A Two-stage Condensation and Separation Method and Separation System for Oil and Gas at the Top of a Crude Atmospheric Distillation Tower

A technology for atmospheric distillation column and column top oil and gas, which is applied in the fields of hydrocarbon purification/separation, fractional condensation purification/separation, chemical instruments and methods, etc., and can solve the problems of wide fractions, high energy consumption, and large equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

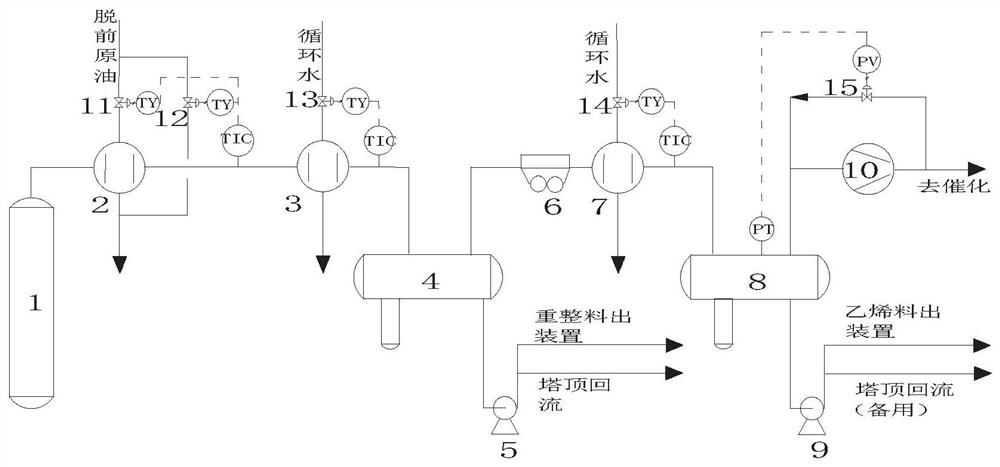

[0057] A certain 2,000,000 tons / year atmospheric distillation unit is provided with tower top oil-gas cooling and separation system of the present invention, during the distillation process of crude oil in atmospheric distillation tower 1, lighter components are distilled from the top of atmospheric distillation tower 1, and After heat exchange and cooling by the first heat exchanger 2 (top oil gas-crude oil heat exchanger) and the second heat exchanger 3 (top oil gas-circulating water heat exchanger), it enters the first return oil tank 4. At this time, the The temperature of the oil gas at the input end of the return oil tank 4 is 85-90°C.

[0058] The liquid phase in the first reflux oil tank 4 is pumped out by the first oil pump 5, and part of it is used as a reformate product to exit the device, and the other part is used as the top reflux of the atmospheric distillation column 1, and the gas phase is passed through the air cooler 6 and the third heat exchanger. The devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com