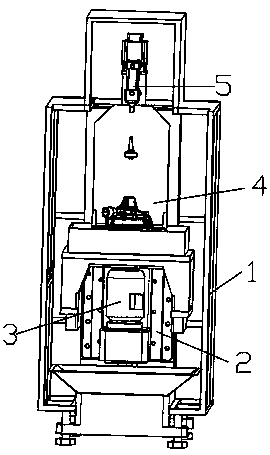

Shell boring, milling and drilling equipment

A drilling equipment, boring and milling technology, applied in the field of production and manufacturing of intelligent processing equipment, can solve problems such as complex shape and high processing ratio, and achieve the effect of avoiding multiple processing and forming, saving time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] For a shell with a regular shape, place the shell on the movable fixture base 2, fix the movable fixture, stop the fixture base on the alignment platform, and automatically adjust the alignment platform to meet the alignment requirements, and then perform drilling.

Embodiment 2

[0042] For shells with irregular shapes, place the shell on the base of the movable fixture, and simulate it with a computer simulation device. The lifting device grabs the shell through mechanical claws, adjusts the position of the mounting plate at the same time, and positions it through the CCD positioning system; If there is no need, confirm whether the telescopic rod is installed according to the telescopic rod; if there is no hole, install the connecting rod, then determine the fixed position, and then adjust the shape of the vacuum capsule, adjust the position of the telescopic rod, and adjust it through the moving device on the power unit. Fixed; at the same time withdraw the movable clamp base.

[0043] For shells with irregular shapes, place the shell on the base of the movable fixture, and simulate it with a computer simulation device. The lifting device grabs the shell through mechanical claws, adjusts the position of the mounting plate at the same time, and positio...

Embodiment 3

[0045] According to the structure and size of the shell, select the number of segments to use the telescopic rod, and also select the size of the corresponding hollow cylinder according to the size of the aperture. On the mounting plate, various types of telescopic rods are provided for optional use.

[0046] For example telescopic rod is provided with six sections, then has five hollow cylinders and a center cylinder, and the outermost layer is the first section, and then the center cylinder is the sixth connection, also has five groups of solid cylinders 7 simultaneously, and the outermost is the first section. One group, followed by the second group, third group, fourth group and fifth group. When it is necessary to use the fifth joint to extend the three joints, the transmission device automatically selects the fourth group of solid cylinders 7, and by rotating the transmission, the fifth joint and the sixth joint protrude together, and stop when the specified length is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com