Self-cleaning polybenzoxazine super-hydrophobic super-oleophylic net film material and application in oil-water separation

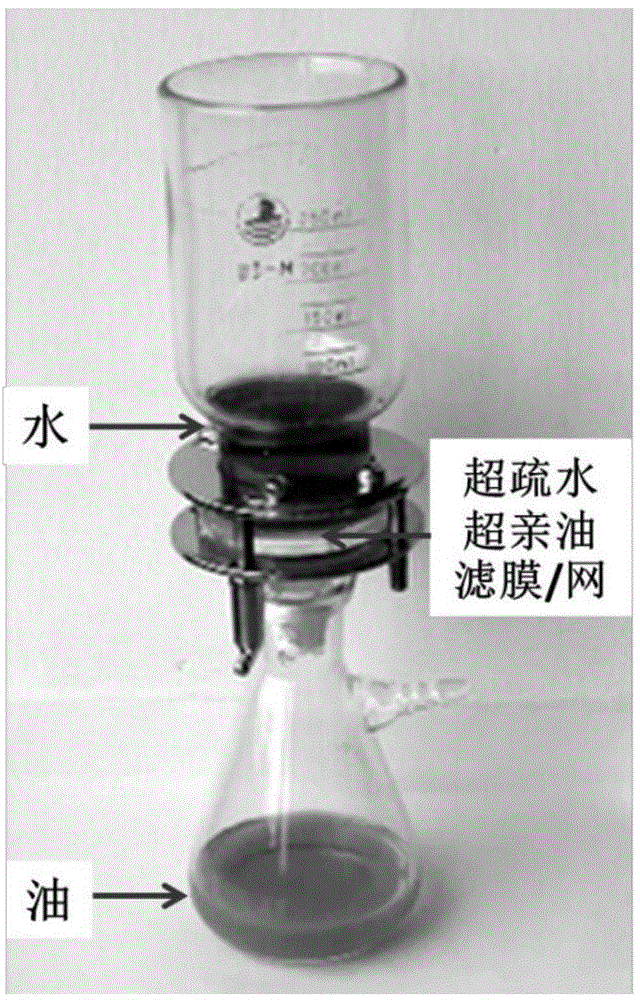

A kind of polybenzoxazine, benzoxazine technology, application in oil-water separation, self-cleaning polybenzoxazine superhydrophobic superoleophilic mesh material and preparation field, can solve the problem of time-consuming and separation efficiency Reduce the problem of reducing and shortening the service life of materials, so as to shorten the process time, simplify the technical process, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Ultrasonic cleaning of 4×5cm polyester fiber non-woven fabric (Shanghai Tianlue Textile New Material Co., Ltd.) with water, ethanol, and acetone for 15 minutes, and dried at room temperature for later use;

[0050] (2) Add 1g of benzoxazine monomer (3-(3-trimethoxysilane) n-propyl-6-methyl-3,4-dihydro-2H-1,3-benzoxazine, MP -aptms, such as formula I-1) is dissolved in 25g chloroform; 1g TiO 2 Nanoparticles (particle size 25-70nm) were added to the above solution, ultrasonically mixed and dispersed for 2 hours to obtain a benzoxazine / nanoparticle blend;

[0051]

[0052] (3) At room temperature, after immersing the clean polyester fiber fabric in the benzoxazine / nanoparticle blend for 30s, pull it out at a pulling speed of 60mm / min, and clamp it vertically with a long tail clip, Immediately after drying, put it into a 160°C curing box for curing for 2 hours.

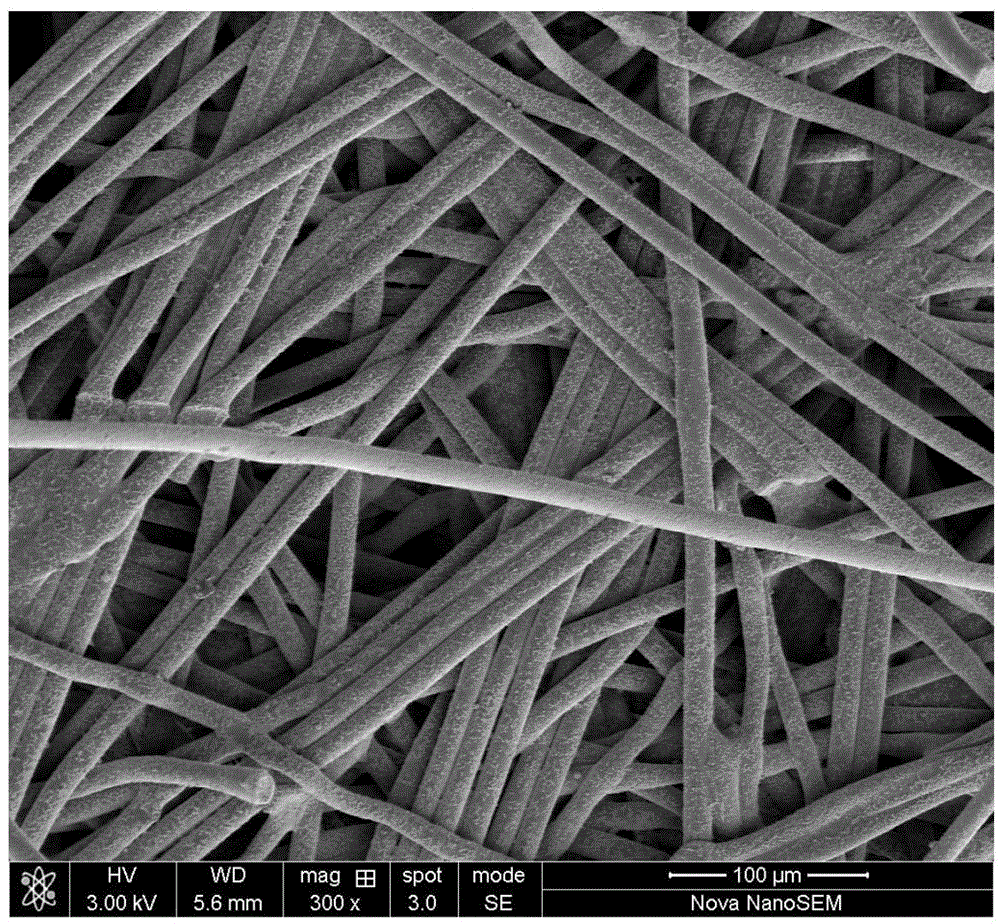

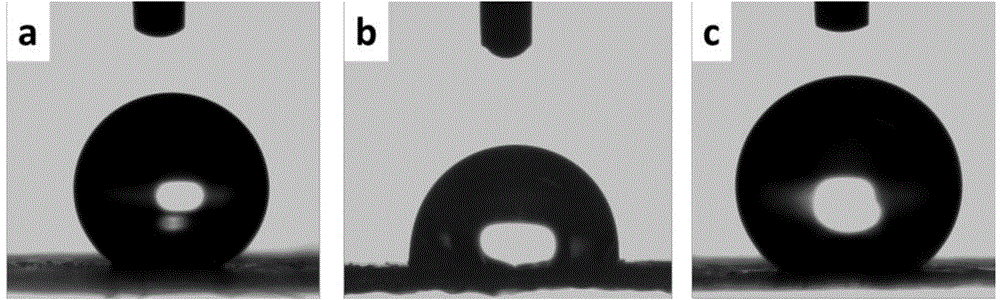

[0053] The scanning electron microscope pictures of its surface morphology are as follows: figure 1 As...

Embodiment 2

[0056] (1) Clean a 200-mesh, 4×5cm stainless steel metal filter screen (Shanghai Baolan Experimental Instrument Manufacturing Co., Ltd.) with water, ethanol, and acetone for 15 minutes, and dry it at room temperature for later use;

[0057] (2) 1g of benzoxazine monomer (6-methyl-3-phenyl-3,4-dihydro-2H-1,3-benzoxazine, MP-a, such as formula I-2) Dissolve in 10g tetrahydrofuran; 0.5g TiO 2 Nanoparticles (particle size 25-70nm) were added to the above solution, ultrasonically mixed and dispersed for 2 hours to obtain a benzoxazine / nanoparticle blend;

[0058]

[0059] (3) At room temperature, after immersing a clean stainless steel filter in the benzoxazine / nanoparticle blend for 30s, pull it out at a pulling speed of 100mm / min, and clamp it vertically with a long tail clip, Immediately after drying, put it into a 210°C curing box for curing for 1 hour.

[0060] Its operating steps and implementation method are all the same as in Example 1, only the mixture of oil and wate...

Embodiment 3

[0062] (1) Ultrasonic cleaning of 4×5cm nylon fiber filter cloth (Shanghai Tianlue Textile New Material Co., Ltd.) with water, ethanol, and acetone for 15 minutes, and then dried at room temperature for later use;

[0063] (2) 1g of benzoxazine monomer (3-hydroxyethyl-6-methyl-3,4-dihydro-2H-1,3-benzoxazine, MP-eta, such as formula I-3 ) was dissolved in 15g ethanol; 0.7g TiO 2 Add nanoparticles (50-60nm in diameter) to the above solution, and ultrasonically mix and disperse for 2 hours to obtain a benzoxazine / nanoparticle blend;

[0064]

[0065] (3) At room temperature, after immersing the clean nylon fiber filter cloth in the benzoxazine / nanoparticle blend for 60s, pull it out at a pulling speed of 120mm / min, and clamp it vertically with a long tail clip After drying, put it into a 150°C curing box to cure for 1 hour.

[0066] Its operating steps and implementation method are all the same as in Example 1, only the mixture of oil and water is changed to the mixture of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com