Sulfonated vinegar residues and preparation method and application thereof

A technology for sulfonating vinegar grains and vinegar grains, which is applied in the field of sulfonation method and the products produced by the method, can solve the problems that vinegar grain waste residues cannot be used reasonably, environmental pollution, etc., and achieve recycling and reuse, technical The process is simple and easy, and the synthesis rate is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 prepares sulfonated vinegar grains with sulfuric acid as sulfonating agent, and the steps are:

[0042] (1) The natural vinegar lees left after the fermentation of aspergillus, yeast, and acetobacter in the solid state are made into vinegar in a solid state, air-dried naturally, and then crushed with a stone mill to a particle size range of 160-180 mesh, and the particles are collected by sieving Graded components, fully rinsed with water to remove free acetic acid, dried, kept the material quality to constant weight, terminated drying, and sampled and analyzed after cooling to calculate the accurate acid value of the solid vinegar grains;

[0043] (2) Accurately weigh 500g of graded vinegar grains (acid value 0.082mmol / g) and a certain amount of sulfonating agent. agent material, then add 1% accelerator (anhydrous aluminum chloride, w / w), spray water (water content 40%, w / w), mix well, put the mixed material into a volatile porcelain crucible, seal Cover ...

Embodiment 2

[0044] Embodiment 2 prepares sulfonated vinegar grains with sodium sulfite as sulfonating agent, and the steps are:

[0045] (1) Same as embodiment 1;

[0046] (2) Accurately weigh 500g of graded vinegar grains (acid value 0.082mmol / g) and a certain amount of sulfonating agent. agent material, then add 1% accelerator (anhydrous ferric chloride, w / w), spray water (water content 40%, w / w), mix well, put the mixed material into a volatilization porcelain crucible, seal Cover the crucible with a lid and red mud, put it in an oven at 150oC for 5 hours, stop heating and cool down; wash the sample with distilled water until the pH of the filtrate reaches 7, collect the filtrate, dry the solid sulfonated vinegar grains, and obtain the final product.

Embodiment 3

[0047] Embodiment 3 prepares sulfonated vinegar grains with sodium sulfamate as sulfonating agent, and the steps are:

[0048] (1) Same as embodiment 1;

[0049] (2) Accurately weigh 500g of graded vinegar grains (acid value 0.082mmol / g) and a certain amount of sulfonating agent. agent material, then add 1% accelerator (anhydrous aluminum chloride, w / w), spray water (water content 40%, w / w), mix well, put the mixed material into a volatile porcelain crucible, seal Cover the crucible with a lid and red mud, put it in a 150oC oven and bake for 5 hours, stop heating and cool down; wash the sample with distilled water, and dry it at 60oC for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

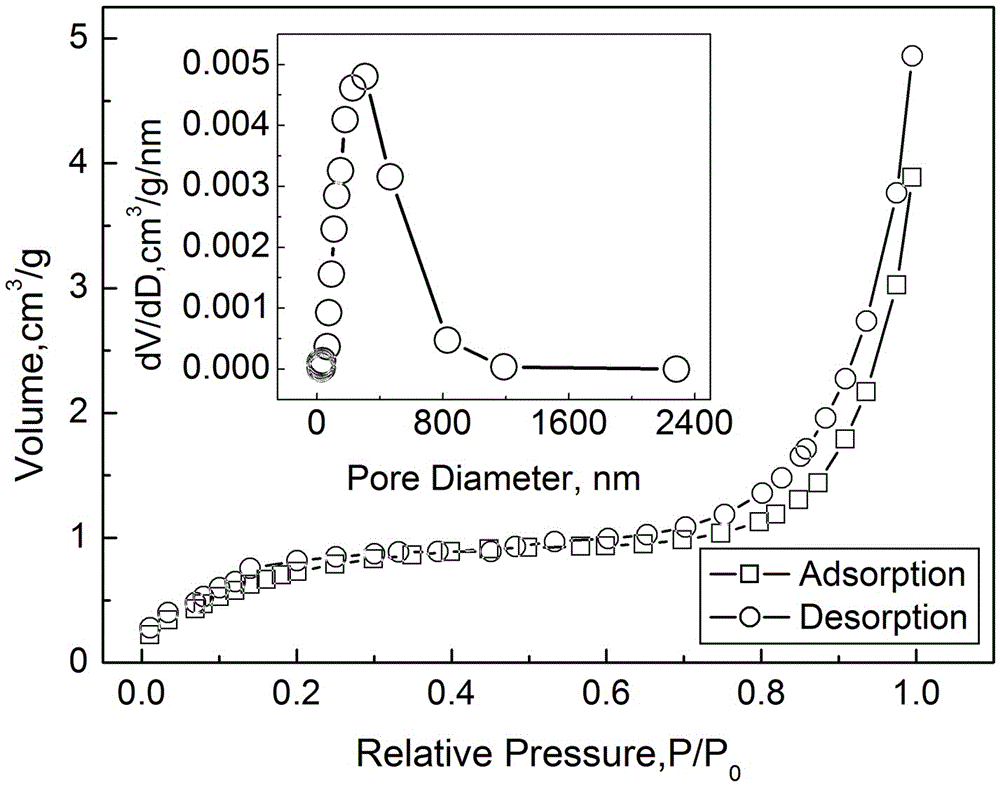

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com