A kind of preparation method and application of isocyanate polymer

A polymer and isocyanic acid technology, applied in the direction of ester copolymer adhesives, adhesive types, etc., can solve the problems of cumbersome operation, many uncontrollable factors, and inapplicability, so as to achieve uniform film and improve film-base bonding Good strength and shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

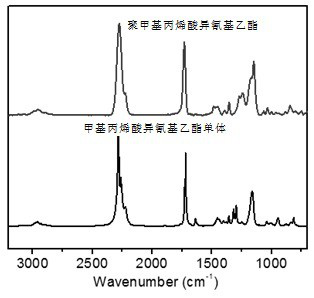

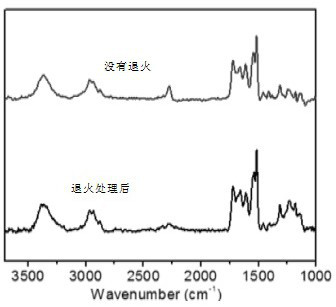

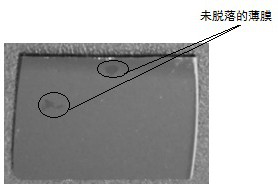

[0033] Place the cotton cloth and the activated silicon wafer as the base material on the sample stage in the reaction chamber, fix the base material so that it is in close contact with the bottom of the chamber, and pump the reaction chamber and pipeline to a vacuum state. The body gas includes initiator and monomer. The initiator is tert-butyl hydroperoxide, and the temperature of the initiator is controlled at 30°C; the monomer is isocyanoethyl methacrylate, and the temperature of the monomer is controlled at 55°C. The flow rates of the monomers are 1sccm and 0.2sccm respectively; the heating temperature of the hot wire in the reaction chamber is 220°C, the chamber pressure is 200mTorr, the substrate temperature is 30°C, the deposition time is 30min, the film thickness is about 400nm, and the deposition rate is about 13nm / min. A polyisocyanoethyl acrylate polymer film was prepared on the surface of the cotton cloth and the surface of the silicon chip. Afterwards, an annea...

Embodiment 2

[0035] Change the flow rate of the isocyanoethyl methacrylate monomer into 0.4sccm in Example 1, and the initiator is perfluorobutylsulfonyl fluoride; other conditions are unchanged, the deposition time is 20min, and the film thickness is about 400nm. The deposition rate is about 20nm / min.

Embodiment 3

[0037] With the isocyanoethyl methacrylate monomer in Example 1, the flow rate is 0.6 sccm; the initiator is replaced by perfluorooctanesulfonyl fluoride, other conditions are the same as in Example 1, the deposition time is 16min, and the film thickness is about is 400nm, and the deposition rate is about 25nm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com