Method for preparing two-dimensional or three dimensional colloid crystal

A technology of three-dimensional colloids and colloidal crystals, applied in colloid chemistry, colloid chemistry, chemical instruments and methods, etc., can solve problems such as self-organization, and achieve the effects of short preparation cycle, high efficiency, and simple technical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

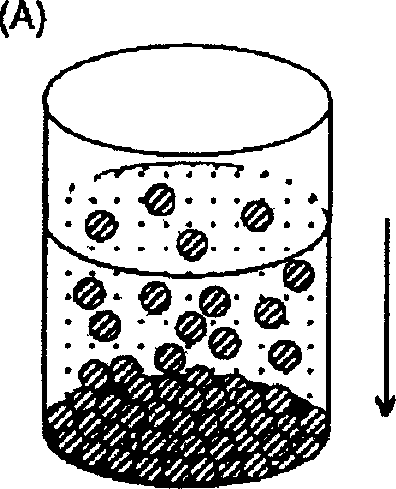

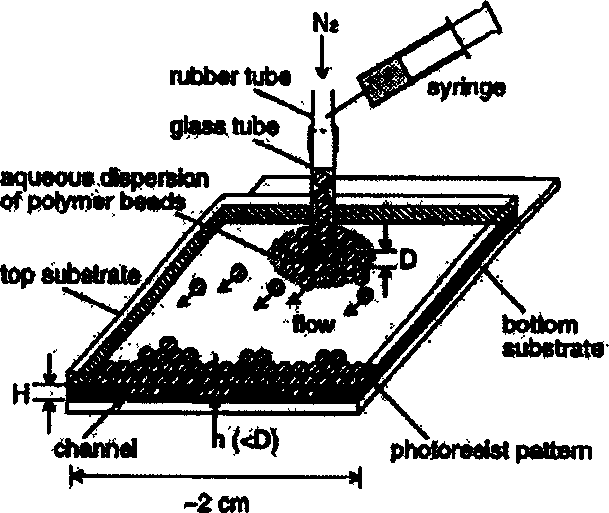

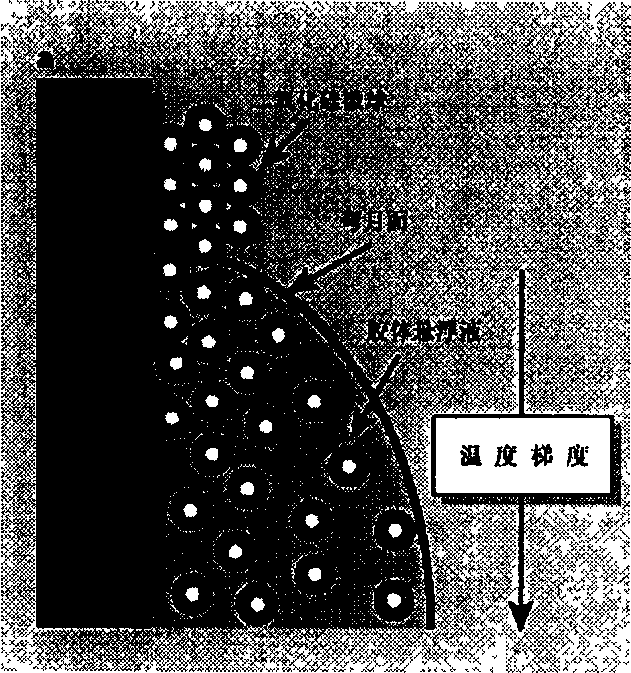

[0028] The invention prepares high-quality two-dimensional and three-dimensional colloidal crystals through the self-assembly process of colloidal microspheres in microcavities under the joint action of gravity and surface tension. See the implementation method figure 2 .

[0029] The present invention first selects a quartz plate as a substrate and lays it flat. Then place a U-row divider with a certain thickness on the quartz plate. Then cover it with a quartz plate of the same size. Finally, while maintaining the relative position of the two quartz plates, fix them.

[0030] The separator in the present invention can be a cylindrical or rectangular dielectric rod in cross section, such as figure 2 shown. The material of the spacer is selected from a dielectric material that can withstand a certain amount of extrusion without deformation.

[0031] The colloidal microsphere suspension of the present invention is dropped into the prepared microcavity, and after standin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com