Filter aid and regeneration method thereof

A filter aid and fly ash technology, applied in the field of filtration, can solve the problems of low utilization level and low utilization efficiency, and achieve the effect of meeting large demand, high value-added application and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Prepare the filter aid used for beer filter aid that the embodiment of the present invention provides:

[0025] Fly ash raw materials are removed by magnetic separation and ground into semi-finished products with a thickness of 2-40 μm. Under the conditions of a solid-liquid ratio of 1:10, an acid mass percentage concentration of 0.6%, a temperature of 120° C., a pressure of 1.2 atmospheres, and a time of 60 minutes, the semi-finished product was dissolved and filtered using a hydrochloric acid solution; water, etc.), or rinse with beer solution. The fly ash after dehydration and rinsing is placed at 110° C. and baked to a constant weight to obtain the filter aid provided by the present invention, that is, the fly ash filter aid.

[0026] The purified fly ash is classified and treated, and particles of 2-20um account for 80% of the class particles, and 0.77-1.0 kg of fly ash filter aid is consumed for filtering per ton of beer.

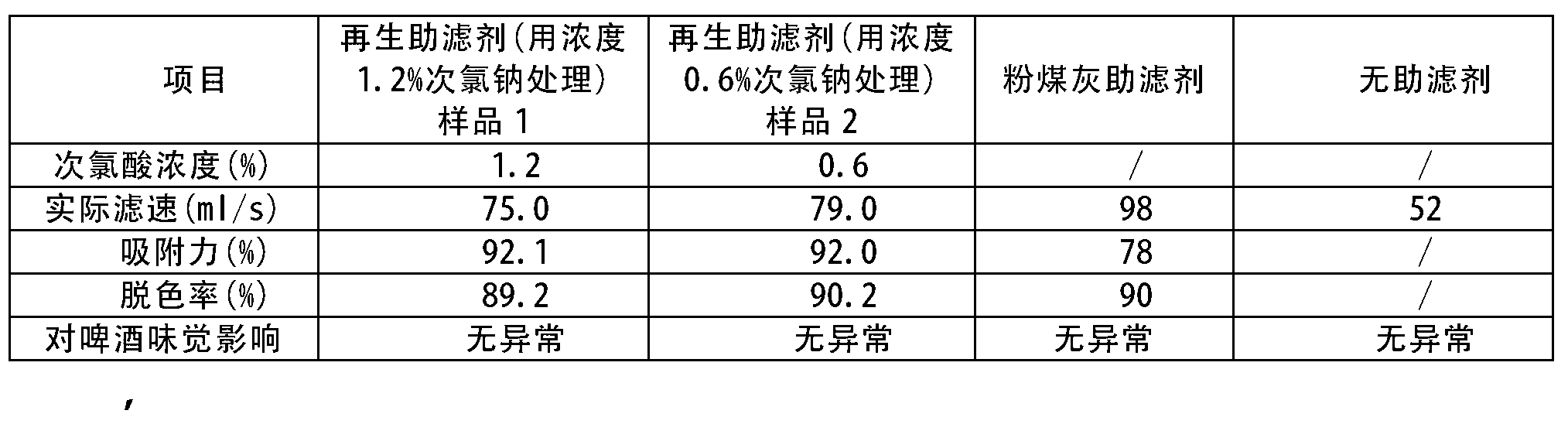

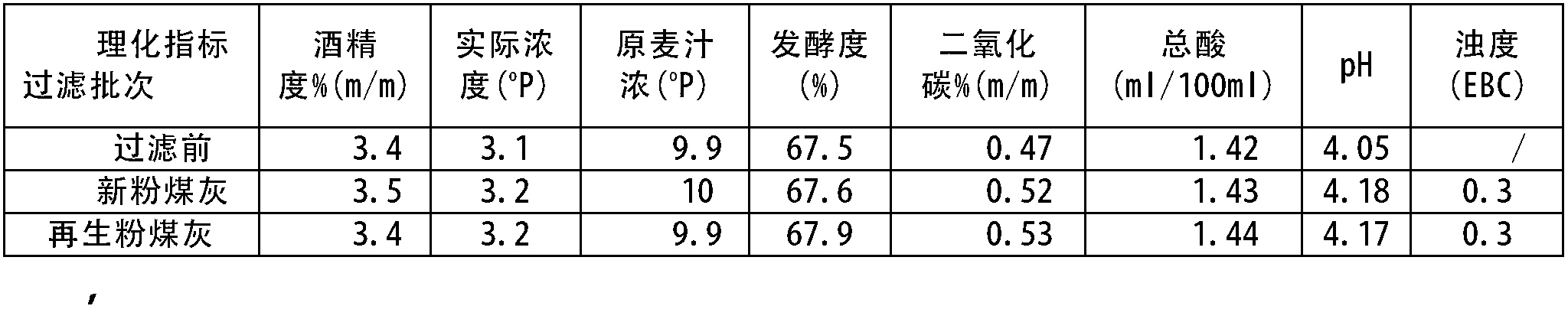

[0027] The regeneration process of fil...

example 2

[0033] Prepare the filter aid that the embodiment of the present invention provides for beer filter aid:

[0034] Fly ash raw materials are removed by magnetic separation and ground into semi-finished products with a thickness of 2-40 μm. In solid-liquid ratio 1: 10, acid mass percent concentration is 0.6%, temperature 120 ℃, pressure 1.2 atmospheric pressure, under the condition of time 60min, use hydrochloric acid solution to dissolve, filter semi-finished product; deionized water, etc.), or rinse with beer solution. The fly ash after dehydration and rinsing is placed at 110° C. and baked to a constant weight to obtain the filter aid provided by the present invention, that is, the fly ash filter aid.

[0035] The purified fly ash is classified and treated, and particles of 2-20um account for 80% of the class particles, and 0.77-1.0 kg of fly ash filter aid is consumed for filtering per ton of beer.

[0036] The regeneration process of the filter aid: the fly ash unloaded o...

example 3

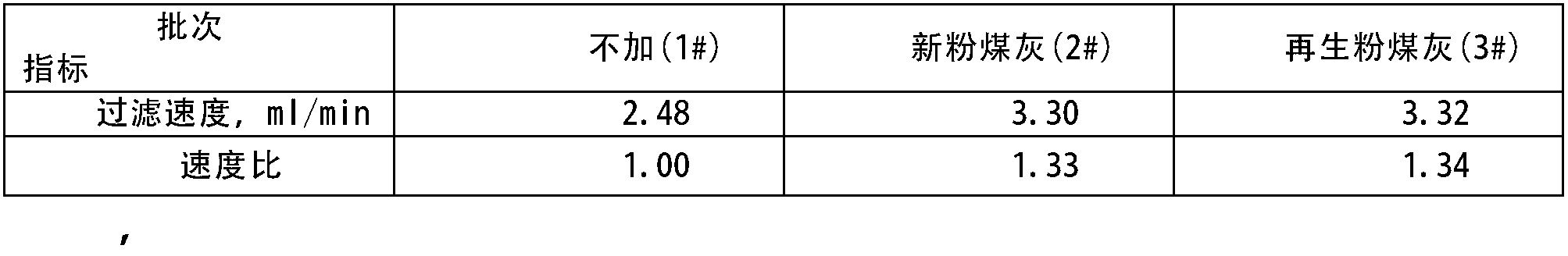

[0042] Preparation of the embodiment of the present invention is used for the filter aid of citric acid fermented liquor filter aid

[0043] Fly ash raw materials are removed by magnetic separation and ground into semi-finished products with a diameter of 40 μm. Under the conditions of a solid-liquid ratio of 1:10, an acid mass percentage concentration of 0.6%, a temperature of 120° C., a pressure of 1.2 atmospheres, and a time of 60 minutes, the semi-finished product was dissolved and filtered using a hydrochloric acid solution; water, etc.), or rinse with a citric acid solution. The fly ash after dehydration and rinsing is placed at 110° C. and baked to a constant weight to obtain the filter aid provided by the present invention, that is, the fly ash filter aid.

[0044] The regeneration process of the filter aid: adopt the regeneration method of the filter aid provided by the present invention, calcinate the used fly ash filter aid at 450°C for 2-5h, and mix the calcined p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com