Phosphorus hybrid flame retardant and preparation method thereof

A flame retardant, phosphorus-based technology, applied in the field of flame retardants, can solve the problems of application limitations of halogen-based flame retardants, and achieve the effects of overcoming the tendency to melt dripping, promoting flame retardant effect, and enhancing flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

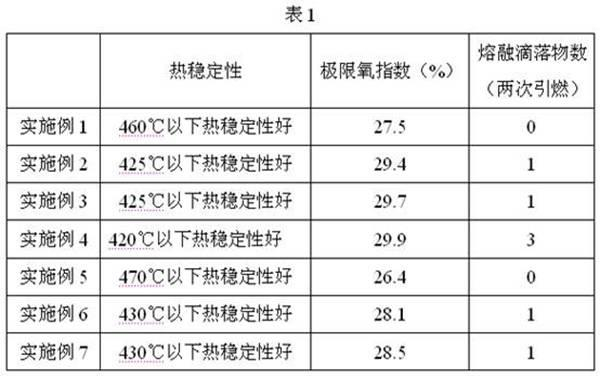

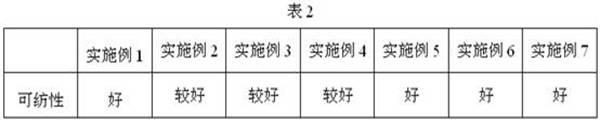

Examples

Embodiment 1

[0025] Get 100 parts of 2-hydroxyethylphenyl hypophosphorous acid, 35 parts of graphene polyphosphazene nanocomposites, 15 parts of montmorillonite, 17 parts of sodium methyl siliconate, 70 parts of cyclohexanol hexaphosphate, according to the following method Preparation: Grind the montmorillonite to a particle size of 20-50nm by ball milling to obtain nano-montmorillonite; add 2-hydroxyethylphenylphosphorous acid, graphene polyphosphazene nanocomposite material and nano-montmorillonite to In cyclohexanol hexaphosphate, ultrasonic treatment was carried out at 35°C for 3 hours, the ultrasonic frequency was 20kHz, and the ultrasonic power was 400W. The rest of the raw materials were added to the ultrasonically treated mixture and mixed evenly to obtain a phosphorus-based mixed flame retardant.

Embodiment 2

[0027] Get 100 parts of 2-hydroxyethylphenyl hypophosphorous acid, 30 parts of graphene polyphosphazene nanocomposite materials, 10 parts of montmorillonite, 20 parts of sodium methyl siliconate, 50 parts of cyclohexanol hexaphosphate, according to the following method Preparation: Grind the montmorillonite to a particle size of 20-50nm by ball milling to obtain nano-montmorillonite; add 2-hydroxyethylphenylphosphorous acid, graphene polyphosphazene nanocomposite material and nano-montmorillonite to In cyclohexanol hexaphosphate, ultrasonic treatment was carried out at 30°C for 4 hours, the ultrasonic frequency was 20kHz, and the ultrasonic power was 400W. The rest of the raw materials were added to the ultrasonically treated mixture and mixed evenly to obtain a phosphorus-based mixed flame retardant.

Embodiment 3

[0029] Get 100 parts of 2-hydroxyethylphenyl hypophosphorous acid, 40 parts of graphene polyphosphazene nanocomposite materials, 13 parts of montmorillonite, 15 parts of sodium methyl siliconate, 70 parts of cyclohexanol hexaphosphate, according to the following method Preparation: Grind the montmorillonite to a particle size of 20-50nm by ball milling to obtain nano-montmorillonite; add 2-hydroxyethylphenylphosphorous acid, graphene polyphosphazene nanocomposite and nano-montmorillonite to the In cyclohexanol hexaphosphate, ultrasonic treatment was carried out at 40°C for 3 hours, the ultrasonic frequency was 20kHz, and the ultrasonic power was 400W. The remaining raw materials were added to the mixture after ultrasonic treatment, and mixed evenly to obtain a phosphorus-based mixed flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com