Patents

Literature

208results about How to "Good flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

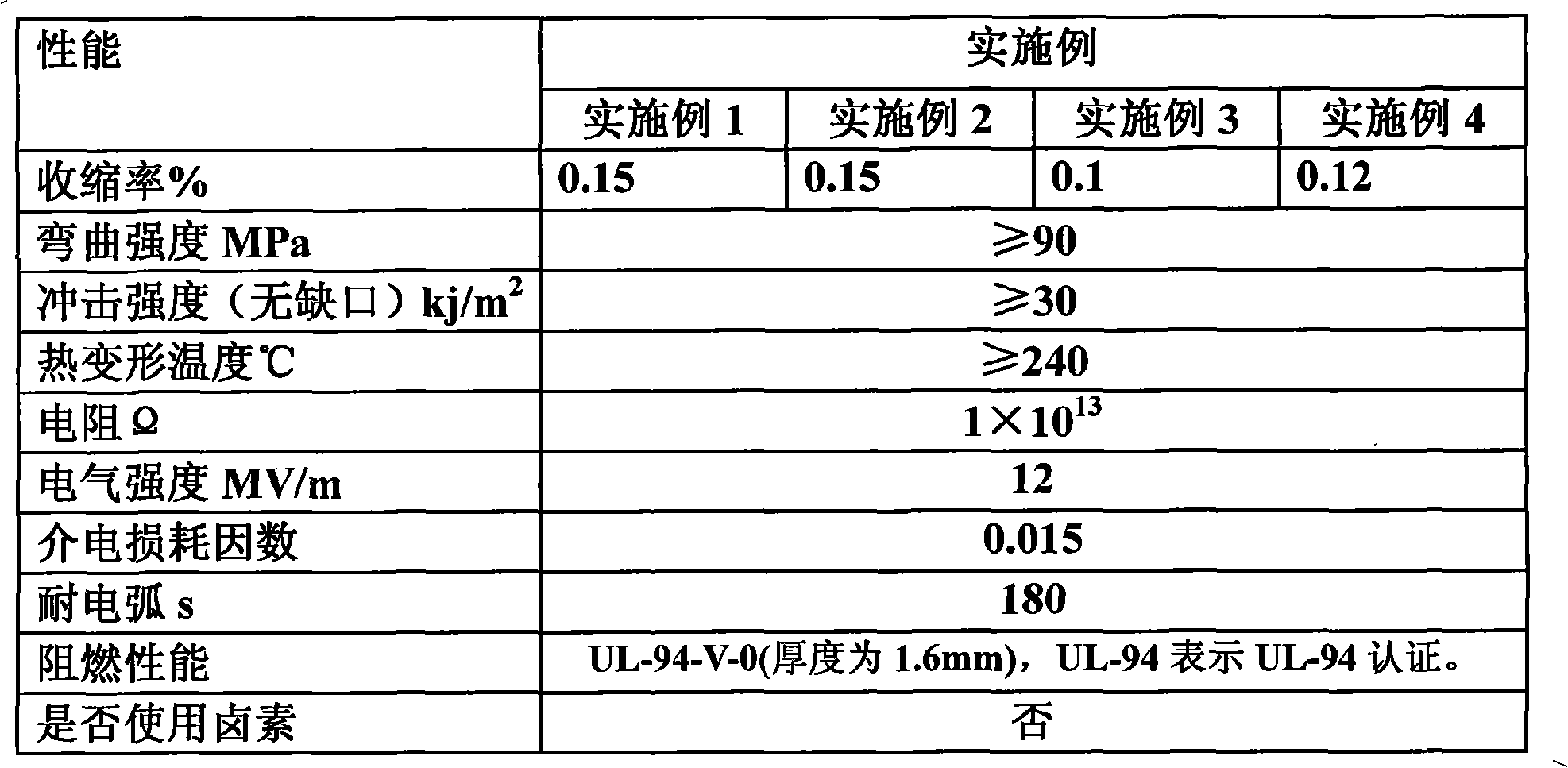

Halogen-free flame-proof unsaturated polyester molding compound

The invention relates to halogen-free flame retardant unsaturated polyester molding compound, which is made of the raw materials according to the part by weight: unsaturated polyester resin accounting for 18.2 parts to 20.5 parts; additive agent accounting for 11.2 parts to 13.3 parts; initiating agent accounting for 0.3 part to 0.55 part; polymerization inhibitor accounting for 0.003 part to 0.005 part; thickening agent accounting for 0.1 part to 0.25 part; filling material accounting for 68 parts to 75 parts; phosphate accounting for 10.2 parts to 14.8 parts; metal oxide accounting for 2.7 parts to 4.6 parts; mould release agent accounting for 1.4 parts to 1.7 parts and reinforced fibers accounting for 15 parts to18 parts. The halogen-free flame retardant unsaturated polyester molding compound has the advantages that the flame retardant effect is good, the intensity is high, the shrinkage is low, the electrical property is excellent, and the halogen-free flame retardant unsaturated polyester molding compound is safe to human body and is environmental friendly due to the flame retardant and halogen-free properties and can be applied to switches, the casing bodies of daily electric appliances and other fabricated parts.

Owner:常熟东南塑料有限公司

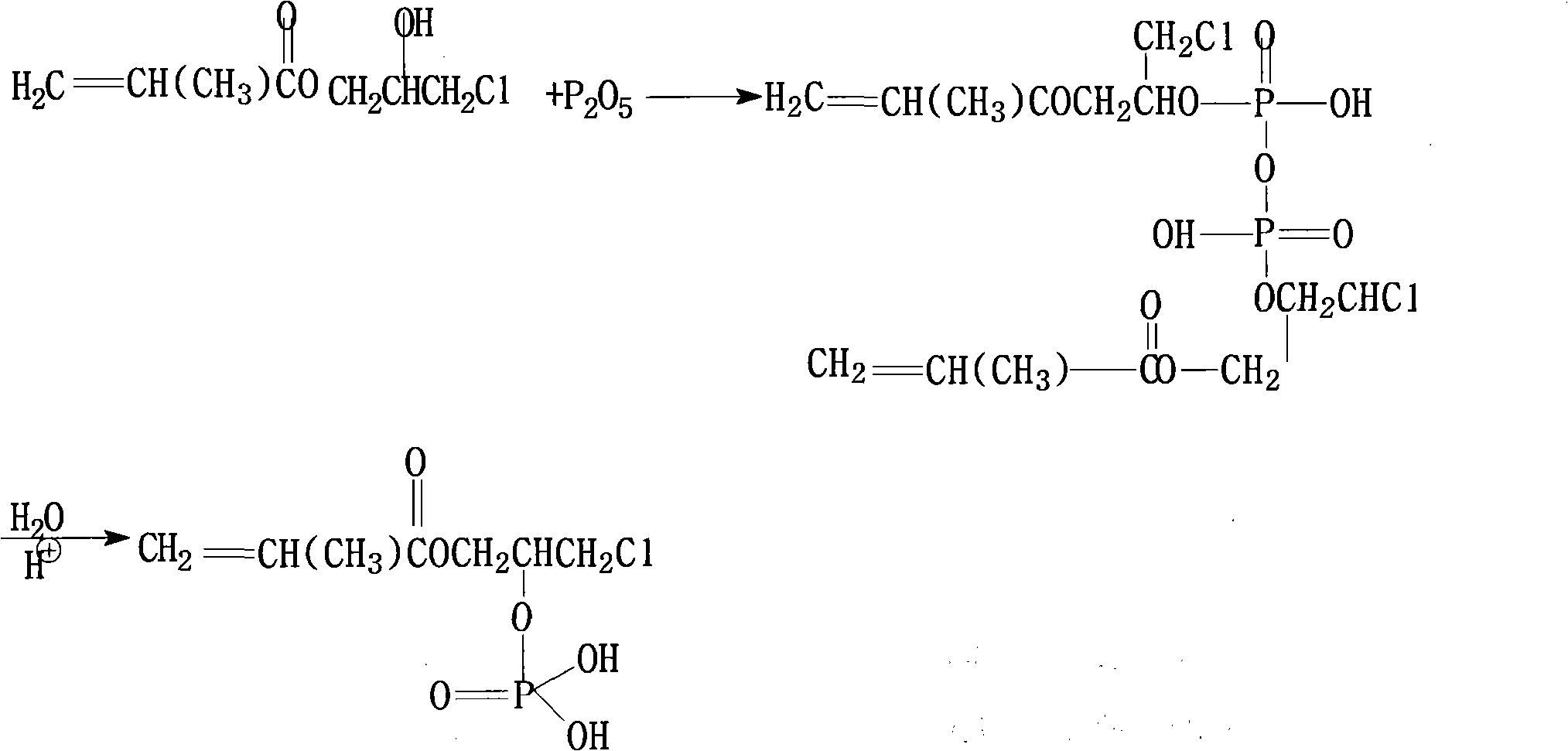

Ultraviolet cured flame-retardant coating and preparation method thereof

ActiveCN101781486AGood flame retardant effectImprove flame retardant performanceFireproof paintsDefoamerPhosphate

The invention provides an ultraviolet cured flame-retardant coating and a preparation method thereof. The components by weight percent are as follows: 25-35 percent of halogenated epoxy acrylate; 10-15 percent of aliphatic polyurethane acrylate; 5-10 percent of phosphate-acrylate; 10-15 percent of halogenated acrylate; 10-28 percent of TMPTA; 5-6 percent of photoinitiator; 10-20 percent of inorganic flame retardant agent; and 3-5 percent of additives. The preparation method is as follows: synthesizing the halogenated epoxy acrylate and the phosphate-acrylate; then weighing the halogenated epoxy acrylate, the aliphatic polyurethane acrylate, the phosphate-acrylate, the halogenated acrylate monomer, the TMPTA, the photoinitiator, the inorganic flame retardant agent and the additives; and stirring to mixing the PA, the epoxy acrylate X-EA and the aliphatic polyurethane acrylate PUA, adding the XA monomer, the TMPTA monomer and the additives such as dispersing agent and defoamer after mixing thoroughly, dispersing at the speed of 900-1200r / min, adding a flame retardant agent, a leveling agent and other residual additives and the photoinitiator after dispersing thoroughly, and then dispersing for 30 minutes at the high speed of 1200-1500r / min.

Owner:瑞通高分子科技(浙江)有限公司

Environment-friendly flame retardant rubber material and preparation method thereof

InactiveCN101792544AGood flame retardant effectExcellent mechanical properties and wear resistancePigment treatment with non-polymer organic compoundsFlame resistanceZinc

The invention provides an environmental-friendly flame retardant rubber material and a preparation method thereof. The environment-friendly flame retardant rubber material comprises the following components in part by weight: 100 parts of rubber matrix, 2 to 3 parts of vulcanizing agent, 1 to 1.5 parts of accelerating agent M, 0.2 to 0.4 part of accelerating agent D, 0.2 to 0.8 part of accelerating agent TMTD, 0.5 to 1.5 parts of stearic acid, 3 to 5 parts of zinc oxide, 1 to 2 parts of anti-aging agent A, and 10 to 15 parts of fire retardant. For the environment-friendly flame retardant rubber material prepared by the method, GB528-83, GB / T1689-1998, and GB / T10707 standards are adopted to test the tensile property, abrasion resistance and flame resistance of the rubber. The result shows that the prepared flame retardant rubber has good flame retardancy, relatively good mechanical property and abrasion resistance, and low production cost and easy implementation.

Owner:SHANGHAI UNIV OF ENG SCI

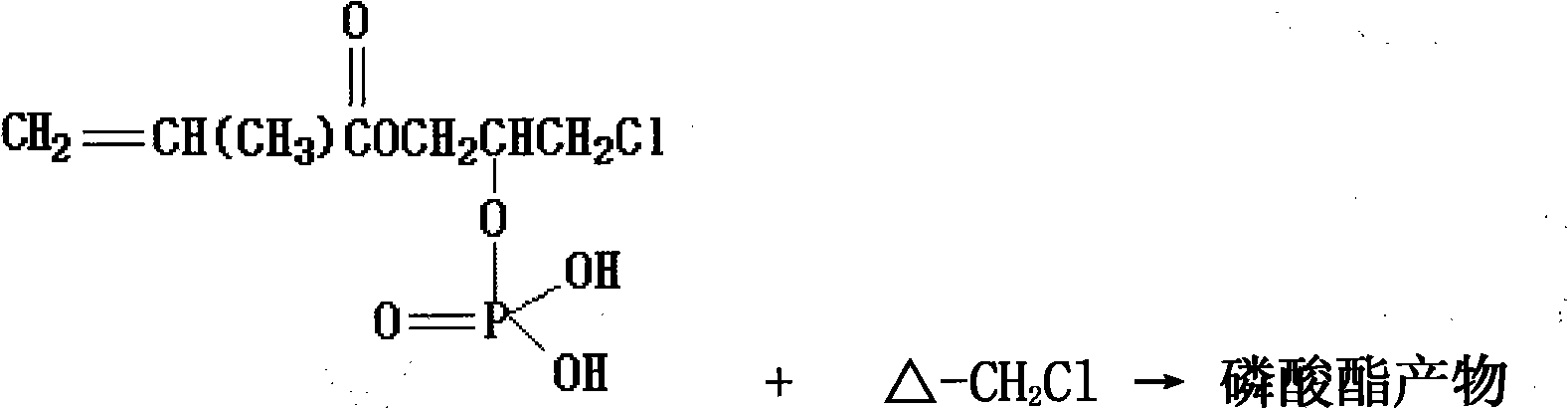

Method for enhancing safety of lithium-ion battery

InactiveCN105742733AIncrease usageGood flame retardant effectCell seperators/membranes/diaphragms/spacersSecondary cells servicing/maintenanceThermal runawayBiomedical engineering

The invention belongs to the technical field of lithium-ion batteries, and particularly relates to a method for enhancing the safety of a lithium-ion battery. The method comprises the steps as follows: a microcapsule is prepared; the microcapsule comprises a capsule core part and a capsule shell part; the capsule core part is coated with the capsule shell part; the capsule core part is a fire retardant for lithium ions; the fire retardant is coated with the capsule shell part to form the microcapsule; the microcapsule is mixed into a solution containing an isolating membrane protecting agent; the surface of an isolating membrane is evenly coated with the solution mixed with the microcapsule; the isolating membrane is used as the isolating membrane for the lithium-ion battery after being dried; and the treated isolating membrane is assembled and applied to the lithium-ion battery in a winding or laminating manner. The method has the beneficial effects that the fire retardant is coated with the microcapsule and is fixed on the surface of the isolating membrane, so that the viscosity of an electrolyte is not affected; the rate and the low-temperature performance of the battery are ensured; protective reaction can be relatively quickly made for the battery when thermal runaway is generated; and the safety improvement effect on the battery is relatively significant.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

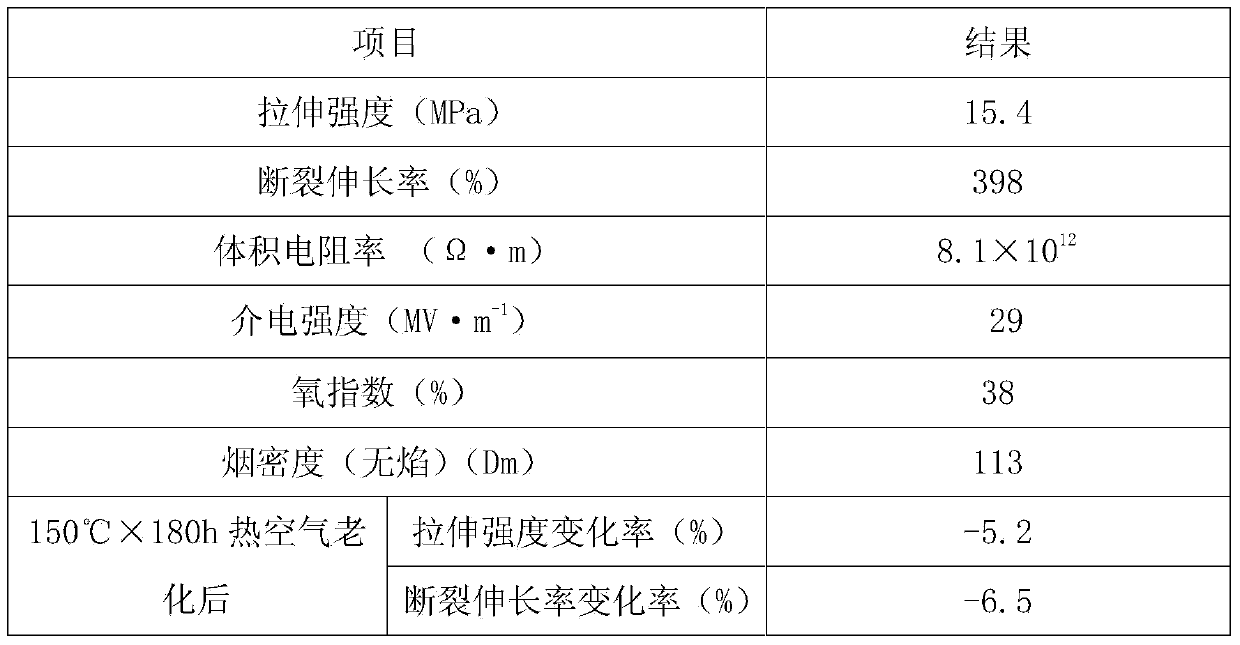

Low-smoke flame-retarding ceramizable PVC material, preparation method, and application thereof

The invention relates to the technical field of PVC materials and particularly relates to a low-smoke flame-retarding ceramizable PVC material, a preparation method and an application thereof. The PVC material includes, by weight, 20-80 parts of PVC resin, 20-60 parts of a plasticizer, 10-30 parts of a flame retardant, 1-10 parts of a smoke inhibitor, 20-80 parts of a ceramization powder, 0.5-5 parts of a compatilizer, 0.02-0.1 parts of an anti-ultraviolet agent, and 0.02-0.1 parts of an antioxidant. The PVC material has excellent flame-retarding effect, low smoke density, high strength, good flexibility and high break elongation, can form a compact ceramized product at the temperature range of 600-1000 DEG C, is low in ceramization temperature and can form compact ceramic. The formed ceramized product has high high-temperature strength and anti-heat-flow-impact capability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

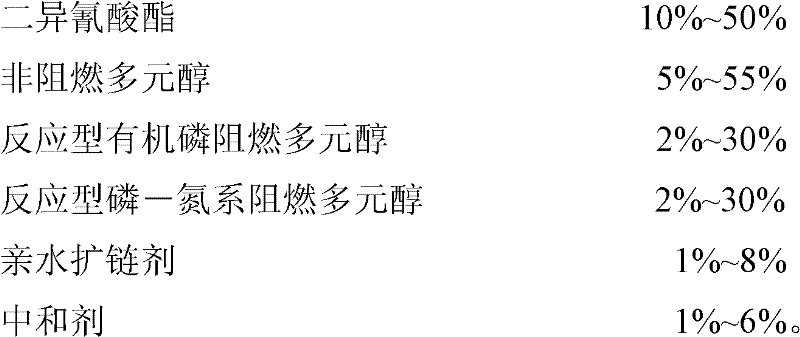

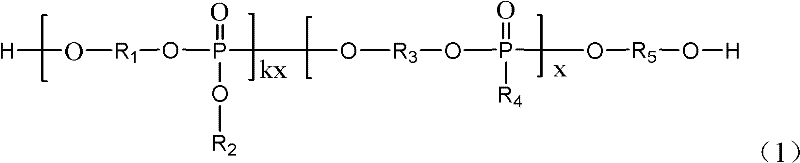

Environmentally-friendly halogen-free reaction type soft and hard segment co-modified flame retardant waterborne polyurethane fabric coating agent and preparation method thereof

The invention relates to an environmentally-friendly halogen-free reaction type soft and hard segment co-modified flame retardant waterborne polyurethane fabric coating agent and a preparation method thereof and belongs to the technical field of light industry. The method comprises the following steps: adding diisocyanate, non-flame retardant polyol, reaction type organic phosphorus flame retardant polyol, reaction type phosphorus-nitrogen system flame retardant polyol and a hydrophilic chain extender into a reaction kettle for reaction while stirring in the presence of N2, thus obtaining a prepolymer; cooling, and then utilizing a solvent to regulate the viscosity of the system; and adding the prepolymer a water solution containing a neutralizing agent, neutralizing, and removing the solvent, thus obtaining a target product. The synthesized inherent flame retardant waterborne polyurethane fabric coating agent has the advantages of environmental friendliness, no toxicity, low smoke, phosphorus-nitrogen synergistic flame retardant effect and significant flame retardant effect; after the coating agent is adopted for performing after-finishing on a fabric, a coating is transparent, the color change of the fabric is less, the fabric is not sticky, the hand feeling of the fabric is not affected, the fabric is resistant to soaping, and the fabric can simultaneously pass the B1 level in a GB / T5455-1997 textiles-burning behavior-vertical method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

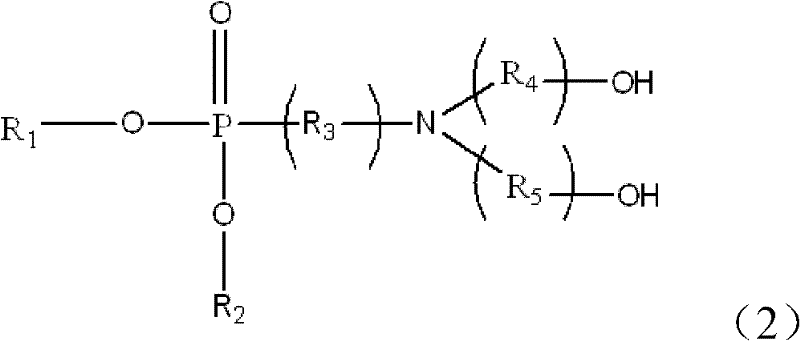

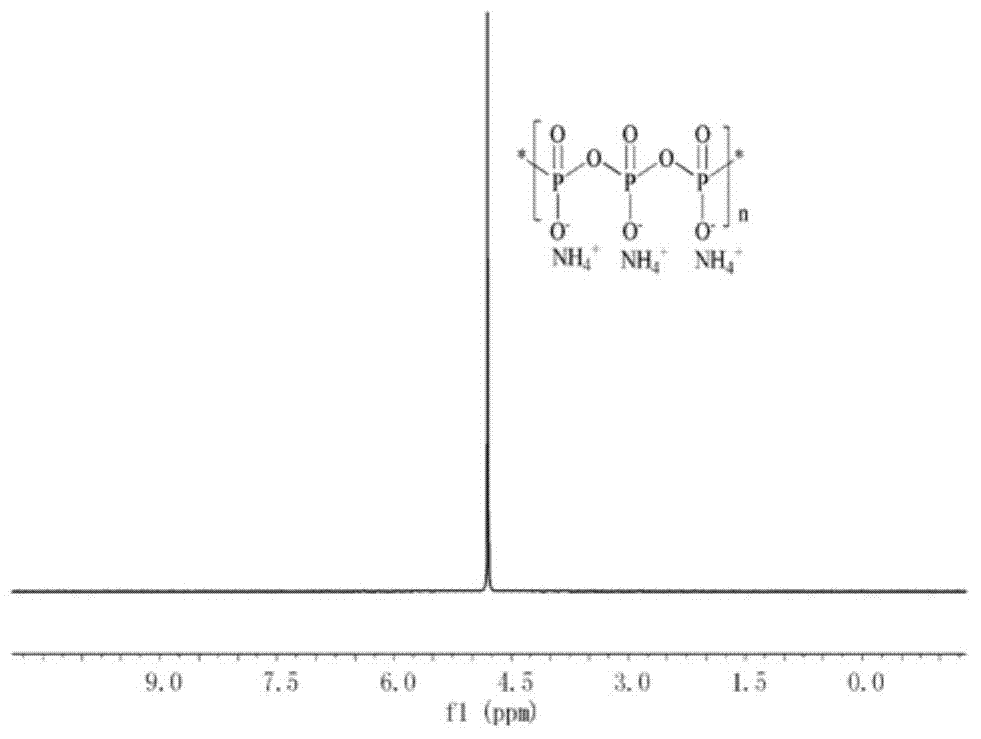

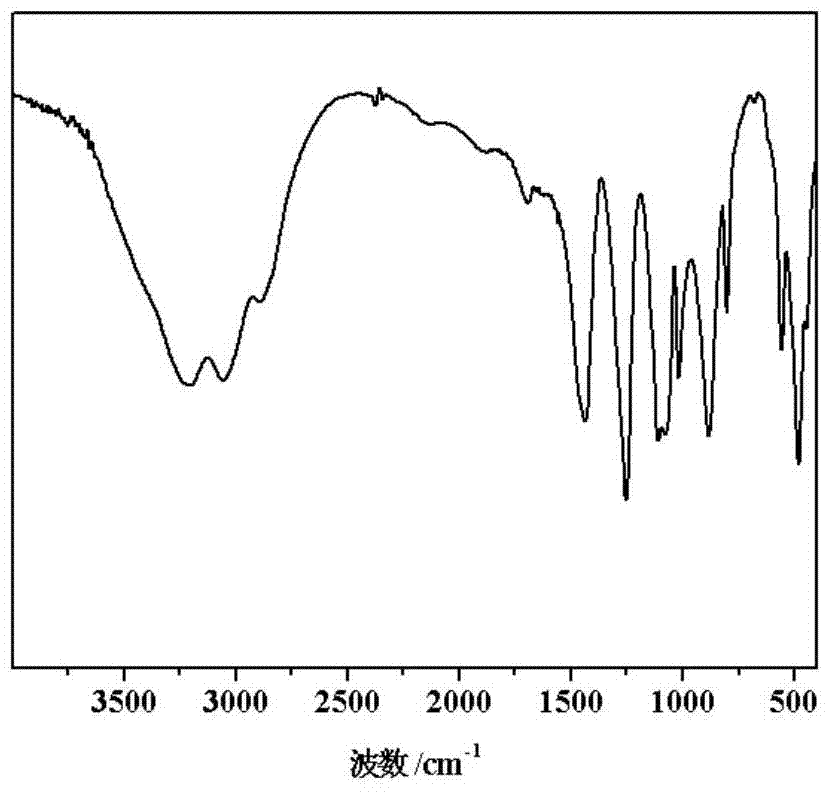

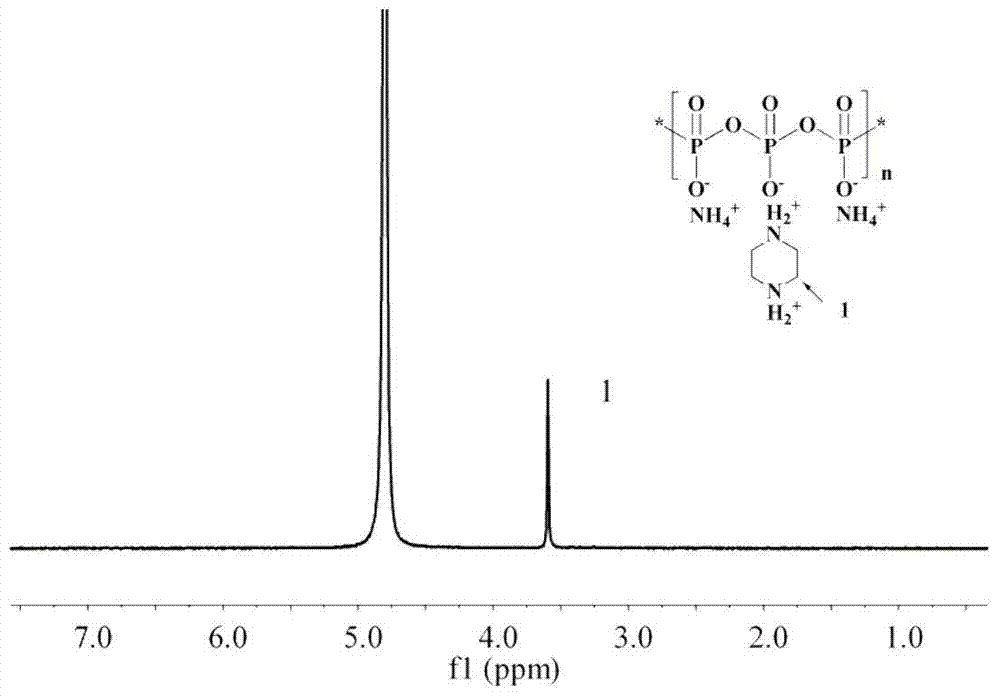

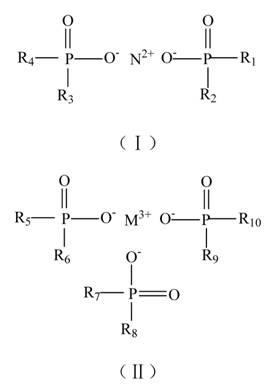

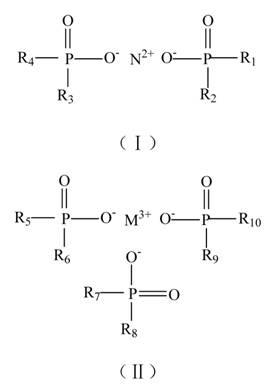

Flame-retardant modified ammonium polyphosphate and preparation method and application thereof

The invention discloses flame-retardant modified ammonium polyphosphate which has the following structural general formula: (img file='DDA0000446234650000011.TIF' wi='1650' he='1656' / ). The invention also discloses a method for preparing the flame-retardant modified ammonium polyphosphate as well as application of adding the flame-retardant modified ammonium polyphosphate into polyolefin or epoxy resins. The flame-retardant modified ammonium polyphosphate provided by the invention has the effects of acid source and air source, also has a novel carbon source effect, can be independently taken as a flame retardant to be applied to a high polymer material and is small in addition amount and good in flame-retardant effect. Moreover, the flame-retardant modified ammonium polyphosphate is mature in preparation method, simple and convenient in operation, easy to control and convenient for industrial production.

Owner:SICHUAN UNIV

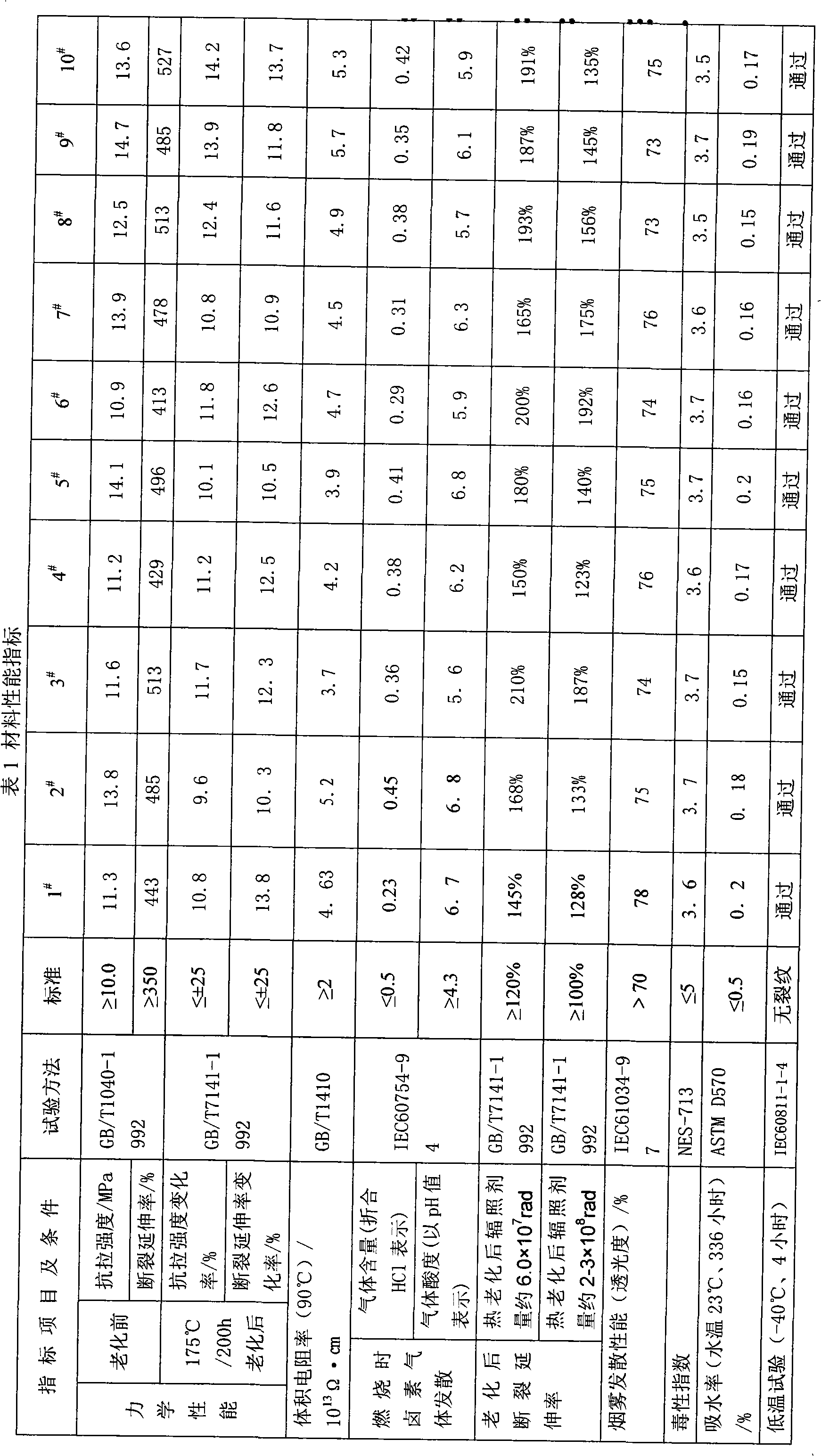

IE-grade KI -type cable insulation material for nuclear power and preparation technology thereof

ActiveCN101649083AReduce surface temperatureGood flame retardant effectPlastic/resin/waxes insulatorsNuclear engineeringNuclear power plant

The invention provides an IE-grade KI-type cable insulation material for nuclear power. A compound flame-retardant system, a plastic modifier and an irradiation resistant additive are compounded, mixed together and modified to prepare the IE-grade KI-type cable insulation material with long service life and irradiation resistance, which are required by a nuclear power station, and the property ofthe IE grade and KI part cable insulation material meets the related requirement of the IEEE383-2003 standard.

Owner:中科英华长春高技术有限公司

Fireproof, waterproof, insulating and decorative integrated composite polyurethane material and preparation method thereof

InactiveCN101935386AGood flame retardant effectReduce manufacturing costCovering/liningsFlooringOrganophosphorous compoundsFilling materials

The invention provides a fireproof, waterproof, insulating and decorative integrated composite polyurethane material which is made by compounding a veneer layer and with a polyurethane insulating layer together, wherein, the polyurethane insulating layer is composed of component A and component B based on mass ratio of 1:1-1.2. The component A comprises the following raw materials in parts by mass: 100 parts of polyether glycol, 5-12 parts of a catalyst, 8-15 parts of HFC-245fa, 2-5 parts of silicone oil, 2-6 parts of water, 5-10 parts of an organophosphorous compound, 10-24 parts of microencapsulated red phosphorus and 10-40 parts of an inorganic nano-filling material; and the component B comprises the following raw materials in parts by mass: 100 parts of isocyanate and 10-40 parts of an inorganic nano-filling material. In the invention, a red phosphorus fire retardant is compounded with a phosphate fire retardant, and the inorganic nano-filling material is added so that various mechanisms of action jointly act, thus achieving better fire retardant effect, reducing the use amount of the fire retardants and not affecting the performances of the material.

Owner:北京立高科技股份有限公司 +1

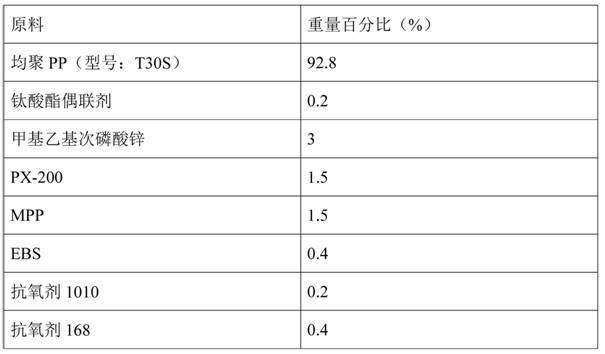

High-voltage breakdown resisting halogen-free precipitate-free antiflaming PP (Polypropylene) for electronic/electric apparatus components

InactiveCN102050994AGood flame retardant effectMeet the breakdown voltage requirementsHalogenPolypropylene

The invention discloses a high-voltage breakdown resisting halogen-free precipitate-free antiflaming PP (Polypropylene) for electronic / electric apparatus components, comprising the following components in percentage by weight: 57.5-97.4% of PP, 0.2-0.5% of coupling agent, 2-10% of halogen-free flame retardant, 0.2-1% of antioxidant, 0-30% of filler, and 0.2-1% of lubricant. The breakdown voltage of the high-voltage breakdown resisting halogen-free precipitate-free antiflaming PP for electronic / electric apparatus is higher than 4000V and the ball pressure values thereof are all below 2mm, which meet the breakdown resisting voltage requirement of the electronic / electric apparatus components; in addition, the antiflaming effect is good, the antiflaming level is up to V2, and the prepared products have precipitation resistance.

Owner:聚石化学(苏州)有限公司

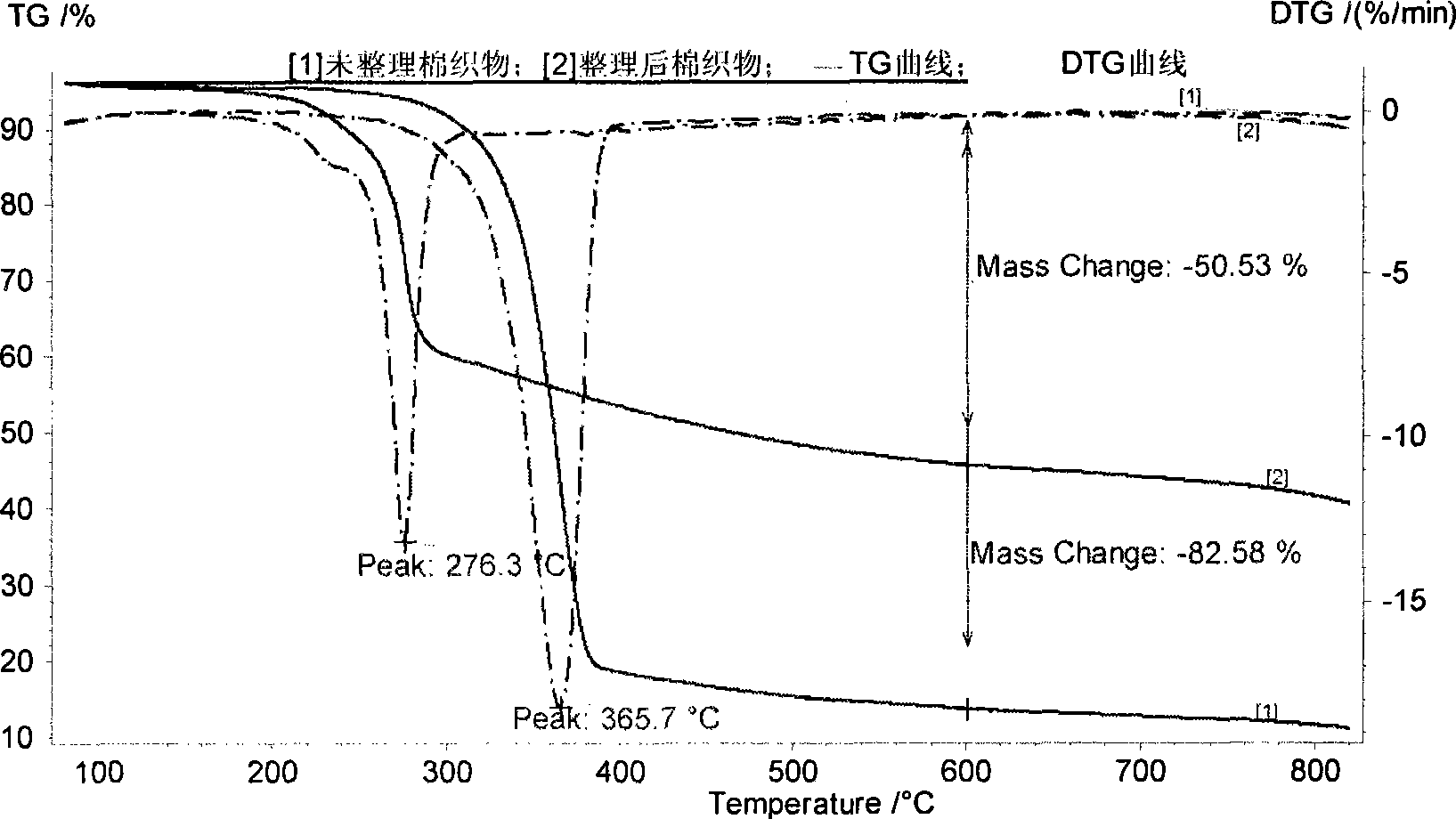

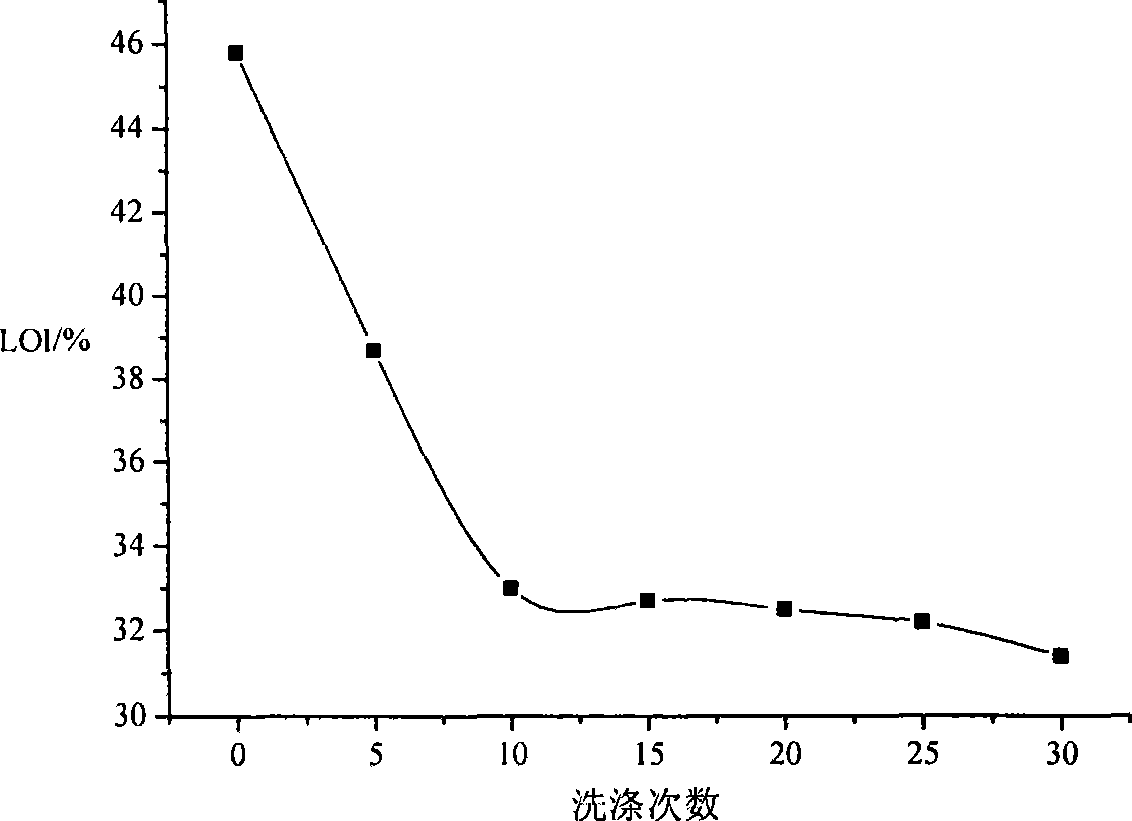

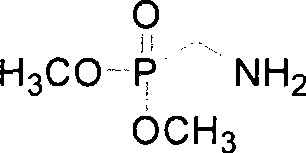

Method for preparing durable flame-proof cotton fabric

InactiveCN101413214AGood flame retardant effectWide variety of sourcesVegetal fibresChemistrySilane coupling

The invention relates to a method for preparing durable flame retardant cotton fabrics, which comprises the following steps: firstly, preparation of a finishing liquid, namely amino-methylphosphonate DAMP, a silane coupling agent gamma-glycidyl oxyl propyl trimethyl silicane and running water are uniformly mixed, and the pH value of the mixture is adjusted to between 3 and 7 by a finishing liquid pH regulator to obtain the finishing liquid; secondly, flame retardant finishing of the cotton fabrics, namely the cotton fabrics are immersed into the finishing liquid for 20 minutes at a temperature of 40 DEG C, padded until the liquid rate is between 75 and 80 percent, dried for 3 minutes at a temperature of between 80 and 100 DEG C, and roasted for 3 minutes at a temperature of between 150 and 180 DEG C; and thirdly, testing of the flame retardant property and the durability of the cotton fabrics after finishing. The method for preparing the flame retardant cotton fabrics has the advantages that raw materials have wide sources; the prepared cotton fabrics have good durability and flame retardant property; and the method has small influence on physical and mechanical properties of the cotton fabrics.

Owner:DONGHUA UNIV

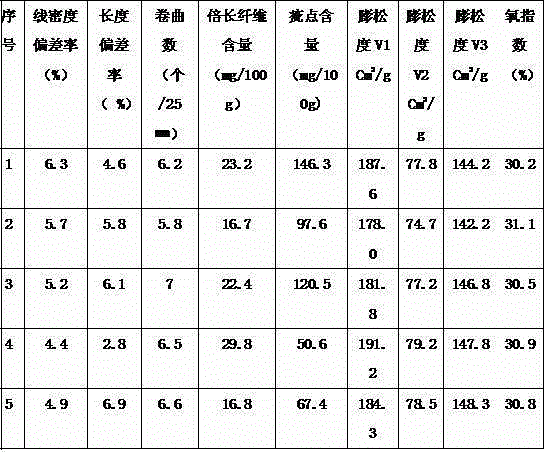

Production method of recycled phosphorus flame retardant polyester staple fibre

ActiveCN102747455AGood flame retardant effectImprove compatibility and uniformityFlame-proof filament manufactureMonocomponent polyesters artificial filamentPhosphinic AcidsPolyester

The invention relates to a production method of recycled phosphorus flame retardant polyester staple fibre. Conventionally, waste PET (Polyethylene Terephthalate) bottle chips are adopted, and phosphorus flame retardant agent and the waste PET bottle chips are mixed, melted and modified to produce flame retardant master batches. At the basis of conventional spinning conditions, the technical difficulties that the thermal stability of the phosphorus flame retardant agent is poor, and due to the acidity of the phosphuret, the viscosity can be reduced in the spinning process, the spinning property is poor and defects are more can be solved though the optimization process. The production method provided by the invention includes the following steps of: firstly mixing phosphorus flame retardant agent 2-carboxyethyl-phenyl phosphinic acid and waste PET bottle chips at weight ratio of 10-12:8-90, and the melting, extruding and pelleting in a screw extruder to prepare the phosphorus flame retardant master batches; and secondly mixing the phosphorus flame retardant master batches and the waste PET bottle chips at weight ratio of 8-10:90-92 and then melt spinning. In such a way, the recycled phosphorus flame retardant polyester staple fibre with the index of flame retardant oxygen reaching above 30% can be obtained.

Owner:广东秋盛资源股份有限公司

Expansion type flame-proof smoke-suppressing soft polyvinyl chloride composition and its preparation method

The invention discloses a bulking-typed flame-proof smoke-resistant flexible-polychloroethylene composition and preparing method, which comprises the following parts: 100% polychloroethylene, 15-50% fire retardant, 3-25% smoke-resistant agent, 30-80% carrier resin, 0.1-20% dispersant, 0.1-10% coupler and 0.05-10% antistatic agent.

Owner:SHANGHAI RES INST OF CHEM IND

High-temperature-resistant and flame-retardant cable material and preparation method thereof

InactiveCN103467819AImproved high temperature resistance and aging resistanceGood flame retardant effectInsulated cablesInsulated conductorsChemistryMagnesium

The invention discloses a high-temperature-resistant and flame-retardant cable material and a preparation method thereof. The cable material is prepared by the following raw materials in parts by weight: 50-70 parts of high density polyethylene, 20-40 parts of ethylene propylene diene monomer, 10-15 parts of thermoplastic polyurethane elastomer, 1.5-2.5 parts of tert-butyl peroxybenzoate, 1-2 parts of zinc methacrylate, 0.5-1.5 parts of isopropyl tri(dioctylpyrophosphate) titanate, 5-10 parts of tall oil, 3-4 parts of accelerant TMTD (tetramethyl thiuram disulfide), 1-2 parts of anti-aging agent ZMTI (zinc 2-mercaptotolylimidazole), 5-8 parts of acetyl triethyl citrate, 10-15 parts of magnesium hydroxide, 1-2 parts of ferric oxide, 3-5 parts of zinc oxide, 5-10 parts of red phosphorus, 2-3 parts of dibasic lead phosphite, 15-20 parts of organic bentonite, 12-16 parts of nano silicon dioxide, and 4-8 parts of composite filler. The cable material has excellent high-temperature resistance and aging resistance, is obvious in flame-retardant effect, does not generation dense smoke, corrosive halide gas or other hazardous substances during combustion, and has the characteristics of high mechanical strength, good wear resistance, good elasticity, good flexibility and the like, thereby widening an application scope of a high density polyethylene cable material greatly.

Owner:JING FENG GRP

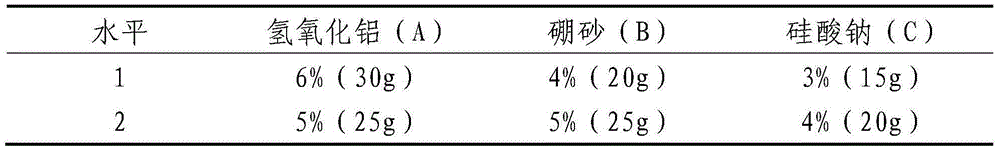

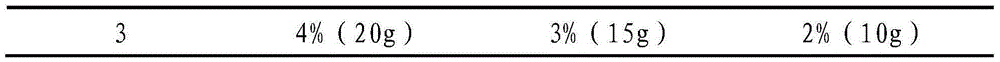

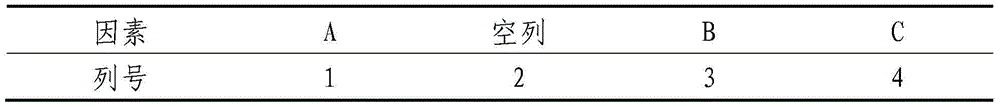

Composite flame retardant and method for preparation of flame retardant fiber board from the same

ActiveCN105131627AGood flame retardant effectGood smoke suppressionDomestic articlesFlat articlesSodium silicateFire retardant

Belonging to the technical field of fireproof material development, the invention specifically relates to a composite flame retardant and a method for preparation of a flame retardant fiber board from the same. The composite flame retardant is composed of aluminum hydroxide, borax and sodium silicate in a mass ratio of 4-6:3-5:2-4. The composite flame retardant provided by the invention has the advantages of good flame retardant effect, low toxicity, good smoke suppression and environmental friendliness, can significantly improve the flame retardant properties of the fiber board, and has cheap price, thus being suitable for industrial production of the flame retardant fiber board.

Owner:GUANGXI UNIV

Anti-static flame-retardant plastic for roller of underground conveying belt of coal mine

InactiveCN101760017AGood flame retardant effectImprove flame retardant performanceRollersPelletizingChemistry

The invention relates to the field of polyamide composite, in particular to anti-static flame-retardant plastic for a roller of an underground conveying belt of a coal mine. The plastic is prepared from the following raw materials in percentage by mass: 30 to 60 percent of nylon 66 slice, 25 to 40 percent of glass fiber, 5 to 20 percent of compatilizer, 5 to 20 percent of red phosphorus flame retardant, 0.5 to 2 percent of antistatic agent, 0.5 to 1.5 percent of lubricant, and 0.2 to 1.0 percent of antioxidant. The preparation method comprises the following steps: 1, weighing the raw materials; 2, putting raw materials except the glass fiber into a high mixing machine for mixing; and 3, adding the glass fiber into the mixed raw materials, a double-screw extruder for extruding and granulating. The plastic has the beneficial effects of well overcoming the defects of static resistance and flame retardancy in the prior art, and poor use effect, ensuring that the product has good flame retardant effect and is antistatic, and having small influence on other physical indexes of the product.

Owner:PINGDINGSHAN HUABANG ENG PLASTIC

High-inflaming-retarding organosilicone sponge material and preparation method thereof

The invention discloses a high-inflaming-retarding organosilicone sponge material and a preparation method thereof. The high-inflaming-retarding organosilicone sponge material is composed of a component A and a component B, the component A comprises double-end hydroxyl polysiloxane, double-end vinyl-containing polysiloxane, hydrosilicone oil, silicon resin, reinforcing filler, a crosslinking inhibitor, graphene and carbon black, and the component B comprises double-end hydroxyl polysiloxane, double-end vinyl-containing polysiloxane, hydroxyl silicone oil, graphene, silicon resin, reinforcing filler, zinc oxide and a catalyst. The component A and the component B are mixed according to the mass ratio being 1:1, curing is carried out for 2-10 minutes at the temperature of 13 DEG C to 35 DEG C, a sponge with a certain foaming ratio can be generated, the high-inflaming-retarding organosilicone sponge material is high in compression strength and excellent in permanent compression deformation resistance and inflaming retarding performance and is extinguished once the material is separated from a fire, no harmful gas is generated during combustion, and the material is widely applied to the fields of building hole plugging, car seats, sofas, mattresses and the like.

Owner:SHANDONG SHIP TECH RES INST

Vermiculite-based composite flame retardant and preparation method thereof

ActiveCN104072805AGood flame retardant effectStrong smoke suppression performancePigment physical treatmentChemistrySilane coupling

The invention discloses a vermiculite-based composite flame retardant and a preparation method thereof. The composite flame retardant is composed of the following components in parts by mass: 20-35 parts of modified vermiculite, 30-45 parts of magnesium hydroxide, 15-25 parts of a phosphorus based flame retardant and 2-5 parts of a silane coupling agent. The preparation method of the vermiculite-based composite flame retardant comprises the steps of carrying out modified treatment on vermiculite, preparing a composite flame retardant and compounding the composite flame retardant. The composite flame retardant prepared by using the method contains no halogen components and has environment-friendly and low-smoke effects; the composite flame retardant is prepared from different flame-retardant components; the flame-retardant and smoke-inhibiting effects of the flame retardant are simultaneously improved by utilizing the synergistic effect of the flame-retardant components.

Owner:XINJIANG AOJILI ENERGY SAVING TECH

Phosphorus hybrid flame retardant and preparation method thereof

InactiveCN102628218AGood flame retardant effectInhibition of drippingFibre treatmentPhosphinic AcidsFire retardant

The invention discloses a phosphorus hybrid flame retardant and a preparation method thereof. The flame retardant comprises the following raw materials by weight: 100 parts of 2-hydroxyethyl phenyl phosphinic acid, 30-50 parts of a graphene polyphosphazenes nano composite material, 10-15 parts of montmorillonite, 10-20 parts of sodium methylsiliconate, and 50-80 parts of inositol hexaphosphate. The phosphorus hybrid flame retardant provided by the invention is mainly composed of phosphorus 2-hydroxyethyl phenyl phosphinic acid, with other components added to the compound so as to obtain the hybrid flame retardant. Components of the flame retardant cooperate and synergize with each other, which overcomes the defect that single phosphorus compounds are liable to generate melted droplets and have poor water resistance. The flame retardant has the advantages of simple preparation, good thermal stability, good water resistance and high flame retardancy.

Owner:济南三太阻燃制品有限公司

A kind of silicon magnesium boron wood nano flame retardant

ActiveCN102294719AGood flame retardant effectGood smoke suppression effectWood impregnation detailsMagnesium carbonate hydroxideSodium silicate

The invention discloses a silicon magnesium boron lumber nano combustion inhibitor, the combustion inhibitor comprises the following raw materials by weight percentage: 30%-36% of sodium silicate hydrate, 24%-30% of elemental silicon, 4%-6% of tin chloride, 20%-30% of zinc borate, 15%-17.5% of basic magnesium carbonate and 2%-2.5% of magnesium chloride, the sodium silicate hydrate, elemental silicon and basic magnesium carbonate have particle sizes of 15nm, 30nm and 50nm and are mixed according to the mass ratio of 1:1:1, the tin chloride, zinc borate and magnesium chloride are micron-grade, sodium silicate hydrate, elemental silicon and basic magnesium carbonate are uniformly mixed, a mixture of the combustion inhibitor and water are performed a disperse treatment for 30-40 minutes by polyethylene glycol, sodium dodecanesulphonate, sodium acid pyrophosphate or sodium hexametaphosphate under the condition of supersonic wave and microwave, the dispersed suspension fluid of the combustion inhibitor is mixed with the aqueous solution of tin chloride, zinc borate and magnesium chloride and stirred for 20m minutes to obtain the silicon magnesium boron lumber nanometer combustion inhibitor. The present invention has the advantages of good fireproof effect, simple technology, easy industrialization, cleanness and no pollution.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Halogen-free flame-retardant polypropylene fiber and preparation method thereof

ActiveCN103173884AGood flame retardant effectSimple processing technologyFlame-proof filament manufactureMelt spinning methodsAmmonium polyphosphateMaleic anhydride

The invention belongs to the technical field of high polymer materials and relates to a polypropylene fiber and a preparation method of the polypropylene fiber. The material comprises the following components in parts by weight: 100 parts of polypropylene, 12-28 parts of ammonium polyphosphate, 2-12 parts of polyol compound, 1-10 parts of organic silicone resin, 1-5 parts of maleic anhydride grafted polypropylene and 0.5-2 parts of an antioxidant. The polypropylene fiber prepared by the invention adopts an expansion type composite synergistic halogen-free and flame-retardant system so as to become a halogen-free, low-smoke, low-toxicity and environment-friendly flame-retardant system and realize a good flame-retardant effect. Compared with the existing expansion type flame-retardant system, the polypropylene fiber disclosed by the invention adopts the ammonium polyphosphate as a main composition part, and the ammonium polyphosphate can be simultaneously used as an acid source and a gas source in an expansion type flame retardant, so that the independent gas source is removed, the reaction of the acidic or the alkaline gas source during the processing process can be avoided, the flame-retardant effect can be prevented from being lowered, and the processing technology is further simplified.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Nano-particle fire retardant modified rigid polyurethane PIR (Polyisocyanurate) foam material and preparation method thereof

The invention provides a nano-particle fiber retardant modified rigid polyurethane PIR (Polyisocyanurate) foam material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing 20 to 70 parts of polyether polyol, 30 to 80 parts of polyester polyol, 2 to 6 parts of foam stabilizer, 1.8 to 7.5 parts of catalyst, 20 to 40 parts of foaming agent, 8 to 15 parts of dimethyl methylphosphonate, nano-particle fiber retardant, and excess polyaryl polymethylene isocyanate; agitating at speed of 2,000 revolutions per minute; quickly pouring into a die within 9 seconds after agitating; and chemically reacting and foaming to obtain the rigid PIR polyurethane foam material, wherein the flame retardant test is carried out after curing for a certain period of time under a temperature of 20 to 70 DEG C. According to the nano-particle fiber retardant modified rigid polyurethane PIR foam material and the preparation method thereof, nano-particles used as the fire retardant of the rigid polyurethane modified PIR foam material can be integrated with the polyurethane foam material, which mainly solves the technical problem that the flame retardation of the foam material is reduced or lost after the fire retardant migrates for a long time. The process has the advantages of being simple in foaming operation, high in heat stability, extremely low in smoke output, small in toxicity, and fast in carbon production, and the nano-particle fiber retardant modified rigid polyurethane PIR foam material is an environment-friendly thermal insulation material.

Owner:BEIJING ACAD OF BUILDING ENG

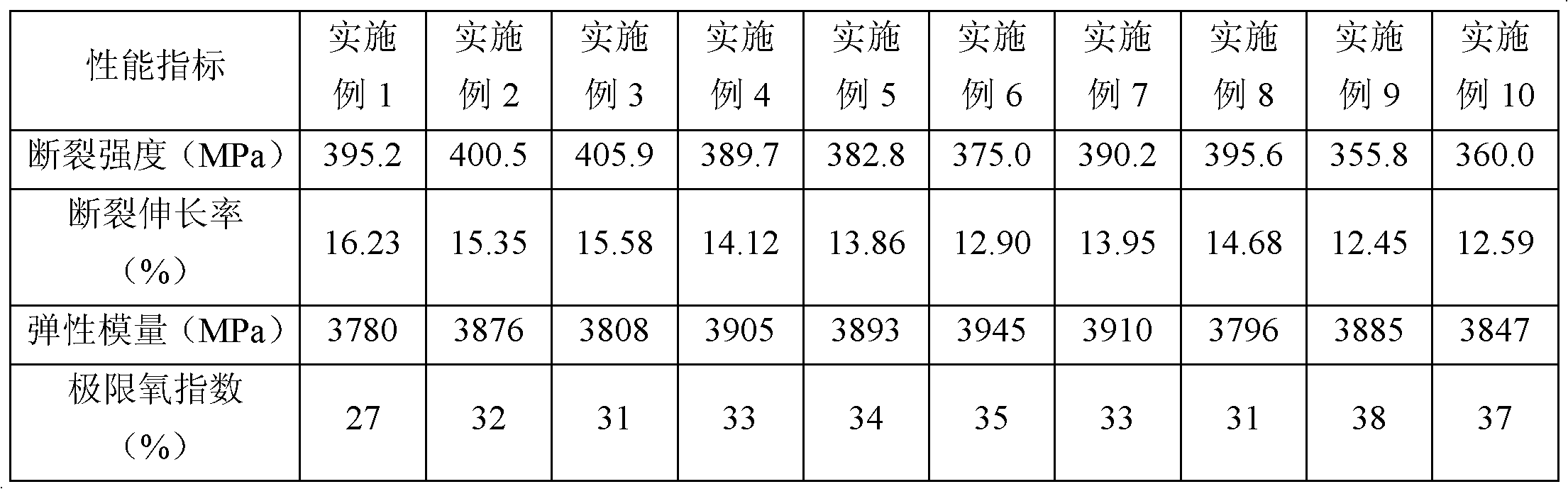

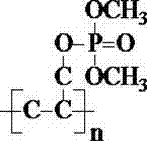

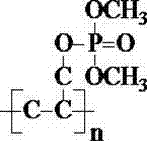

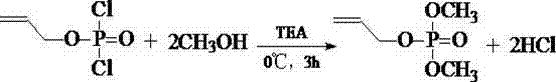

Polypropylene-based dimethyl phosphate flame retardant and preparation method thereof

InactiveCN102561036AHigh flame retardant efficiencyGood flame retardant effectFibre treatmentPolypropylenePhosphate

The invention discloses a polypropylene-based dimethyl phosphate flame retardant and a preparation method thereof. The preparation method comprises the following steps of: reacting allyl alcohol with phosphorus oxychloride, performing stirring reaction at the temperature of 0 DEG C by using triethylamine or pyridine as an acid capturer, dripping methanol to react with the triethylamine mixed solution, filtering, evaporating to obtain an allyl dimethyl phosphate monomer, reacting with potassium persulfate, regulating the pH value, performing graft polymerization reaction by microwave irradiation, filtering, separating the supernate, distilling, and thus obtaining the polypropylene-based dimethyl phosphate flame retardant. The flame retardant does not contain halogen, and is good in thermal stability and easy and convenient to synthesize; the phosphorus content of the flame retardant reaches 18.7 percent; and the flame retardant has a good lasting flame-retardant effect, and is suitable for flame-retardant finishing of fibers of hemp, hair, silk and the like and plastics.

Owner:TAIYUAN UNIV OF TECH

Production method of high-quality flame retardant polyester industrial filament

InactiveCN108677269AHigh strength of finished productGood flame retardant effectFlame-proof filament manufactureFilament forming substance formingPolyesterEngineering

The invention relates to a production method of a high-quality flame retardant polyester industrial filament. The production method comprises the following steps: drying a flame retardant master batch, accurately weighing and dosing the flame retardant master batch and a high viscosity slice, extruding, fusing, metering, slowly cooling, laterally blowing air to cool, applying oil, drawing and setting through five pairs of rollers, tying an interlaced knot, winding and molding. The product strength (more than or equal to 6.4 cn / dt) is high, and the limit oxygen index LOI (more than or equal to32%) is high.

Owner:WUXI SUOLIDE TECH DEV CO LTD

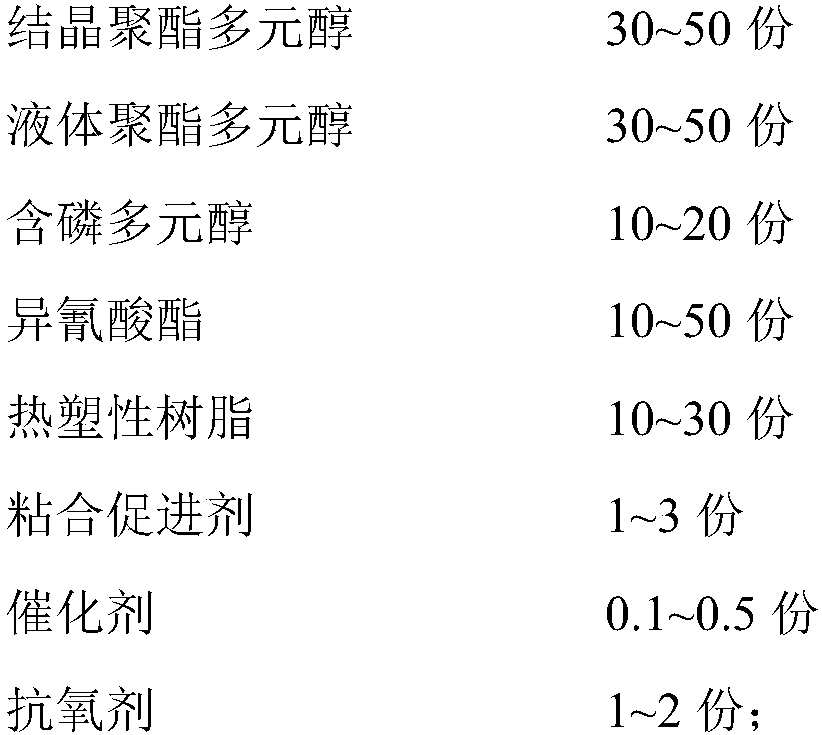

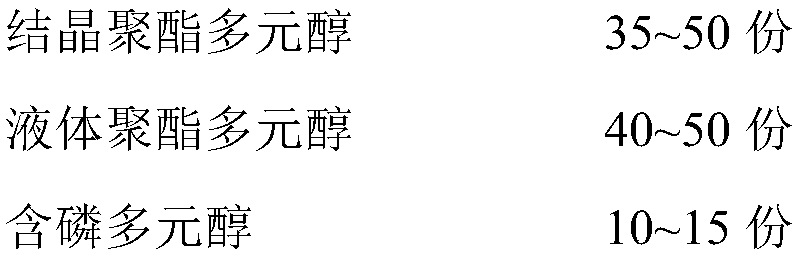

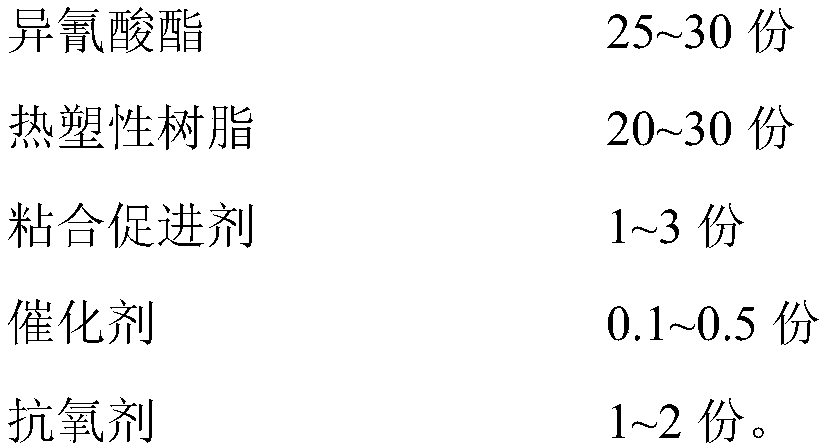

Reactive polyurethane hot melt adhesive and preparation method thereof

ActiveCN108559437AImprove adhesionGood flame retardant effectPolyureas/polyurethane adhesivesMacromolecular adhesive additivesSolventChemistry

The invention relates to a reactive polyurethane hot melt adhesive and a preparation method thereof. The reactive polyurethane hot melt adhesive comprises the following raw materials in parts by weight: 30 to 50 parts of crystalline polyester polyol, 30 to 50 parts of liquid polyester polyol, 10 to 20 parts of phosphorus-containing polyol, 10 to 50 parts of isocyanate, 10 to 30 parts of thermoplastic resin, 1 to 3 parts of adhesion promoter, 0.1 to 0.5 part of catalyst and 1 to 2 parts of antioxidant. The reactive polyurethane hot melt adhesive has the advantages of excellent flame retardancyand adhesion, and has the advantages of fast curing speed, high final bonding strength, good environmental resistance, low atomization value and the like, and is particularly suitable for the field ofhigh flame-retardant requirements, thereby having good market prospect. Besides, the reactive polyurethane hot melt adhesive is an one-component moisture-curing polyurethane adhesive, belongs to thesolvent-free environment-friendly adhesive agent industry, and can be used for bonding substrates such as plastic, glass, metal, textile and the like.

Owner:GUANGZHOU BAIYUN CHEM IND

Thermoplastic resin composition with excellent flame retardancy and impact resistance

The invention discloses a thermoplastic resin compound with outstanding flame- proof and anti- vibration property. The component proportions are as follows: panlite 60- 90, polyacryl-nitrile- butadiene- polystyrene 10- 40, additional compatiable agent 1- 10, additional phosphate compound 5- 15, additional polyorganosilicon oxidant 1- 10, additional metal oxidant or inorganic acidic metal salt 1- 5. The product is characterized by environmental protection, high- efficiency flame proof and good mechanical property.

Owner:浙江荣泰塑胶有限公司 +1

Anti-corrosion waterproof coating for evanescent mode

InactiveCN104690219APrevent coating from crackingGood flame retardant effectFoundry mouldsFoundry coresAmmonium polyphosphateSolvent

The invention discloses an anti-corrosion waterproof coating for an evanescent mode. The anti-corrosion waterproof coating is characterized by consisting of the following components in parts by weight: 30-40 parts of an ethylene-vinlacetate copolymer, 20-30 parts of polyisocyanate, 18-22 parts of bisphenol-A epoxy resin, 8-12 parts of ammonium polyphosphate, 8-12 parts of perchloro-ethylene resin, 8-15 parts of pentaerythritol, 2-4 parts of methylene dual-methyl naphthalene sulfonic acid sodium, 0.6-0.8 part of melamine, 4-6 parts of methyl cellulose, 2-4 parts of a preservative, 1.5-2 parts of antimonous oxide, 3-5 parts of a filler and 25-35 parts of a solvent. The prepared coating has an elastic effect, can effectively prevent a coating layer from being cracked, has a good flame retardant effect, and is high in adhesive force and excellent in corrosion resistance.

Owner:QINGDAO DAYUN MACHINERY

Anti-flaming wall paper

InactiveCN102776805AStop burningGood flame retardant effectSpecial paperPaper coatingDiphenyl phosphateBisphenol A

The invention relates to anti-flaming wall paper, comprising a bonding layer, a paper layer and an anti-flaming layer. The anti-flaming wall paper is characterized in that the formula compositions of the anti-flaming layer are, by weight percent, 15 to 20 parts of resorcinol bi(diphenyl phosphate) (RDP) and 25 to 30 parts of bisphenol A bi(diphenyl phosphate) (BDP), wherein the bonding layer is a double faced adhesive tape; and the anti-flaming layer is directly coated on the paper layer. When the wall paper is burnt by fire, substances in the anti-flaming layer become carbon rapidly to isolate oxygen; as such, the flame is blocked, and the anti-flaming effect is remarkable; and moreover, the wall paper is simple in preparation process and low in production cost.

Owner:SUZHOU CUIZHI NEW TECH DEV

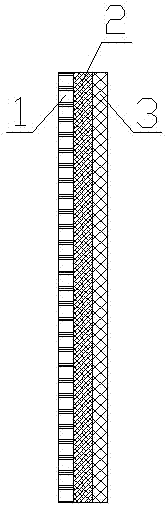

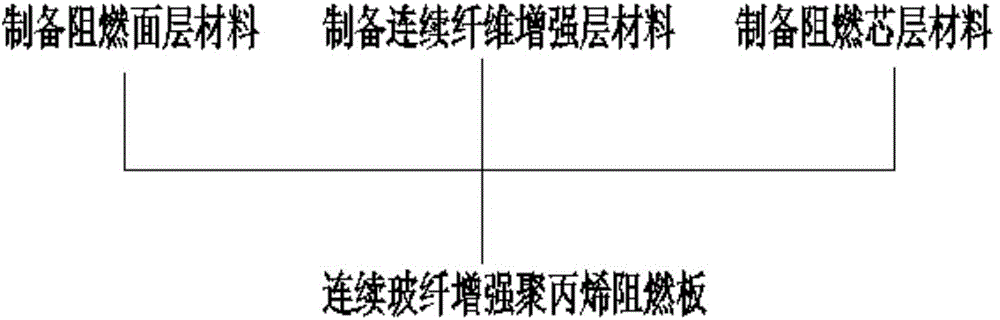

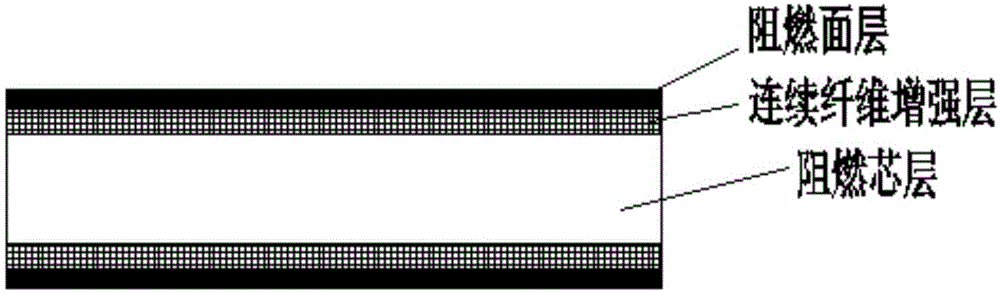

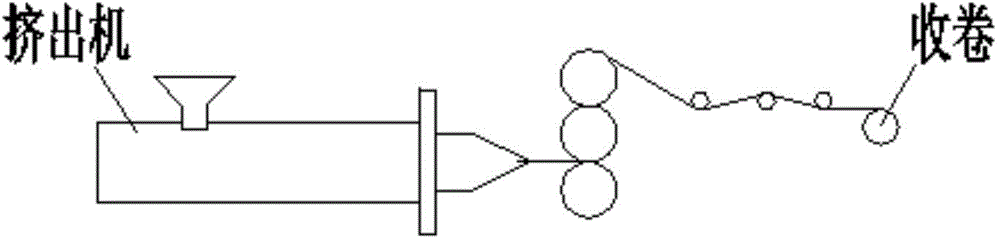

Continuous fiber-reinforced flame-retardant PP (polypropylene) board and preparation method thereof

InactiveCN104608447ALow manufacturing costGood flame retardant effectSynthetic resin layered productsLaminationPolypropylenePolymer chemistry

The invention relates to a continuous fiber-reinforced flame-retardant PP (polypropylene) board and a preparation method thereof. The board consists of a flame-retardant surface layer, a continuous fiber-reinforced layer and a flame-retardant core layer. The preparation method comprises steps as follows: (1) preparing flame-retardant surface layer materials; (2) preparing continuous fiber-reinforced layer materials; (3) preparing a flame-retardant core layer material; (4) sequentially laying one flame-retardant surface layer material, one continuous fiber-reinforced layer material, the flame-retardant core layer material, the other continuous fiber-reinforced layer material and the other flame-retardant surface layer material, and performing heating, pressurizing and cooling molding through a double-steel-belt press to obtain the continuous fiber-reinforced flame-retardant PP board. The board has excellent mechanical properties and solves the problem that continuous fiber-reinforced thermoplastic composites are inflammable.

Owner:NINGBO HUAYE MATERIAL TECH

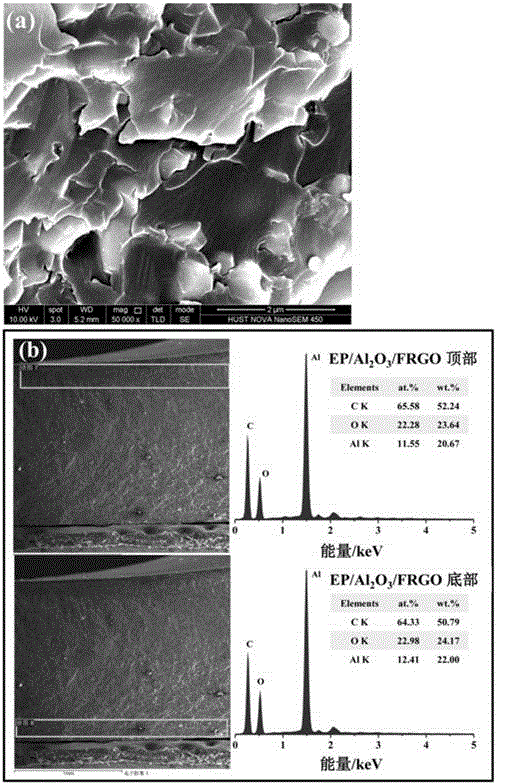

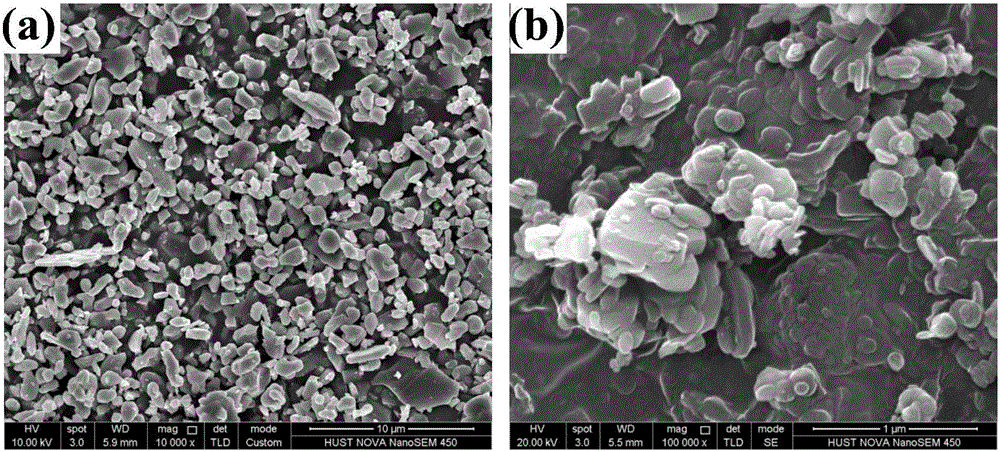

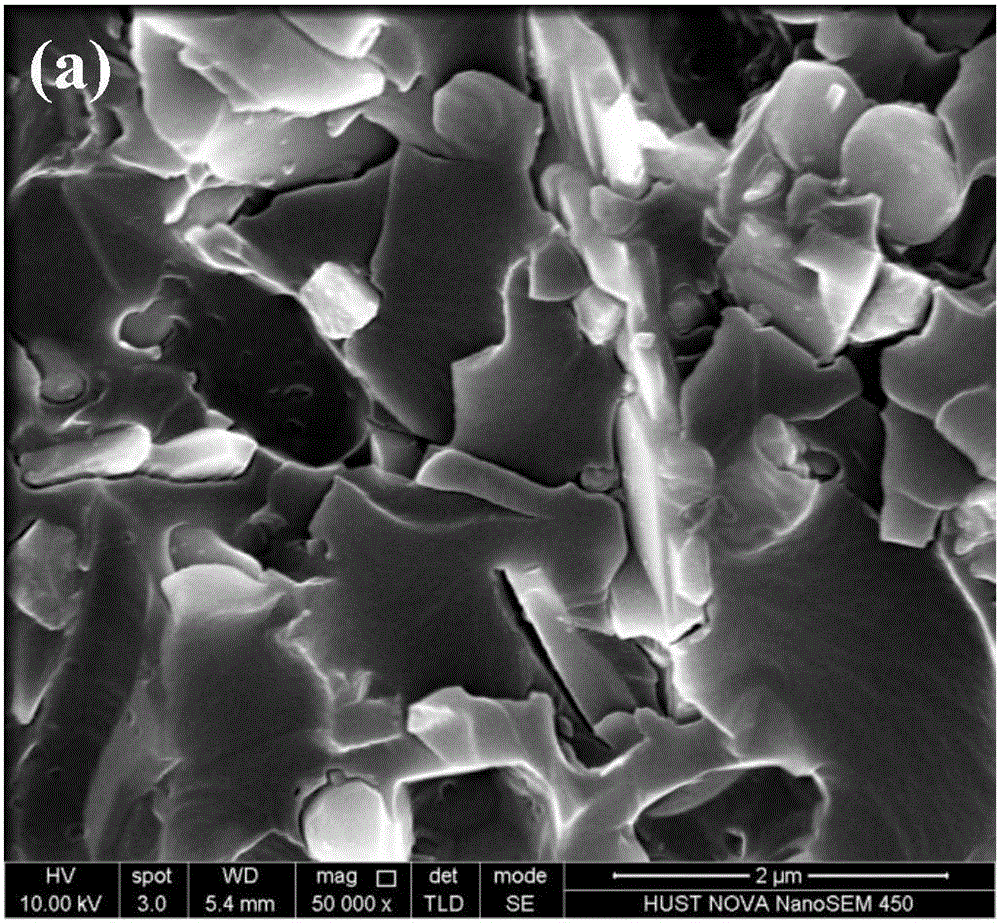

Composite material integrating flame retardance and heat conductivity and preparation method thereof

InactiveCN106674899AGood flame retardant effectExcellent flame retardant and thermal conductivityCvd grapheneMechanical properties of carbon nanotubes

The invention discloses a composite material integrating flame retardance and heat conductivity and a preparation method thereof. The composite material is prepared from flame-retardant graphene, heat conductive filler and an epoxy resin base material and is an epoxy resin-based composite material of which the heat conductivity and the flame retardance are synergistically enhanced by the flame-retardant graphene and the heat conductive filler, wherein the flame-retardant graphene occupies 0.5 to 5 weight percent of the composite material; the heat conductive filler occupies 10 to 70 weight percent of the composite material; the flame-retardant graphene is at least one of reduced graphene oxide and organic flame retardant modified reduced graphene oxide. According to the composite material disclosed by the invention, by modifying the structure, the components, the dosage, the adding technology and the like of critical additives in a polymer-based heat conductive composite material, compared with the prior art, the problems that the mechanical performance, the heat performance and the processing fluidity of the polymer-based heat conductive composite material in which the additives are added are poor can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com