of calcium stearate, 3 parts of polymer rubber powder, 2 parts of polypropylene fiber anti-crack fiber, 30 parts of hydrogen peroxide (27.5% by mass), 2 parts of water repellent, 300 parts of water, added to a gravity-free mixer and mixed for 3 minutes, poured into the mold, and formed after molding and curing Foamed concrete insulation board.

[0027] After testing, the compressive strength of the foamed concrete insulation board in this example reaches 1.32MPa, and the dry apparent density is 227kg / m 3 , the water absorption rate (V / V) is 0.28%, the thermal conductivity (25°C) is 0.05, the combustion performance reaches A1 level, and has a certain compressive effect, which can be used as a thermal insulation board in the thermal insulation system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Dry apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com