A lithium ion marks polymer and its preparation method

An imprinted polymer, lithium ion technology, applied in chemical instruments and methods, other chemical processes, chemical recycling and other directions, can solve the problems of orange peel not being comprehensively utilized, waste, environmental pollution, etc., to achieve regeneration and reuse, high-efficiency Select the effect of strong adsorption and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

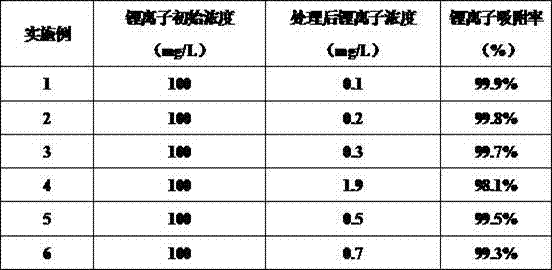

Examples

Embodiment 1

[0021] (1) Orange peel cellulose pretreatment

[0022] Take 10g of orange peel powder and 200g of 80% ethanol solution in a round bottom flask, reflux extraction for 4h, centrifuge to obtain solid and mother liquor, mother liquor is used to extract flavonoids and other components, ethanol recycling, solid Wash and drop with pure water until the cellulose no longer releases yellow organic matter; add the obtained solid into 100ml of sodium hydroxide solution with a concentration of 0.4g / L, stir for 1h, and centrifuge to obtain alkalized orange peel cellulose; The alkalized orange peel cellulose was added into 100 g of a mass percentage concentration of 20% isopropanol solution, soaked for 3 hours, and centrifuged to obtain alkalized alcoholized orange peel cellulose;

[0023] (2) Polyacrylamide graft modification

[0024] Pour the alkalized alcoholized orange peel cellulose obtained in step (1) into a three-necked flask equipped with a mechanical stirrer and a condenser, add 9...

Embodiment 2

[0032] (1) Orange peel cellulose pretreatment

[0033] Get 10g orange peel powder and 200g mass percentage concentration and be 85% ethanol solution in the round-bottom flask, reflux extraction 3.5h, centrifugation obtains solid and mother liquor, mother liquor is used for extracting components such as flavonoids, ethanol recycling, The solid was washed and dropped with pure water until the cellulose no longer released yellow organic matter; the obtained solid was added to 100ml of sodium hydroxide solution with a concentration of 0.4g / L, stirred for 3h, and centrifuged to obtain alkalized orange peel cellulose; The obtained alkalized orange peel cellulose was added to 100 g of isopropanol solution with a concentration of 15% by mass, soaked for 12 hours, and centrifuged to obtain alkalized alcoholized orange peel cellulose;

[0034] (2) Polyacrylamide graft modification

[0035] Pour the alkalized alcoholized orange peel cellulose obtained in step (1) into a three-necked fla...

Embodiment 3

[0041] (1) Orange peel cellulose pretreatment

[0042] Take 10g of orange peel powder and 200g of 90% ethanol solution in a round-bottomed flask, reflux extraction for 3h, centrifuge to obtain solid and mother liquor, mother liquor is used to extract flavonoids and other components, ethanol recycling, solid Wash and drop with pure water until the cellulose no longer releases yellow organic matter; add the obtained solid into 100ml of sodium hydroxide solution with a concentration of 0.5g / L, stir for 2 hours, and centrifuge to obtain alkalized orange peel cellulose; The alkalized orange peel cellulose was added into 100 g of a mass percent concentration of 15% isopropanol solution, soaked for 8 hours, and centrifuged to obtain alkalized alcoholized orange peel cellulose;

[0043] (2) Modification of thiosemicarbazide

[0044] The alkalized alcoholized orange peel cellulose obtained in step (1) is added to 10 g of formaldehyde solution with a concentration of 36% by mass, and dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com