Method for preparing graphene polyphosphazene nano composite material

A technology of nanocomposite materials and olefinic polyphosphazene, which is applied in the field of nanographene functional materials, can solve problems affecting the excellent performance of graphene and structural defects of graphene, and achieve simple reaction operation and process conditions, low cost, and good application Prospects and Effects of Economic Benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

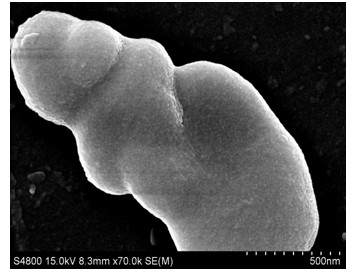

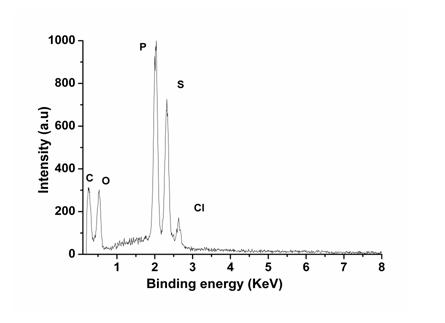

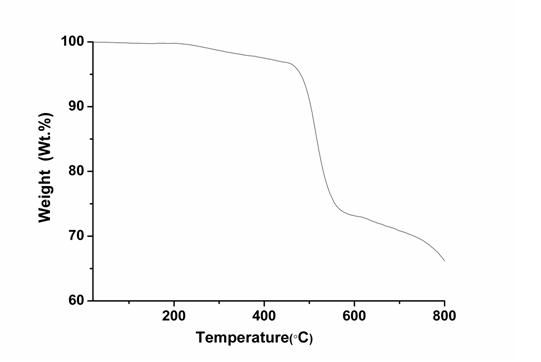

Image

Examples

Embodiment 1

[0022] Weigh 2.0 g of natural graphite in a reaction vessel, add 50 mL of concentrated sulfuric acid with a mass concentration of 95%, and add 6.0 g of KMnO 4 , react at low temperature for 2 hours; place in a constant temperature water bath at about 35°C, and continue to react at medium temperature for 1h; add 90 mL of deionized water, control the temperature at about 100°C, and continue to react at high temperature for 1h; then transfer the reaction solution into a beaker, and use The reaction solution was diluted with deionized water, and the mass concentration was 30% H 2 o 2 Solution until no bubbles are generated, the product is washed with acidic aqueous solution and deionized water respectively, and graphite oxide is obtained after vacuum drying.

[0023] 0.05g of graphite oxide was ultrasonically dispersed in 50ml of deionized water to obtain graphene oxide, and 5 mL of a mass concentration of 85% hydrazine hydrate solution was added thereto, placed in an oil bath at...

Embodiment 2

[0030] Weigh 2.0 g of natural graphite in a reaction vessel, add 50 mL of concentrated sulfuric acid with a mass concentration of 95%, and add 6.0 g of KMnO 4 , react at low temperature for 2 hours; place in a constant temperature water bath at about 35°C, and continue to react at medium temperature for 1h; add 90 mL of deionized water, control the temperature at about 100°C, and continue to react at high temperature for 1h; then transfer the reaction solution into a beaker, and use The reaction solution was diluted with deionized water, and the mass concentration was 30% H 2 o 2 Until no bubbles are generated, the product is washed with acidic aqueous solution and deionized water respectively, and graphite oxide is obtained after vacuum drying.

[0031] 0.05g of graphite oxide was ultrasonically dispersed in 50ml of deionized water to obtain graphene oxide, and 5 mL of a mass concentration of 85% hydrazine hydrate solution was added thereto, placed in an oil bath at 95°C for...

Embodiment 3

[0034] Weigh 2.0 g of natural graphite in a reaction vessel, add 50 mL of concentrated sulfuric acid with a mass concentration of 95%, and add 6.0 g of KMnO 4 , react at low temperature for 2 hours; place in a constant temperature water bath at about 35°C, and continue to react at medium temperature for 1h; add 90 mL of deionized water, control the temperature at about 100°C, and continue to react at high temperature for 1h; then transfer the reaction solution into a beaker, and use The reaction solution was diluted with deionized water, and the mass concentration was 30% H 2 o 2 Until no bubbles are generated, the product is washed with acidic aqueous solution and deionized water respectively, and graphite oxide is obtained after vacuum drying.

[0035] 0.05g of graphite oxide was ultrasonically dispersed in 50ml of deionized water to obtain graphene oxide, and 5 mL of a mass concentration of 85% hydrazine hydrate solution was added thereto, placed in an oil bath at 95°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com