Method for preparing graphene polyphosphazene nano composite material

A nano-composite material, a technology of polyphosphazene, applied in the field of nano-graphene functional materials, can solve problems such as graphene structural defects, affecting the excellent performance of graphene, etc., achieve low cost, easy to achieve large-scale production, and simple process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 2.0 g of natural graphite in a reaction vessel, add 50 mL of concentrated sulfuric acid with a mass concentration of 95%, and add 6.0 g of KMnO 4 , react at low temperature for 2 hours; place in a constant temperature water bath at about 35°C, and continue to react at medium temperature for 1h; add 90 mL of deionized water, control the temperature at about 100°C, and continue to react at high temperature for 1h; then transfer the reaction solution into a beaker, and use The reaction solution was diluted with deionized water, and the mass concentration was 30% H 2 o 2 Solution until no bubbles are generated, the product is washed with acidic aqueous solution and deionized water respectively, and graphite oxide is obtained after vacuum drying.

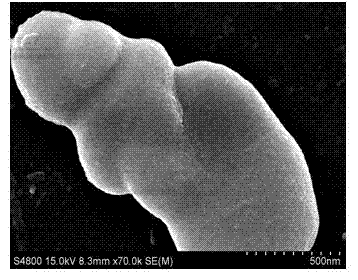

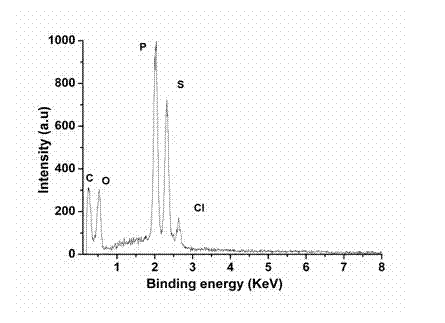

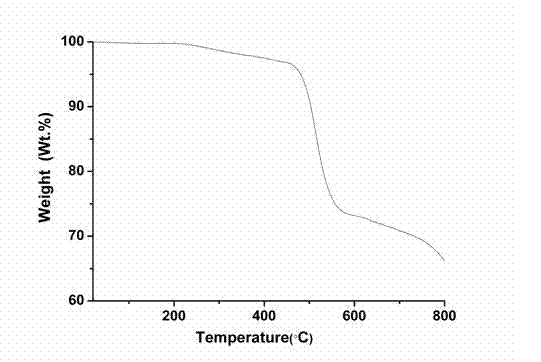

[0023] 0.05g of graphite oxide was ultrasonically dispersed in 50ml of deionized water to obtain graphene oxide, and 5 mL of a mass concentration of 85% hydrazine hydrate solution was added thereto, placed in an oil bath at...

Embodiment 2

[0030] Weigh 2.0 g of natural graphite in a reaction vessel, add 50 mL of concentrated sulfuric acid with a mass concentration of 95%, and add 6.0 g of KMnO 4 , react at low temperature for 2 hours; place in a constant temperature water bath at about 35°C, and continue to react at medium temperature for 1h; add 90 mL of deionized water, control the temperature at about 100°C, and continue to react at high temperature for 1h; then transfer the reaction solution into a beaker, and use The reaction solution was diluted with deionized water, and the mass concentration was 30% H 2 o 2 Until no bubbles are generated, the product is washed with acidic aqueous solution and deionized water respectively, and graphite oxide is obtained after vacuum drying.

[0031] 0.05g of graphite oxide was ultrasonically dispersed in 50ml of deionized water to obtain graphene oxide, and 5 mL of a mass concentration of 85% hydrazine hydrate solution was added thereto, placed in an oil bath at 95°C for...

Embodiment 3

[0034] Weigh 2.0 g of natural graphite in a reaction vessel, add 50 mL of concentrated sulfuric acid with a mass concentration of 95%, and add 6.0 g of KMnO 4 , react at low temperature for 2 hours; place in a constant temperature water bath at about 35°C, and continue to react at medium temperature for 1h; add 90 mL of deionized water, control the temperature at about 100°C, and continue to react at high temperature for 1h; then transfer the reaction solution into a beaker, and use The reaction solution was diluted with deionized water, and the mass concentration was 30% H 2 o 2 Until no bubbles are generated, the product is washed with acidic aqueous solution and deionized water respectively, and graphite oxide is obtained after vacuum drying.

[0035] 0.05g of graphite oxide was ultrasonically dispersed in 50ml of deionized water to obtain graphene oxide, and 5 mL of a mass concentration of 85% hydrazine hydrate solution was added thereto, placed in an oil bath at 95°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com