Patents

Literature

551 results about "Polyphosphazene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

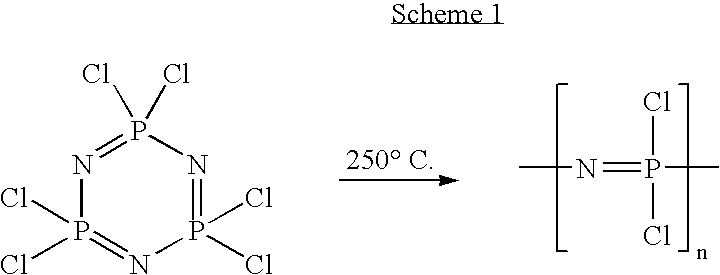

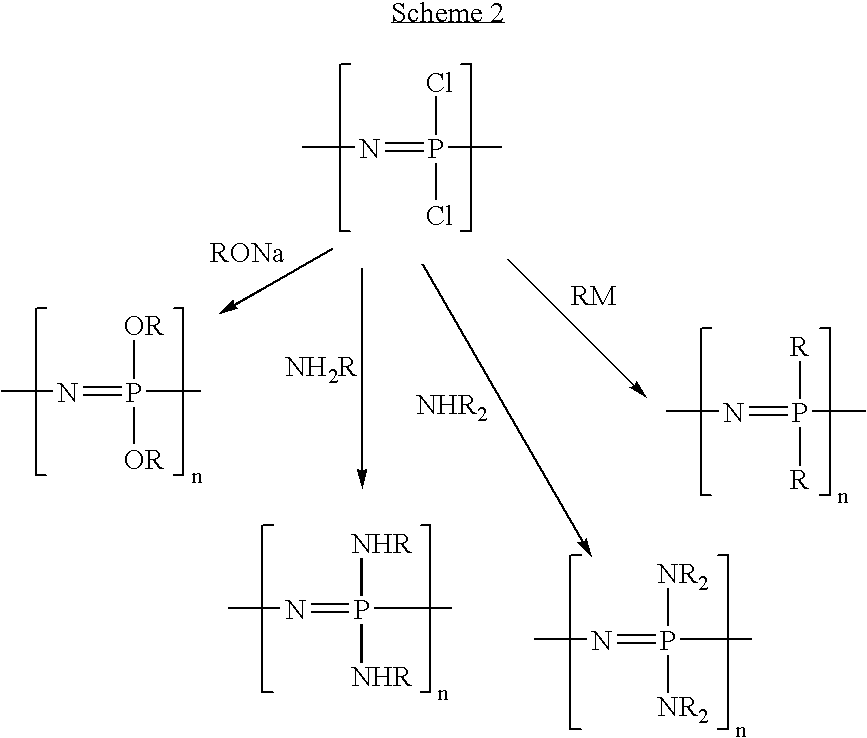

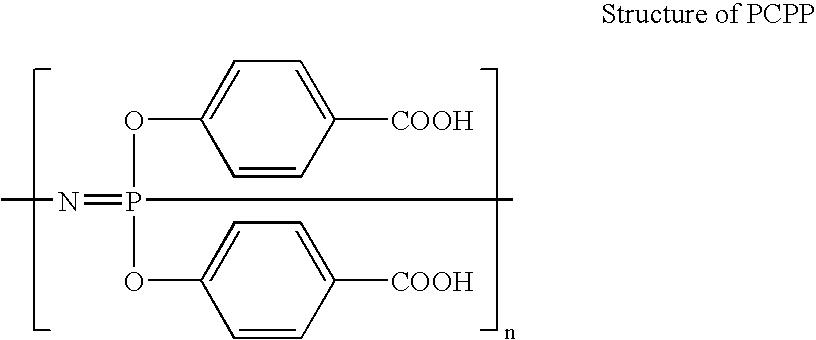

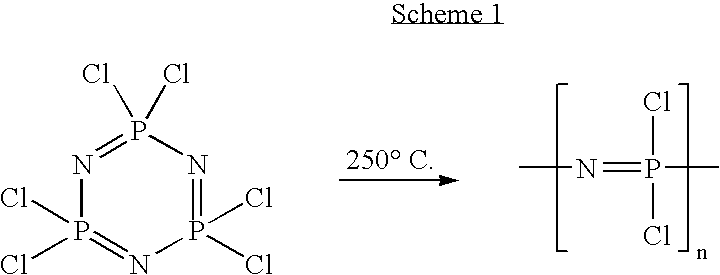

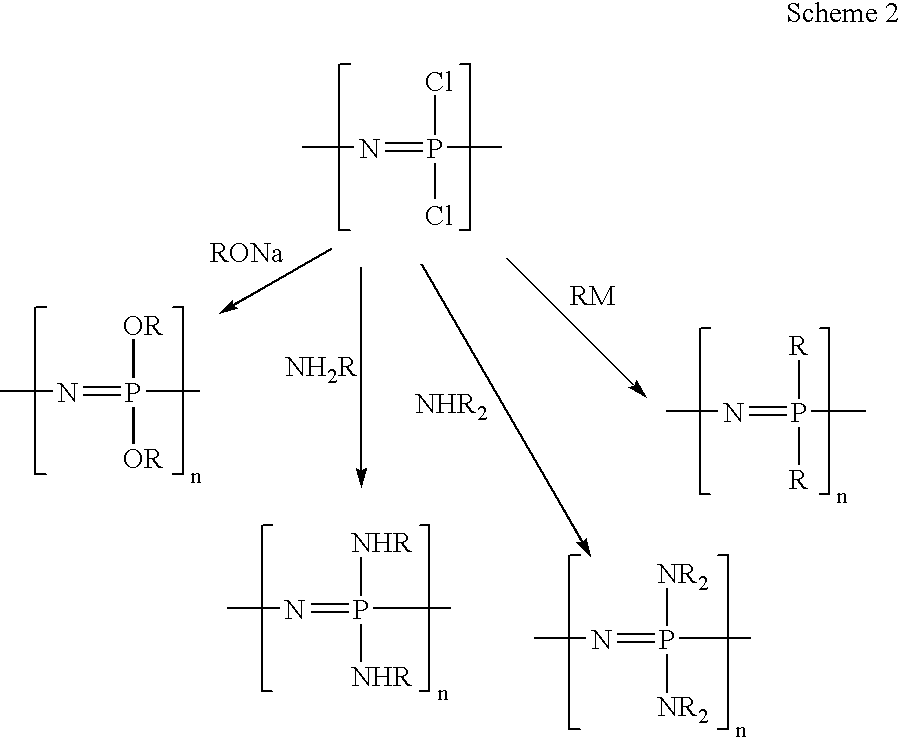

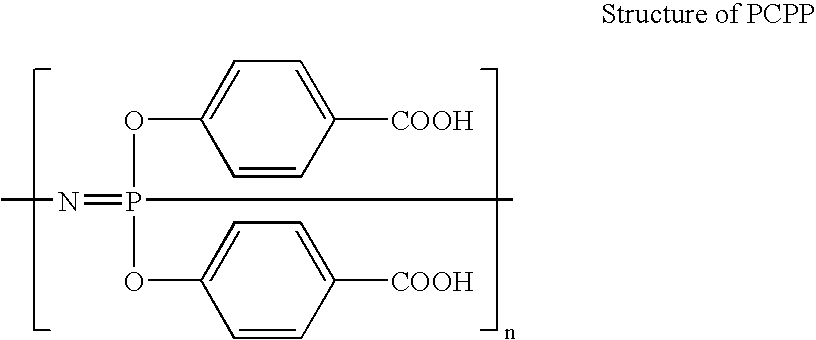

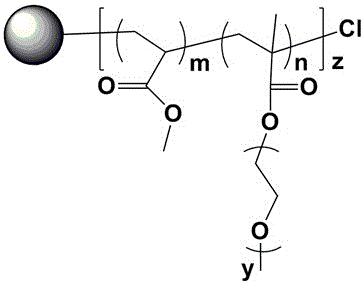

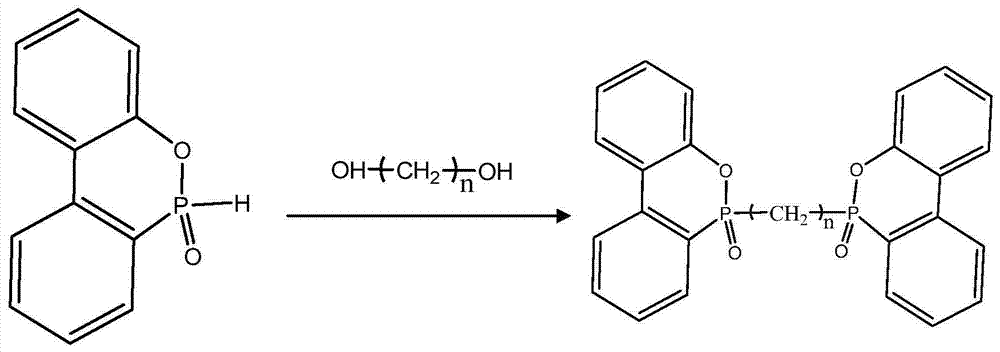

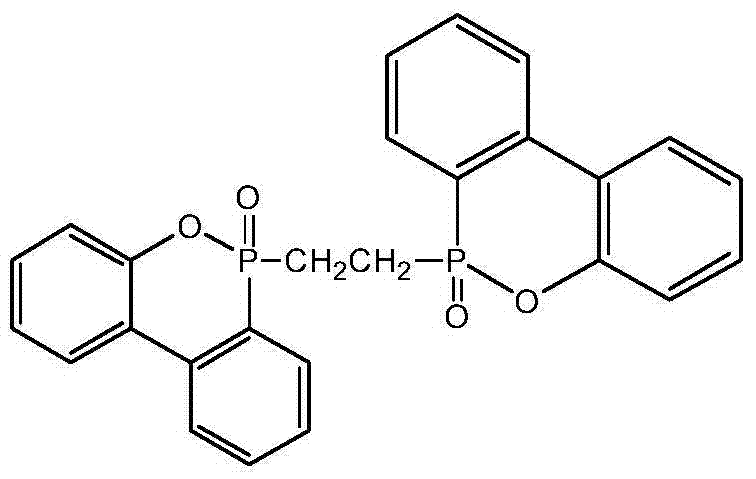

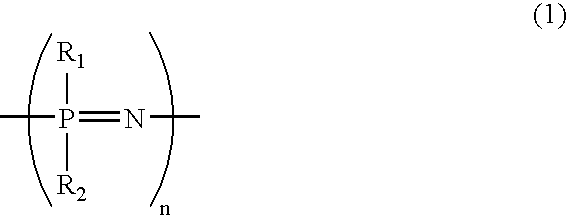

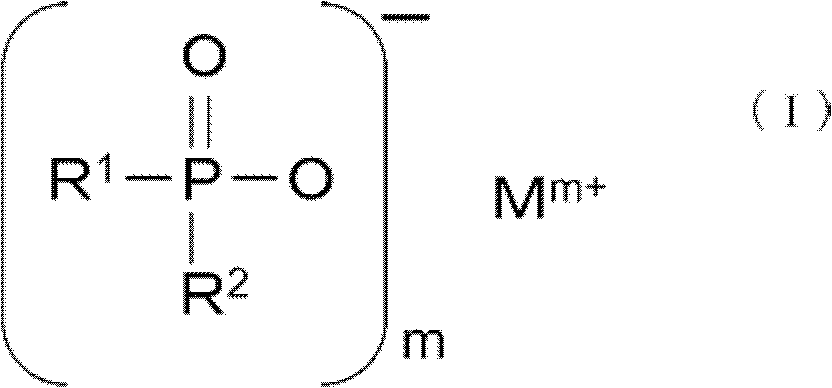

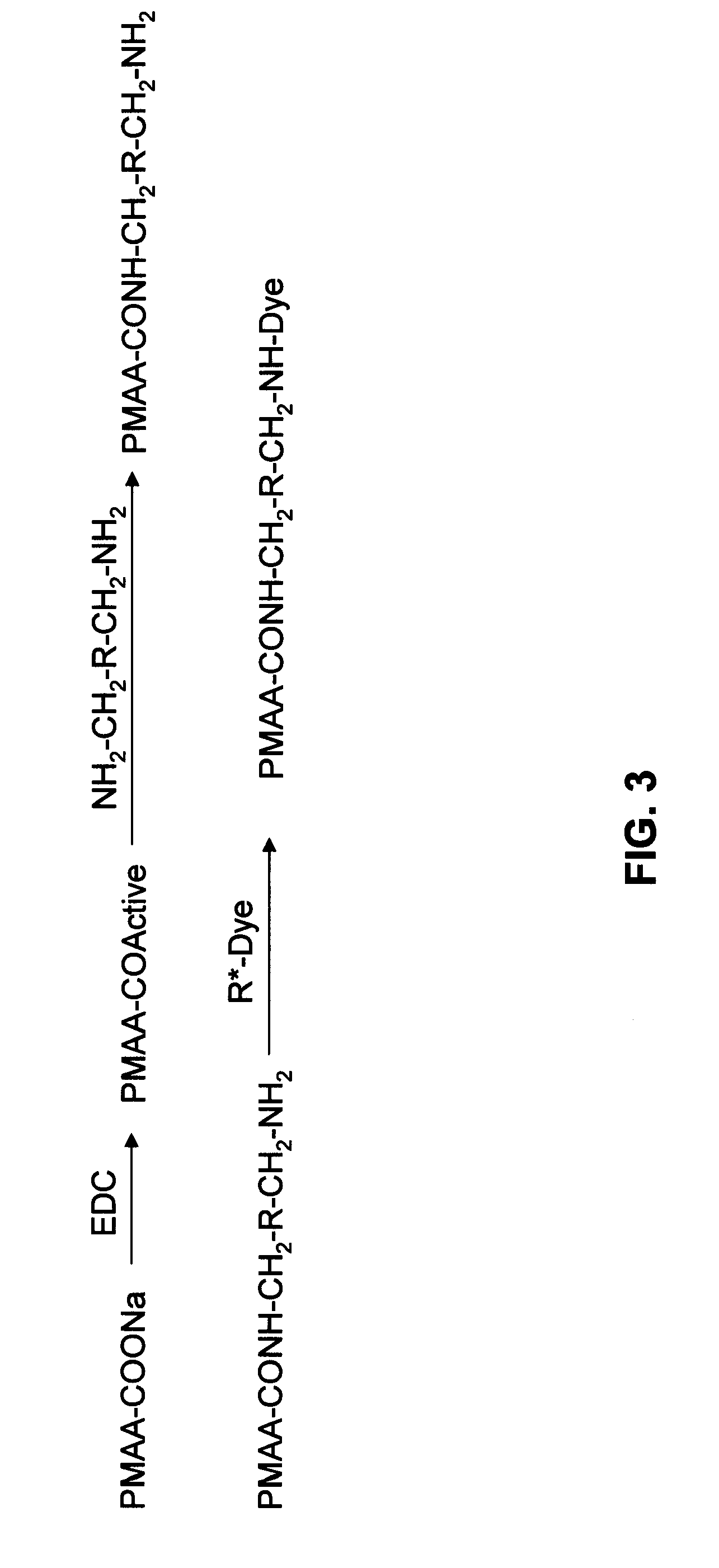

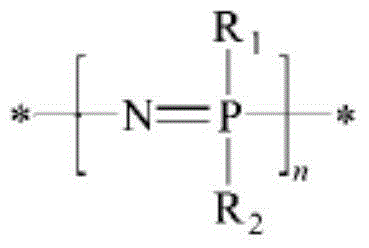

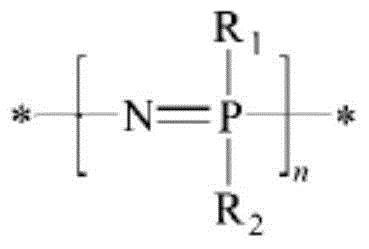

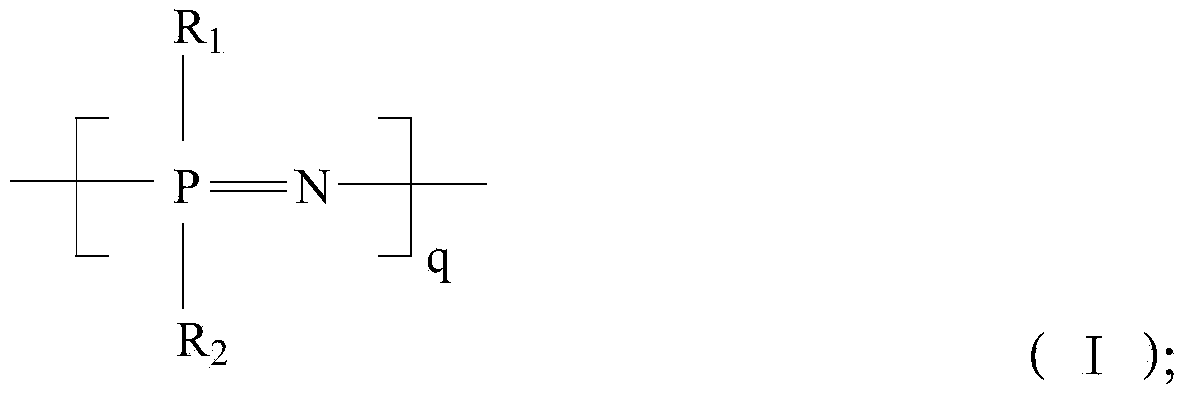

Polyphosphazenes include a wide range of hybrid inorganic-organic polymers with a number of different skeletal architectures that the backbone P-N-P-N-P-N-. In nearly all of these materials two organic side groups are attached to each phosphorus center. Linear polymers have the formula (N=PR¹R²)ₙ, where R¹ and R² are organic (see graphic). Other architectures are cyclolinear and cyclomatrix polymers in which small phosphazene rings are connected together by organic chain units. Other architectures are available, such as block copolymer, star, dendritic, or comb-type structures. More than 700 different polyphosphazenes are known, with different side groups (R) and different molecular architectures. Many of these polymers were first synthesized and studied in the research group of Harry R. Allcock.

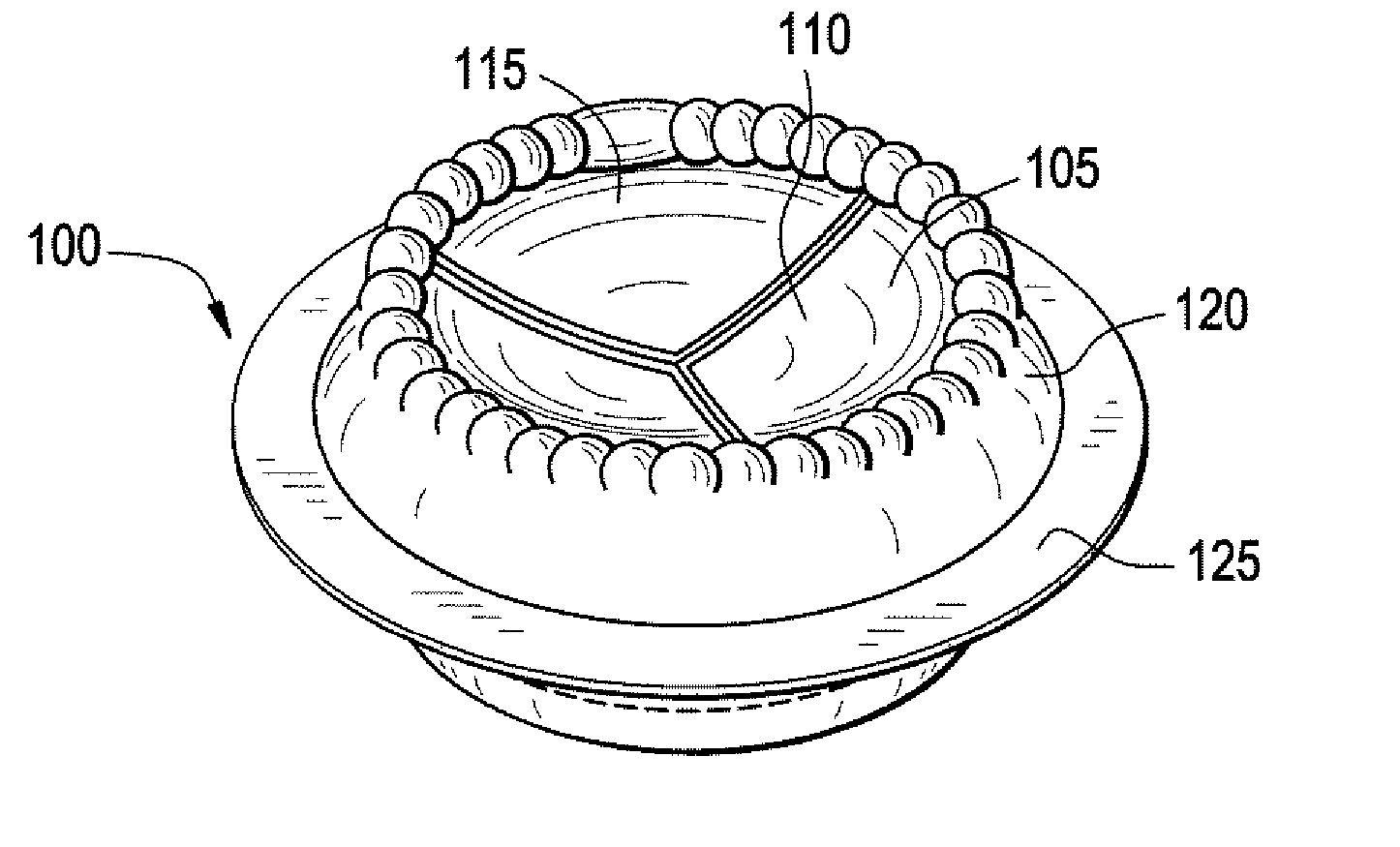

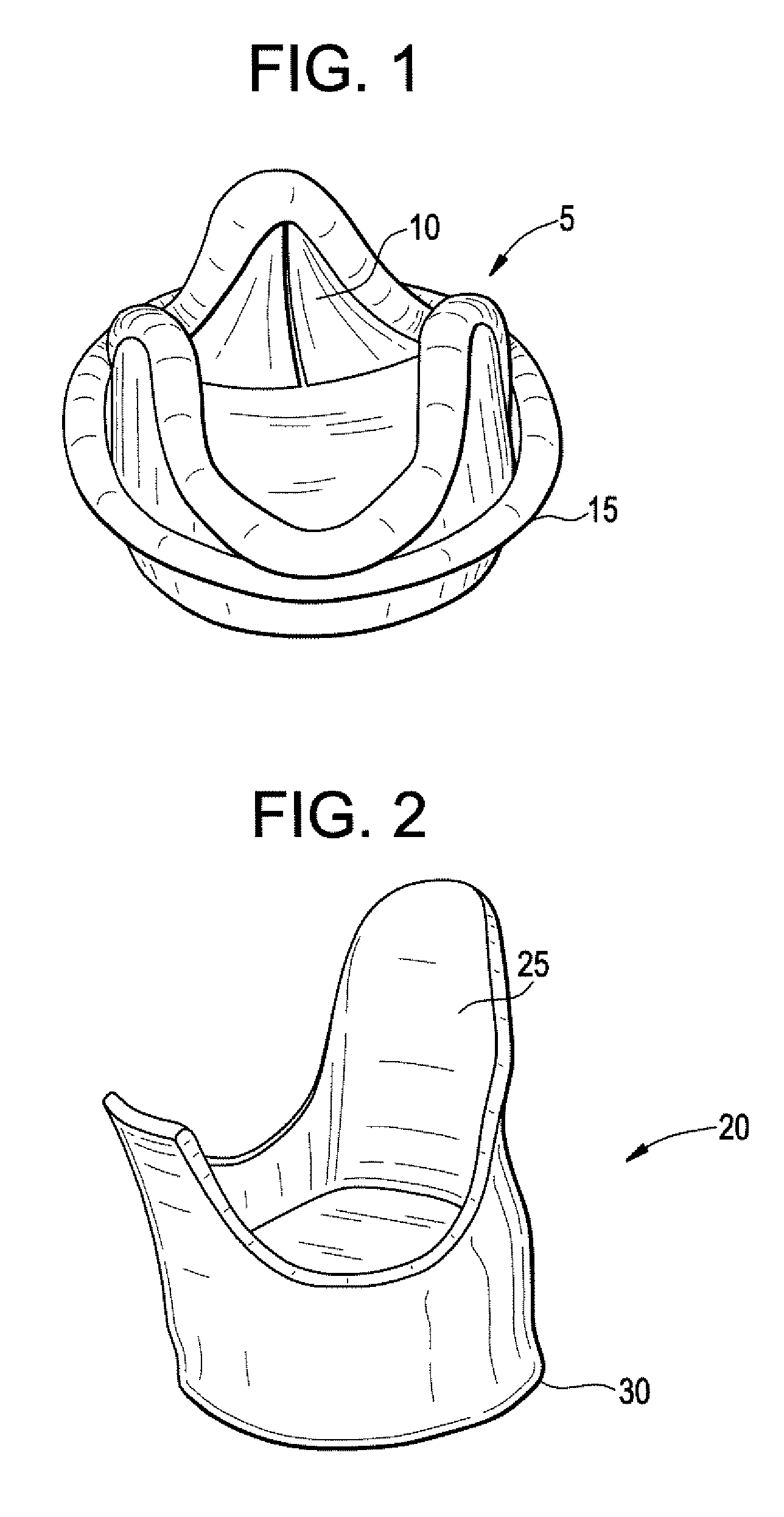

Bioprosthetic Heart Valve With Polyphosphazene

This disclosure encompasses a bioprosthetic heart valve having a polyphosphazene polymer such as poly[bis(trifluoroethoxy)phosphazene], which exhibits improved antithrombogenic, biocompatibility, and hemocompatibility properties. A method of manufacturing a bioprosthetic heart valve having a polyphosphazene polymer is also described.

Owner:CELONOVA BIOSCIENCES INC

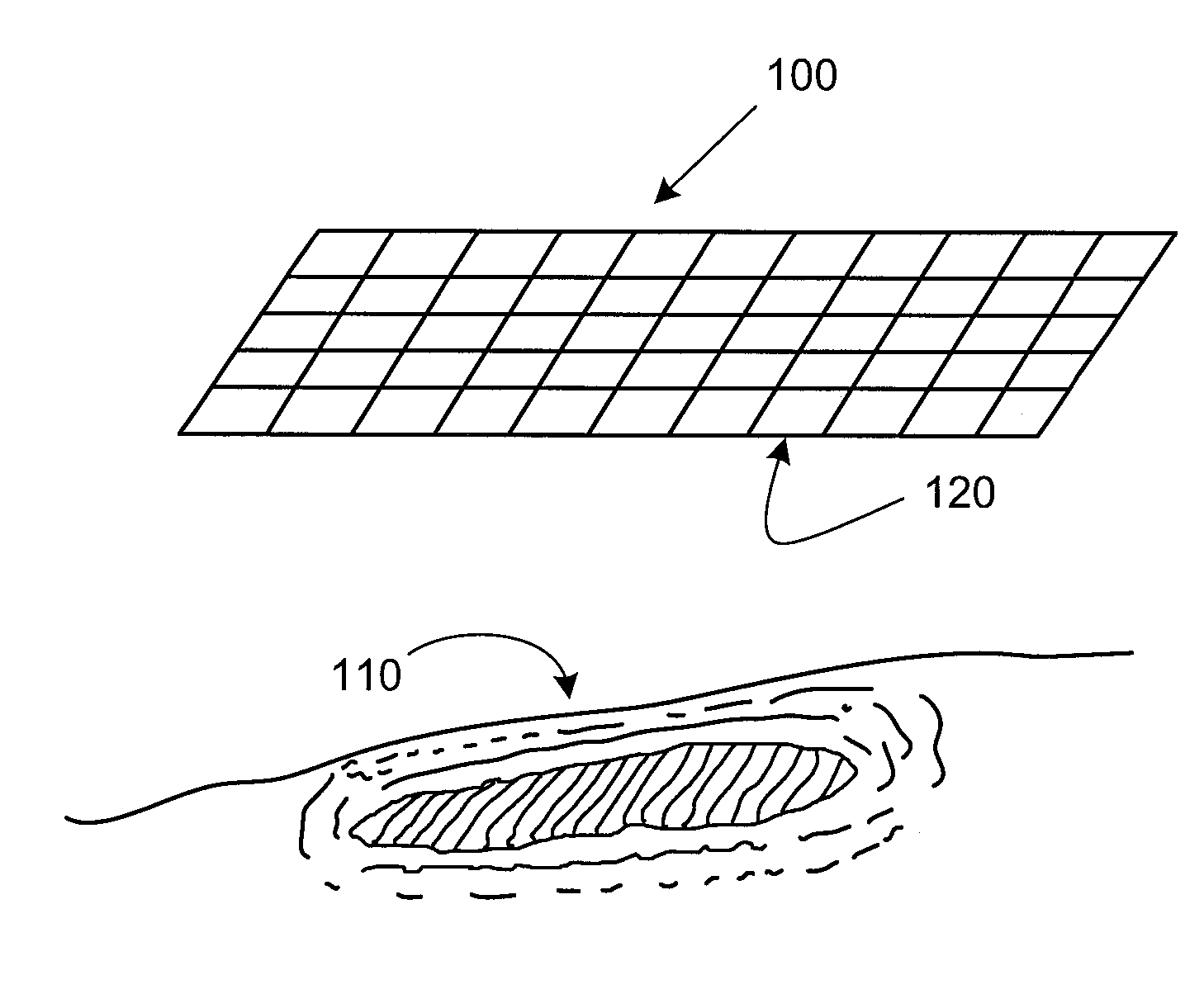

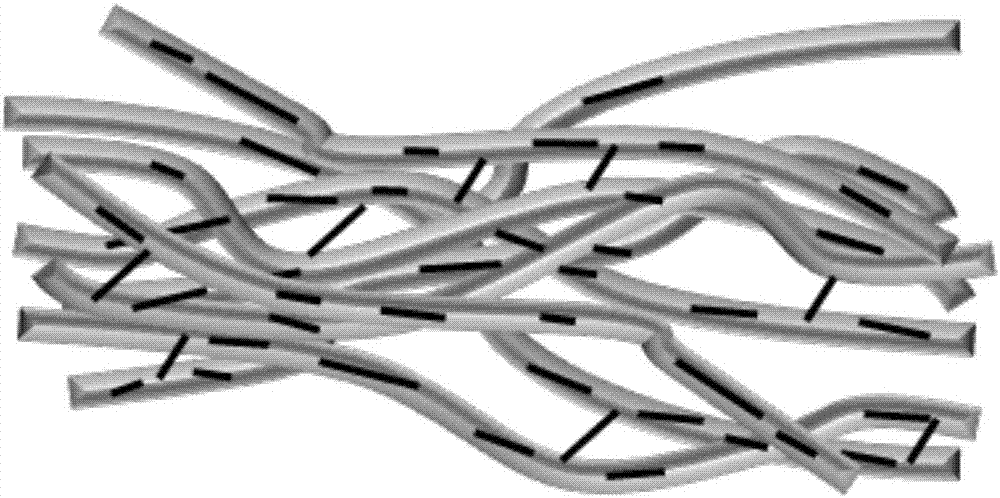

Polymeric nanofibers for tissue engineering and drug delivery

Polymeric nanofibers have been developed which are useful in a variety of medical and other applications, such as filtration devices, medical prosthesis, scaffolds for tissue engineering, wound dressings, controlled drug delivery systems, cosmetic skin masks, and protective clothing. These can be formed of any of a variety of different polymers, either non-degradable or degradable. In a preferred embodiment demonstrated in the following examples, nanofibers are formed of biodegradable and non biodegradable polyphosphazenes, their blends with other polyphosphazenes or with organic, inorganic / organometallic polymers as well as composite nanofibers of polyphosphazenes with nanosized particles such as hydroxyapatites.

Owner:PENN STATE RES FOUND

Solid polymer battery electrolyte and reactive metal-water battery

In one implementation, a reactive metal-water battery includes an anode comprising a metal in atomic or alloy form selected from the group consisting of periodic table Group 1A metals, periodic table Group 2A metals and mixtures thereof. The battery includes a cathode comprising water. Such also includes a solid polymer electrolyte comprising a polyphosphazene comprising ligands bonded with a phosphazene polymer backbone. The ligands comprise an aromatic ring containing hydrophobic portion and a metal ion carrier portion. The metal ion carrier portion is bonded at one location with the polymer backbone and at another location with the aromatic ring containing hydrophobic portion. The invention also contemplates such solid polymer electrolytes use in reactive metal / water batteries, and in any other battery.

Owner:BATTELLE ENERGY ALLIANCE LLC

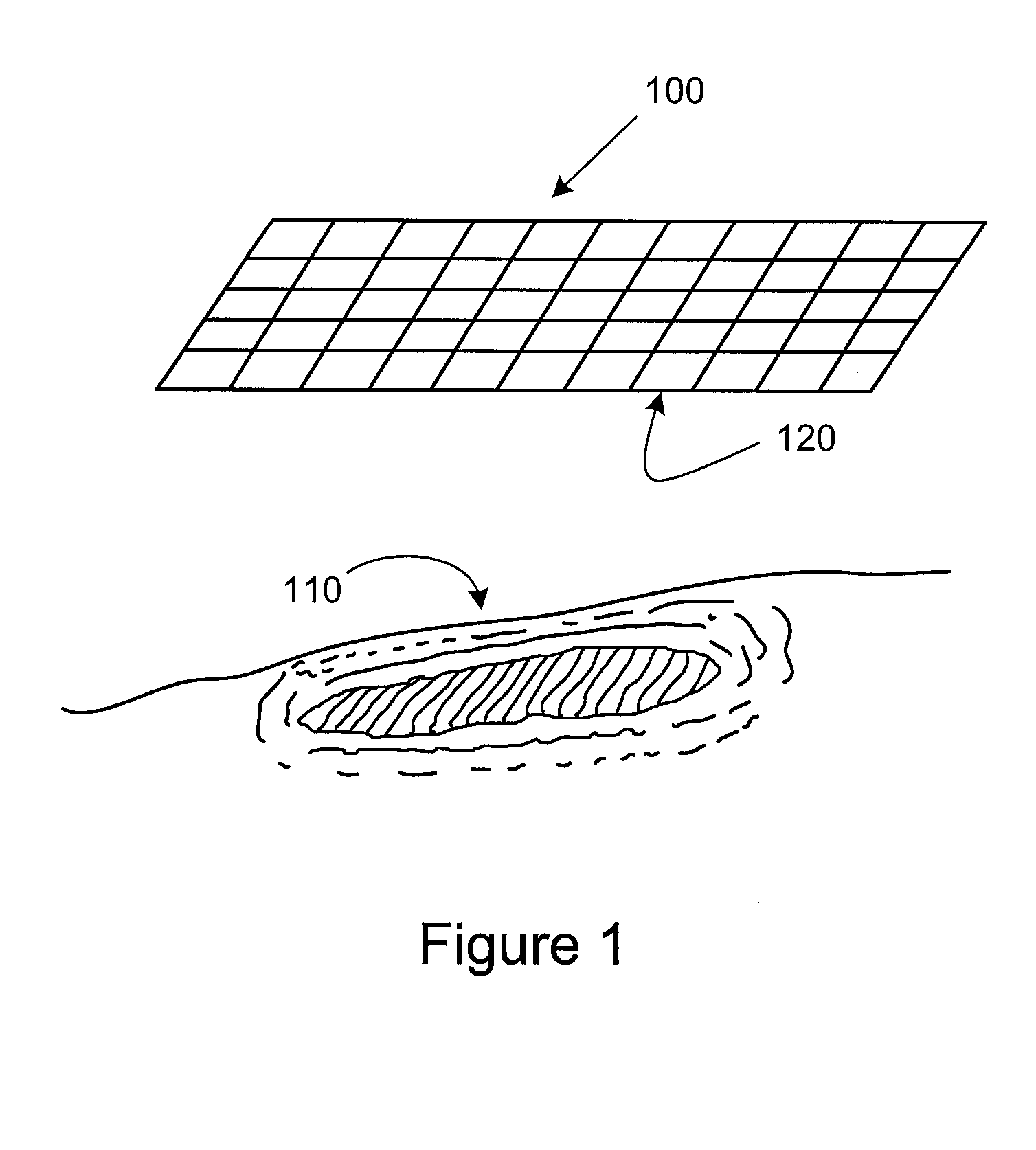

Multi-Functional Wound Dressing Matrices and Related Methods

InactiveUS20100047324A1Promote tissue growthPromote optimal healingAdhesive dressingsAbsorbent padsParticulatesPolyphosphazene

Various embodiments are directed to multi-functional wound-care dressing matrices that can protect and promote new tissue growth at a wound site. The multi-functional wound care matrix can incorporate polyphosphazenes of formula I, as a component that can be configured into various forms, including as fibrous mats, porous membranes, nonporous films, particulate formulations, and equivalents. The multi-functional wound-care dressing matrix of the present disclosure exhibit high-performance properties conferred by polyphosphazenes of formula I. Exceptional biocompatible properties of polyphosphazenes of formula I provide an ideal tissue-contacting surface for the multi-functional wound-care dressing matrix of interest.

Owner:CELONOVA BIOSCIENCES INC

Polymeric nanofibers for tissue engineering and drug delivery

Polymeric nanofibers have been developed which are useful in a variety of medical and other applications, such as filtration devices, medical prosthesis, scaffolds for tissue engineering, wound dressings, controlled drug delivery systems, cosmetic skin masks, and protective clothing. These can be formed of any of a variety of different polymers, either non-degradable or degradable. In a preferred embodiment demonstrated in the following examples, nanofibers are formed of biodegradable and non biodegradable polyphosphazenes, their blends with other polyphosphazenes or with organic, inorganic / organometallic polymers as well as composite nanofibers of polyphosphazenes with nanosized particles such as hydroxyapatites.

Owner:PENN STATE RES FOUND

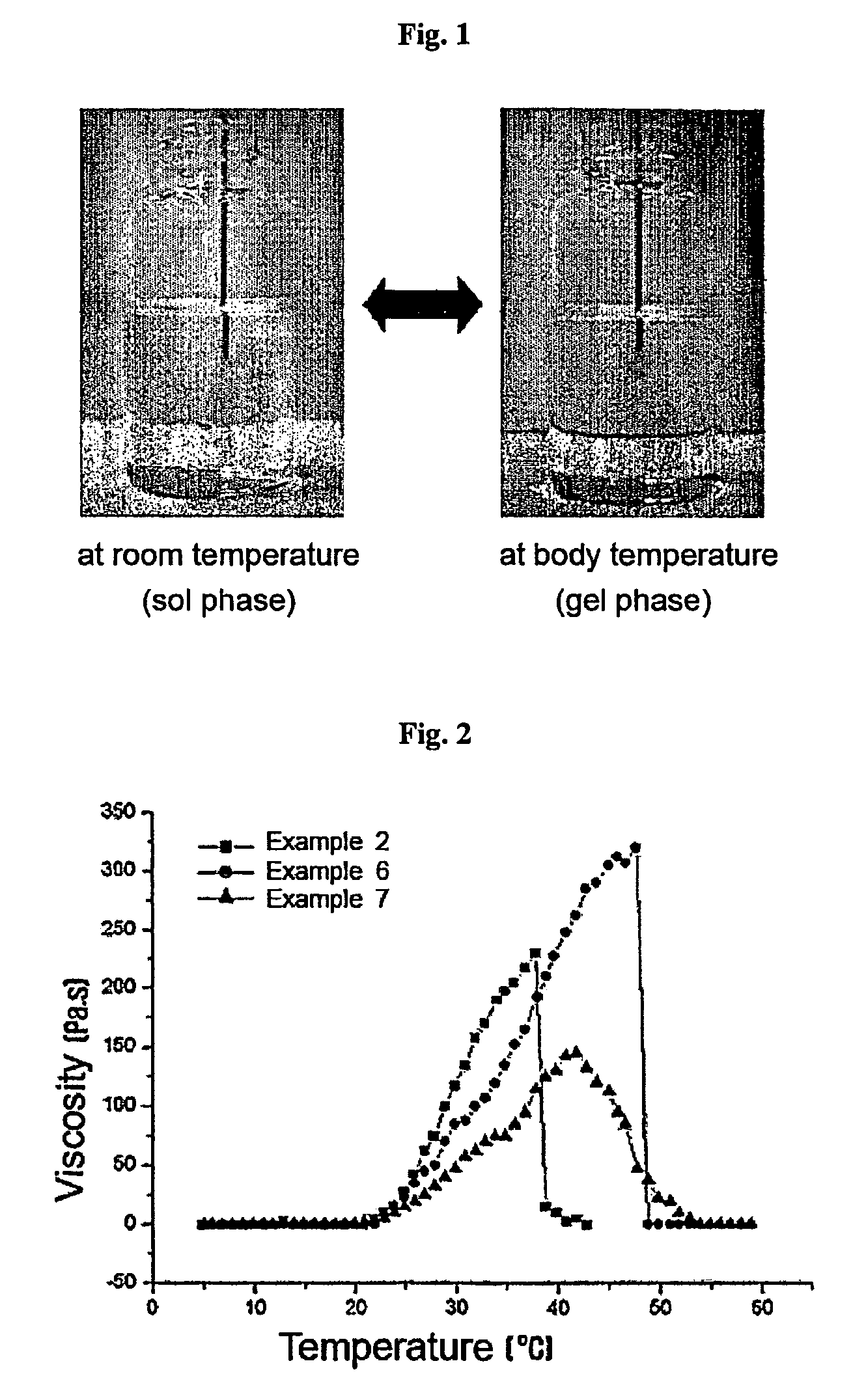

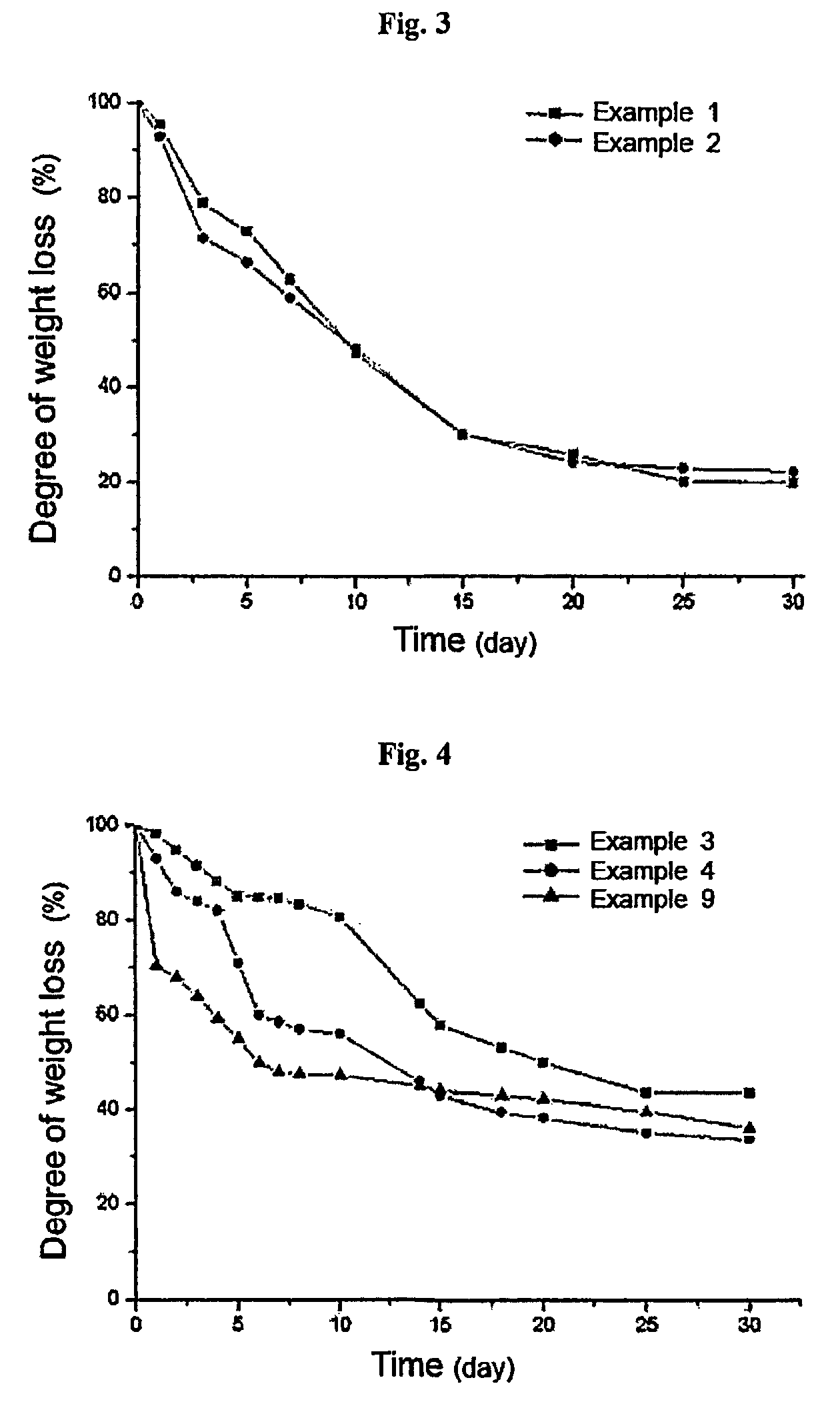

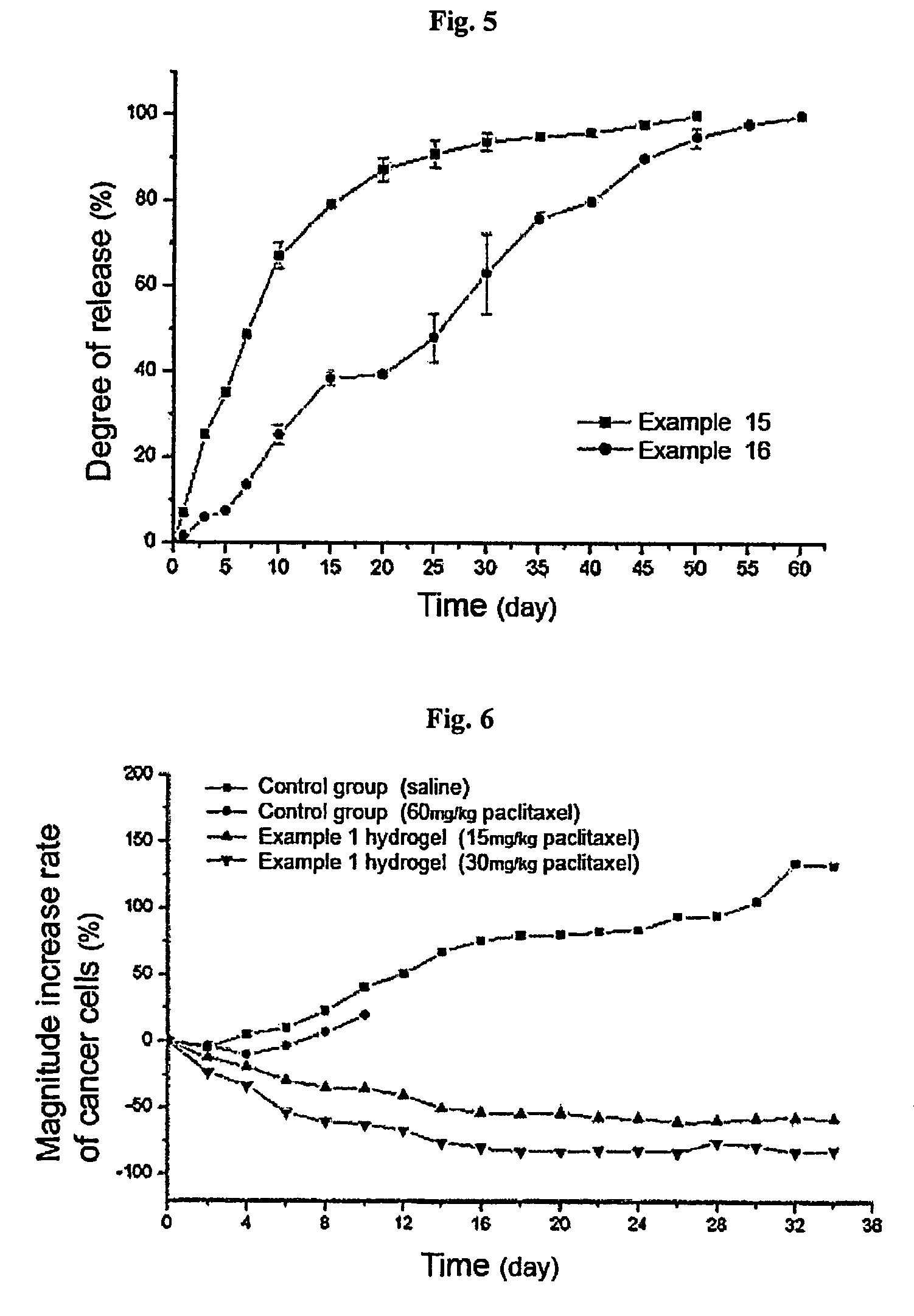

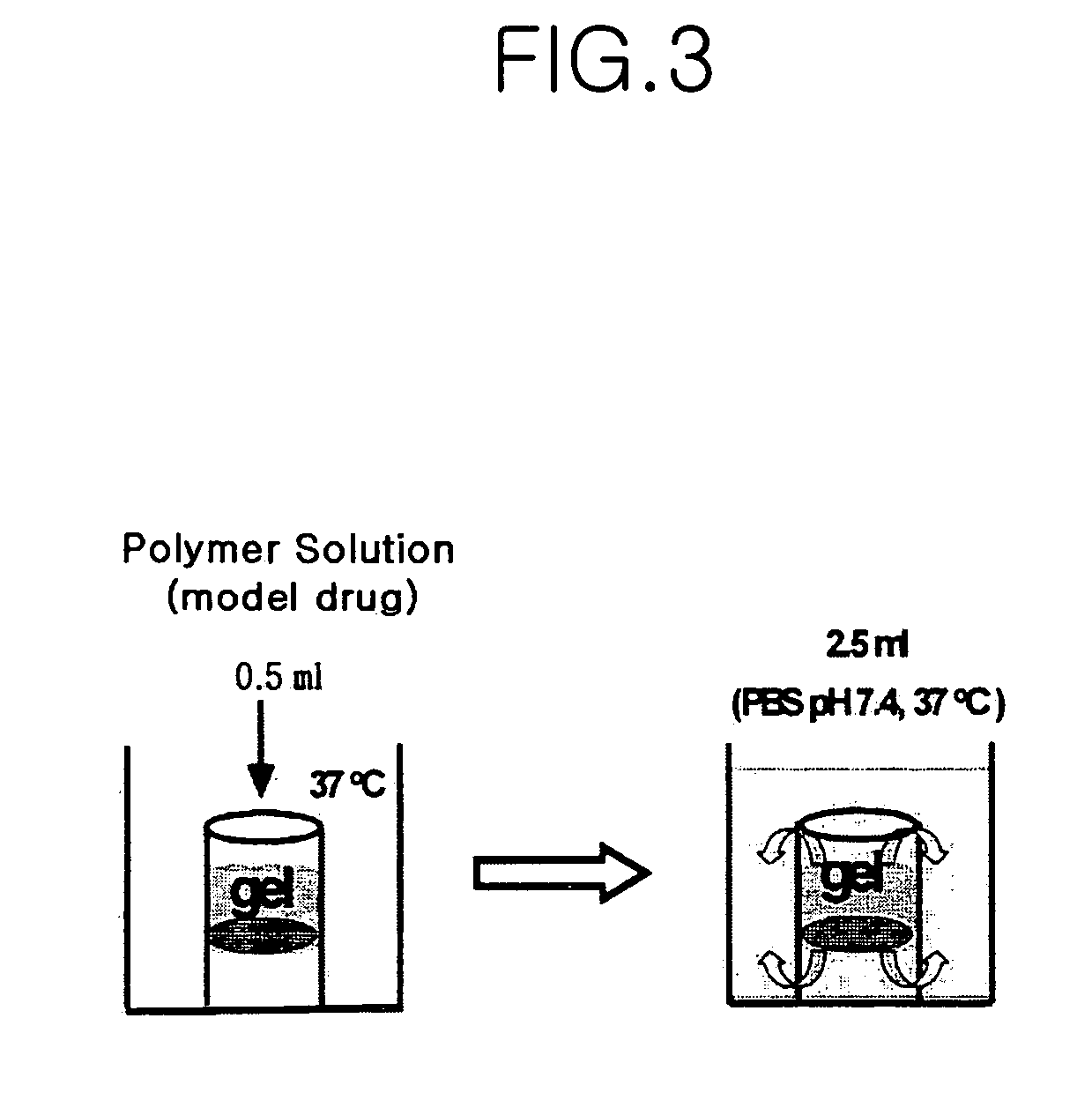

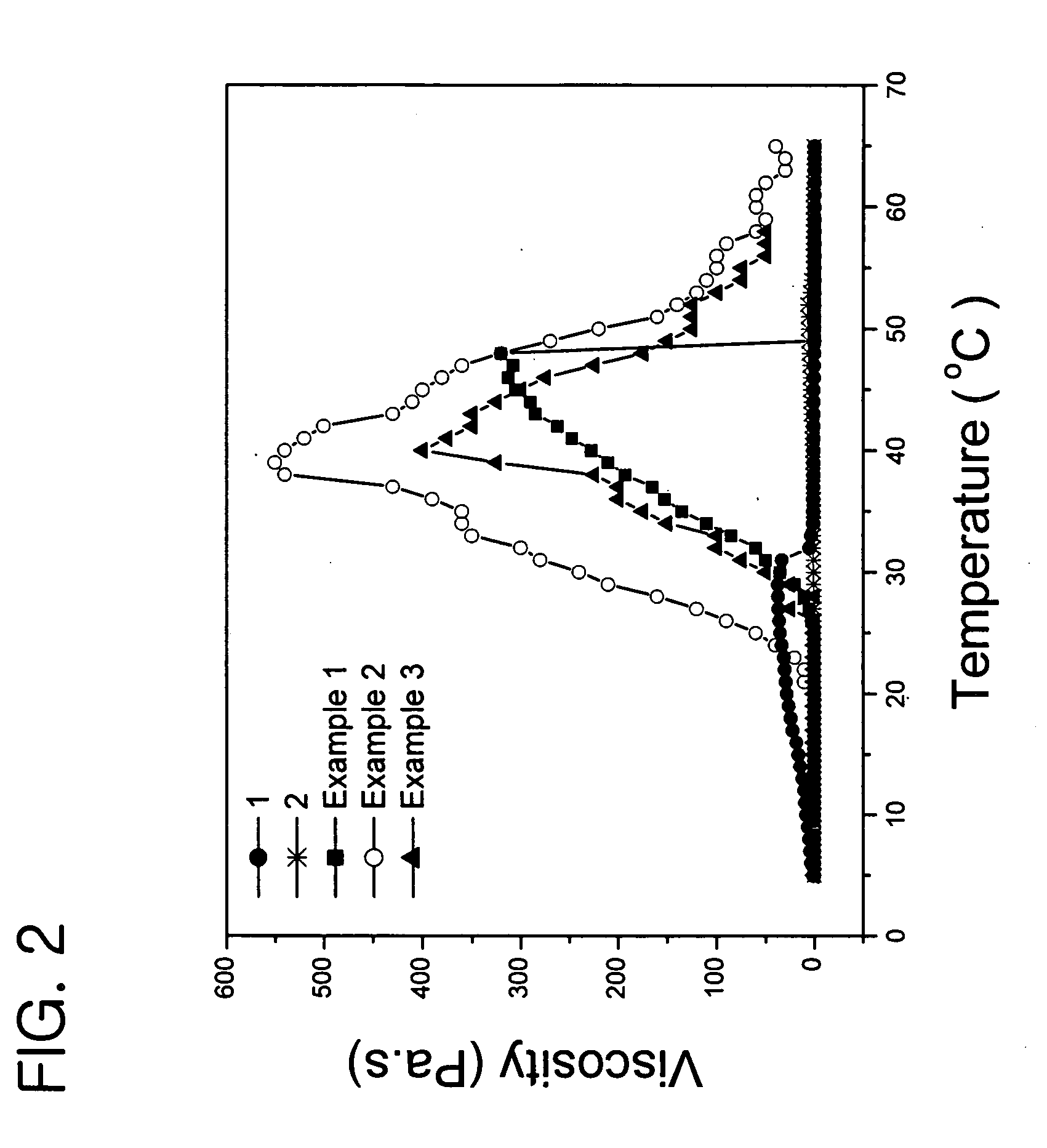

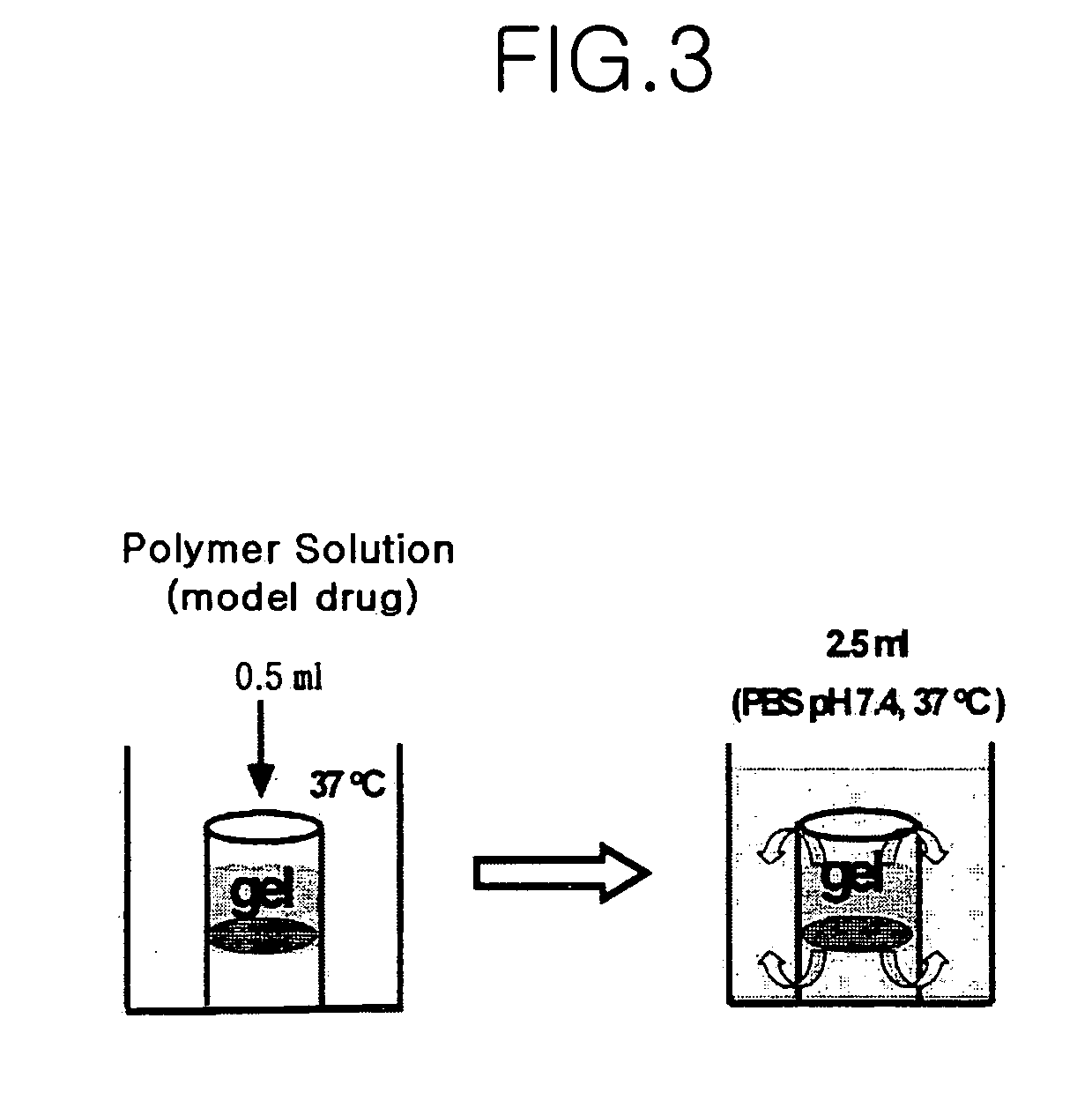

Thermosensitive polyphosphazene-bioactive molecule conjugates, preparation method thereof and use thereof

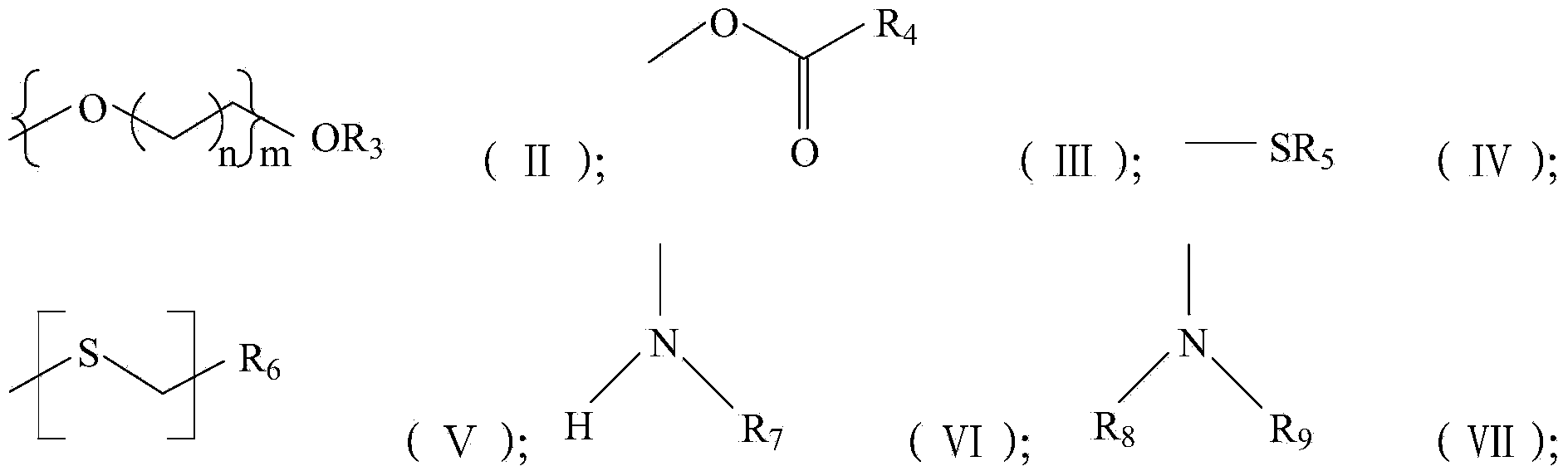

The present invention relates to a poly(organophosphazene)-bioactive molecule conjugates in which biodegradable and thermosensitive poly(organophosphazene) with a functional group showing the sol-gel phase transition with change of temperature is combined with various bioactive molecules, such as drugs, a preparation method thereof, and a use thereof for delivery of bioactive molecules.

Owner:KOREA INST OF SCI & TECH

All-solid-state composite polymer electrolyte and preparation method thereof

InactiveCN106410269AReasonable structure ratioImprove mechanical propertiesSecondary cellsPolyesterIonic liquid

The invention discloses an all-solid-state composite polymer electrolyte and a preparation method thereof. An adopted polymer matrix is a hyperbranched polymer or a star-like polymer. Different types of lithium salt are added into the polymers, and are compounded with substances such as inorganic fillers (such as nanoparticles, nanofibers), ionic liquid, carbonic ester compounds as well as other linear or branched polymers (such as polyether, polydioxolane, polycaprolactone, polyphosphazene, polyurethane, Makrolon, polyamide, polyimide, polyester, polyvinylidene fluoride, polytetrafluoroethylene, polyhexafluoropropylene or corresponding segmented copolymers or graft polymers thereof and the like) respectively, a film can be formed through a solution pouring process, the all-solid-state composite polymer electrolyte is prepared, and the room-temperature conductivity of the electrolyte is approximate to 10<-4> S / cm. The solid electrolyte has potential applications in electrochemical devices such as secondary lithium ion batteries, supercapacitors, electronic sensors, electrochromic devices and the like.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

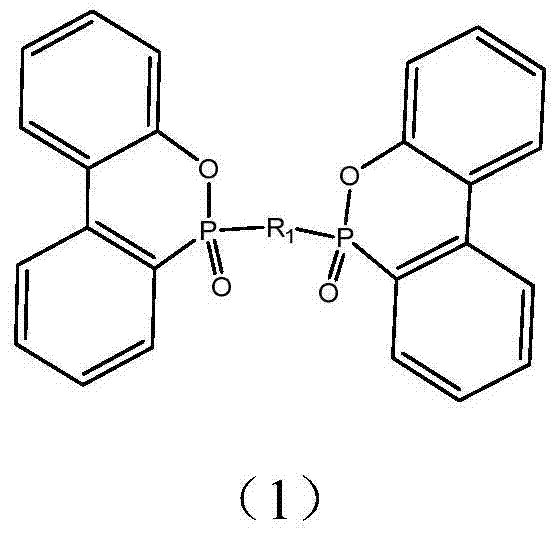

Phosphorus-containing flame retardant composition, and phosphorus-containing polyphenyl ether resin composition, prepreg and laminated board using the same

ActiveCN104774476AExcellent dielectric propertiesImprove heat resistanceSynthetic resin layered productsCircuit susbtrate materialsDielectricHalogen

The invention provides a phosphorus-containing flame retardant composition, including: a hypophosphite compound, a DOPO derivative and a polyphosphazene compound. The composition as a flame retardant can play a synergistic effect of several phosphorus-containing compounds, realizes halogen-free flame retardance under small addition amount and reaches level V-0. The invention also provides a contains a polyphenyl ether resin composition containing the above phosphorus-containing flame retardant compositions and a prepreg and a copper clad laminated board prepared from the same. After curing, the polyphenyl ether resin composition achieves flame retardance of V-0 grade under the condition to which the halogen flame retardant does not apply and keeps good dielectric property and heat resistance of polyphenyl ether resin; the prepreg and copper clad laminated board made from the composition have good dielectric property and heat resistance, and realize halogen-free flame retardance to UL 94-V0 grade while ensuring excellent heat resistance and dielectric property; and the composition is applicable to the field of high speed and high frequency printed circuit board, and is in line with the future requirements of green and environmental protection.

Owner:GUANGDONG SHENGYI SCI TECH

Polymer blend proton exchange membrane and method for manufacturing the same

ActiveUS20110136016A1Excellent comprehensive propertyHigh degree of sulfonationNon-metal conductorsFuel cells groupingPolymer sciencePhenolphthalein

The present invention relates to a polymer blend proton exchange membrane comprising a soluble polymer and a sulfonated polymer, wherein the soluble polymer is at least one polymer selected from the group consisting of polysulfone, polyethersulfone and polyvinylidene fluoride, the sulfonated polymer is at least one polymer selected from the group consisting of sulfonated poly(ether-ether-ketone), sulfonated poly(ether-ketone-ether-ketone-ketone), sulfonated poly(phthalazinone ether keton), sulfonated phenolphthalein poly(ether sulfone), sulfonated polyimides, sulfonated polyphosphazene and sulfonated polybenzimidazole, and wherein the degree of sulfonation of the sulfonated polymer is in the range of 96% to 118%. The present invention further relates to a method for manufacturing the polymer blend proton exchange membrane.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD

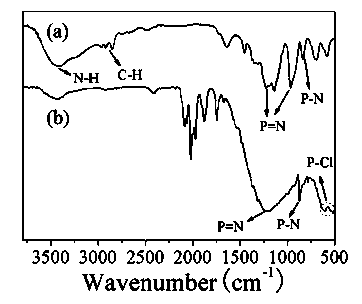

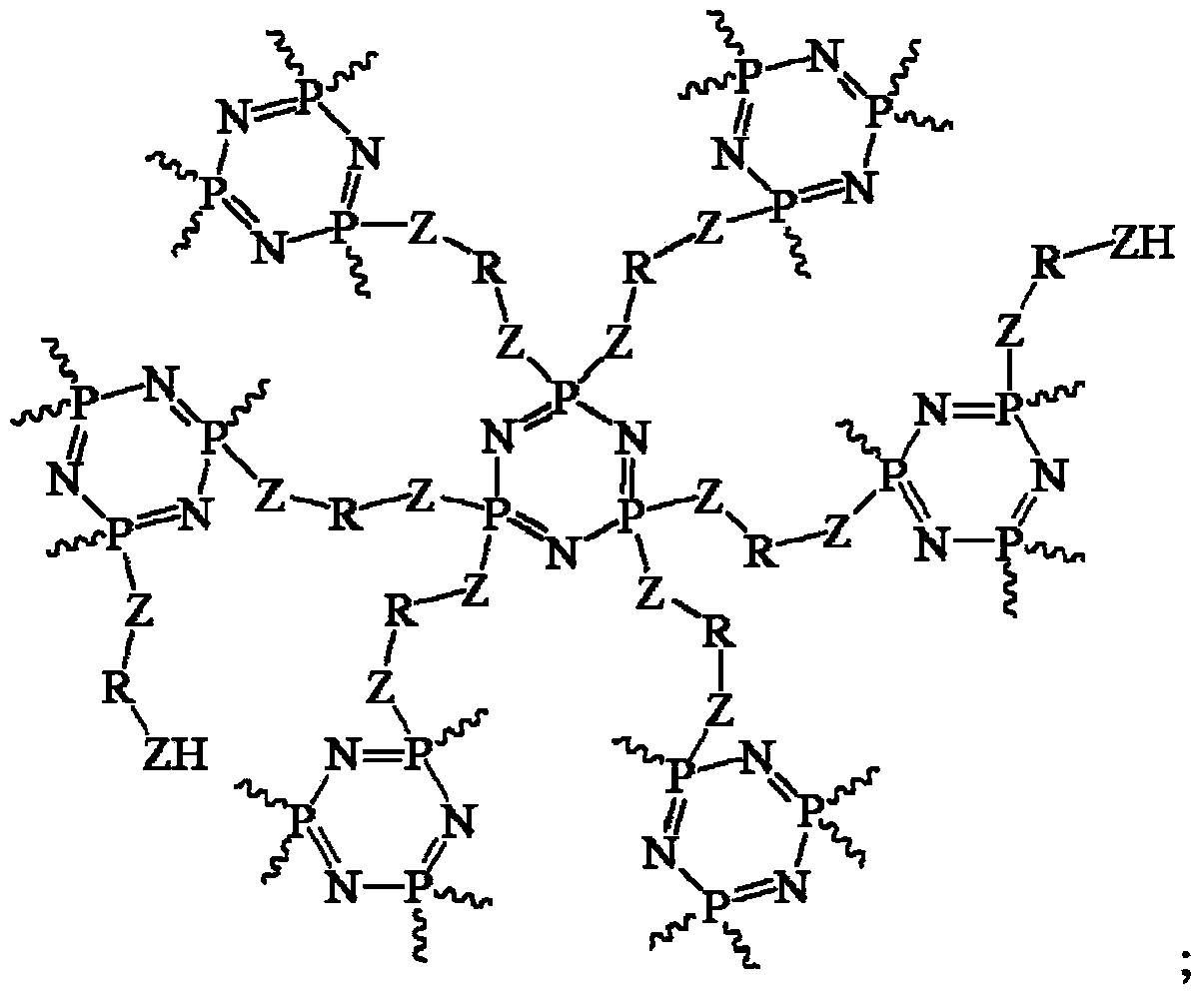

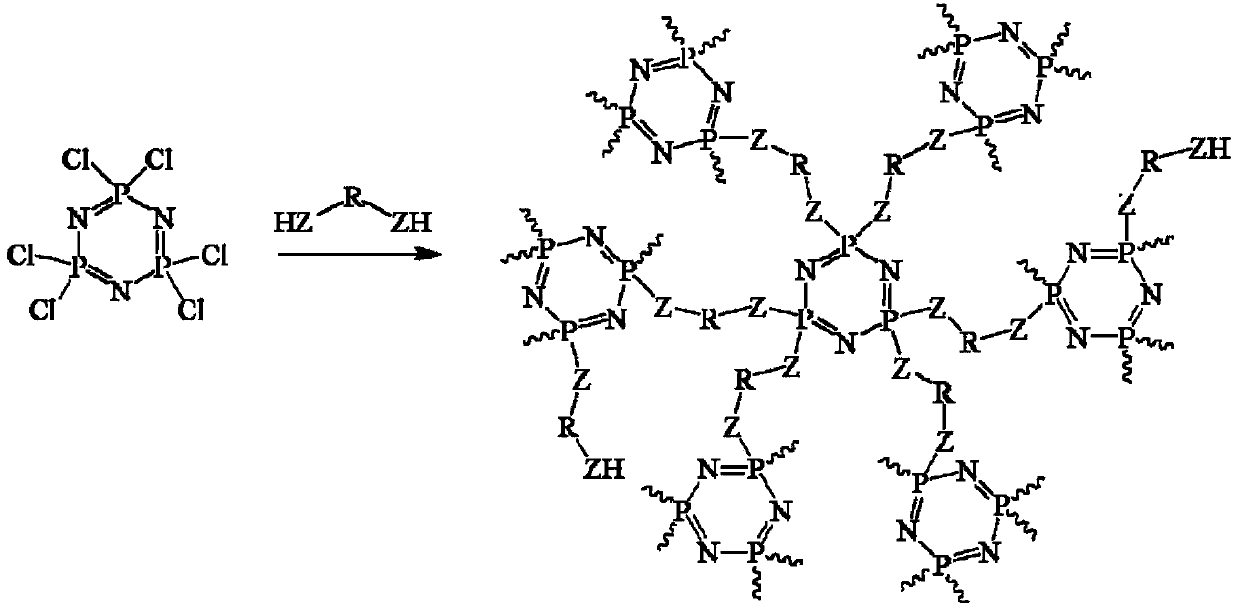

Hyperbranched polyphosphazene flame retardant charring agent and preparing method thereof

An efficient hyperbranched polyphosphazene flame retardant charring agent is prepared by reacting hexachlorocyclotriphosphazene with a binary compound containing two active groups. The charring agent has characteristics of good foaming charring performance, excellent flame retardant effects and good processing performance, and can be widely used in plastics, rubber, coating, adhesives, and other polymer materials. A preparing method adopts a one-pot method, and has characteristics of continuous reaction process, short reaction time and high production efficiency. By controlling the mole ratio of the hexachlorocyclotriphosphazene to the binary compound, no end-capping agent is added in the reaction process. When compared with the addition of end-capping agents in synthesis processes in triazine type charring agent patents, the synthetic process of the charring agent is simplified.

Owner:苏州安鸿泰新材料有限公司

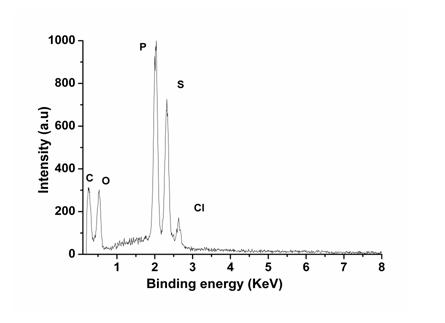

Method for preparing graphene polyphosphazene nano composite material

The invention belongs to the technical field of a nano graphene functional material and relates to a method for preparing a graphene polyphosphazene nano composite material. The method comprises the following steps of: performing a reaction of natural graphite and strong acid and a strong oxidizing substance to generate graphite oxide; carrying out ultrasonic dispersion on the graphite oxide to prepare graphene oxide; adding a reducing agent (hydrazine hydrate) to carry out reduction so as to obtain graphene; ultrasonically dispersing the graphene into a specific solvent; sequentially adding phosphonitrilic chloride trimerl, 4,4'-dihydroxy diphenyl sulfone and triethylamine; and performing an ultrasonic reaction for a certain time and carrying out simple post treatment to obtain the graphene polyphosphazene nano composite material. The method has a simple technological process, low cost and high yield. In the prepared composite material, graphene is uniformly coated by polyphosphazene. The composite material has good nano functionality, stable structure performance and wide application prospect.

Owner:JIANGSU UNIV

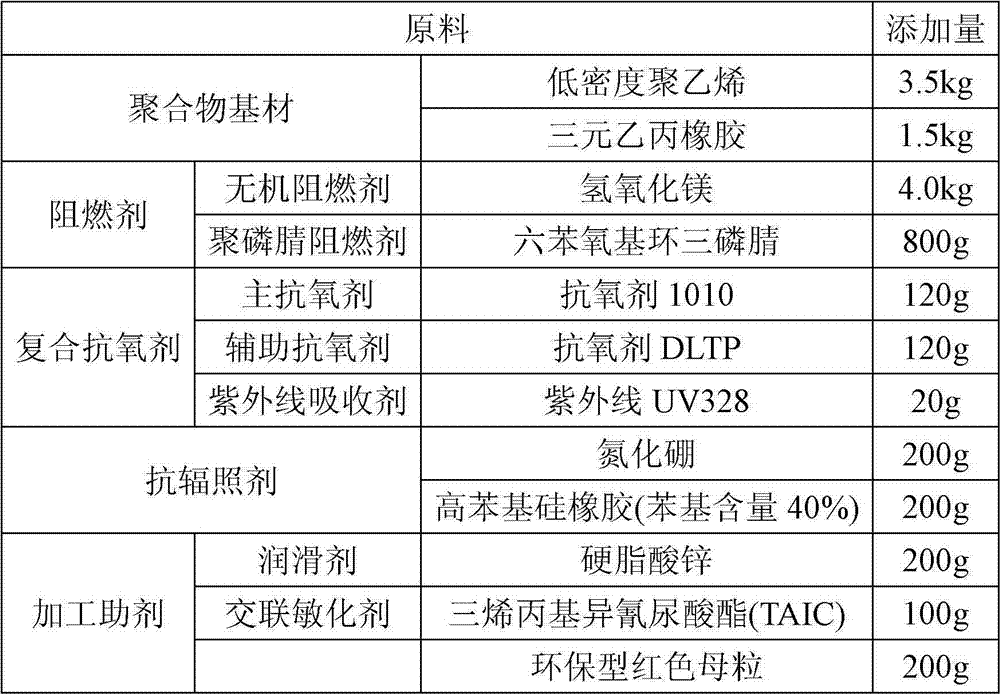

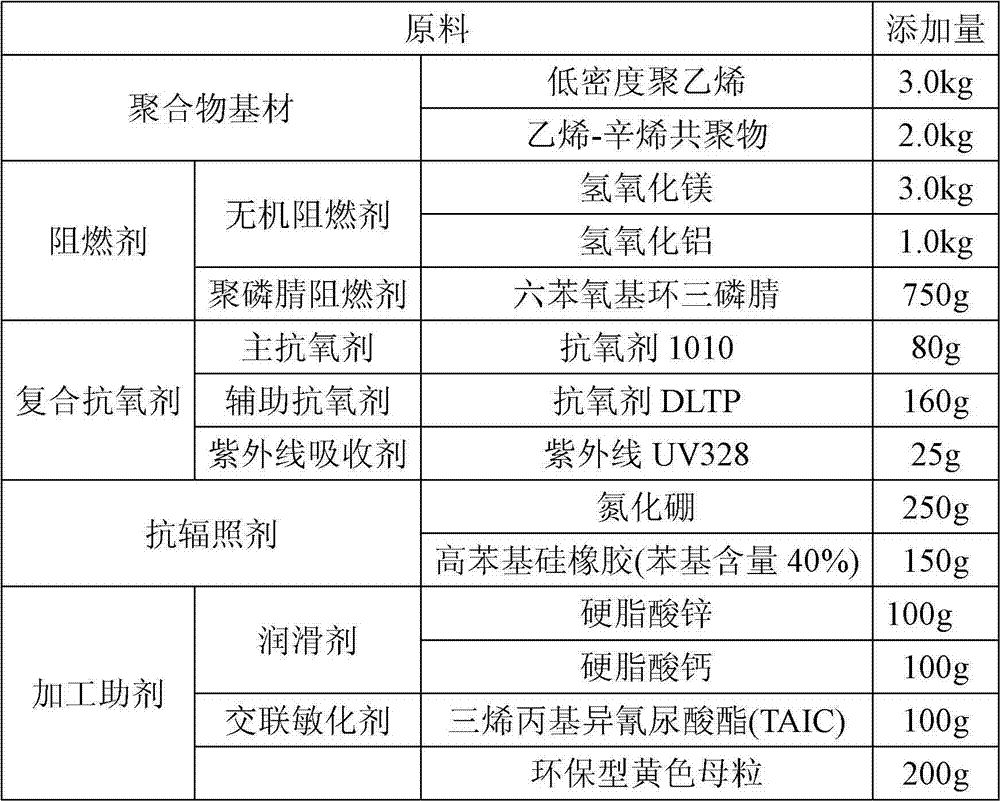

Halogen-free inflaming retarding insulating material of nuclear cable and cable insulating layer as well as preparation method and application thereof

ActiveCN102952316AStable radiation resistanceImprove electrical performanceInsulated cablesInsulated conductorsLow-density polyethyleneCross-link

The invention discloses a halogen-free inflaming retarding insulating material of a nuclear cable and a cable insulating layer as well as a preparation method and an application thereof. The halogen-free inflaming retarding insulating material of the nuclear cable comprises raw materials as follows: a polymer substrate comprises the components of: 100 parts of low-density polyethylene and ethylene propylene diene monomer; an inorganic flame retardant comprises the component of: 70-100 parts of magnesium hydroxide; a polyphosphazene flame retardant comprises the component of: 10-20 parts of hexaphenoxycyclotriphosphazene; a compound antioxidant comprises the components of: 4-8 parts of a main antioxidant, an auxiliary antioxidant and an ultraviolet absorbent; an anti-irradiation agent comprises the components of: 5-15 parts of an anti-irradiation agent A and an anti-irradiation agent B; a machining auxiliary agent comprises the components of: 4-10 parts of a cross-linking sensitizer and a lubricating agent, wherein the anti-irradiation agent A is high phenyl silicone rubber and / or phenylene silicone rubber; and the anti-irradiation agent B is boron carbide and / or boron nitride. The insulating material has the stable irradiation performance and electric performance, and good inflaming retarding performance, and is low-smoke, halogen-free and low-toxin.

Owner:青岛中科汉缆高分子材料有限公司

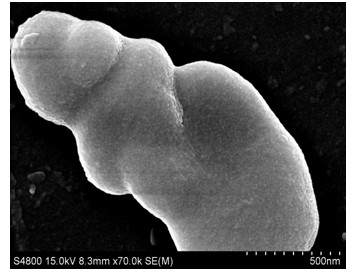

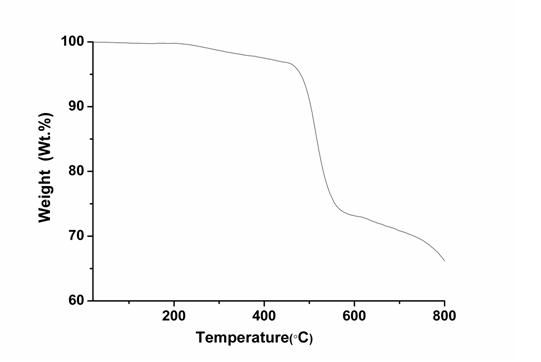

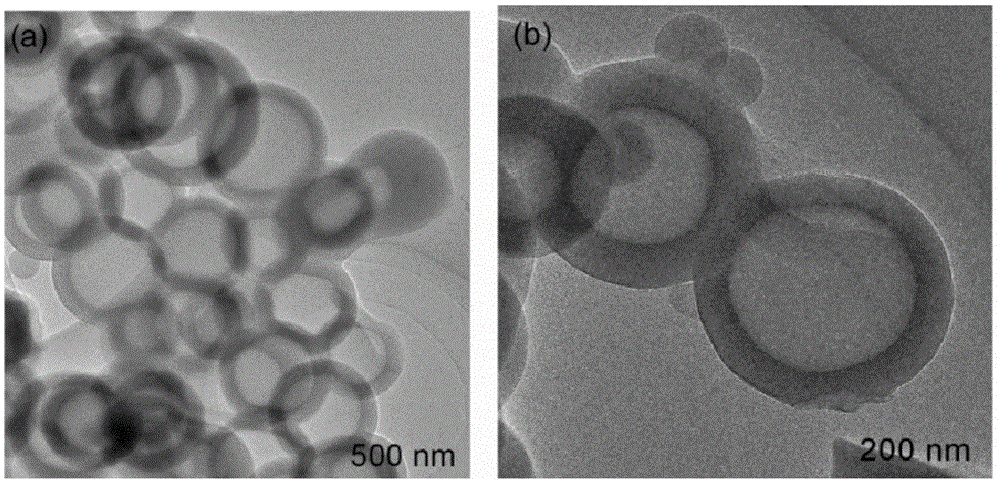

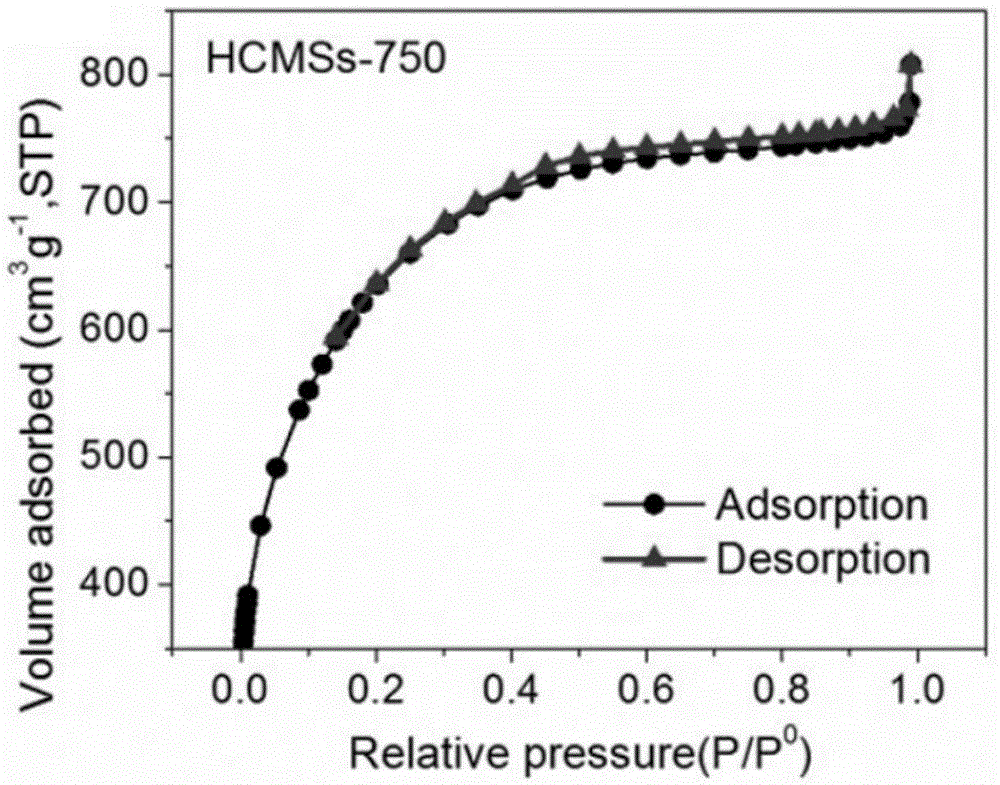

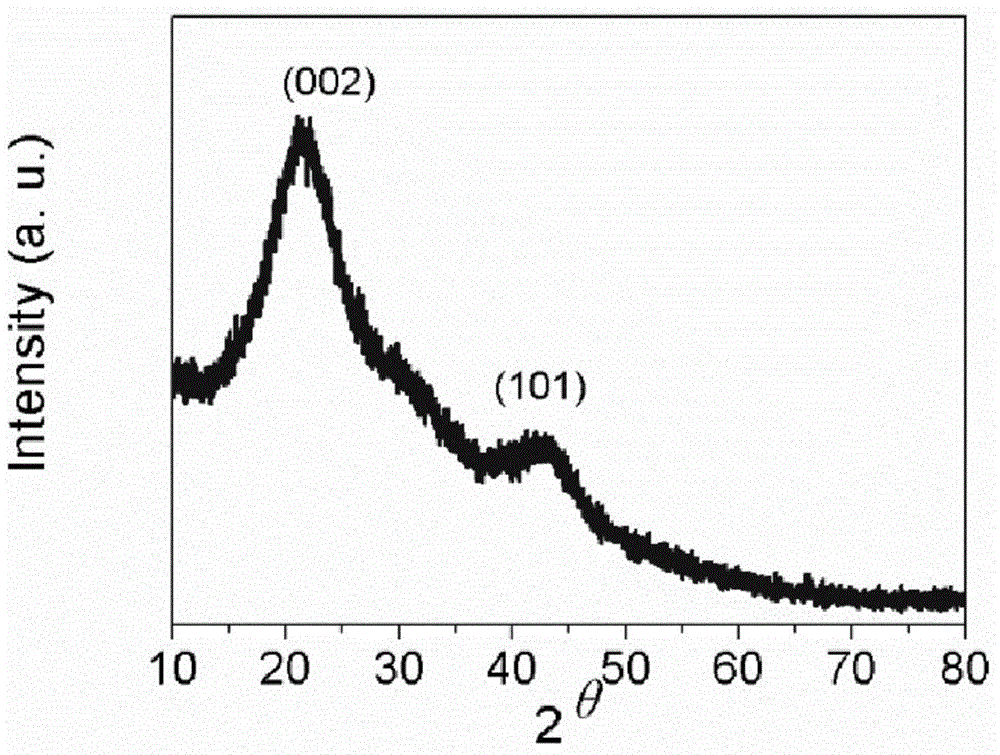

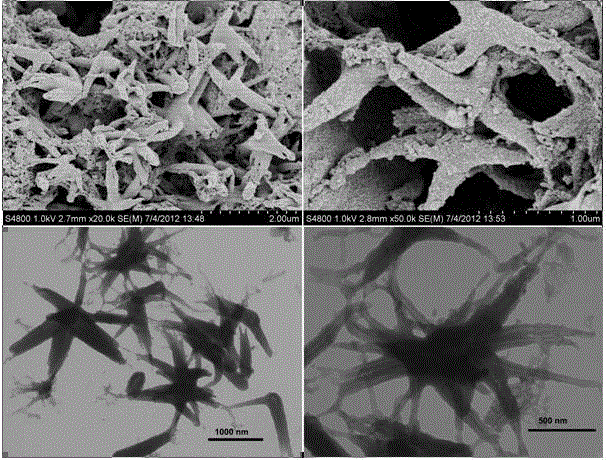

Heteroatom doped hollow porous carbon microspheres and preparation method thereof

The invention provides heteroatom doped hollow porous carbon microspheres and a preparation method thereof. A micro-nano capsule formed by 4,4'-thiobisbenzenethiol and triethylamine is taken as a template, hollow polyphosphazene microspheres are prepared by coating and modifying the surface of the template through polyphophazene, finally, carbonization and activation treatment are performed in an inert atmosphere, and the heteroatom doped hollow porous carbon microspheres are obtained. The following complicated template removal process of a hard template method is avoided; a large quantity of non-carbon atoms in the polyphophazene molecular structure provide a necessary condition for formation of the heteroatom doped structures in the hollow carbon microspheres. According to the preparation method, the yield is high, the material structure is uniform, the specific surface area is large, and the preparation method is an efficient method for preparation of the heteroatom doped hollow porous carbon microspheres.

Owner:上海鸿鹄骥航科技有限公司

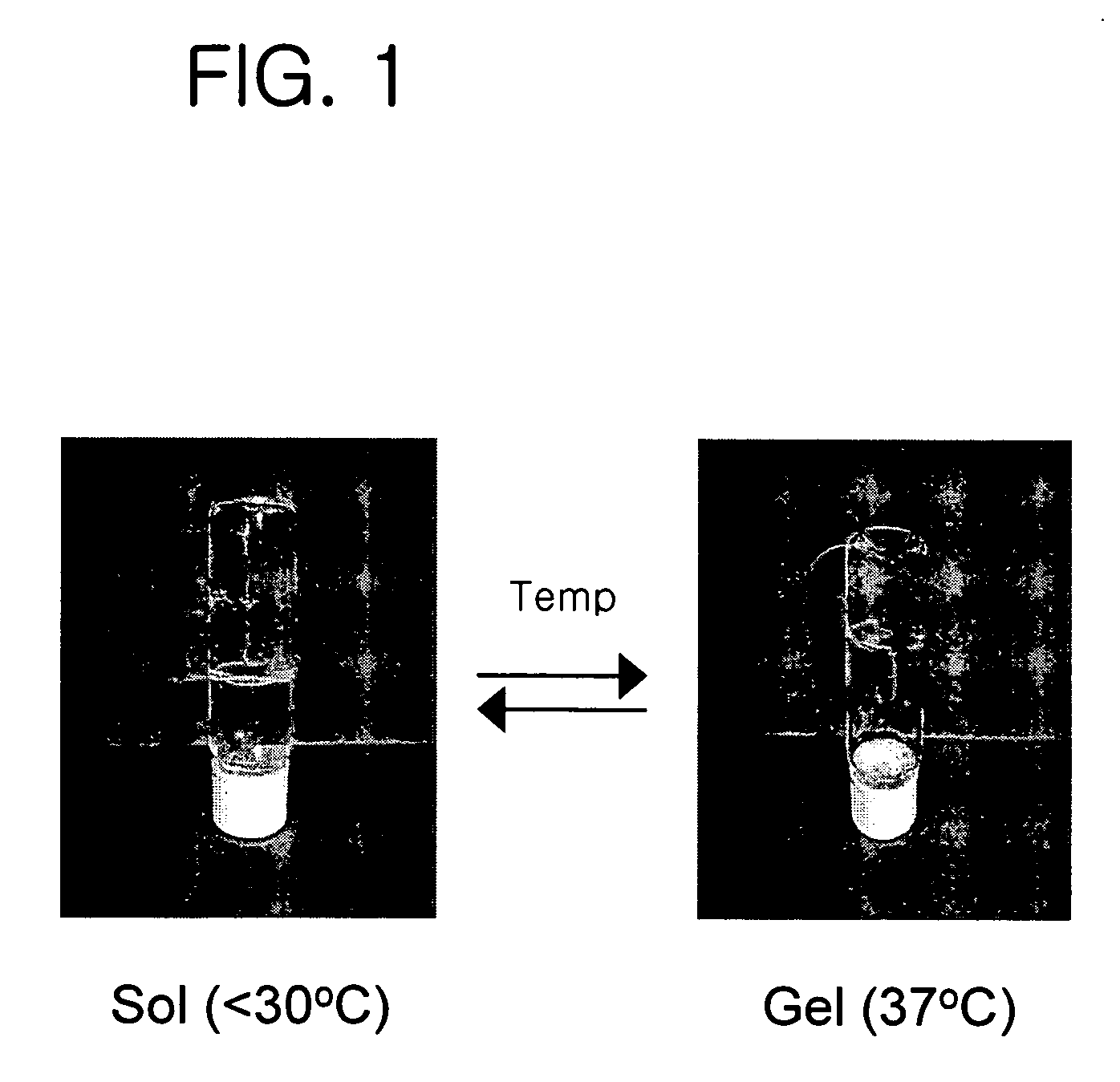

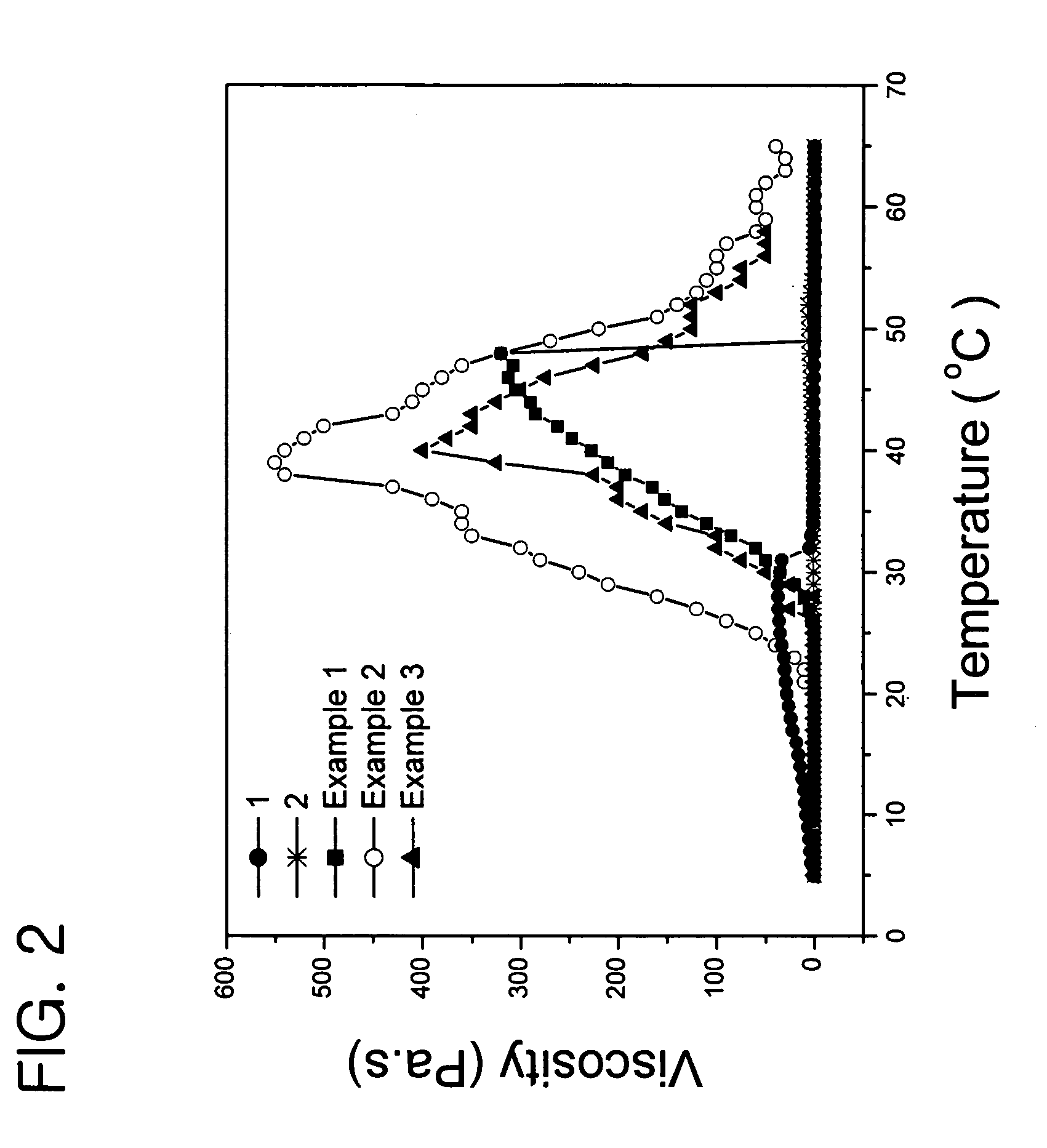

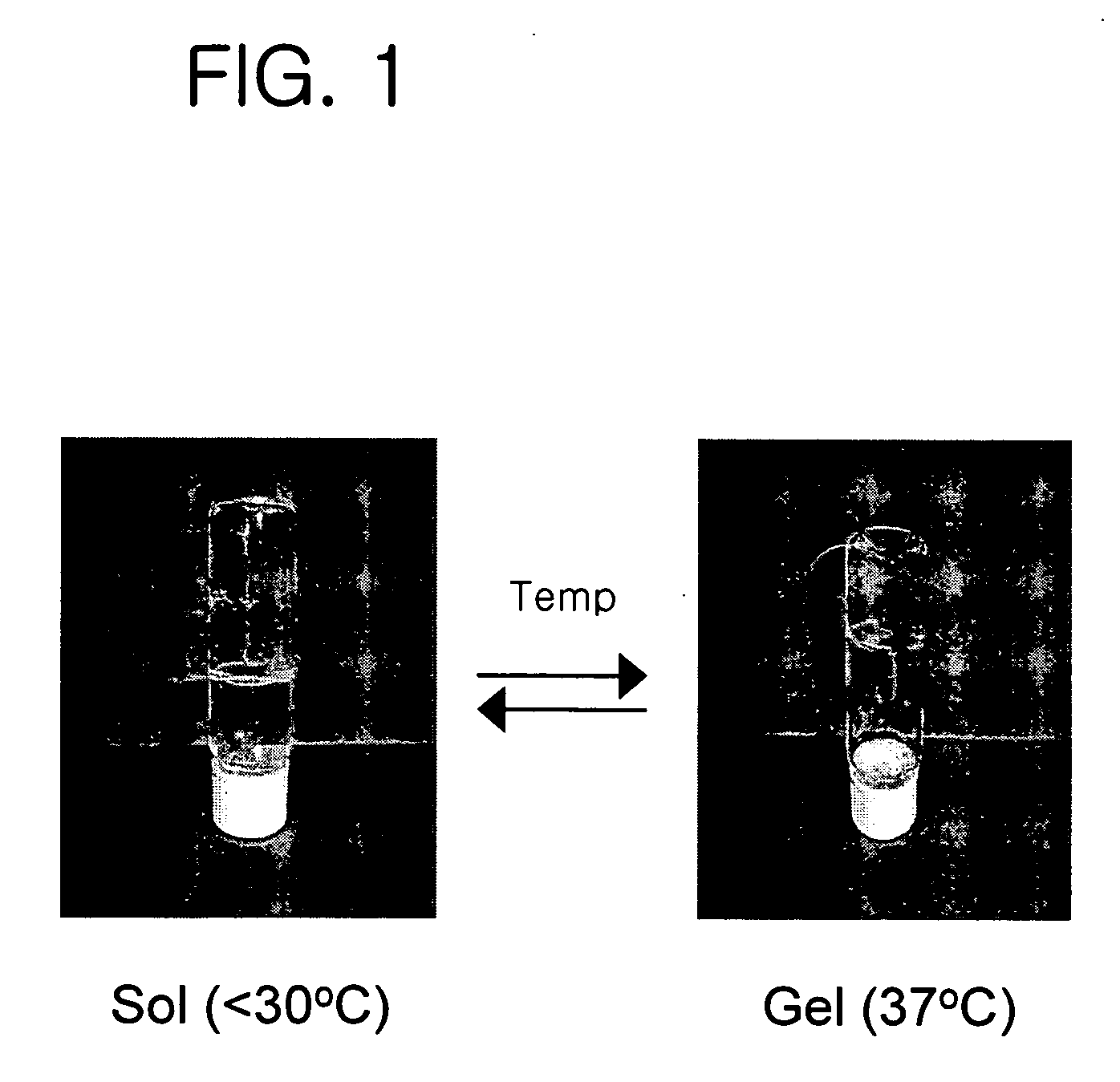

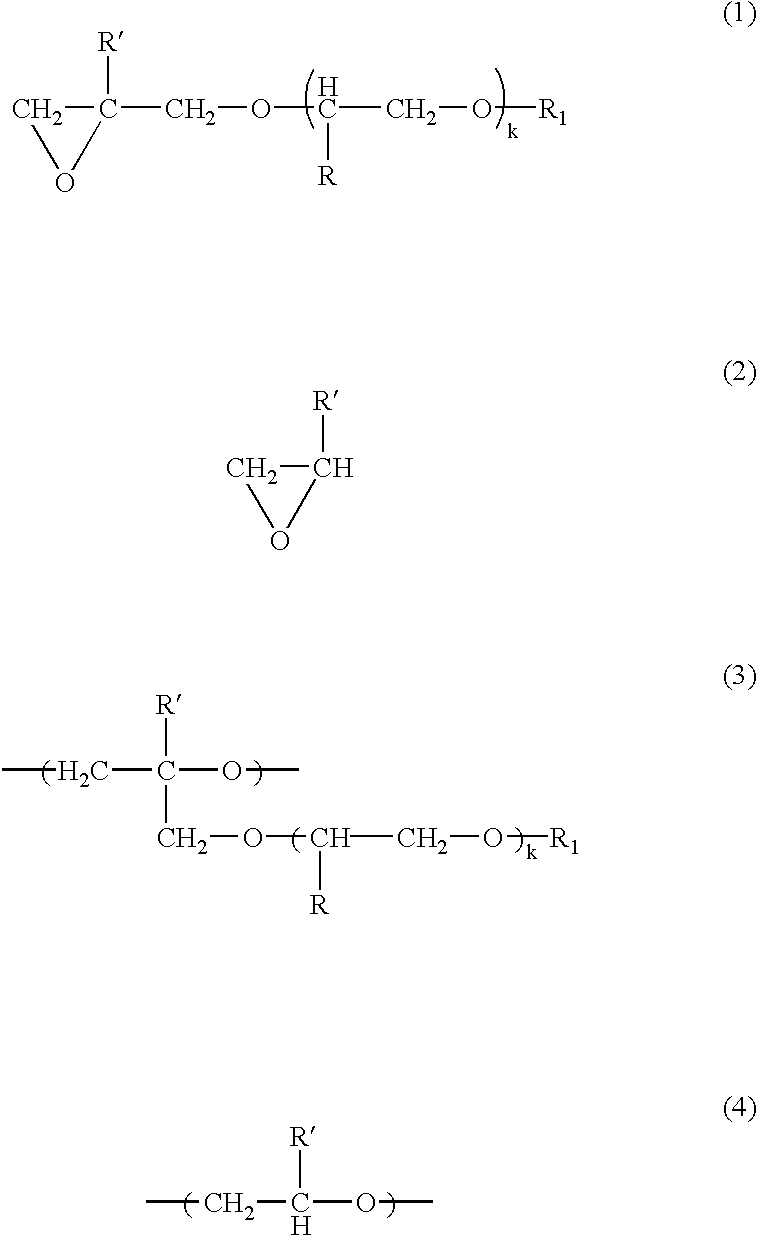

Thermosensitive poly (organophosphazenes), preparation method thereof and injectable thermosensitive polyphosphazene hydrogels using the same

ActiveUS7259225B2Improve gel propertiesAerosol deliveryOintment deliveryPolymer sciencePolyphosphazene

Disclosed are polyphosphazenes of Formula 1 showing a sol-gel behavior with a temperature change, a preparation method thereof, and injectable thermosensitive polyphosphazene hydrogels using the same

Owner:KOREA INST OF SCI & TECH

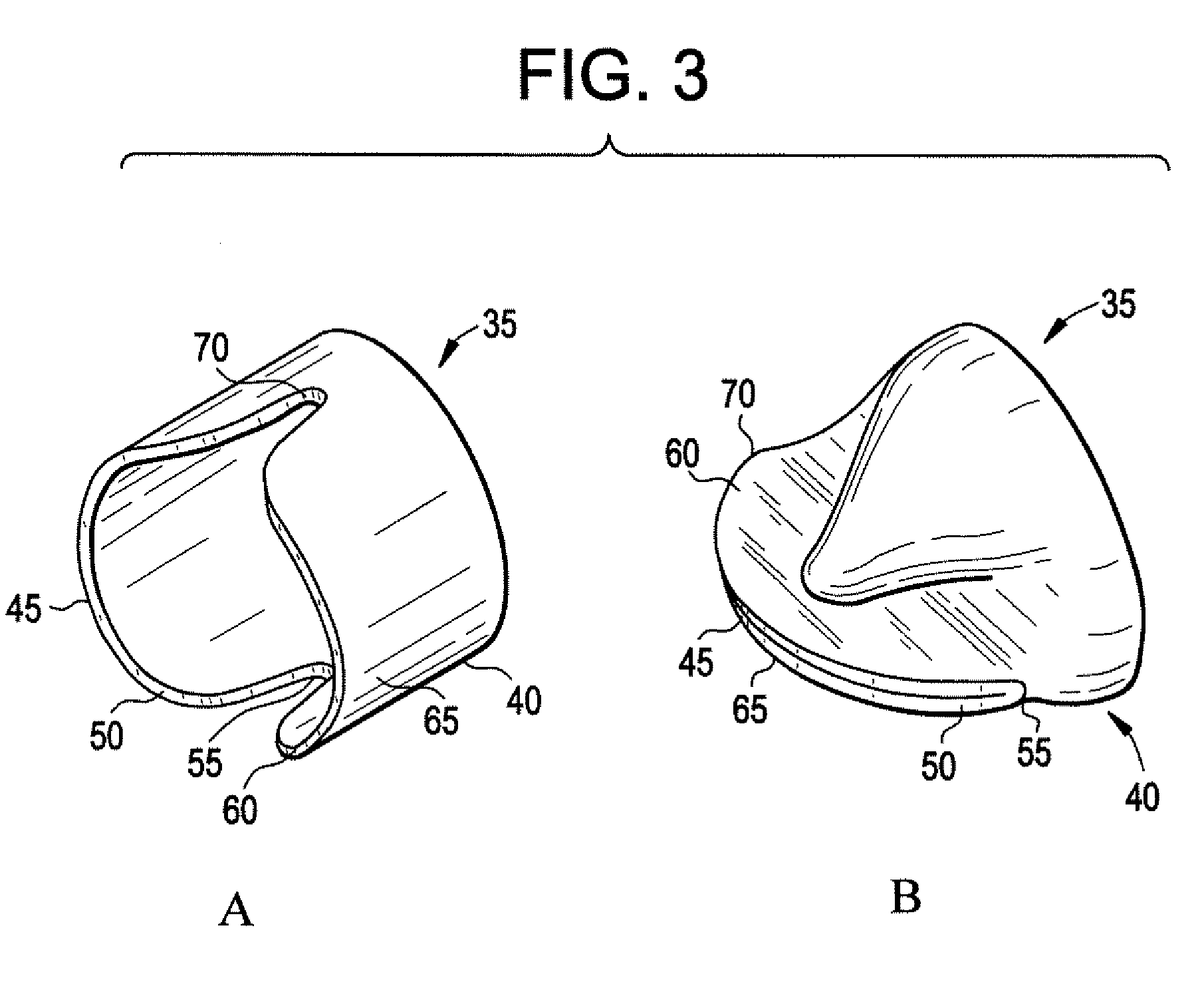

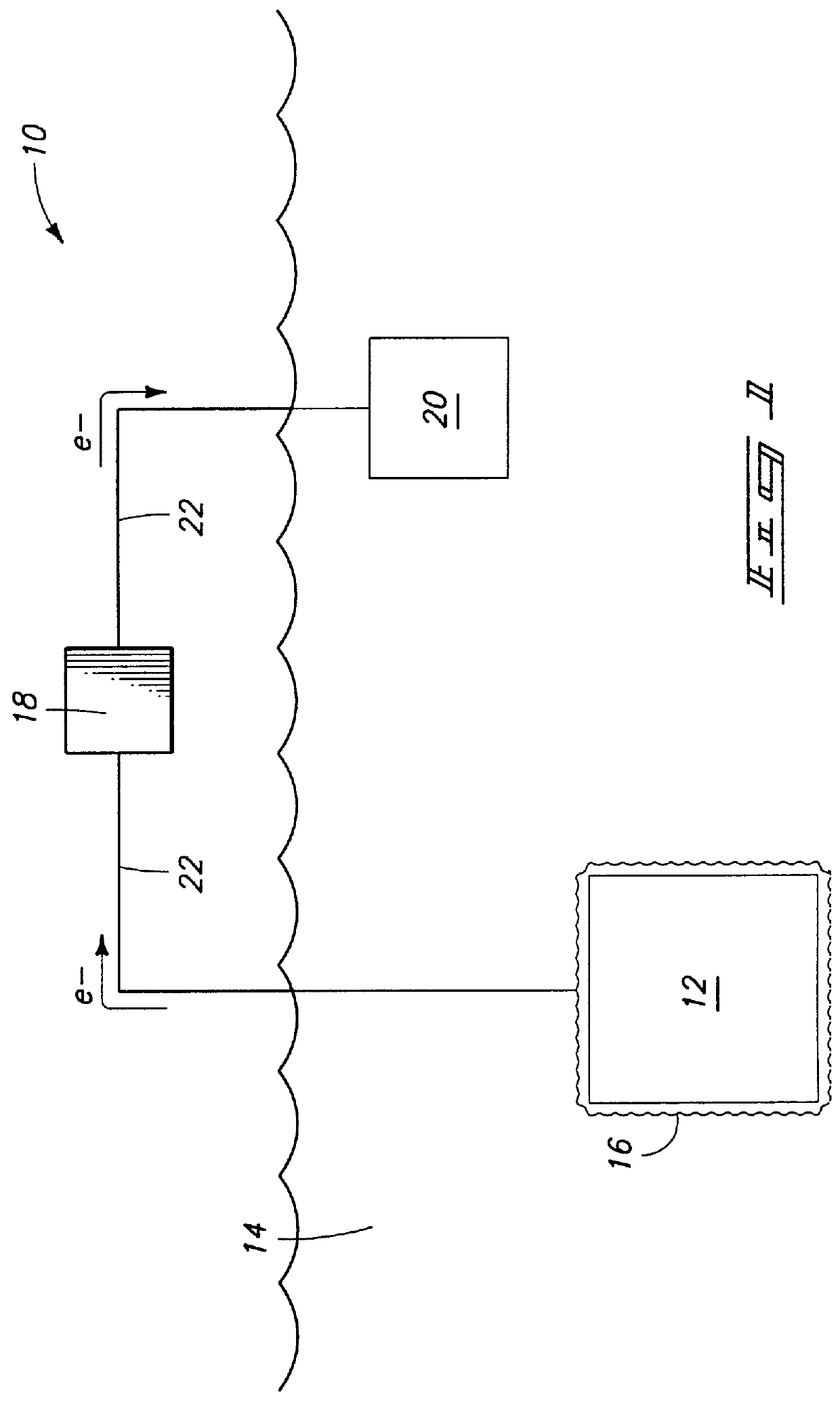

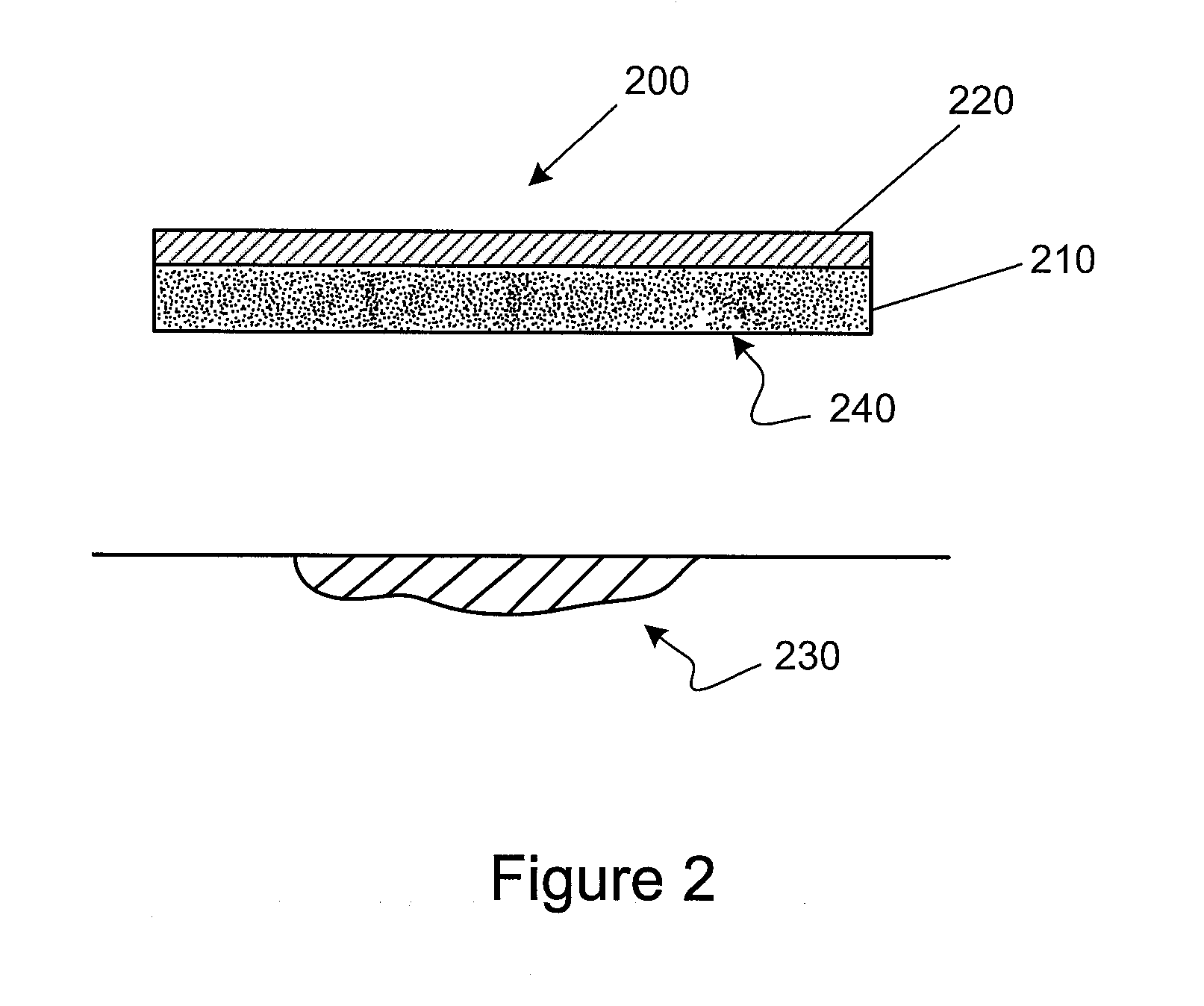

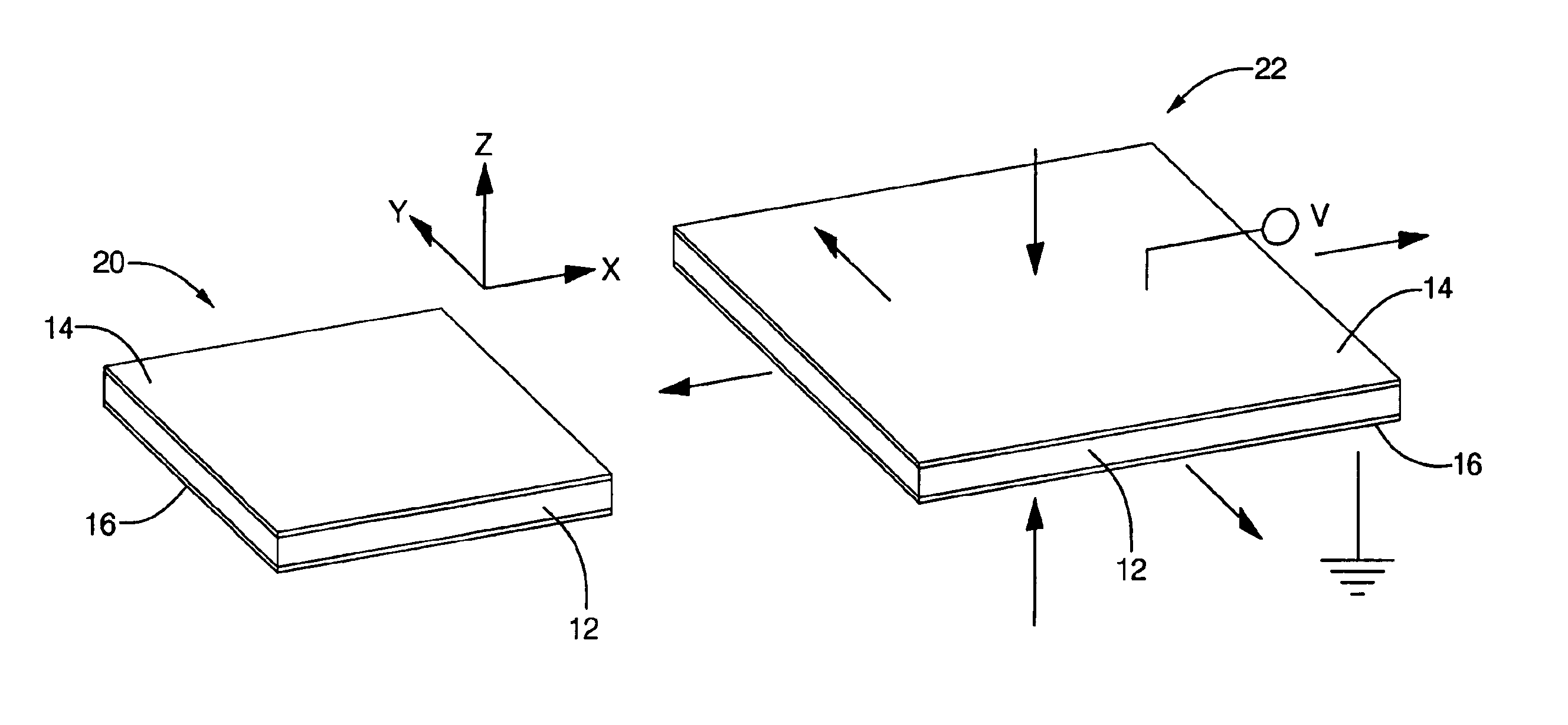

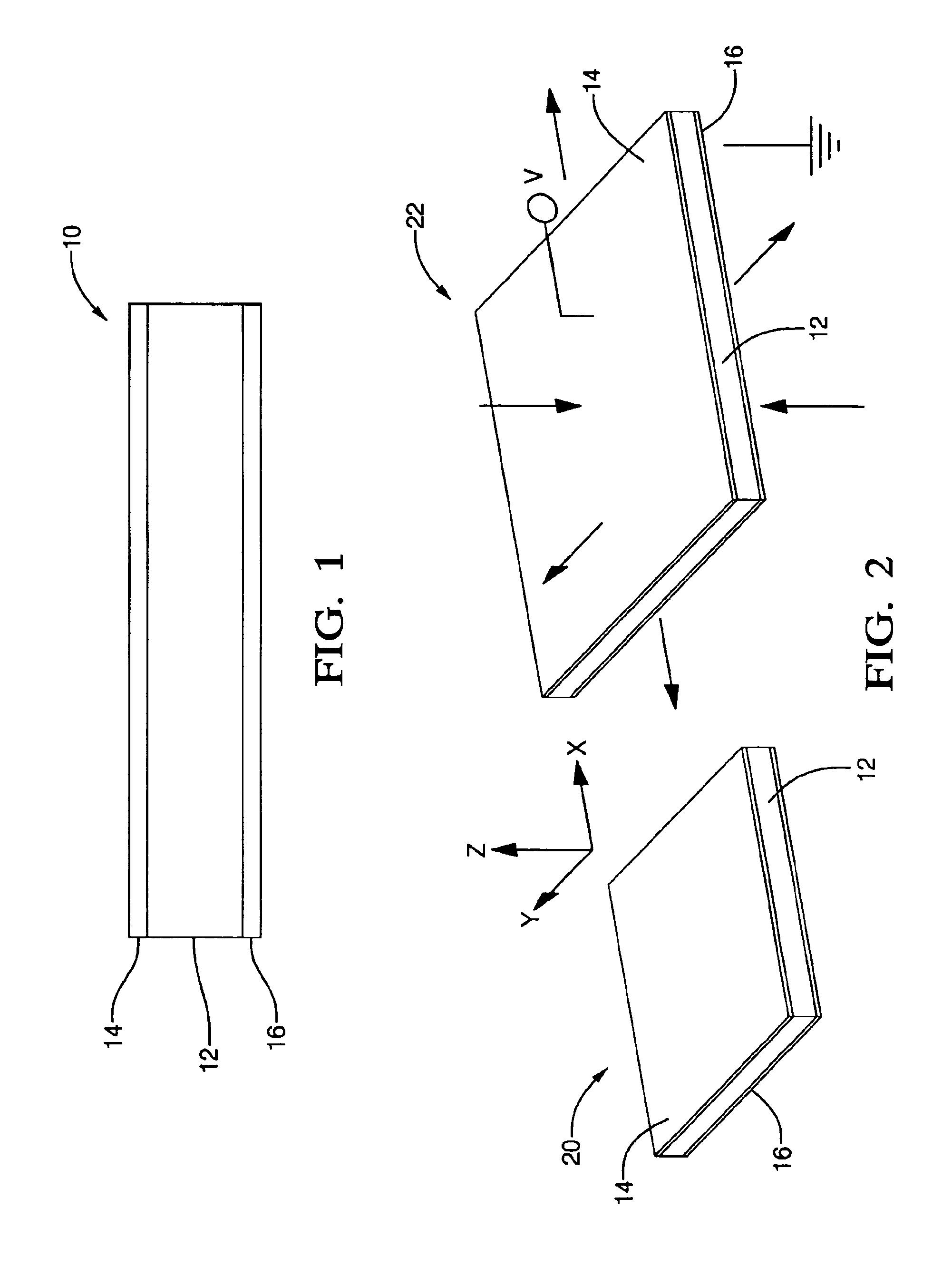

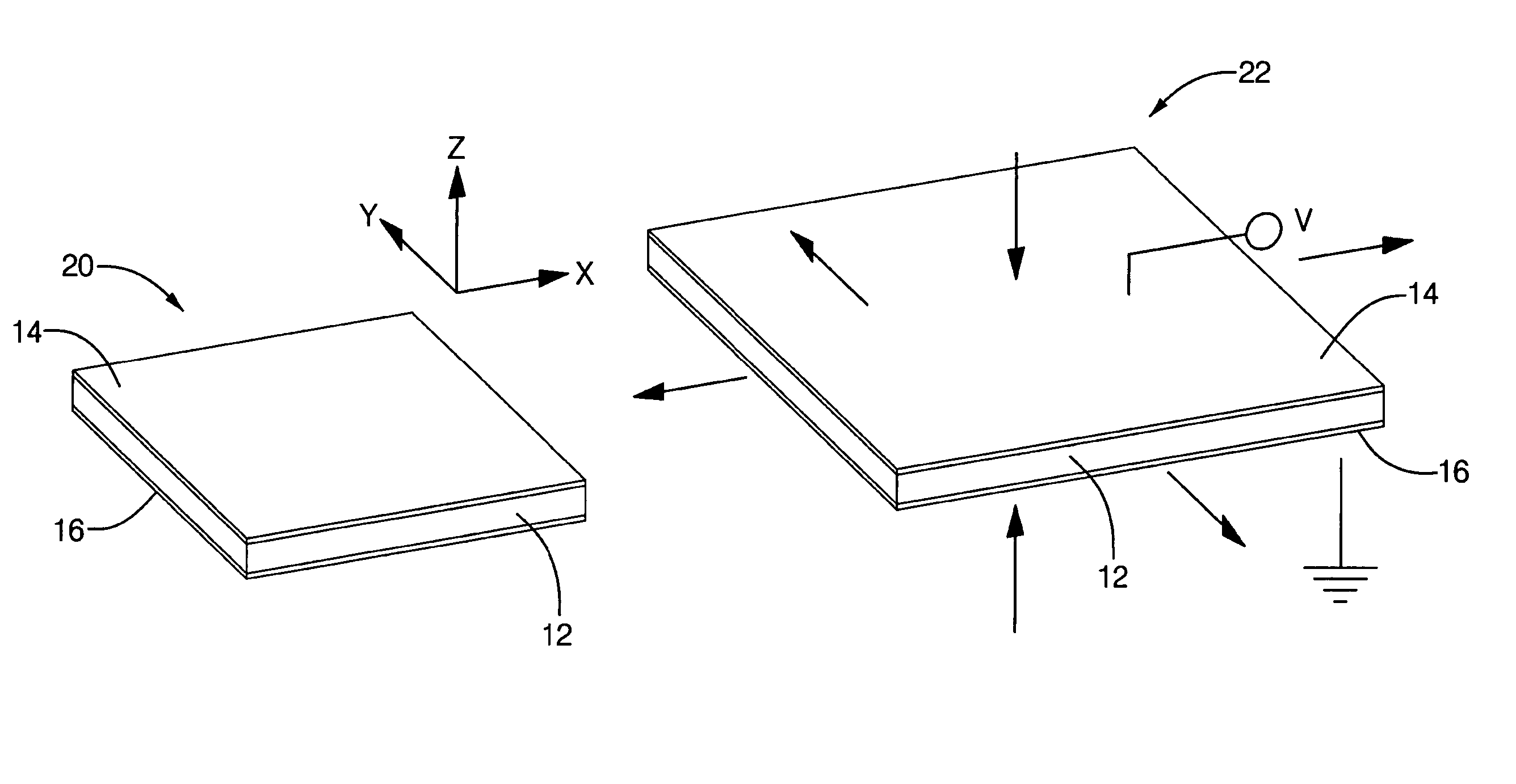

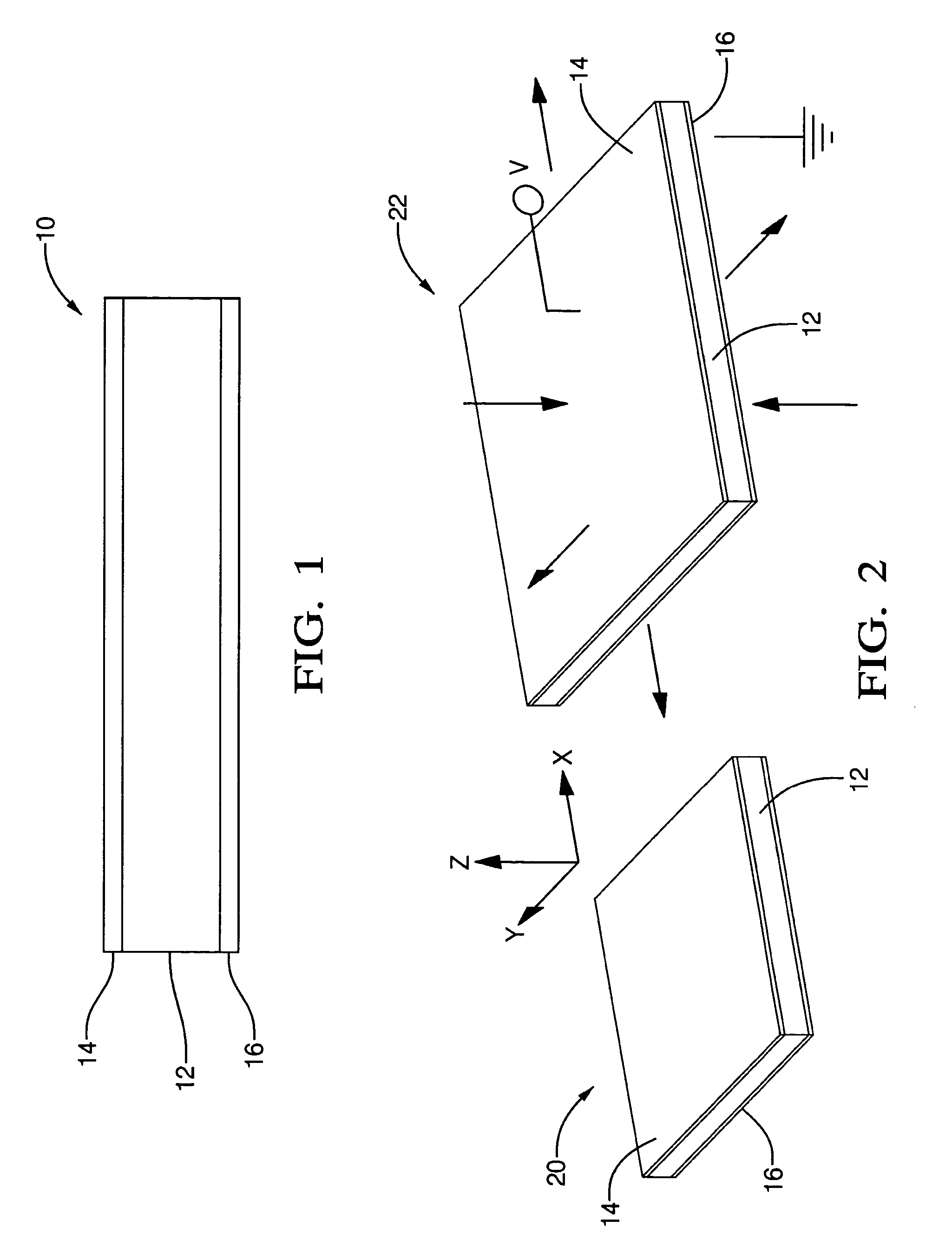

Elastomeric polyphosphazene transducers, methods of making, and methods of use thereof

InactiveUS6876125B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElastomerPolyphosphazene

This disclosure relates to transducers, methods of making transducers and methods of converting between electrical energy and mechanical energy. The transducers comprise an elastomeric film disposed between two electrodes wherein at least one electrode can be a compliant electrode. The elastomeric film comprises a polyphosphazene.

Owner:STRATTEC POWER ACCESS

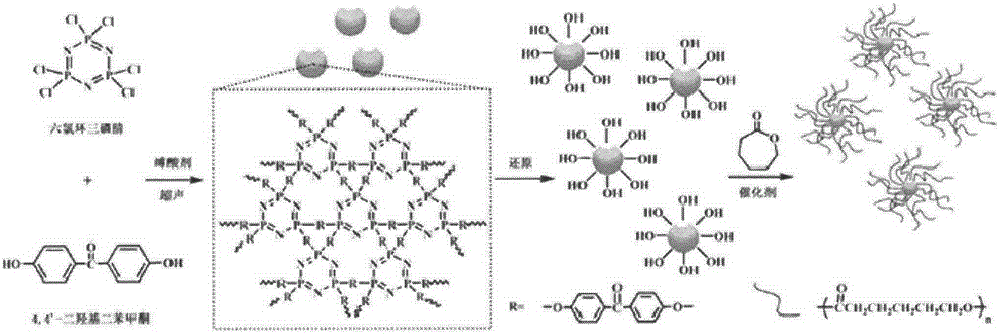

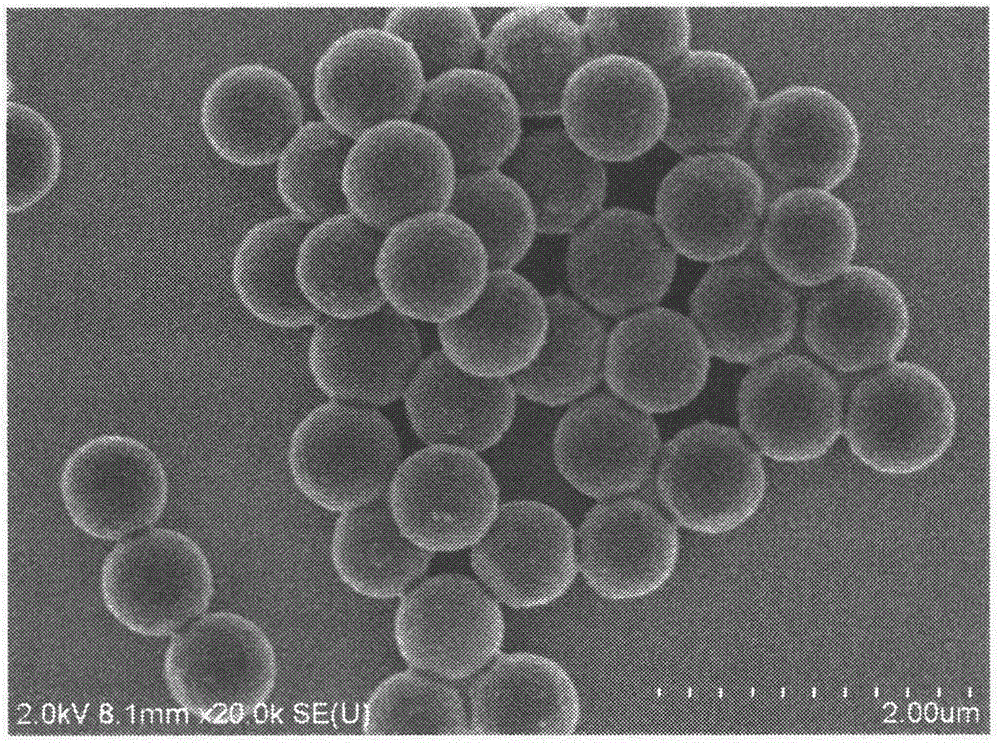

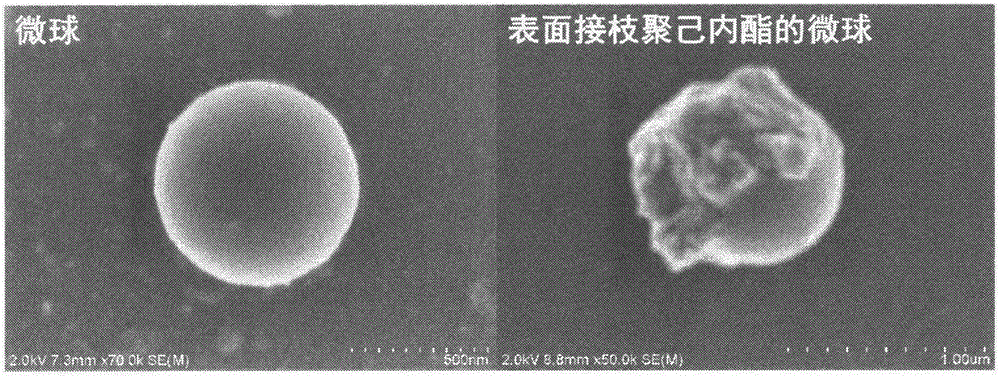

Polyphosphazene microsphere-based phenolic resin molding plastic additive and preparation method thereof

The invention provides a polyphosphazene microsphere-based phenolic resin molding plastic additive and a preparation method thereof, and belongs to the technical field of preparation of phenolic resin molding plastic additivs. The preparation method of the phenolic resin molding plastic additive comprises the following steps: 1, carrying out a condensation polymerization reaction on phosphonitrilic chloride trimer and 4,4'-dihydroxybenzophenone in an organic solvent in the presence of an acid binding agent to obtain a solution; 2, separating a solid product from the solution to obtain microspheres; 3, reducing the microspheres under certain conditions to obtain microspheres with surfaces containing hydroxyl groups; and 4, grafting the surfaces of the microspheres with polycaprolactone under certain conditions to modify the microspheres in order to obtain microspheres with polycaprolactone grafted surfaces. The phenolic resin molding plastic additive has a highly crosslinked polyphosphazene and a smooth polycaprolactone shell, has strong bonding force to the phenolic resin matrix, and can improve the impact strength, the tensile strength, the heat resistance and the flame resistance of phenolic resin molding plastics.

Owner:JIANGNAN UNIV +1

Elastomeric polyphosphazene transducers, methods of making, and methods of use thereof

InactiveUS20050046313A1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionPolyphosphazeneTransducer

This disclosure relates to transducers, methods of making transducers and methods of converting between electrical energy and mechanical energy. The transducers comprise an elastomeric film disposed between two electrodes wherein at least one electrode can be a compliant electrode. The elastomeric film comprises a polyphosphazene.

Owner:STRATTEC POWER ACCESS

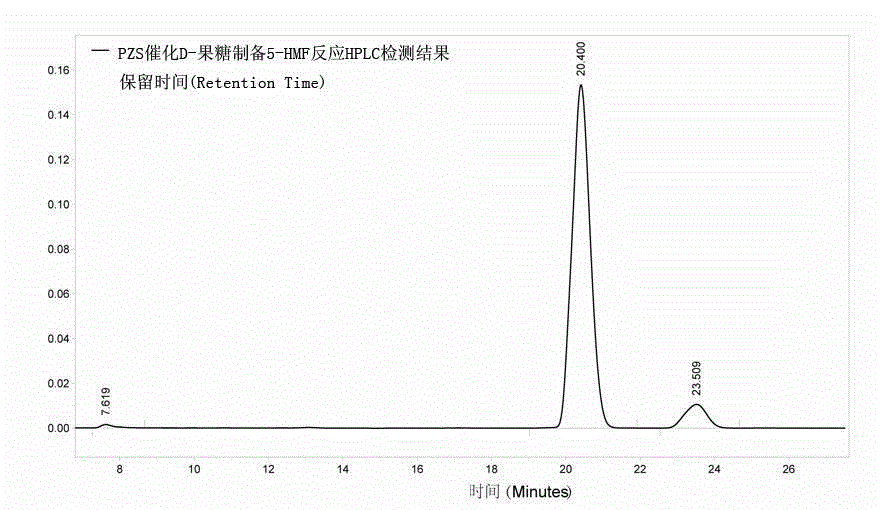

Method for preparing 5-hydroxymethylfurfural

InactiveCN102911142AImprove conversion rateHigh selectivityOrganic chemistryPtru catalystFuraldehyde

The invention belongs to the technical field of productions of chemical products, in particular to a method for preparing 5-hydroxymethylfurfural. The method includes steps of taking a macromolecular polyphosphazene polymer matrix as a solid acid type heterogeneous catalyst, taking monosaccharide, disaccharide or polysaccharide as raw materials, reacting for 5minutes to 24 hours in single-component solvent or double-component solvent such as dimethyl sulfoxide, acetonitrile, methyl isobutyl ketone, water and the like at the temperature of 25-120 DEG C under normal pressure, and finally producing the 5-hydroxymethylfurfural efficiently. The method has the advantages that conversion efficiency of raw material is high, HMF selectivity is good, operation conditions are mild, reaction speed is high, the processing is simple and environment-friendly, the catalyst is easy to prepare and the like, corrosion to equipment and environment pollution due to common liquid strong-acid homogenous catalysts are avoided, and a new way is developed for preparing commodity chemicals and substitute fuels according to regenerative biological resources.

Owner:FUDAN UNIV

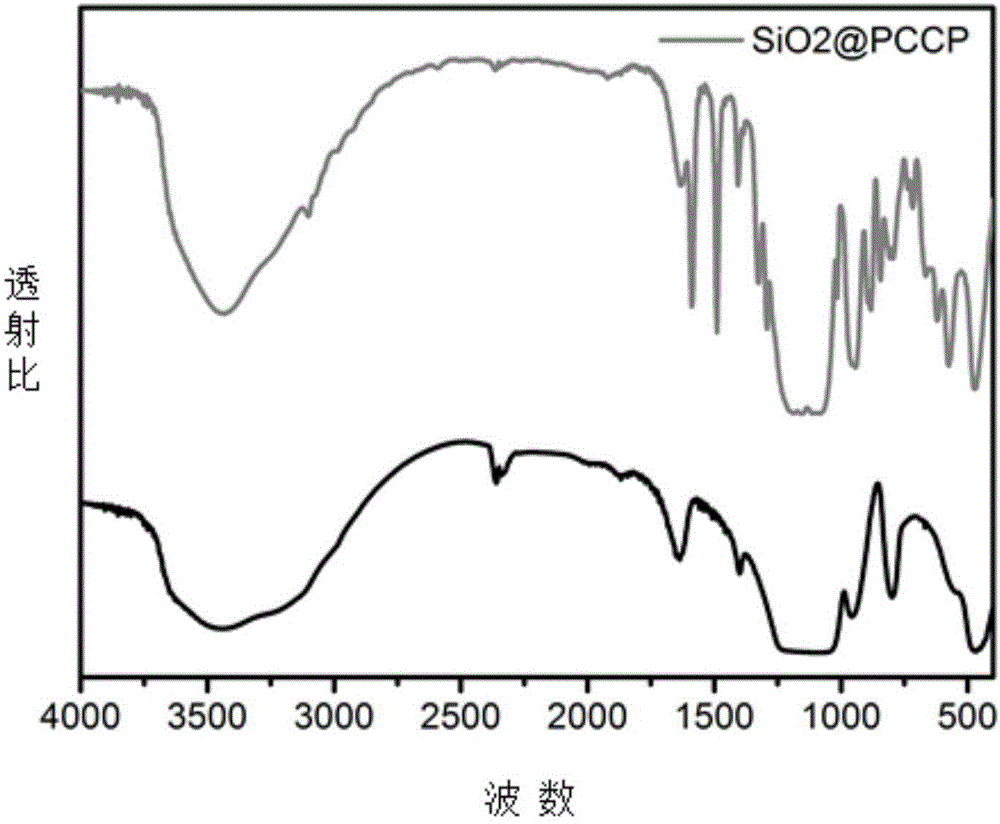

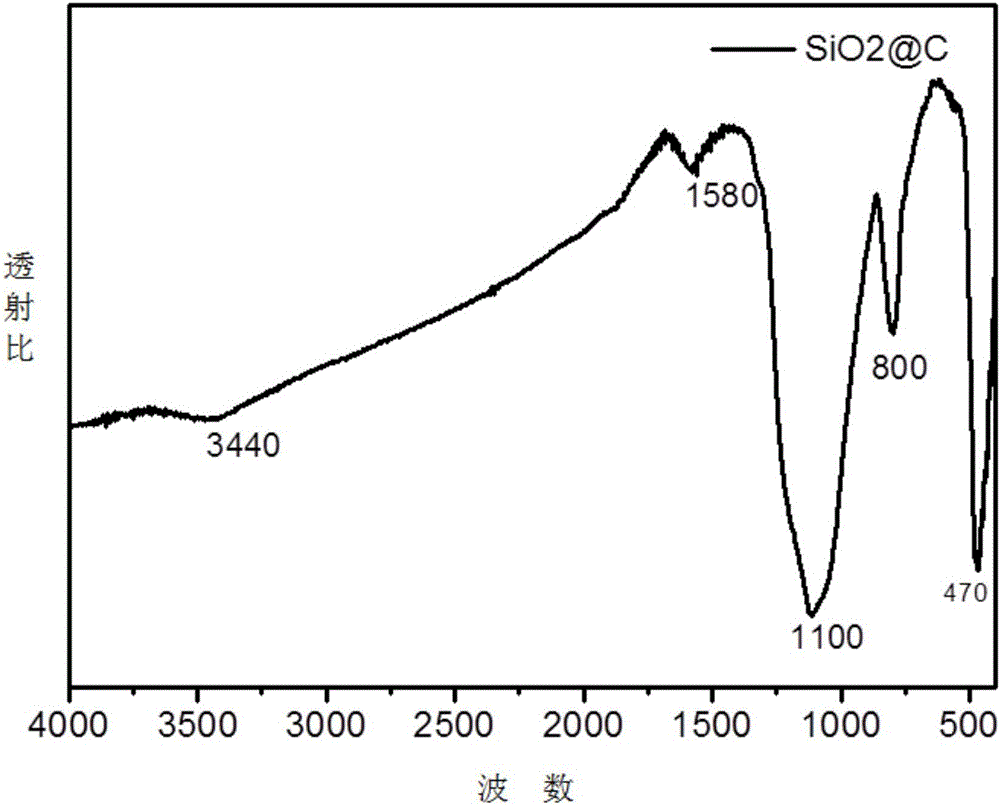

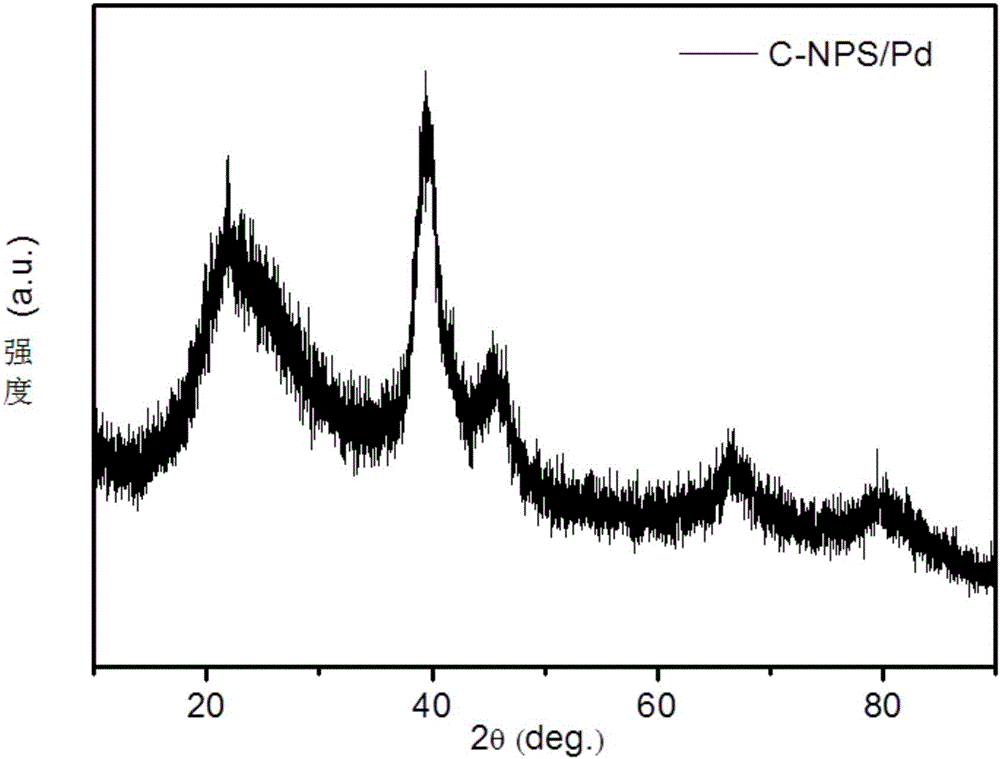

Heteroatom doped hollow carbon sphere material loaded precious metal nano particle and preparation thereof

ActiveCN106006549ASimple manufacturing processSuitable for large-scale productionMaterial nanotechnologyCell electrodesEtchingPolyphosphazene

The invention relates to a heteroatom doped hollow carbon sphere material loaded precious metal nano particle and preparation thereof. The preparation comprises the following steps that firstly, heteroatom doped hollow carbon spheres are prepared, wherein 1-1, silicon dioxide serves as a template, comonomer phosphonitrilic chloride trimer and 4,4-dyhydroxyl bi-phenol are added, a polymerization reaction is carried out, and polyphosphazene wrapping silicon dioxide is generated; 1-2, the polyphosphazene wrapping silicon dioxide is calcined, and heteroatom doped carbon spheres with silicon dioxide as cores are obtained; 1-3, ultrasonic etching continues to be carried out, and after washing and drying, the heteroatom doped hollow carbon spheres are obtained; secondly, the prepared heteroatom doped hollow carbon spheres are dispersed into water, a precious metal precursor and a complexing agent are added, pH is adjusted to be 8-14, a reducing agent is added, stirring is carried out for a reaction, and after drying, the target product is obtained. Compared with the prior art, the catalyst has good electrocatalytic activity and electrochemical stability, and the preparation process is simple.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

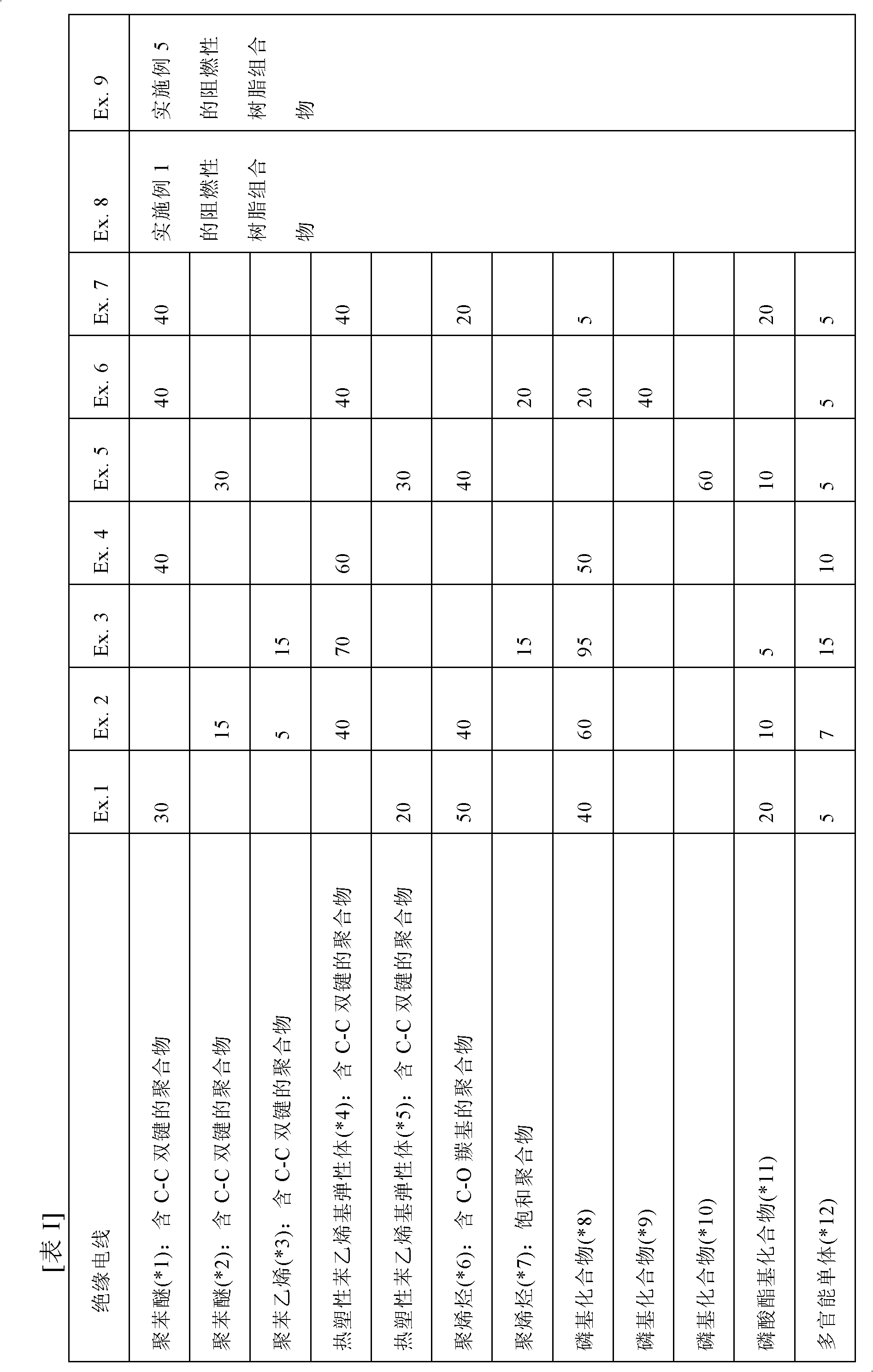

Flame-retardant resin composition, and insulated electric wire, flat cable, and molded article, which are made using same

InactiveCN102575106AImprove heat resistanceRubber insulatorsPlastic/resin/waxes insulatorsElectrical conductorPolyphosphazene

Owner:SUMITOMO ELECTRIC IND LTD

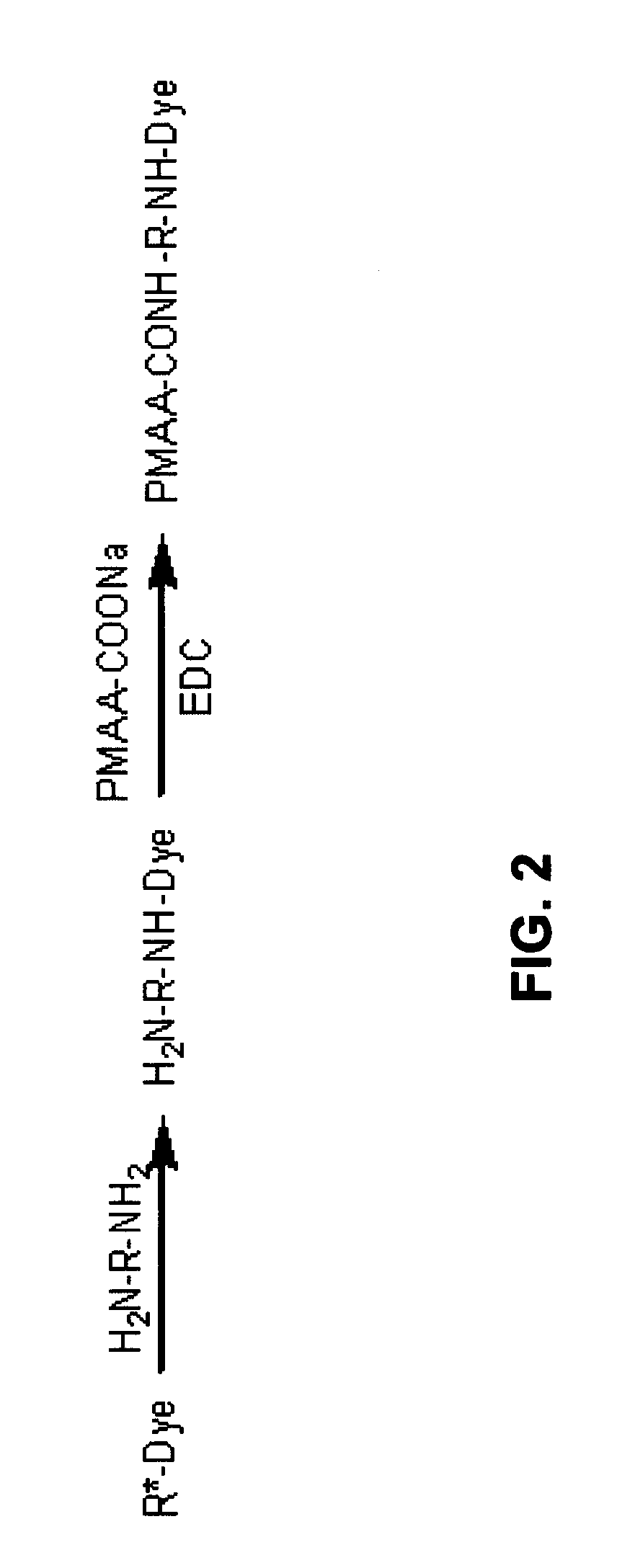

Color-Coded Polymeric Particles of Predetermined Size for Therapeutic and/or Diagnostic Applications and Related Methods

InactiveUS20100028260A1Minimizes probabilityPowder deliveryGenetic material ingredientsPolyphosphazeneMedicine

Various embodiments are directed to color-coded and size-calibrated polymeric particles comprising an acrylate-based hydrogel core incorporating one or more chromophores of interest, and an outer shell comprising polyphosphazenes of formula I, useful for various therapeutic and / or diagnostic procedures. In various embodiments, the color-coded and size-calibrated polymeric particles can be employed in any particle-mediated procedure, including as embolic agents, dermal fillers, and various implantable devices for a broad range of clinical and cosmetic applications. The incorporation of a particular chromophore formulation that correlates with a pre-determined size specificity for implantable and loadable polymeric particles (“color-coded and size-calibrated”) enables the visual detection and identification of particles exhibiting a particular size of interest, and minimizes the probability of user-introduced or procedural errors.

Owner:VARIAN MEDICAL SYSTEMS

Preparation method of self-crosslinked phosphazene elastomer

The invention discloses a preparation method of a self-crosslinked phosphazene elastomer. Crosslinking of the polyphosphazene is realized via heating, adding of cross-linking agent is not needed, and mechanical properties and thermal properties of an obtained crosslinked product are excellent. According to the preparation method, a substituent group with terminal hydroxyl groups is mixed with alkoxy, phenoxyl, and the like so as to take the place of polydichlorophosphazene, the phosphazene elastomer capable of realizing crosslinking is obtained, and dehydration reaction of crosslinking points is realized via heating and drying so as to form crosslink bonds. When the phosphazene elastomer is dried at 100 DEG C for 24h, self-crosslinking can be realized, and mechanical properties of the linear phosphazene elastomer are improved greatly, product thermal stability is improved, and the initial thermal decomposition temperature can be increased by 30 to 50 DEG C. The phosphazene elastomer is capable of realizing crosslinking in drying processes, and the crosslinking method of the phosphazene elastomer is simple, so that crosslinking difficulty and crosslinking cost of linear substituted polyphosphazene are reduced greatly, and the preparation method possesses significant importance on scale production of phosphazene derivative elastomer materials.

Owner:BEIJING UNIV OF CHEM TECH

Electrolyte

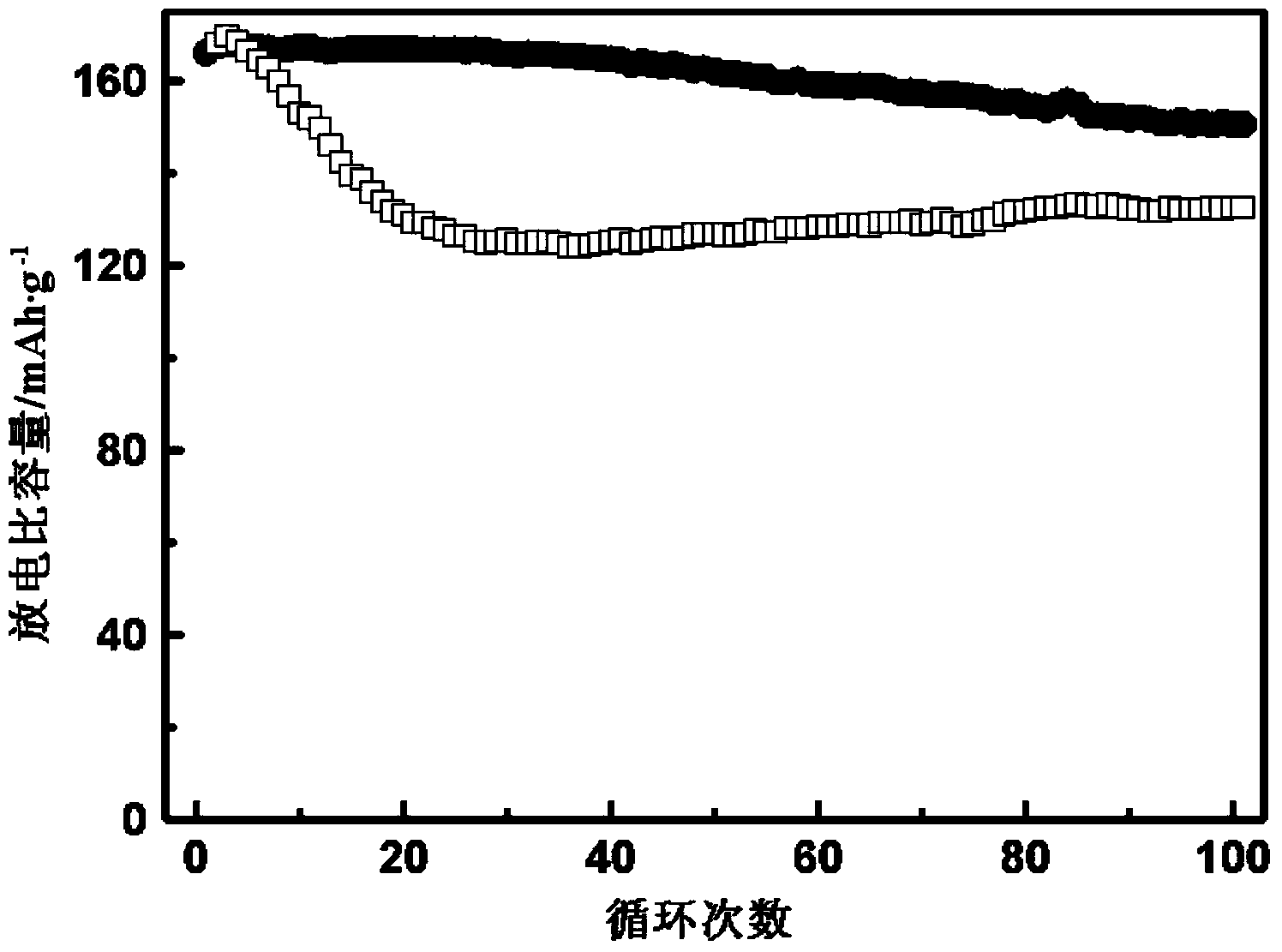

ActiveCN103762380AReduce oxidative decompositionGood chemical stabilitySecondary cellsSide chainLithium-ion battery

The invention provides an electrolyte which comprises a non-aqueous organic solvent, lithium salt and a polyphosphazene compound. According to the application, the side chain of the polyphosphazene compound added into the electrolyte is a long-chain group containing O, N or S and other heteroatom, so a compact high lithium ion conductive coating layer is formed on the surface of a cathode material of a lithium ion battery, therefore, the direct contact of the electrolyte and the cathode material is effectively inhibited; the oxygenolysis of the electrolyte is reduced; the circularity of the high voltage lithium ion battery is improved; meanwhile, the additive polyphosphazene compound has a flame-retardant property, so that the flammability of the electrolyte is lowered; the safety performance of the battery is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

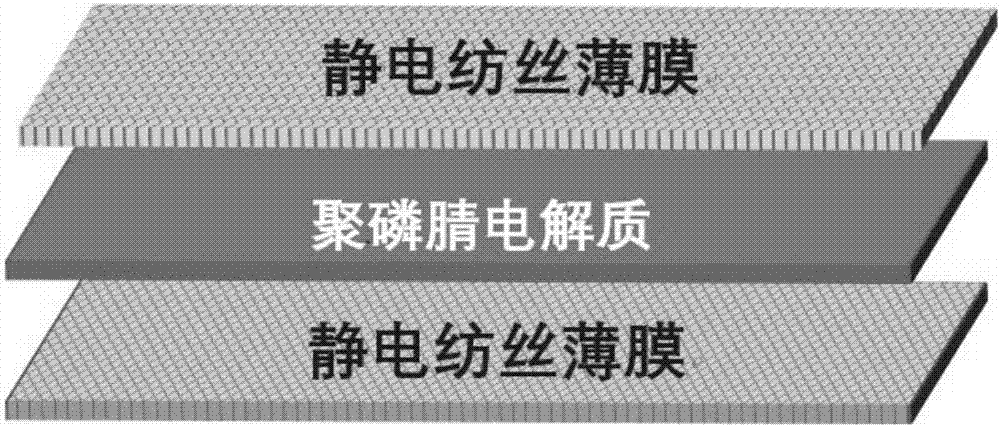

Solid electrolyte with double conducting ion networks and preparation method of solid electrolyte

ActiveCN106898811AImprove mechanical propertiesImprove film formationSolid electrolytesSecondary cellsSolid state electrolytePolyphosphazene

The invention relates to solid electrolyte with double conducting ion networks and a preparation method of the solid electrolyte, and solves the technical problem that existing polyphosphazene solid electrolyte is poor in mechanical property and low in conductivity. The solid electrolyte consists of a porous film and a polyphosphazene electrolyte material, wherein the porous film consists of a polymer, inorganic solid electrolyte and lithium salt; the porous film is a framework of the polyphosphazene electrolyte; and the polyphosphazene electrolyte is a carrier of lithium ions. The invention simultaneously provides a preparation method of the solid electrolyte. The solid electrolyte can be widely used in the field of preparation of the electrolyte.

Owner:BEIJING UNIV OF CHEM TECH

Interface modified carbon fiber/resin matrix composite material and preparation method thereof

The invention discloses an interface enhanced modification method of a carbon fiber composite material. Specifically, the method disclosed by the invention comprises the steps of connecting hexachlorocyclotriphosphazene on the surface of carbon fiber, and performing in-situ polymerization and grafting of polyphosphazene to obtain modified carbon fiber with active groups on the surface. Therefore, the number of interface chemical bonds of the carbon fiber and resin matrix composite material is increased, so that the interface performances of the carbon fiber and resin matrix composite material are significantly improved. The invention further provides the carbon fiber prepared on the basis of the method, a composite material prepared by using the carbon fiber, and a product prepared by using the composite material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

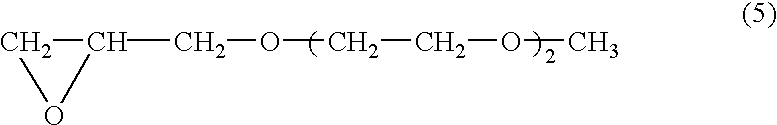

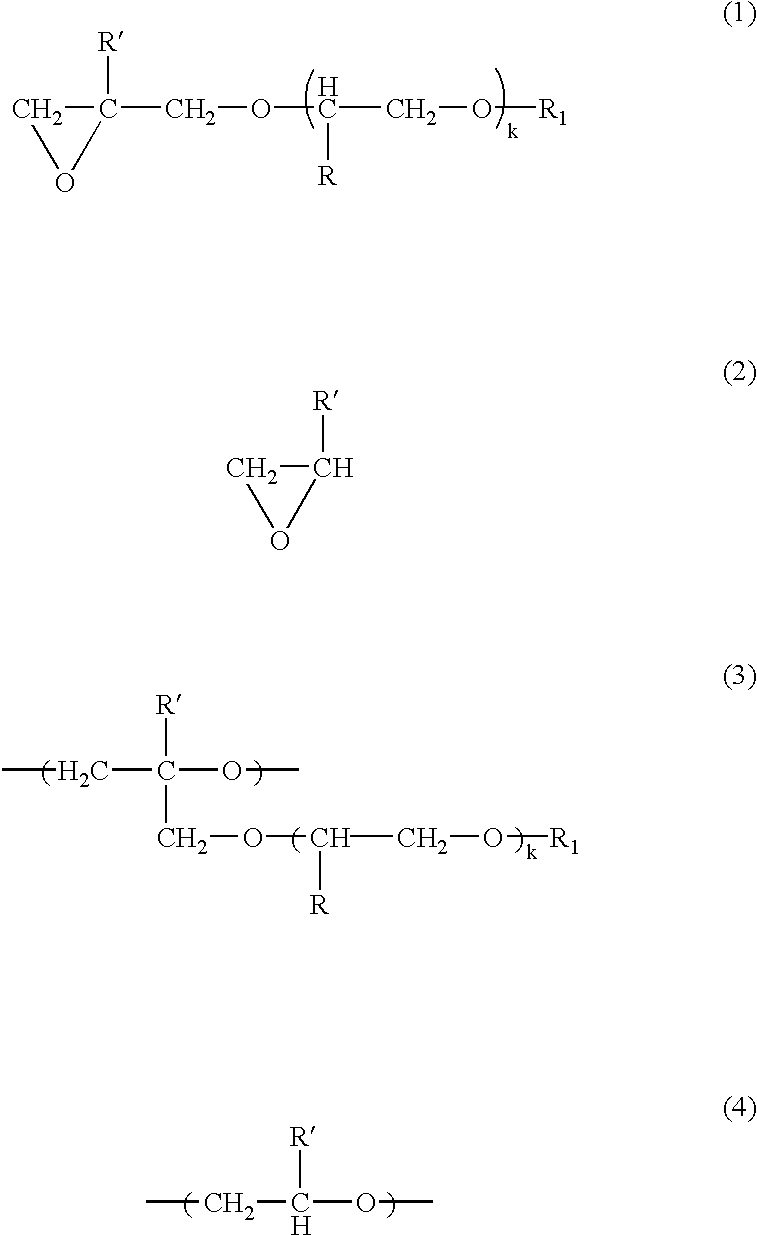

Thermosensitive poly (organophosphazenes), preparation method thereof and injectable thermosensitive polyphosphazene hydrogels using the same

Disclosed are polyphosphazenes of Formula 1 showing a sol-gel behavior with a temperature change, a preparation method thereof, and injectable thermosensitive polyphosphazene hydrogels using the same.

Owner:KOREA INST OF SCI & TECH

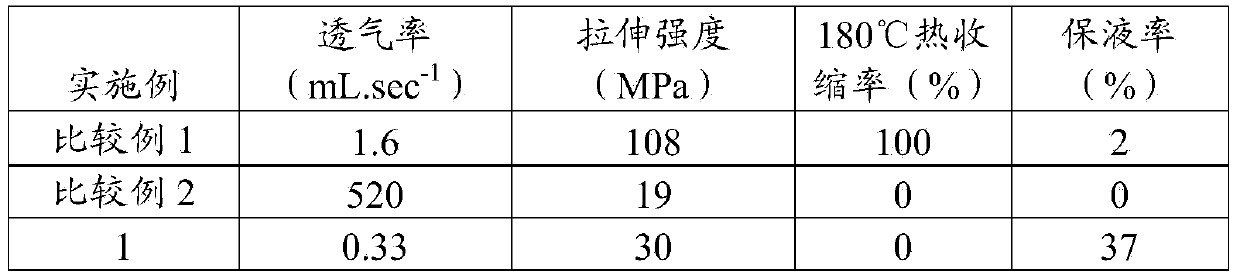

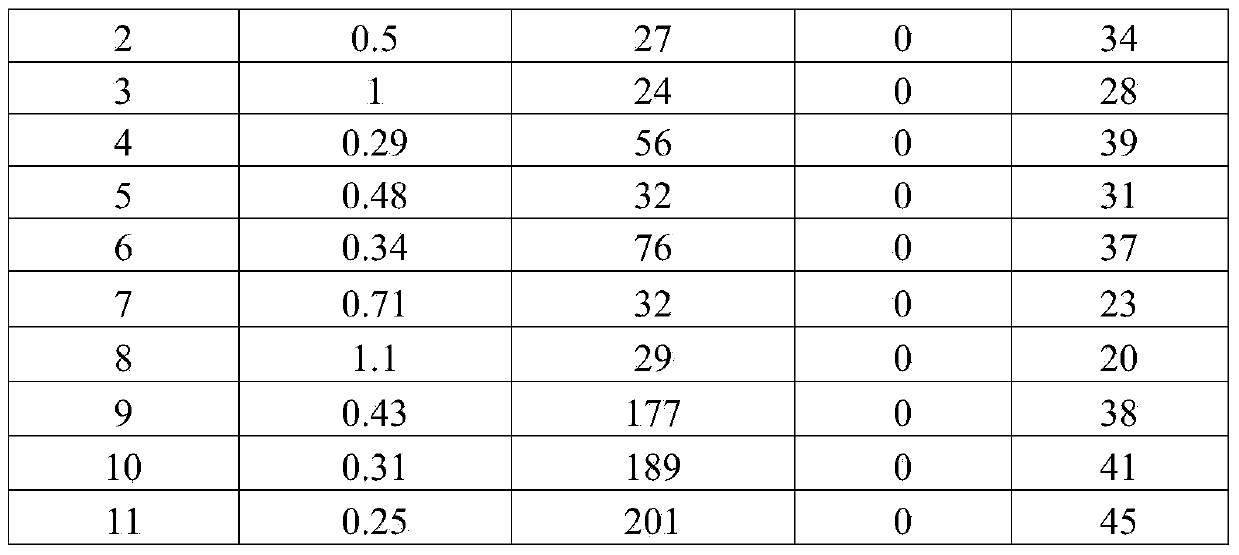

Porous diaphragm, preparation method of porous diaphragm as well as lithium ion battery

ActiveCN104051687AImprove heat resistanceAvoid explosionSecondary cellsCell component detailsHigh surfaceLithium-ion battery

The invention provides a porous diaphragm. The porous diaphragm is made of a heat-resisting polymer, wherein the heat-resisting polymer comprising one or more of polyphosphazene, polysulfone, polyether sulfone, polyether ether ketone, polyether amide and polyacrylonitrile. The porous diaphragm provided by the invention has relatively high surface energy, so that the porous diaphragm has favorable wettability, and has good interaction with electrolyte, so that the liquid retention rate of the lithium ion battery diaphragm is improved, and the development of the battery cycle performance is facilitated. The invention also provides a preparation method of the porous diaphragm. According to the preparation method provided by the invention, the heat-resisting polymer acts as a raw material, and holes are formed by a method of phase conversion and pore forming, so that the porous diaphragm has relatively high surface energy and excellent heat-resisting performance, and meanwhile the hole wall of the diaphragm has curvature, so that the micro short circuit of the lithium ion battery and self discharge can be avoided, and the liquid leakage phenomenon can be relieved. The invention also provides the lithium ion battery, and the porous diaphragm provided by the invention is a battery diaphragm.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

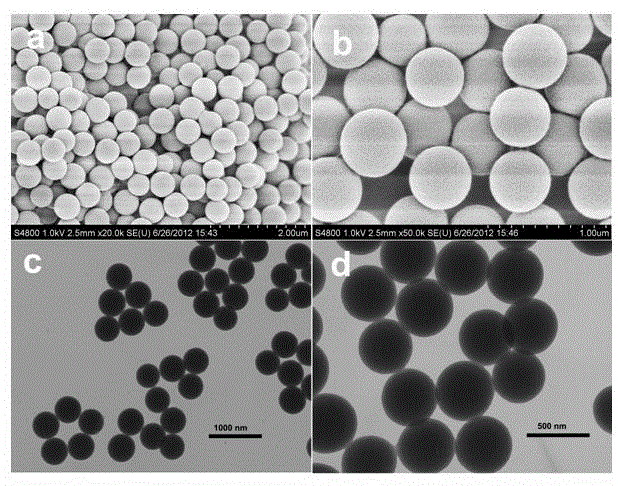

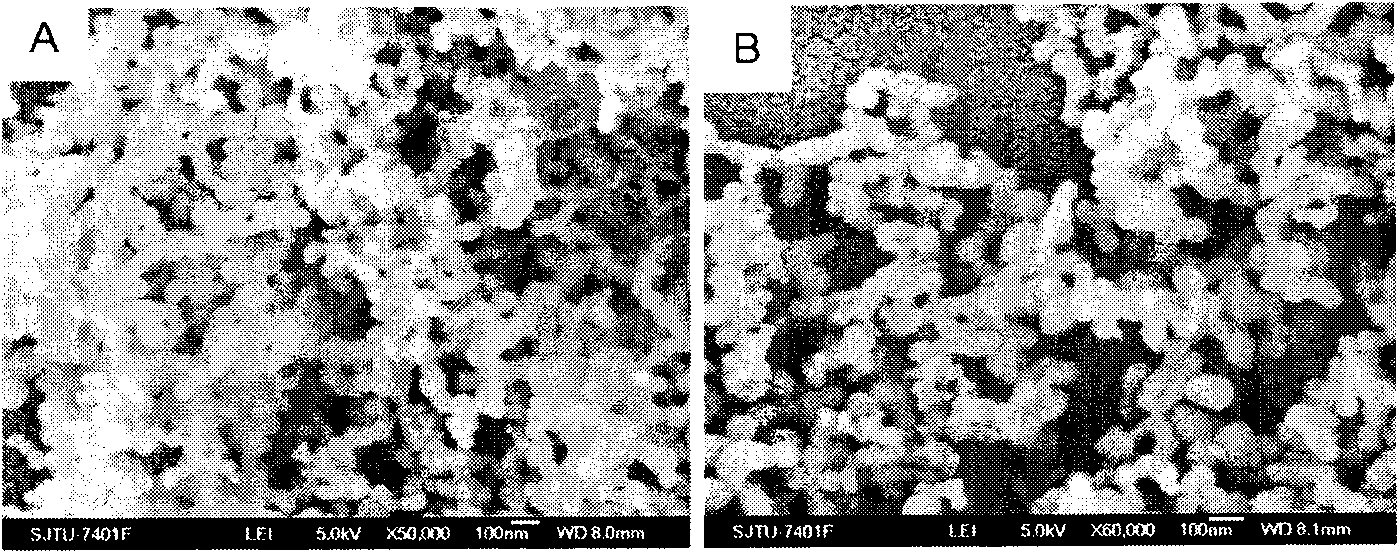

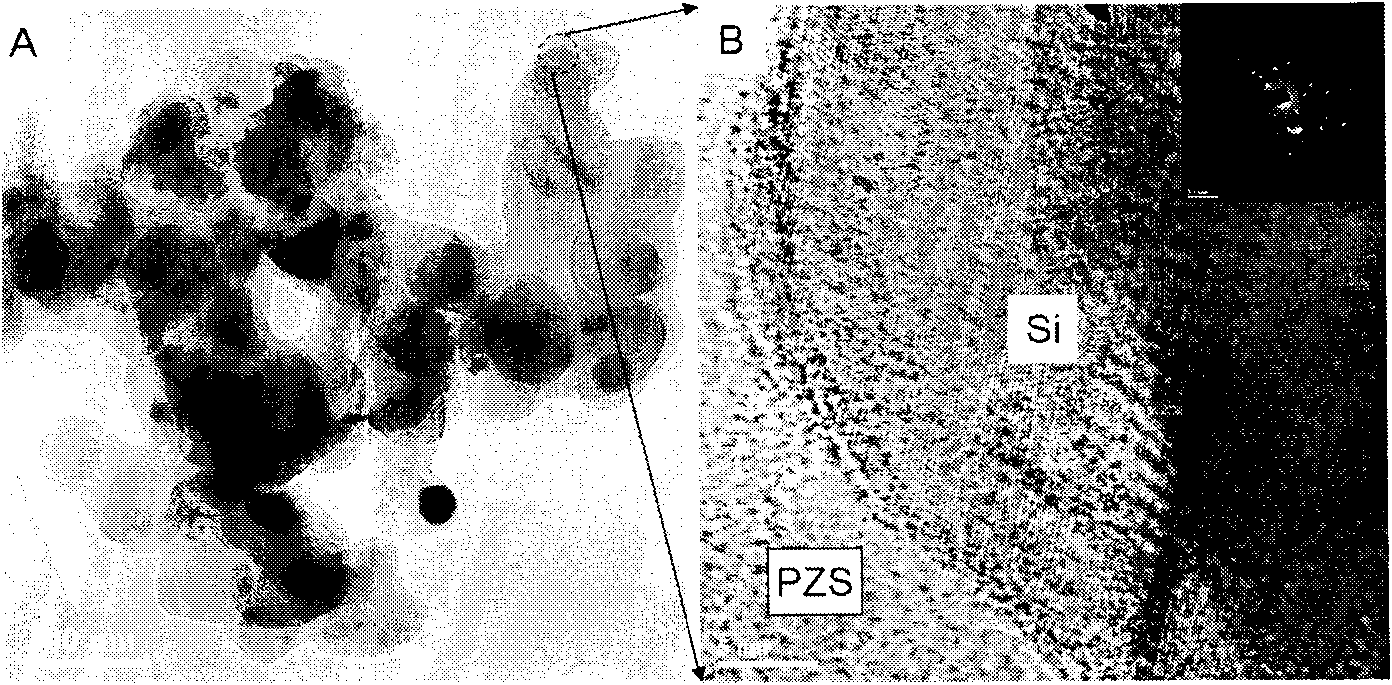

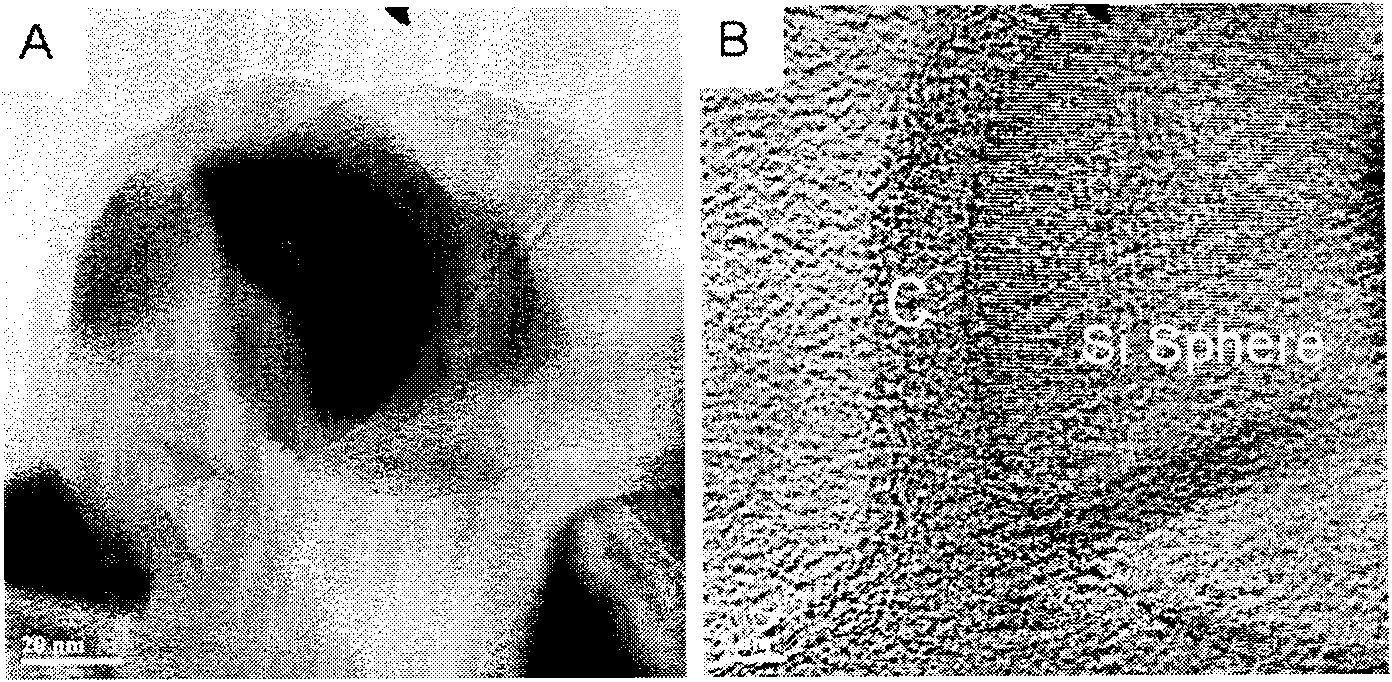

Preparation method of silicon/porous carbon nano-composite particle

InactiveCN101632913ATightly boundSimple preparation processMicroballoon preparationMicrocapsule preparationMicrospherePorous carbon

The invention discloses a preparation method of a silicon / porous carbon nano-composite particle, comprising the following steps: dispersing silica beads, hexachlorocyclotriphosphazene and 4,4'-dihydroxydiphenylsulfone into an organic solvent under an ultrasound condition, then adding triethylamine, an acid binding agent, into the solvent for ultrasonic reaction at a temperature of 20-40 DEG C for 6-10h, and after the reaction, obtaining a core-shell structured silicon / polyphosphazene nano-composite particle through the processes of centrifugal separation, washing and vacuum drying; transferring the obtained silicon / polyphosphazene nano-composite particle into a quartz tube type carbonizing plant, under the protection of inert atmosphere, heating up the plant at a rate of 1-5 DEG C / min and insulating the plant at a temperature of 600 DEG C for 2h, then continuing heating up the plant at a rate of 1-5 DEG C / min to a preset temperature of 700-1000 DEG C and insulating the plant for 5h, then naturally cooling the plant to room temperature, thus obtaining the silicon / porous carbon nano-composite particle. The silicon / porous carbon nano-composite particle has the core-shell structure with the silica beads as the core and the porous carbon as the shell. The specific capacity of lithium-ion batteries using the silicon / porous carbon nano-composite particle as the anode material is higher than 950mAh / g, the initial efficiency thereof reaches 73% and the capacity decrease after 40 cycles is as low as 7.5-38%, therefore, the lithium-ion batteries show higher specific capacity, higher initial efficiency and good cycle stability.

Owner:SHANGHAI JIAO TONG UNIV

Porous film, process for producing the same, and uses thereof

InactiveUS20020160268A1High strengthHigh affinityElectrolytic capacitorsLayered productsVinyl etherPolyolefin

A porous film having high strength, homogeneous porous structure, and excellent affinity for electrolytic solutions and suitable for use as a separator for batteries and capacitors; a process for producing the film; and a battery and capacitor each employing the porous film as a separator. The porous film comprises a resin composition including from 70 to 99.9% by weight of an high molecular weight polyolefin resin and from 0.1 to 30% by weight of a polymer having a polyacrylate, polymethacrylate, poly (ethylene oxide), poly (propylene oxide), poly(ethylene propylene oxide), polyphosphazene, poly(vinyl ether) or polysiloxane structure as or in a main chain and having a chain oligo (alkylene oxide) structure in side chains. The porous film can be obtained by heating and kneading the high molecular weight polyolefin resin and the polymer in a solvent to thereby obtain a kneaded product, forming the kneaded product into a gel-state sheet, rolling and / or stretching the sheet, and then subjecting the sheet to a solvent-removing treatment.

Owner:NITTO DENKO CORP

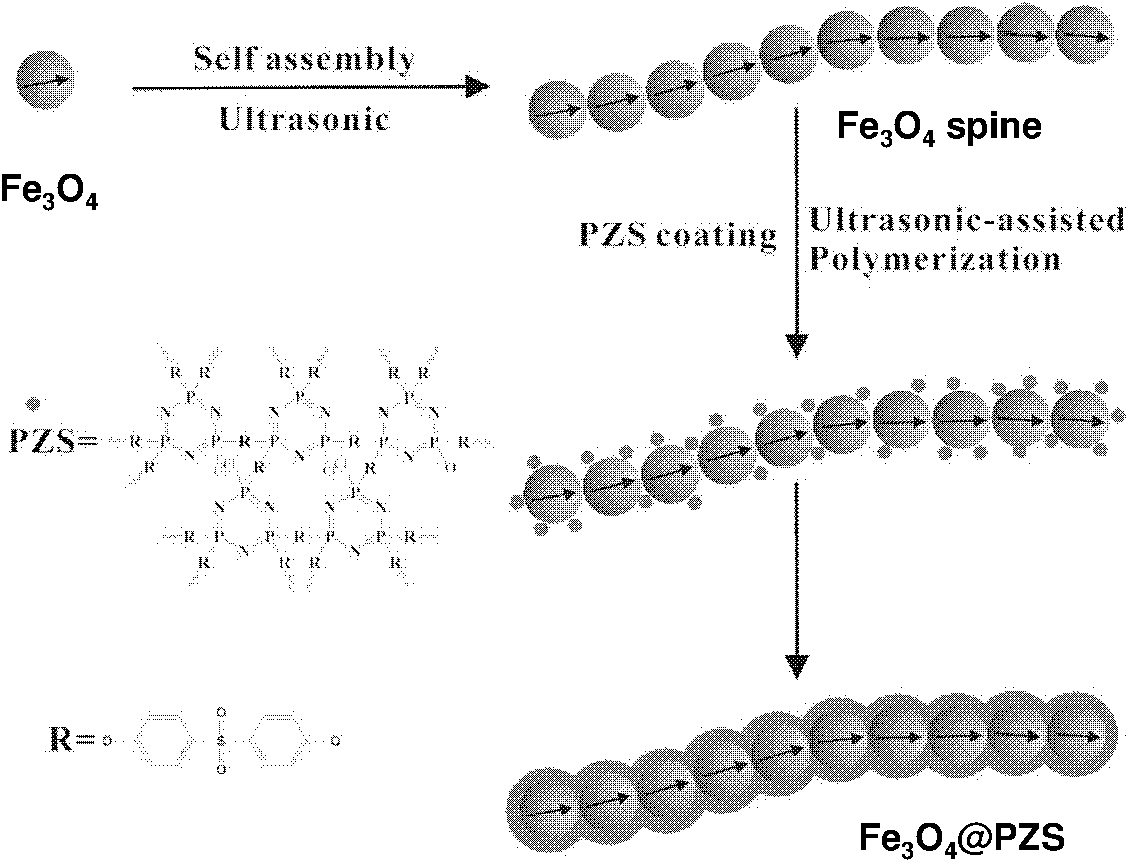

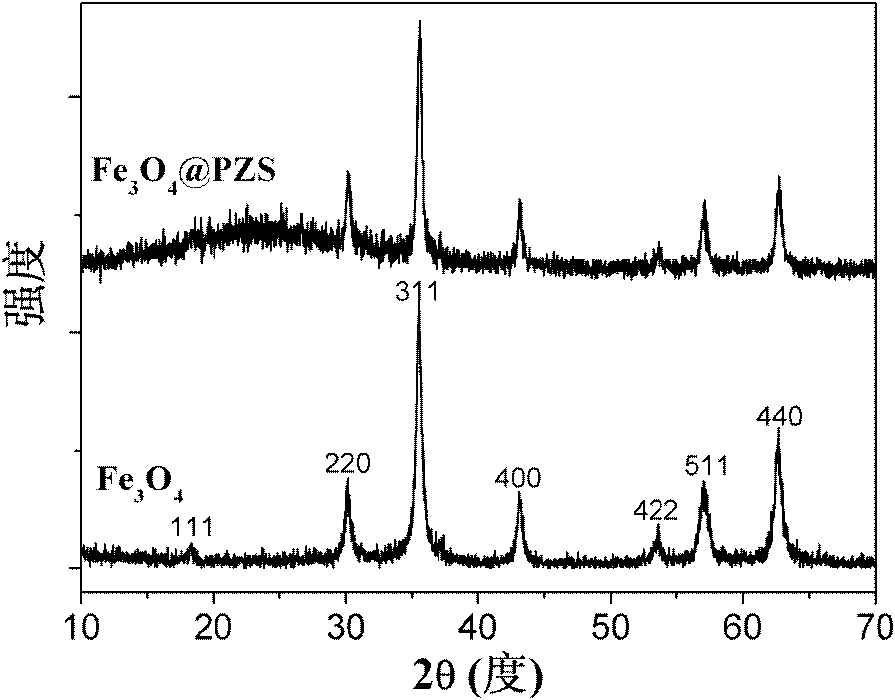

One-dimensional ferroferric oxide magnetic nano chain and preparation method thereof

InactiveCN101885513AThe corresponding strength of the magnetic field is highGood biocompatibilityFerroso-ferric oxidesDispersion stabilityUltrasonic dispersion

The invention relates to a one-dimensional ferroferric oxide magnetic nano chain and a preparation method thereof in the technical field of nanometer. The preparation method comprises the following steps: putting ferroferric oxide nano druses into a mixed solution of absolute ethyl alcohol and tetrahydrofuran for ultrasonic dispersion; respectively adding HCCP and BPS in the solution for further ultrasonic dispersion, and finally adding triethylamine; and preparing the one-dimensional ferroferric oxide magnetic nano chain packed by loop crosslinking type polyphosphazenes after the reaction at room temperature. The one-dimensional magnetic nano material has excellent dispersion stability in water and polar solvents such as ethanol, acetone, tetrahydrofuran and the like, and is convenient for the following-up surface modification and application; simultaneously, compared with the zero dimension ferroferric oxide nano druses, the one-dimensional ferroferric oxide magnetic nano material has high T2 relaxation rate, and excellent biological application value of magnetic separation and magnetic resonance imaging (MRI) and the like.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com