A kind of preparation method of molybdenum disulfide/polyphosphazene/ferric oxide electrode material

A technology of ferric oxide and molybdenum disulfide, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of high interface resistance, poor electrolyte stability, etc., achieve low equipment requirements, improve performance, and respond The effect of simple operation and process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

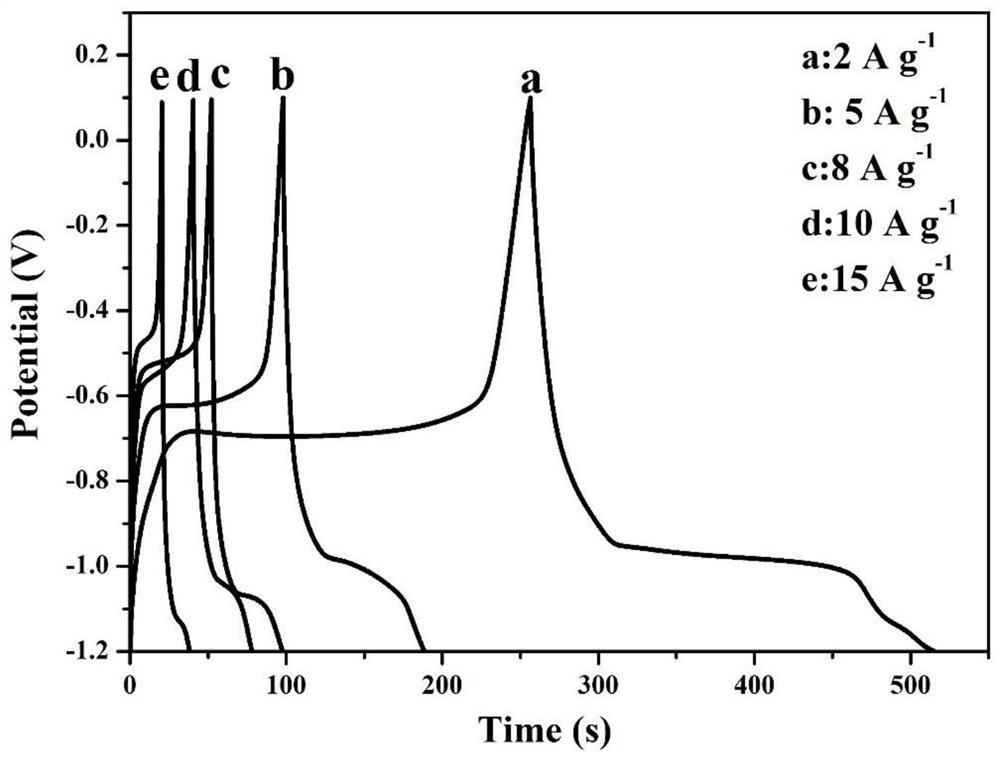

Examples

Embodiment 1

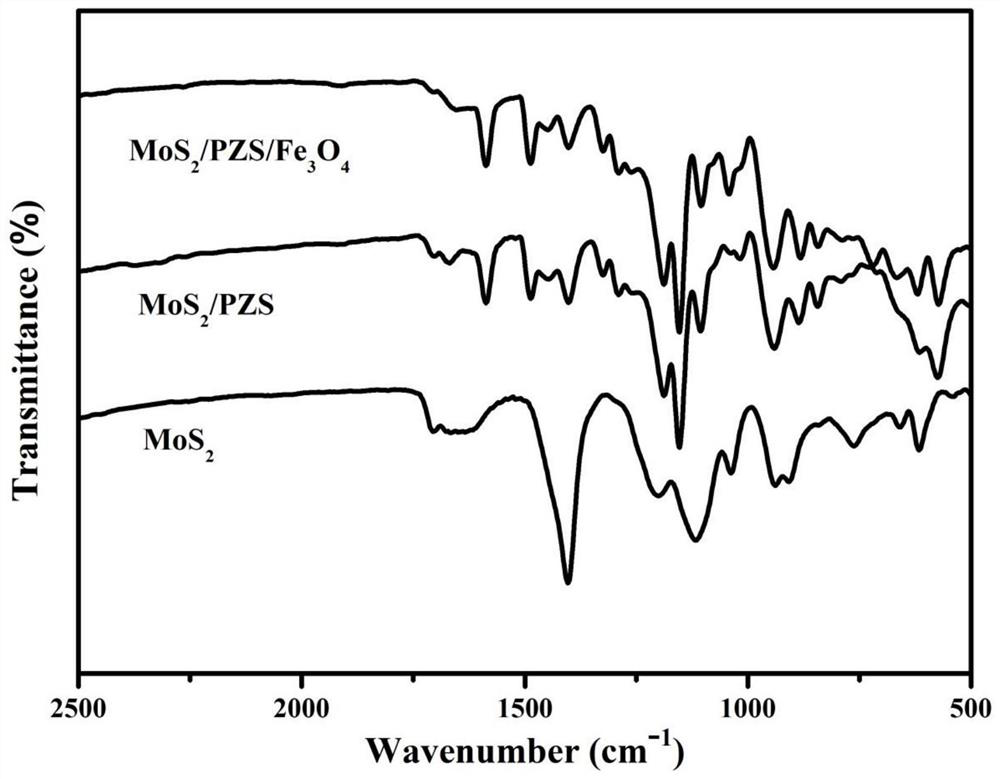

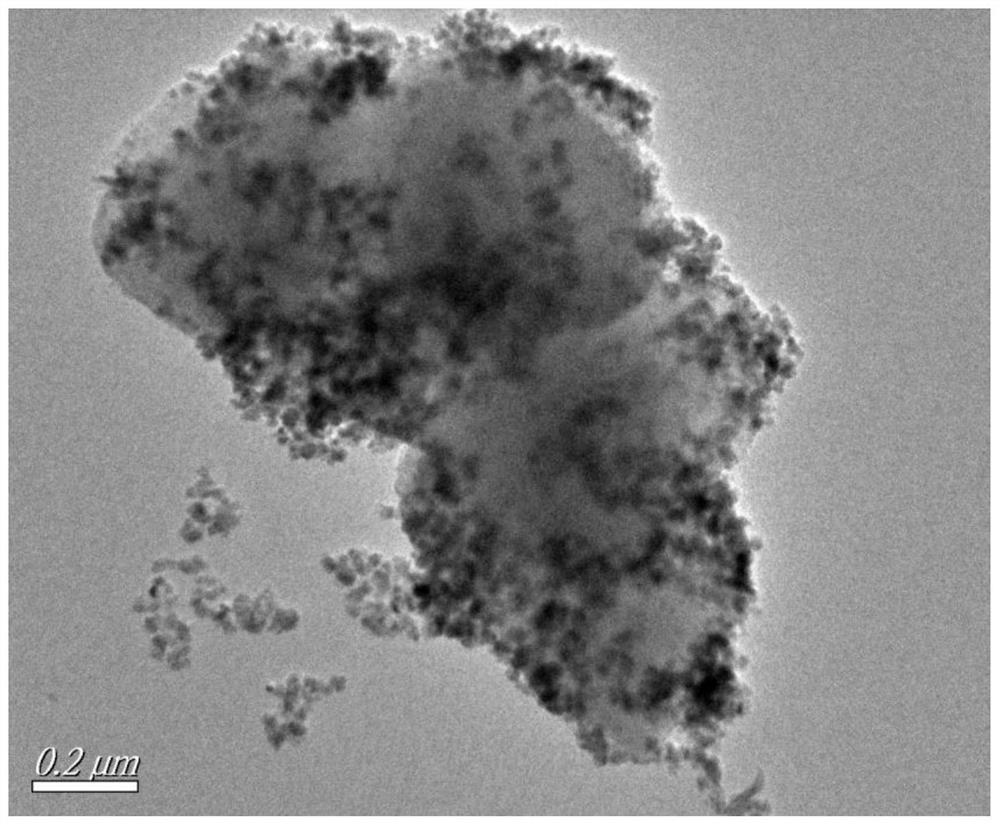

[0025] (1) Molybdenum disulfide (MoS 2 ) preparation: weigh 24mg molybdenum trioxide (MoO 3 ), 28mg of thioacetamide (TAA) and 200mg of urea, dispersed in 20mL of deionized water, transferred to the stainless steel reactor lining after magnetic stirring, sealed, put into 200 ℃ blast drying oven for 18h reaction; after the reaction After cooling to room temperature, the prepared product was washed with deionized water and absolute ethanol, and finally vacuum-dried at 50°C to obtain MoS 2 .

[0026] (2)MoS 2 Preparation of / PZS composite: Weigh 0.1g molybdenum disulfide, ultrasonically disperse it in a mixture of 150mL tetrahydrofuran and ethanol, then add the precursor of polyphosphazene (PZS) 0.1g hexachlorocyclotriphosphazene and 0.25g 4 , 4'-dihydroxydiphenylsulfone, and 3mL triethylamine was added, and after ultrasonic reaction for 5h, the mixture was washed with deionized water and absolute ethanol respectively, and dried in a vacuum oven at 50°C to obtain MoS 2 / PZS c...

Embodiment 2

[0033] (1) Molybdenum disulfide (MoS 2 ) preparation: weigh 24mg molybdenum trioxide (MoO 3 ), 28mg of thioacetamide (TAA) and 200mg of urea, dispersed in 20mL of deionized water, transferred to the stainless steel reactor lining after magnetic stirring, sealed, put into 200 ℃ blast drying oven for 24h reaction; after the reaction After cooling to room temperature, the prepared product was washed with deionized water and absolute ethanol, and finally vacuum-dried at 50°C to obtain MoS 2 .

[0034] (2)MoS 2 Preparation of / PZS composite: Weigh 0.1g molybdenum disulfide, ultrasonically disperse it in a mixture of 150mL tetrahydrofuran and ethanol, then add the precursor of polyphosphazene (PZS) 0.1g hexachlorocyclotriphosphazene and 0.25g 4 , 4'-dihydroxydiphenylsulfone, and 3mL triethylamine was added, and after ultrasonic reaction for 5h, the mixture was washed with deionized water and absolute ethanol respectively, and dried in a vacuum oven at 50°C to obtain MoS 2 / PZS c...

Embodiment 3

[0037] (1) Molybdenum disulfide (MoS 2 ) preparation: weigh 24mg molybdenum trioxide (MoO 3 ), 28mg of thioacetamide (TAA) and 200mg of urea, dispersed in 20mL of deionized water, transferred to the stainless steel reactor lining after magnetic stirring, sealed, put into 200 ℃ blast drying oven for 18h reaction; after the reaction After cooling to room temperature, the prepared product was washed with deionized water and absolute ethanol, and finally vacuum-dried at 50°C to obtain MoS 2 .

[0038] (2)MoS 2 Preparation of / PZS composite: Weigh 0.1g molybdenum disulfide, ultrasonically disperse it in a mixture of 150mL tetrahydrofuran and ethanol, then add 0.05g hexachlorocyclotriphosphazene and 0.1g 4 , 4'-dihydroxydiphenyl sulfone, and 2 mL of triethylamine was added, and after ultrasonic reaction for 5 hours, the mixture was washed with deionized water and absolute ethanol, and dried in a vacuum oven at 50°C to obtain MoS 2 / PZS complex.

[0039] (3)MoS 2 / PZS / Fe 3 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com