Patents

Literature

31results about How to "Increase the solid-to-liquid ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

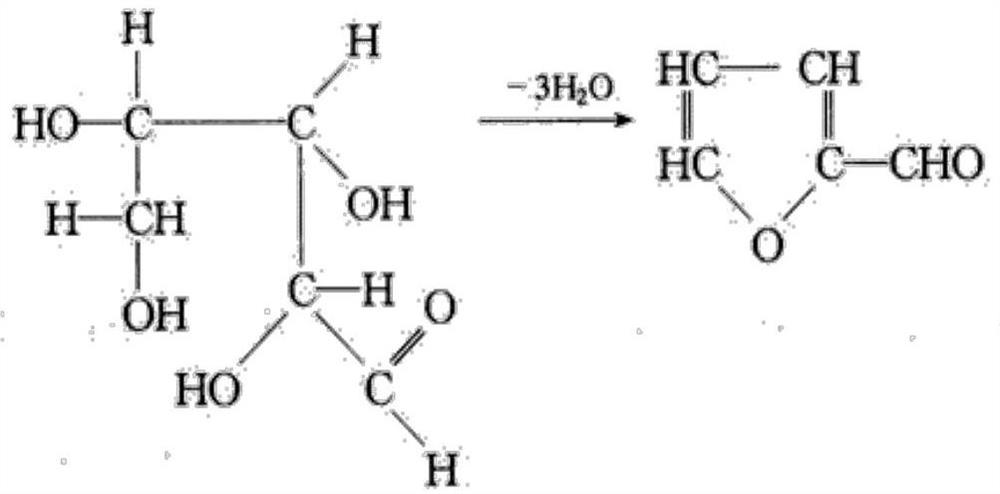

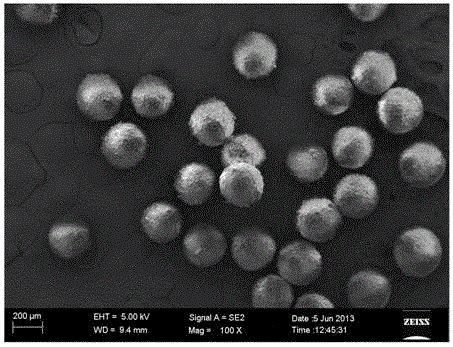

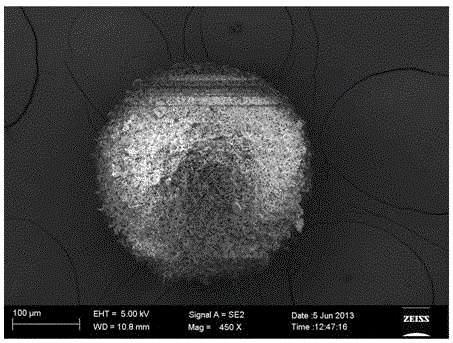

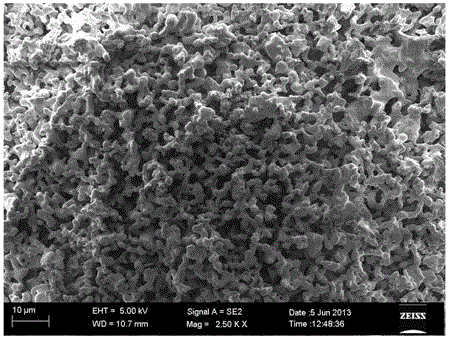

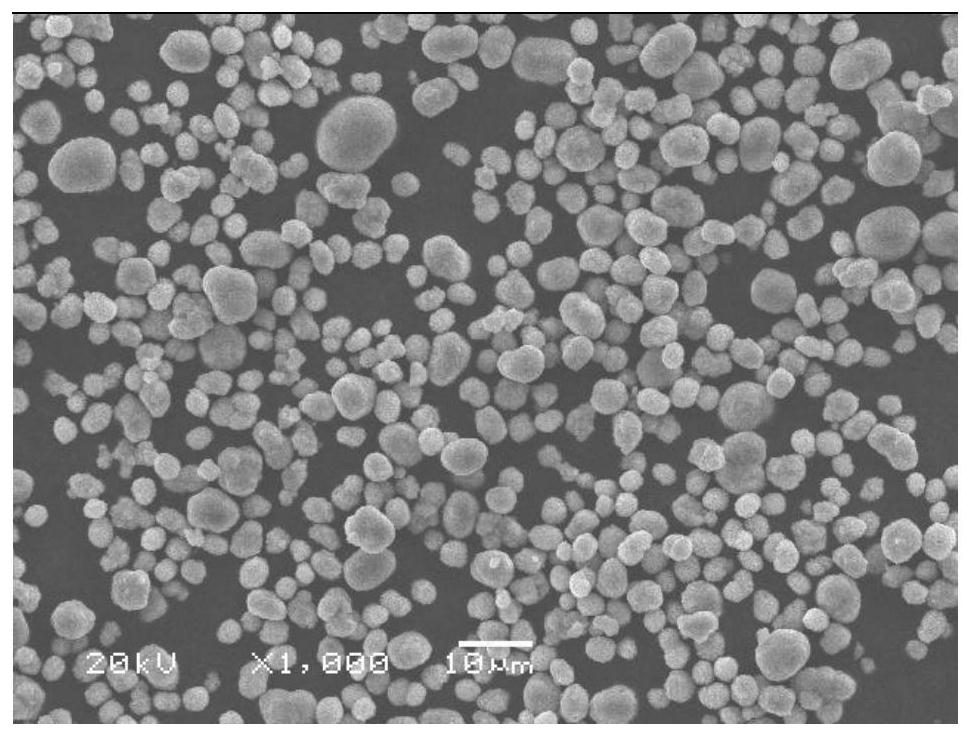

High-density and small-particle size nickel-cobalt-manganese hydroxide and preparation method thereof

InactiveCN107640792AHigh density and small tap densityLow tap densityCell electrodesSecondary cellsHigh densityManganese

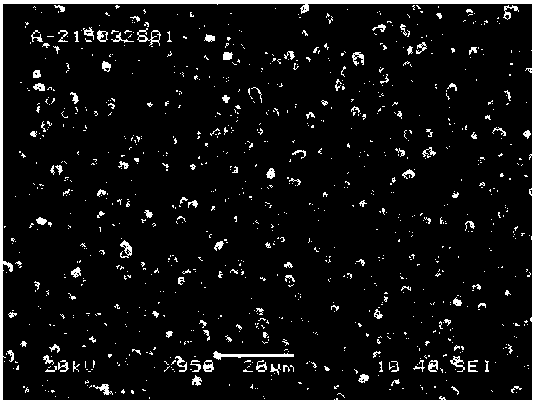

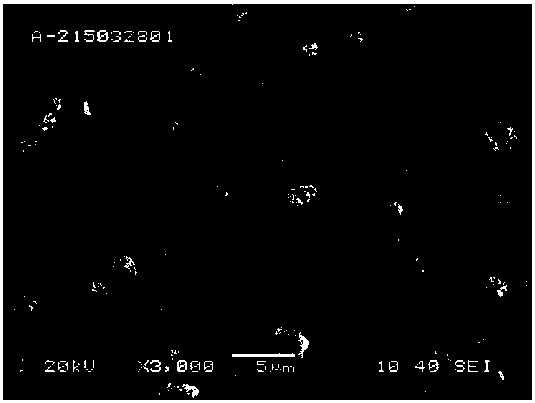

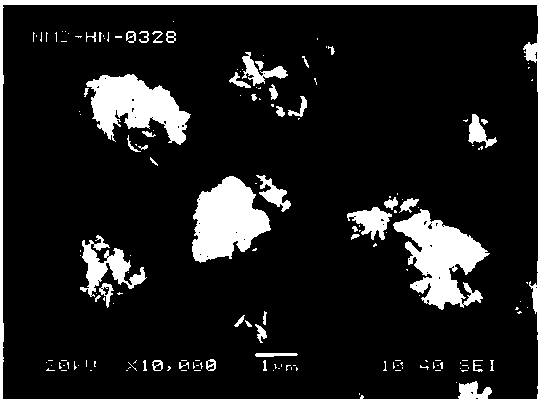

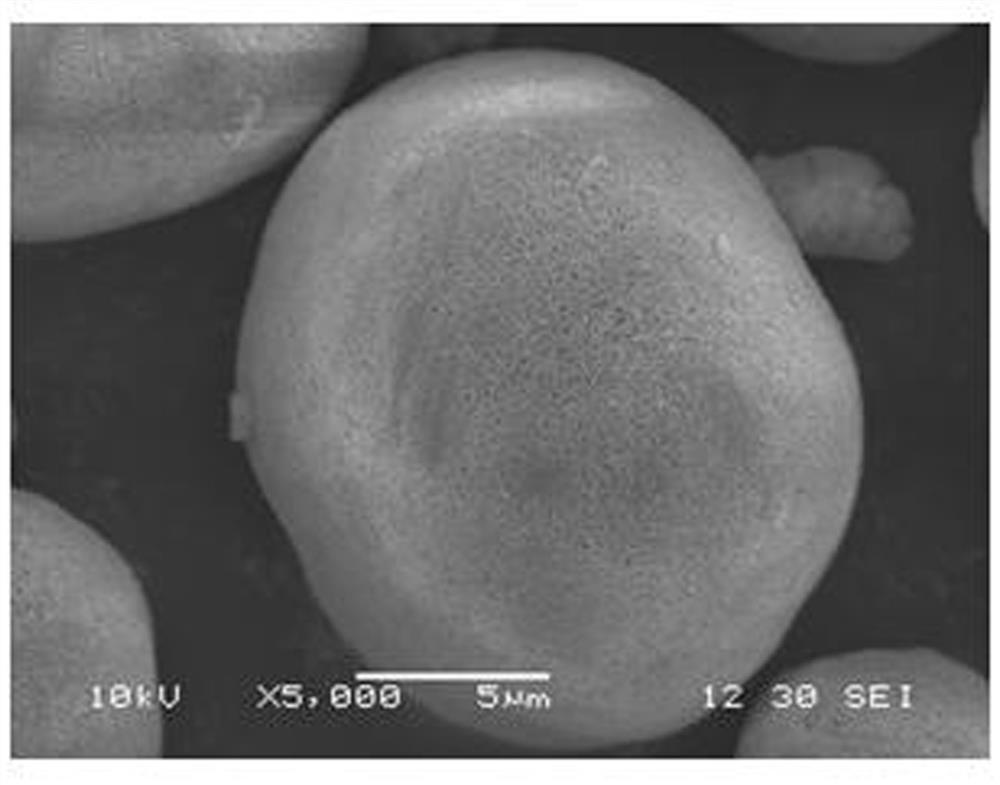

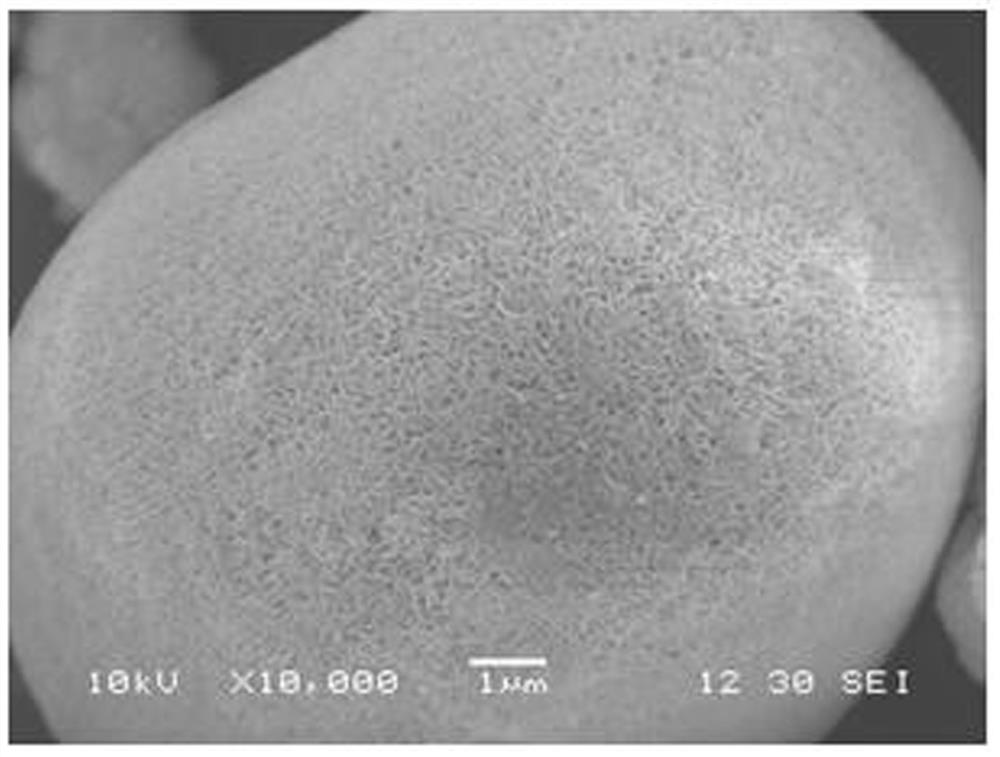

The invention discloses a high-density and small-particle size nickel-cobalt-manganese hydroxide and a preparation method thereof. For the high-density and small-particle size nickel-cobalt-manganesehydroxide provided by the invention, a general chemical formula is NixCoyMnz(OH)2, wherein x+y+z=1, x is larger than or equal to 0.3 and smaller than or equal to 0.8, y is larger than or equal to 0.1and smaller than or equal to 0.4, and z is larger than or equal to 0.1 and smaller than or equal to 0.4; the particle sizes are d10 larger than or equal to 2 microns, d50 equal to 2.5-4 microns and d90 smaller than or equal to 6 microns, the tap density is larger than or equal to 1.4g / cm<3>, the specific surface area is 5-20m<2> / g, and the shape is spherical or spheroidal. The invention also discloses the preparation method of the high-density and small-particle size nickel-cobalt-manganese hydroxide. The preparation method is strong in controllability, can stably control the particle sizes ineach production batch without using a surfactant and is low in production cost, high in efficiency and good in physicochemical index of a final product.

Owner:ZHUJI PAWA NEW ENERGY

Method for oxidizing CaSO3 in desulfurized fly ash in alkaline condition

The invention discloses a method for oxidizing CaSO3 in desulfurized fly ash in an alkaline condition. The method comprises the following steps of: (1) adding 2 to 10 times water by weight to the desulfurized fly ash, and uniformly stirring to obtain desulfurized fly ash slurry; (2) slowly adding H2O2 and / or persulfate solution with weight concentration being 10 to 30% of to the desulfurized fly ash slurry, wherein the molar mass ratio of H2O2 and / or persulfate to CaSO3 is 1- 2: 1; and (3) stirring and reacting mixtures of the desulfurized fly ash slurry, H2O2 and / or persulfate solution for 0.5 to 4 hours. According to the oxidization method, the pH of the solution does not need to be adjusted and metallic ions do not need to add, so that the reaction conditions are mild, and as a result, the oxidization cost is reduced, and the corrosion to the equipment is reduced; and the method has the characteristics of short reaction time, high efficiency, etc.

Owner:武汉钢铁有限公司 +1

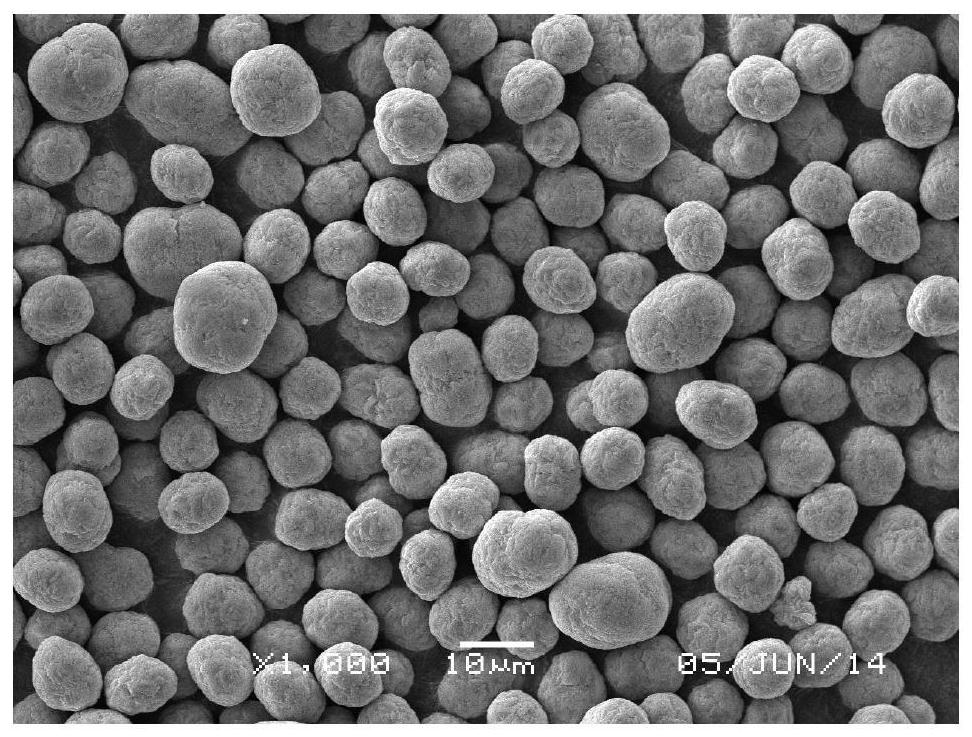

Wet-method zirconium-doped concentration-gradient nickel-cobalt-aluminum ternary precursor and preparation method thereof

ActiveCN110127777AIncrease capacityImprove cycle stabilityNickel compoundsConcentration gradientCobalt

The invention discloses a wet-method zirconium-doped concentration-gradient nickel-cobalt-aluminum ternary precursor and a preparation method thereof. The nickel-cobalt-aluminum ternary precursor hasa chemical general formula of NixCoyAlz(OH)2, wherein x+y+z=1, 0.3<=x<=0.9, 0.01<=y<=0.4, and 0.01<=z<=0.4; the Zr element accounts for 0.001%-3% of the total mass of the nickel-cobalt hydroxide precursor, the ternary precursor consists of three layers, and the inner layer is a zirconium-doped nickel-cobalt binary precursor with a molecular formula of NixCoy(OH)2; and the outer layer is a zirconium-doped nickel-cobalt-aluminum ternary precursor with a molecular formula of NixCoyAlz(OH)2, and the intermediate layer is a concentration-gradient precursor between the zirconium-doped nickel-cobaltbinary precursor and the zirconium-doped nickel-cobalt-aluminum ternary precursor. The invention also includes the method for preparing the nickel-cobalt-aluminum ternary precursor. The zirconium-doped nickel-cobalt-aluminum ternary precursor has a narrow particle size distribution and good particle morphology, the doped element is distributed uniformly through complex controlled crystallizing co-precipitation, and a positive-electrode precursor prepared from the zirconium-doped nickel-cobalt-aluminum ternary precursor has high specific capacity, good cycling stability, good processability andstable performance.

Owner:ZHUJI PAWA NEW ENERGY

Method for separating magma in producing soda process

InactiveCN1472139AIncrease production capacityReduce production loadCarbonate preparationSodium bicarbonateSlurry

A process for separating crystal slurry in the production of sodium carbonate includes such steps as synthesizing sodium bicarbonate crystal in carbonizing tower, discharging the crystal slurry, hydraulic cyclone separating, alkali filtering to obtain solid and calcining. Its advantage is low load of alkali filter to increase its productivity by 20%.

Owner:JIANGSU DEBANG CHEMICAL INDUSTRY GROUP CO LTD

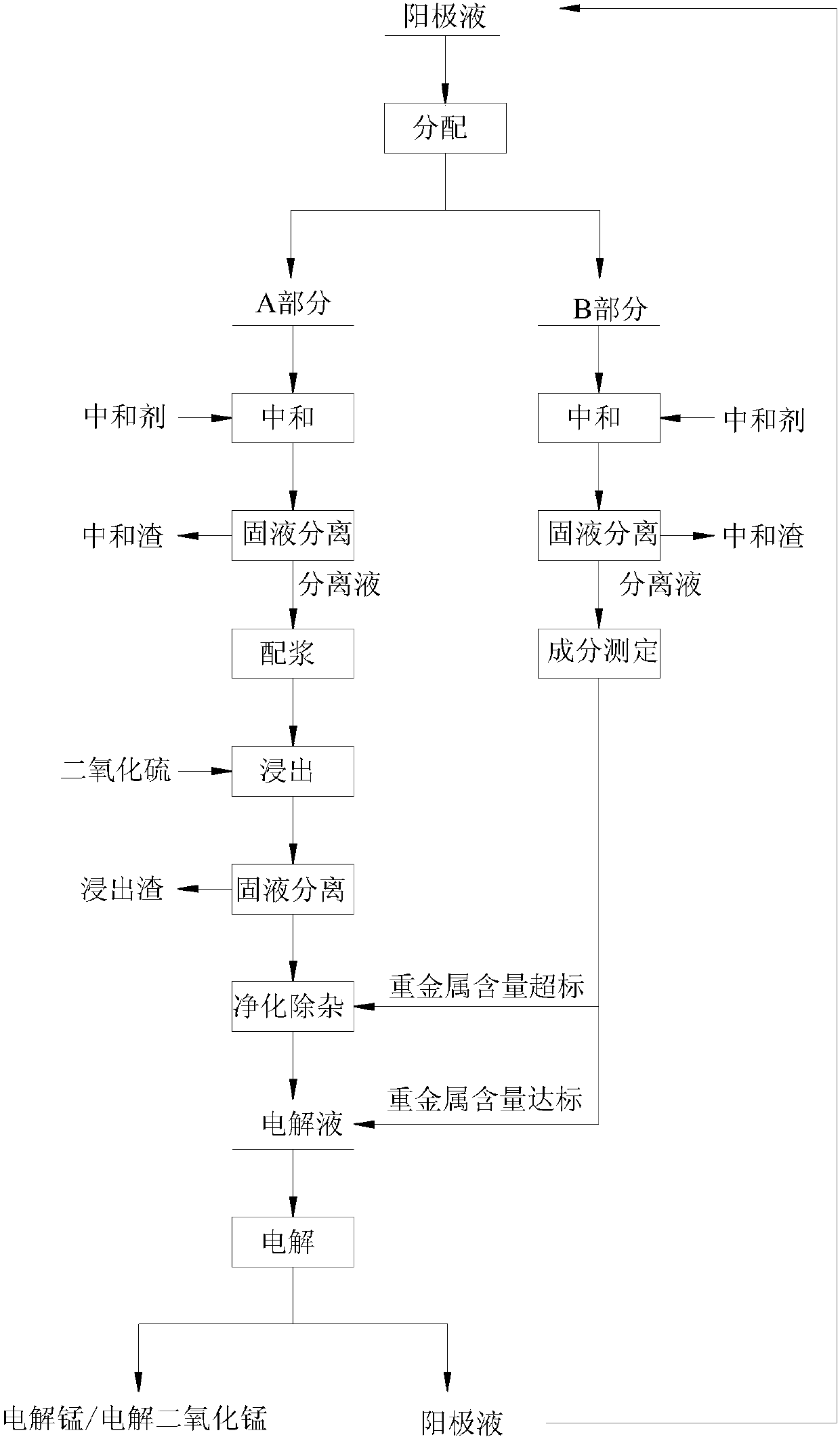

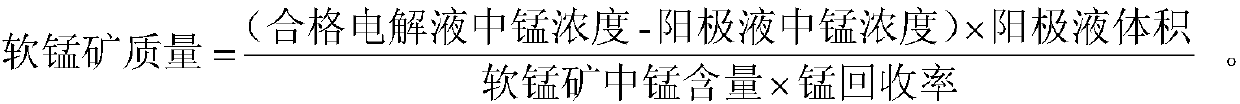

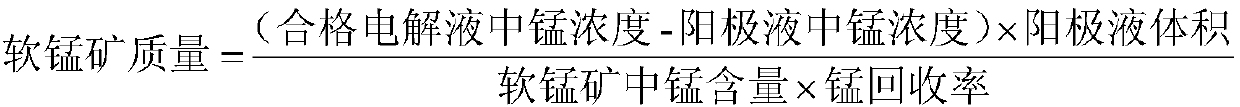

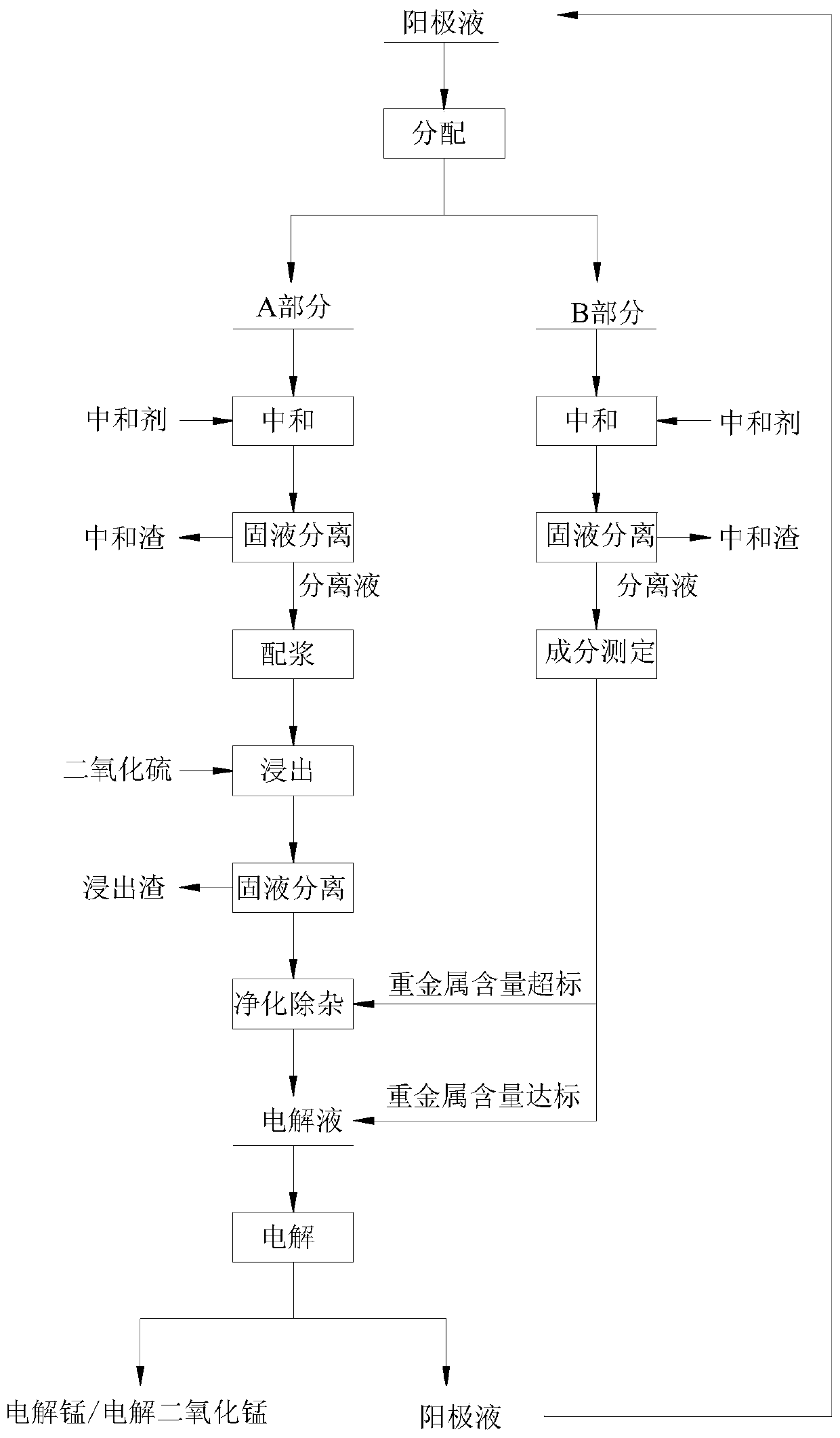

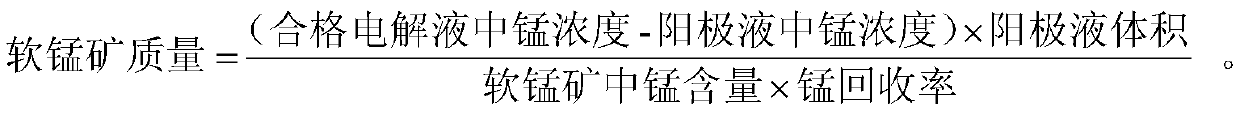

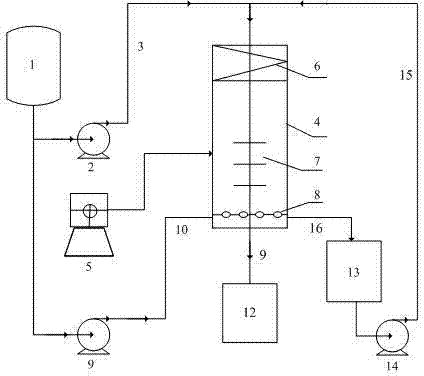

Method for preparing manganese sulfate electrolyte by leaching pyrolusite through sulfur dioxide

ActiveCN107699714AIncrease the solid-to-liquid ratioIncrease profitHigh concentrationPregnant leach solution

The invention provides a method for preparing a manganese sulfate electrolyte by leaching pyrolusite through sulfur dioxide. According to the main concept, the method comprises the steps that only a part of an anolyte and whole-process pyrolusite are used for preparing a fluid, and after the fluid reacts with the sulfur dioxide, a high-concentration manganese sulfate solution is obtained; after the other part of the anolyte is neutralized and subjected to liquid-solid separation, a low-concentration manganese sulfate solution with the manganese sulfate concentration being identical to that ofthe prior anolyte is obtained; and the two manganese sulfate solutions are blended to obtain the qualified electrolyte with the manganese sulfate concentration meeting electrolysis requirements. By adopting the method, the utilization efficiency of the sulfur dioxide and the pyrolusite in the leaching process can be improved, and the capital construction cost and operation cost of a leaching technology and a leachate impurity removing technology are lowered.

Owner:SICHUAN UNIV

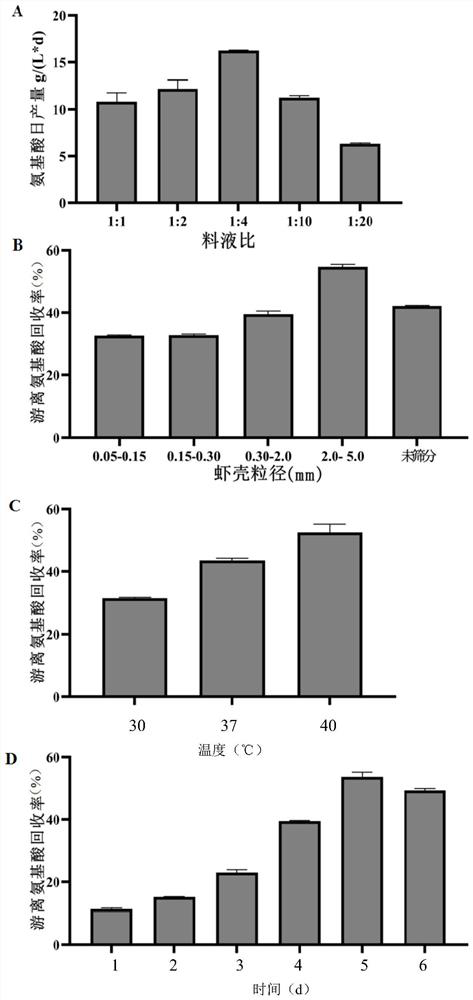

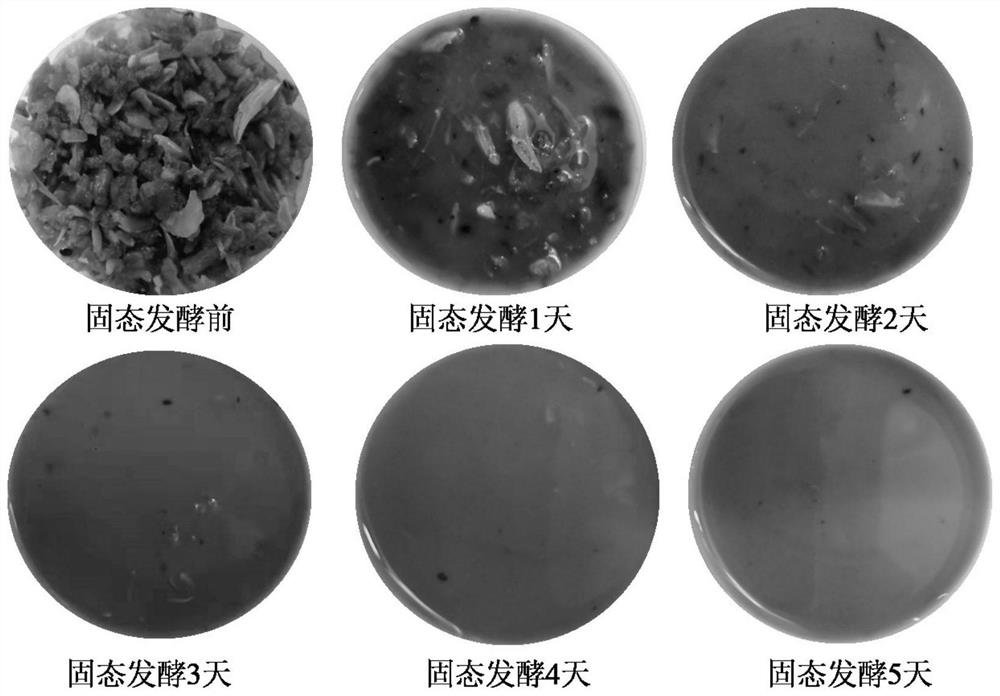

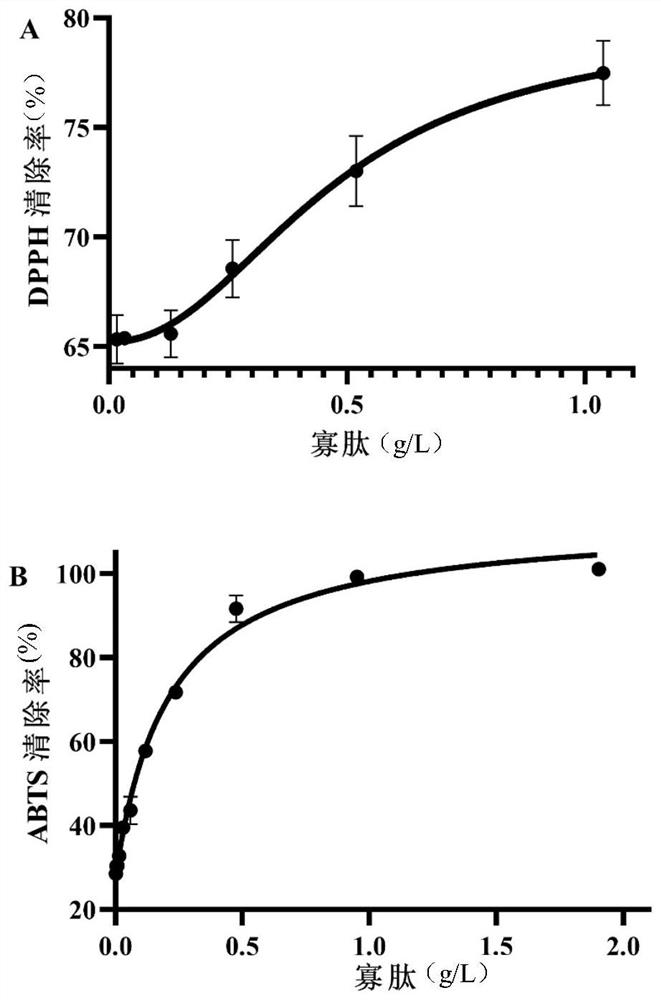

Method for producing amino acid, oligopeptide, calcium lactate and chitin by treating shrimp shell waste through solid-state fermentation of streptomyces and application of amino acid, oligopeptide, calcium lactate and chitin

ActiveCN114438144ARealize direct productionImprove cleanlinessOrganic active ingredientsPeptide/protein ingredientsNutritionCALCIUM LACTOBIONATE

The invention discloses a method for producing amino acid, oligopeptide, calcium lactate and chitin by treating shrimp shell waste through streptomyces solid state fermentation and application of the method, and belongs to the technical field of biological engineering. The invention relates to a method for producing amino acid, oligopeptide, calcium lactate and chitin by treating shrimp shell waste through streptomycete solid state fermentation, which comprises the following steps: inoculating streptomycete seed fermentation liquor into a fermentation culture medium containing the shrimp shell waste to obtain fermentation liquor, and separating to obtain first supernate and first precipitate; and preparing an amino acid product, membrane separation raffinate, an oligopeptide product, chitin and calcium lactate. According to the method, a large amount of amino acid is produced from shrimp shell waste for the first time, the recovery rate reaches 61.55%, the free amino acid concentration reaches 82.5 g / L, the amino acid productivity reaches 16.5 g / (L * d), the content of essential amino acid reaches 58.52%, and the shrimp shell waste is an excellent medicine and health care product raw material, a food nutrition additive and a feed additive.

Owner:SOUTH CHINA UNIV OF TECH

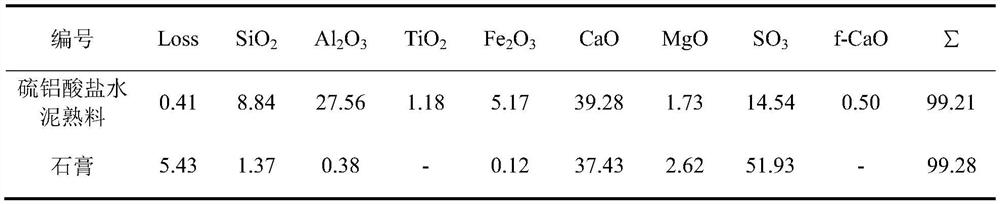

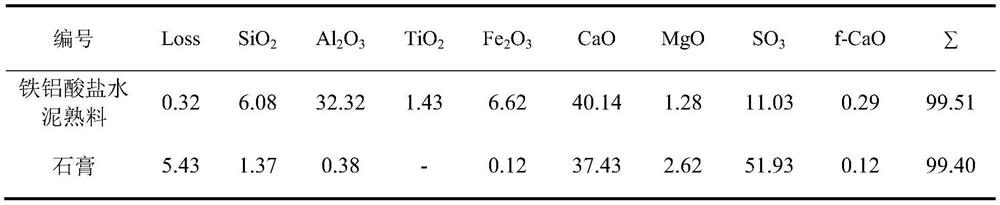

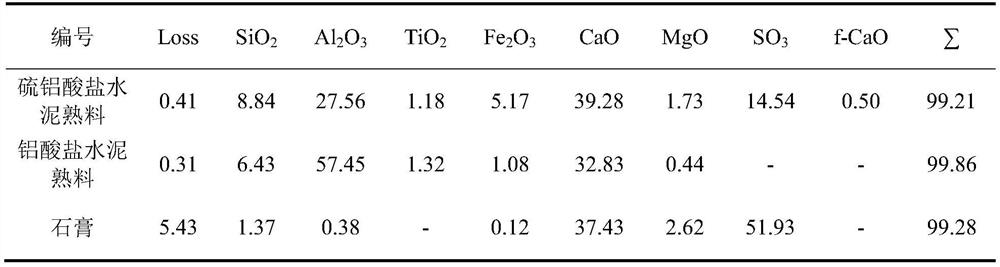

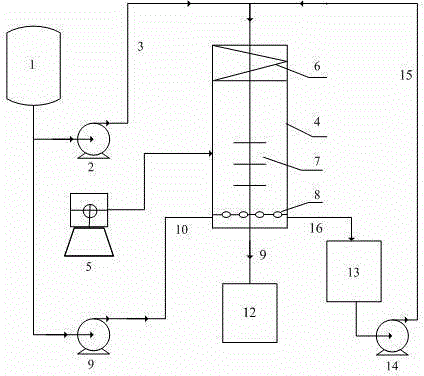

Mineral additive for shotcrete as well as preparation method and application of mineral additive

PendingCN112321187AIncrease the solid-to-liquid ratioIntensity lastsFoundation engineeringBuilding material handlingMineralogyCorrosion

The invention relates to a mineral additive for shotcrete as well as a preparation method and application of the shotcrete. The mineral additive comprises the following components in percentage by weight: 60%-90% of clinker containing aluminum active minerals, 10%-35% of gypsum and 0-5% of chemical additive. A concrete accelerator comprises a liquid accelerator and the shotcrete mineral additive which are respectively added into concrete at different moments. According to the invention, when the wet-spraying concrete is sprayed out, the reaction can be quickly generated, the solid-to-liquid ratio is quickly increased, the concrete is quickly tackified and quickly coagulated and hardened, hydrated minerals generating strength are continuously increased, the strength is continuously improved, hydrated slurry is more compact, the durability such as later strength, sulfuric acid corrosion resistance and the like is greatly improved, and therefore, the common problem of wet shotcrete is fundamentally solved.

Owner:北京中研国信检测技术服务有限公司 +1

Method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation

ActiveCN103060481AImprove reaction efficiencyReduce concentrationBiofuelsGlucose productionPhysical chemistryEngineering

The invention discloses a method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation. The method comprises: first conducting standing infiltration on straw particles with a dilute acid solution, then loading the straw particles into a cylindrical reactor, performing fed-batch of the dilute acid solution to the reactor, and at the same time, applying the action of microwave and compressing the straw particles, and discharging the liquid in the reactor; after solid-liquid separation, re-injecting the acid solution and dispersing the straw particles uniformly; carrying out fed-batch of the filtrate obtained from the separation to the reactor, and at the same time, applying the action of microwave and compressing the straw particles, and discharging the liquid in the reactor; and repeating the operations till the end of the reaction. By infiltrating the straw particles in the acid solution in advance and adopting a filtrate cyclic compression mode, the method provided in the invention reduces the concentration and dosage of the acid solution, increases the reaction product concentration, and enhances the reaction speed simultaneously.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing light calcium carbonate and magnesium sulfate heptahydrate from salt mud

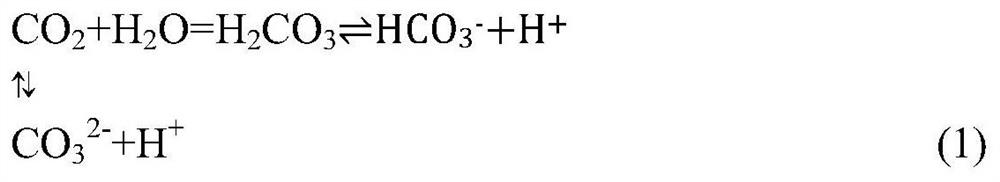

ActiveCN109574055BIncrease the solid-to-liquid ratioIncrease the carbonization reaction rateCalcium/strontium/barium carbonatesMagnesium sulfatesSaline waterMagnesium salt

The invention provides a method for producing light calcium carbonate and magnesium sulfate heptahydrate from salty mud. The method includes mixing the salt mud (mainly comprising magnesium hydroxideand calcium carbonate) produced by a brine refining process with calcium sulfate, adding a certain amount of water for pulping, injecting carbon dioxide for a carbonization reaction to convert the calcium sulfate and the magnesium hydroxide into calcium carbonate sediments and soluble magnesium sulfate, and performing filtration to separate calcium and magnesium salt; drying a filter cake to obtain a light calcium carbonate product, and concentrating, crystalizing and drying filtrate to obtain a magnesium sulfate heptahydrate product. The method has the advantages that the greenhouse gas carbon dioxide is fastened while the light calcium carbonate and magnesium sulfate heptahydrate products are obtained through compressive utilization of the calcium and magnesium salt in the salty mud, harmless comprehensive utilization of the salty mud is realized, and certain economic benefits can be acquired.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for producing high-purity ferrous sulfate water and ferrous sulfate heptahydrate by using waste acid

PendingCN113149082AReduce the risk of contaminationIncrease productionIron sulfatesNitric acidHazardous waste treatmentFerrous sulfate heptahydrate

The invention belongs to the technical field of environment-friendly wastewater and hazardous waste treatment, and provides a method for producing high-purity ferrous sulfate water and ferrous sulfate heptahydrate by using waste acid. The method comprises the following steps: mixing waste nitric acid or waste acid mixed liquor with a sulfuric acid reagent in proportion; adding iron powder, and performing stirring for 0.5-2 hours; adding a precipitator, then adding liquid caustic soda to adjust the pH value to 4.5-4.8, and adding sodium sulfide; carrying out filter pressing on the mixed solution to obtain high-purity ferrous sulfate water; adding a small amount of concentrated sulfuric acid into the high-purity ferrous sulfate water, pumping the mixture into a negative pressure evaporator for evaporation, discharging the mixture into a crystallization kettle for cooling crystallization, and discharging the mixture into a centrifugal machine for centrifugation to obtain the high-purity ferrous sulfate solid. According to the invention, through reasonable design of process steps and actual reaction, recycling of the waste nitric acid and the mixed acid is realized, waste of ferric salt resources is avoided, the problems of difficult treatment and high-cost emission of the waste nitric acid and the mixed acid are solved, resource comprehensive treatment and utilization of the waste nitric acid and the mixed acid are realized, and the method is simple in process, lower in cost and green and environment-friendly.

Owner:3R ENVIRONMENTAL TECH CO LTD

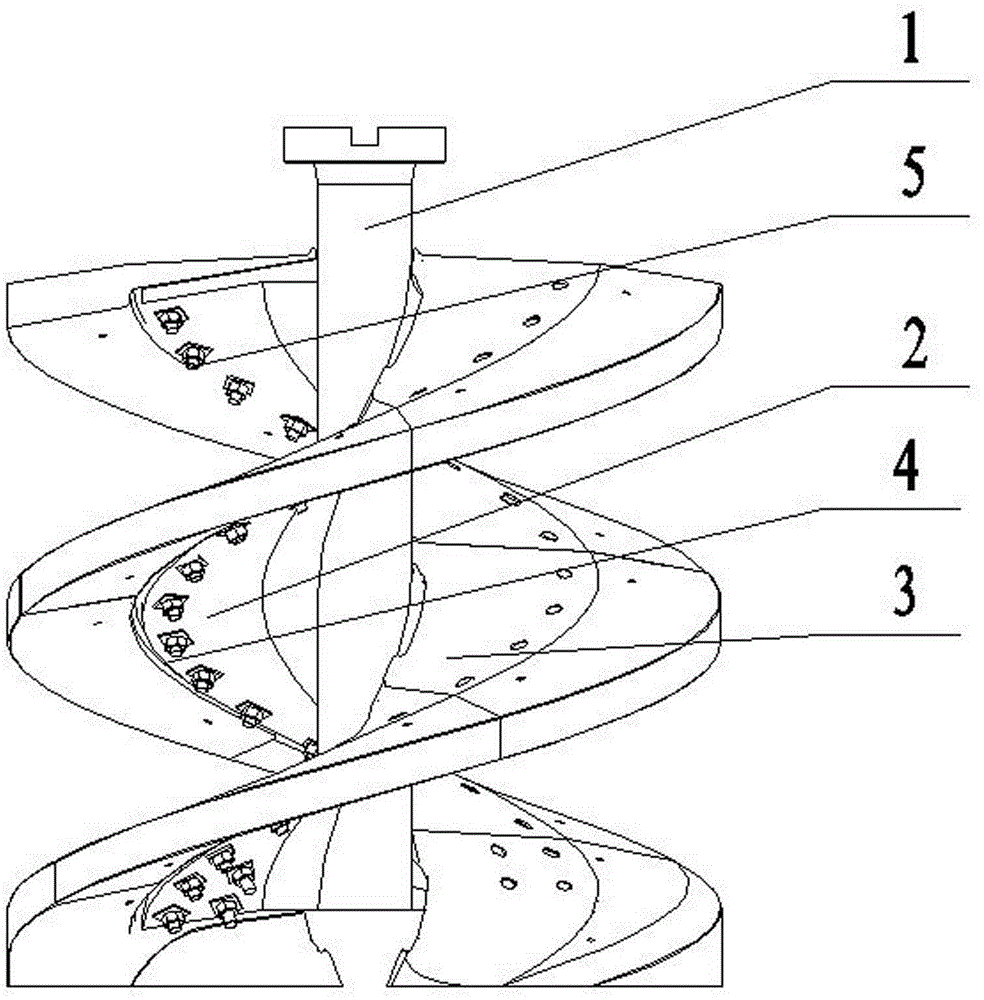

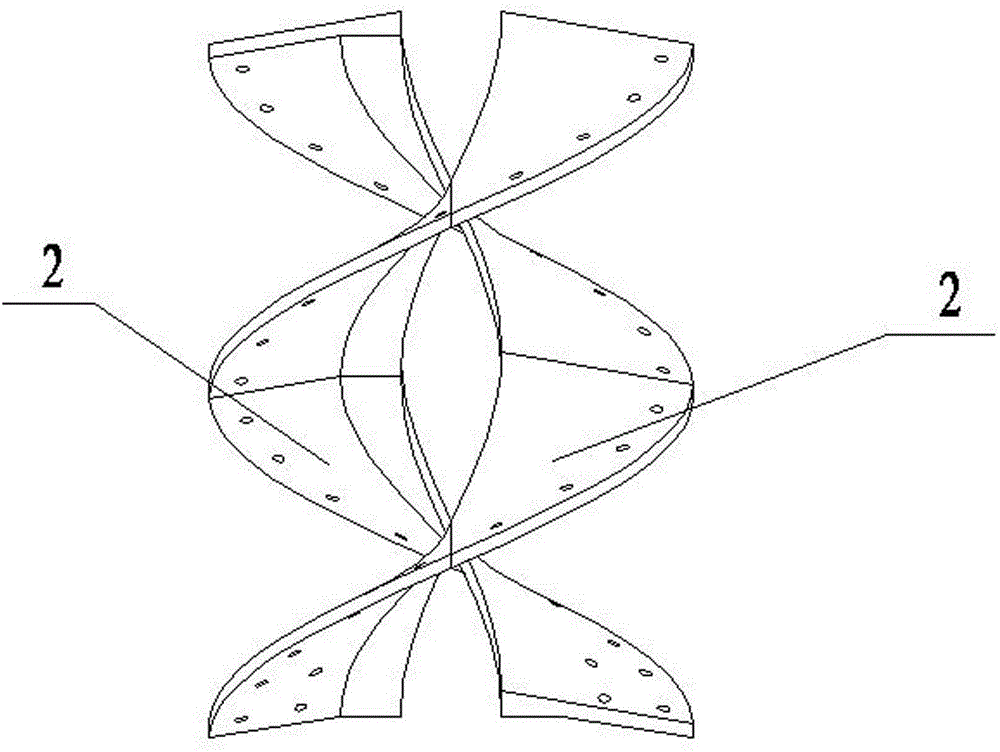

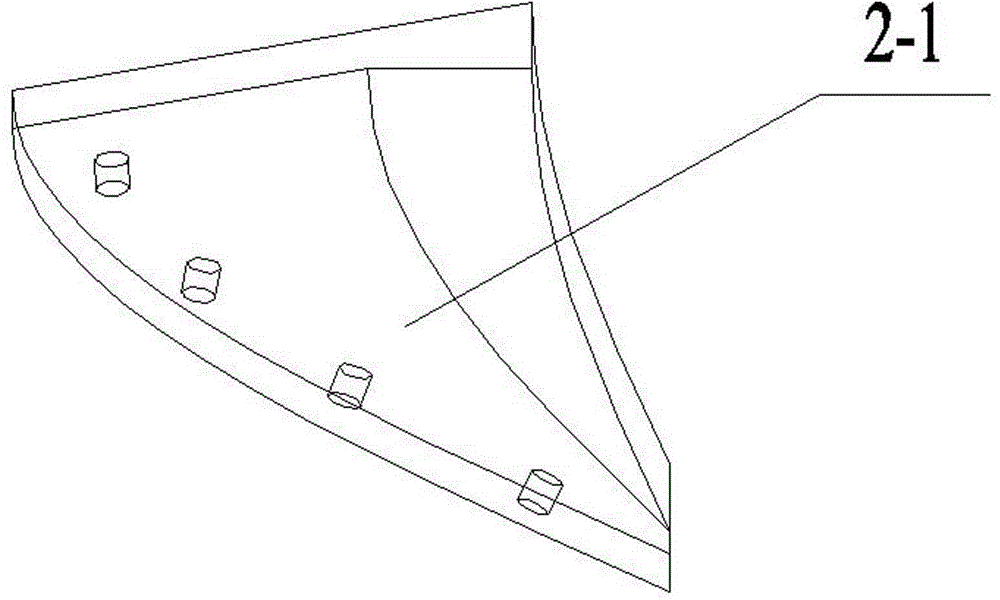

Spiral stirrer of vertical type spiral stirring grind

ActiveCN103721800BStable Lagrangian streamlined trajectoryImprove grinding efficiencyRotary stirring mixersGrain treatmentsDrive shaftDiameter ratio

The invention relates to a spiral stirrer of a vertical type spiral stirring grind. The spiral stirrer is characterized by being provided with a transmission shaft, and the circumference surface of the transmission shaft is provided with a spiral twined spiral supporting plate; the spiral supporting plate is provided with a spiral lining plate the shape of which is same with the twined shape, the width of the spiral lining plate is greater than the spiral supporting plate, and a half of the spiral supporting plate is packaged in the spiral lining plate; the spiral lining plate takes the spiral middle diameter as a boundary, the included angle of the normal fracture surface upper boundary and the horizontal surface is 2-3 degrees in the inner side of the spiral middle diameter, the included angle of the normal fracture surface upper boundary and a horizontal surface is 8-12 degrees in the outer side of the spiral middle diameter, the spiral lifting angle at a middle diameter position is 25-35 degrees, and the spiral height-diameter ratio is 1.0-1.1. The spiral stirrer provided by the invention has the advantages that a specific structure of the spiral supporting plate and the spiral lining plate is adopted, a grinding material and a grinding medium are fully dispersed and contacted, the full turbulent motion is generated, a slurry stream fluid microvitum has the stable Lagrange streamline motion trail, and the grinding efficiency of a stirring grind machine is high.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Treatment method of electrolytic manganese residue

ActiveCN110551898AAvoid washing effect is not obviousAvoid the disadvantages that manganese slag is not easy to meltAmmonium sulfatesProcess efficiency improvementElectrolysisManganese

The invention discloses a treatment method of electrolytic manganese residue. Electrolytic manganese anode liquor is adopted for high-pressure flushing of electrolytic manganese slagging slurry, the characteristics of high acid and low manganese of the electrolytic manganese anode liquor are matched with the high pressure condition, manganese residue filer cake slurrying is thorough, the recyclingrate of manganese metal and ammonium sulfate in the manganese residue can be greatly improved, a filter cake is subjected to washing by clean water on a filter press, the defects that after manganeseresidue compaction, cleaning is carried out, the cleaning effect is not obvious, and the manganese residue is not prone to being dissolved into liquor can be overcome, the acid soluble manganese andthe ammonium sulfate can be efficiently recycled, the clean water consumption amount is reduced, on the filter press, the filter cake is subjected to alkali cleaning, the alkali liquor is put into thefilter press, and perpendicularly penetrates through the filter cake and continuously circulates, curing of residual manganese in the manganese residue and removing of ammonia nitrogen are achieved,the solid liquid ratio is large, the drug consumption amount is obviously reduced, according to the treatment method of the electrolytic manganese residue, the water soluble manganese recycling rate is larger than or equal to 90%, the recycling ammonium sulfate is larger than or equal to 90%, the manganese residue water containing rate is smaller than or equal to 28%, and the aim of harmless treatment of electrolytic manganese residue is achieved.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

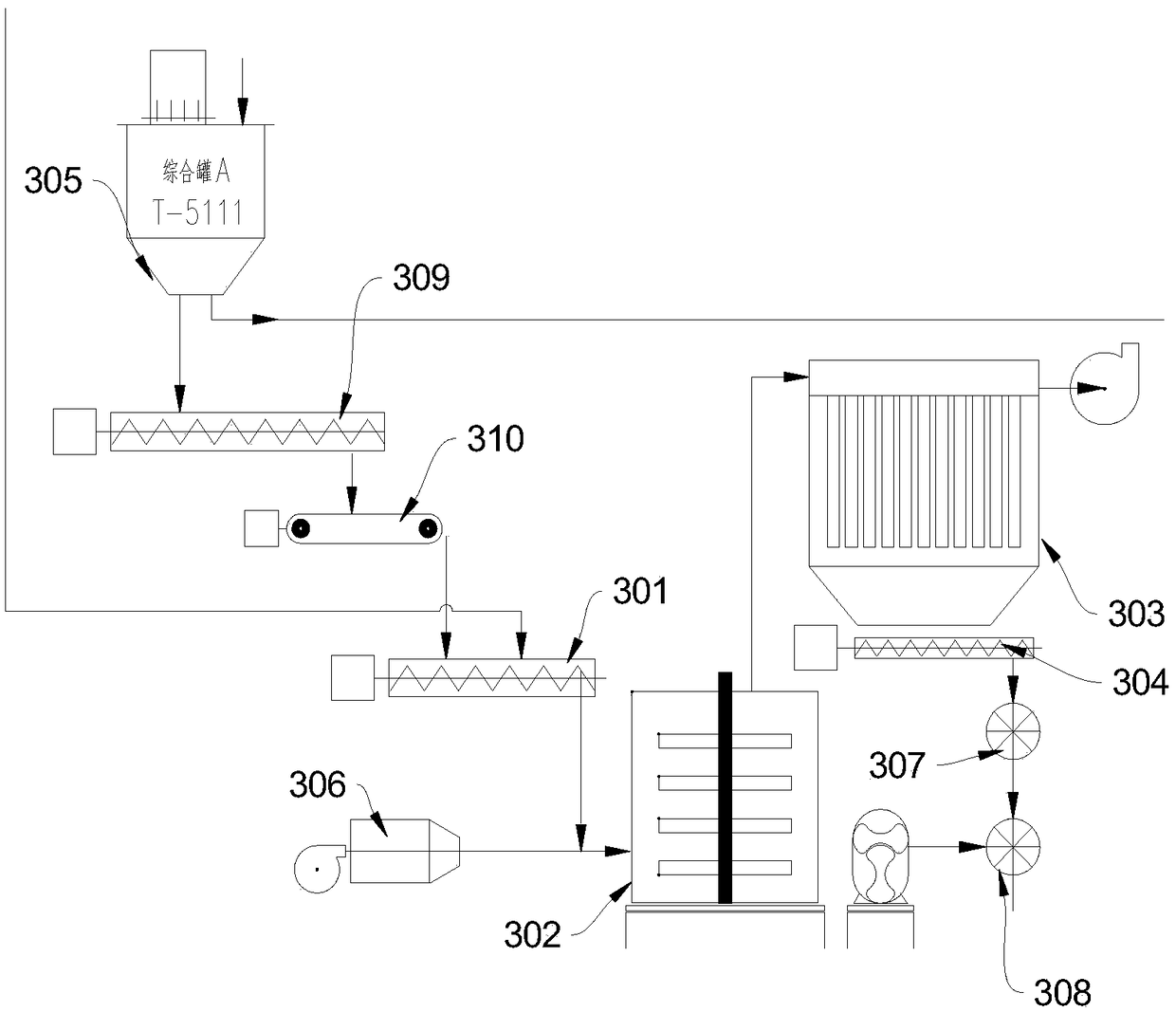

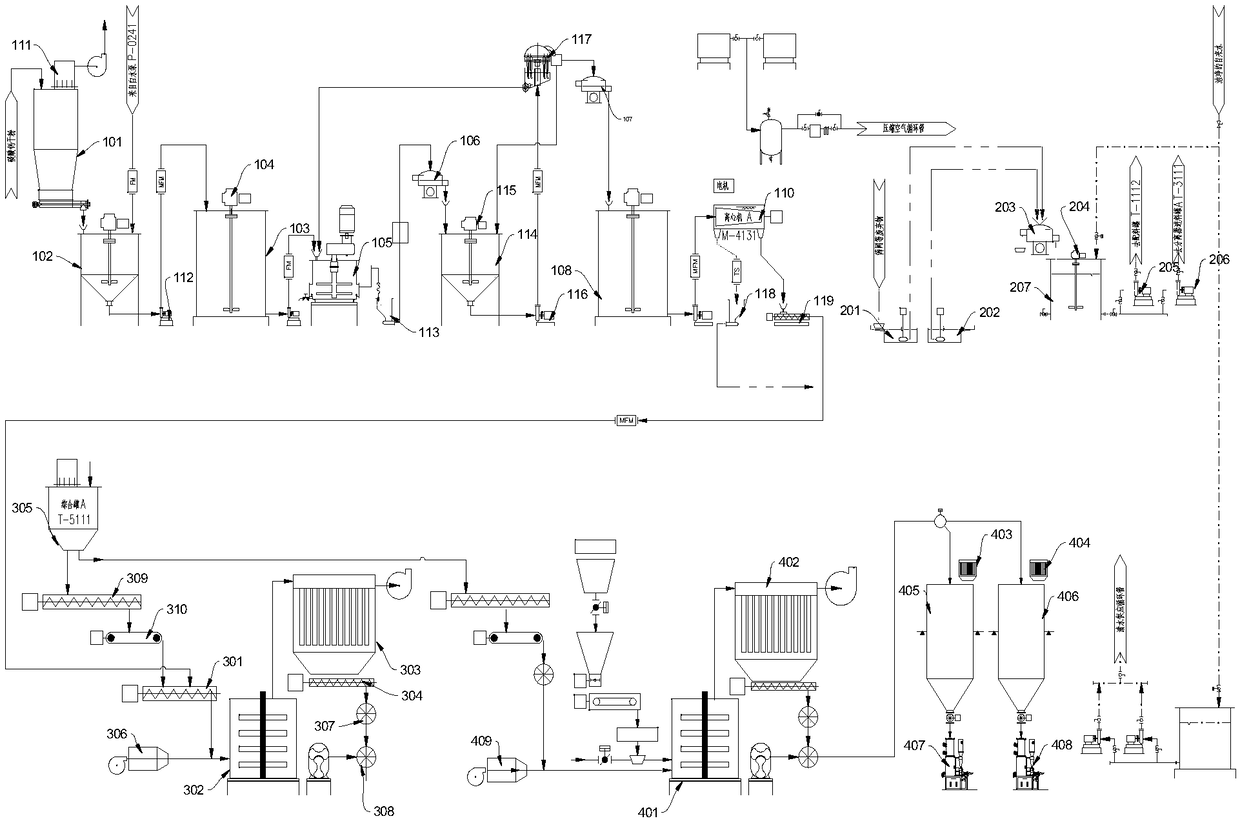

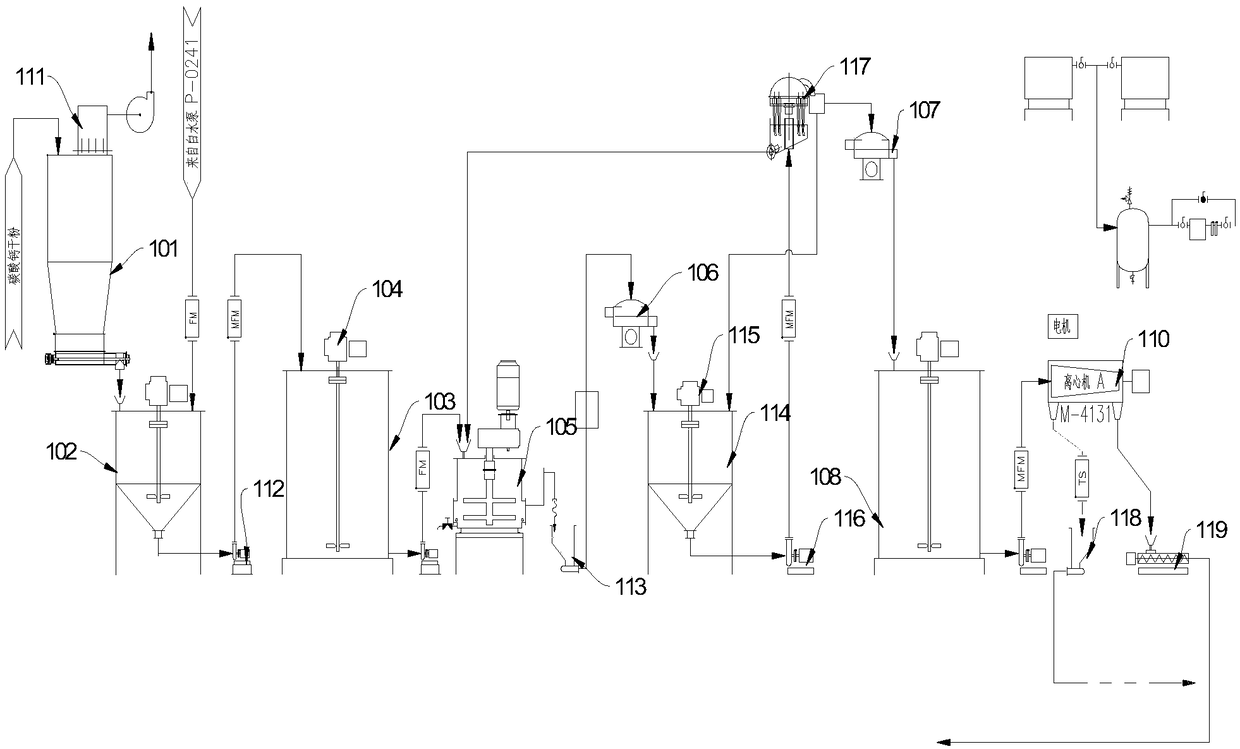

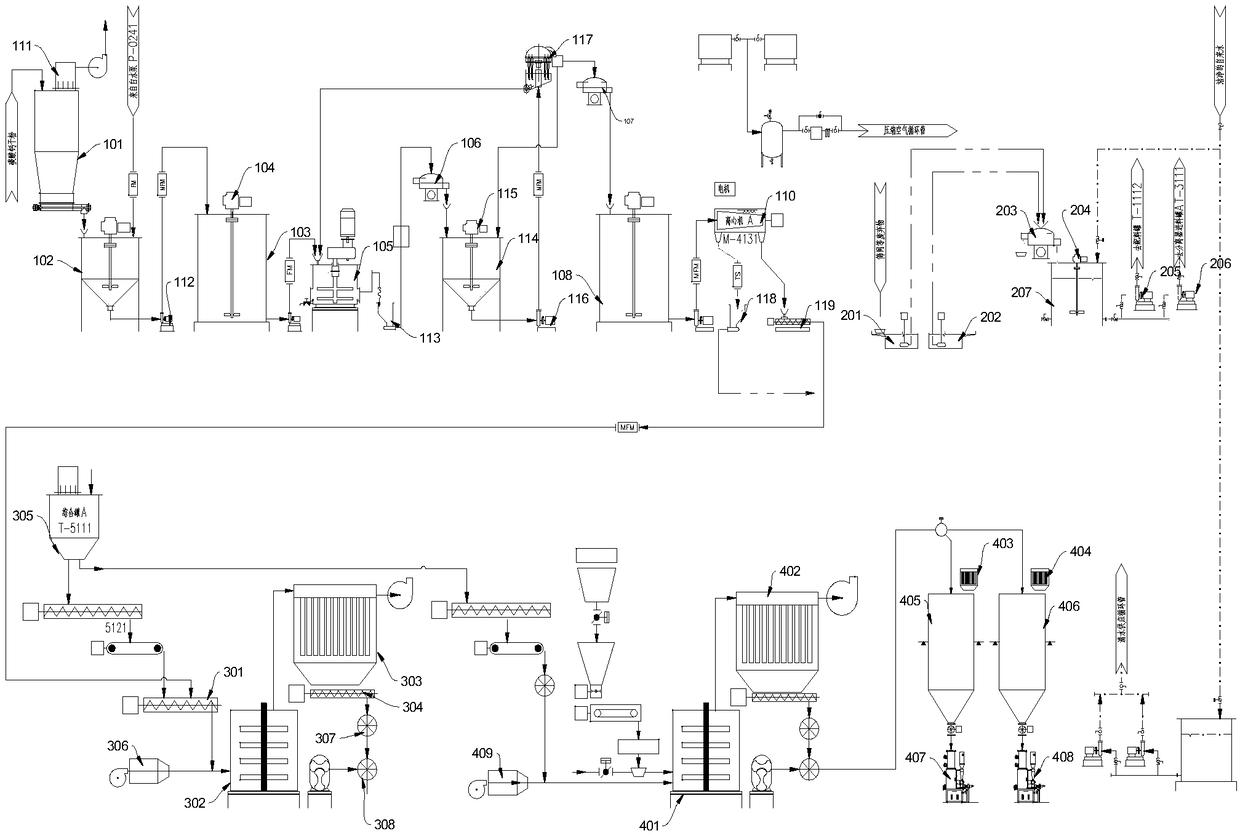

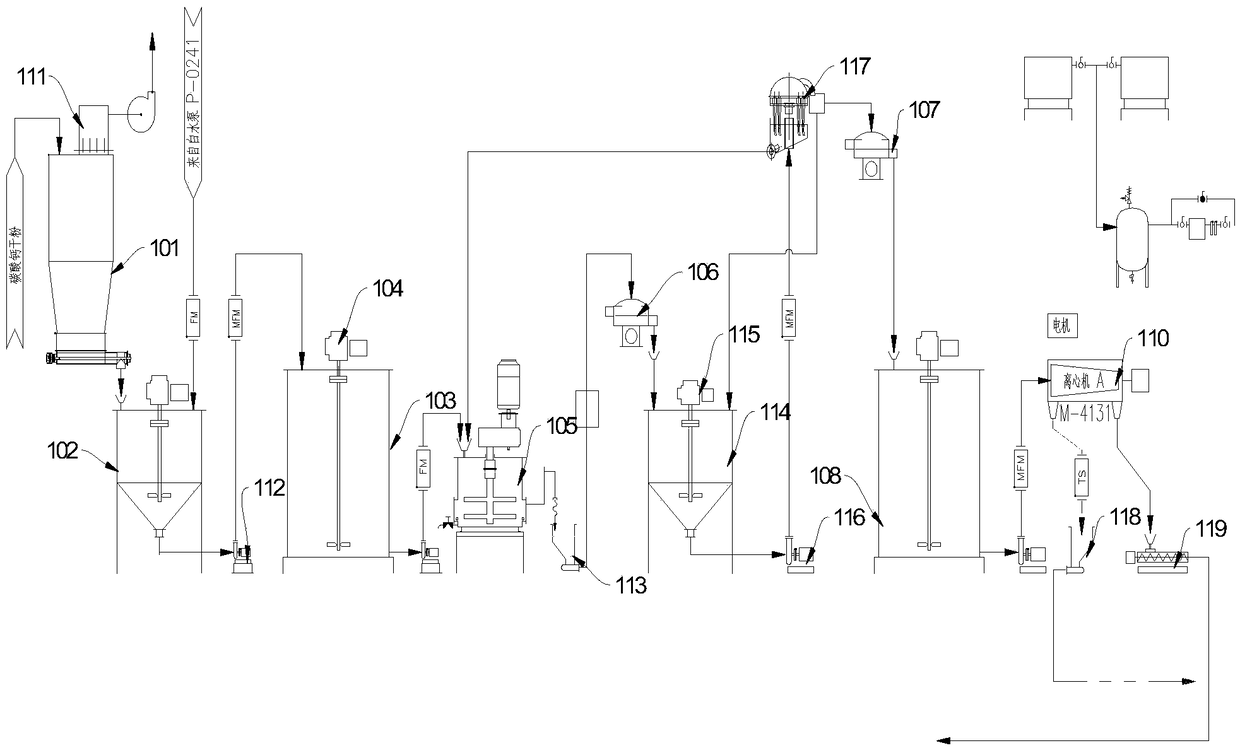

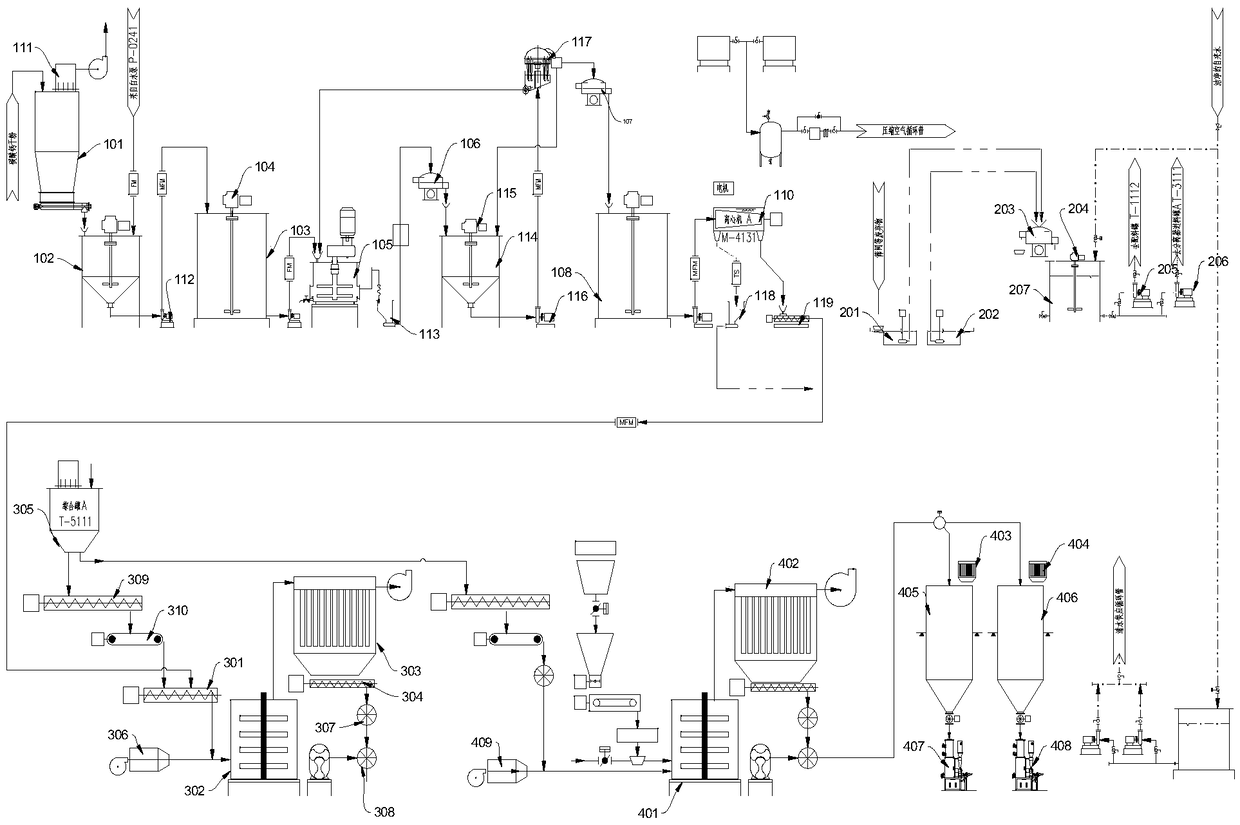

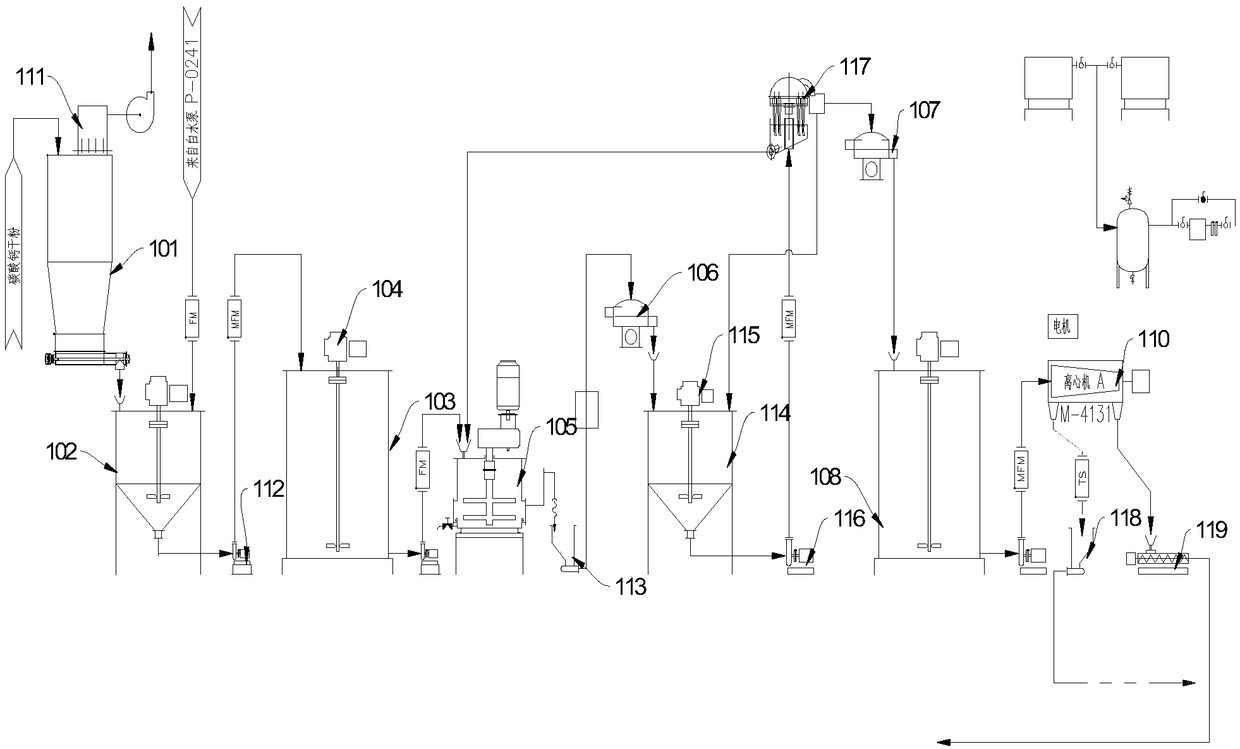

System and method for producing calcium carbonate dry powder

InactiveCN109233341AImprove processing fluidityImprove production stabilityPigment physical treatmentPulp and paper industryScrew conveyor

The invention discloses a system and a method for producing calcium carbonate dry powder. Compared with the prior art, the system comprises a drying and back mixing stirrer, a drying and scattering machine, a drying and scattering dust remover, a dust remover discharging screw conveyor and a comprehensive tank, wherein the drying and scattering machine is connected with the drying and back mixingstirrer; the drying and scattering dust remover is connected with the drying and scattering machine; the dust remover discharging screw conveyor is connected with the drying and scattering dust remover; the comprehensive tank is connected with the dust remover discharging screw conveyor; the comprehensive tank is connected with the drying and back mixing stirrer. Compared with the prior art, according to the system for producing the calcium carbonate dry powder, provided by the invention, produced calcium carbonate powder is higher in quality, the processing fluidity of a calcium carbonate material is favorably increased, and the comprehensive quality of the calcium carbonate material is increased, so that the production stability and the product quality of an air-permeable membrane are increased. The invention also provides a method for producing the calcium carbonate dry powder. The method provided by the invention has the beneficial effects.

Owner:CHANGSHA WANRONG MILLING EQUIP

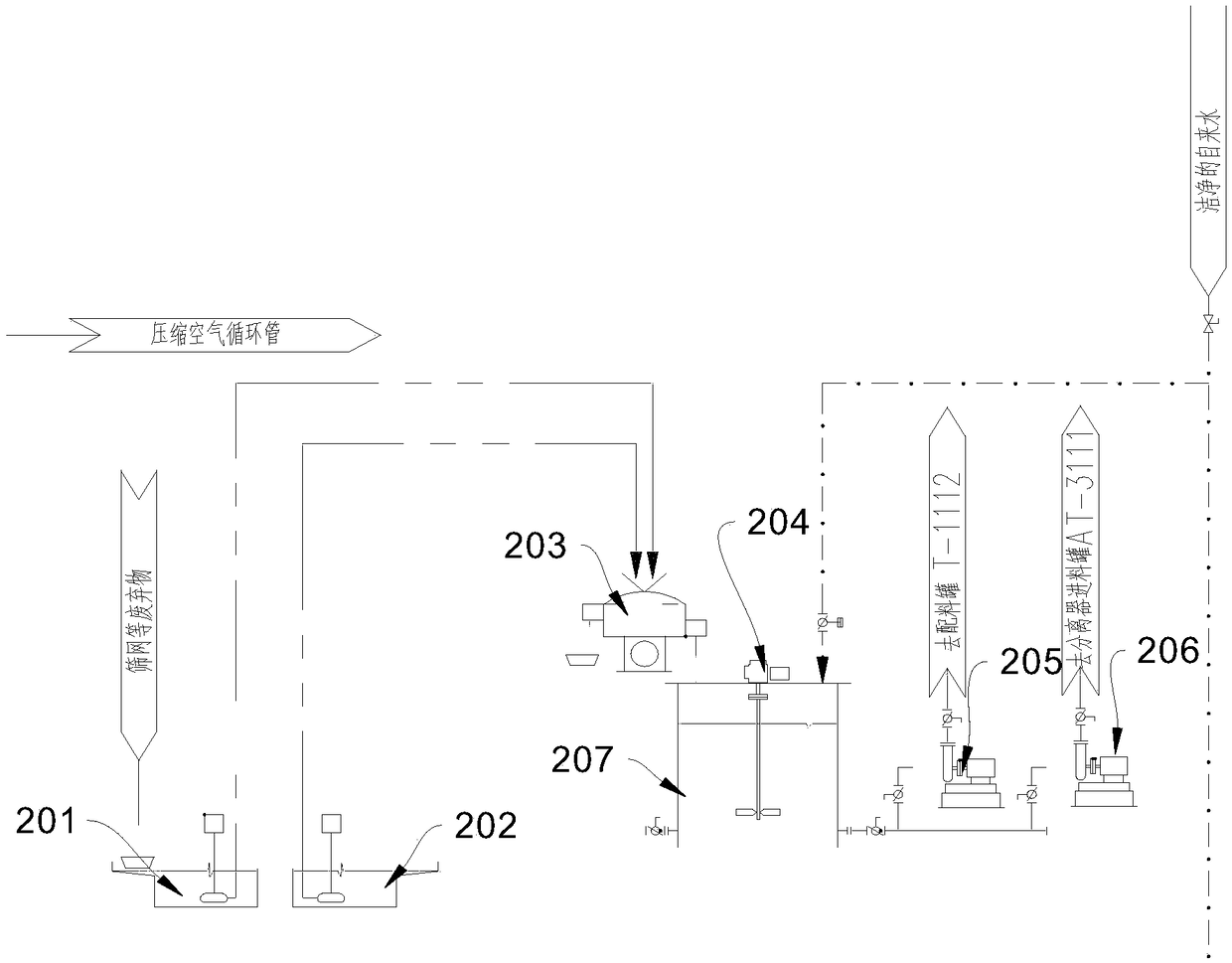

Production system of modified heavy calcium carbonate dry powder

InactiveCN109266043AImprove processing fluidityImprove qualityPigment physical treatmentCycloneBuffer tank

The invention discloses a production system of modified heavy calcium carbonate dry powder. Compared with the prior art, the system includes a batching apparatus, a first buffer tank, a wet mill, a first screening device, a hydraulic cyclone separation system, a second screening device, a second buffer device, a centrifugal dehydrator, a drying feedback stirrer, a drying beater, a drying and beating dust removal device, a comprehensive tank, an acid-coating and modification machine, an acid-coating and modification dust removal device, a first acid-coating cloth bag filter, a second acid-coating cloth bag filter, a modified product storage tank and a modified product packaging machine. The second screening device is connected with the hydraulic cyclone separation system, the centrifugal dehydrator is connected with the second buffer device, the comprehensive tank is connected with the drying and beating dust removal device and the drying feedback stirrer, and the acid-coating and modification machine is connected with the comprehensive tank. According to the scheme, compared with the prior art, the produced modified calcium carbonate powder is excellent in quality, the processing fluidity and other comprehensive quality of the calcium carbonate material are easily improved, the production stability of gas-permeable membranes and the product quality are improved.

Owner:CHANGSHA WANRONG MILLING EQUIP

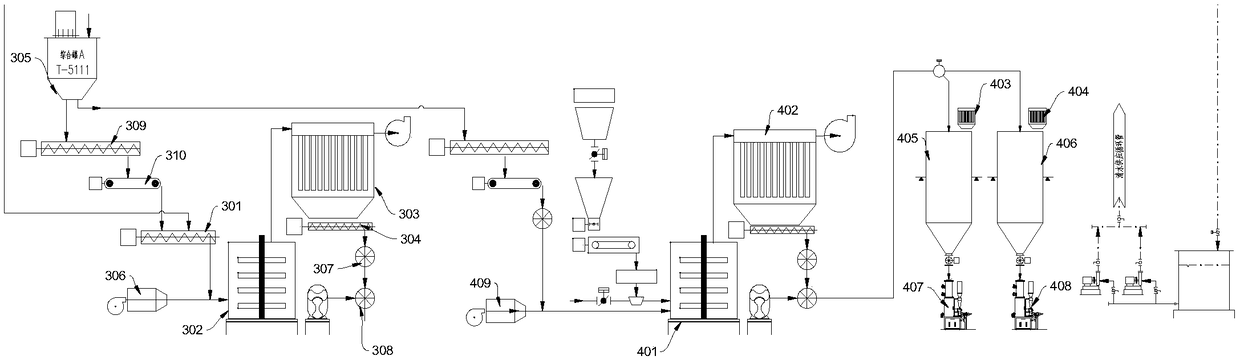

Modified calcium carbonate dry powder production system and method

InactiveCN109370259AIncrease the solid-to-liquid ratioReduce energy consumptionPigment physical treatmentPulp and paper industryStorage tank

The invention discloses a modified calcium carbonate dry powder production system which comprises a drying back mixing agitator; a drying dispersing machine connected with the drying back mixing agitator; a drying dispersing dust remover connected with the dry dispersing machine; an integrated tank connected with the drying dispersing dust remover and the drying back mixing agitator; an acid-modifying machine connected with the integrated tank; an acid-modifying dust remover connected with the acid-modifying machine; a bag filter connected to the acid-modifying dust remover; a product storagetank connected to the bag filter; a packaging machine connected to the product storage tank compared with the prior art. Compared with the prior art, the modified calcium carbonate dry powder production system produces modified calcium carbonate powder with better quality, improves the processing flow property of a calcium carbonate material, improves the overall quality of the material and further improves the production stability and the product quality of a breathable membrane. The invention also provides a modified calcium carbonate dry powder production method which also has the above advantages.

Owner:CHANGSHA WANRONG MILLING EQUIP

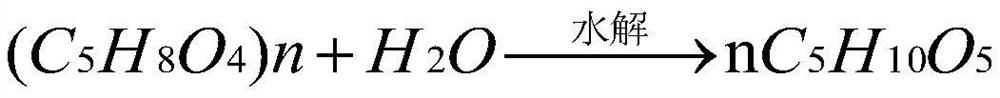

Furfural hydrolysis method

PendingCN113999193AHigh content of stock solutionShort hydrolysis timeOrganic chemistryThioureaReaction temperature

The invention discloses a furfural hydrolysis method which comprises the following steps: S1, fully mixing screened and crushed corncobs and dilute sulphuric acid according to a certain proportion, and putting the mixture into a reaction container; S2, introducing steam from the bottom of the reaction container in S1 for hydrolysis, and controlling certain pressure and temperature; and S3, adding a certain amount of a polymerization inhibitor, and after hydrolysis reaction for a certain time, condensing a generated water vapor mixture to obtain a furfural stock solution. The method overcomes the defects in the prior art, is reasonable in design, reduces the loss caused by furfural polymerization in the hydrolysis process by increasing the hydrolysis reaction temperature, increasing the solid-to-liquid ratio, shortening the hydrolysis time and adding a certain amount of thiourea as a polymerization inhibitor, improves the furfural yield, reduces the steam consumption, and has higher social use value and application prospect.

Owner:安徽金轩科技有限公司

A kind of wet-process zirconium-doped concentration gradient nickel-cobalt-aluminum ternary precursor and its preparation method

A kind of wet-process zirconium-doped concentration gradient nickel-cobalt-aluminum ternary precursor and preparation method thereof, the chemical general formula of the nickel-cobalt-aluminum ternary precursor is Ni x CoyAl z (OH) 2 , where x+y+z=1, and 0.3≤x≤0.9, 0.01≤y≤0.4, 0.01≤z≤0.4, the Zr element accounts for 0.001%-3% of the total mass of the nickel-cobalt hydroxide precursor; ternary The precursor is composed of three layers, the inner layer is zirconium-doped nickel-cobalt binary precursor, the molecular formula is: Ni x co y (OH) 2 , whose outer layer is a ternary precursor of zirconium-doped nickel-cobalt-aluminum, whose molecular formula is: Ni x co y al z (OH) 2 , the intermediate layer is a concentration gradient precursor between the zirconium-doped nickel-cobalt binary precursor and the zirconium-doped nickel-cobalt-aluminum ternary precursor, and the present invention also includes the preparation method of the nickel-cobalt-aluminum ternary precursor. The zirconium-doped nickel-cobalt-aluminum ternary precursor of the present invention has narrow particle size distribution and good particle morphology; the complexation controls the crystallization co-precipitation to make the doping elements uniform, and the positive electrode precursor prepared by using it has high specific capacity, good cycle stability and processing performance Well, stable performance.

Owner:ZHUJI PAWA NEW ENERGY

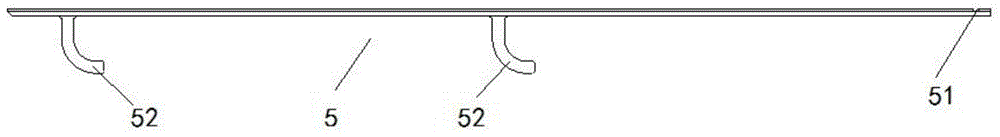

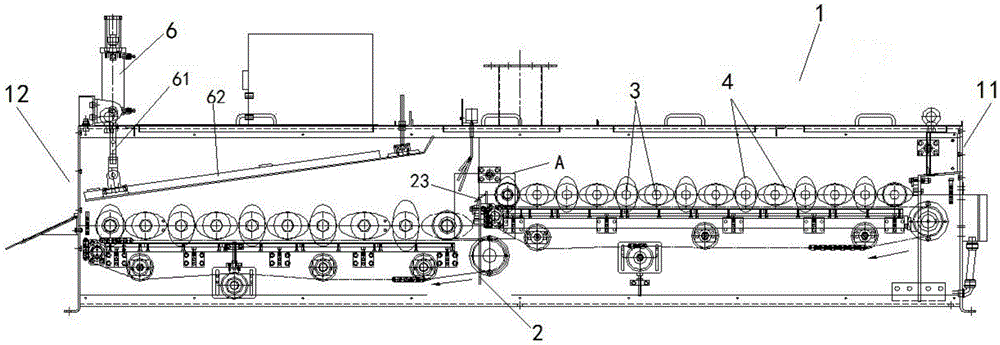

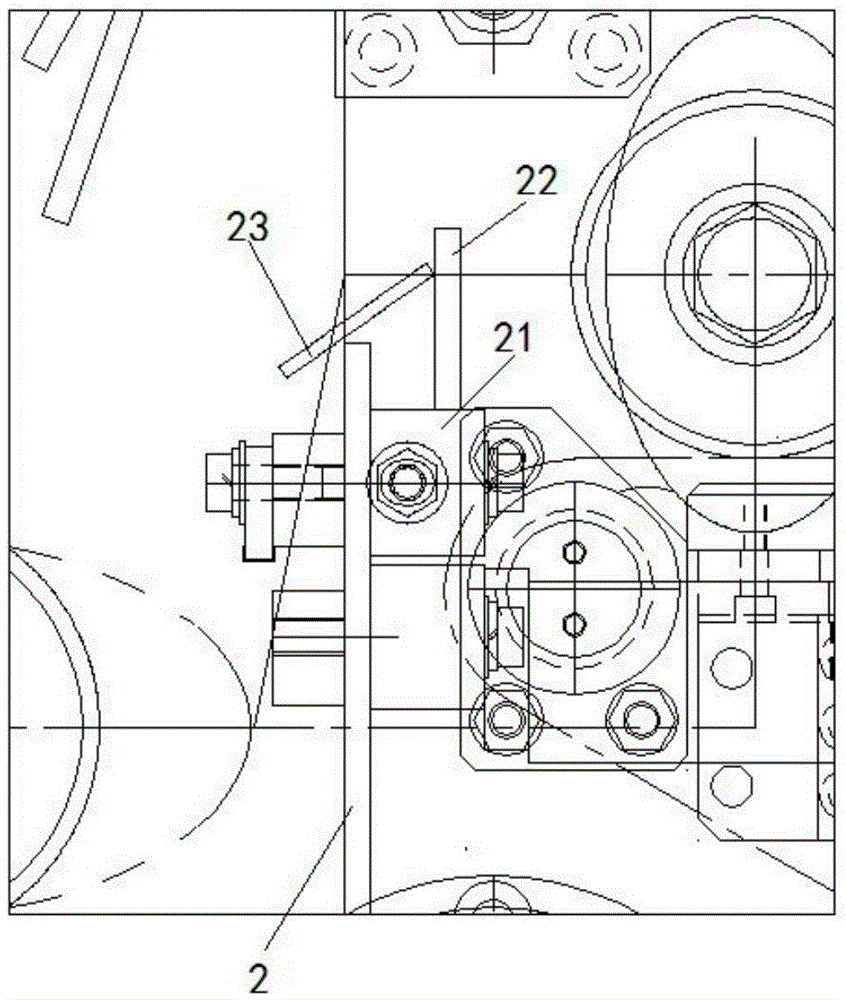

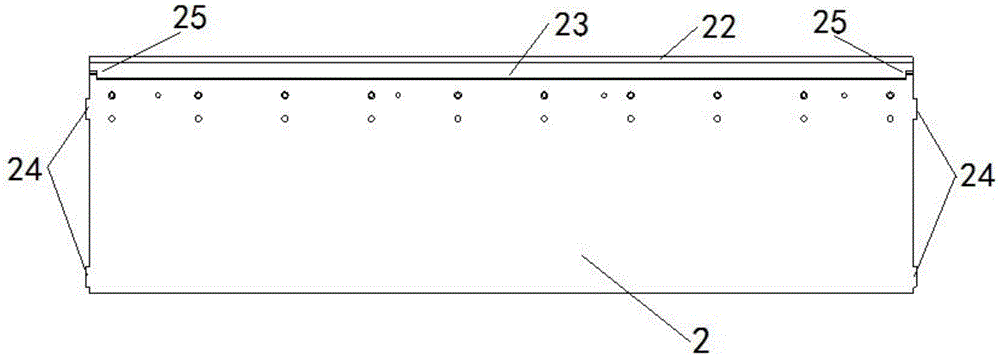

Ellipse superposition solid-liquid separation apparatus

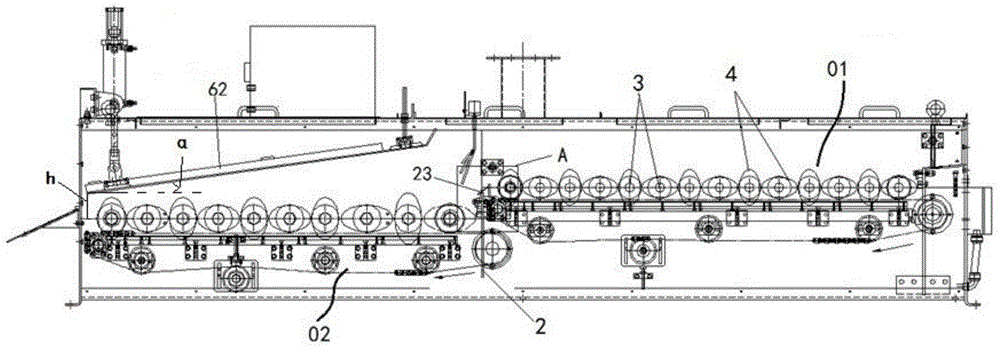

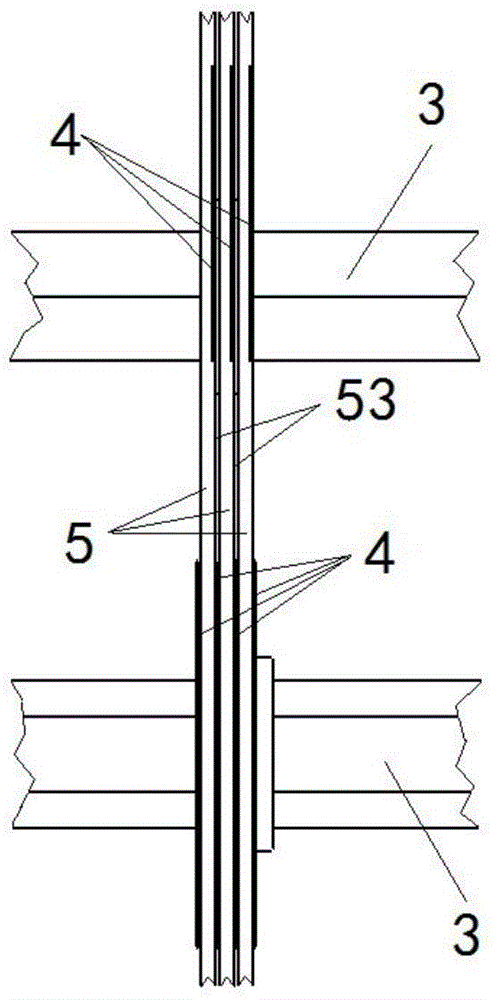

ActiveCN104528972AReduce moisture contentStable moisture contentMultistage water/sewage treatmentEllipseDehydration

The invention provides an ellipse superposition solid-liquid separation apparatus. The apparatus comprises a natural dehydration segment used for bearing and conveying a processed material and gradually realizing natural hydration of the processed material in the bearing and conveying process, and a squeezing dehydration segment used for receiving the processed material naturally dehydrated by the natural dehydration segment, further realizing squeezing dehydration on the processed material by using a squeezing board and discharging, a ratio of the total area of water drainage gaps arranged on a natural dehydration segment carrying surface to the total area of the natural dehydration segment carrying surface is greater than 1:10 and smaller than 4:10, a ratio of the total area of water drainage gaps arranged on a squeezing dehydration segment carrying surface to the total area of the squeezing dehydration segment carrying surface is greater than 1:15 and smaller than 1:5, a ratio of the length of the natural dehydration segment to the length of the squeezing dehydration segment is greater than 1:1 and smaller than 4:1, and the length of the natural dehydration segment is at least 1.5m; and the processed material conveying speed of the natural dehydration segment and the processed material conveying speed of the squeezing dehydration segment are not greater than 0.3m / s respectively. The ellipse superposition solid-liquid separation apparatus has the advantages of compact structure, high dehydration efficiency and good stability.

Owner:江苏碧诺环保科技有限公司

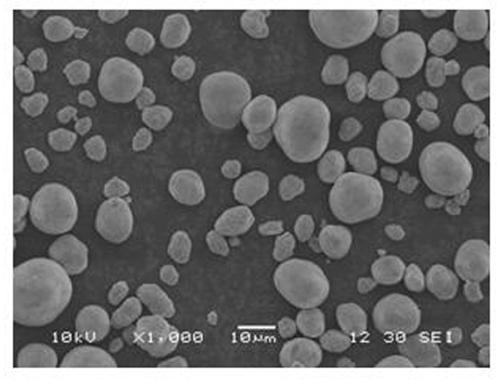

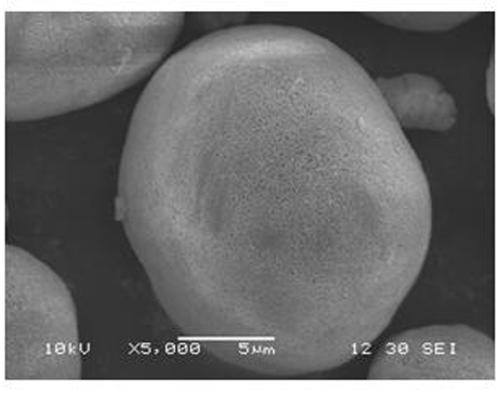

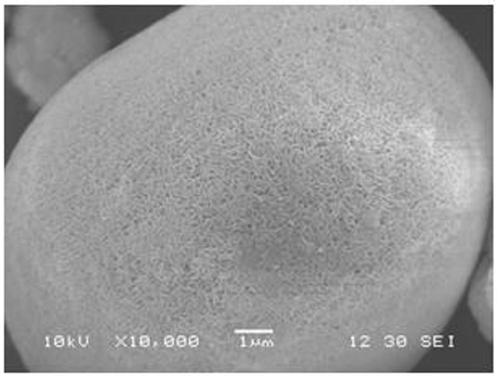

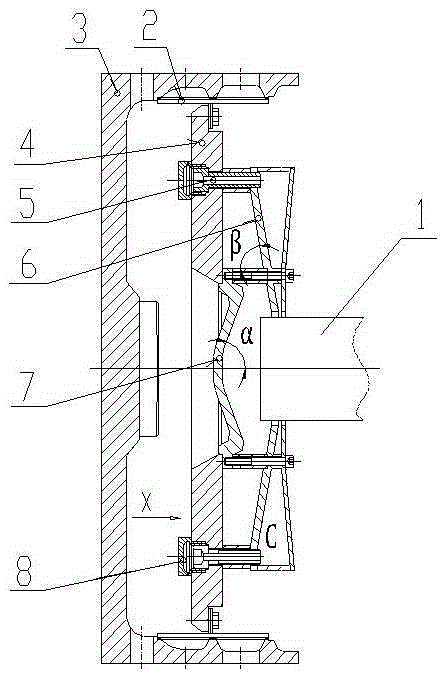

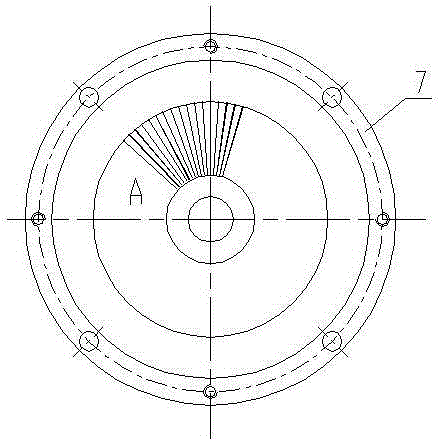

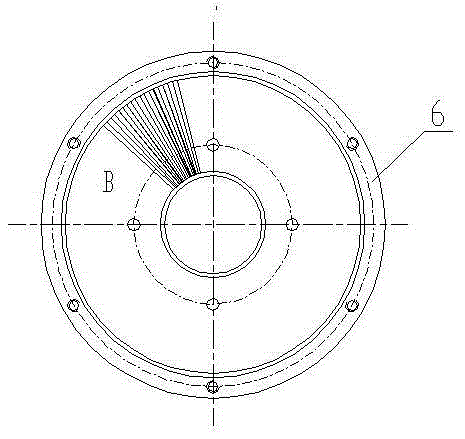

Device and method for preparing monodisperse spherical porous beta-TCP particles

The invention discloses a device for preparing monodisperse spherical porous beta-TCP particles. The device comprises an outer shell as well as a crucible and a collection bin which are arranged in the outer shell, wherein the collection bin is arranged at the bottom of the outer shell, and the crucible is arranged at the upper part of the collection bin; a stirring bar is arranged in the crucible, and the upper end of the stirring bar is connected with piezoelectric ceramic; an opening is formed in the bottom of the crucible, and a baffle is also arranged at the bottom of the crucible; a hole is formed in the baffle, and an upper vent tube is arranged at the upper part of the outer shell; a lower vent tube is arranged at the middle lower part of the outer shell, and a pump body is also arranged at the bottom of the outer shell. The invention also discloses a method for preparing the monodisperse spherical porous beta-TCP particles. The method comprises the following steps of pre-processing of raw powder, suspension configuration, POEM ejection, and collection of particles and sintering. The beta-TCP particle prepared by the invention has the advantages of communicated porous structure, uniform and controllable particle size, high surface sphericity and the like.

Owner:DALIAN UNIV OF TECH

A method suitable for preparing manganese sulfate electrolyte by leaching pyrolusite with sulfur dioxide

ActiveCN107699714BIncrease the solid-to-liquid ratioIncrease profitHigh concentrationPregnant leach solution

The invention provides a method for preparing a manganese sulfate electrolyte by leaching pyrolusite through sulfur dioxide. According to the main concept, the method comprises the steps that only a part of an anolyte and whole-process pyrolusite are used for preparing a fluid, and after the fluid reacts with the sulfur dioxide, a high-concentration manganese sulfate solution is obtained; after the other part of the anolyte is neutralized and subjected to liquid-solid separation, a low-concentration manganese sulfate solution with the manganese sulfate concentration being identical to that ofthe prior anolyte is obtained; and the two manganese sulfate solutions are blended to obtain the qualified electrolyte with the manganese sulfate concentration meeting electrolysis requirements. By adopting the method, the utilization efficiency of the sulfur dioxide and the pyrolusite in the leaching process can be improved, and the capital construction cost and operation cost of a leaching technology and a leachate impurity removing technology are lowered.

Owner:SICHUAN UNIV

Method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation

ActiveCN103060481BImprove reaction efficiencyReduce concentrationBiofuelsFermentationPhysical chemistryCyclic compression

The invention discloses a method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation. The method comprises: first conducting standing infiltration on straw particles with a dilute acid solution, then loading the straw particles into a cylindrical reactor, performing fed-batch of the dilute acid solution to the reactor, and at the same time, applying the action of microwave and compressing the straw particles, and discharging the liquid in the reactor; after solid-liquid separation, re-injecting the acid solution and dispersing the straw particles uniformly; carrying out fed-batch of the filtrate obtained from the separation to the reactor, and at the same time, applying the action of microwave and compressing the straw particles, and discharging the liquid in the reactor; and repeating the operations till the end of the reaction. By infiltrating the straw particles in the acid solution in advance and adopting a filtrate cyclic compression mode, the method provided in the invention reduces the concentration and dosage of the acid solution, increases the reaction product concentration, and enhances the reaction speed simultaneously.

Owner:CHINA PETROLEUM & CHEM CORP +1

A multi-stage elliptical solid-liquid separator

The invention provides a multi-stage oval superposed solid-liquid separator comprises two stages of carrying surfaces which are connected end to end, wherein each stage of carrying surfaces can be used for carrying an treated object with a certain solid-liquid ratio to the tail end from the beginning end and dehydrating the treated object in the process; the treated object is longitudinally conveyed from the front-stage carrying surface to the rear-stage carrying surface, and the terrain at the tail end of the front-stage carrying surface is higher than that at the beginning end of the rear-stage carrying surface to form terrain difference; a guide structure is arranged between the adjacent two stages of carrying surfaces for guiding the treated object from the tail end of the front-stage carrying surface to the beginning end of the rear-stage carrying surface. After being conveyed to the tail end through the front-stage carrying surface, the treated object is turned over and dropped to the beginning end of the rear-stage carrying surface by virtue of the guide structure, and the water in the treated object is turned over and guided out, so that the water of the treated object is discharged in a facilitated manner, the solid-liquid ratio of the treated object is increased, water produced by squeezing is reduced, water draining requirements of a liquid outlet structure are lowered, and the dehydrating effects of the squeezed treated object are improved.

Owner:江苏碧诺环保科技有限公司

A device and method for preparing monodisperse spherical porous β-tcp particles

The invention discloses a device for preparing monodisperse spherical porous beta-TCP particles. The device comprises an outer shell as well as a crucible and a collection bin which are arranged in the outer shell, wherein the collection bin is arranged at the bottom of the outer shell, and the crucible is arranged at the upper part of the collection bin; a stirring bar is arranged in the crucible, and the upper end of the stirring bar is connected with piezoelectric ceramic; an opening is formed in the bottom of the crucible, and a baffle is also arranged at the bottom of the crucible; a hole is formed in the baffle, and an upper vent tube is arranged at the upper part of the outer shell; a lower vent tube is arranged at the middle lower part of the outer shell, and a pump body is also arranged at the bottom of the outer shell. The invention also discloses a method for preparing the monodisperse spherical porous beta-TCP particles. The method comprises the following steps of pre-processing of raw powder, suspension configuration, POEM ejection, and collection of particles and sintering. The beta-TCP particle prepared by the invention has the advantages of communicated porous structure, uniform and controllable particle size, high surface sphericity and the like.

Owner:DALIAN UNIV OF TECH

A distribution acceleration disk device for a two-stage pusher centrifuge

ActiveCN104001628BIncrease the solid-to-liquid ratioIncrease flushing functionRotary centrifugesEngineeringDouble stage

The invention relates to a double-stage material-pushing centrifuge distribution acceleration plate device and aims to increase solid-liquid ratio of materials during operation of a centrifuge and use the liquid discharged in advance to wash the screen of a separation section. The device comprises a feed pipe, a primary rotary hub, a material pushing plate located in the primary rotary hub and a primary rotary hub screen assembled between the primary rotary hub and the material pushing plate and is characterized in that a horn-shaped hole is formed in the center of the material pushing plate, an inner distribution acceleration plate is disposed at the horn-shaped hole, an outer distribution acceleration plate is disposed on the outer side of the inner distribution acceleration plate, a sealed space is disposed on the outer side of the outer distribution acceleration plate, a nozzle penetrating the material pushing plate is disposed at the edge of the sealed space, and a screen area is disposed on each of the inner distribution acceleration plate and the outer distribution acceleration plate. The double-stage material-pushing centrifuge distribution acceleration plate device has the advantages that material solid-liquid ratio is increased, the thickening is achieved by the power and containing space of the device, separation effect is increased, and application range of the centrifuge is expanded.

Owner:ZHEJIANG QINGJI CENTRIFUGE MFG

Low-crystallization fiber extraction and sugar making technology

ActiveCN109666712AImprove mass transfer effectRealize comprehensive utilizationFermentationGlucose productionCelluloseFiber

The invention discloses a low-crystallization fiber extraction and sugar making technology. Lignocellulose is prepared into slurry, then the slurry is screened by using a super-frequency vibrating screen, and crystallized fiber is separated to obtain a low-crystallization fiber aqueous solution; enzyme hydrolysis is carried out on a solid material by using cellulase after solid-liquid separation to obtain glucose. According to the technology, comprehensive utilization of agricultural and forestry straw biomass is better achieved, the utilization rate of agricultural byproducts is increased, and the problems about environment and land are solved; the low-crystallization fiber is separated and extracted and is made the best use of; the low-crystallization fiber has the advantages of being large in specific surface area, small in physical size and good in aqueous solution mass transfer effect, so that the low-crystallization fiber is very suitable for carrying out enzymolysis saccharification, the enzyme consumption can be reduced, the solid-liquid ratio can be increased, and the enzymolysis cost is reduced.

Owner:江苏集萃工业生物技术研究所有限公司

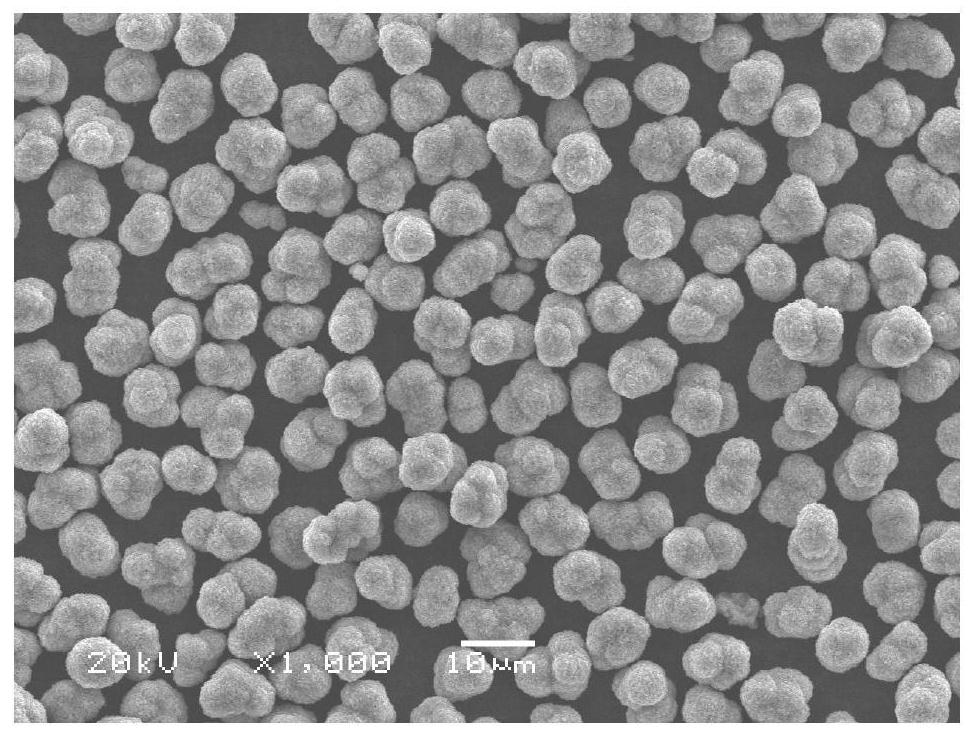

A kind of different particle size narrow distribution ternary precursor and its preparation method

ActiveCN108598441BPromote spheroidizationEvenly distributedCell electrodesAqueous sodium hydroxideManganese

The invention discloses a ternary precursor with a narrow distribution of different particle sizes and a preparation method thereof. The complexation-controlled crystallization co-precipitation method is adopted, and nucleation, growth, and nucleation in a continuously increasing solid-liquid ratio environment are carried out in a first reaction kettle. , Nickel-cobalt-manganese soluble salt solution and sodium hydroxide aqueous solution carry out co-precipitation reaction under the complexation of ammonia to prepare narrowly distributed crystal nuclei, and then transfer part of the small particle size nickel-cobalt-manganese hydroxide in the first reactor to Go to the second reactor to increase the solid-liquid ratio to grow to a medium particle size, and then transfer part of the material from the second reactor to the third reactor to increase the solid-liquid ratio and continue to grow to the required large particle size. Not only can three kinds of nickel-cobalt-manganese hydroxide precursors with different particle sizes, uniform element distribution, good sphericity, narrow particle size distribution and high tap density be obtained at the same time, but also because the materials in the second reactor and the third reactor The particle size itself is large, and the feeding speed can be increased to a certain extent during the regrowth, and the production efficiency can be improved.

Owner:DONGGUAN UNIV OF TECH

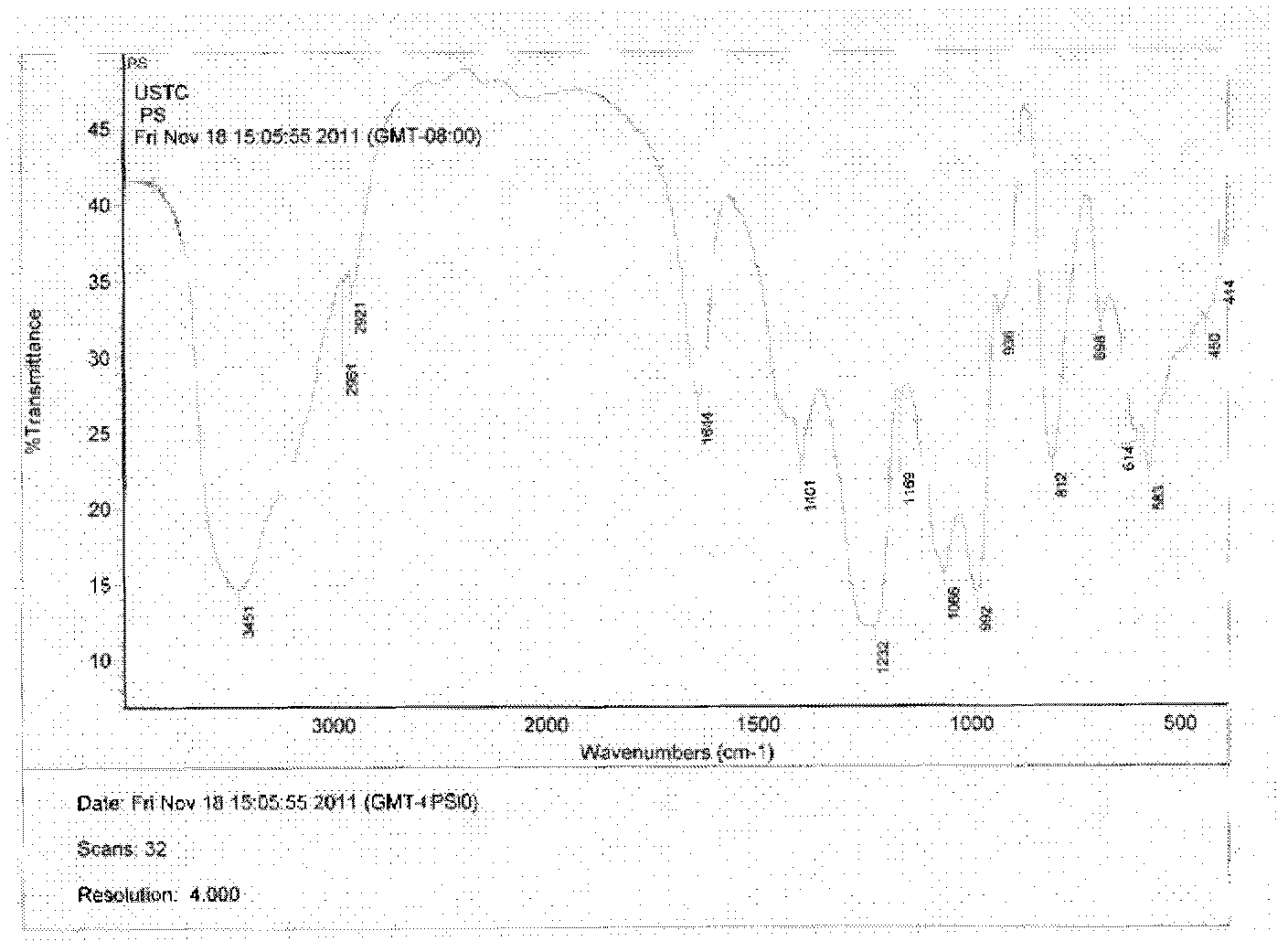

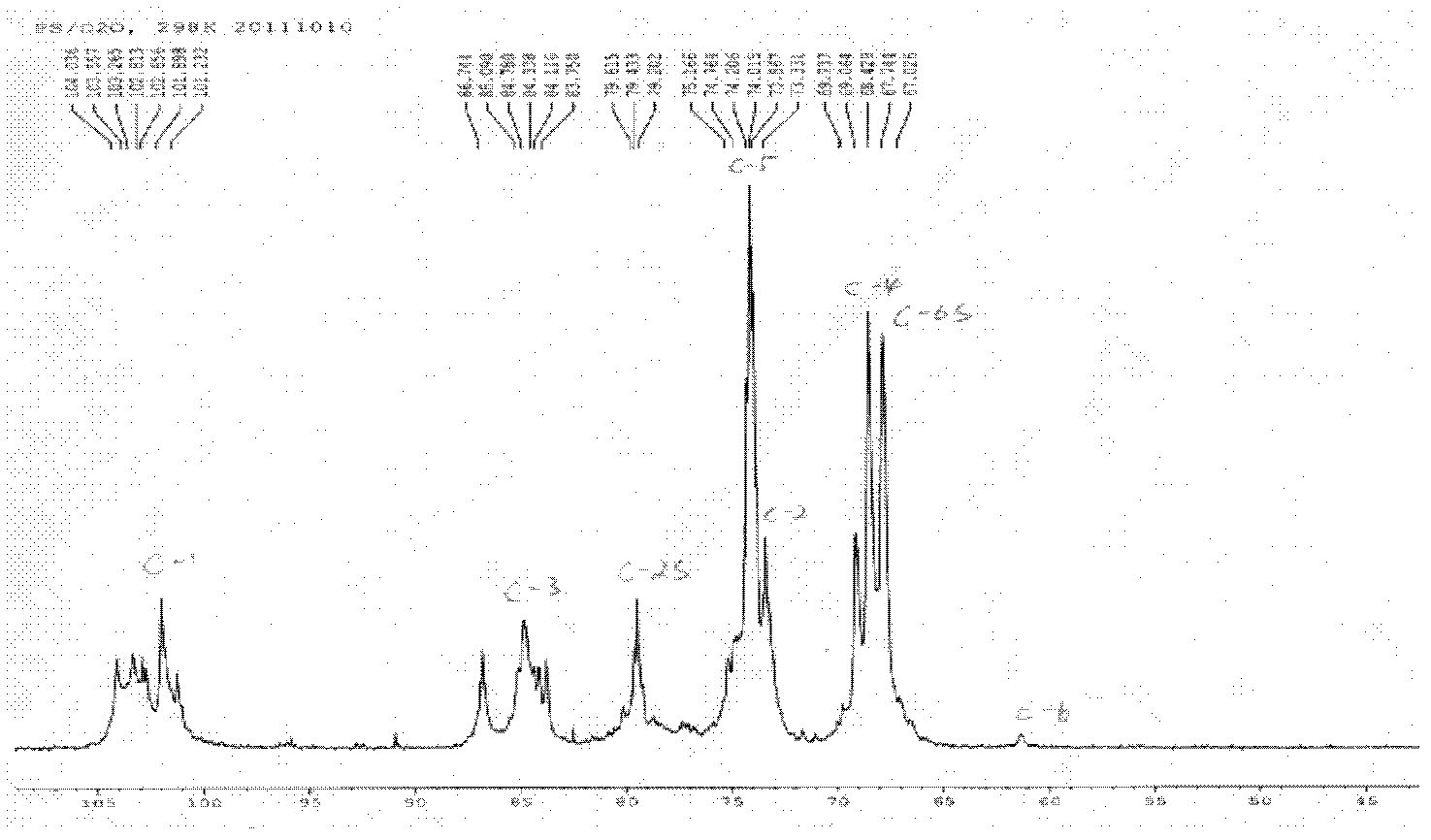

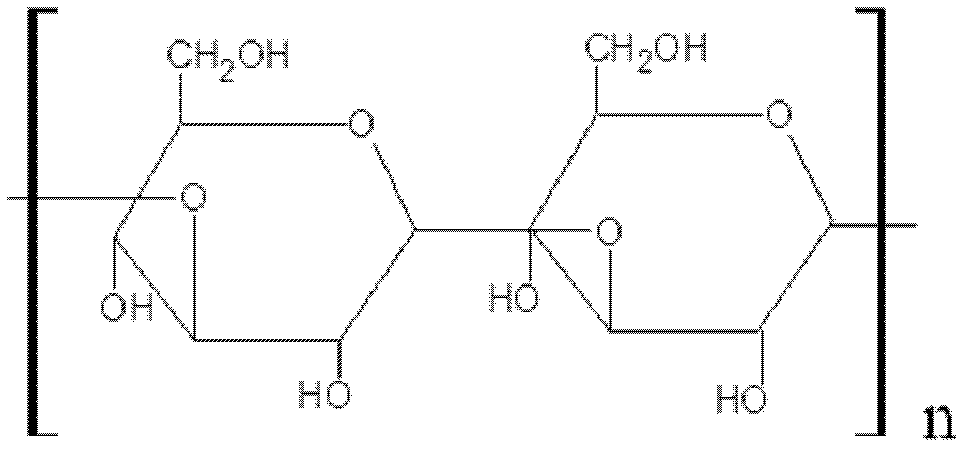

Preparation method of pachyman sulfate

ActiveCN102603910BIncreased chance of collisionIncrease the solid-to-liquid ratioOrganic active ingredientsBlood disorderRotary evaporatorSulfate radicals

The invention discloses a preparation method of pachyman sulfate. The preparation method comprises the following steps of: adding sulfamic acid and an organic solvent in a reaction bottle of a rotary evaporator; preheating to reaction temperature; after fully dissolving the sulfamic acid, adding dried pachyman powder; vacuuming a reaction system; cooling to room temperature after the reaction is finished; adjusting the pH of reaction solution to 9-10 with saturated alkali solution; continuously vacuuming to remove ammonia and repeatedly vacuuming until the reaction solution has no ammonia smell; maintaining the pH value to be over 7 until the pH value does not go down; then adding ethanol; precipitating polysaccharide sulfate; filtering and then dissolving in water again; filtering; placing in an ultrafilter to desalinate and concentrate; and detecting residual quantity of free sulfate radicals in eluent by using saturated barium chloride solution until no white precipitate is produced. According to the preparation method, the sulfation efficiency is greatly increased, polysaccharide molecule degradation and production of sugar ring double ring are suppressed, the color of a product becomes light, and the final quality of the product is obviously improved.

Owner:合肥创新医药技术有限公司

A kind of low crystallization fiber extraction sugar production process

ActiveCN109666712BImprove mass transfer effectRealize comprehensive utilizationFermentationGlucose productionFiberEnzymatic hydrolysis

The invention discloses a process for extracting sugar with low crystallization fiber. Lignocellulose is made into slurry, and then sieved by an ultra-frequency vibrating screen to separate the crystallized fiber to obtain an aqueous solution of low crystallization fiber, which is used after solid-liquid separation. Cellulase enzymatically hydrolyzes solid materials to obtain glucose. The process of the invention better realizes the comprehensive utilization of agricultural and forestry straw biomass, improves the utilization rate of agricultural and sideline products, and solves the problems of the environment and land; separates and extracts low-crystalline fibers to make the best use of them; utilizes low-crystalline fibers With large specific surface area, small physical size and good mass transfer effect in aqueous solution, it is very suitable for enzymatic saccharification, which can reduce the amount of enzyme used, increase the solid-liquid ratio, and reduce the cost of enzymatic hydrolysis.

Owner:江苏集萃工业生物技术研究所有限公司

Oxidation method of caso3 in desulfurization ash under alkaline conditions

The invention discloses a method for oxidizing CaSO3 in desulfurized fly ash in an alkaline condition. The method comprises the following steps of: (1) adding 2 to 10 times water by weight to the desulfurized fly ash, and uniformly stirring to obtain desulfurized fly ash slurry; (2) slowly adding H2O2 and / or persulfate solution with weight concentration being 10 to 30% of to the desulfurized fly ash slurry, wherein the molar mass ratio of H2O2 and / or persulfate to CaSO3 is 1- 2: 1; and (3) stirring and reacting mixtures of the desulfurized fly ash slurry, H2O2 and / or persulfate solution for 0.5 to 4 hours. According to the oxidization method, the pH of the solution does not need to be adjusted and metallic ions do not need to add, so that the reaction conditions are mild, and as a result, the oxidization cost is reduced, and the corrosion to the equipment is reduced; and the method has the characteristics of short reaction time, high efficiency, etc.

Owner:武汉钢铁有限公司 +1

A kind of treatment method of electrolytic manganese slag

ActiveCN110551898BAvoid the disadvantages that are not easy to dissolveHigh recovery rateAmmonium sulfatesProcess efficiency improvementAmmoniacal nitrogenManganese

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com