Patents

Literature

34results about How to "High sulfonation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of methyl naphthalenesulfonic acid-methyl aldehyde condensation compound

InactiveCN101386587ALow impurity contentHigh sulfonation efficiencyOrganic chemistryOrganic dyesMethyl aldehydeSulfate

The present invention provides a method for preparing a condensation compound of methylol naphthalene sulphonic acid formaldehyde. The method comprises the following steps that methylnaphthalene is adopted as the material, and is sulfonated with 104.5 percent of fuming sulfuric acid in advance; the sulfonated product is condensed with formaldehyde; and, finally the pH is adjusted to between 6 and 9 by liquid alkali, and thus the methylol naphthalene sulphonic acid formaldehyde condensation compound is obtained. The method does not need to add an azeotrope former, and does not need to add and distill of sulfonated bodies every time. The process is simplified, the manufacturing cost is saved, and the impurity content in the product is reduced. Additionally, the 104.5 percent of fuming acid is adopted to sulfonate. Not only the efficiency of methylnaphthalene sulfuration is improved, but also the total acidity of the condensation reaction process is reduced. The subsequent process completely adopts liquid alkali. No calcium sulfate calcium offscum is produced. Compared with the adoption of concentrated sulfuric acid, the quality of the product is equivalent in dispersancy, calcium and magnesium ions are not produced, and the product is stable in heat resistance.

Owner:ZHEJIANG LONGSHENG GROUP +1

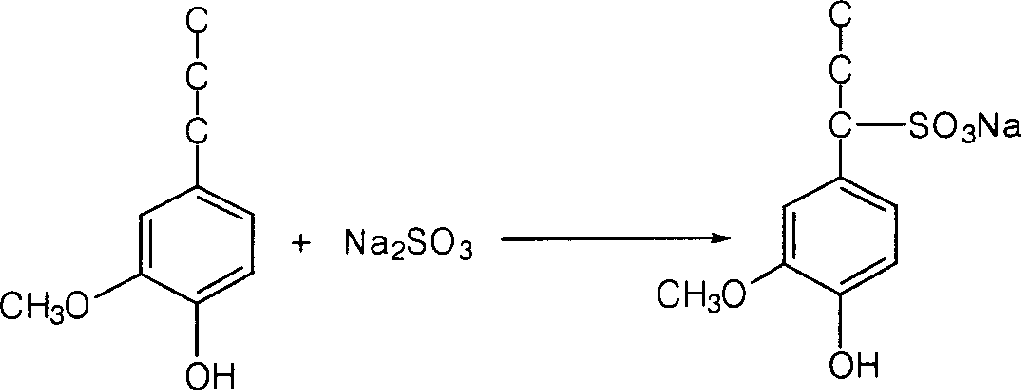

High efficiency straw pulp sulfonated alkali lignin water-reducing agent and method for preparing same

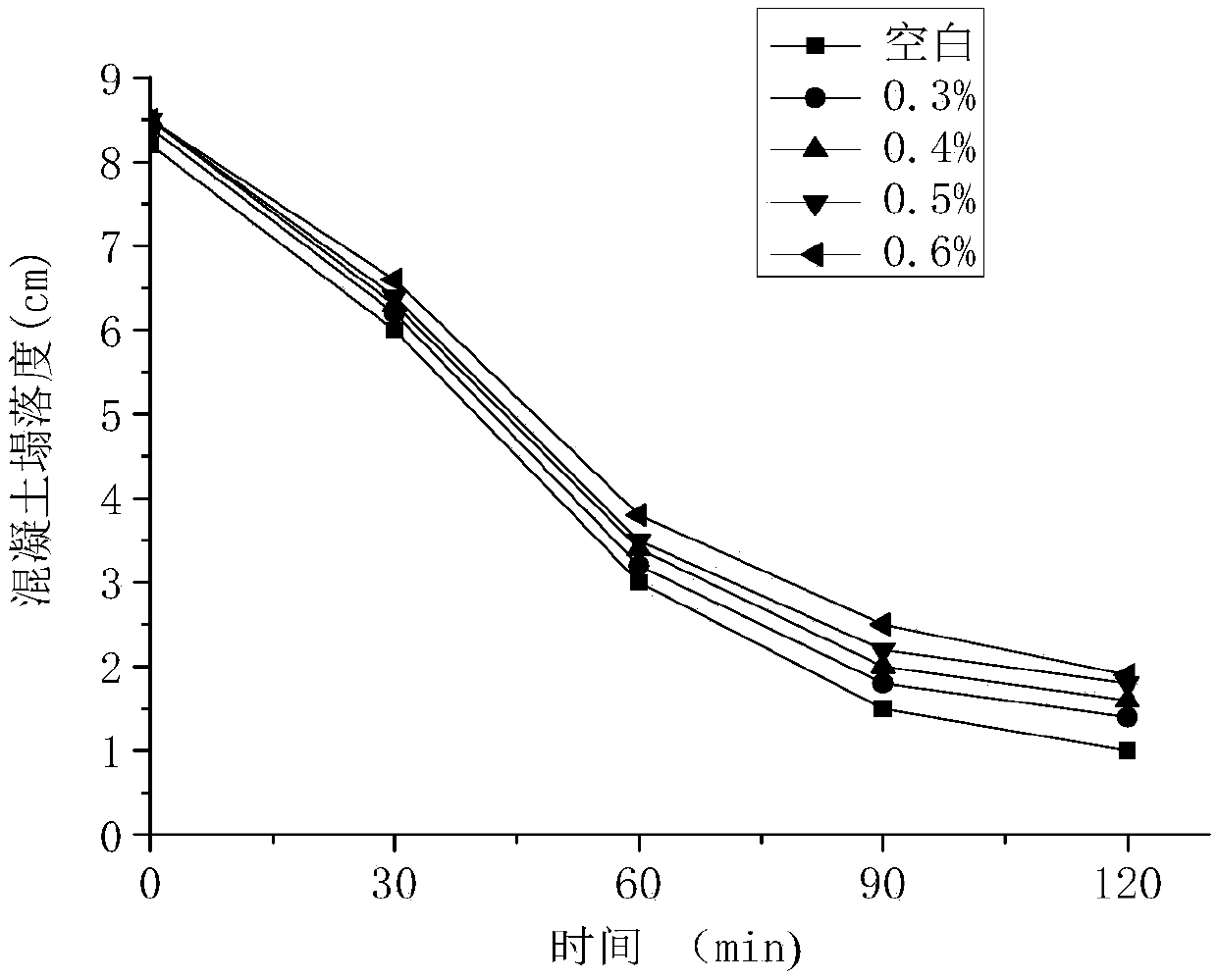

The present invention is the preparation process of high efficiency sulfonated straw pulp alkali lignin water reducing agent for concrete or mortar in building engineering. The preparation process includes adding 200 weight portions of water into 100 weight portions of straw pulp alkali lignin, regulating pH value to 3-10, heating to 40-100 deg.c, adding 5-15 weight portions hydrogen peroxide and 0.1-2 weight portions of transition metal salt, catalytically oxidizing for 0.5-1 hr, adding 5-50 weight portions of condensing agent and 5-50 weight portions of sulfite for sulfomethylation of 1-5 hr, and cooling the reaction product to room temperature to obtain the liquid product. The high efficiency sulfonated straw pulp alkali lignin water reducing agent has high water reducing rate, moderate delayed setting, high slump maintaining property, and high compatibility to cement and other water reducing agent.

Owner:SOUTH CHINA UNIV OF TECH

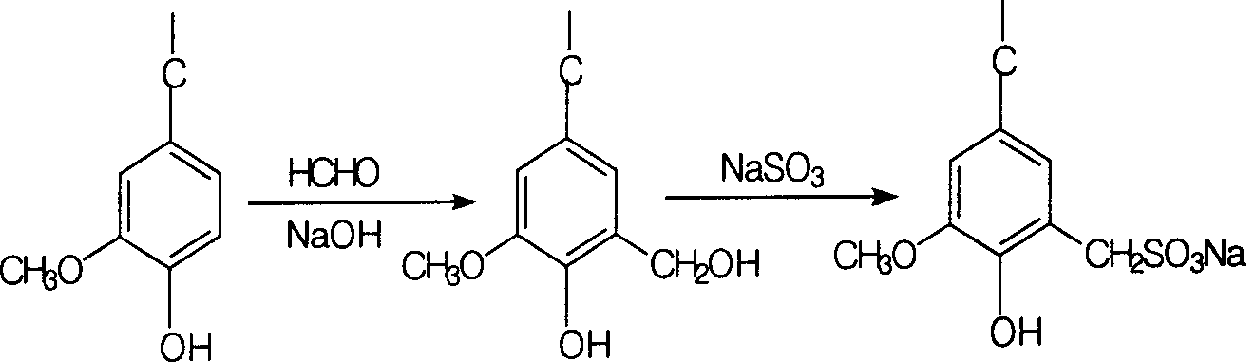

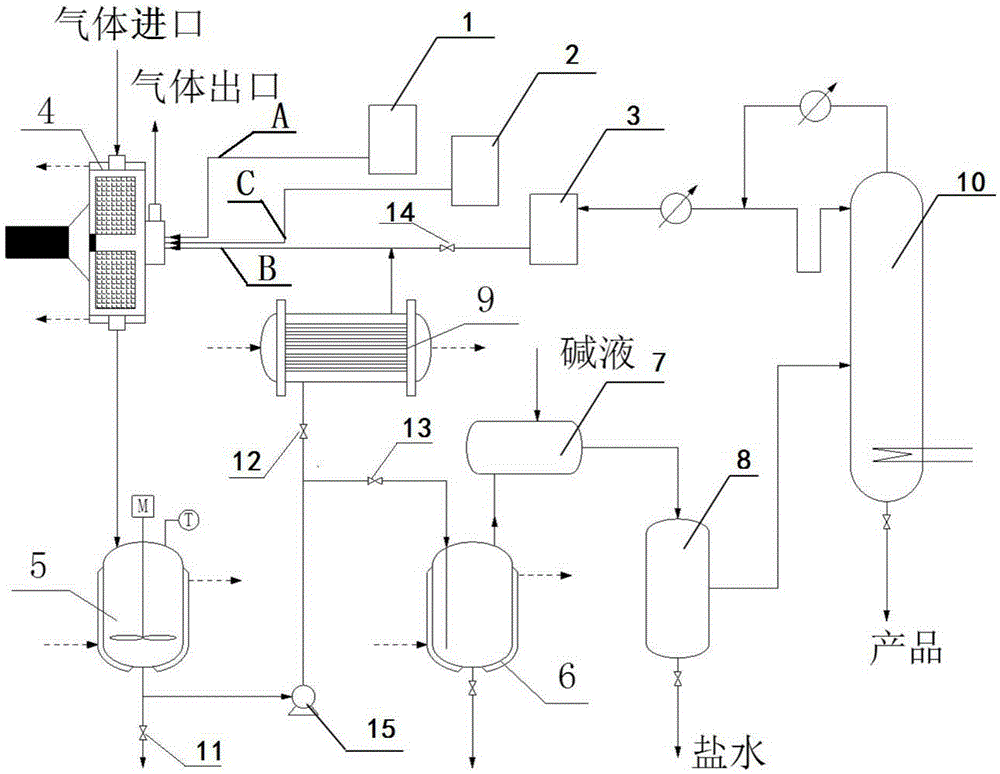

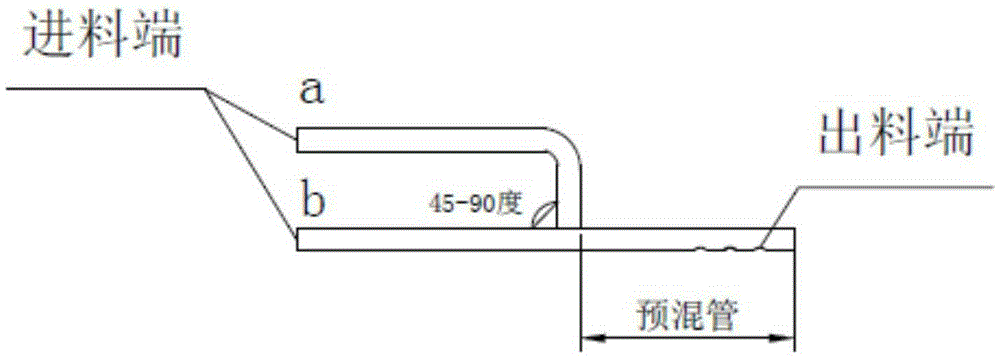

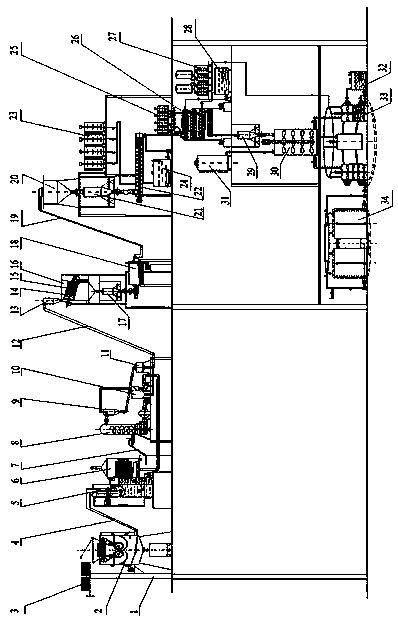

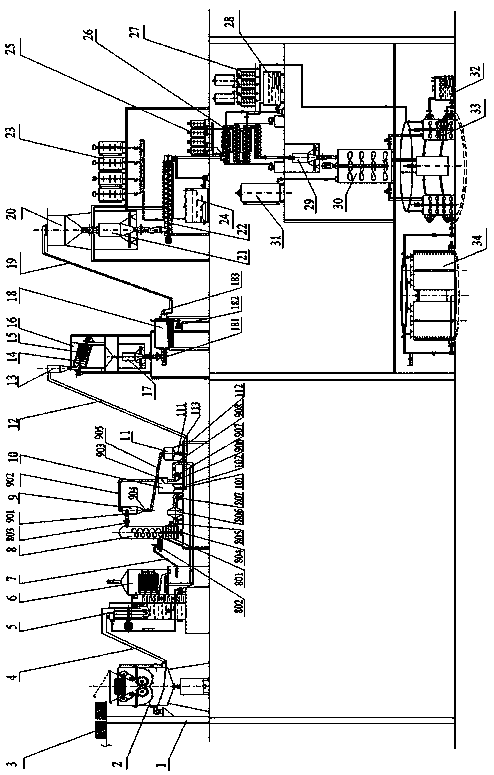

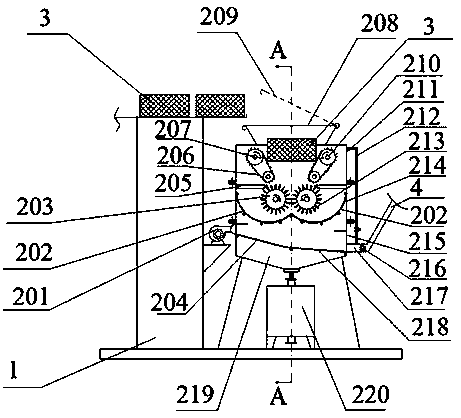

System device for preparing sulphonate surfactant through supergravity sulfonating method and application

InactiveCN106606991AShort stayNot easy to bring outTransportation and packagingSulfonic acids salts preparationSolventSide reaction

The invention discloses a system device for preparing a sulphonate surfactant through a supergravity sulfonation method and application. The system device comprises batching systems, a supergravity reaction system, heat removing systems and a post-processing system. The batching systems comprise the sulfonation agent batching system, the organic solvent for heat removing batching system and the raw material waiting for being sulfonated batching system; the supergravity reaction system comprises a supergravity reactor and a feeding device; the heat removing systems comprise the outer heat removing system and the cold shock heat removing system; and the post-processing system comprises a circulating stirring system, a circulating pump, an overflow aging system, a neutralization system, a water-separating system and a solvent recovery system. The system device is adopted to conduct a sulfonation reaction, diluted gaseous or liquid sulfur trioxide serves as a sulfonating agent, so that the reaction is controllable, and the reaction heat quantity can be removed timely. According to the system device for preparing the sulphonate surfactant through the supergravity sulfonation method, the supergravity technology is applied in the process of sulfonation quick reaction, so that raw materials can be evenly distributed rapidly, the occurrence probability of a side reaction is reduced, and the product quality is improved.

Owner:BEIJING UNIV OF CHEM TECH

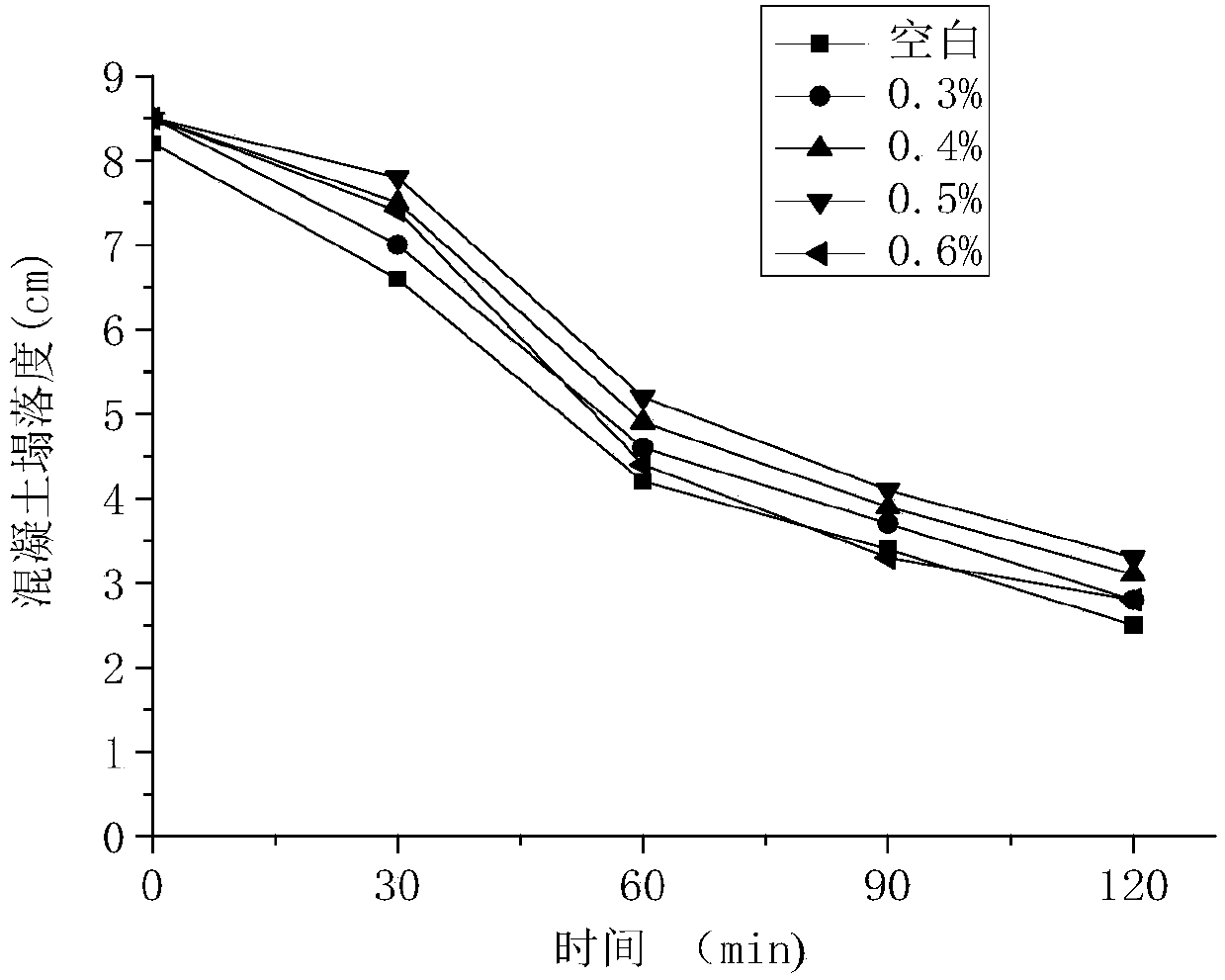

Preparation method and application of ester ether sulfonated composite water reducing agent based on straw modification

The invention discloses a preparation method and application of an ester ether sulfonated composite water reducing agent based on straw modification. The water reducing agent is prepared from crop straw hydrolyzed powder through primary oxidation-sulfonation esterification modification, secondary oxidation-sulfonation esterification modification and primary methylolation-etherification modification of straw lignocellulose, wherein the straw hydrolyzed powder is obtained by performing primary crushing, washing, drying, fine crushing and micro crushing pretreatment on crop straw and then hydrolyzing straw powder. Crushing and hydrolyzing pretreatment are performed on a crop straw raw material, stepwise sulfonation modification is firstly performed on straw lignin and cellulose to form sulphonate, and then etherification modification is performed on the lignocellulose to obtain the straw-based ester ether sulfonated composite water reducing agent; the problem that the water reducing rateof the straw-based water reducing agent is 10-15% and is relatively low is solved; the obtained water reducing agent can be directly applied to the situation that the water reducing rate is about 25%and the delayed coagulation time is moderate; a technology is continuous, compact, easy to operate, low in cost, anti-settling and easy to industrialize.

Owner:TIANSHUI NORMAL UNIV

Preparation method for xylan polysulfate

The invention discloses a preparation method for xylan polysulfate, and belongs to the technical field of xylan polysulfate. The preparation method for the xylan polysulfate comprises the following steps of 1, preparing a first mixture; 2, preparing a second mixture; 3, preparing a xylan polysulfate crude product; and 4, preparing a xylan polysulfate finished product. The preparation method has the advantages that the xylan polysulfate is prepared by taking a sulfur trioxide compound as a sulfonating agent in a polar organic solvent, so that 1, the high sulfonating efficiency can be ensured through the organic solvent, 2, the serious environmental pollution burden caused by pyridine as a solvent in the prior art can be avoided, and 3, the sulfur trioxide compound is stable in property andgood in safety and can be conveniently applied in production.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

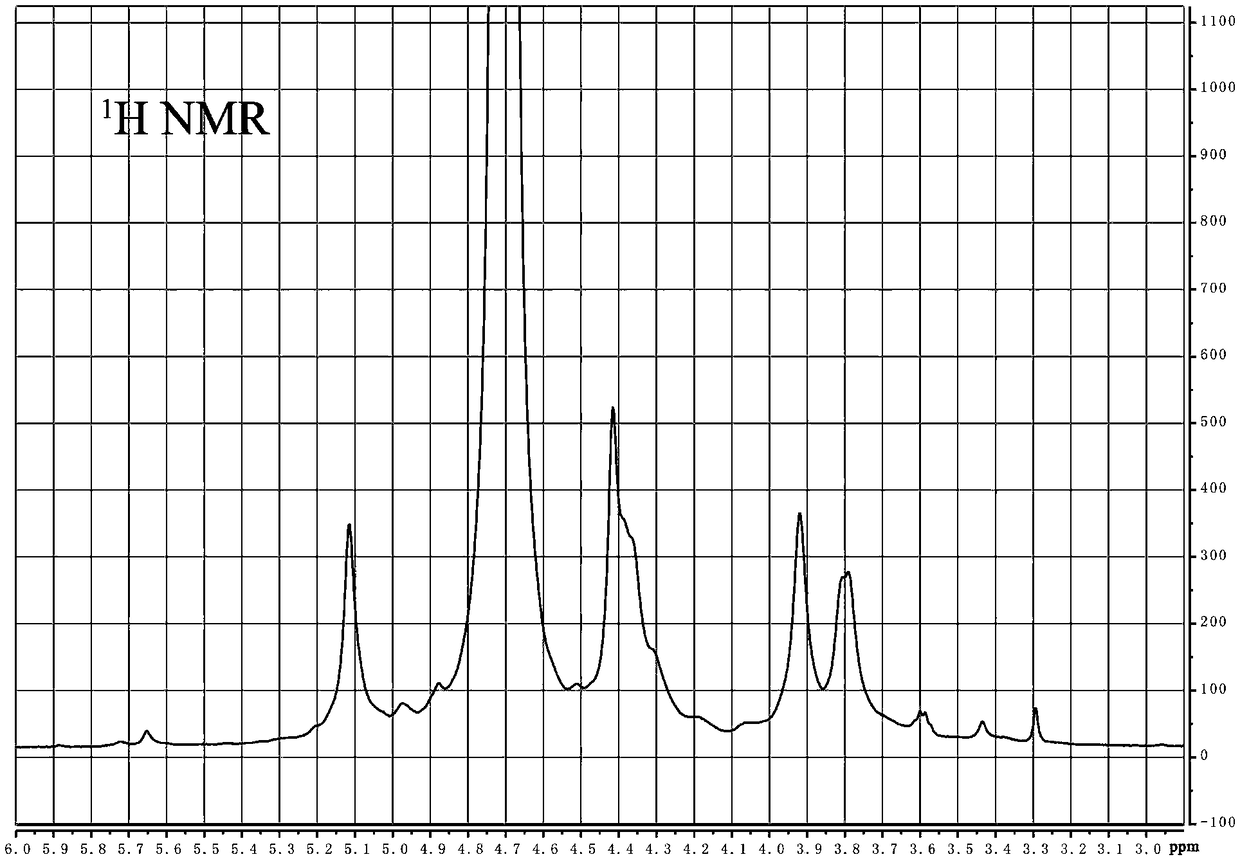

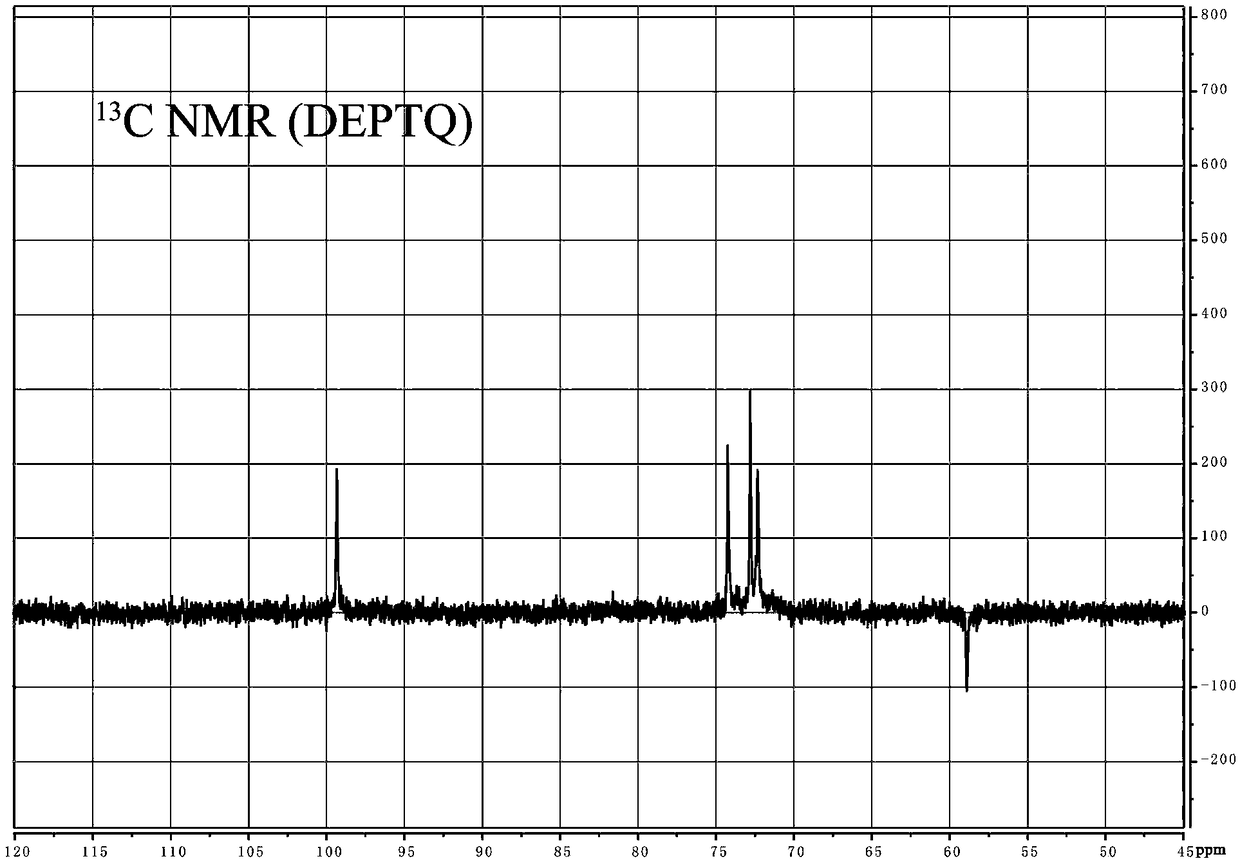

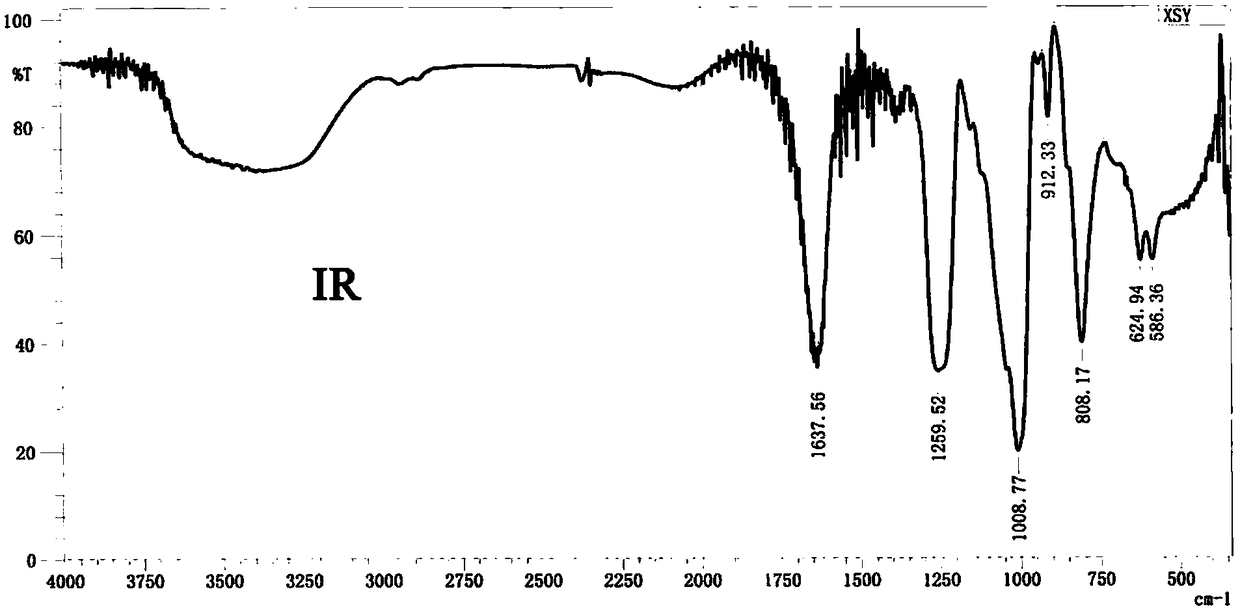

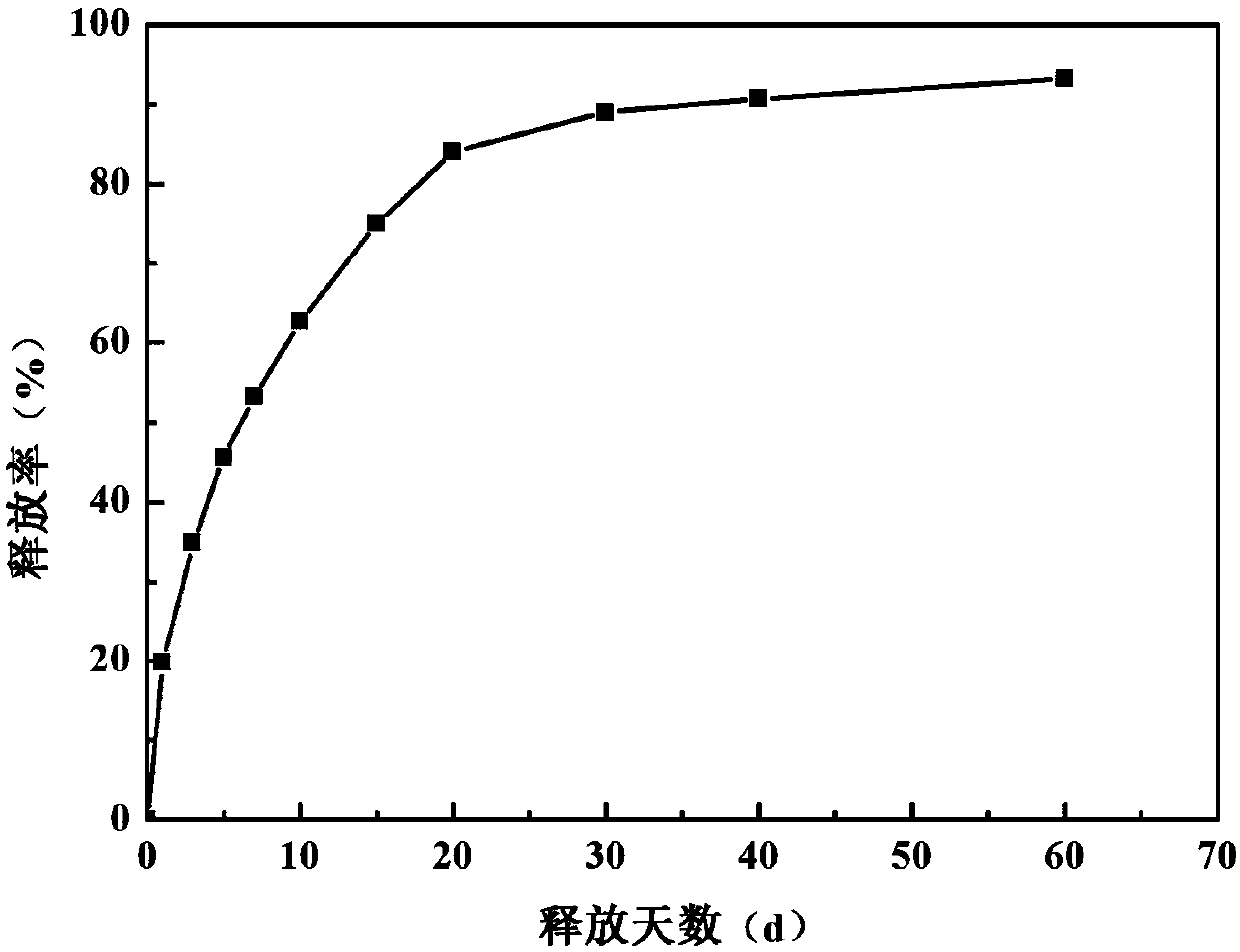

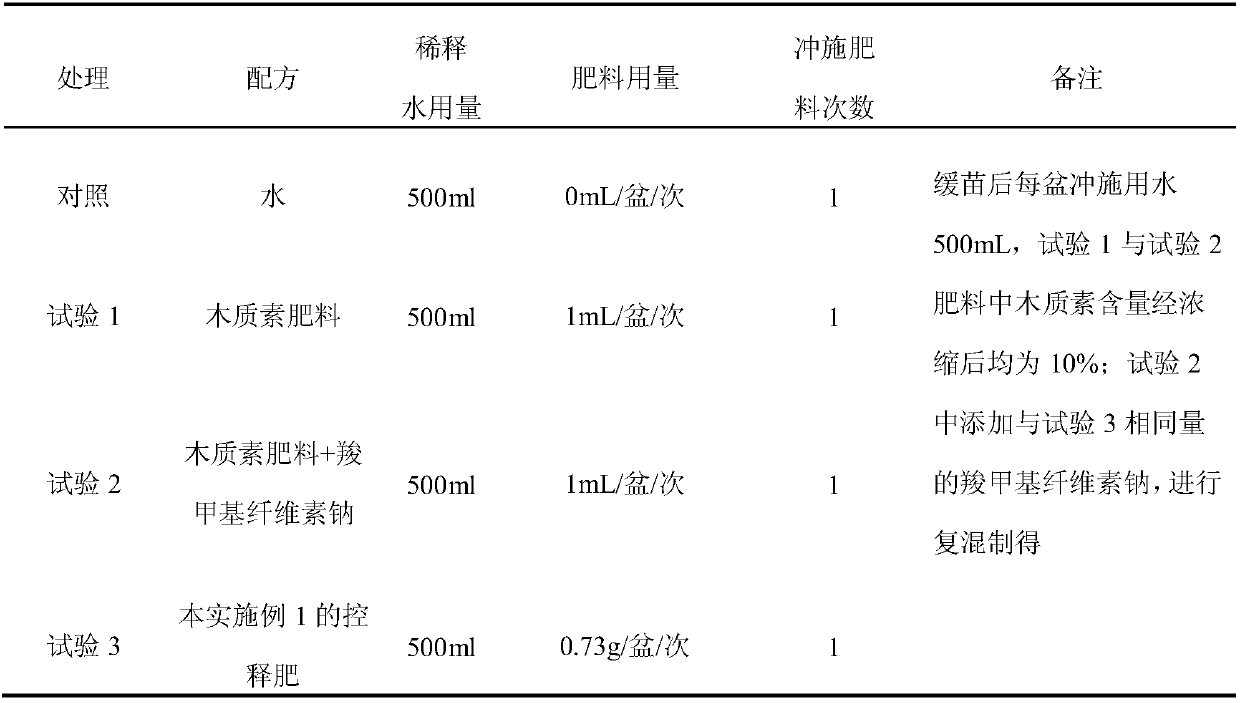

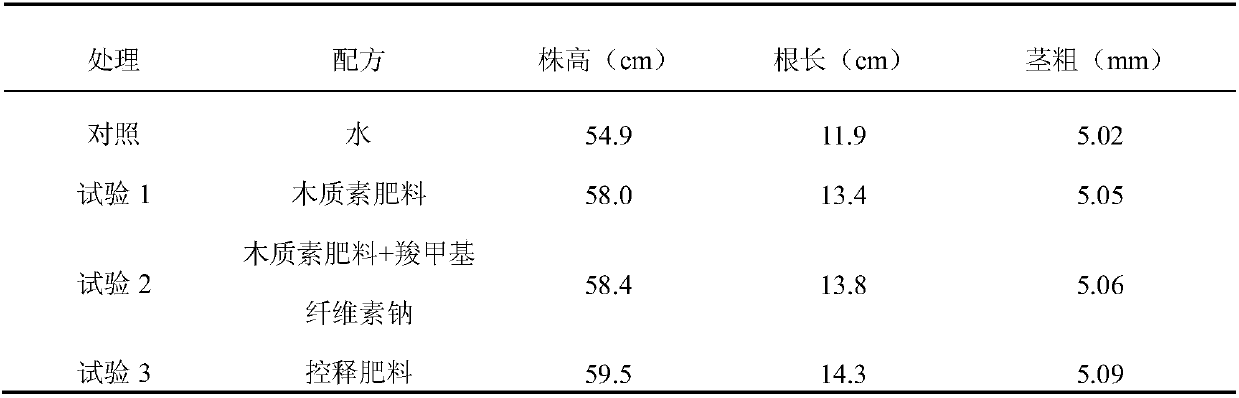

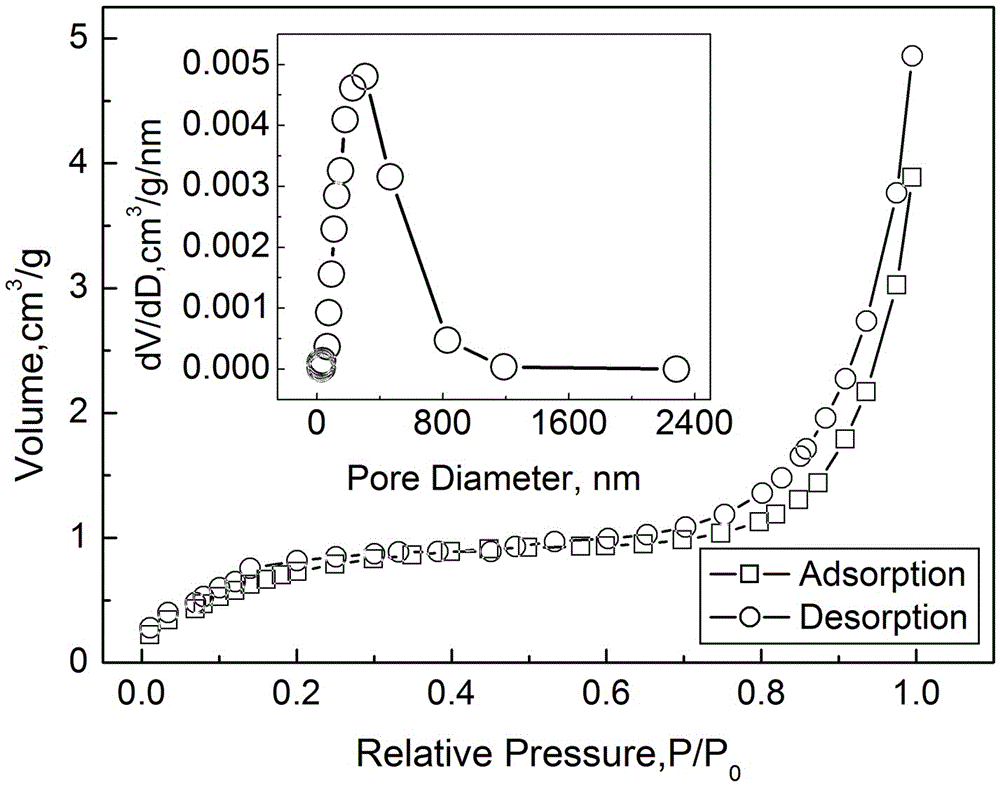

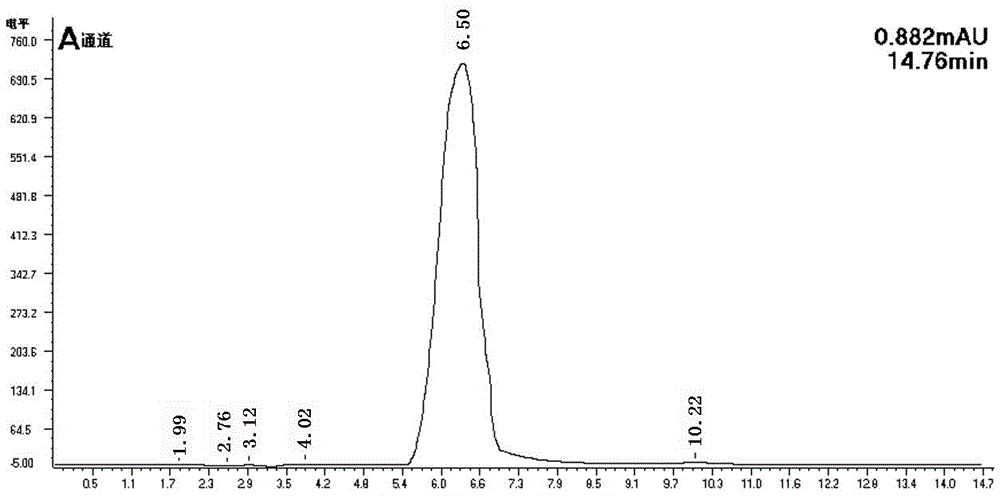

Controlled-release fertilizer as well as preparation method and application thereof

InactiveCN107827548AGood effectEasy to separateOrganic fertilisersAmmonium salt fertilisersCelluloseCopper salt

The invention relates to controlled-release fertilizer as well as a preparation method and application thereof. The controlled-release fertilizer is prepared by taking straw powder as a raw material,carrying out sulfonation treatment under the existence of sulfite, a buffer agent, anthraquinone and copper salt, then carrying out alkalization treatment by sodium hydroxide and finally carrying outchloroacetic acid treatment. The invention also provides the preparation method and the application of the controlled-release fertilizer. In the controlled-release fertilizer provided by the invention, the molecular weight of lignin is small, the sulfonating rate is high, and the lignin and cellulose in plant straw are fully utilized; the controlled-release fertilizer can be applied by adding water or be applied as base fertilizer or topdressed fertilizer, a slow release effect is good, and release of nutrients can be effectively controlled.

Owner:KINGENTA ECOLOGICAL ENG GRP +2

Preparation method of polystyrene sulfonic acid type ion exchange resin for water purification

The invention discloses a preparation method of polystyrene sulfonic acid type ion exchange resin for water purification. The preparation method comprises the following steps: stirring styrene, divinylbenzene, tribromomethane, methanol and benzoyl peroxide, in order to obtain a first preformed material; uniformly mixing water, polyvinyl alcohol and 2-methyl methacrylate, adding methylene blue with stirring till complete dissolving, and adding the first preformed material with stirring to obtain a second preformed material; adding chloroform into the second preformed material for swelling, adding a sulfuric acid solution and chlorosulfonic acid with stirring, evaporating the chloroform, cooling the temperature, adding water, carrying out a standing, removing a water layer, and washing a product till the pH is 7 to obtain a third preformed material; adding a sodium hydroxide solution into the third preformed material with stirring, carrying out a filtering, washing a product till the pH is 7, adding water with stirring, heating to 92-97 DEG C, carrying out an insulation and a filtering, adding absolute ethyl alcohol with stirring for backflow, carrying out cooling and filtering, washing a product till the pH is 7, and carrying out a drying to obtain the polystyrene sulfonic acid type ion exchange resin for water purification.

Owner:ANHUI WANDONG CHEM

Sulfonated vinegar residues and preparation method and application thereof

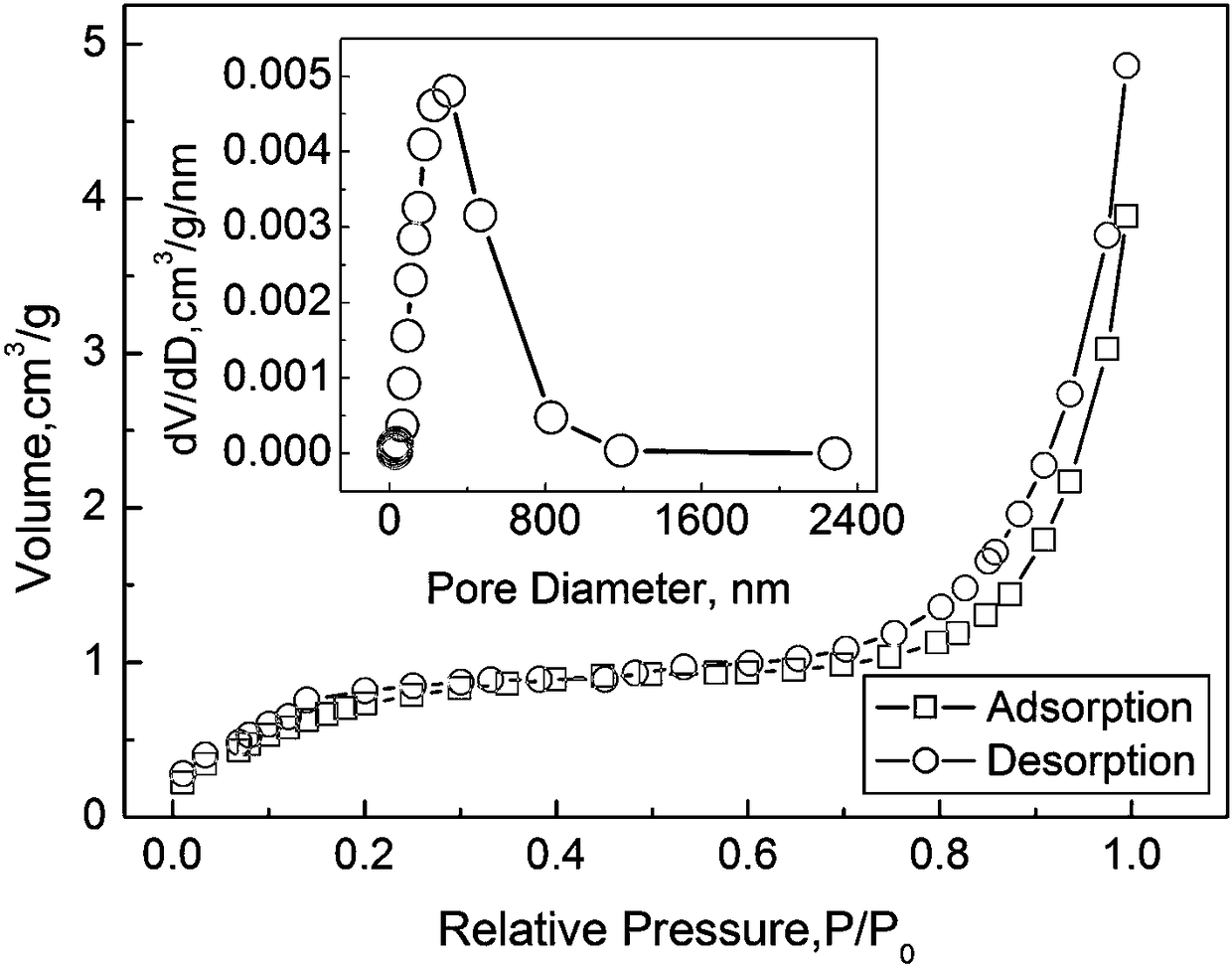

ActiveCN105562082ASimple technical processHigh sulfonation efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryGranularity

The invention discloses sulfonated vinegar residues and a preparation method and application thereof, and belongs to the field of chemical industry production and pharmaceutical production. The sulfonated vinegar residues are formed by mixing vinegar residues with sulfonating agent and baking vinegar residues and sulfonating agent through a wet method, wherein the sulfonated vinegar residues have the granularity of about 170-190 meshes, the specific surface area of 2.3864-2.5417 m<2> / g and the aperture of 0.3+ / -0.04 micron, and the content of sulfo groups in each gram of sulfonated vinegar residues is 41.382-53.298 mg. By means of the wet-method baking technology, vinegar residues are efficiently sulfonated; the sulfonated vinegar residues are little in sewage discharge, low in cost, high in sulfonating efficiency and long in service life, and a sulfonated vinegar residue catalyst is high in activity.

Owner:LULIANG UNIV

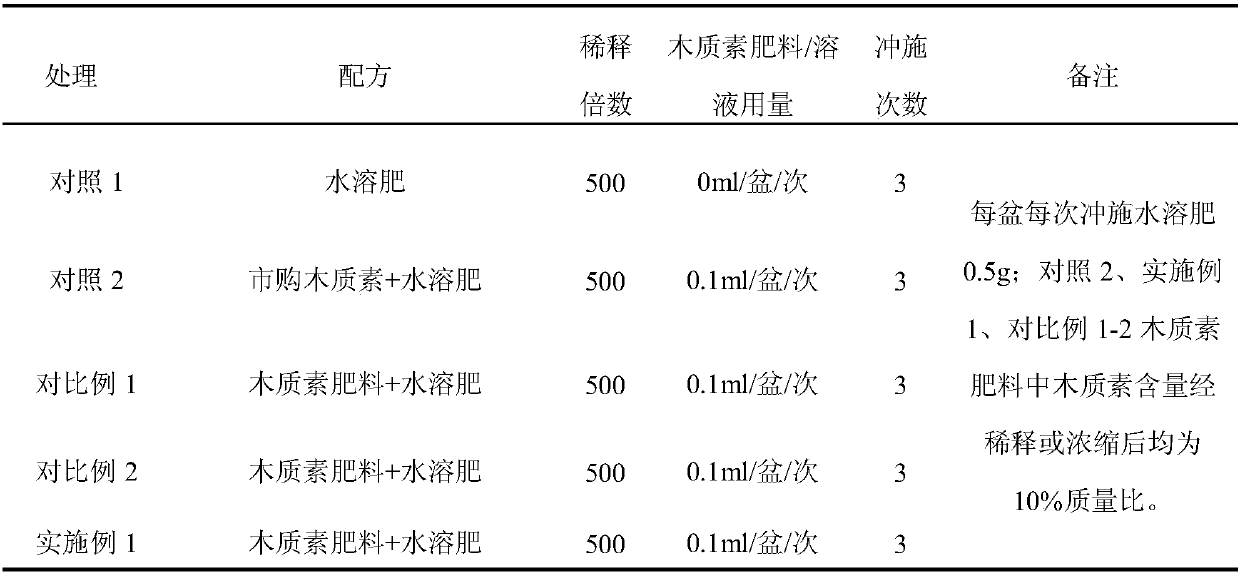

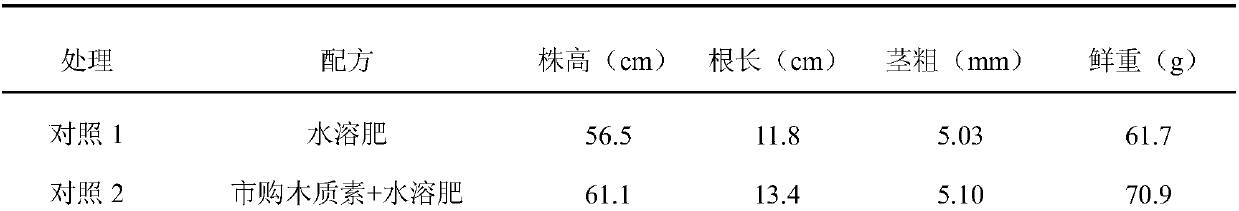

Lignin fertilizer and preparation method and application

InactiveCN107935676APlay a role in antibacterialLow priceAmmonium salt fertilisersOrganic fertilisersWater solubleSulfite

The invention relates to a lignin fertilizer and a preparation method and application. The lignin fertilizer takes straw as a raw material, and straw together with sulfite, a buffering agent, anthraquinone and copper salt undergoes a one-step reaction to prepare a liquid fertilizer. The content of lignin is 1.5-3.5% according to a mass ratio, and the weight average molecular weight of lignin is 2000-5000. The invention further provides a preparation method and application of the lignin fertilizer. Lignin in plant straw is fully applied at a high value. The lignin is small in molecular weight,high in sulfonation rate, good in sulfonation and beneficial for crop absorption. The preparation step is simplified, and the lignin fertilizer is obtained through a one-step charging reaction.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Method of increasing alkaline lignin sulfonation yield

The invention belongs to the field of increasing alkaline lignin reaction activity and discloses a method of increasing alkaline lignin sulfonation yield. In the method, alkaline lignin is subjected to pretreatment to increase the alkaline lignin sulfonation yield. The pretreatment includes the steps of: 1) adding the alkaline lignin to 1-ethyl-3-methylimidazole acetate or 1-ethyl-3-methylimidazole chloride salt, and uniformly mixing the components for treatment; 2) after the treatment is completed, adding water to terminate the reaction; 3) centrifuging and freeze-drying the reaction product to prepare pretreated alkaline lignin; and 4) performing pressure-reduced distillation to recycle the 1-ethyl-3-methylimidazole acetate or the 1-ethyl-3-methylimidazole chloride salt. The solvents in the pretreatment method are green and environment-friendly and can be recycled without pollution, so that the method has simple process and operations, is suitable for industrial production and has excellent application prospect.

Owner:SOUTH CHINA UNIV OF TECH

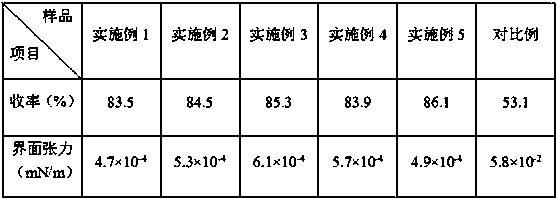

Petroleum sodium sulfonate composition as well as preparation method and application thereof

The invention provides a petroleum sodium sulfonate composition as well as a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing 5 to 95weight percent of a fraction 1 of which the average molecular weight is 252 to 312, 5 to 95 weight percent of a fraction 2 of which the average molecular weight is 313 to 395 and 0 to 50 weight percent of a fraction 3 of which the average molecular weight is 396 to 490 according to 100 percent of the total weight of a mixed material, thus obtaining the mixed material; adding a diluent into the mixed material, thus obtaining a diluted product; carrying out sulfonation treatment on the diluted product by adopting an SO3 gas, thus obtaining a sulfonated product, wherein the diluent is prepared from one or a combination of several alcohols of which the carbon chain lengths are C3 to C10, and the dosage of the diluent is 0.1 to 10 percent of the weight of the mixed material; then neutralizing petroleum sulfonic acid in the sulfonated product by adopting a sodium hydroxide aqueous solution until the pH (Potential of Hydrogen) value of a system is 7 to 11, thus obtaining the petroleum sodiumsulfonate composition.

Owner:PETROCHINA CO LTD

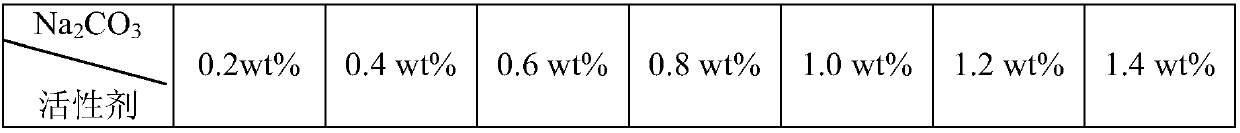

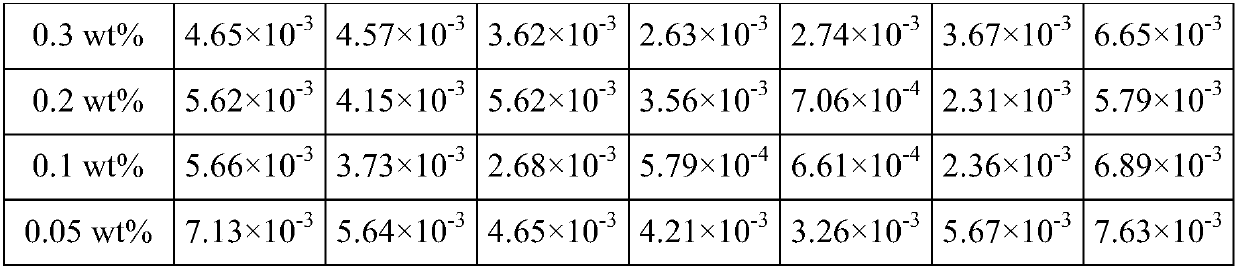

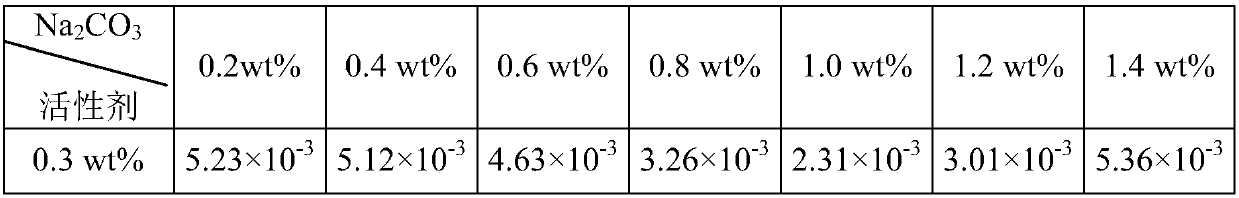

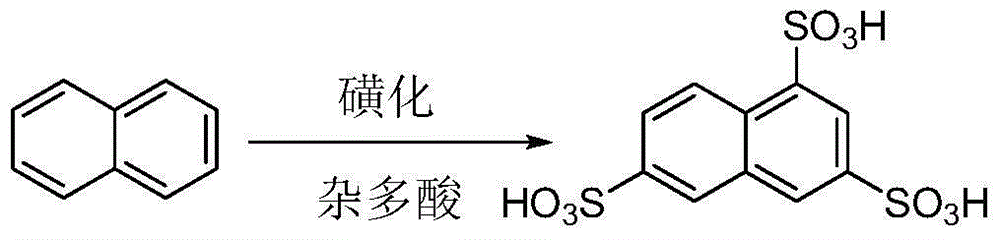

A kind of preparation method of H acid monosodium salt

The invention discloses a preparation method for an H acid monosodium salt. The preparation method comprises the following steps: (1) enabling refined naphthalene and sulfuric acid to be subjected to a sulfonation reaction in the presence of heteropolyacid with a catalyzing amount to obtain a sulfonated product; then adding sulfur trioxide to carry out a secondary sulfonation reaction; reacting completely to obtain a sulfonated material; (2) carrying out a nitration reaction on the sulfonated material and nitric acid to obtain a nitrated material; (3) enabling the nitrated material to be subjected to a hydrogenation reduction reaction in the presence of a hydrogenation catalyst to obtain an amino T acid; (4) adding methanol and sodium hydroxide into the amino T acid and heating and reacting to obtain an alkali melt; and (5) adjusting the pH (Potential of Hydrogen) value of the alkali melt to 3-6 and carrying out acidification and separation to obtain the H acid monosodium salt. According to the preparation method, a specific catalyst is added in a sulfonation step so that the reaction temperature is reduced, a reaction condition is moderate and the corrosion to equipment is reduced.

Owner:JIANGSU MINGSHENG CHEM

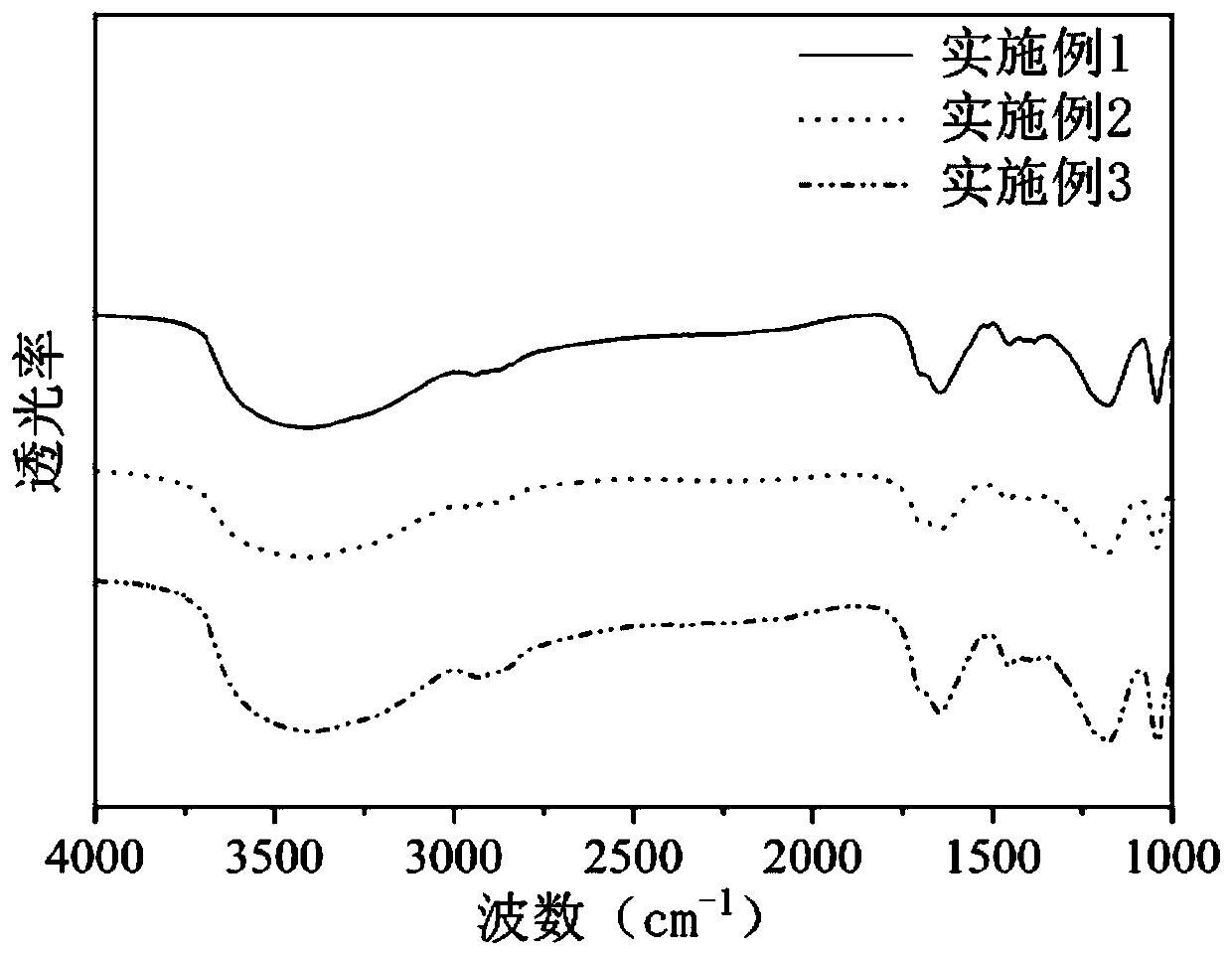

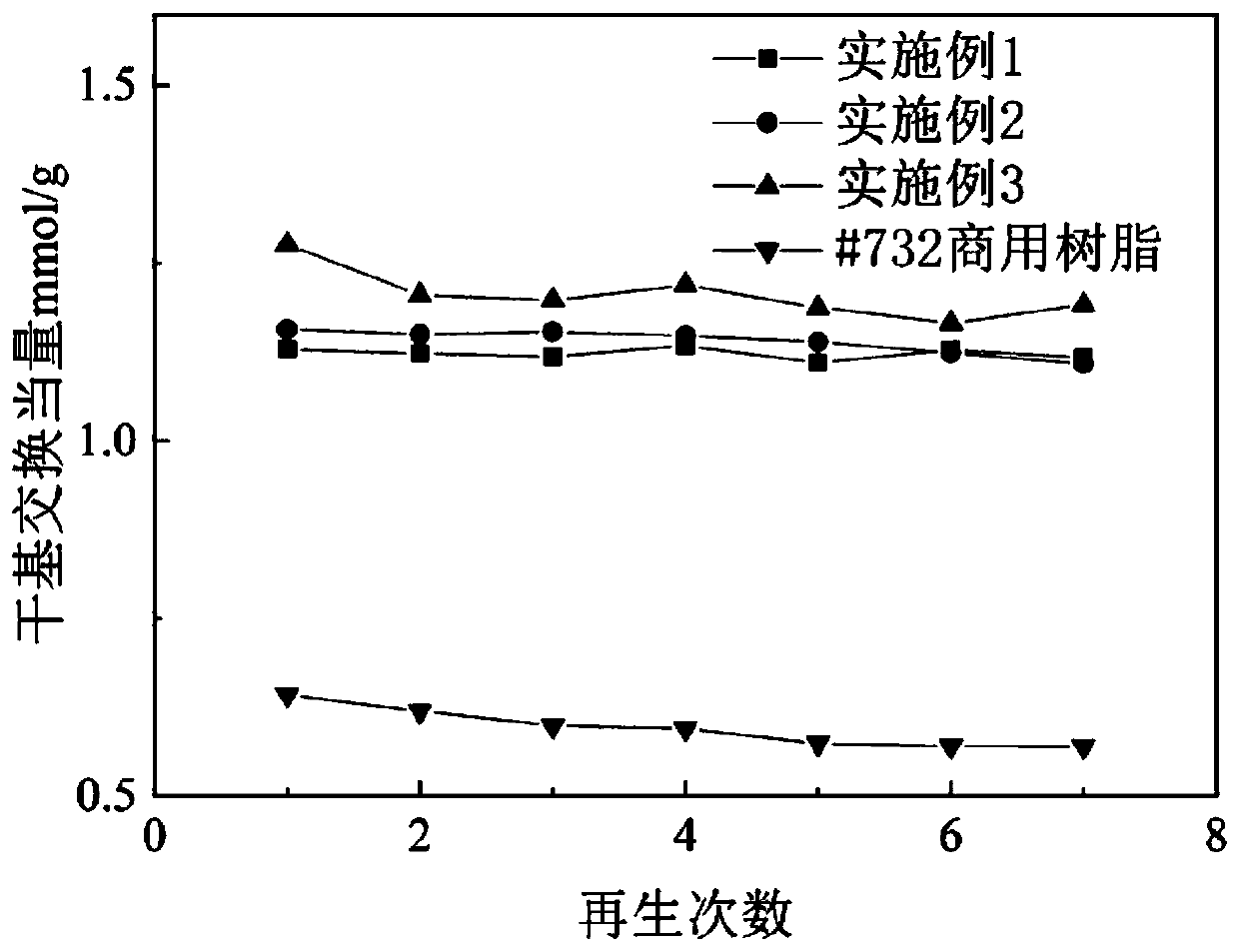

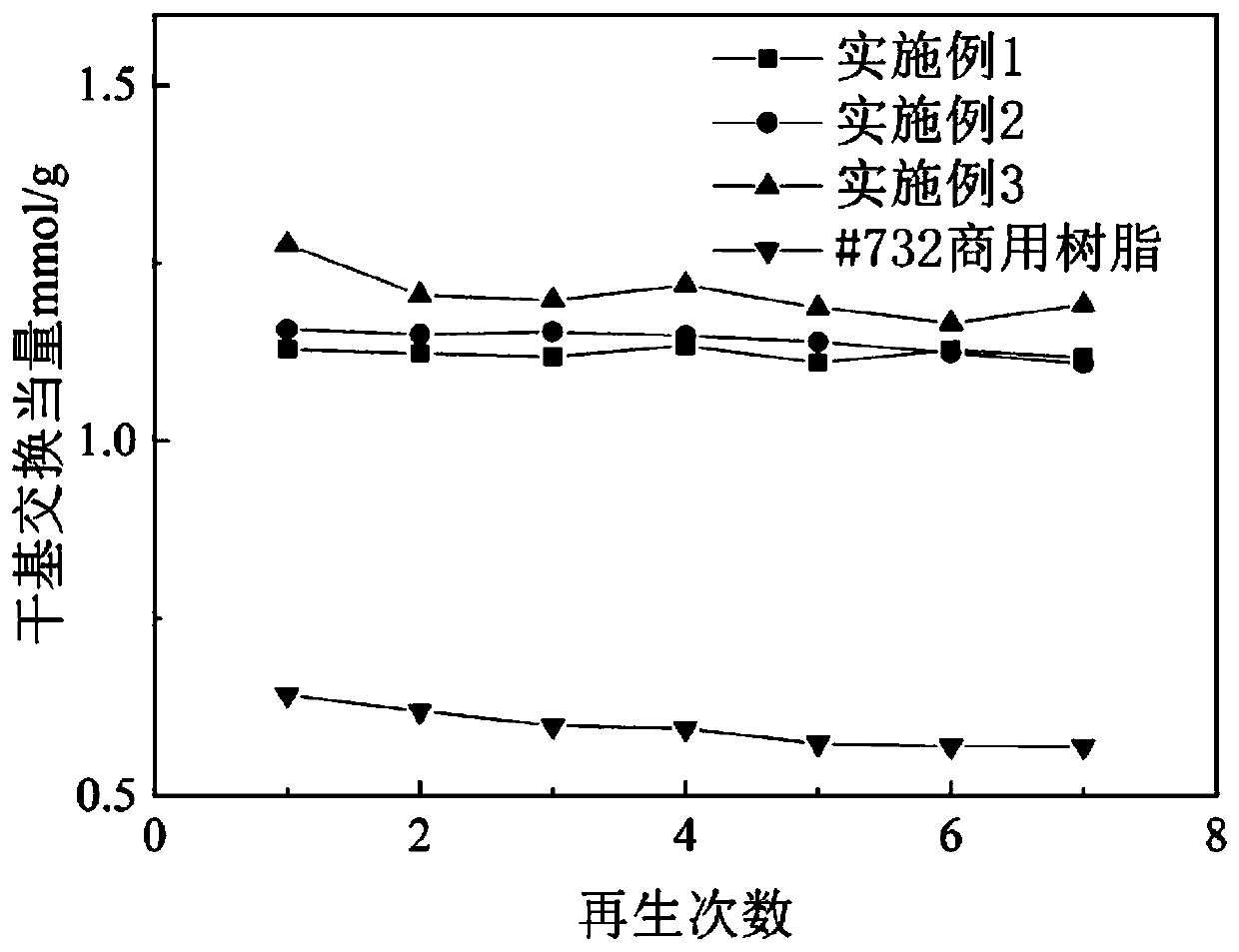

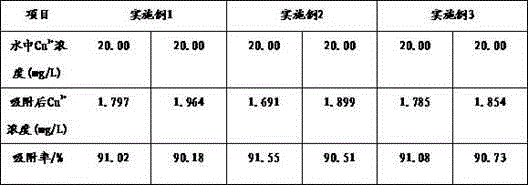

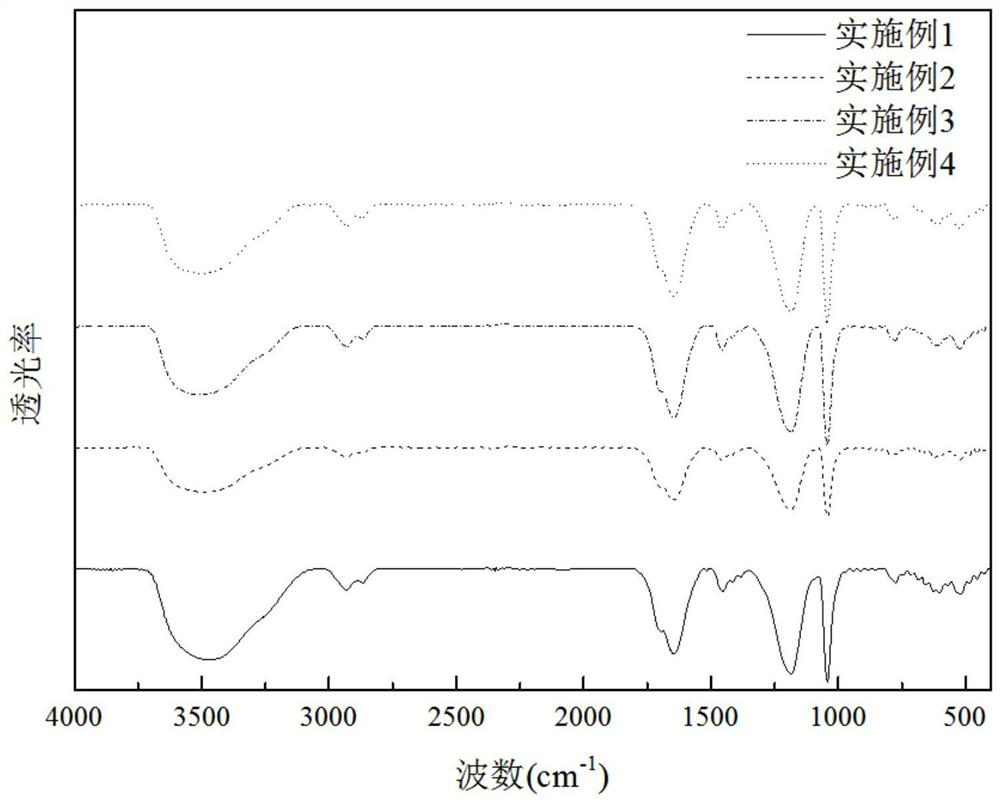

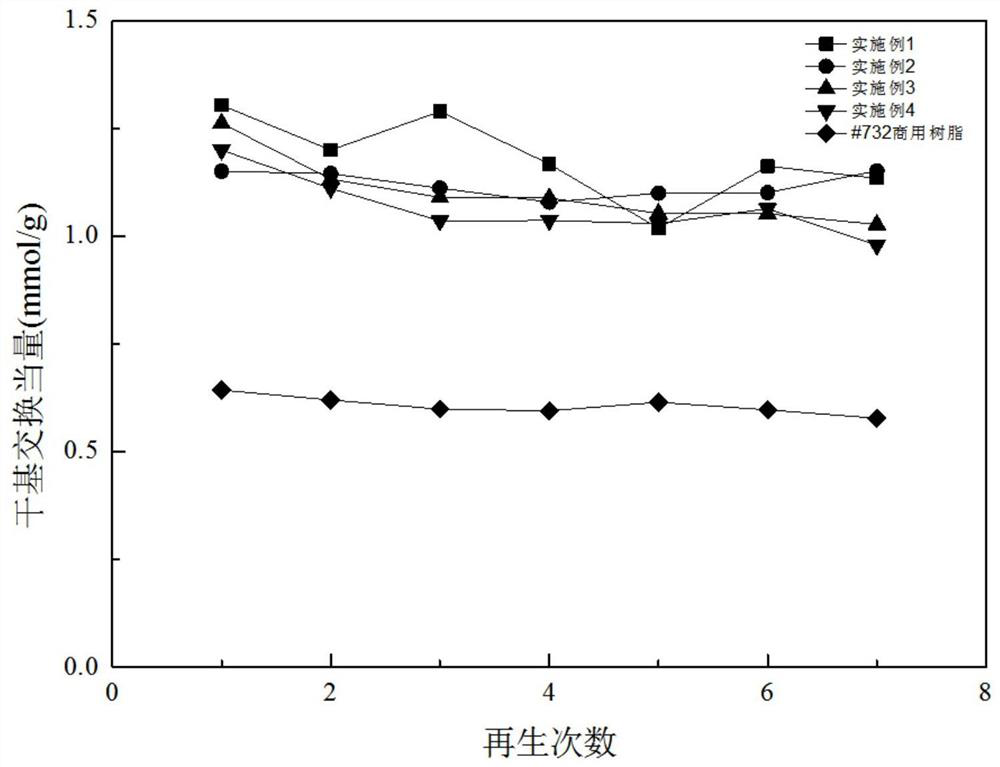

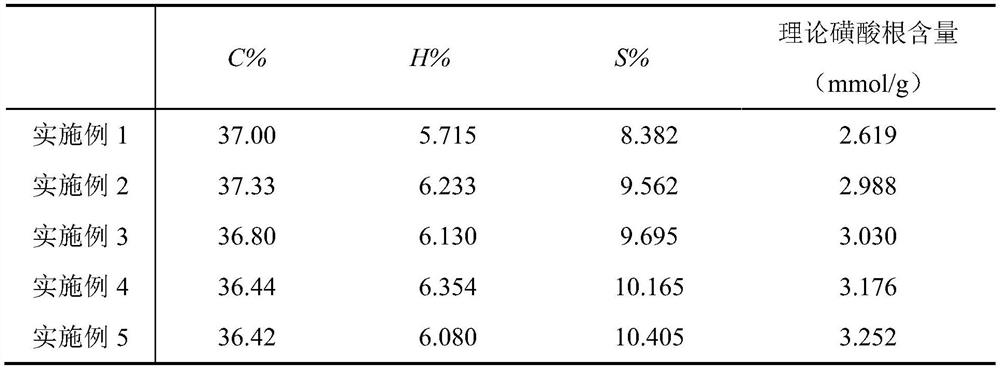

Crosslinked lignosulfonic acid based cation exchange resin as well as preparation method and application thereof

ActiveCN109970936ALow costMild sulfonation reactionWater contaminantsWater/sewage treatment by ion-exchangeKetoneEquivalent weight

The invention belongs to the technical field of cation exchange resin and discloses a crosslinked lignosulfonic acid based cation exchange resin as well as a preparation method and application thereof. The method comprises the steps: carrying out an aldol condensation reaction on sulfite, ketone, lignosulfonate and aldehyde to obtain an active polycondensate; and adding a crosslinking agent for athermal insulation curing crosslinking reaction to obtain the crosslinked lignosulfonic acid based cation exchange resin, wherein the dosages of all the components are calculated in parts by mass: 3-8parts of sulfite, 4-10 parts of ketone, 5-15 parts of lignosulfonate, 5-15 parts of aldehyde and 2-5 parts of crosslinking agent. According to the resin disclosed by the invention, not only is the ketone sulfonated to introduce a great number of sulfonic acid groups, but also lignosulfonate also contains a great number of sulfonic acid groups, and therefore, the product is high in sulfonated group content, can be used as a biomass-based strongly-acidic cation exchange resin, has the characteristics of high exchange equivalent weight and relatively low cost, can be used in the field of industrial water treatment and can be particularly applied as a strongly-acidic cation exchange resin to the removal of calcium and magnesium ions in hard water.

Owner:SOUTH CHINA UNIV OF TECH

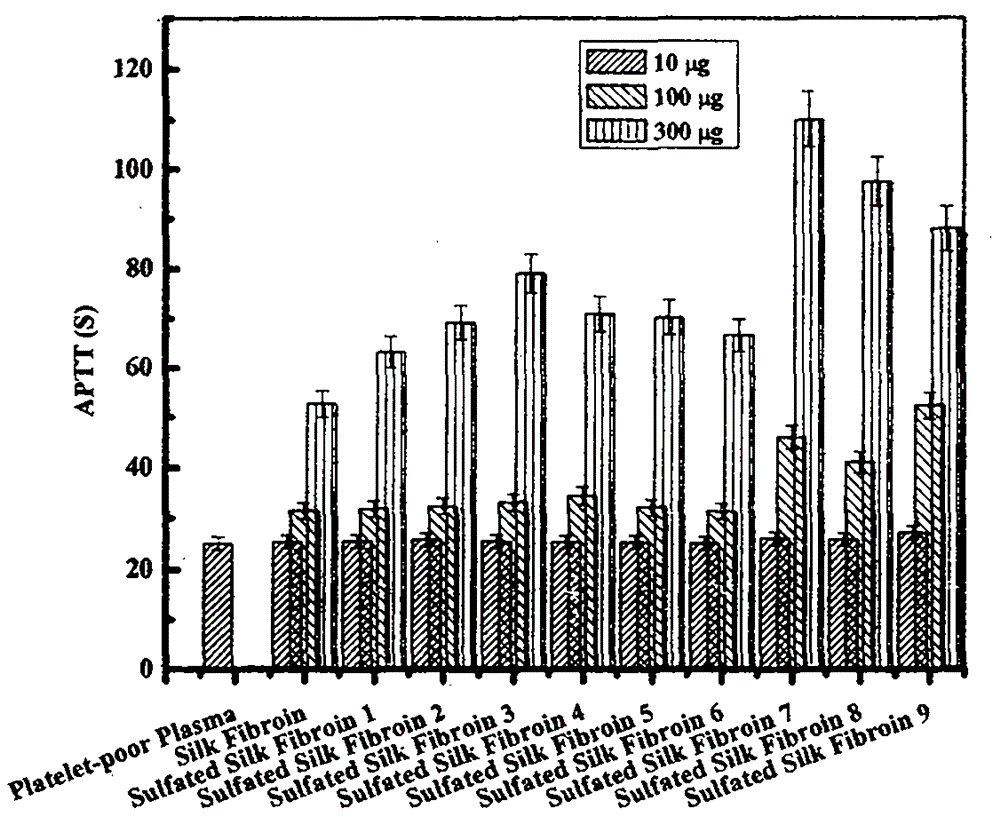

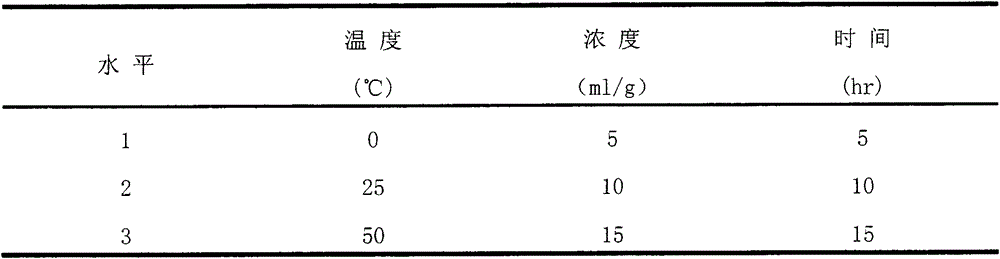

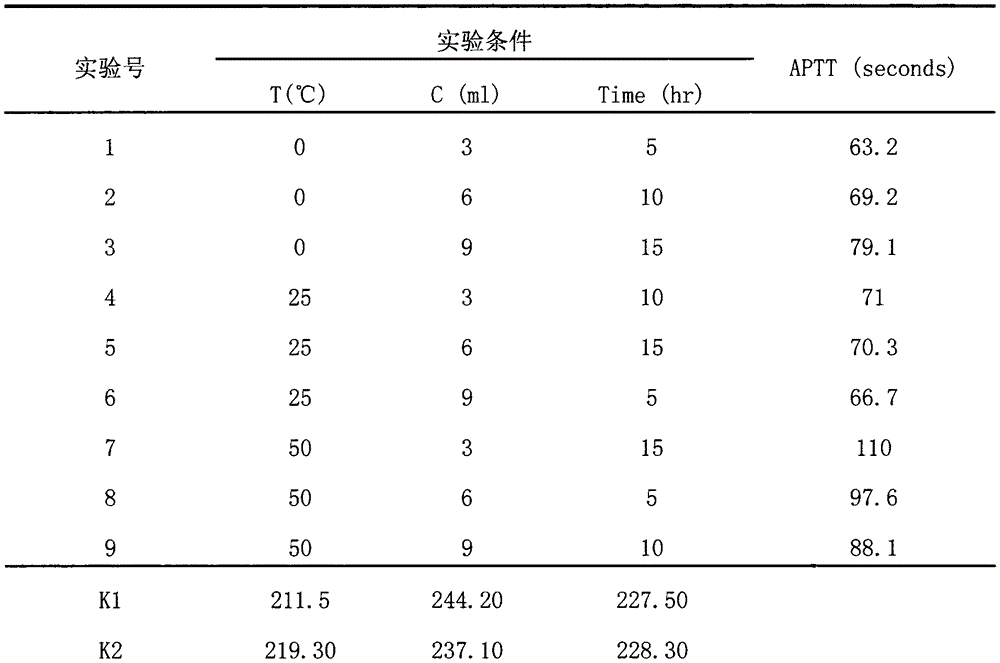

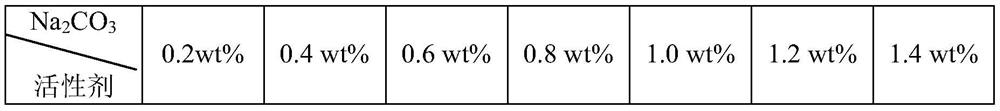

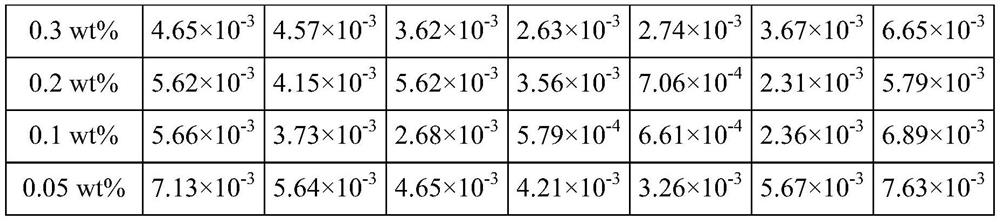

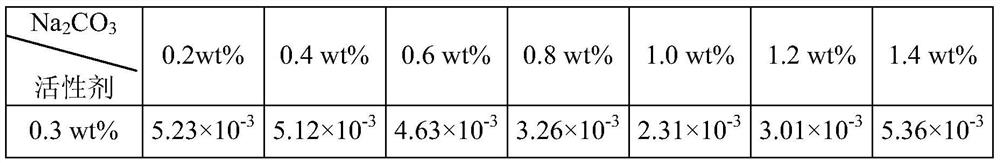

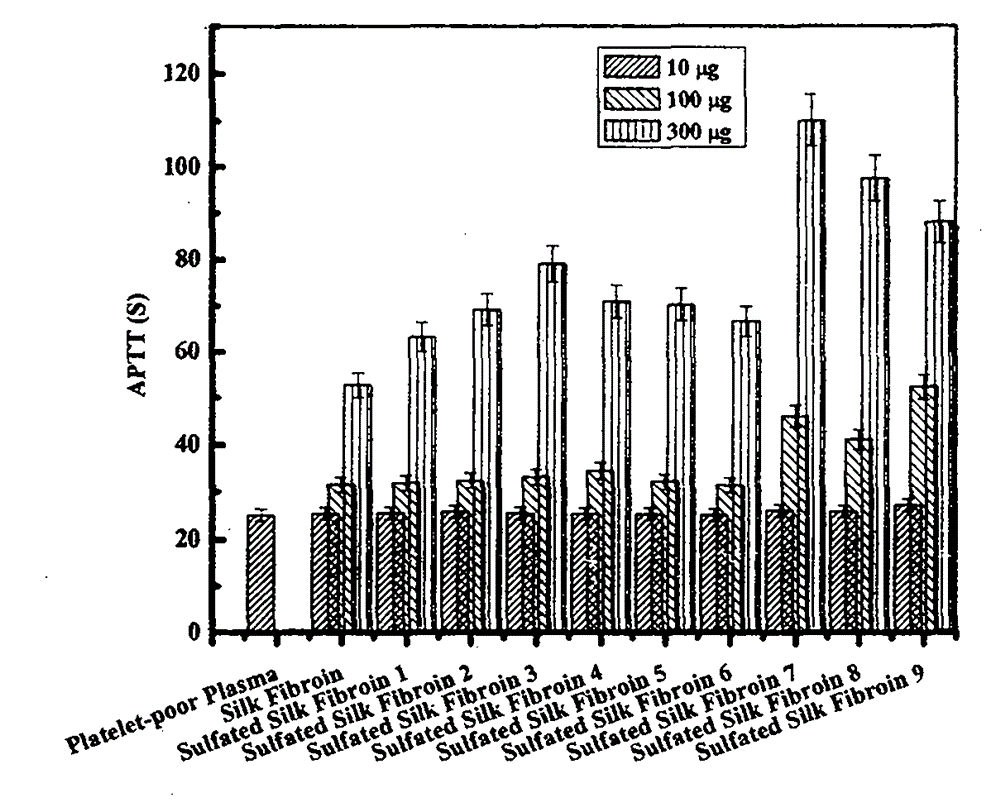

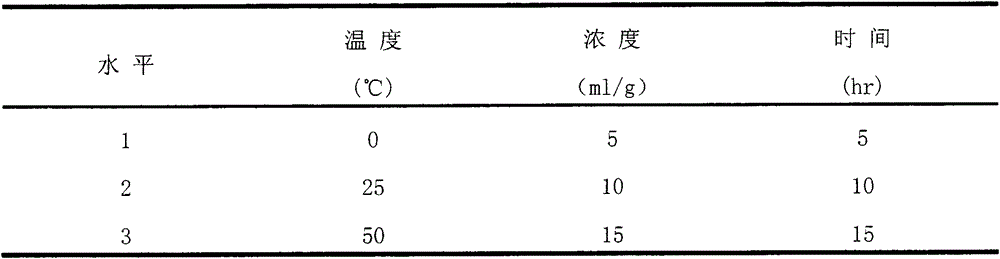

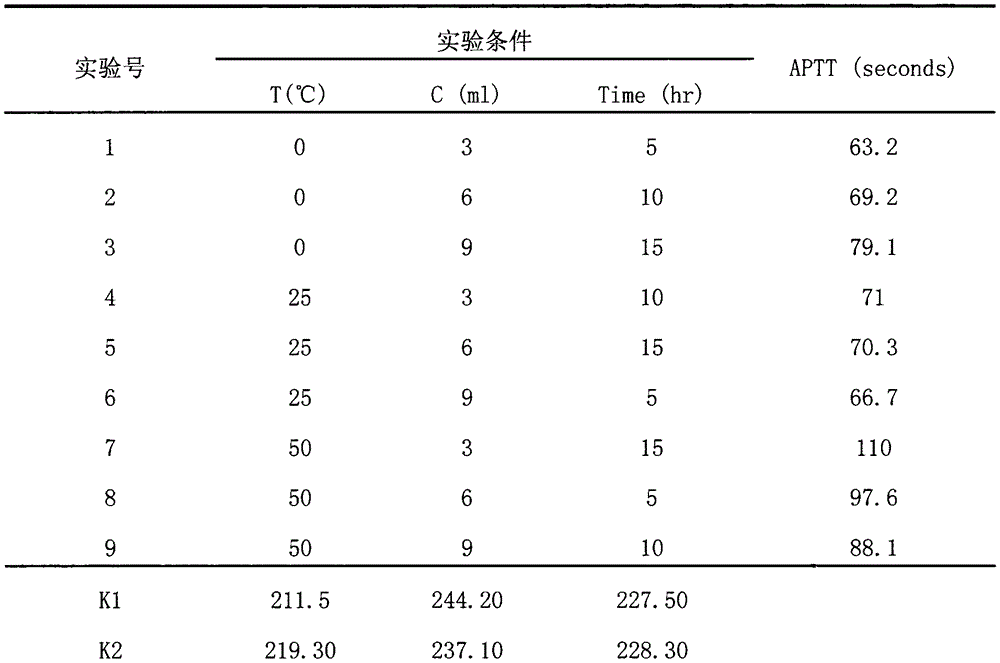

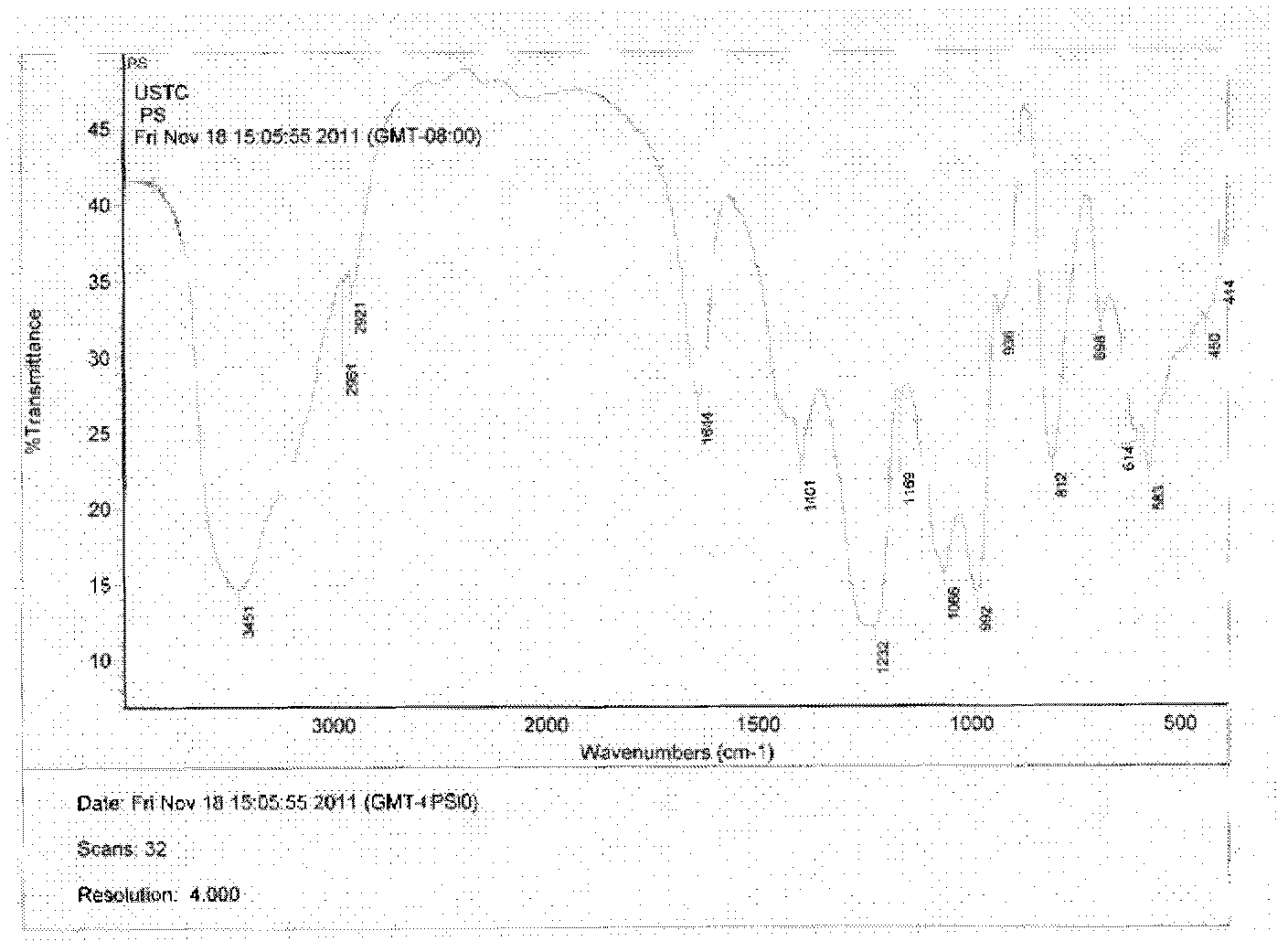

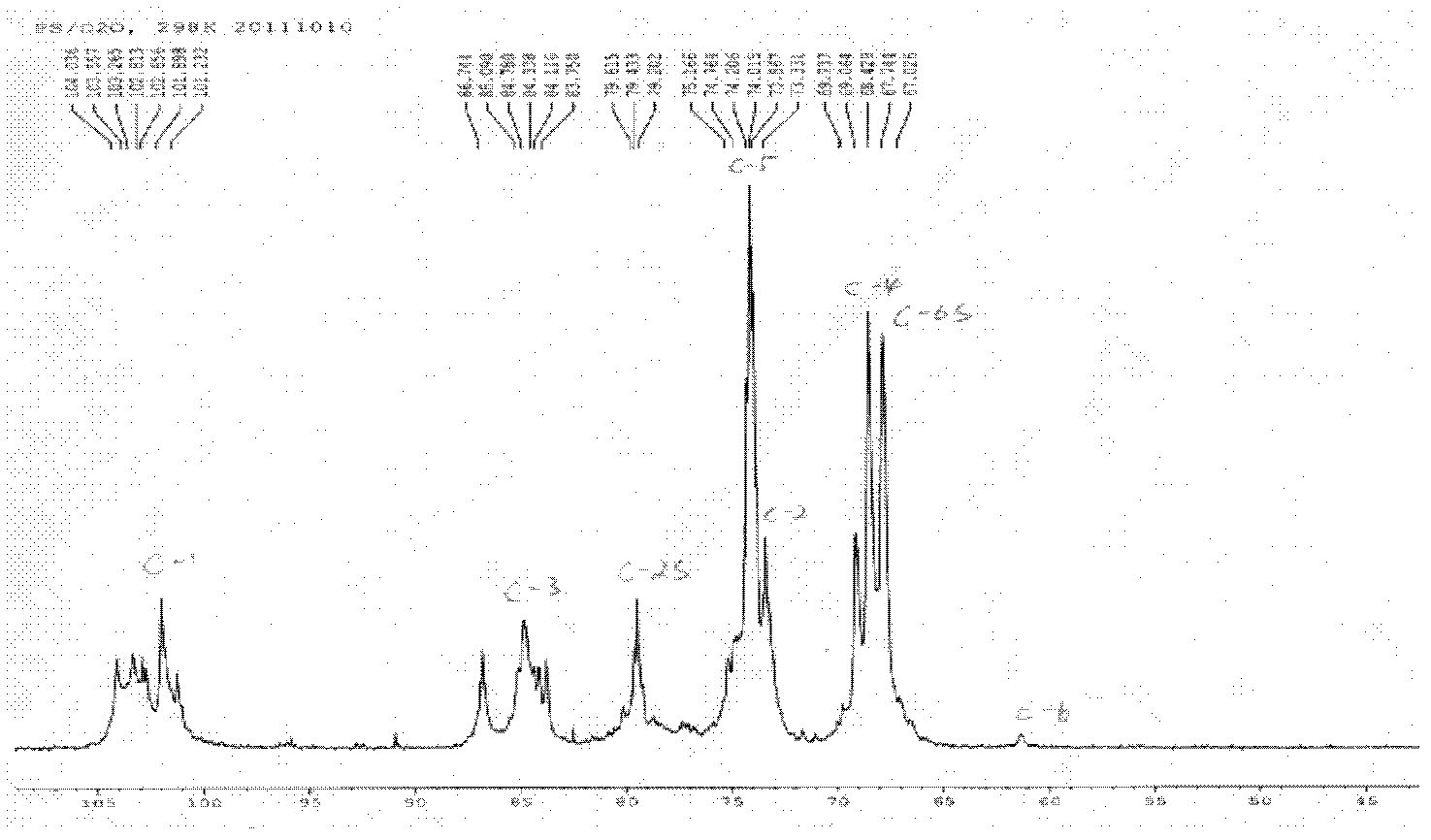

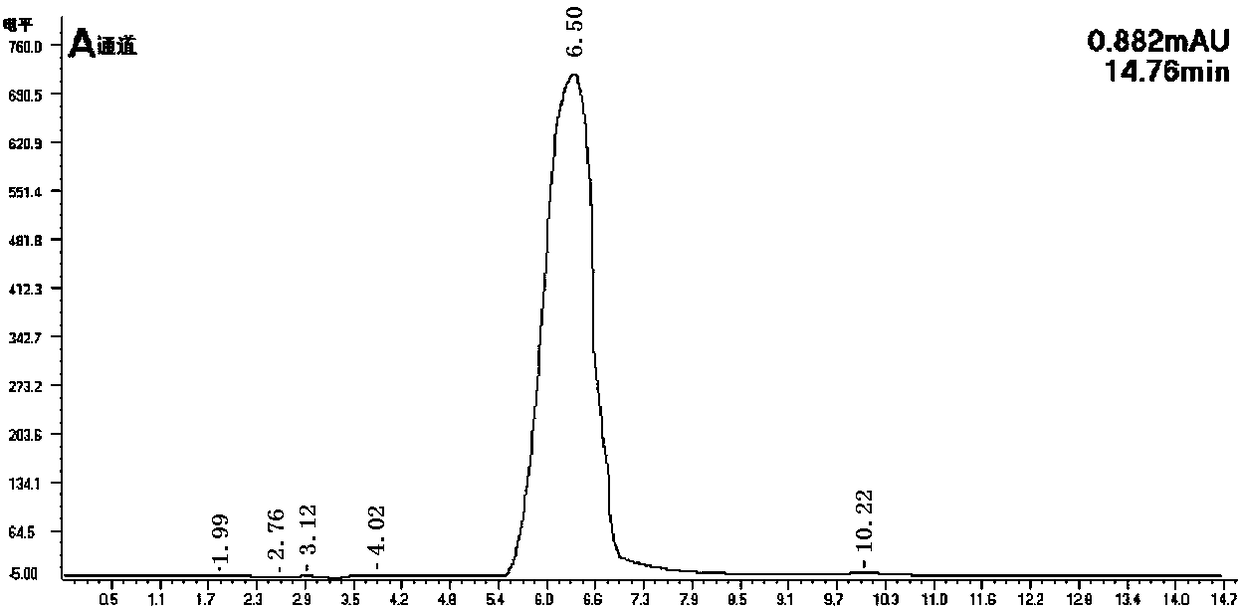

Direct sulfonation method preparation of sulfonated silk fibroin

The invention discloses a silk fibroin sulfonation modification method and technical screening of anticoagulant properties of sulfonated silk fibroin, belongs to the field of biological (medical) materials, and mainly relates to the following steps: natural silk is boiled in an alkaline (0.5% (wt%) Na2CO3 water solution) for degumming, and rinsed with distilled water, then silk fibroin fiber is dried at the temperature of 50 DEG C, then the dried silk fibroin is reacted with chlorosulfonic acid, a corresponding sulfonated modified silk fibroin solution is obtained by all steps of a sulfonation process optimized by an orthogonal method, then is neutralized into a neutral solution by use of a sodium hydroxide solution, then cooled to room temperature, transferred into a dialysis bag for dialysis for 72hr, concentrated by rotary evaporation, and frozen and dried to obtain sulfonated modified silk fibroin powder. By the optimized sulfonation process, the use amount of the chlorosulfonic acid can be reduced, the anticoagulant properties of the sulfonated silk fibroin can be improved, the repeatability is good, the product is pure, and the composition is stable.

Owner:SOUTHWEST JIAOTONG UNIV

Petroleum sulfonate and preparation method thereof

InactiveCN109824552AHigh yieldLow asphaltene contentOrganic compound preparationSulfonic acids salts preparationHydrogenSulfur trioxide

The invention discloses petroleum sulfonate and a preparation method thereof. The petroleum sulfonate comprises a petroleum component, a catalyst, an alkali solution, hydrogen and sulfur trioxide. Thepreparation method of the petroleum sulfonate includes preparing a sulfonated raw material; performing primary sulfonation and extraction to obtain unsulfonated oil and an extracting agent containingpetroleum sulfonic acid; repeating sulfonation and extraction on the unsulfonated oil until no unsulfonated oil is obtained; combining and distilling the extracting agent containing the petroleum sulfonic acid to obtain the petroleum sulfonic acid; performing ageing and neutralizing to obtain a petroleum sulfonate solution, and concentrating and drying the petroleum sulfonate solution to obtain apetroleum sulfonate product. The petroleum sulfonate product has high good interfacial tension performance, a sulfonation reactor has less coking during preparation and long operating cycle, and thecost is reduced.

Owner:高路生

Application of araboxylan sulfonate to preparation of medicine for treating osteoarthritis

ActiveCN109793751AGood curative effectHigh sulfonation efficiencyOrganic active ingredientsAntipyreticSulfonateArabinoxylan

The invention discloses an application of araboxylan sulfonate to preparation of a medicine for treating osteoarthritis, and belongs to the technical field of medicines. According to a large number ofstudies, the araboxylan sulfonate has very obvious osteoarthritis treating functions, inflammation can be eliminated, cartilage repair can be promoted, and illness states can be reversed to a certaindegree, so that the araboxylan sulfonate can be used for preparing the medicine for treating the osteoarthritis.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

Preparation method of barium diphenylamine sulfonate

InactiveCN105017093AShortened completelyGuaranteed to completeSulfonic acids salts preparationAnilineHydrolysis

Owner:TIANJIN GUANGFU TECH DEV

A kind of petroleum sulfonic acid sodium salt composition and its preparation method and application

The invention provides a petroleum sulfonic acid sodium salt composition, a preparation method and application thereof. The preparation method comprises taking the total weight of the mixture as 100%, 5wt%-95wt% fraction 1 with an average molecular weight of 252-312, 5wt%-95wt% fraction 2 with an average molecular weight of 313-395 and 0-50wt% % average molecular weight is that fraction 3 of 396-490 is mixed homogeneously, obtains mixture; Add diluent in mixture, obtain the product after dilution, adopt SO 3 The gas is subjected to sulfonation treatment on the diluted product to obtain a product after sulfonation treatment; wherein, the diluent includes one or a combination of alcohols with a carbon chain length of C3-C10, and the amount is the weight of the mixture 0.1%-10% of 0.1%-10%; and then use sodium hydroxide aqueous solution to neutralize the petroleum sulfonic acid in the product after sulfonation treatment until the pH value of the system is 7-10 to obtain the petroleum sulfonic acid sodium salt composition.

Owner:PETROCHINA CO LTD

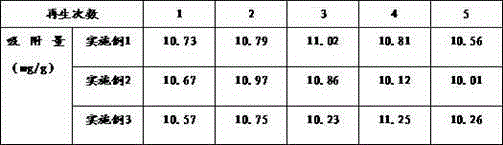

A kind of magnetic phenolic humic acid resin and preparation method thereof

InactiveCN103611513BShort reaction timeImprove efficiencyOther chemical processesCombustible gas purificationCross-linkWastewater

The invention relates to magnetic phenol formaldehyde-humic acid resin and a preparation method thereof. The preparation method for the magnetic phenol formaldehyde-humic acid resin comprises the following steps of adding a sulfonated sodium humate solution into water-soluble phenol formaldehyde resin, uniformly stirring the mixed solution, adding magnetic fluid, stirring for mixing, heating the mixed solution to 100 DEG C, performing cross-linking reaction for 30 to 90 minutes at constant temperature, activating the magnetic phenol formaldehyde-humic acid resin in a calcium acetate solution, filtering and drying. According to the magnetic phenol formaldehyde-humic acid resin and the preparation method thereof, the magnetic phenol formaldehyde-humic acid resin can be prepared, is high in Cu<2+> ion adsorption performance, and can be used for removing copper ions from wastewater; the resin adsorbed with the copper ions is easy to regenerate, and can be separated by adopting an external magnetic field.

Owner:LIAOCHENG UNIV

A method for preparing biochar from organic waste by sulfonated carbon low-temperature catalysis

ActiveCN105618025BEasy to introduceHigh reactivityPhysical/chemical process catalystsBiofuelsSocial benefitsBiomass carbon

The invention relates to a method for preparing biomass charcoal by catalyzing organic waste at a low temperature with sulfonated char. Agricultural waste is prepared into biomass charcoal at a medium-temperature oxygen limited condition, and then the biomass charcoal is sulfonated by 95%-98% fuming sulphuric acid and is blanched and freeze-dried to obtain a sulfonated char catalyst, and the sulfonating efficiency is 1.9-2.5mmol / g. The method of preparing biomass charcoal by catalyzing organic waste at a low temperature comprises the steps of uniformly mixing the sulfonated char catalyst, crushed organic waste and water in a certain ratio, and heating the mixture in a closed reactor at the temperature of 100-130 DEG C and the rotation rate of 60-100 revolutions / h for 1-2 hours, thereby obtaining the biomass charcoal by reaction. According to the invention, not only is the difficulty of processing organic waste is solved, but also charcoal making with low cost is realized, wherein the cost is only 10%-15% of that of ordinary high-temperature charcoal making, and furthermore, the biomass charcoal has large specific surface area and good adsorption performance, can be widely applied to adsorption and purification in sewage treatment and has good economic and social benefits.

Owner:天津滨海道顺科技发展有限公司

Preparation of Sulfonated Silk Fibroin by Direct Sulfonation

The invention discloses a silk fibroin sulfonation modification method and technical screening of anticoagulant properties of sulfonated silk fibroin, belongs to the field of biological (medical) materials, and mainly relates to the following steps: natural silk is boiled in an alkaline (0.5% (wt%) Na2CO3 water solution) for degumming, and rinsed with distilled water, then silk fibroin fiber is dried at the temperature of 50 DEG C, then the dried silk fibroin is reacted with chlorosulfonic acid, a corresponding sulfonated modified silk fibroin solution is obtained by all steps of a sulfonation process optimized by an orthogonal method, then is neutralized into a neutral solution by use of a sodium hydroxide solution, then cooled to room temperature, transferred into a dialysis bag for dialysis for 72hr, concentrated by rotary evaporation, and frozen and dried to obtain sulfonated modified silk fibroin powder. By the optimized sulfonation process, the use amount of the chlorosulfonic acid can be reduced, the anticoagulant properties of the sulfonated silk fibroin can be improved, the repeatability is good, the product is pure, and the composition is stable.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of 1-butyl-3-methylimidazolium chloride salt-licl-dmf system prepares the method for microfiber corn stalk

ActiveCN107501571BEffective swellingReduce cohesionOther chemical processesWater contaminantsVacuum dryingHydroxy compound

Owner:QILU UNIV OF TECH

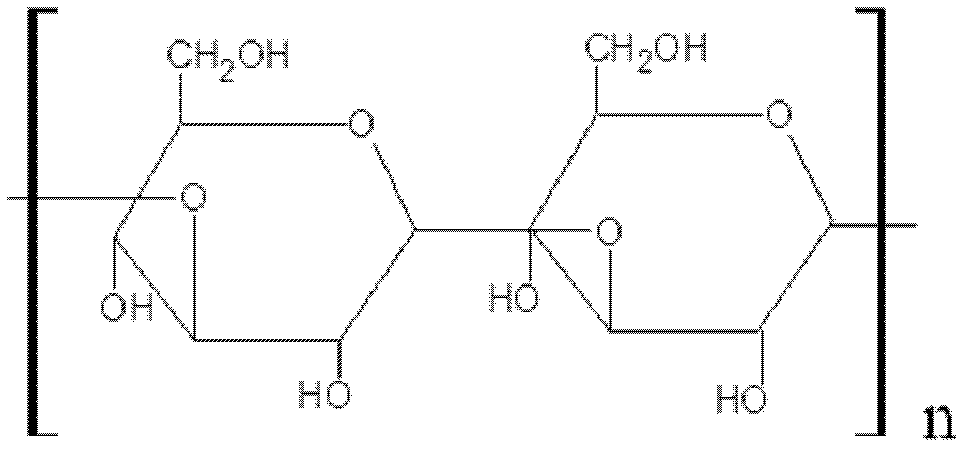

Preparation method of pachyman sulfate

ActiveCN102603910BIncreased chance of collisionIncrease the solid-to-liquid ratioOrganic active ingredientsBlood disorderRotary evaporatorSulfate radicals

The invention discloses a preparation method of pachyman sulfate. The preparation method comprises the following steps of: adding sulfamic acid and an organic solvent in a reaction bottle of a rotary evaporator; preheating to reaction temperature; after fully dissolving the sulfamic acid, adding dried pachyman powder; vacuuming a reaction system; cooling to room temperature after the reaction is finished; adjusting the pH of reaction solution to 9-10 with saturated alkali solution; continuously vacuuming to remove ammonia and repeatedly vacuuming until the reaction solution has no ammonia smell; maintaining the pH value to be over 7 until the pH value does not go down; then adding ethanol; precipitating polysaccharide sulfate; filtering and then dissolving in water again; filtering; placing in an ultrafilter to desalinate and concentrate; and detecting residual quantity of free sulfate radicals in eluent by using saturated barium chloride solution until no white precipitate is produced. According to the preparation method, the sulfation efficiency is greatly increased, polysaccharide molecule degradation and production of sugar ring double ring are suppressed, the color of a product becomes light, and the final quality of the product is obviously improved.

Owner:合肥创新医药技术有限公司

A kind of cross-linked sulfonated aldehyde and ketone cation exchange resin and its preparation method and application

ActiveCN109749031BLow costMild sulfonation reactionOrganic cation exchangersPolymer sciencePolystyrene

Owner:SOUTH CHINA UNIV OF TECH

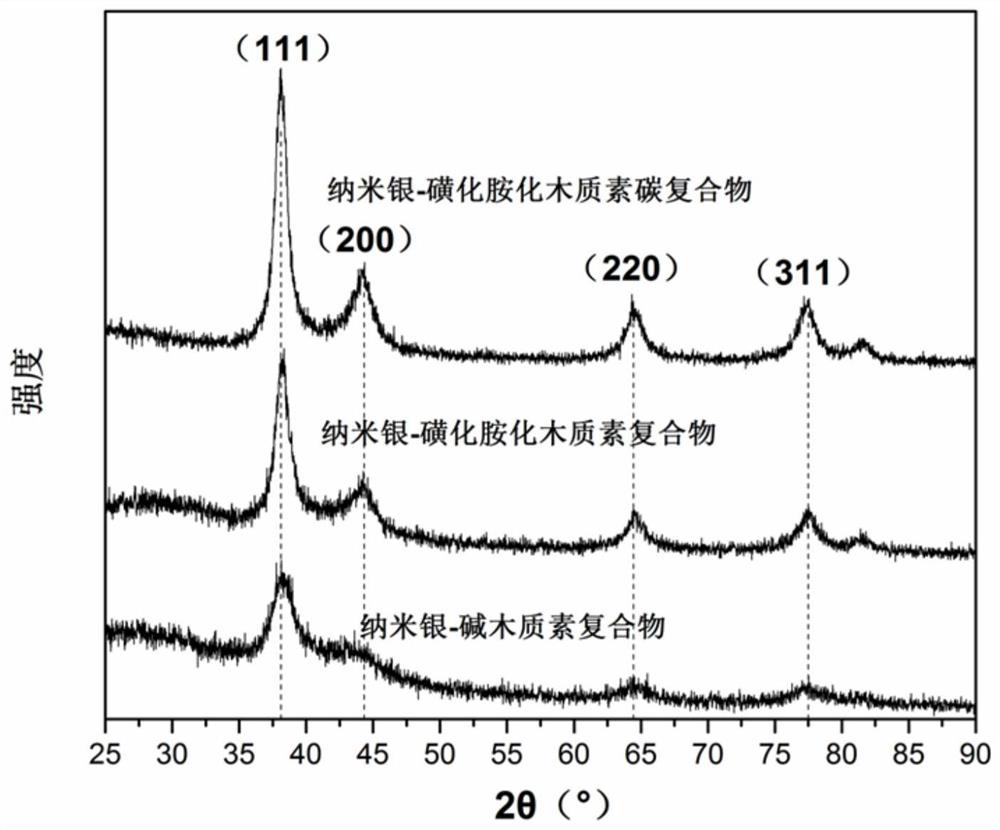

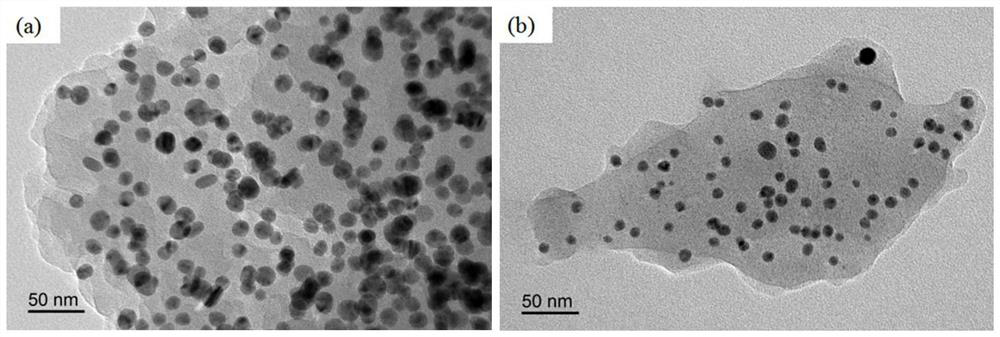

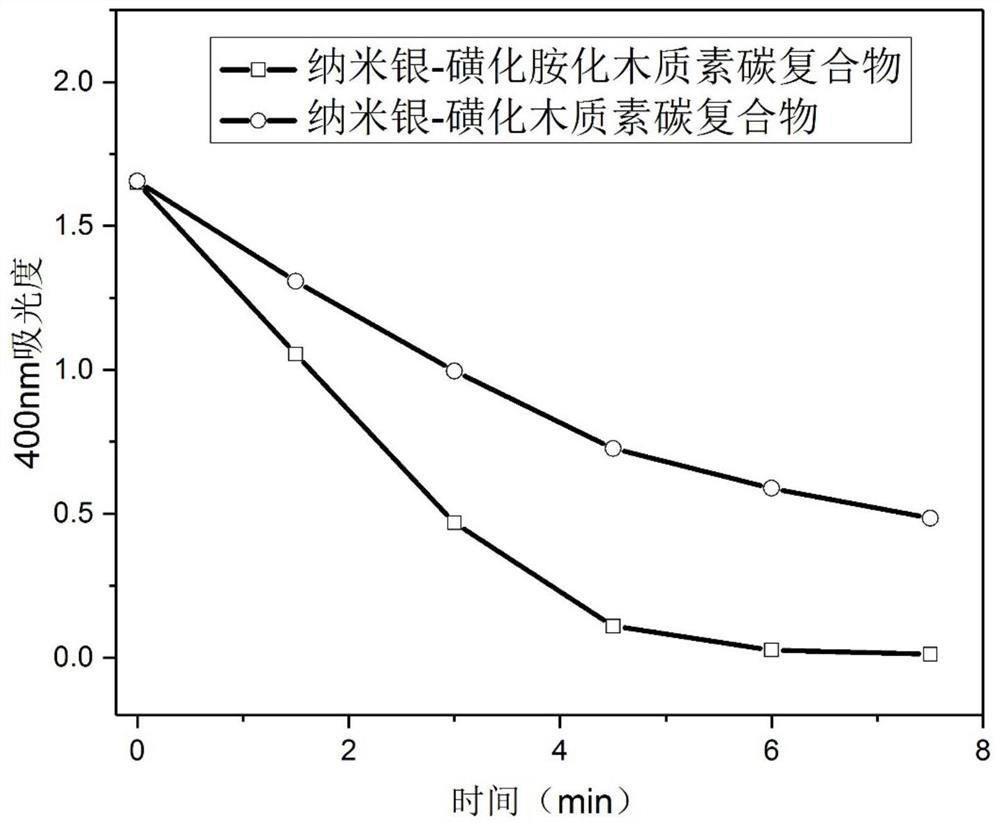

A kind of nano silver-lignin carbon composite material and its preparation method and application

ActiveCN110180536BImprove production efficiencyIncrease loadOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon compositesPtru catalyst

The invention belongs to the technical field of catalysts, and discloses a nano-silver-lignin-carbon composite material and a preparation method and application thereof. The method of the present invention comprises the following steps: (1) after the lignin is nanosized under the action of a nanometerizing agent, a sulfonating agent is added to carry out a sulfonation reaction to obtain a sulfonated lignin; (2) reacting with formaldehyde and an aminating agent to obtain a sulfonated lignin (3) react with silver salt to obtain nano-silver; (4) mix with carbonization activator and carbonize at high temperature to obtain nano-silver-lignin-carbon composite material; the mass ratio of each component is as follows: lignin 100 parts; 1-10 parts of nanometerization reagent; 5-20 parts of sulfonating reagent; 50-150 parts of formaldehyde; 50-150 parts of amination reagent; 10-40 parts of silver salt; The composite material of the invention has high nano-silver loading capacity and good recycling performance, and can be applied to the fields of catalytic materials, bactericidal materials, biological materials, optical materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

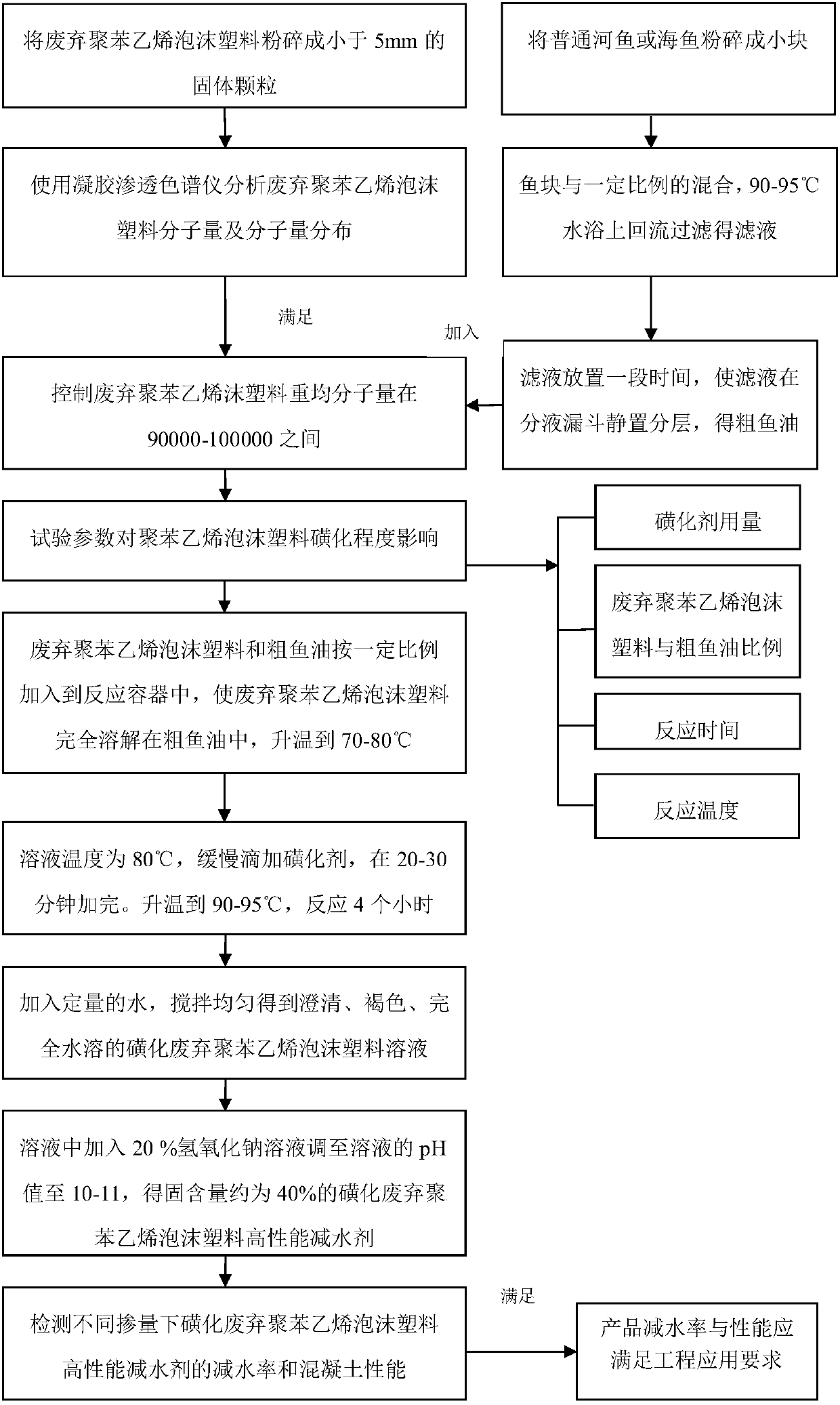

A preparation method of sulfonated waste polystyrene foam high-performance water reducer

The invention discloses a preparation method of a sulfonated waste expanded polystyrene high-performance water reducing agent. According to the preparation method, natural biological fish oil is used as a solvent, so that the problem of environmental pollution caused when a large amount of toxic organic solvents need to be used in the traditional production process of sulfonated waste EPS high-efficiency water reducing agents is avoided, the clean production of the whole production process of the sulfonated waste EPS high-efficiency water reducing agents is realized, the production process of the sulfonated waste EPS high-efficiency water reducing agents is simplified, and the production efficiency is improved; and meanwhile, the fish oil contains effective components such as unsaturated fatty acid, so that defects of poor fluidity retentivity and short coagulation time of traditional concrete doped with the sulfonated waste EPS high-efficiency water reducing agents are further overcome, and the novel sulfonated waste expanded polystyrene high-performance water reducing agent has relatively high water reducing effect and fluidity retentivity.

Owner:湖北凌安科技有限公司

Method for preparing micro-fibre corn stalks by 1-butyl-3-methimidazole chloride-LiBr-DMF (dimethylformamide) system

ActiveCN107501572AEffective swellingReduce cohesionOther chemical processesWater contaminantsFiberChloride

The invention discloses a method for preparing micro-fibre corn stalks by a 1-butyl-3-methimidazole chloride-LiBr-DMF (dimethylformamide) system. The method comprises the following steps: crushing and drying corn stalks; performing high-shear sulphonating treatment at a certain temperature by taking a 1-butyl-3-methimidazole chloride-LiBr-DMF compound system as a solvent and adding a pyridine sulphur trioxide compound; filtering, washing and performing vacuum drying on a material which is subjected to the sulphonating treatment, so as to obtain the micro-fibre corn stalks with high sulphonation degree. According to the method, the corn stalk fibres can be effectively swelled and free hydroxyls can be released by combining 1-butyl-3-methimidazole chloride with LiBr, so that the cohesive force of a raw material is weakened, and the sulphonating modifying efficiency of sulphur trioxide-pyridine complex is improved. According to the method, the degradation of hemicellulose and lignin components of the corn stalks can be reduced remarkably; a modifying process is simple and feasible; the modified products of micro-fibres are high in yield and sulphonation degree and large in specific surface area; value-added utilization of agricultural waste is realized; moreover, a modifying liquid is easy to recycle and utilize.

Owner:QILU UNIV OF TECH

A kind of 1-butyl-3-methylimidazolium chloride salt-libr-dmf system prepares the method for microfiber corn stalk

ActiveCN107501572BEffective swellingReduce cohesionOther chemical processesWater contaminantsSulfur trioxide pyridine complexChloride

The invention discloses a method for preparing micro-fibre corn stalks by a 1-butyl-3-methimidazole chloride-LiBr-DMF (dimethylformamide) system. The method comprises the following steps: crushing and drying corn stalks; performing high-shear sulphonating treatment at a certain temperature by taking a 1-butyl-3-methimidazole chloride-LiBr-DMF compound system as a solvent and adding a pyridine sulphur trioxide compound; filtering, washing and performing vacuum drying on a material which is subjected to the sulphonating treatment, so as to obtain the micro-fibre corn stalks with high sulphonation degree. According to the method, the corn stalk fibres can be effectively swelled and free hydroxyls can be released by combining 1-butyl-3-methimidazole chloride with LiBr, so that the cohesive force of a raw material is weakened, and the sulphonating modifying efficiency of sulphur trioxide-pyridine complex is improved. According to the method, the degradation of hemicellulose and lignin components of the corn stalks can be reduced remarkably; a modifying process is simple and feasible; the modified products of micro-fibres are high in yield and sulphonation degree and large in specific surface area; value-added utilization of agricultural waste is realized; moreover, a modifying liquid is easy to recycle and utilize.

Owner:QILU UNIV OF TECH

Sulfonated vinegar grains, its preparation method and application

ActiveCN105562082BSimple technical processHigh sulfonation efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryGram

The invention discloses sulfonated vinegar residue, its preparation method and application, and belongs to the fields of chemical industry and pharmaceutical production. A kind of sulfonated vinegar residue is made by mixing vinegar residue and sulfonating agent and baking it by wet method. The particle size is about 170-190 mesh. The amount of sulfonic acid group in every gram of vinegar residue is 41.382-53.298 mg. The specific surface area It is 2.3864-2.5417 m2 / g, and the pore diameter is 0.3±0.04μm. The invention adopts wet baking technology to achieve efficient sulfonation of vinegar residue, with less pollutant discharge, low cost, high sulfonation efficiency, high activity of the sulfonated vinegar residue catalyst and long service life.

Owner:LULIANG UNIV

Preparation method and application of a straw-based ester ether sulfonated composite water reducer

ActiveCN109678382BImprove hydrolysis efficiencyGood modification effectCelluloseAgricultural science

The invention discloses a preparation method and application of a straw-modified ester ether sulfonated composite water-reducer. The water-reducer is made from crop straw hydrolyzed powder through primary oxidation-sulfonated esterification of straw lignocellulose Modification, secondary oxidation-sulfonated esterification modification and primary methylolation-etherification modification. The straw hydrolyzed powder is obtained by hydrolyzing the straw powder after primary crushing, washing, drying, finely crushing and finely crushing pretreatment of crop straw. In the present invention, the raw materials of crop straws are pulverized and hydrolyzed for pretreatment, and straw lignin and cellulose are subjected to step-by-step sulfonation modification to form sulfonate esters, and then lignocellulose etherification modification is carried out to obtain straw-based ester ethers. The sulfonated composite water reducer has improved the low water reducing rate of 10-15% of the straw-based water reducer, and the obtained water reducer can be directly used in the situation where the water reducing rate is about 25% and the retarding time is moderate , the process is continuous and compact, easy to operate, low in cost, anti-sedimentation and easy to industrialize.

Owner:TIANSHUI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com