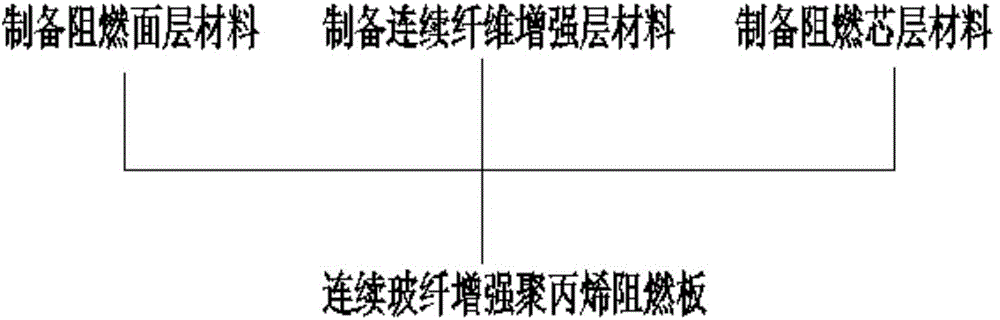

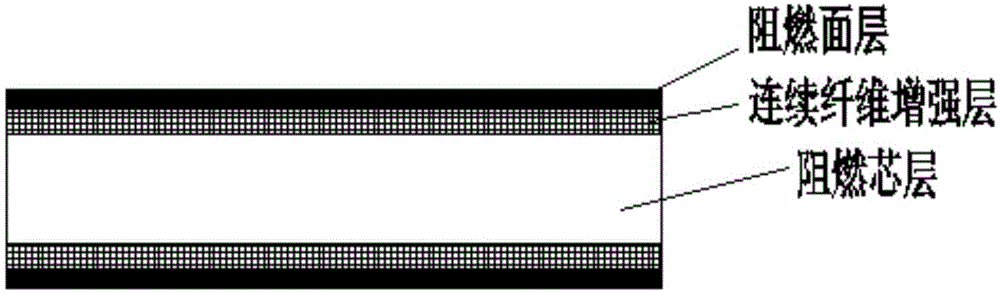

Continuous fiber-reinforced flame-retardant PP (polypropylene) board and preparation method thereof

A continuous fiber and polypropylene technology, which is applied in the field of continuous fiber reinforced polypropylene flame retardant sheet and its preparation, can solve the problems of continuous fiber reinforced thermoplastic composite material being inflammable, and achieve good flame retardant effect and reduce manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Manufacturing process of flame retardant surface material: resin modification→extrusion→winding→polypropylene flame retardant film

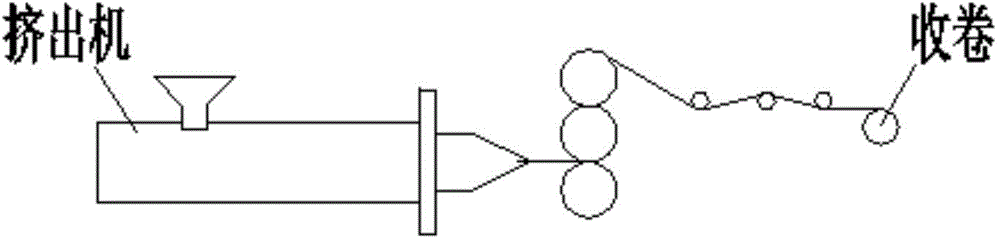

[0030] Such as image 3 As shown, modify polypropylene, add 5% maleic anhydride grafted PP and 20% phosphorus nitrogen silicon system composite flame retardant and mix to a uniform state, and use cast film equipment to make a film with a thickness of 0.1mm.

[0031] (2) The manufacturing process of the continuous fiber reinforced layer: resin modification → extrusion impregnation of continuous glass fiber → continuous fiber reinforced polypropylene unidirectional prepreg tape → continuous fiber reinforced unidirectional prepreg tape multi-layer cross composite → continuous fiber reinforced layer

[0032] Such as Figure 4 As shown, the polypropylene is modified by adding 8% maleic anhydride grafted PP, heated and melted by the extruder to extrude onto the stretched continuous glass fiber, and fully impregnated through the impregnation...

Embodiment 2

[0040] (1) Manufacturing process of flame retardant surface material: resin modification→extrusion→winding→polypropylene flame retardant film

[0041] Such as image 3 As shown, modify polypropylene, add 8% maleic anhydride grafted PP and 30% phosphorus nitrogen silicon system composite flame retardant and mix to a uniform state, and use cast film equipment to make a 0.3mm film.

[0042] (2) The manufacturing process of the continuous fiber reinforced layer: resin modification → extrusion impregnation of continuous glass fiber → continuous fiber reinforced polypropylene unidirectional prepreg tape → continuous fiber reinforced unidirectional prepreg tape multi-layer cross composite → continuous fiber reinforced layer

[0043] Such as Figure 4 As shown, the polypropylene is modified by adding 10% maleic anhydride grafted PP, heated and melted by the extruder to extrude onto the stretched continuous glass fiber, and fully impregnated through the impregnation mold to obtain con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com