Patents

Literature

96results about How to "Realize recycling and reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite carbon dioxide adsorption material, preparation method and application thereof

ActiveCN104056599AImprove adsorption capacityEasy to spreadOther chemical processesDispersed particle separationSorbentChemical adsorption

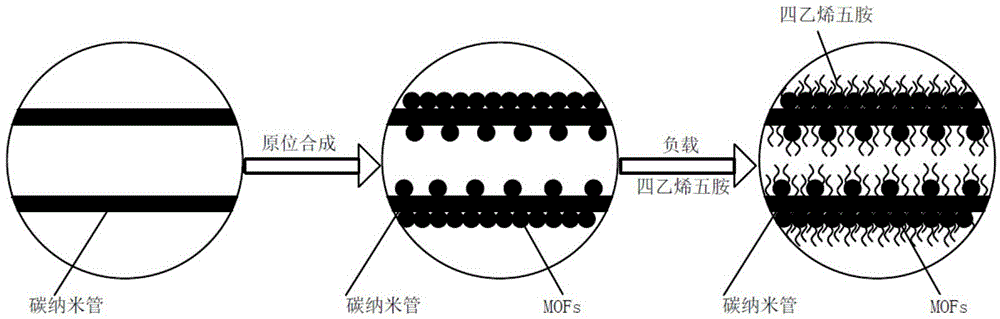

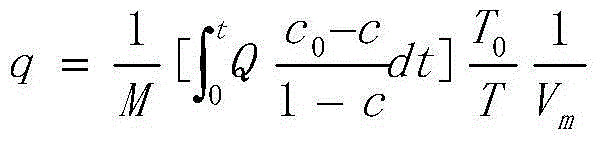

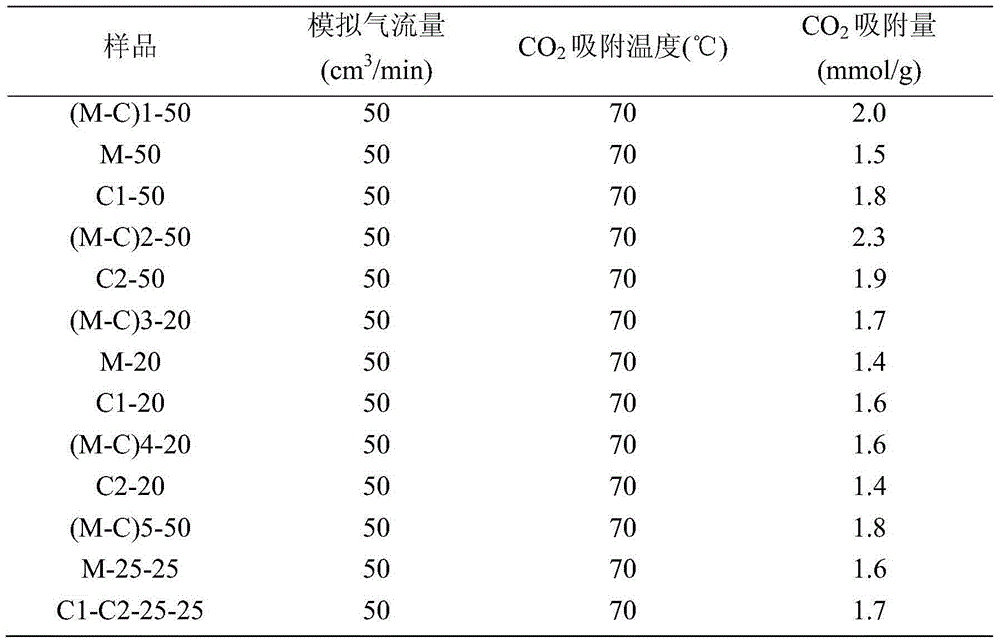

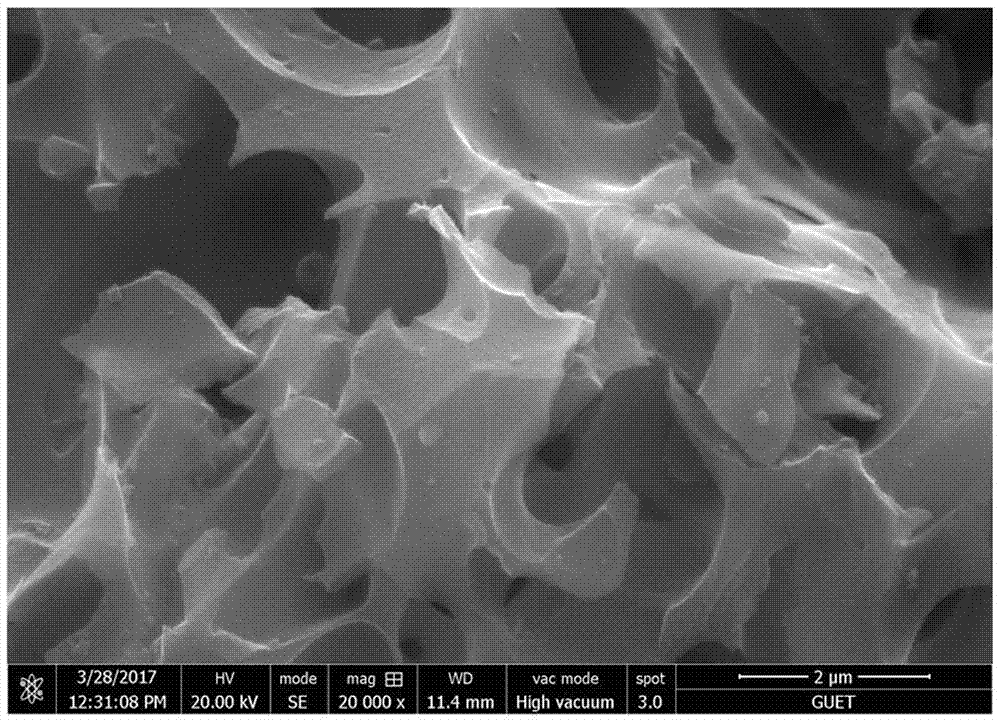

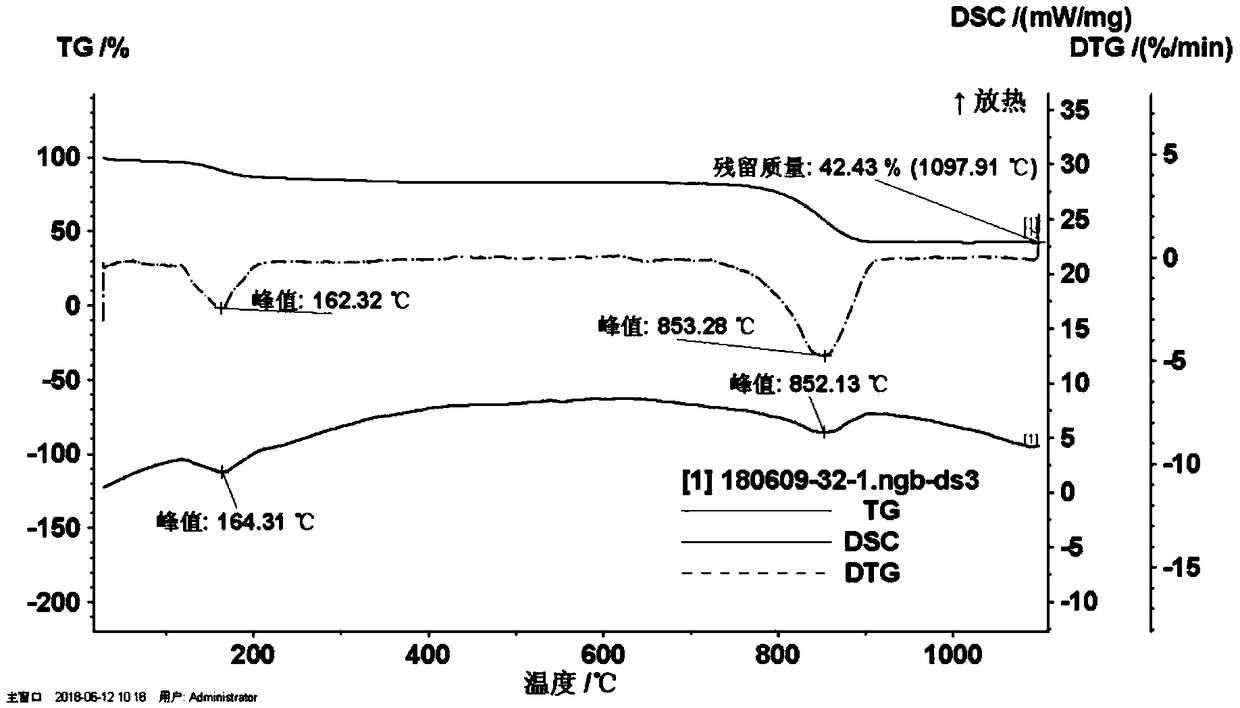

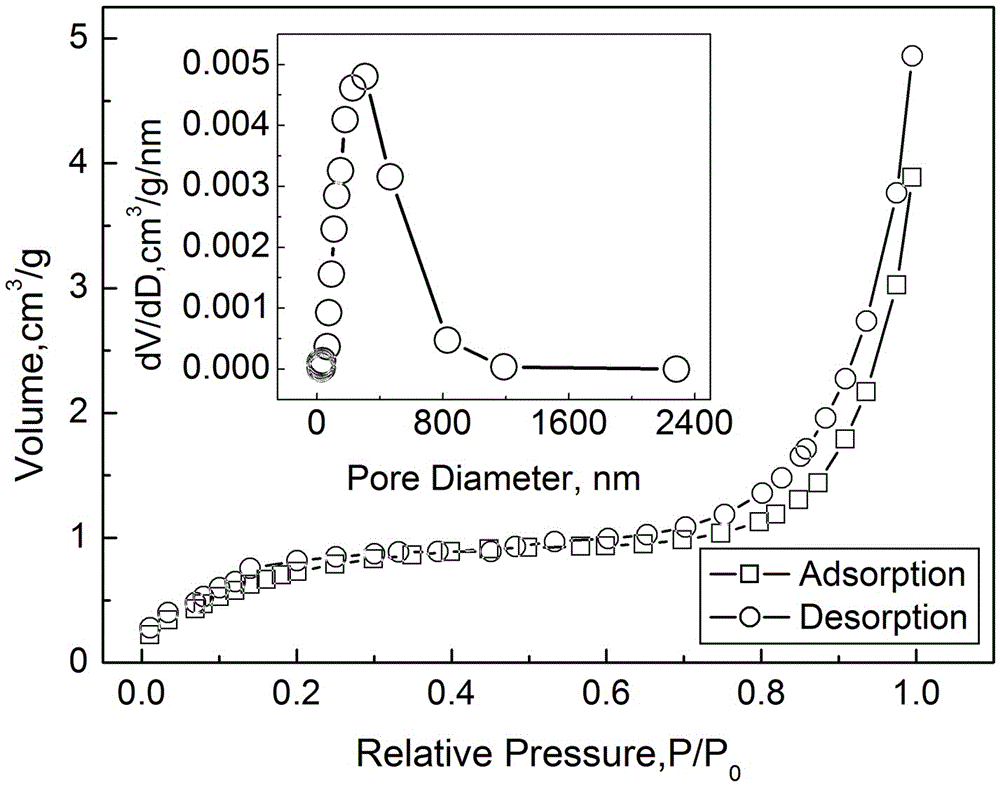

The invention discloses a composite carbon dioxide adsorption material, which includes an in-situ synthesized MOFs(metal-organic frameworks)-graphite based composite material and organic amine loaded on the MOFs-graphite based composite material. The mass ratio of the MOFs-graphite based composite material to the organic amine is 0.1-10:1. The composite carbon dioxide adsorption material provided by the invention realizes the combined action of physical adsorption and chemical adsorption, can adsorb and store carbon dioxide at medium and low temperature, and realizes regeneration and reuse of the adsorbent under certain conditions. The composite carbon dioxide adsorption material has good adsorption capacity, high selectivity and cycling stability on carbon dioxide, and can overcome the disadvantages of easy volatilization and easy corrosion of equipment in organic amine so as to meet the industrial processing requirements. The invention also discloses a preparation method of the composite carbon dioxide adsorption material and application in adsorption of carbon dioxide in flue gas.

Owner:ZHEJIANG UNIV

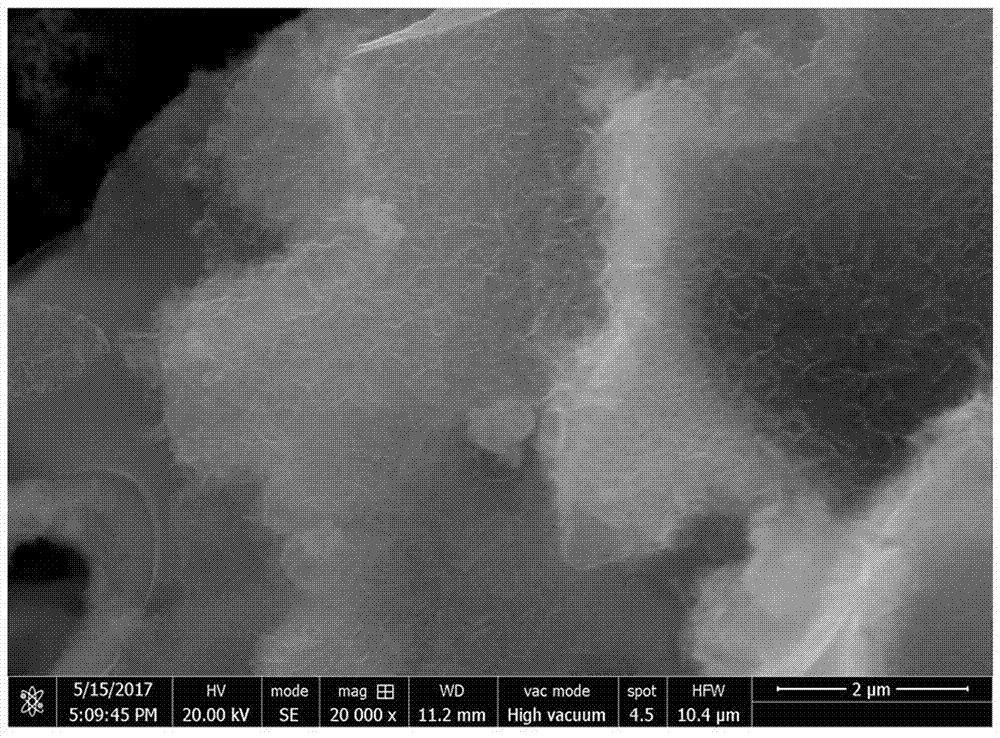

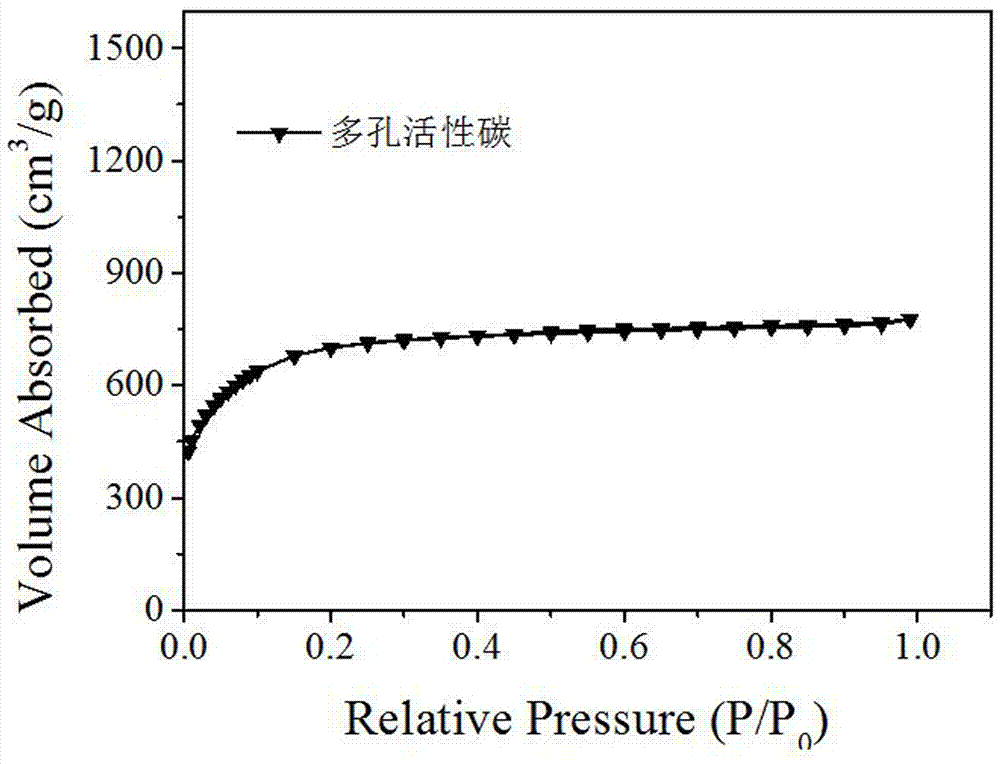

Porous active charcoal material supporting cobalt nanoparticle material, preparation method, and application thereof

InactiveCN107159214ALow costConducive to the realization of standardized productionHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsFuel cellsPorous carbon

The invention discloses a porous active charcoal material supporting cobalt nanoparticle material, which is prepared by performing hydrothermal treatment and subsequent treatment to glucose and a nitrogen-containing compound to obtain a porous carbon material, and supporting cobalt particles onto the carbon material through an impregnating chemical reduction method. The material is 3026-3277 m<2> / g in specific surface area, is more than 95.18% in micropore content, and has uniform distribution in pore size, which is mainly distributed in 1.24-1.95 nm. The preparation method includes the steps of: 1) preparing a nitrogen-containing precursor; 2) preparing the porous carbon material; and 3) supporting the cobalt nanoparticles. The material, when being used as a catalyst for catalyzing hydrolytic hydrogen release of ammonia borane, can complete the hydrogen release within 10 min, hydrogen release rate reaching 865.2 ml*min<-1>*g<-1>. The material can be recycled, and after circulation for 4 times, the hydrogen release time can be maintained in 10-45 min and hydrogen release rate can be maintained at 208.2-865.2 ml*min<-1>*g<-1>. The preparation method is simple and has low production cost. The material can be recycled, has good practicability, and has wide application prospect in the fields of hydrogen production, fuel cells, etc.

Owner:GUILIN UNIV OF ELECTRONIC TECH

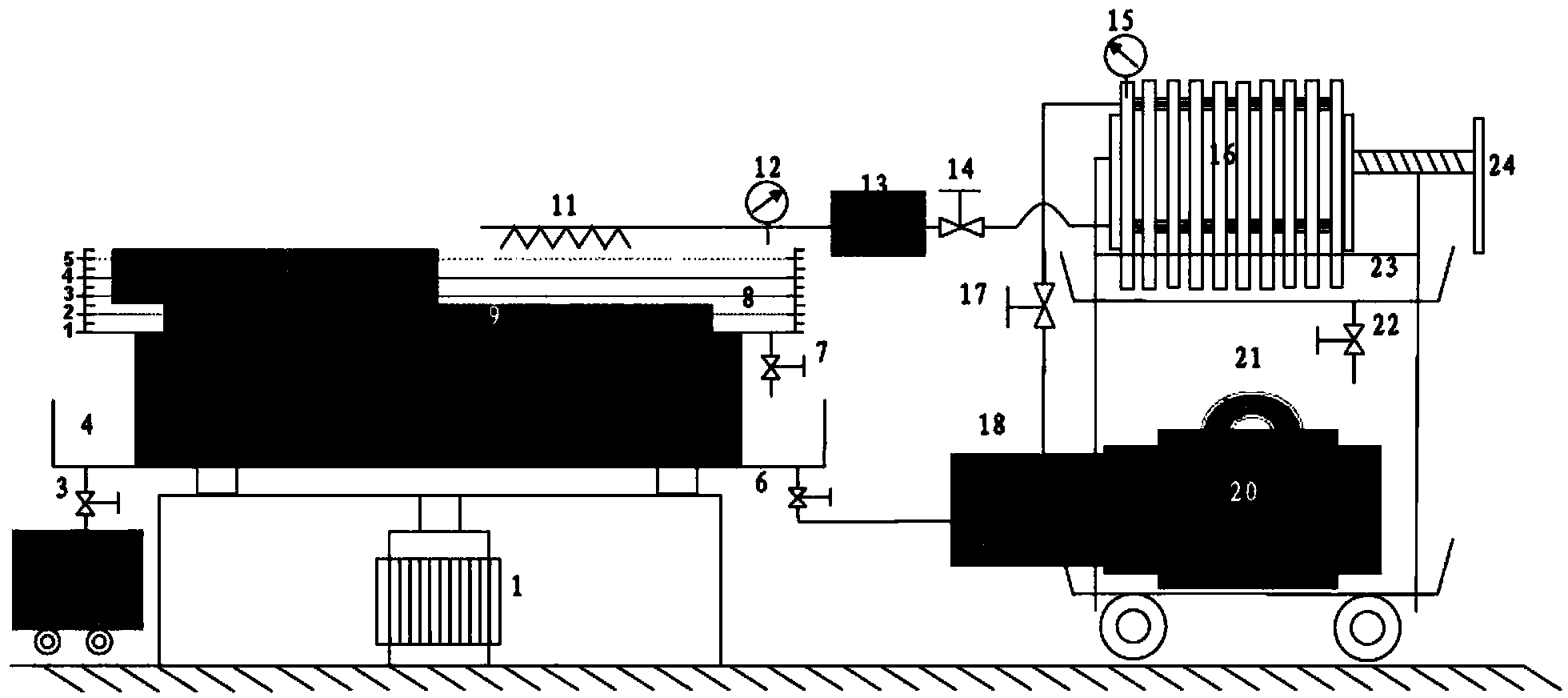

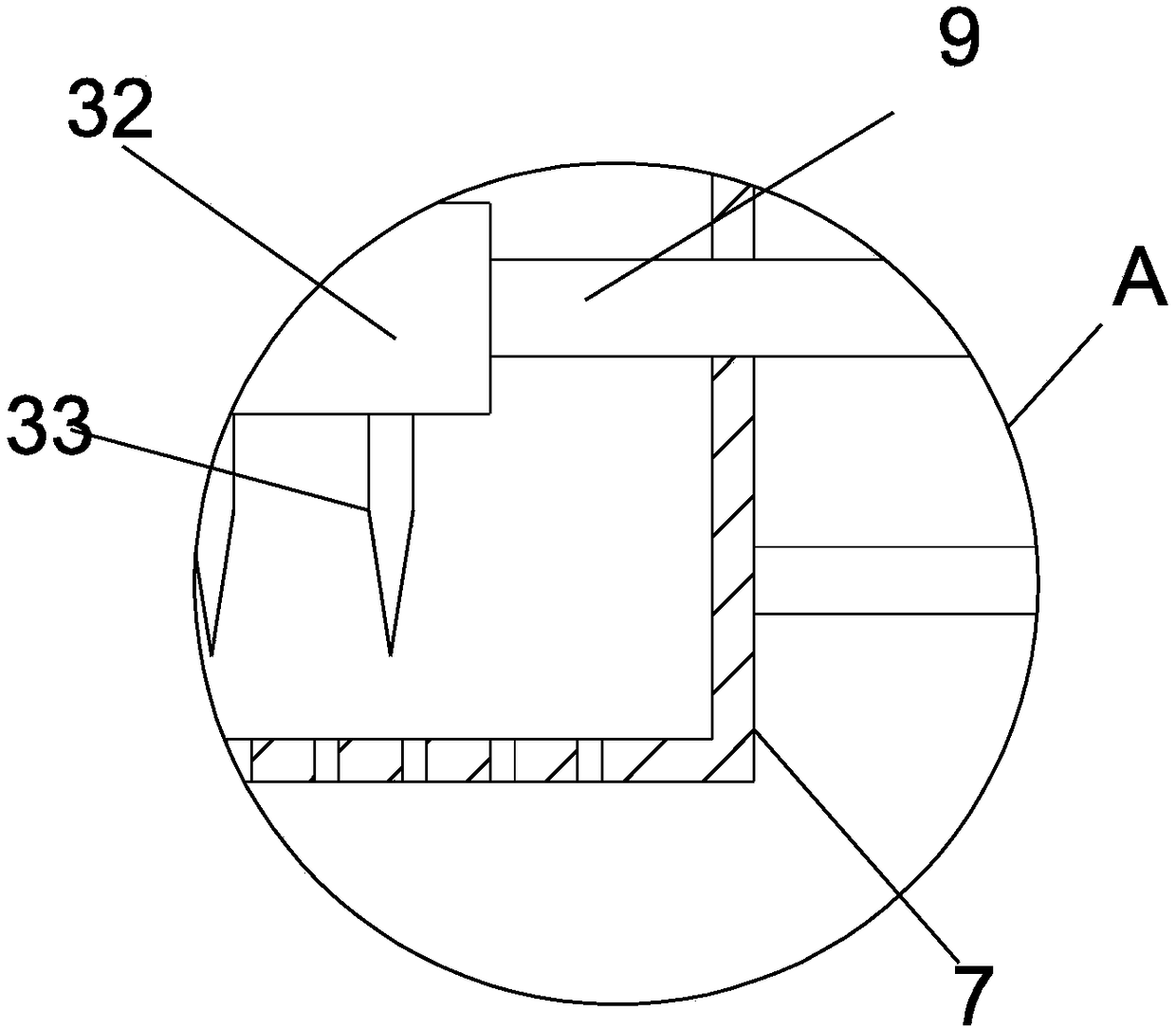

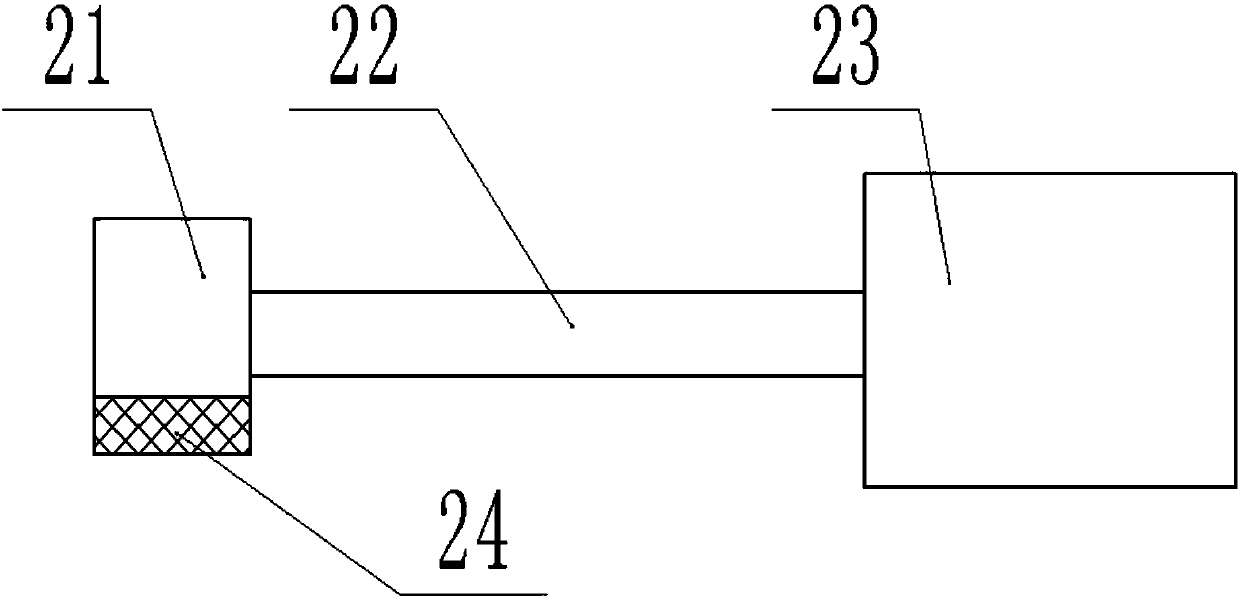

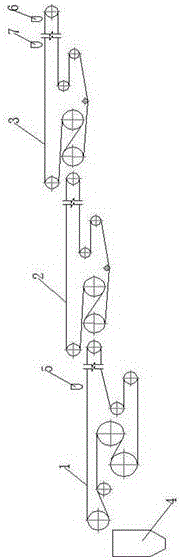

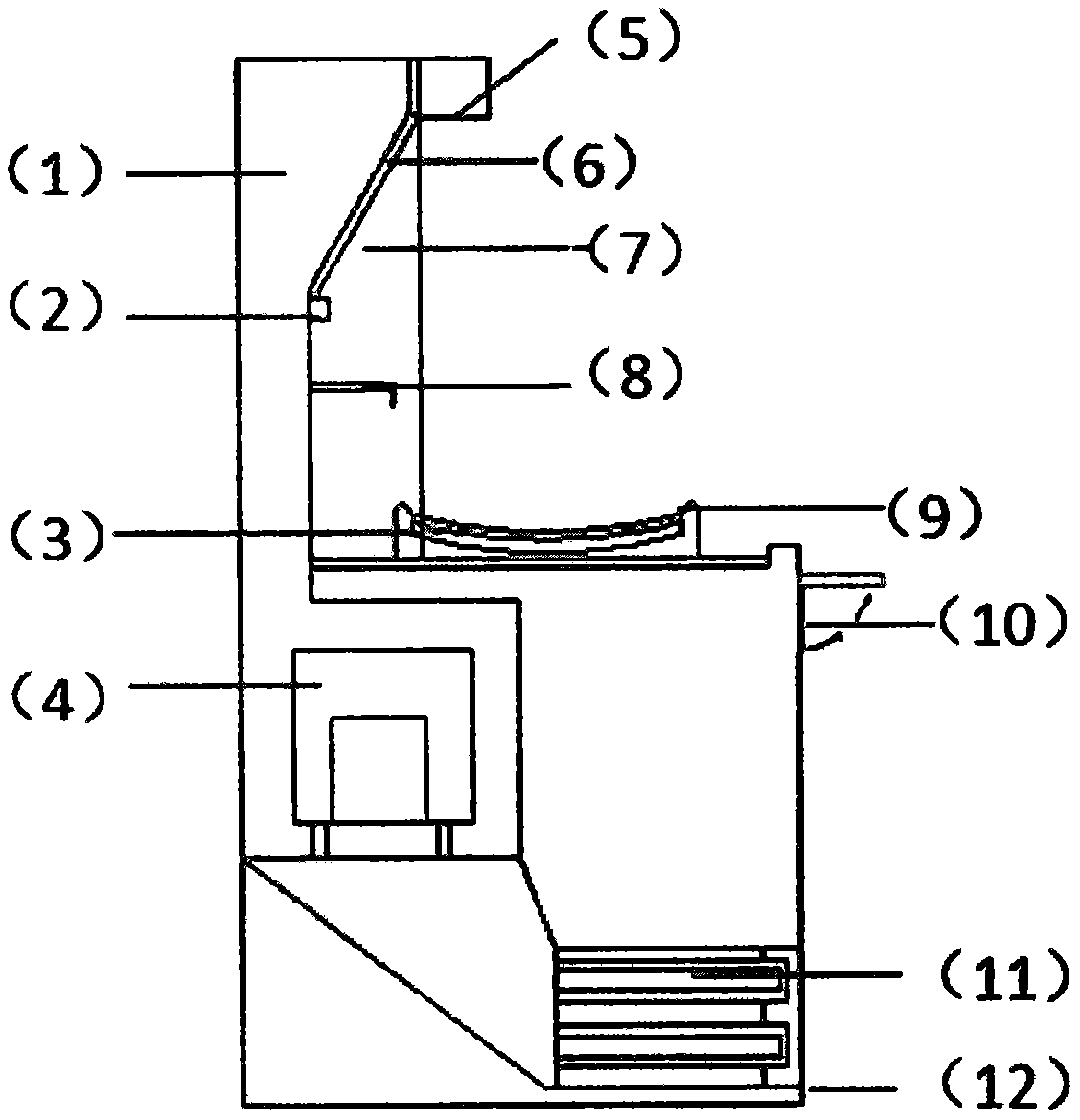

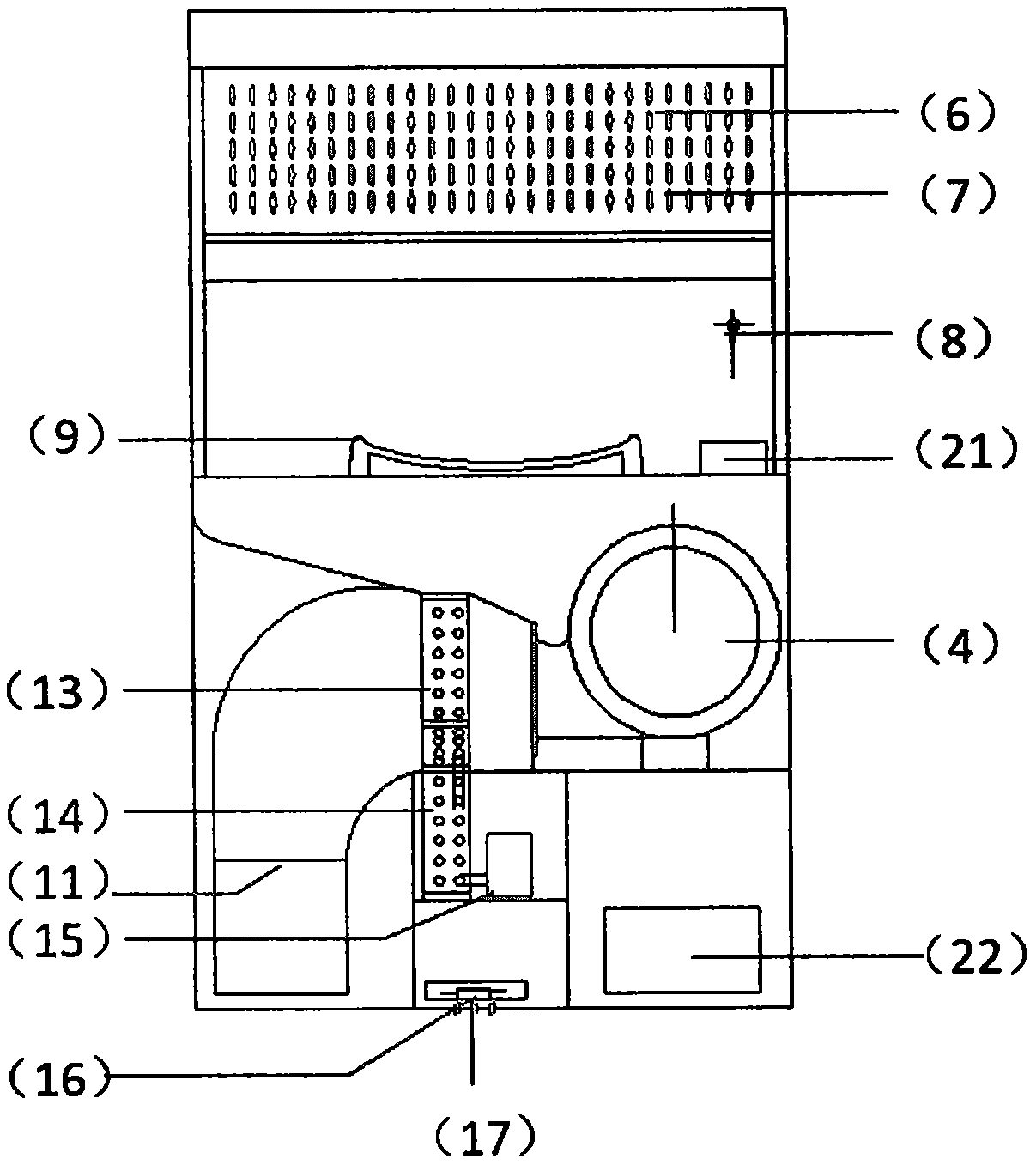

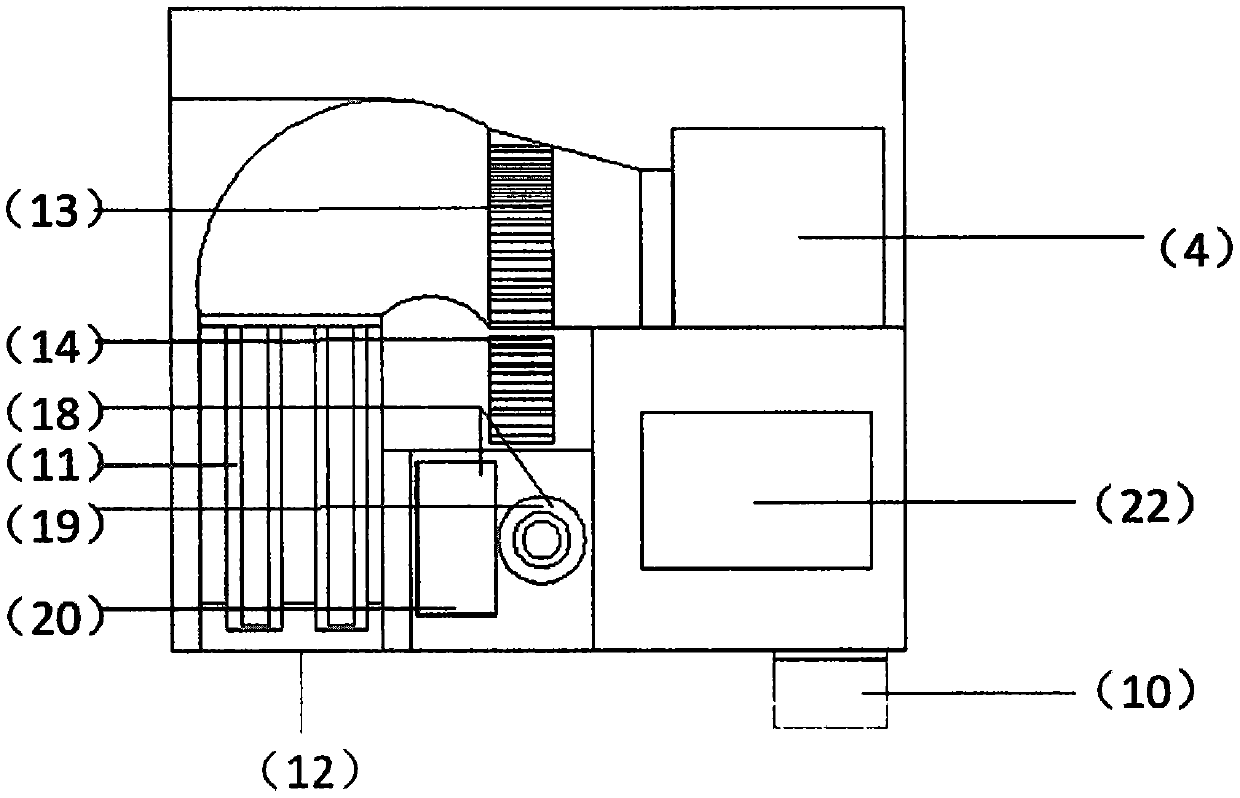

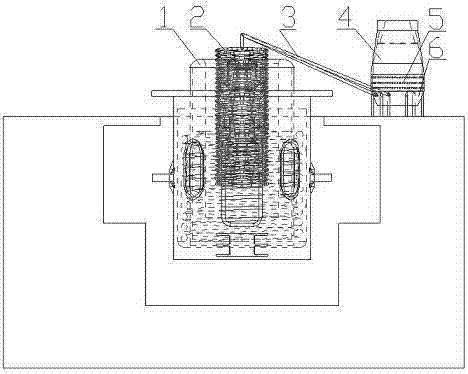

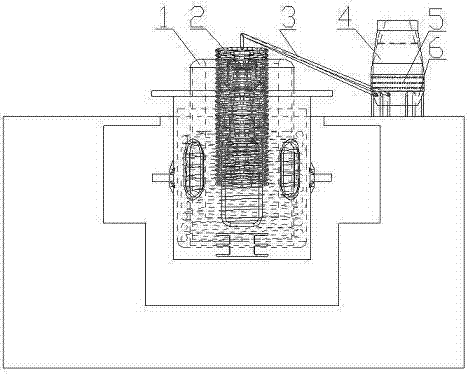

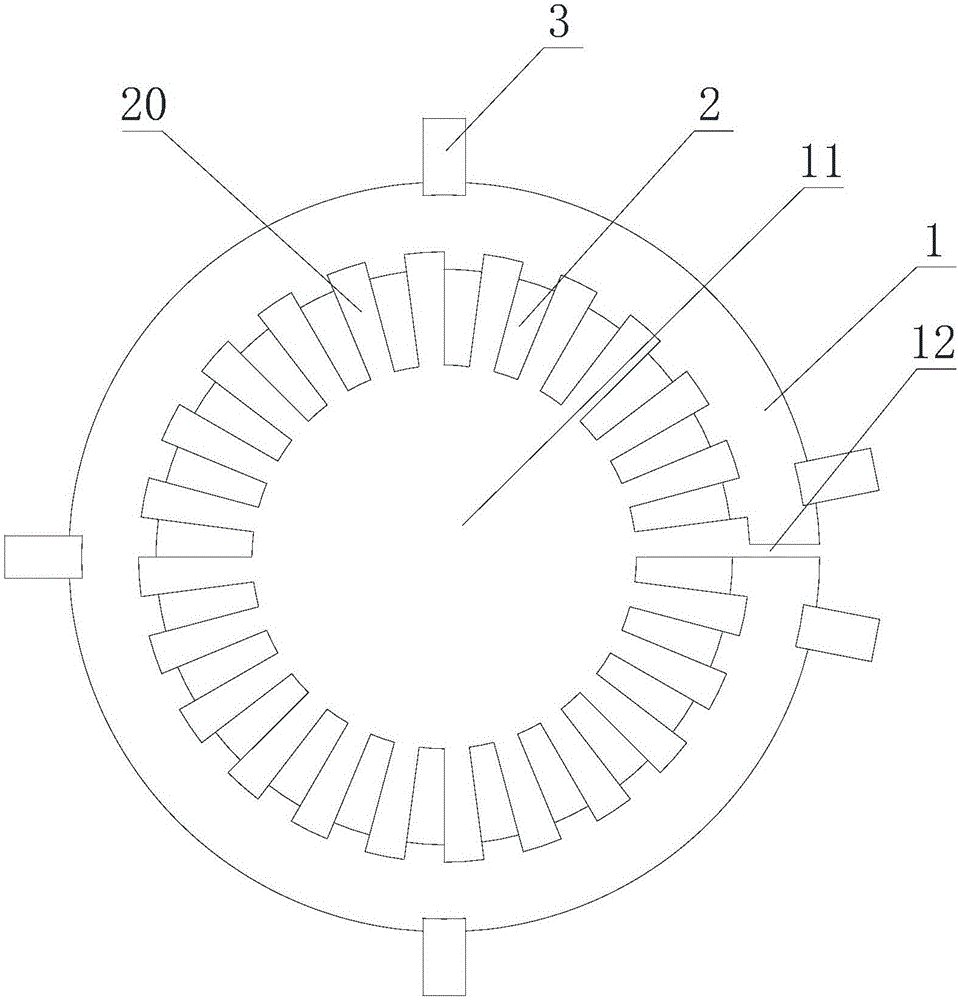

Large immersion type ring polishing machine

ActiveCN103372805AGrain size parameters are stableImprove machining accuracyPolishing machinesSurface roughnessProcess engineering

A large immersion type ring polishing machine mainly comprises a marble polishing disc, a large liquid storage groove, a polishing solution storage tank, a magnetic stirrer, an electric pump, a polishing solution filtering device, a spraying nozzle device and the like. The magnetic stirrer is arranged in the polishing solution storage tank and performs continuous stirring. The polishing solution filtering device adopts a multilayer filtering film type filtering device and can perform multilayer grading filtering according to needs. By means of the large immersion type ring polishing machine, immersion type polishing processing of the large immersion type ring polishing machine is achieved, temperature balance performance is good, polishing surface shape errors caused by uneven polishing temperature are reduced, surface shape precision and surface roughness of a large-caliber plane optical element are improved, and surface defects of elements can be effectively controlled. Furthermore, the immersion type ring polishing machine adopts a mode of cyclic utilization of polishing solution, so that consume of the polishing solution can be greatly reduced, and processing cost is reduced.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

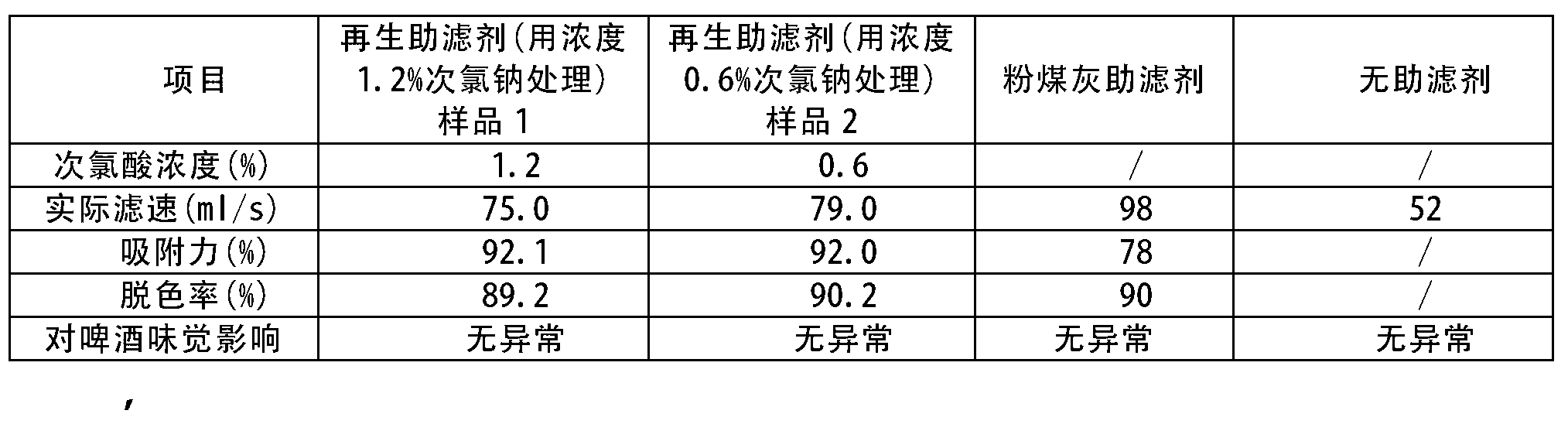

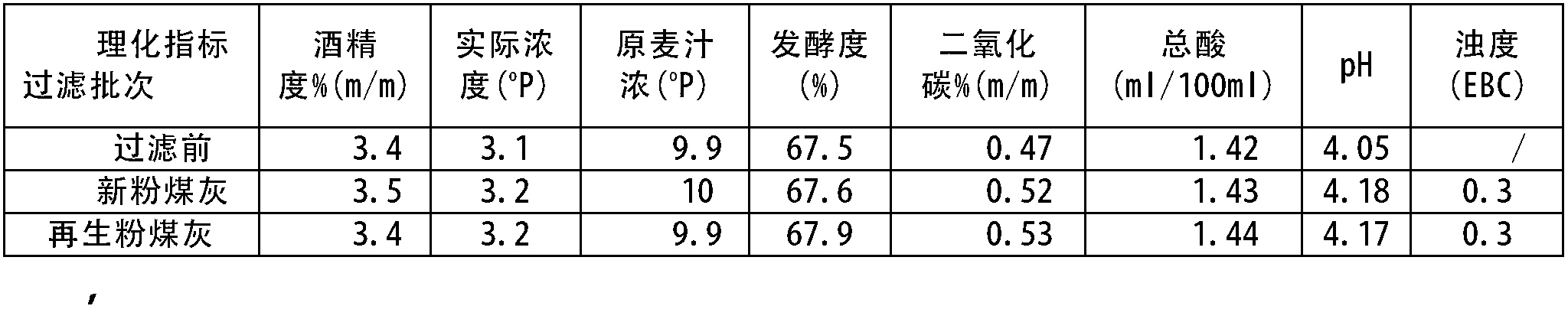

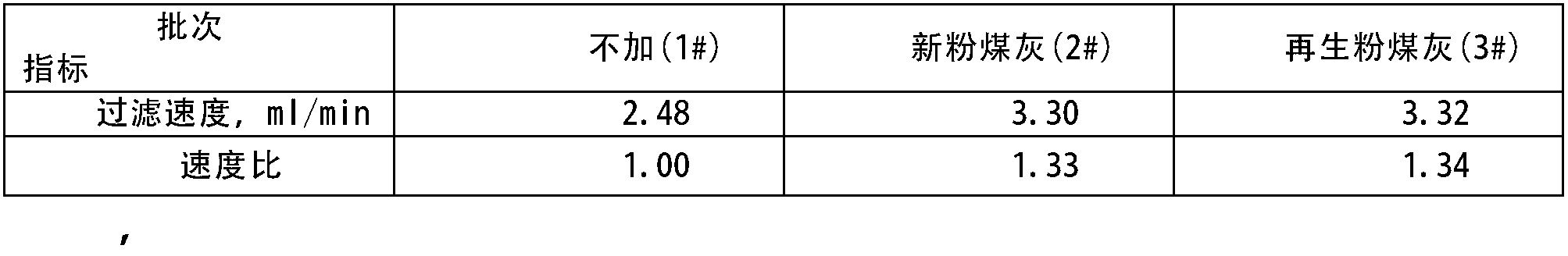

Filter aid and regeneration method thereof

ActiveCN103157437AHigh value-added applicationsStrong physical adsorption capacityOther chemical processesCombustible gas purificationChemical industrySlag

The invention provides a filter aid which comprises coal ash or furnace slag. The coal ash or furnace slag is pretreated, wherein the pretreatment comprises the following steps: performing pickling or alkaline washing on the coal ash or furnace slag, and controlling the acid-base mass percent to be 0.1-0.8 percent; or adding lime, and controlling the lime addition amount to be 0.1-0.5 percent of the weight of the coal ash or furnace slag; or adding salt or base, wherein the addition amount of the salt or base is 0.05-1 percent of the mass of the coal ash or furnace slag; or adding the salt, wherein the addition amount of the salt is 1-10 percent of the mass of the coal ash or furnace slag; and stewing the coal ash or furnace slag in which the salt is added at the temperature of 90-200 DEG C for 1-5 hours under sealing conditions, wherein the salt is heated to generate gas. The filter aid disclosed by the invention takes the coal ash and the furnace slag as raw materials and can be widely applied to the industries of coloring, sugaring, beer, chemical industry and the like.

Owner:中铝山东有限公司

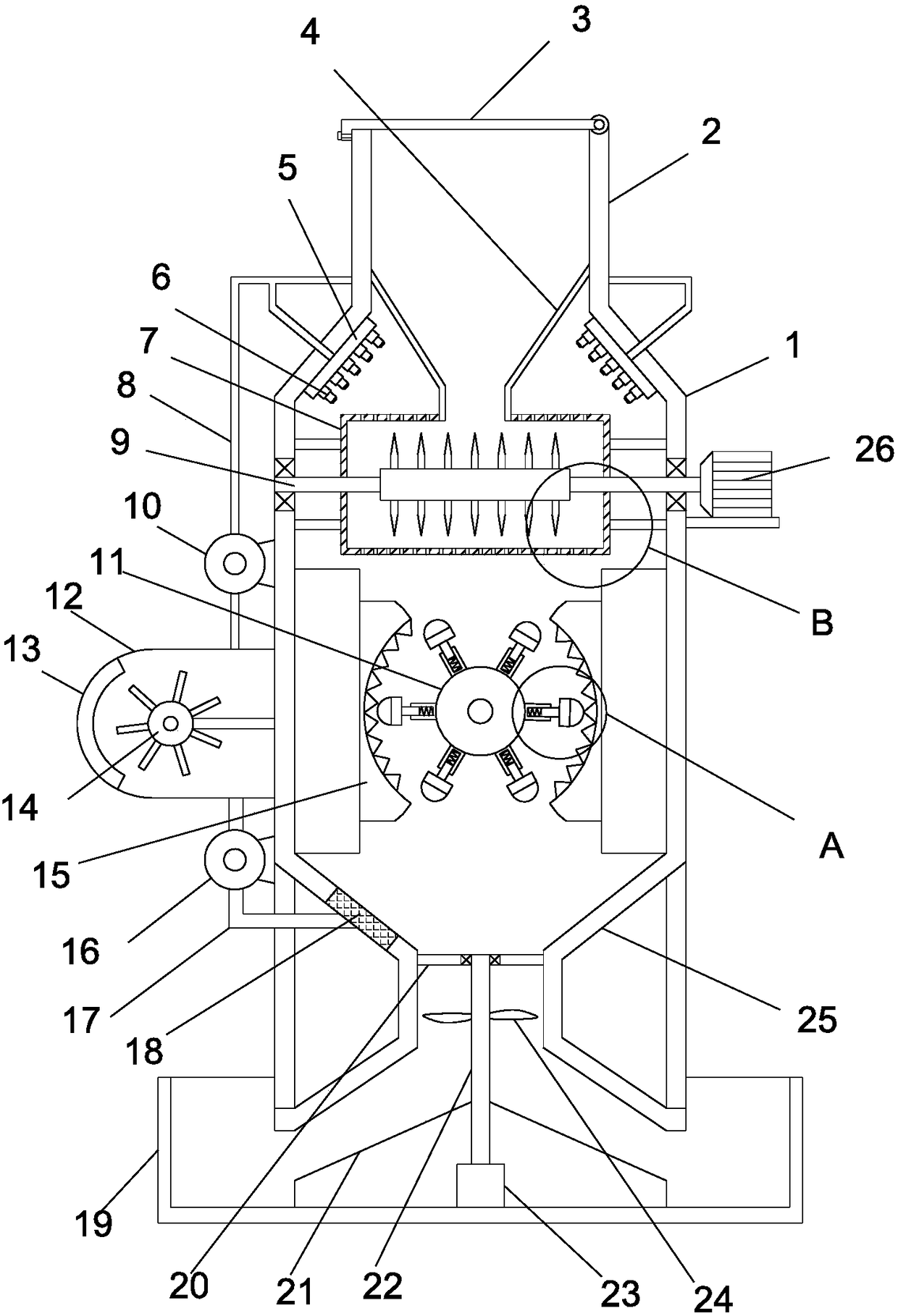

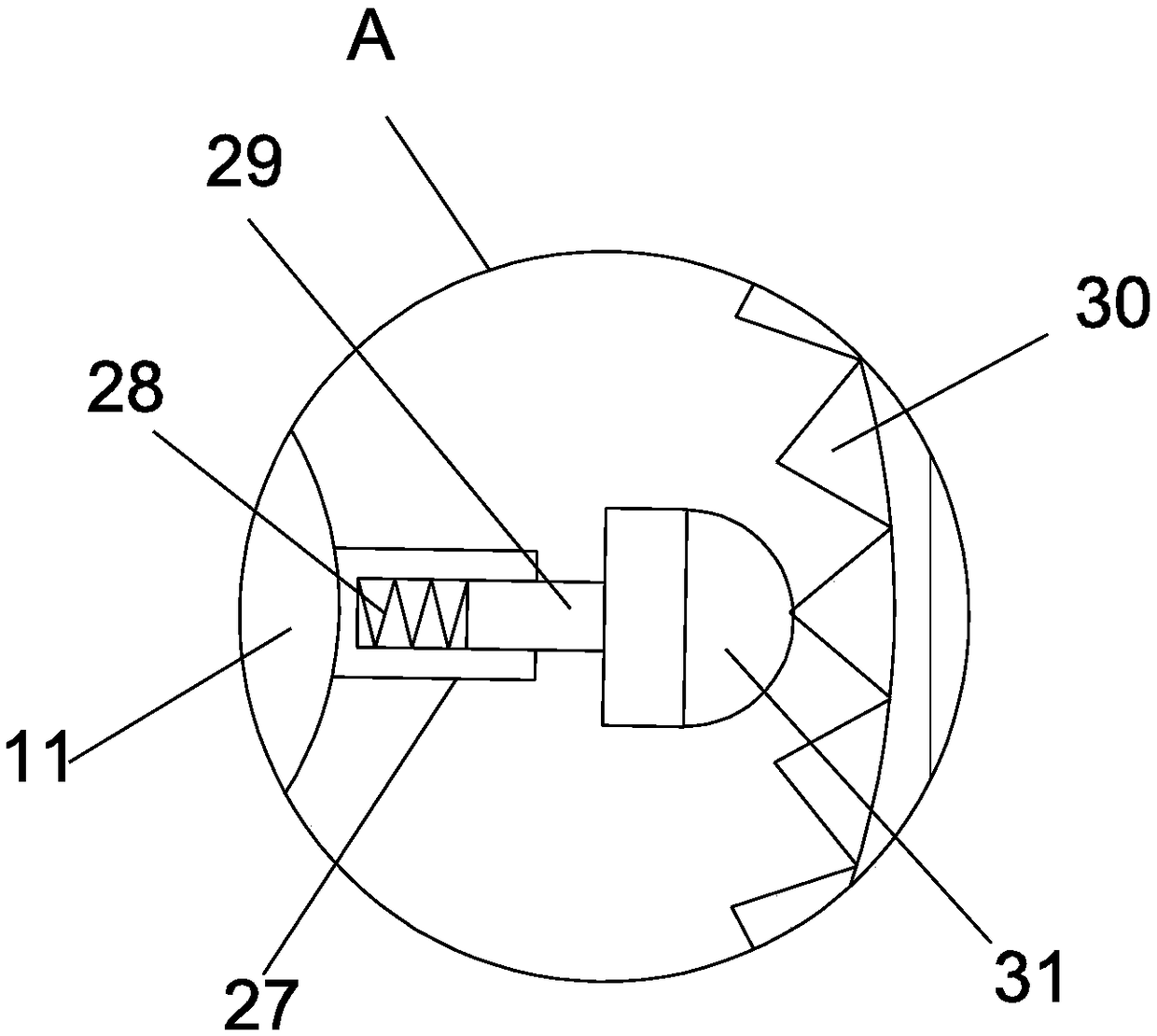

Energy-saving type grain crushing air dryer

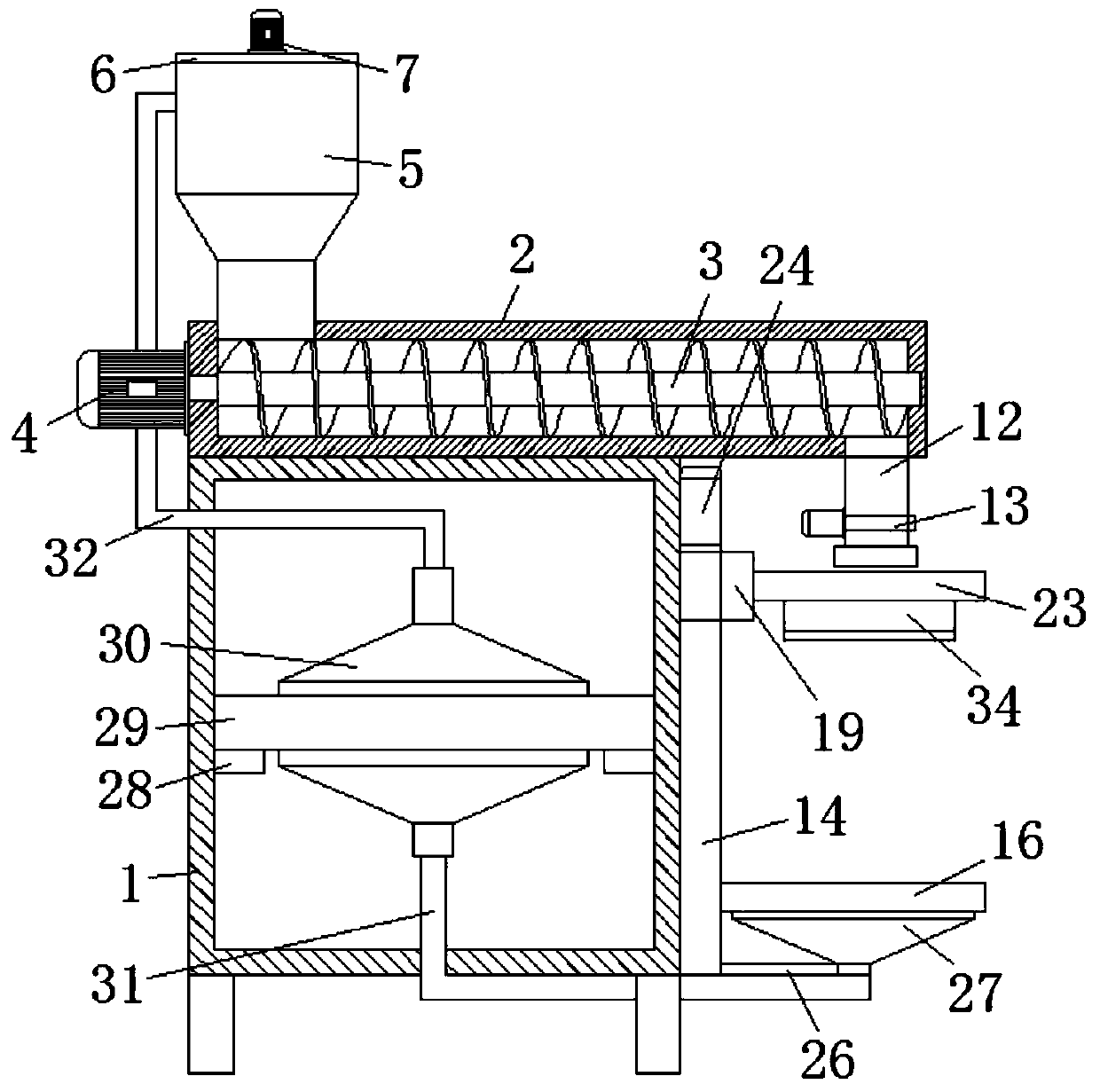

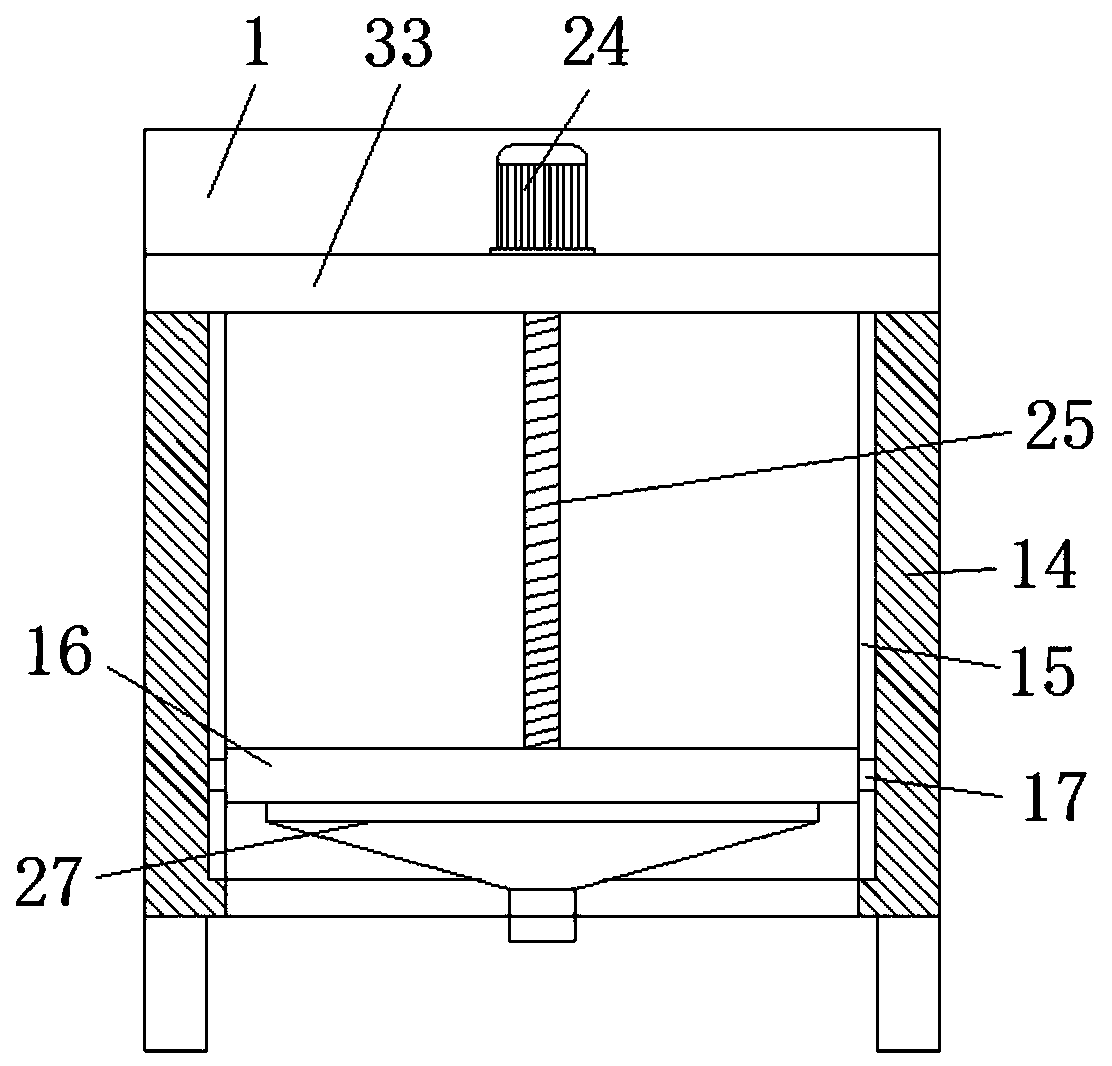

InactiveCN108452927APromote fragmentationSpeed up sievingDrying gas arrangementsGrain treatmentsDrive shaftEngineering

The invention discloses an energy-saving type grain crushing air dryer which comprises a body, wherein a material feeding pipe is vertically and fixedly mounted on the body; a movable cover plate is arranged on the material feeding pipe in a rotatable manner; a second motor is fixedly mounted on the right side wall of the body; an output shaft of the second motor is coaxially and fixedly equippedwith a driving shaft; a conical channel is formed inside the body; a horizontal rod is arranged in the conical channel; a rotating shaft is arranged on the horizontal rod in a rotatable manner. According to the energy-saving type grain crushing air dryer disclosed by the invention, a crushing roller drives a crushing blade to crush grains in a crushing meshed barrel in a rotatable manner, so thatcrushing of the grains is promoted, in addition, a rotary dispersion effect on the grains is achieved, screening of grain particles by the crushing meshed barrel is promoted, and drying of the grainsby hot air is accelerated; a grinding convex block and crushing teeth squeeze and grind the grains in a rotatable manner, so that the crushing and refining degree is greatly increased; the hot air canbe recycled inside the body, so as to realize cyclic and repeated use of heat energy; therefore, energy is greatly saved, and the grain drying efficiency is improved.

Owner:李凯

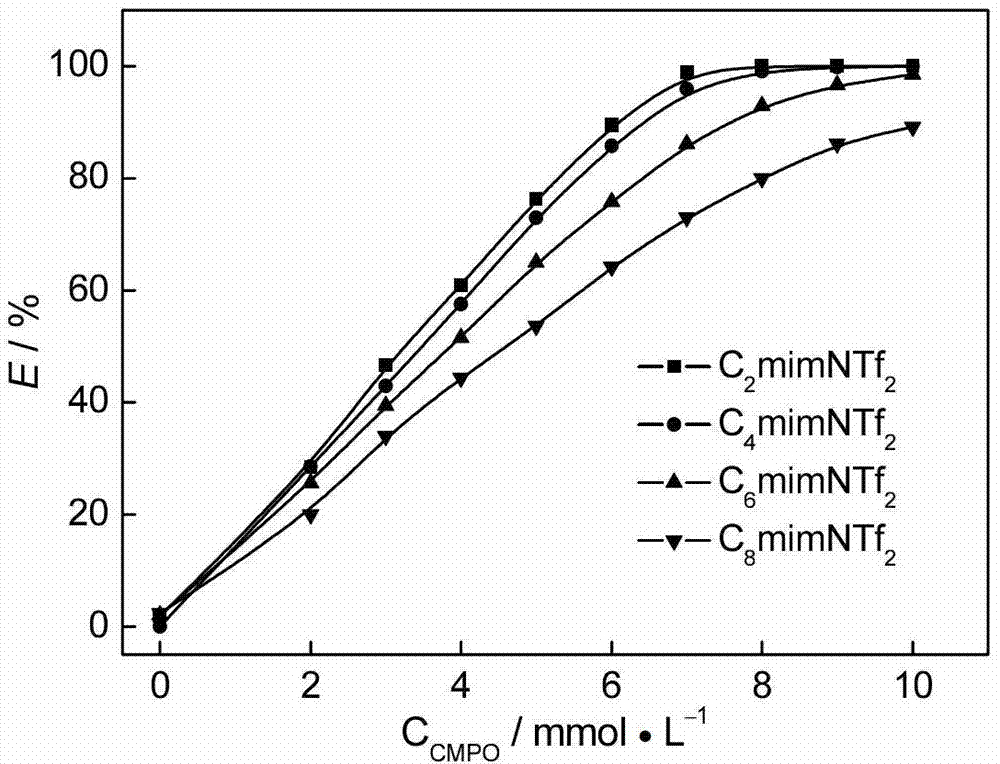

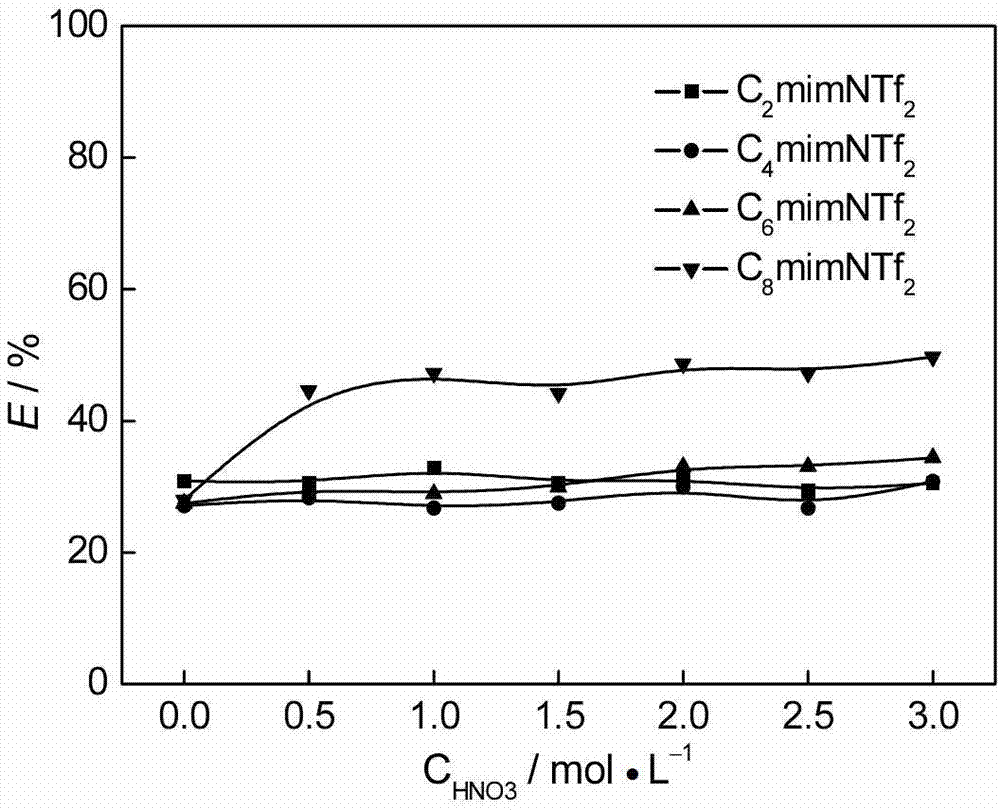

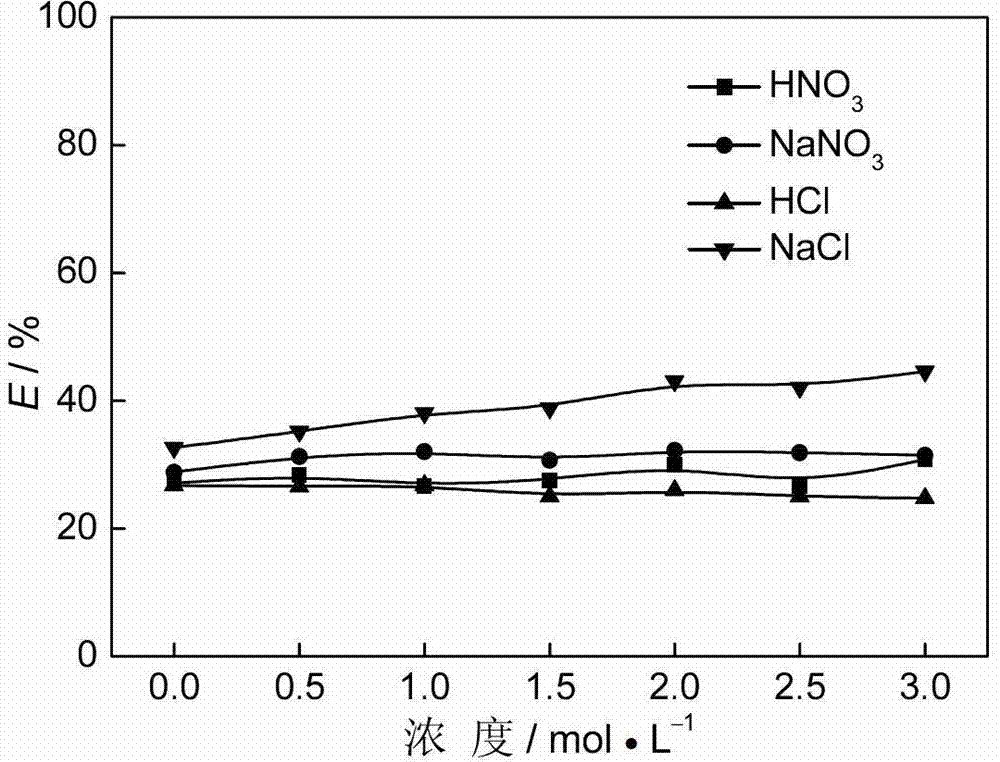

Method for extracting and separating thorium ions by using ion liquid extraction-supercritical CO2 reverse extraction technology

InactiveCN103045881ARealize recycling and reuseEfficient extractionProcess efficiency improvementAqueous solutionIonic liquid

The invention discloses a method for efficiently extracting thorium ions from water phase and efficiently reversely extracting the thorium ions from ion liquid phase by combining with the ion liquid extraction-supercritical CO2 reverse extraction technology. The method adopts ion liquid as thinner and adopts CMPO as extraction agent to efficiently extract out the thorium ions from water solution, and the extraction distribution ratio is up to more than 103; then from an ion liquid system loaded with the thorium ions, the efficient reverse extraction of the thorium ions in different ion liquid extraction systems with acetonitrile solution of TRPO as entrainer by using the supercritical CO2 extraction technology, and the reverse extraction efficiency can be up to more than 99 percent. The method adopts the ion liquid as the thinner, so that the extraction capacity of the system to the thorium ions can be largely improved. sc-CO2 is used as the thinner in the reverse reaction process, so that the loss of the ion liquid in the reverse extraction process can be furthest reduced, the pollution to the ion liquid is avoided, and the reverse extraction efficiency is improved.

Owner:PEKING UNIV

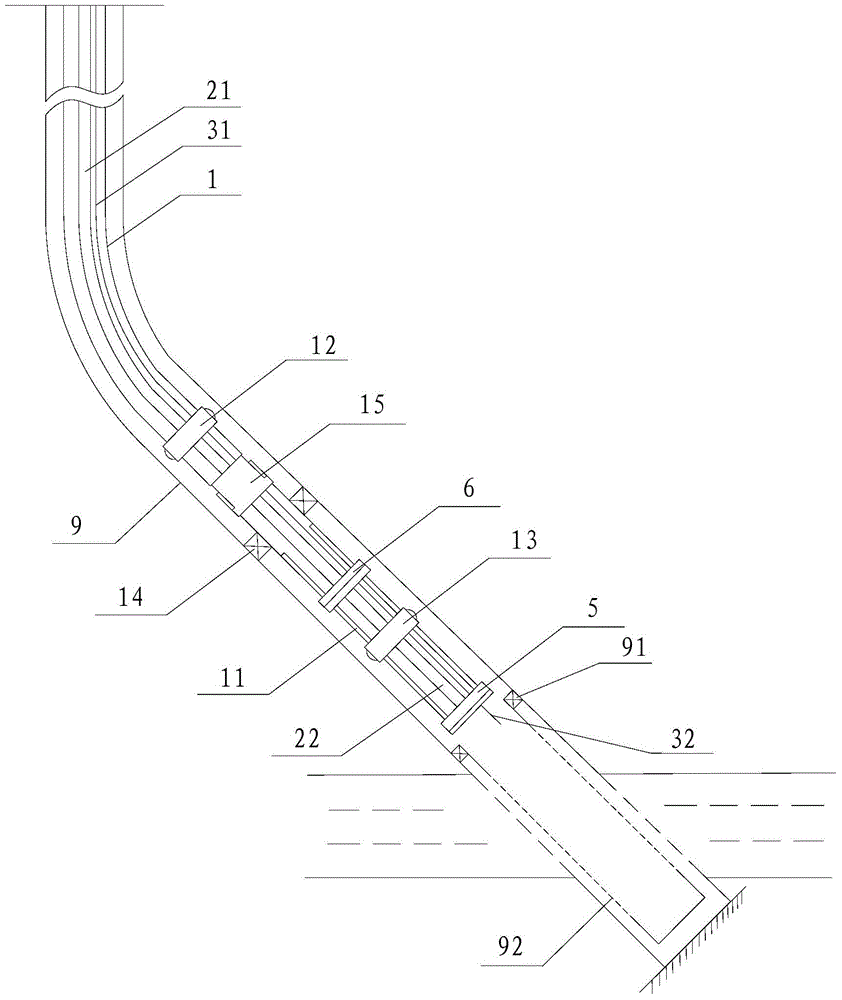

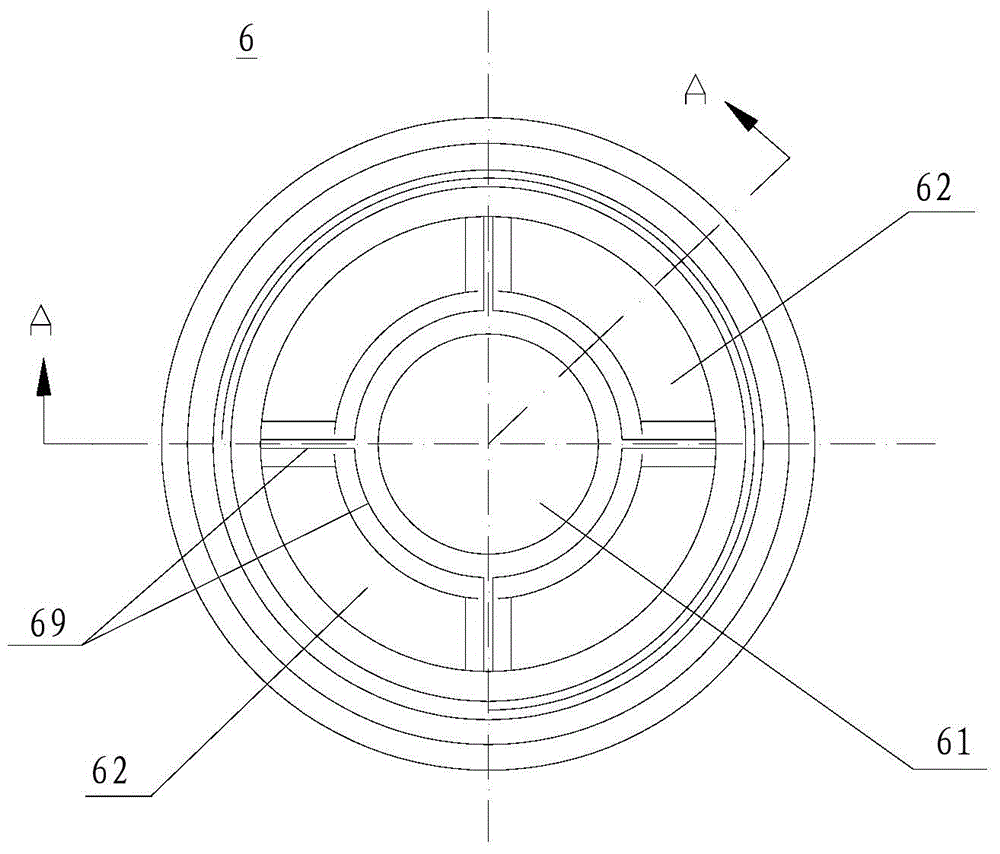

Deviated well in-situ combustion continuous-tube electric ignition tubular column and ignition method

The invention provides a deviated well in-situ combustion continuous-tube electric ignition tubular column and an ignition method. The tubular column comprises an oil tube, wherein an electric ignition cable and a monitoring cable are arranged in the oil tube; at least one guiding and centering device is arranged between tube sections of the oil tube; a guiding and limiting stopper is arranged on the bottom end of the oil tube; the electric ignition cable penetrates through the guiding and centering device so as to be suspended in the oil tube; the bottom end of the electric ignition cable is connected with an electric igniter; the electric igniter is supported in the guiding and limiting stopper; the monitoring cable respectively penetrates through the guiding and centering device and the guiding and limiting stopper so as to be suspended in the oil tube; the bottom end of the monitoring cable is stretched out of the oil tube so as to be connected with a sensor. Therefore, air can be heated uniformly during a highly-deviated well ignition process, and the highly-deviated well ignition effect is improved; in addition, the monitoring cable is arranged in the oil tube, so that the monitoring cable cannot be stuck by a packer during the process of pulling out the oil tube, the recycle and the reuse of the monitoring cable are realized, and the investment cost is reduced.

Owner:PETROCHINA CO LTD

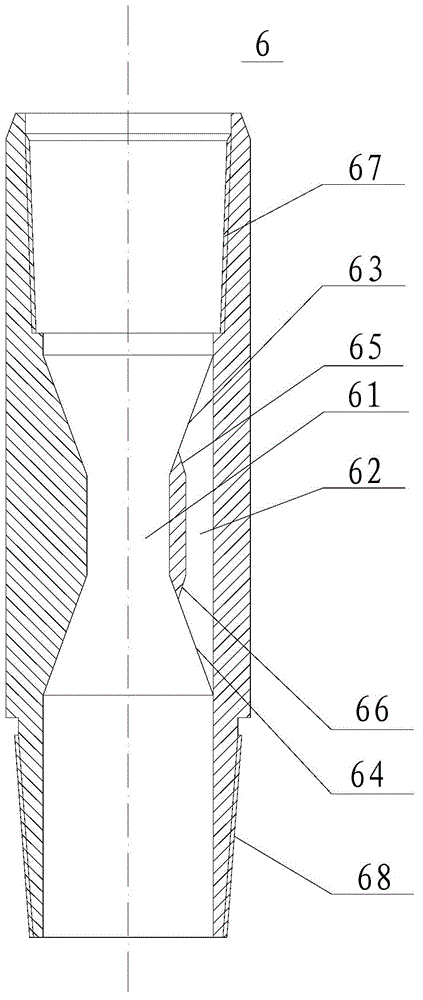

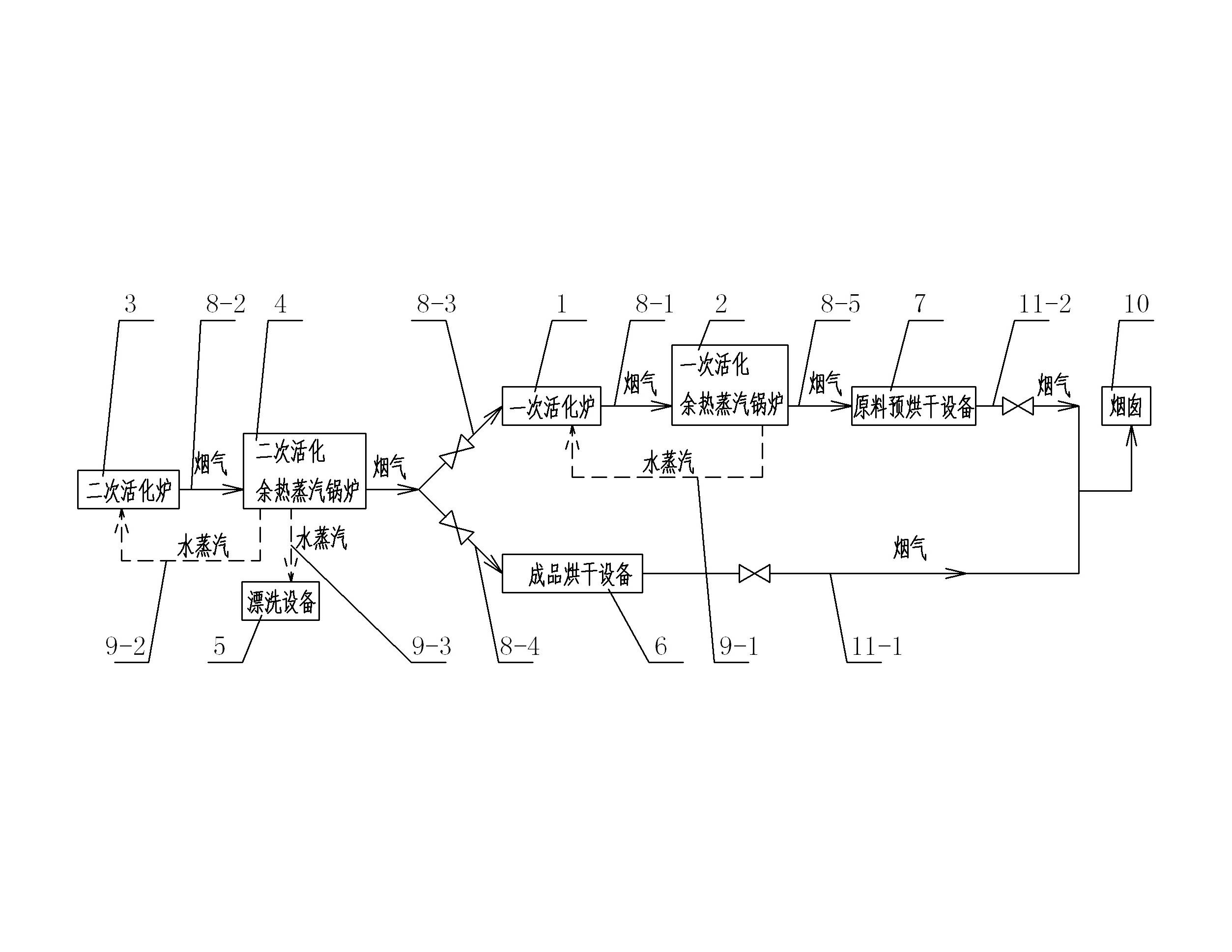

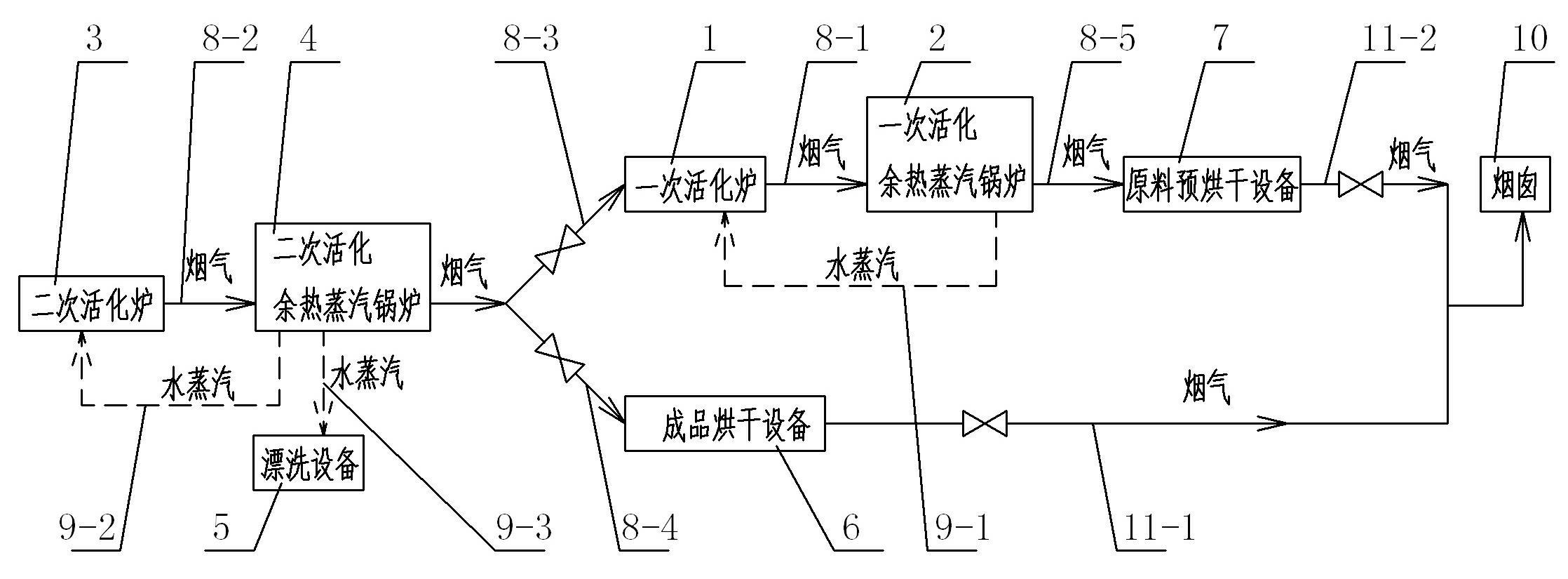

Zero-coal-consumption activated carbon production process and production device used in same

InactiveCN102161484AZero coal consumptionImprove industrial high-tech content and competitivenessCarbon compoundsEnergy inputProcess engineeringEnvironmental geology

The invention relates to a zero-coal-consumption activated carbon production process and a production device used in the process. The production device comprises activation equipment, rinsing equipment and finished product drying equipment, wherein the activation equipment comprises a primary activation equipment and a secondary activation equipment, and the primary activation equipment comprises a primary activation furnace and a primary activation waste heat steam boiler which are connected by a first smoke conveying pipeline and a first vapor conveying pipeline; and the secondary activation equipment comprises a secondary activation furnace and a secondary activation waste heat steam boiler which are connected by a second smoke conveying pipeline and a second vapor conveying pipeline, and a third smoke conveying pipeline is connected between the secondary activation waste heat steam boiler and the primary activation furnace. In the invention, the activation process of the activated carbon are divided into two steps which are sequentially carried out in two sets of activation equipment; therefore, heat generated by the activation reaction of activated carbon is fully recycled so as to realize the ' zero coal consumption' in the production process of activated coal.

Owner:李立建 +2

Novel sewage treatment apparatus

InactiveCN104944670AEasy to handleRealize recycling and reuseMultistage water/sewage treatmentActivated carbon filtrationSewage

The invention relates to a novel sewage treatment apparatus. The apparatus comprises a sewage inlet pipeline, a sewage treatment tank and a water draining pipeline, the middle portion of the sewage treatment tank is provided with a separator plate, the separator plate divides the sewage treatment tank into a left treatment chamber and a right treatment chamber, the separator plate is a hollow cavity structure, the lower portion of the left sidewall of the separator plate is provided with a left water inlet, the upper portion of the right sidewall of the separator plate is provided with a right water outlet, a stainless steel screen frame and a double layer filter screen are sequentially arranged in the left treatment chamber from top to bottom, the right sidewall is also provided with a first magnet and a second magnet, an active carbon filter layer and a cation resin exchange filter layer are sequentially arranged in the right treatment chamber from top to bottom, and the top end is provided with an ultraviolet generator and a medicine adding mouth. The novel sewage treatment apparatus adopting the above structure realizes efficient treatment of wastewater, and greatly reduces pollution substances or impurities in treated water in order to further realize cycle treatment and reuse of sewage.

Owner:TIANJIN ZHONGBANG ENVIRONMENTAL PROTECTION EQUIP

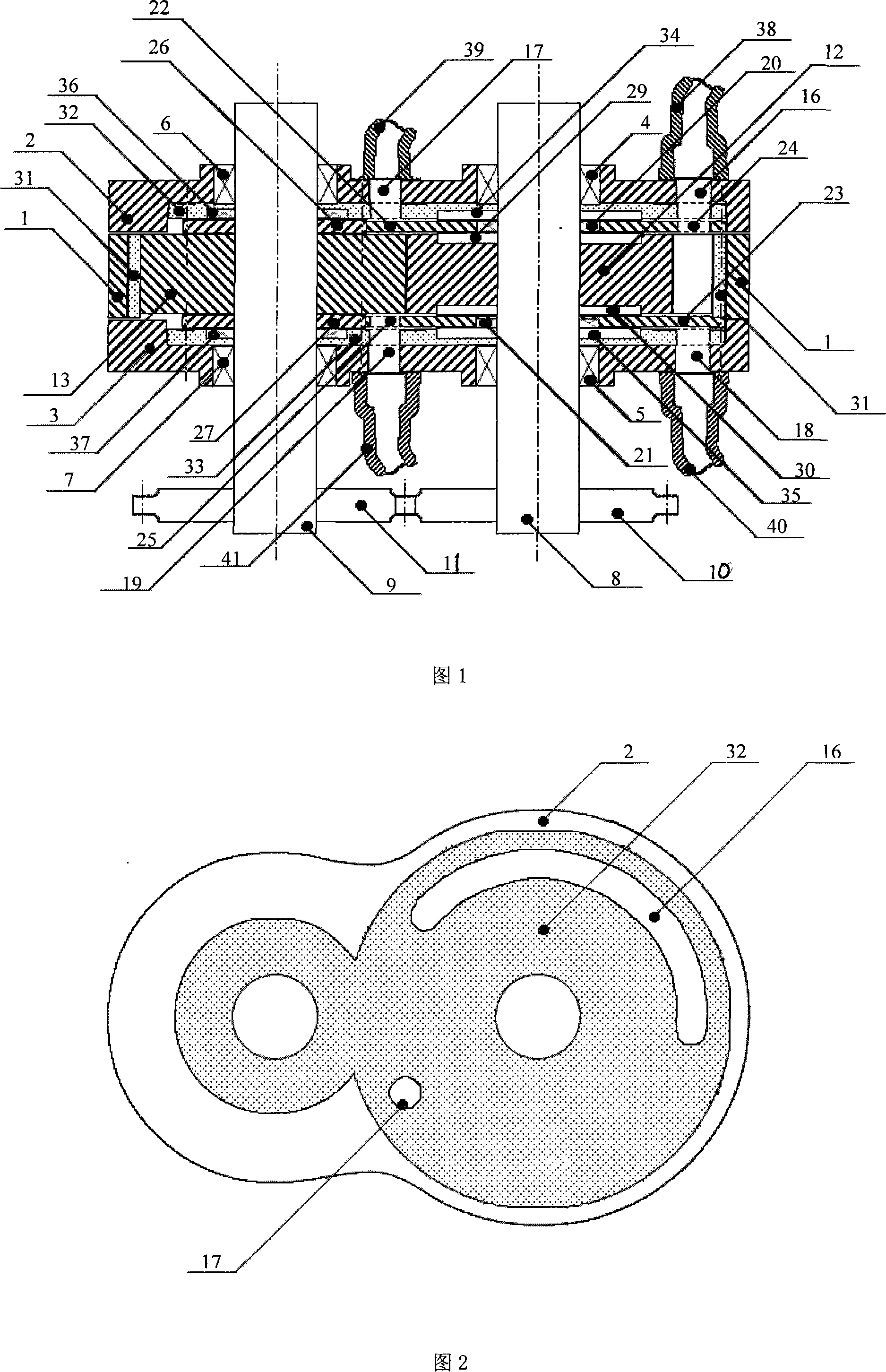

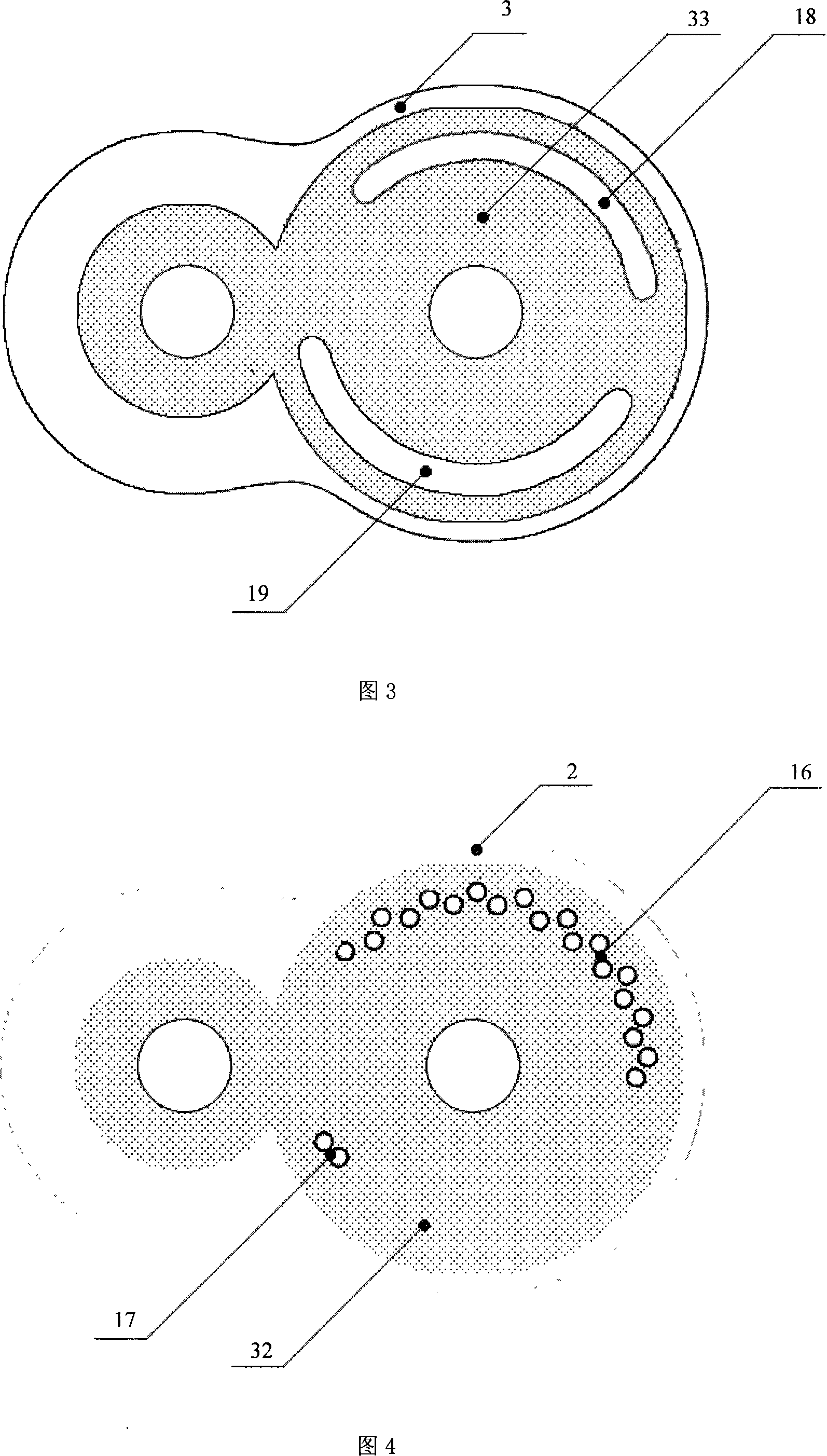

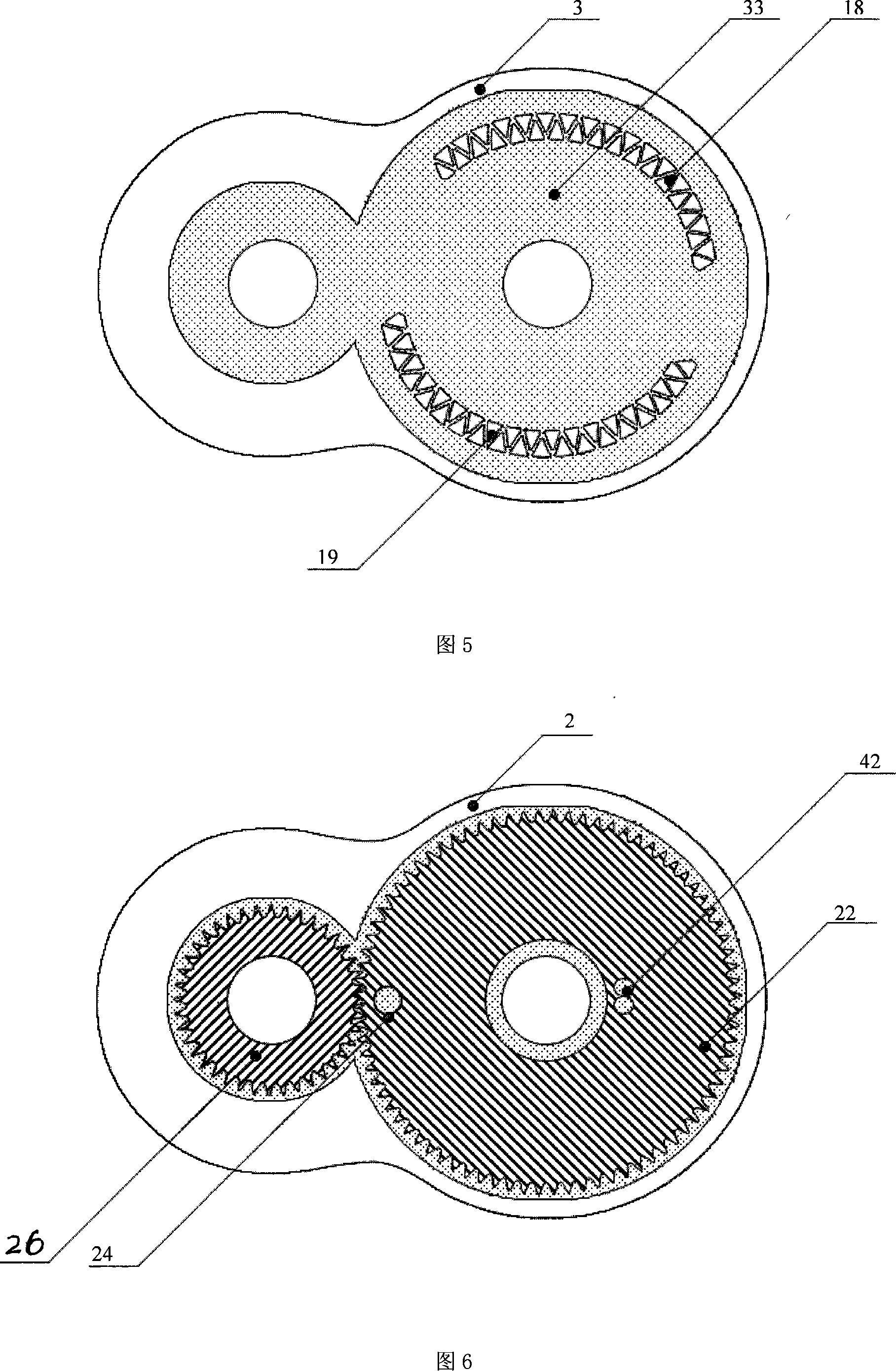

All-rotation engine

InactiveCN101070779AAffect operating efficiencyReduced structureInternal combustion piston enginesReciprocating motionRotary engine

This invention relates to engine, specificly, which is a rotary engine as a whole to resolve the existing unreasonable and complex structure design and low efficiency problem of the rotary engine. The entire rotating engine includes two circular cavity within the cylinder block and cylinder head fixed with before and after lids. The cylinder head and cylinder block in the two circular cavity through the center has a bearing on the support of before and after lids which can rotates at the same time. These two are fixed on a rotating shaft rotary piston round and seal rotating round. Before and after the end surface of cylinder head are equipped with separate exhaust vent, gas mixture into the pores, a fresh gas hole and fresh gas into the hole. At the two ends of rotary piston has former valve gear and after valve gear with stomata above. The whole structure of the rotary engine is scientific-designed and rational. The main part of campaign activities components are one-way rotary movement, no swing, reciprocating movement components. It can be widely applied to cars, motorbikes and other areas of power-needed.

Owner:符晓友

Novel medical plastic garbage incineration system

InactiveCN107631306AImprove processing efficiencyEasy to operateIncinerator apparatusCrusherIncineration

The invention provides a novel medical plastic garbage incineration system, which belongs to the field of plastic garbage treatment, and comprises an incineration device, a purification shell and a conveying device. The incineration device is vertically placed; a connecting pipe is arranged between the conveying device and the incineration device; the conveying device is in threaded connection tothe left end of the connecting pipe; the right end of the connecting pipe is fixedly connected with the incineration device; a feed hopper is arranged at the upper end of the conveying device; a crusher is arranged in the feed hopper; a conveyor is arranged at the lower end of the crusher and is fixedly connected with the conveying device; the incineration device comprises a water inlet pipe, an air outlet pipe, an oxygen tank, an ignition device, an incineration plate and a water outlet pipe; an incineration cavity is arranged in the incineration device; and the incineration plate fixedly connected onto the incineration device is arranged under the middle part of the incineration cavity. The invention provides the medical plastic garbage treatment device, which is high in treatment efficiency, simple to operate, reasonable in design, wide in application range, high in treatment efficiency and low in cost.

Owner:HUIAN WEIKE ELECTRONICS TECH CO LTD

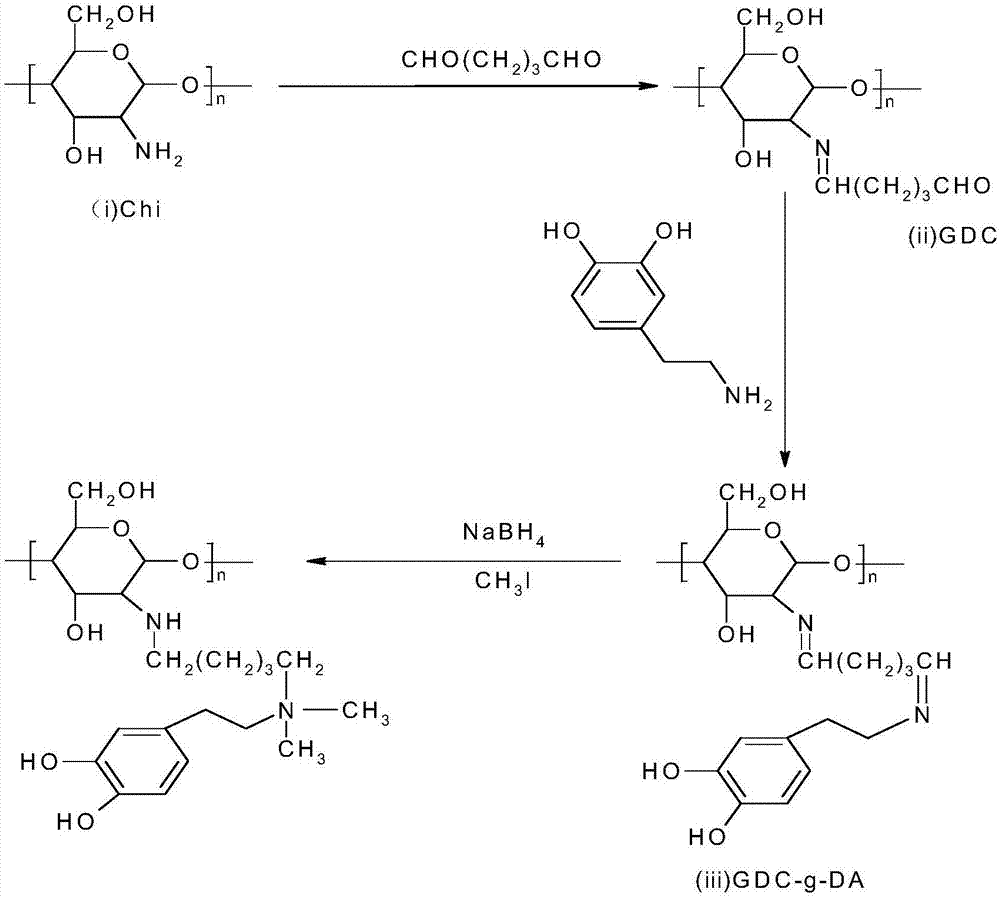

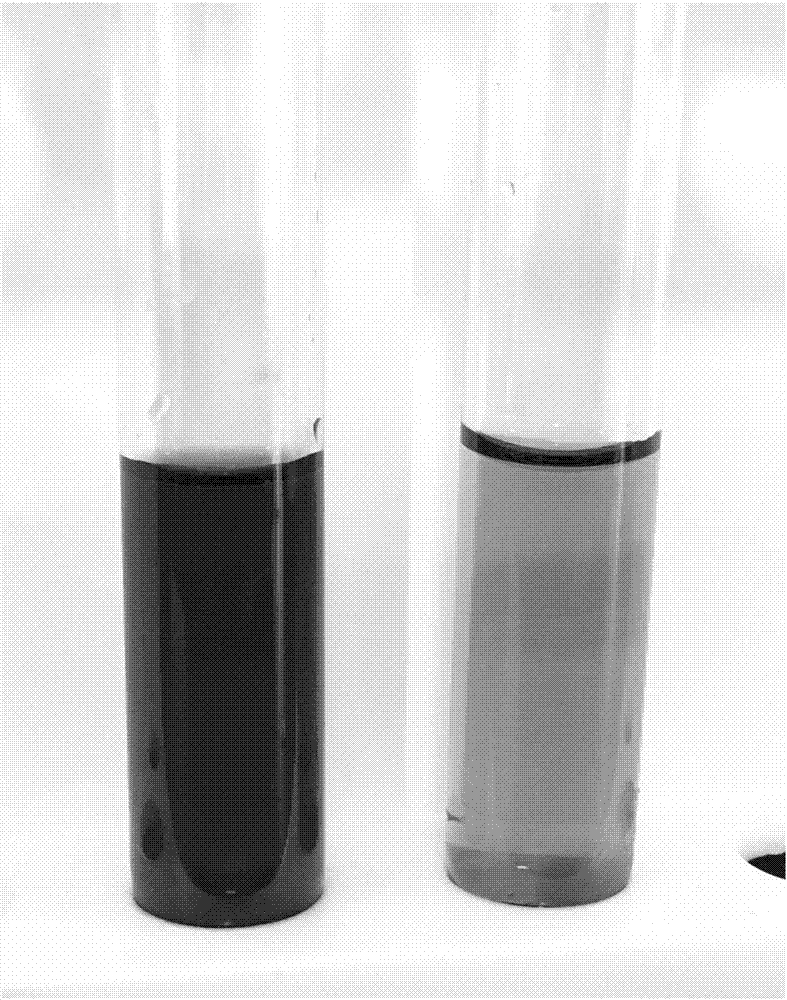

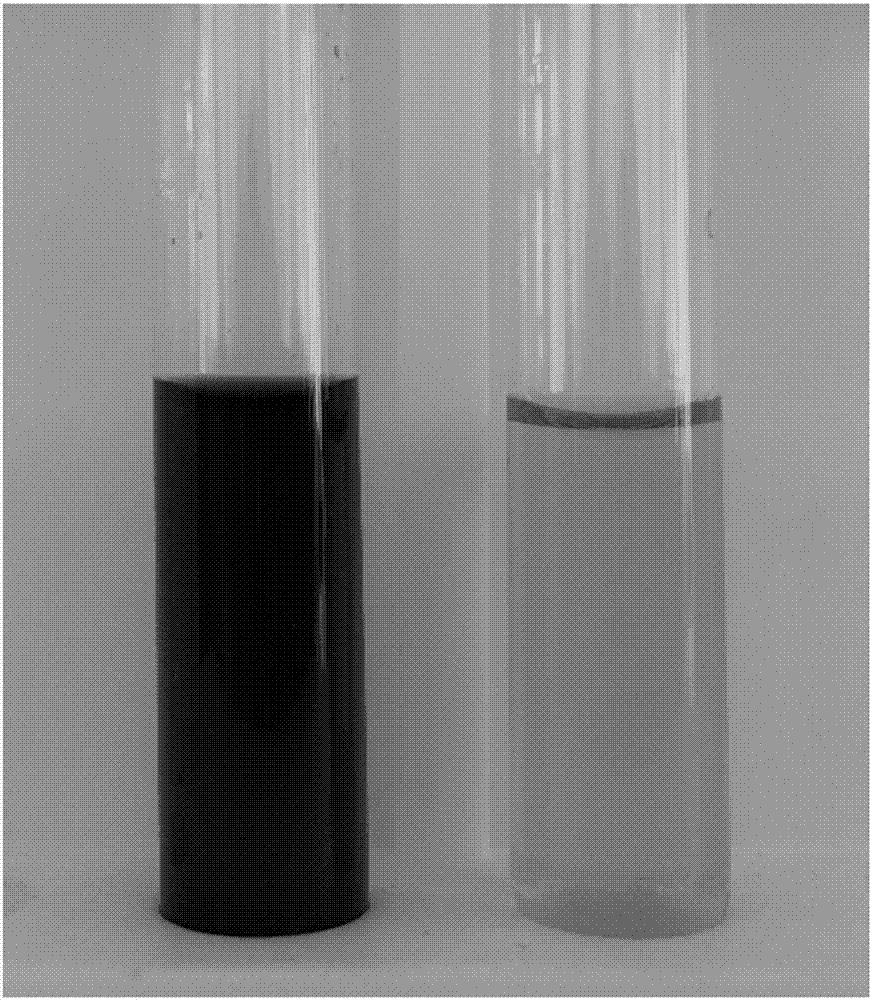

Dopamine-modified chitosan flocculant

ActiveCN107055729AGood biocompatibilityLow priceWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationFlocculationSolubility

The invention provides a chitosan flocculant for treating sewage containing polyacrylamide. The chitosan flocculant is prepared through grafting of chitosan with dopamine adopting an o-dyhydroxyl structure by the aid of glutaraldehyde under the acidic condition. Materials used in the flocculant are green and pollution-free and cause less damage to the environment. The novel flocculant synthesized by grafting chitosan with dopamine greatly increases the adsorption capability and the dissolubility of chitosan and has a flocculation good effect on sewage containing polyacrylamide; secondary flocculation of dye sewage can be realized by use of precipitates obtained after sewage containing polyacrylamide is treated by the flocculant, and a relatively ideal flocculation effect is obtained. By means of the flocculant, secondary recycling of polyacrylamide is realized, the flocculant has a better flocculation effect on the sewage containing polyacrylamide and printing and dyeing sewage, the flocculation efficiency is greatly improved, and the flocculation cost is saved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Belt replacing method for coal mine belt conveyors

ActiveCN106697723ARealize synchronous replacementRealize recycling and reuseConveyorsArticle deliveryEnvironmental structureEngineering

The invention discloses a belt replacing method for coal mine belt conveyors. According to the method, the system structure of the two existing belt conveyors and the roadway environment structure are utilized, a double-speed prop pulling hoist is mounted on each conveyor head, new belts and used belts are mechanically connected by fully utilizing traction force of the prop pulling hoists and the two belt conveyors, and the used belts slide to drag the new belts to slowly enter the belt conveyors; and after the new belts and the used belts are circulated for a circle, replacing of the used belts with the new belts is achieved, and meanwhile, recycling of the whole used belts is achieved. By means of the method, synchronous replacement of the belts of the two cross-heading conveyors for a coal mine is achieved, and the method has the construction advantages of safety, high efficiency and time and labor saving, and promotes safety production of the mine.

Owner:枣庄矿业(集团)有限责任公司蒋庄煤矿

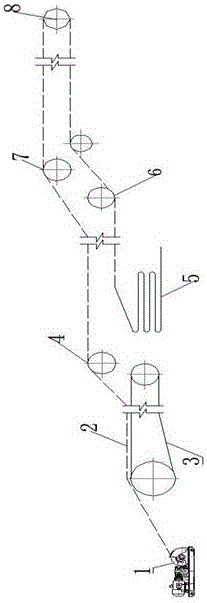

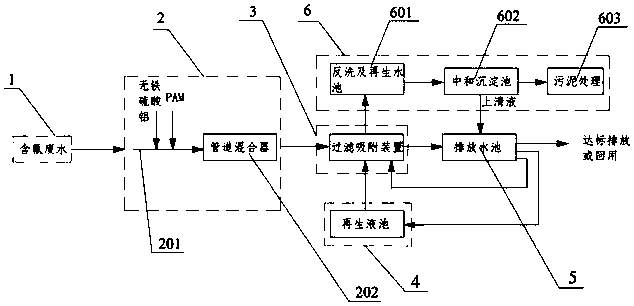

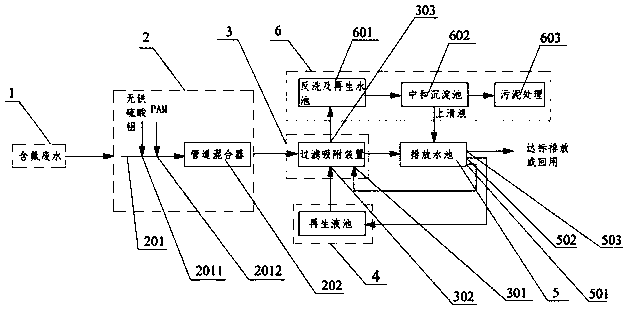

Advanced disposal system and method of low-concentration fluorine-containing wastewater

ActiveCN109607868ALittle impact on water qualityExtend the life cycleWater contaminantsTreatment involving filtrationIon contentFlocculation

The invention discloses an advanced disposal system and method of low-concentration fluorine-containing wastewater. The system comprises a low-concentration fluorine-containing wastewater pool, a flocculation reaction unit, a filtration adsorption unit, a regeneration unit, a drainage system, a waste liquid disposal unit, an automatic liquid level monitoring interlocking system and an online fluorine ion detection control system. The system is used for efficiently disposing the low-concentration fluorine-containing wastewater in the presence of different flocculants and activated alumina, andtherefore purified water with the fluorine ion content below 0.5mg / L can be obtained. The system and a disposal process integrate filtration, adsorption and regeneration into a whole part and have theadvantages that the structure is simple, operation is convenient, the disposal efficiency is high, and the purification effect is great. Standard discharge of fluorine-containing wastewater disposalis achieved completely, and water obtained after disposal can be directly recovered and serve as a water source for preparing pure water.

Owner:HENAN LONGYU COAL CHEM

Method for recovering metal elements in waste lithium ion batteries

ActiveCN104164568AAchieve separationHigh crystallinityWaste accumulators reclaimingProcess efficiency improvementElectrical batteryDissolution

The invention discloses a method for recovering metal elements in waste lithium ion batteries, which comprises the following steps: (1) dispersing mechanically-pulverized waste battery powder in a sodium hydroxide solution for dissolution, and carrying out swirl separation to obtain plastic powder and carbon powder from the upper layer of the solution and obtain copper powder and electrode powder from the lower part; (2) obtaining an aluminum hydroxide precipitate; (3) obtaining copper sulfate solid powder; (4) obtaining a lithium carbonate precipitate; (5) and obtaining cobalt oxalate. The method comprehensively separates the metal elements cobalt, copper, aluminum and lithium in the battery powder; the aluminum hydroxide, copper sulfate, cobalt oxalate and lithium carbonate prepared by the method have the advantages of high uniformity and high crystallinity; and the method implements recovery and reutilization of the battery materials, and is low in cost and suitable for industrialized large-scale production.

Owner:贵州中伟资源循环产业发展有限公司

Method for recovering and extracting cobalt, copper, aluminum and lithium four metal elements in waste lithium-ion batteries by using liquid phase reaction

InactiveCN104124487BAchieve separationHigh crystallinityWaste accumulators reclaimingProcess efficiency improvementAluminium hydroxideCrystallinity

The invention discloses a method for recovering and extracting four metal elements including cobalt, copper, aluminum and lithium in a waste lithium ion battery by using liquid phase reaction. The method comprises the following steps: (1), dispersing 1-1000 g of mechanically crushed waste battery powder in a sodium hydroxide solution, after completely dissolving a dissoluble part in the battery powder, separating plastic powder and carbon powder from an upper layer of the solution and separating electrode powder in a lower layer of the solution by using a cyclone separation method, and obtaining copper powder from a filter net at a middle layer of the solution; (2), obtaining aluminum hydroxide sediment; (3), obtaining lithium carbonate sediment; and (4), obtaining cobalt oxalate. According to the method, the separation of cobalt, copper, aluminum and lithium is realized, aluminum hydroxide, cobalt oxalate and lithium carbonate prepared by using the method are uniform and consistent, and high in degree of crystallinity; and aluminum hydroxide, copper powder, cobalt oxalate and lithium carbonate are obtained, therefore, recycling of a battery material is realized, the cost is low, and the method is suitable for large-scale industrialized production.

Owner:宁波卡尔新材料科技有限公司

Nano-fiber supported cobalt-silver alloy material as well as preparation method and application thereof

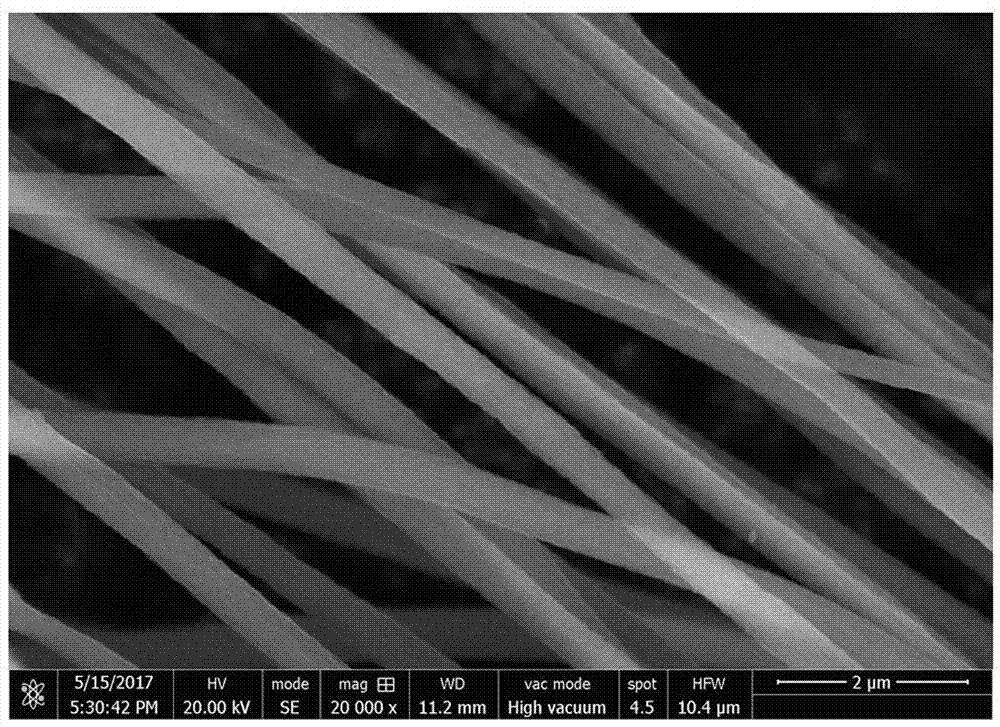

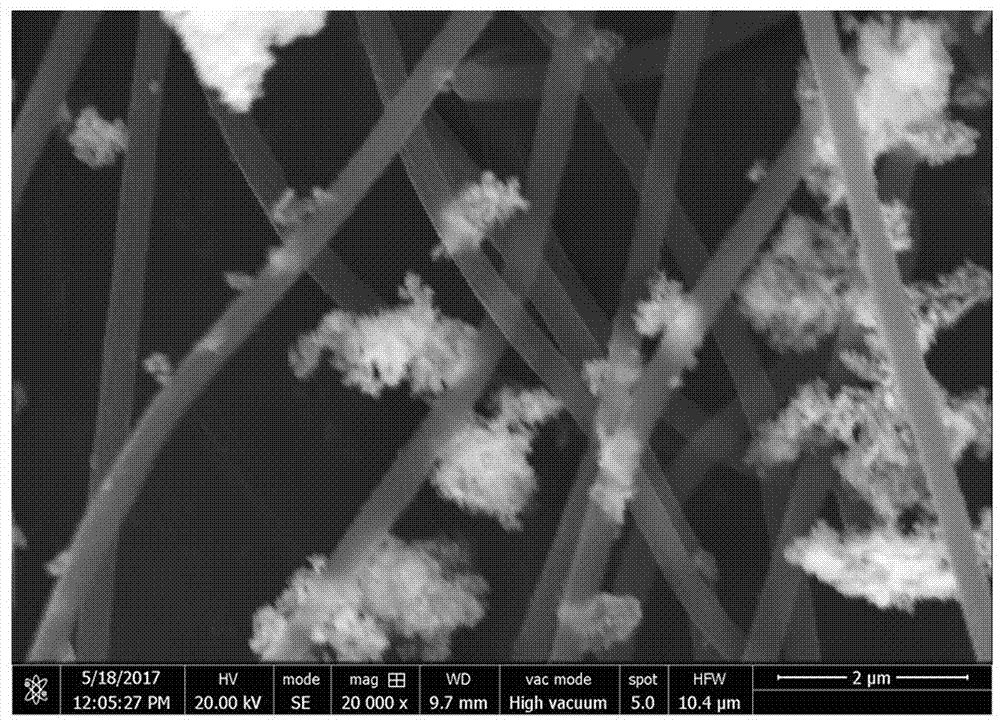

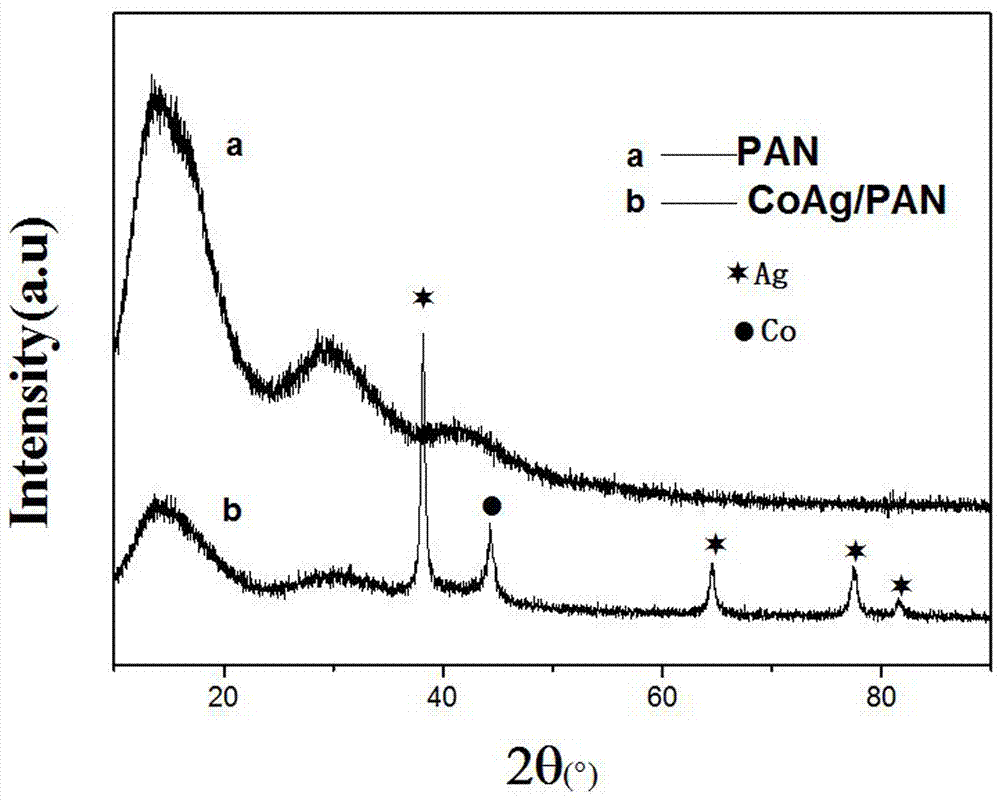

ActiveCN107321383AScattered and not reunitedEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsElectro-spinningFiberHydrogen desorption

The invention discloses a nano-fiber supported cobalt-silver alloy material. Nano-fiber is prepared with an electrostatic spinning method, cobalt particles are prepared with an impregnation chemical reduction method, a cobalt-silver alloy is prepared with an oxidation reduction method and supported on the nano-fiber, and the nano-fiber supported cobalt-silver alloy material is obtained. The preparation method of the nano-fiber supported cobalt-silver alloy material comprises steps as follows: 1) the nano-fiber is prepared with the electrostatic spinning method; 2) the cobalt particles are firstly prepared with the impregnation chemical reduction method; 3) the cobalt-silver alloy is prepared with the oxidation reduction method and supported on the nano-fiber. When the material is used as a catalyst for preparation of hydrogen through ammonia borane hydrolysis, hydrogen desorption is completed in 40 min, the hydrogen desorption rate is high, cycle tests indicate that the material has good cycle performance. The nano-fiber exists in the form of a cylindrical shape and has a high specific surface area and stable properties, the cobalt-silver alloy is uniformly and stably supported on the nano-fiber, is uniformly dispersed, does not agglomerate and can quickly catalyze ammonia borane to be hydrolyzed for hydrogen preparation, and accordingly, the material has broad application prospects in hydrogen preparation, fuel cells and other fields.

Owner:GUILIN UNIV OF ELECTRONIC TECH

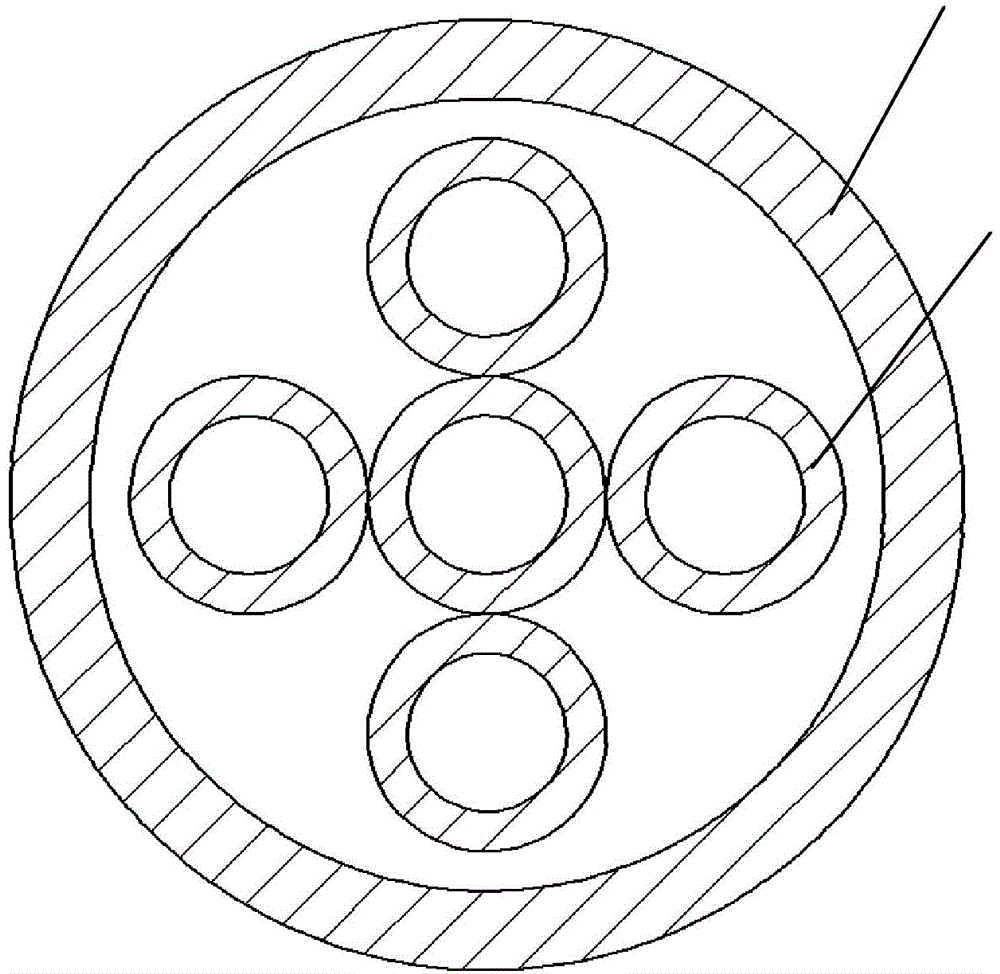

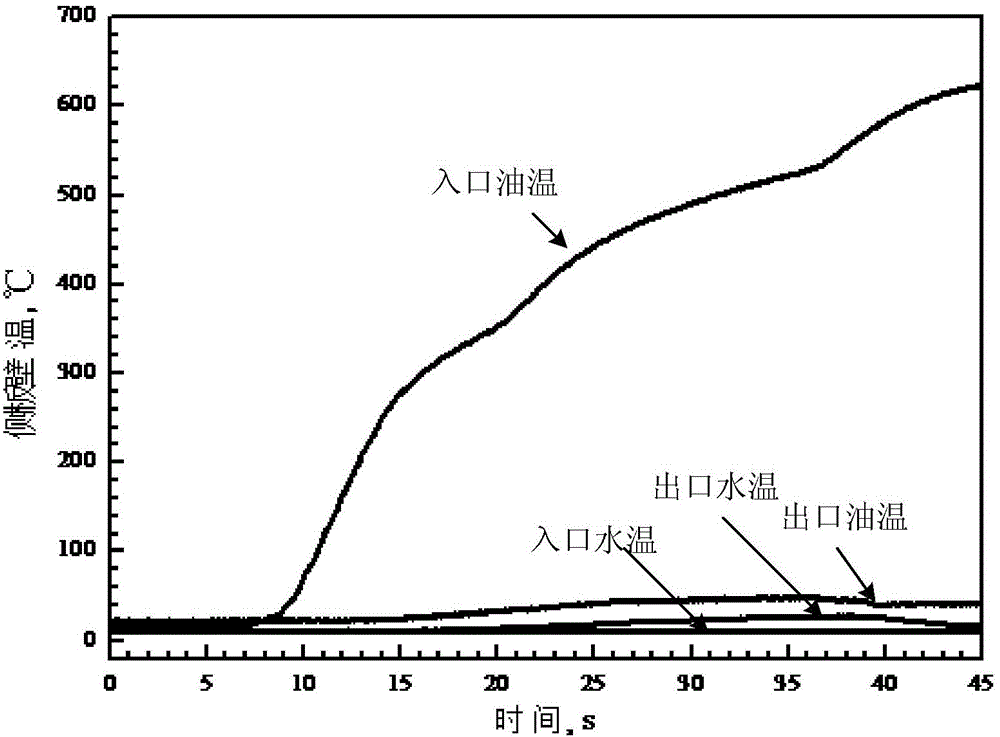

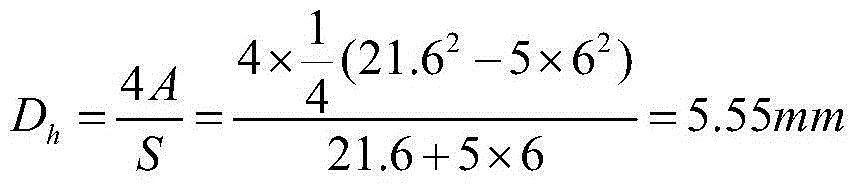

Device for recycling high temperature kerosene of scramjet engine

InactiveCN103557716ARealize recycling and reuseAvoid pollutionSteam/vapor condensersKeroseneEngineering

The invention discloses a device for recycling high temperature kerosene of a scramjet engine. The device is composed of one telescoping condenser or formed by serially connecting a plurality of telescoping condensers, each telescoping condenser comprises an outer layer casing pipe and a plurality of inner layer liner pipes, the inner layer liner pipes are located in the outer layer casing pipe, the high temperature kerosene is fed into the inner layer liner pipes, normal temperature water serving as a cooling liquid is fed into the outer layer casing pipe, and the high temperature kerosene is cooled through heat convection. According to the device, the cooling kerosene of the scramjet engine can be rapidly cooled from around 600 DEG C to below 50 DEG C, so that recycling of the cooling kerosene is achieved, and environmental pollution is avoided.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

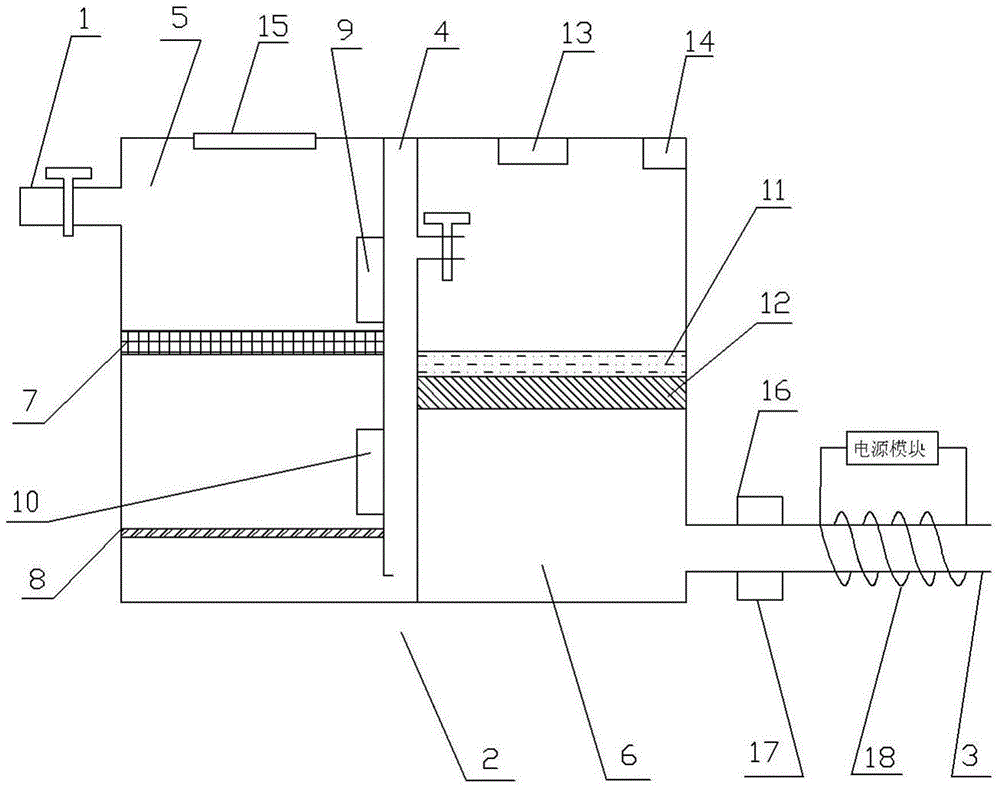

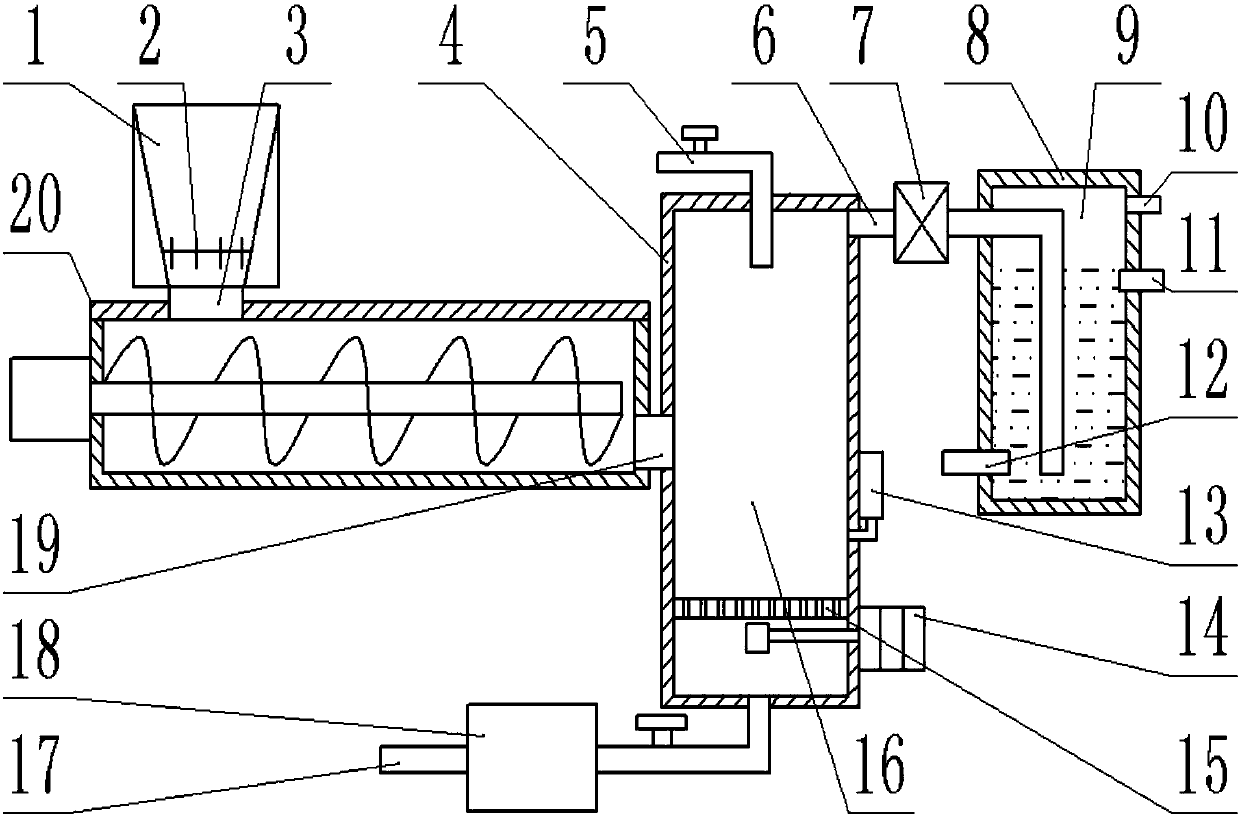

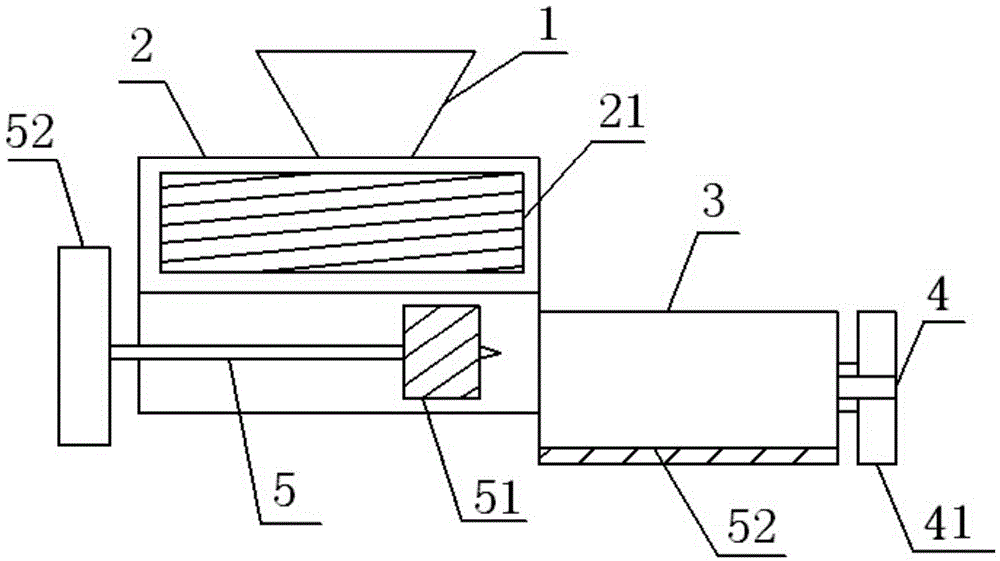

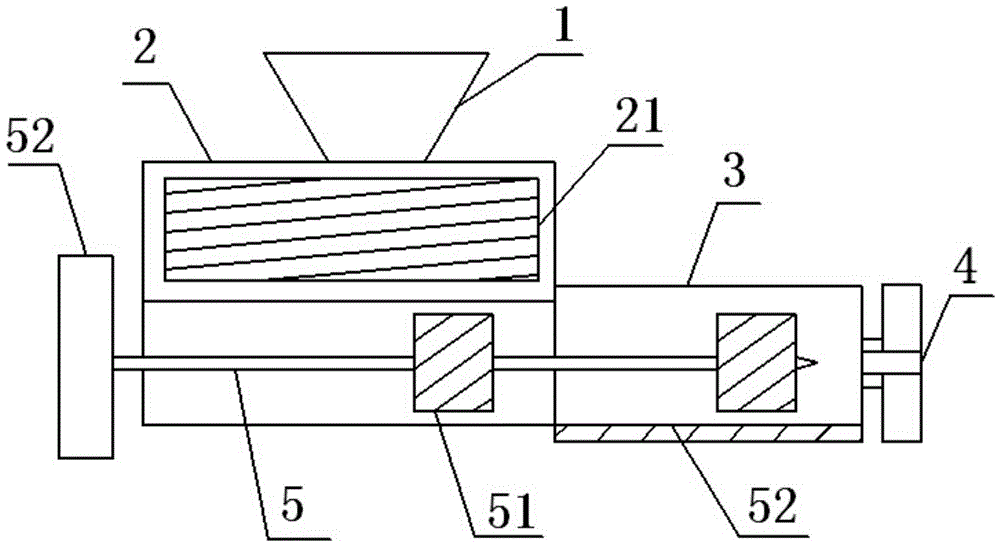

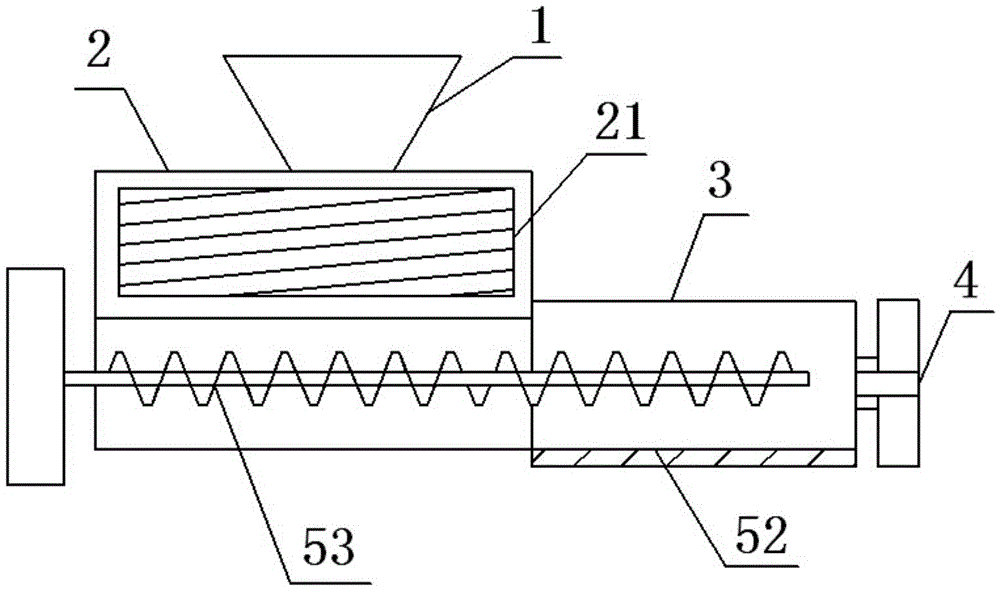

Recovering device for waste 3D printing consumables

InactiveCN104972664ARealize recycling and reuseLow costAdditive manufacturing apparatusMolten stateConsumables

The invention discloses a recovering device for waste 3D printing consumables. The recovering device comprises a feed inlet and a crushing chamber connected with the feed inlet, wherein the crushing chamber is connected with a heating chamber and a conveying assembly conveying waste 3D printing consumables to the heating chamber, and the heating chamber is provided with a discharge out used for outputting heat-molten recovered waste 3D printing consumables. According to the invention, the waste 3D printing consumables enter a feed chamber through the feed inlet, then are conveyed to the heating chamber from the feed chamber via the conveying assembly and turn into molten semi-fluid under heating; the heated waste 3D printing consumables are output from the discharge outlet in a semi-fluid state; the semi-fluid is rapidly cooled when passing through an output port and becomes filamentous; thus, recovery of the waste 3D printing consumables is realized, the utilization rate of 3D printing consumables is increased, and the waste 3D printing consumables is prevented from polluting the environment.

Owner:北京威控睿博科技有限公司

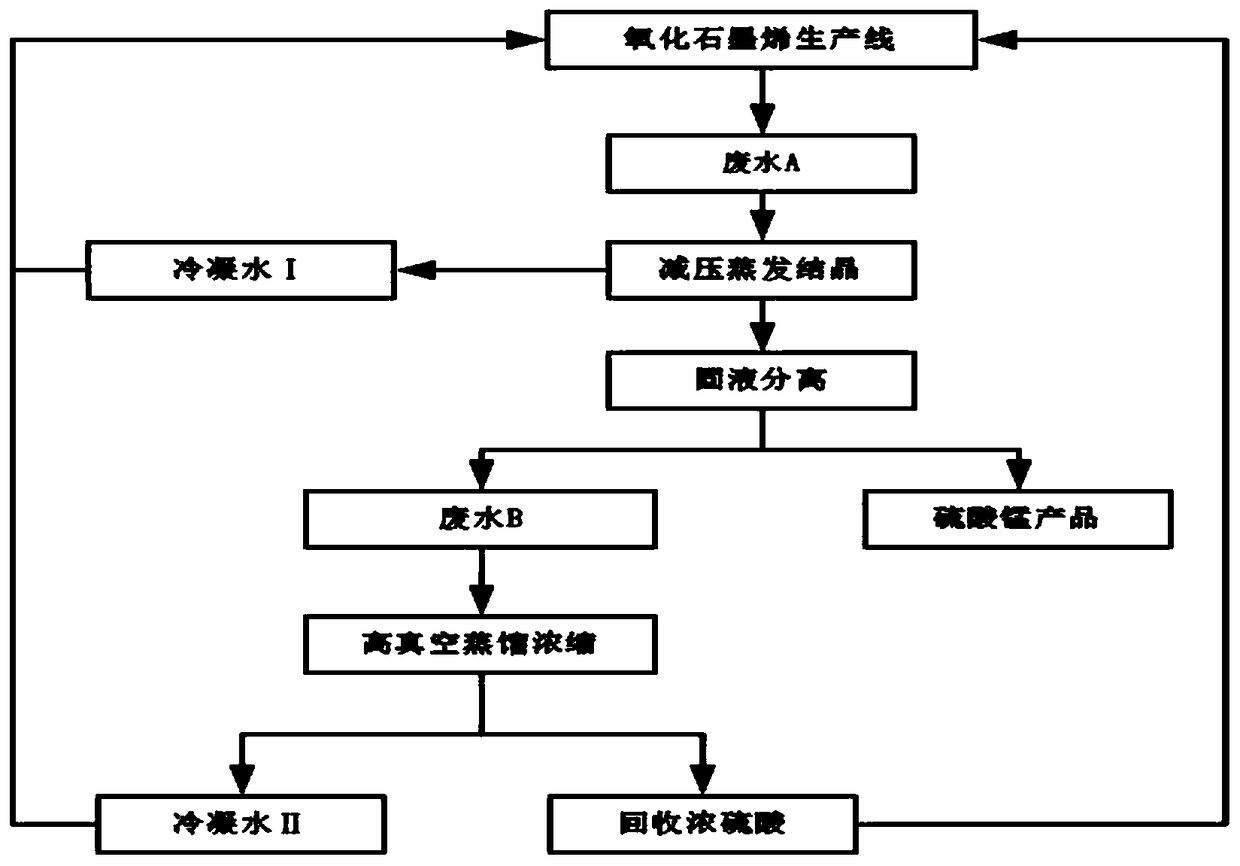

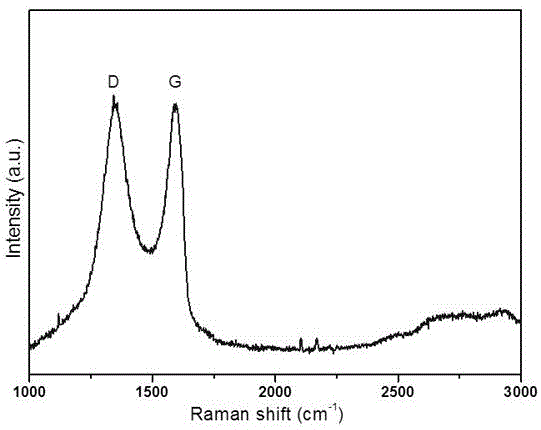

Treatment method for resource utilization of waste liquid in production of graphene oxide

ActiveCN109319999AClose the loopZero pollutionTreatment involving filtrationSulfur-trioxide/sulfuric-acidResource utilizationSulfate

The invention relates to a treatment method for resource utilization of waste liquid in production of graphene oxide. The treatment method comprises the following steps of (1) pretreating the wastewater, so as to obtain wastewater A; (2) evaporating and crystallizing the wastewater A, and filtering, so as to obtain crystals, condensate water I and wastewater B; washing and drying the crystals, soas to obtain manganese sulfate crystals; (3) distilling and concentrating the wastewater B under a vacuum condition, so as to obtain condensate water II and recycled acid; returning the condensate water I, the condensate water II and the recycled acid back into the production technology for recycling. The treatment method for the resource utilization of the waste liquid in the production of the graphene oxide has the advantages that the characteristic of dissolving degree of the manganese sulfate in sulfuric acid is utilized, and the crystals are removed by the evaporation and crystallizationtechnology, so as to obtain the manganese sulfate; the obtained wastewater in the separating process is concentrated into finished acid, and the finished acid and the condensate water produced in theevaporation process are returned back into the production process for recycling, so as to realize the purposes of zero drainage and high-efficiency recycling of the wastewater in the production process of the graphene oxide.

Owner:新疆烯金石墨烯科技有限公司

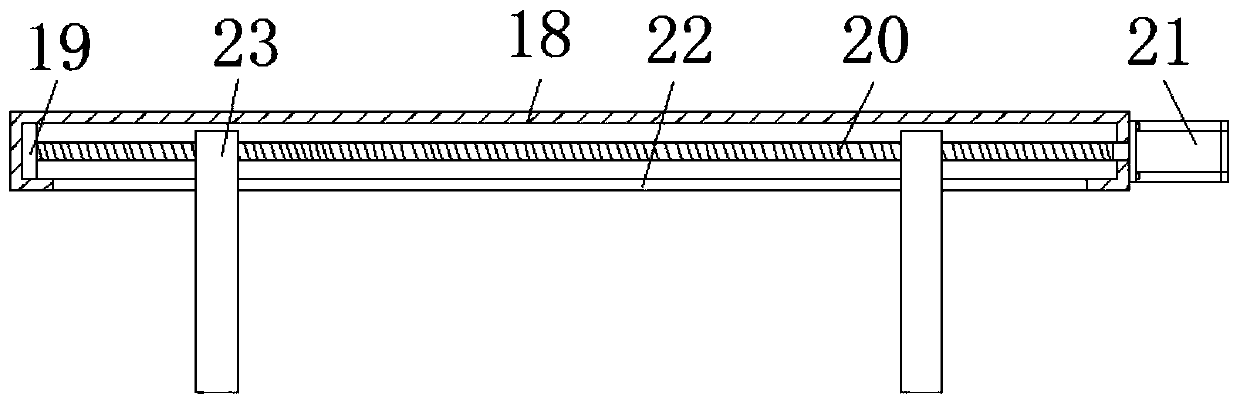

Device capable of repeatedly utilizing pore water pressure gauges and manufacturing method of device

ActiveCN105256785APrecise positioningSo as not to damageIn situ soil foundationPore water pressureEngineering

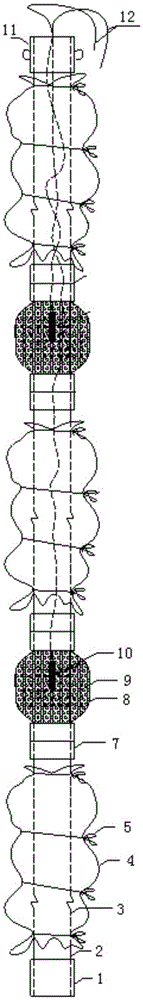

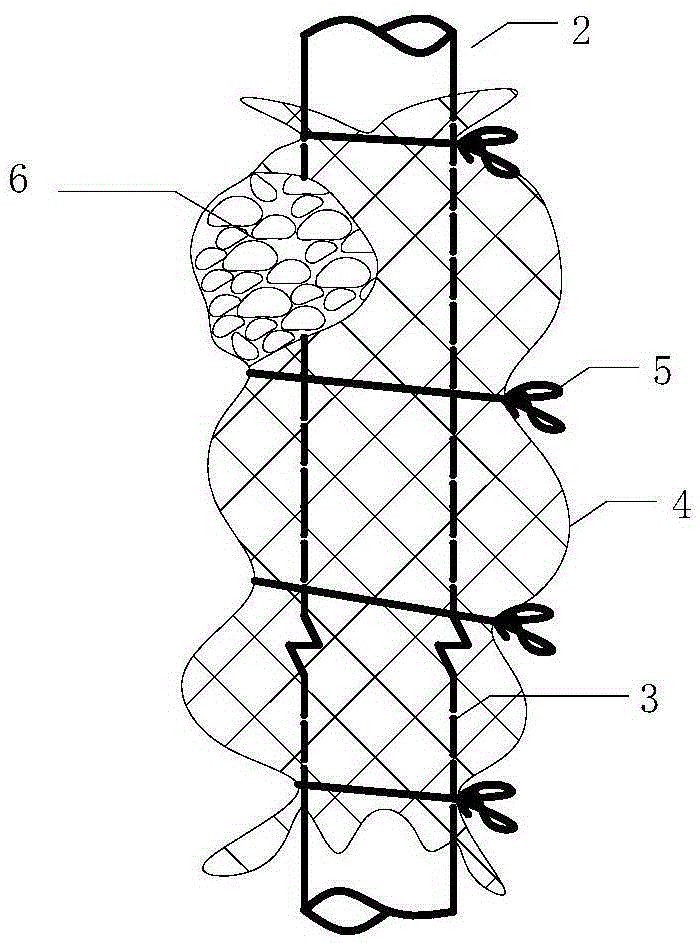

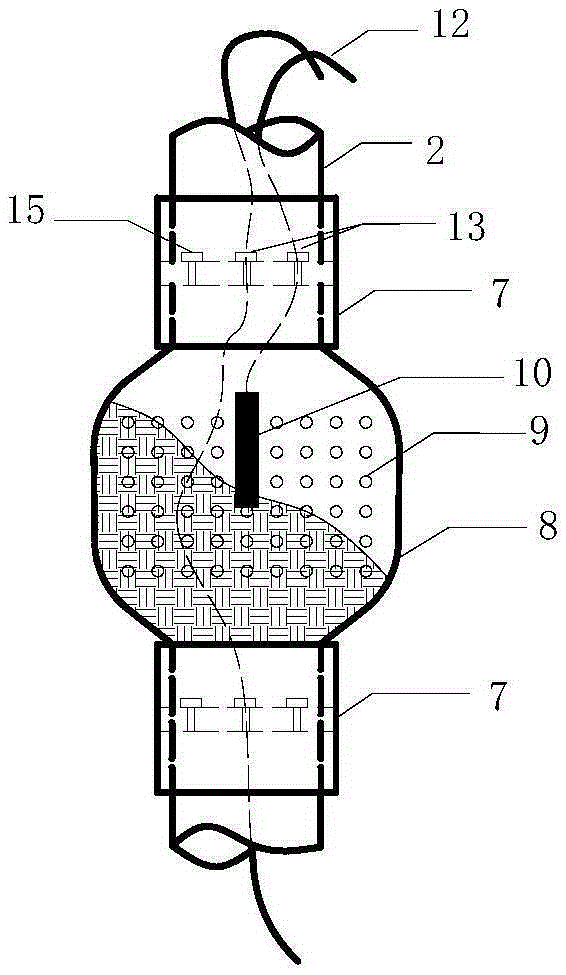

The invention discloses a device capable of repeatedly utilizing pore water pressure gauges. The device comprises a plurality of steel pipes arranged from top to bottom. A filter pipe is arranged between every two adjacent steel pipes. The upper end and the lower end of each filter pipe are connected and fixed to the two corresponding steel pipes respectively through two connecting sleeves so as to form a pipe structure of the whole device. A bottom end sleeve is arranged at the bottom of the steel pipe at the lowest end of the pipe structure, and a top end sleeve with an opening in the upper portion is arranged on the top of the steel pipe at the uppermost end of the pipe structure. Holes are formed in the side walls of the filter pipes of the pipe structure. The side walls of the filter pipes are wrapped by non-woven fabric. Each filter pipe is internally provided with one pore water pressure gauge. Wires of the pore water pressure gauges are led out of the opening in the upper portion of the top end sleeve. According to the device, the multiple pore water pressure gauges are embedded in one single drill hole. Meanwhile, the device is convenient to assemble and disassemble, and it can be guaranteed that the pore water pressure gauges are not damaged in the monitoring process. The invention further discloses a manufacturing method of the device capable of repeatedly utilizing the pore water pressure gauges.

Owner:HUNAN UNIV OF SCI & TECH

Sulfonated vinegar residues and preparation method and application thereof

ActiveCN105562082ASimple technical processHigh sulfonation efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryGranularity

The invention discloses sulfonated vinegar residues and a preparation method and application thereof, and belongs to the field of chemical industry production and pharmaceutical production. The sulfonated vinegar residues are formed by mixing vinegar residues with sulfonating agent and baking vinegar residues and sulfonating agent through a wet method, wherein the sulfonated vinegar residues have the granularity of about 170-190 meshes, the specific surface area of 2.3864-2.5417 m<2> / g and the aperture of 0.3+ / -0.04 micron, and the content of sulfo groups in each gram of sulfonated vinegar residues is 41.382-53.298 mg. By means of the wet-method baking technology, vinegar residues are efficiently sulfonated; the sulfonated vinegar residues are little in sewage discharge, low in cost, high in sulfonating efficiency and long in service life, and a sulfonated vinegar residue catalyst is high in activity.

Owner:LULIANG UNIV

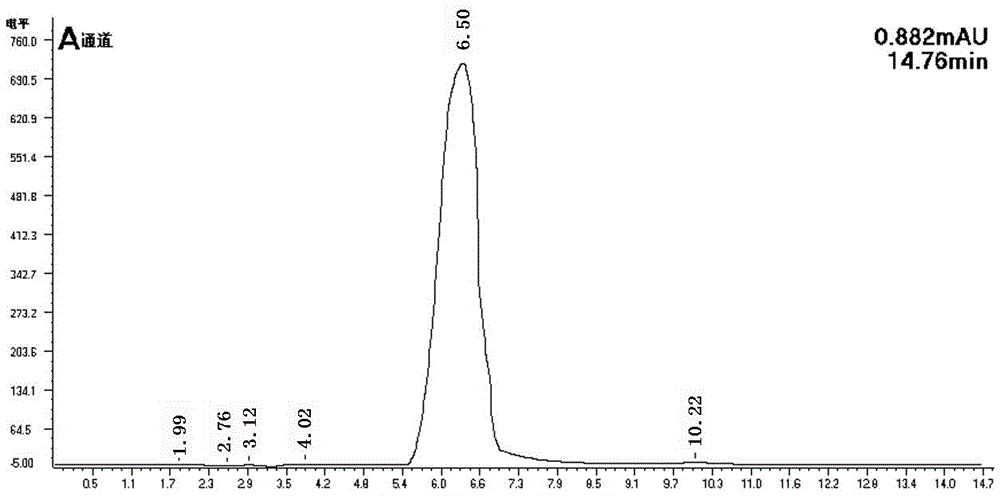

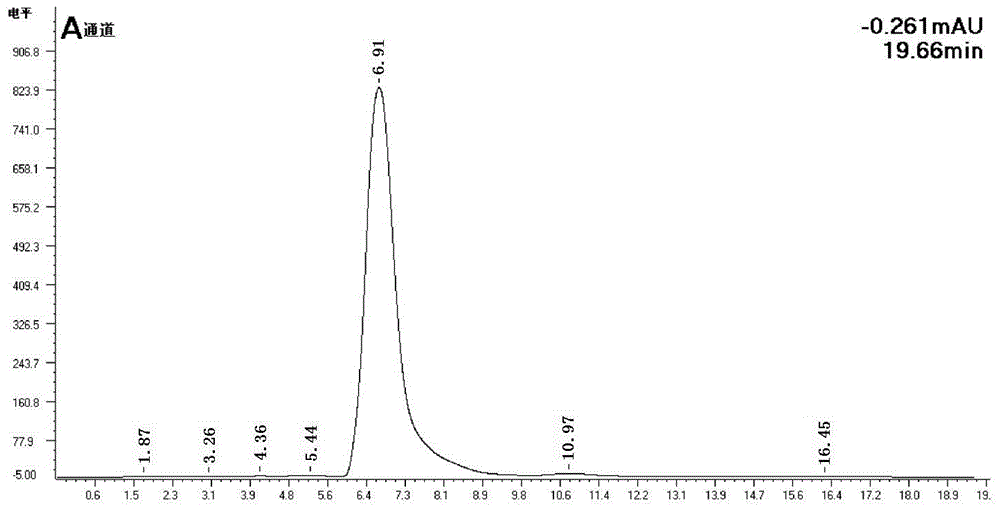

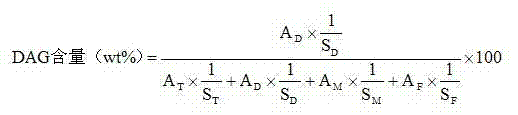

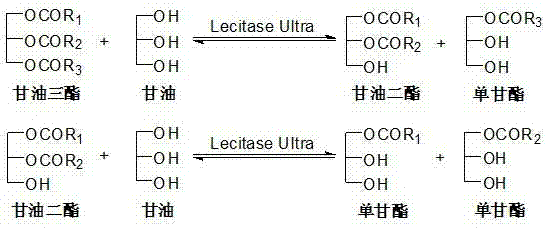

Preparation method of diglyceride-enriched functional oil

InactiveCN102199634BVigorousEasy to recycle and reuseChemical recyclingOn/in organic carrierVegetable oilPhospholipase

The invention relates to a preparation method of diglyceride-enriched functional oil. The method comprises following steps of: (1) immobilizing Lecitase Ultra; (2), carrying out a glycerolysis reaction on vegetable oil under the catalysis of immobilized Lecitase Ultra; and (3) carrying out product separation. The Lecitase Ultra used in the preparation method disclosed by the invention has low price which is only 5-10 percent of the price of lipase; and resin DA-201 for Lecitase Ultra immobilization has low cost. The immobilized Lecitase Ultra has good catalysis effect, high diglyceride content, less byproducts and recycling performance of the immobilized Lecitase Ultra; and therefore the diglyceride-enriched functional oil prepared by the preparation method disclosed by the invention has lower cost and favorable application prospect in the industry.

Owner:SOUTH CHINA UNIV OF TECH

Zero-emission cooking fume purifying treatment and air conditioning integrated stove

PendingCN110469878AImprove oil fume separation rateImprove purification efficiencyDomestic stoves or rangesLighting and heating apparatusZero emissionEngineering

The invention aims at providing a zero-emission cooking fume purifying treatment and air conditioning integrated stove. The kitchen ventilator theory, the air conditioning theory and the air purifyingtheory are combined, cooking fume exhausted out of a kitchen is separated, purified, recycled and exhausted without pollution, and the problems that in the prior art, an integrated stove is poor in cooking fume separation effect, low in oil contamination recycling rate, high in kitchen temperature, poor in kitchen air quality, inconvenient to mount and troublesome in cleaning are solved.

Owner:金百利科技(深圳)有限公司

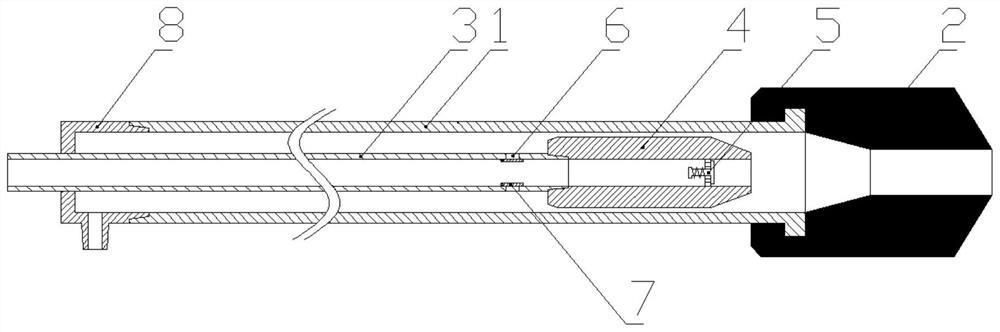

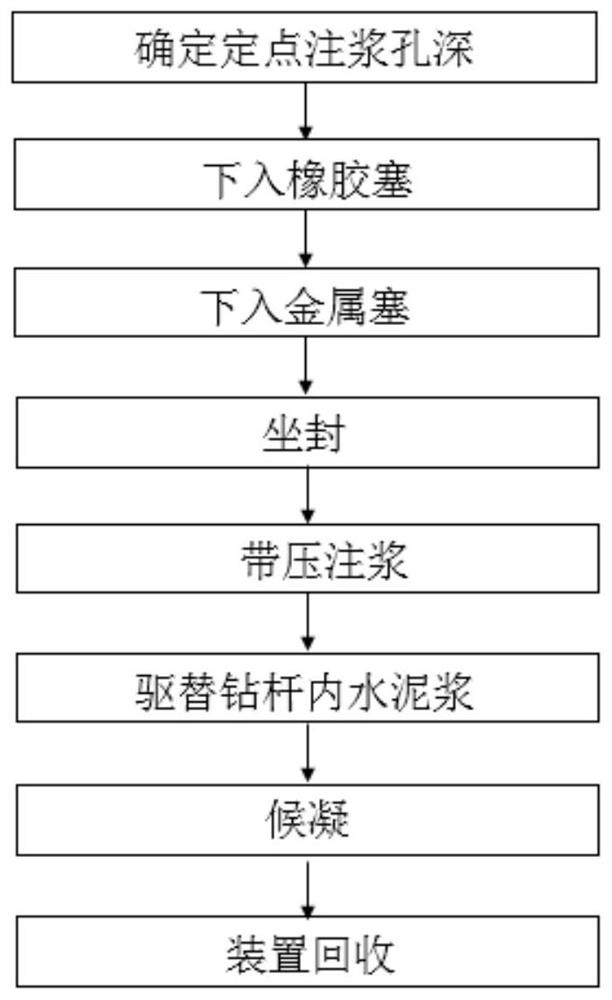

Underground coal mine directional long drilling recyclable fixed-point grouting device

ActiveCN113309487AAvoid wastingImprove drilling efficiencyDirectional drillingSealing/packingMining engineeringCoal

The invention discloses an underground coal mine directional long drilling recyclable fixed-point grouting device. The recyclable fixed-point grouting device is composed of a large-diameter drill rod, a rubber plug, a small-diameter drill rod, a metal plug, a bypass water tool and a one-way valve, the rubber plug, the metal plug and the bypass water tool are all provided with through holes, the large-diameter drill rod is fixedly connected with the rubber plug, the small-diameter drill rod is in threaded connection with the metal plug, the one-way valve is fixed into a through hole in the metal plug, the small-diameter drill rod and the metal plug can freely pass through a through hole in the large-diameter drill rod, the metal plug can pass through a through hole in the rubber plug under the action of force to form sealing, and the small-diameter drill rod can penetrate through the bypass water tool to form simple sealing. The invention further discloses an underground coal mine directional long drilling recyclable fixed-point grouting method. Deep hole fixed-point grouting of a directional long drill hole can be achieved, directional drilling difficulty and even drill hole scrapping caused by local hole section stratum breakage are avoided, and the hole forming rate and the hole forming efficiency of the directional drill hole are improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Automatic packaging machine for concrete products for maritime work

InactiveCN110758827AImprove stabilityAvoid shakingLarge containersSolid materialElectric machineryStructural engineering

The invention discloses an automatic packaging machine for concrete products for maritime work. The automatic packaging machine comprises an installation box. The upper surface of the installation boxis fixedly connected with a conveying barrel. The interior of the conveying barrel is rotationally connected with a spiral conveying shaft. The middle of the rear surface of the spiral conveying shaft is fixedly connected with a first motor, and the output end of the first motor transversely penetrates through the conveying barrel and is fixedly connected with one end of the spiral conveying shaft. The lower surface of one end, away from the first motor, of the conveying barrel is fixedly connected with a discharging barrel, and the discharging barrel communicates with the conveying barrel. The upper surface of one end, corresponding to the first motor, of the conveying barrel is fixedly connected with a hopper, and the hopper communicates with the conveying barrel. According to the automatic packaging machine, height adjustment can be achieved according to packaging bags of different specifications, packaging is facilitated, the situation that dust flies in the air during packaging,flying dust is caused, and air is polluted can be avoided, and waste is avoided.

Owner:JIANGSU DONGPU PILE

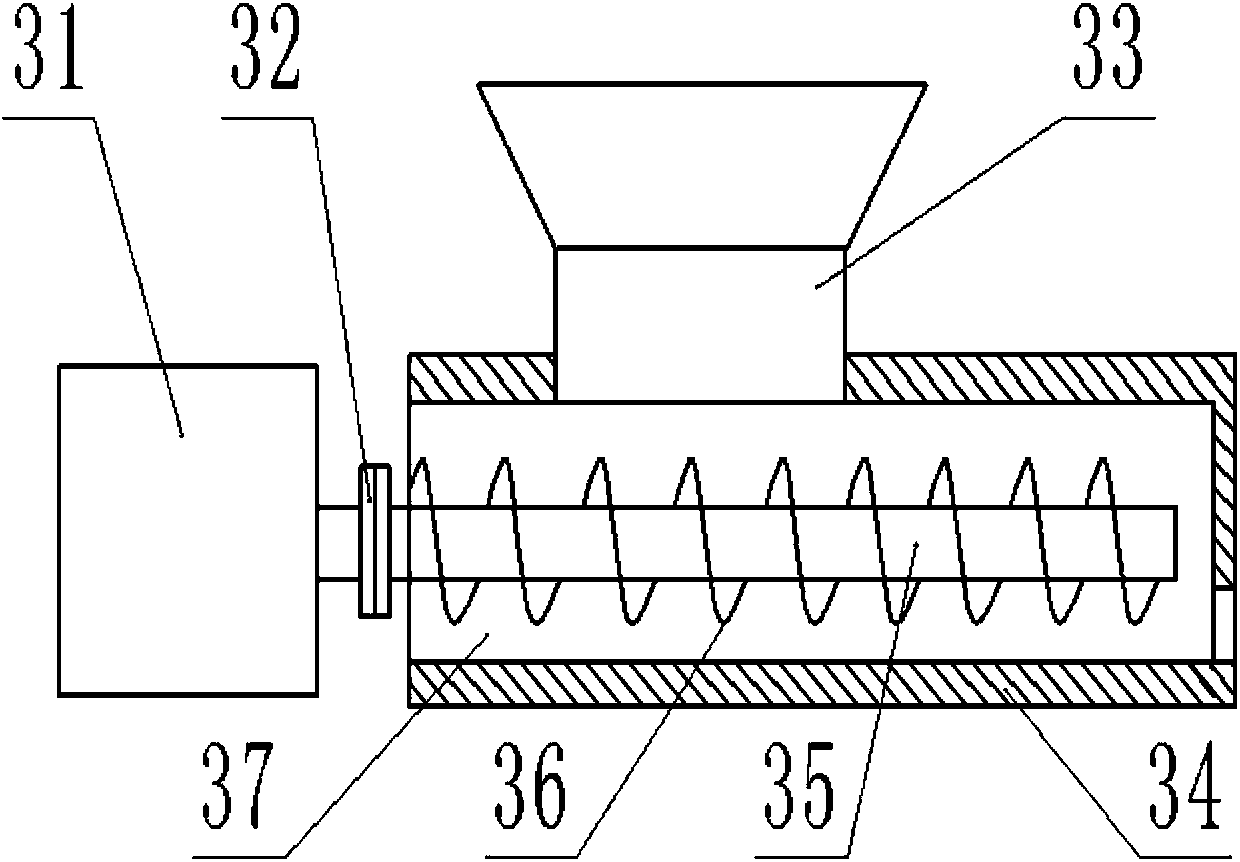

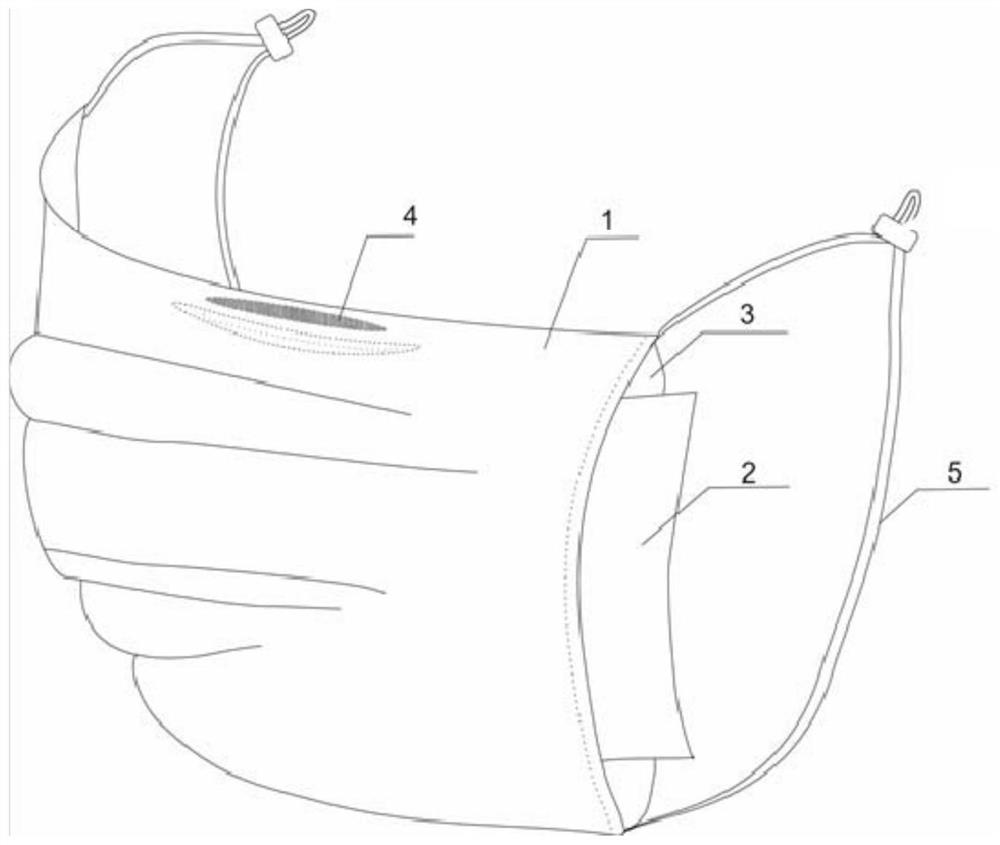

Environment-friendly mask and recycling method thereof

InactiveCN111685414ARealize recycling and reuseEnables reusabilityProtective garmentSpecial outerwear garmentsFiberNasal bridge

The invention provides an environmentally-friendly mask, the mask comprises an outer layer, a filter element layer, a skin-friendly inner layer, a nose bridge strip and ear bands, wherein the outer layer, the filter element layer and the skin-friendly inner layer form a mask main body in sequence, the nose bridge strip is fixed at the middle upper part of the mask main body, the ear bands are fixed at the two ends of the mask main body, and fibers forming the outer layer, the filter element layer and the skin-friendly inner layer are all made of thermoplastic high polymer materials. The invention further discloses a recycling method of the mask, the abandoned mask is dried, and then a single / double-screw extruder is adopted to prepare heatable particles which can be reused. The problem that waste masks cannot be recycled is solved.

Owner:SOUTH CHINA UNIV OF TECH

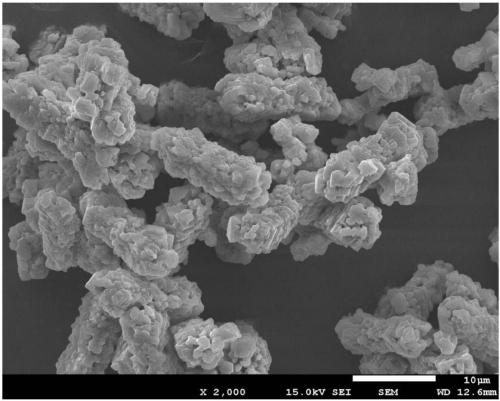

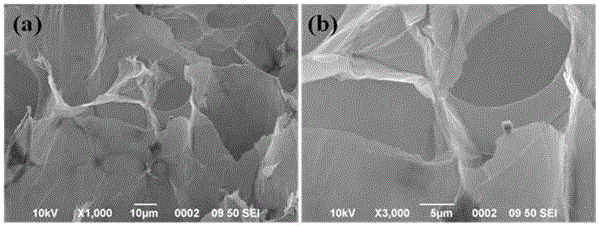

Carbon aerogel material for reducing and treating Cr (VI) in waste water and preparation method thereof

InactiveCN106582599ARealize recycling and reusePhysical/chemical process catalystsWater/sewage treatment by irradiationReduction treatmentFreeze-drying

The invention discloses a carbon aerogel material for reducing and treating Cr (VI) in waste water and a preparation method thereof, and belongs to the technical field of synthesis of photocatalytic materials. The key point of the technical scheme comprises that the preparation method comprises the steps: firstly, adopting an improved Hummers' method, preparing graphene oxide with a graphite powder as a raw material; then making the prepared graphene oxide into a graphene oxide aqueous solution with the mass concentration of 2-10 mg / mL, adjusting the pH value of the graphene oxide aqueous solution to 2-13, then placing in a microwave oven, and reducing under a heating condition with the power of 400-800 W; and carrying out dialysis treatment, and freeze-drying to obtain the macroscopic monolithic bulk carbon aerogel material. The invention provides the macroscopic monolithic bulk carbon aerogel material which can efficiently reduce Cr (VI) in chromium-containing waste water under natural sunlight illumination; the carbon aerogel material can be prepared by the simple process and can realize repeated recycling by elastic deformation.

Owner:HENAN NORMAL UNIV

Rapid cooling device and cooling method for furnace lining

InactiveCN102419095ARealize recycling and reuseRapid coolingFurnace cooling arrangementsSteelmakingWater resources

The invention relates to a rapid cooling device and a cooling method for a furnace lining. By the device and the method, not only a steelmaking furnace lining can be rapidly cooled, but also resources are not wasted. The device comprises the furnace lining in which a heat absorption coil consisting of a plurality of circles of water-cooled coiled pipes is arranged. A water inlet of the heat absorption coil is communicated with an outlet of a water cooling recovery tower through a water inlet pipe. An inlet of the water cooling recovery tower is communicated with an outlet of the heat absorption coil through a water returning pipe. The device and the method have the advantages that: the steelmaking furnace lining can be rapidly cooled, cooling water can be recovered and recycled, water resources are saved, and an environment is protected.

Owner:芜湖双金机械配件有限公司

Fireproof sealing depth control device

InactiveCN106674971AIncrease frictionProtect safe operationCable inlet sealing meansEngineeringFriction force

The invention relates to a fireproof sealing depth control device, which comprises a bearing plate, wherein a through hole for a cable to penetrate through is formed in the middle of the bearing plate; an opening communicating with the through hole is formed in the bearing plate; a hoop for tightly holding a cable is arranged on the bearing plate; a space for being filled with a fireproof blocking material is arranged in the hoop; a fixing plate for clamping the bearing plate on a protective pipe is arranged on the bearing plate. The fireproof sealing depth control device provided by the invention has the advantages that the cable is arranged in the through hole of the bearing plate, and is tightly held by the hoop, and the space of the hoop is filled with the fireproof blocking material, so that the friction forces between the fireproof blocking material and the cable as well as the fireproof blocking material and a pipe wall can be effectively increased, the control device is enabled to have the weight for bearing the fireproof blocking material, the repaired fireproof blocking material can be effectively prevented from sliding downwards along an inner wall of the protective pipe, a use effect of the fireproof blocking material of the cable is fully played, the safety operation of the cable is effectively protected, the installation time and the maintenance time are saved, and the cost is saved.

Owner:平湖市通用电气安装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com