Direct sulfonation method preparation of sulfonated silk fibroin

A technology of silk fibroin and sulfonated silk fibroin, applied in the field of direct sulfonation method to prepare sulfonated silk fibroin, can solve the problem of low sulfonation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

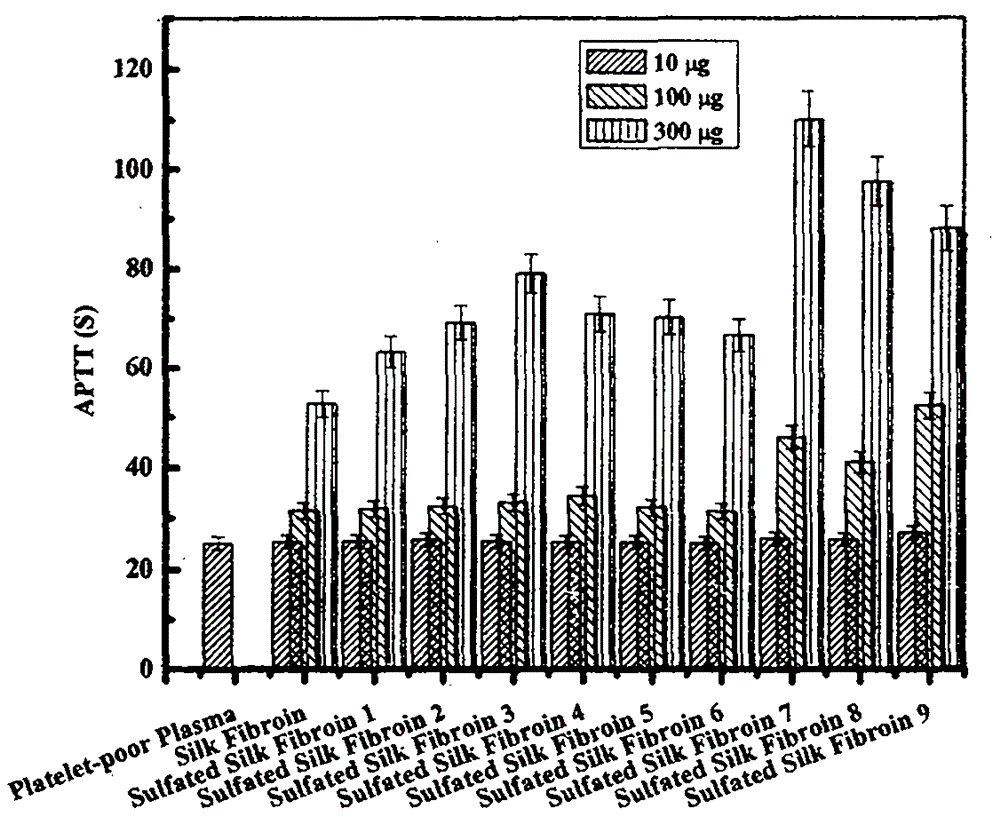

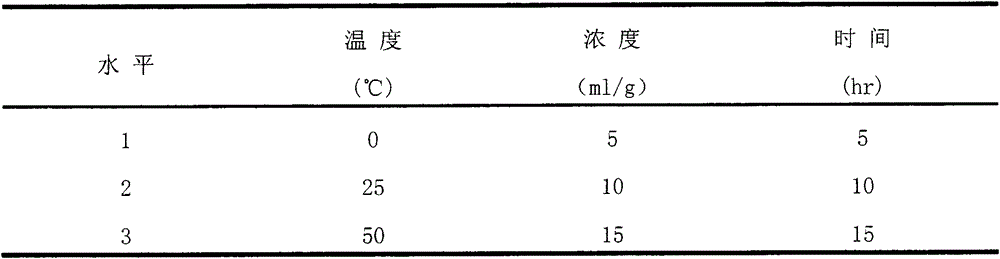

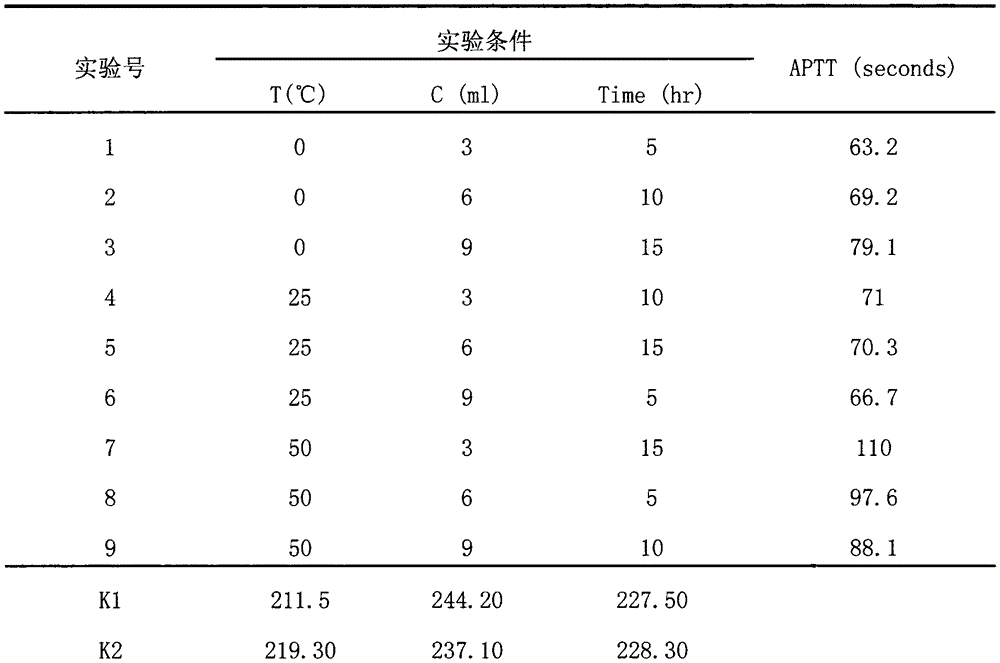

[0004] Process parameters such as temperature, concentration and reaction time of sulfonation reaction are as follows:

[0005]

[0006] Note on concentration ratio: 1g of silk fibroin corresponds to the dosage of 5, 10, and 15ml of chlorosulfonic acid;

[0007] Temperature conditions: 0, 25, 50°C;

[0008] Time conditions: 5, 10, 15hr;

[0009] Weigh 1.20g of degummed and dried silk fibroin fiber with a balance, put it into a 100ml round single-necked flask, press the silk fibroin to the bottom of the bottle with a glass rod, and then add 6ml of chlorosulfur (see orthogonal table) dropwise acid solution, rotate the flask to make the silk fibroin fully infiltrated by chlorosulfonic acid, and then use a vacuum cock to connect the flask to a container containing CaCl 2 The desiccant drying tower is used to remove the water generated by the reaction between serine and tyrosine hydroxyl (-OH) on silk fibroin and chlorosulfonic acid, and placed in an oil bath at 50°C (see orth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com