A kind of magnetic phenolic humic acid resin and preparation method thereof

A technology of phenolic humic acid and water-soluble phenolic resin, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of negative application and sustainable development, high energy consumption, high processing cost, and achieve increased repetition The effect of regeneration and utilization times, high separation efficiency and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

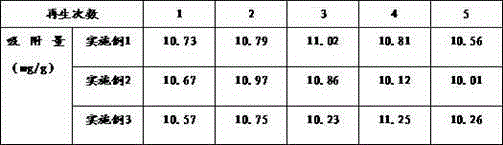

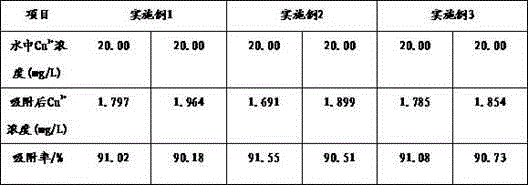

Examples

Embodiment 1

[0026] Embodiment 1 A kind of magnetic phenolic humic acid resin, preparation method is:

[0027] (1) Preparation of ferrofluid: 10 grams of Fe 2 (SO 4 ) 3 , 5.2 g FeSO 4 ·7H 2 O was dissolved in 100ml of water three times, after the dissolution was complete, 1.8g of oleic acid was added, and then 100ml of water was added, and the prepared NaOH solution was added dropwise to the solution until the pH value of the solution was 13. The above solution was put into a microwave synthesizer for reaction, and the reaction temperature of the microwave synthesizer was controlled at 65° C., the power was 600 W, and the reaction time was 30 minutes. Finally the reaction product was dialyzed for 4 days.

[0028] (2) Preparation of water-soluble phenolic resin: add 45 grams of phenol and 45 grams of formaldehyde to the reaction bottle, start stirring, and heat up to dissolve; adjust the pH to 9-10 with 20% NaOH solution, and raise the reaction temperature to 85°C for reaction After 4...

Embodiment 2

[0031] A kind of magnetic phenolic humic acid resin of embodiment 2, preparation method is:

[0032] (1) Preparation of magnetic fluid: 12 grams of Fe 2 (SO 4 ) 3 , 5.4 g FeSO 4 ·7H 2 O was dissolved in 100ml of water three times, after the dissolution was complete, 2.0g of oleic acid was added, and then 100ml of water was added, and the prepared NaOH solution was added dropwise to the solution until the pH value of the solution was 13. The above solution was put into a microwave synthesizer for reaction, and the reaction temperature of the microwave synthesizer was controlled at 65° C., the power was 600 W, and the reaction time was 30 minutes. Finally the reaction product was dialyzed for 4 days.

[0033] Preparation of water-soluble phenolic resin: Add 50 grams of phenol and 50 grams of formaldehyde to the reaction bottle, start stirring, raise the temperature to 60°C until dissolved; adjust the pH to 9-10 with 20% NaOH solution, raise the reaction temperature to 85°C ...

Embodiment 3

[0036] Embodiment 3 A kind of magnetic phenolic humic acid resin, the preparation method is:

[0037] (1) Preparation of magnetic fluid: 14 grams of Fe2(SO4)3, 5.8 grams of FeSO4 7H2O were dissolved in 100ml of water three times, after the dissolution was complete, 2.3 grams of oleic acid was added, then 100ml of water was added, and the solution was added dropwise to configure NaOH solution to pH 13. The above solution was put into a microwave synthesizer for reaction, and the reaction temperature of the microwave synthesizer was controlled at 65° C., the power was 600 W, and the reaction time was 30 minutes. Finally the reaction product was dialyzed for 4 days.

[0038] (2) Preparation of water-soluble phenolic resin: Add 60 grams of phenol and 60 grams of formaldehyde to the reaction bottle, start stirring, and heat up to dissolve; use 20% NaOH solution to adjust the pH to 9-10, and raise the reaction temperature to 85°C for reaction After 30-60 minutes, add formaldehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com