A kind of agricultural film and preparation method thereof

An agricultural film and base film technology, applied in the field of agricultural film, can solve the problems of reducing the transparency of the film and affecting the mechanical properties of the film, and achieve the effects of good durability, avoiding outward migration, and good cold resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

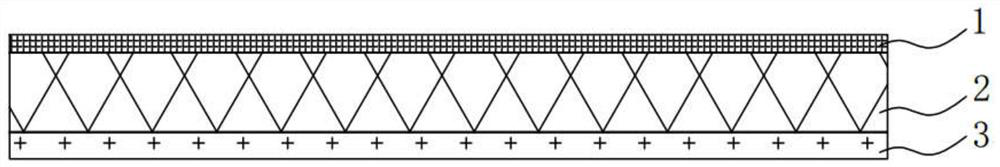

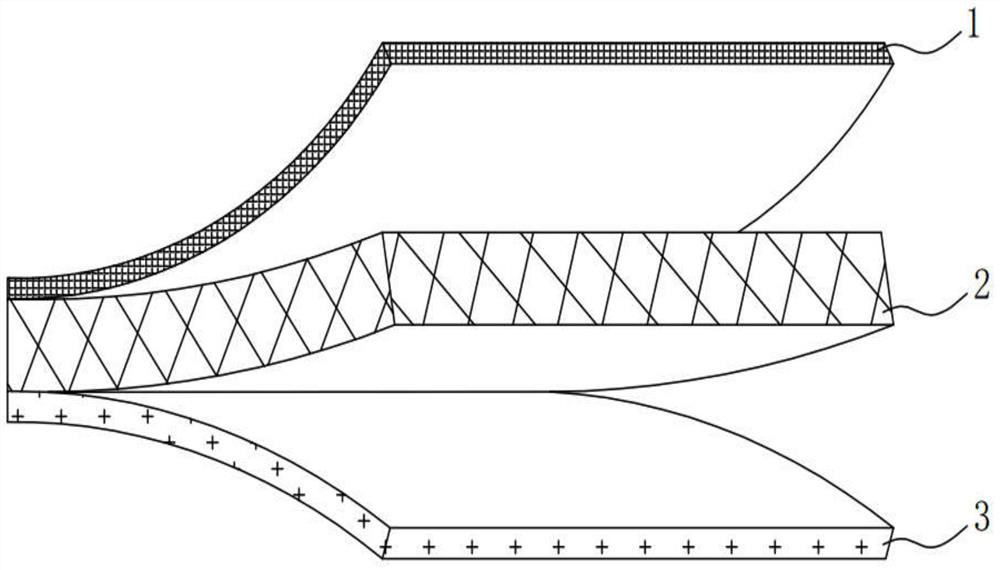

Image

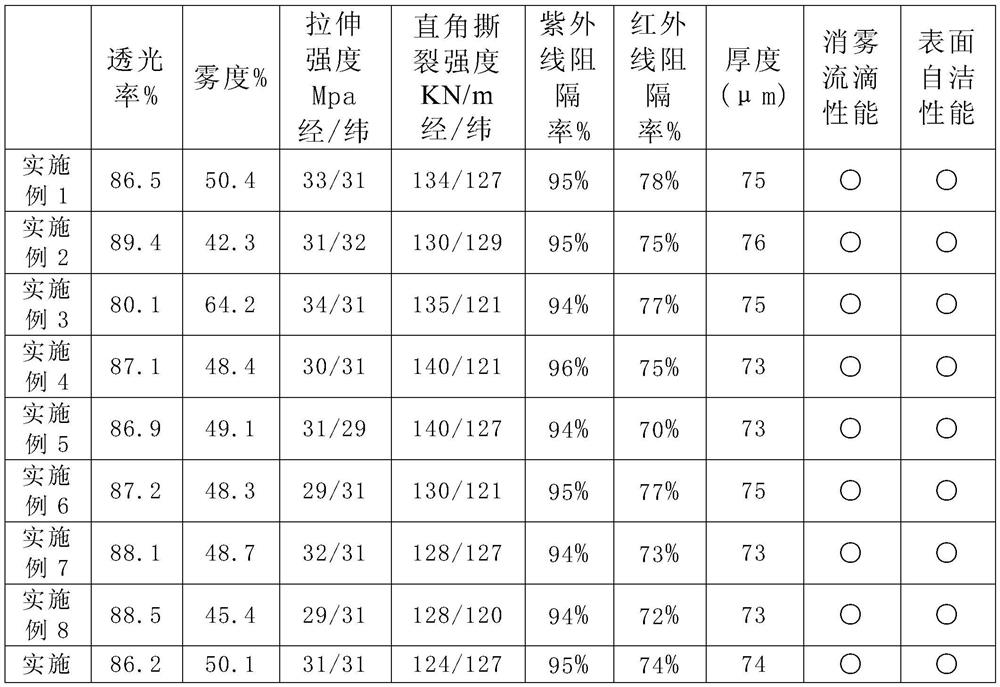

Examples

Embodiment 1

[0072] S1: Preparation of PVC transparent base film

[0073] First weigh the following raw materials in parts by weight:

[0074] PVC resin: 100

[0075] Calcium zinc composite stabilizer: 3

[0076] Triphenyl phosphite: 0.6

[0077] Primary plasticizer: 37

[0078] Auxiliary plasticizer: 10

[0079] Epoxidized soybean oil: 3

[0080] Ethylene-vinyl acetate copolymer: 3

[0081] Vinyl chloride grafted chlorinated polyethylene copolymer: 3

[0082] Monoglycerides of fatty acids: 1.2

[0083] Anti-ultraviolet agent: 0.7

[0084] Antioxidant: 0.7

[0085] Light stabilizer: 0.4

[0086] Brightener: 0.02

[0087] The main plasticizer is trioctyl trimellitate; the auxiliary plasticizer is dioctyl adipate; the anti-ultraviolet agent is triazine-5; Base-4-hydroxyphenyl) propionate] pentaerythritol ester; light stabilizer is poly 1-(2-hydroxyethyl-2,2,6,6-tetramethyl-4-hydroxypiperidine succinate; The whitening agent is 2.5-bis-(5-tert-butyl-2-benzoxazolyl)thiophene.

[0...

Embodiment 2

[0112] The difference with embodiment 1 is only that the number of parts of ethylene-vinyl acetate copolymer in the PVC transparent base film raw material of embodiment 2 is 2 parts, and the number of parts of vinyl chloride grafted chlorinated polyethylene copolymer is 2 parts.

Embodiment 3

[0114] The difference with embodiment 1 is only that the number of parts of ethylene-vinyl acetate copolymer in the PVC transparent base film raw material of embodiment 3 is 4 parts, and the number of parts of vinyl chloride grafted chlorinated polyethylene copolymer is 4 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com