High-purity aluminum oxide with small primary crystal and production method of high-purity aluminum oxide

A technology of high-purity alumina and production method, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of increasing pollution, large size of primary crystal, and increasing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

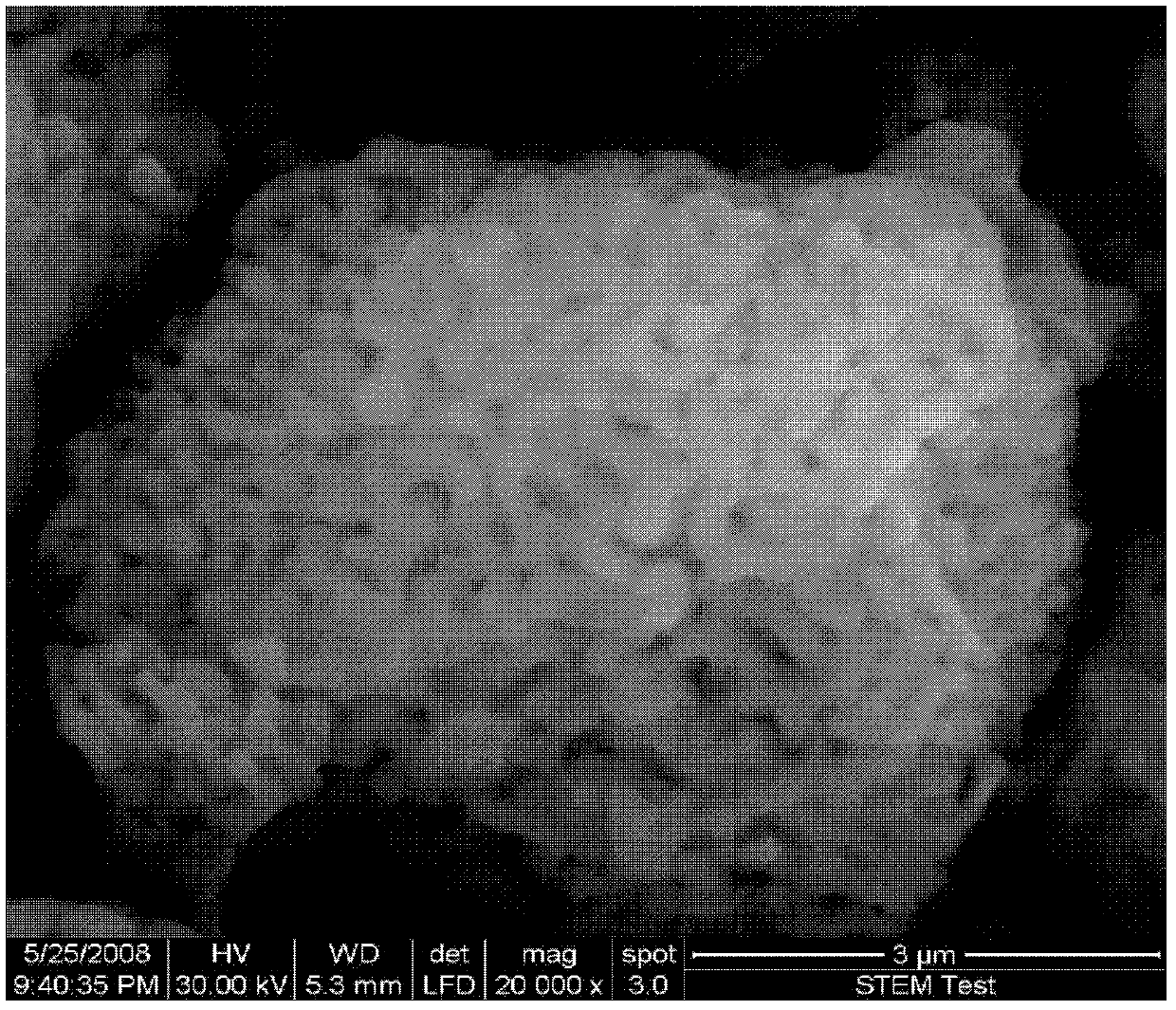

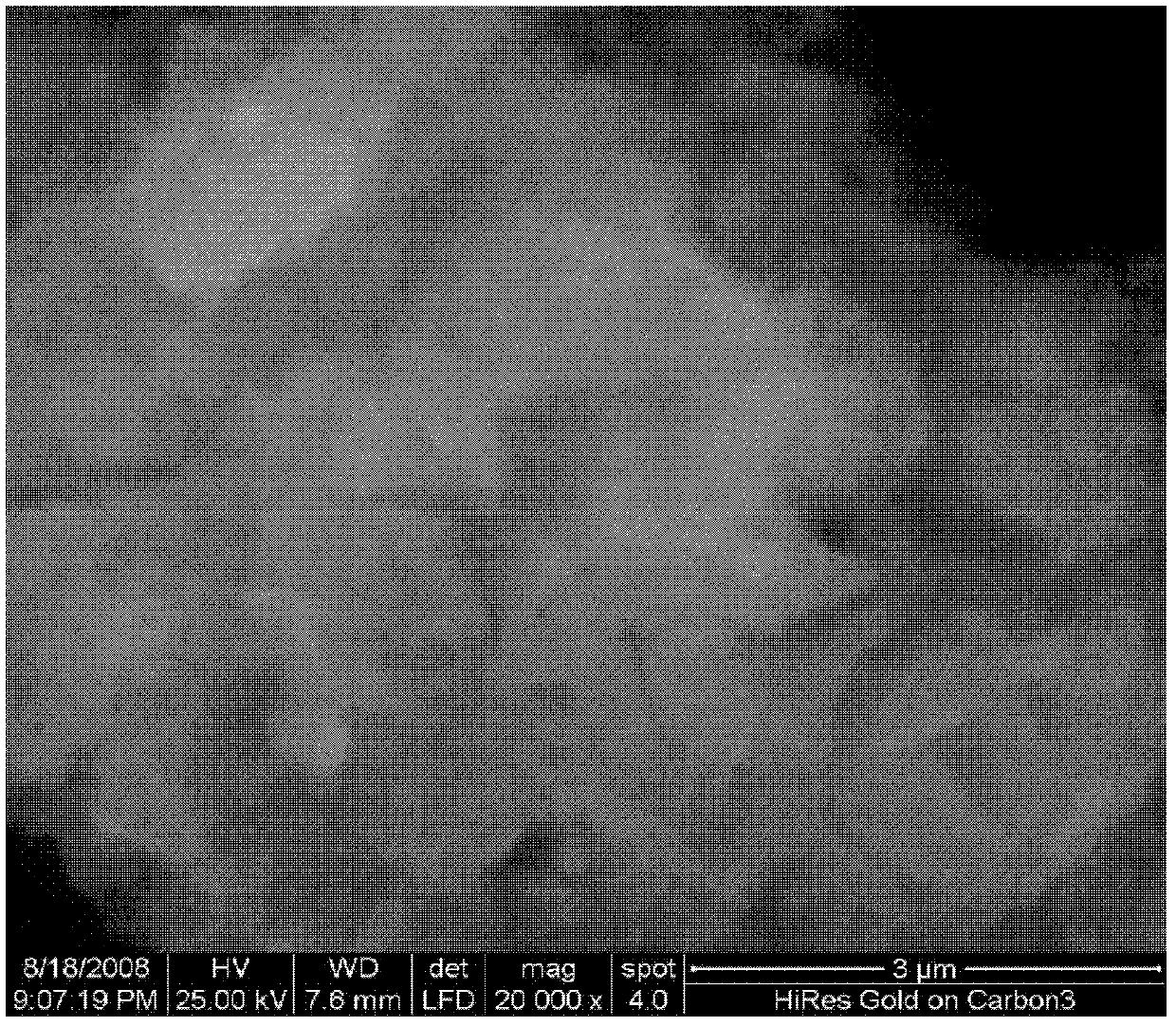

Image

Examples

Embodiment 1

[0014] The specific implementation method of producing small primary crystal high-purity alumina described in the present invention is as follows:

[0015] 1. Liquefy industrial aluminum hydroxide and liquid caustic soda at a high temperature of 110°C to produce sodium metaaluminate solution. Al 2 o 3 The concentration is controlled at 120g / L. At the same time of liquefaction, one or both of activated quicklime or slaked lime is added, and the amount added is 200 times the silicon content.

[0016] 2. After the liquefaction is complete, add industrial aluminum hydroxide again to fully absorb and precipitate impurities. After the addition of aluminum hydroxide was completed, it was stirred under compressed air for 10 min.

[0017] 3. After the stirring is completed, carry out 2 cycles of filtration through a plate and frame filter press.

[0018] 4. Obtain the sodium metaaluminate semen after filtration, and first remove the Al 2 o 3 Dilute the concentration to 50g / L, co...

Embodiment 2

[0022] A specific implementation method for producing small primary crystal high-purity alumina is as follows:

[0023] 1. Liquefy industrial aluminum hydroxide and liquid caustic soda at a high temperature of 150°C to produce sodium metaaluminate solution. Al 2 o 3 The concentration is controlled at 200g / L. At the same time of liquefaction, one or both of activated quicklime or slaked lime is added, and the amount added is 500 times the silicon content.

[0024] 2. After the liquefaction is complete, add industrial aluminum hydroxide again to fully absorb and precipitate impurities. After the addition of aluminum hydroxide was completed, it was stirred under compressed air for 50 min.

[0025] 3. After the stirring is completed, carry out 5 cycles of filtration through a plate and frame filter press.

[0026] 4. Obtain the sodium metaaluminate semen after filtration, and first remove the Al 2 o 3 Dilute the concentration to 120g / L, control the temperature at 90°C, add ...

Embodiment 3

[0030] A specific implementation method for producing small primary crystal high-purity alumina is as follows:

[0031] 1. Liquefy industrial aluminum hydroxide and liquid caustic soda at a high temperature of 130°C to produce sodium metaaluminate solution. Al 2 o 3 The concentration is controlled at 160g / L. One or both of active quicklime or slaked lime is added at the same time of liquefaction, and the amount added is 350 times the silicon content.

[0032] 2. After the liquefaction is complete, add quantitative industrial aluminum hydroxide again to fully absorb and precipitate impurities. After adding aluminum hydroxide, stir under compressed air for 30~40min.

[0033] 3. After the stirring is completed, carry out 5 cycles of filtration through a plate and frame filter press.

[0034] 4. Obtain the sodium metaaluminate semen after filtration, and first remove the Al 2 o 3 Dilute the concentration to 80~90g / L, control the temperature at 75°C, add one or both of salic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com