Static combined bearing for screw rod

A combined bearing and hydrostatic bearing technology, used in metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of reducing the service life of machine tools, transmission accuracy, accelerated wear, etc., and achieve high oil film stiffness and load bearing capacity. , the effect of improving precision and novel structure

Inactive Publication Date: 2012-06-13

威海华东重工有限公司

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, with the rapid development of the machine tool industry, the scale of heavy-duty machine tools is getting larger and larger, and the load on the mechanical transmission of the column driven by the long screw is also increasing. To support the axial force generated during the transmission process, because the bearing bears a huge axial force, sintering will occur between the cylindrical roller and the front and rear parts of the bearing, and the wear will be accelerated, which will greatly reduce the service life and transmission accuracy of the machine tool

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0014] Due to the adoption of the above-mentioned structure, the present invention has a novel structure, reduces the influence of thermal deformation on the rotation accuracy of the lead screw, greatly improves the oil film stiffness and load-bearing capacity, can withstand extremely large axial loads, and prolongs the service life of the machine tool , Improve the accuracy of machine tools and other advantages.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

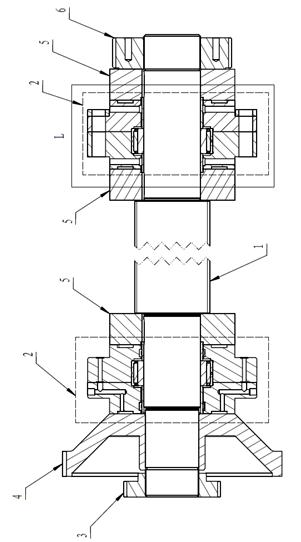

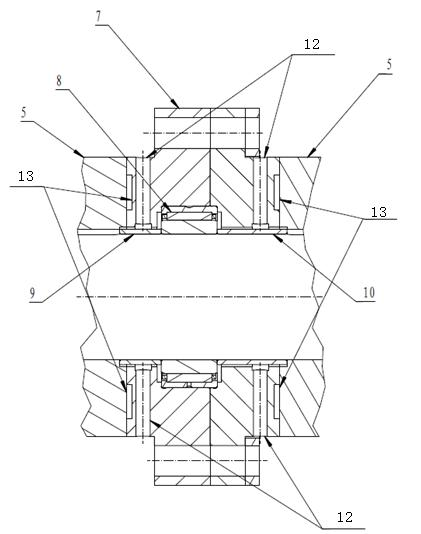

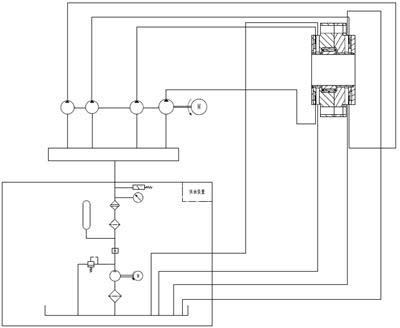

The invention relates to the field of a bearing, in particular to a static combined bearing for a screw rod. The static combined bearing comprises an oil supply device used for supplying oil through a throttler and is characterized in that the static combined bearing is provided with a static bearing, a rolling needle bearing, a locking screw nut, a front separation sleeve, a back separation sleeve and regulating pads, a step groove is arranged in the inner circumferential direction of the static bearing, an outer ring of the rolling needle bearing is fixedly arranged in the step groove, the outer ring of the rolling needle bearing is tightly pressed in the axial direction and the radial direction through the static bearing surrounded at the outer side, the front end of an inner circle of the rolling needle bearing is tightly pressed through the front separation sleeve, the back end of the inner circle of the rolling needle bearing is tightly pressed through the back separation sleeve, positions of the side surface of the static bearing, corresponding to the front separation sleeve and the back separation sleeve, are provided with oil discharge openings, annular oil grooves are respectively arranged on two end surfaces of the static bearing, two ends of the static bearing are respectively and tightly pressed with the regulating pads through the locking screw nut, and the annular oil grooves form annular oil cavities through the regulating pads and are communicated with the throttler and the oil supply device through oil supply openings arranged on the static bearing. Therefore, lubricating oil films with sufficient pressure are respectively formed at two sides of the static combined bearing, simultaneously, the static bearing and the front and back regulating pad form liquid friction, the influence caused by terminal deformation on the rotation precision of the screw rod is reduced, the axial load bearing capability is greatly enhanced, and the service life is greatly prolonged.

Description

technical field [0001] The invention relates to the field of bearings, in particular to a static pressure combined bearing for long lead screws subjected to relatively large axial loads in heavy machine tools. Background technique [0002] In various mechanical transmissions, thrust roller bearings and cylindrical roller bearings are usually used at both ends of the long screw to bear the axial load and radial combined load of the screw. higher. However, with the rapid development of the machine tool industry, the scale of heavy-duty machine tools is getting larger and larger, and the load on the mechanical transmission of the column driven by the long screw is also increasing. To support the axial force generated during the transmission process, because the bearing bears a huge axial force, sintering will occur between the cylindrical roller and the front and rear parts of the bearing, and the wear will be accelerated, which will greatly reduce the service life and transm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q5/40

Inventor 王斌尹财席浩然车忠伟张建州

Owner 威海华东重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com