Method for producing amino acid, oligopeptide, calcium lactate and chitin by treating shrimp shell waste through solid-state fermentation of streptomyces and application of amino acid, oligopeptide, calcium lactate and chitin

A solid-state fermentation and waste technology, applied in the field of bioengineering, can solve the problems of ineffective recycling, high equipment requirements, high cost, etc., and achieve the effect of increasing utilization value, reducing processing procedures, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: Determination of various components of shrimp shell waste

[0058] After the shrimp shell waste was dried at 65°C, the shrimp shell waste powder was obtained, which was stored at -20°C for future use. The methods for determining protein, minerals, chitin and moisture in shrimp shell waste are as follows:

[0059] (1) Protein: Because chitin contains nitrogen, in order to eliminate interference, the shrimp shell powder was first treated with 1M NaOH solution at 90°C for 3 hours, and the protein concentration of the supernatant was determined by the Kjeldahl method (GB 5009.5-2016). The protein content in the shrimp shell was measured to be 54.52%;

[0060] (2) Minerals: use 1M hydrochloric acid solution to treat the shrimp shell powder at 40°C for 6 hours to remove minerals, measure the weight loss after drying, and the mineral content in the shrimp shells can be measured, which is 20.10%;

[0061] (3) Chitin: firstly treat the shrimp shell powder with 1M...

Embodiment 2

[0063] Embodiment 2: process shrimp shell by Streptomyces solid state fermentation

[0064] Streptomyces sp. SCUT-1 described in Chinese patent application CN201910491700.8, a Streptomyces strain and its application in degrading feathers, was used as the fermentation strain. Streptomyces sp. SCUT-1, with the preservation number GDMCC No:60612, was preserved in the Guangdong Provincial Microbial Culture Collection Center on March 20, 2019, Building 59, Compound, No. 100 Xianlie Middle Road, Guangzhou City.

[0065] Streptomyces sp. SCUT-1 was inoculated on Gaoshi No. 1 solid medium, pH = 7.2, and cultured at 37°C for 7 days to obtain a Streptomyces sp. SCUT-1 spore plate.

[0066] Streptomyces sp. SCUT-1 spores were inoculated in LB medium, pH = 7.2, and cultured at 40°C for 18 hours to obtain a seed fermentation broth with OD = 7-10 at a wavelength of 660nm;

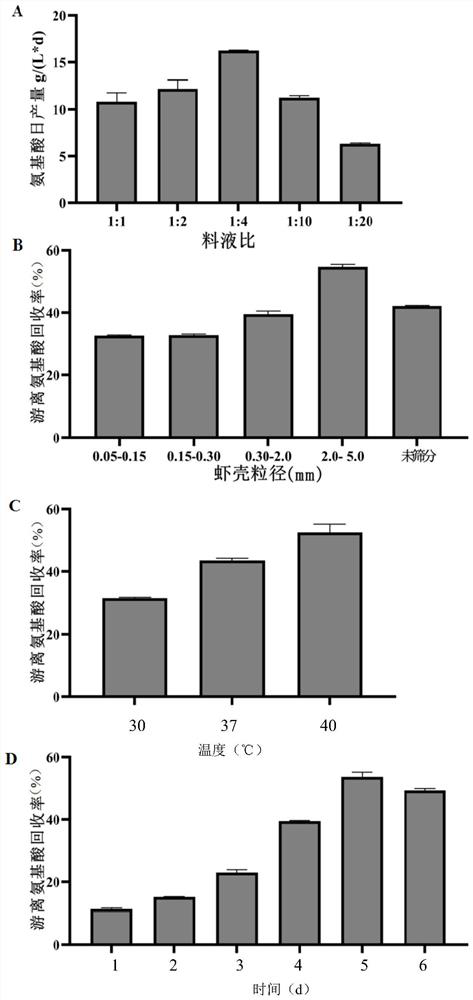

[0067] Shrimp shell waste was sieved using a standard sieve to obtain shrimp shell waste with different particle size...

Embodiment 3

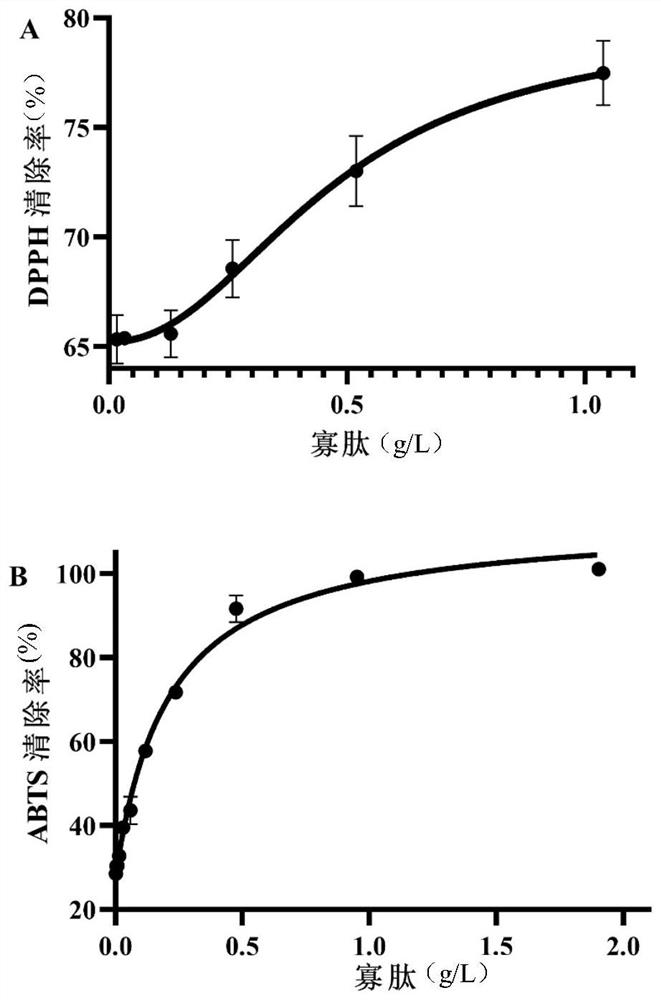

[0074] Example 3: Separating amino acids and oligopeptides from production and analyzing their components

[0075] Streptomyces sp. SCUT-1 was inoculated on Gaoshi No. 1 solid medium, pH = 7.2, and cultured at 37°C for 7 days to obtain a Streptomyces sp. SCUT-1 spore plate.

[0076] Streptomyces sp. SCUT-1 spores were inoculated in LB medium, pH = 7.2, and cultured at 40°C for 18 hours to obtain a seed fermentation broth with OD = 9 at a wavelength of 660nm;

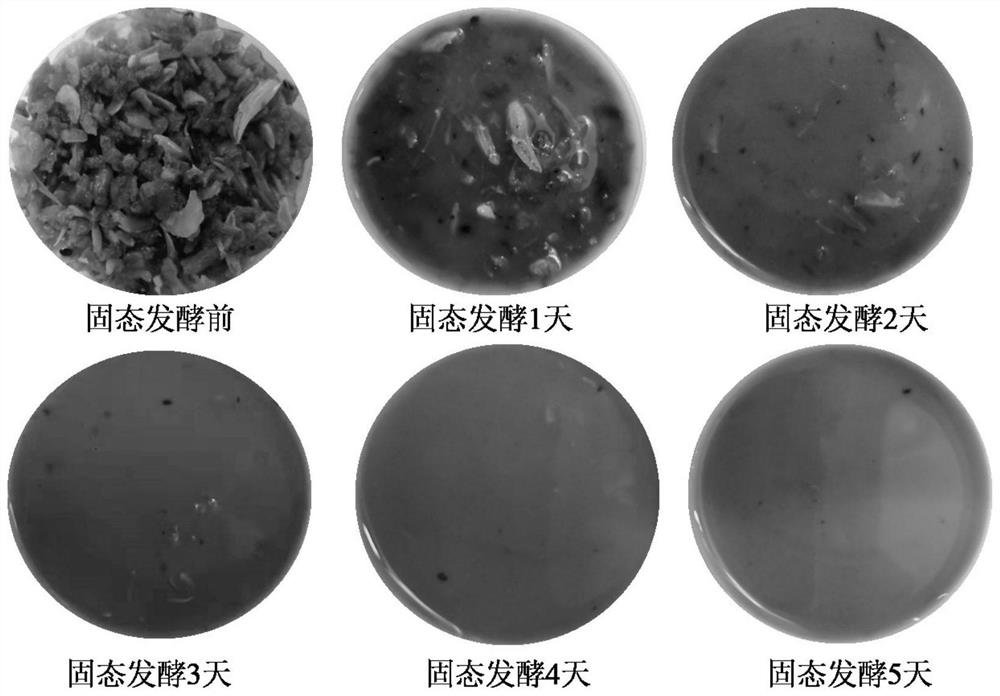

[0077] 25g of shrimp shell waste powder with a particle size of 2.0-5.0mm, 0.3g / L of potassium dihydrogen phosphate, 0.4g / L of dipotassium hydrogen phosphate, 0.5g / L of sodium chloride and 100mL of water were prepared as a fermentation medium; That is: the solid-liquid ratio of shrimp shell waste powder to the water used in the fermentation medium is 1:4, sterilized by moist heat at 121°C for 20 minutes, and after cooling to room temperature, add the seed fermentation liquid with OD=9 at 660nm wavelength, in which the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com