High-power fiber laser amplification stage fiber entrance point replaceable heat exchange module

A fiber laser and heat exchange module technology, applied in the direction of lasers, laser parts, laser parts, etc., can solve the problems of increasing maintenance costs and maintenance time, burning out fiber slots, temperature rise, etc., to achieve fast and convenient maintenance and replacement, Fast heat dissipation and optimized cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the purpose, structure and function of the present invention, a heat exchange module with a high-power fiber laser amplification stage replaceable fiber entry point of the present invention will be described in further detail below with reference to the accompanying drawings.

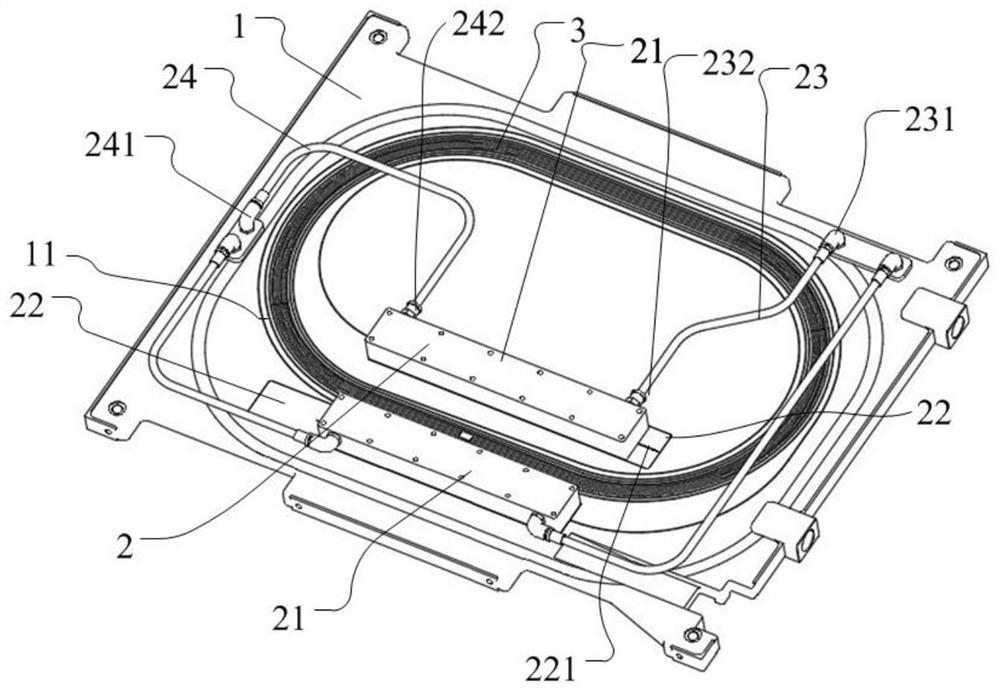

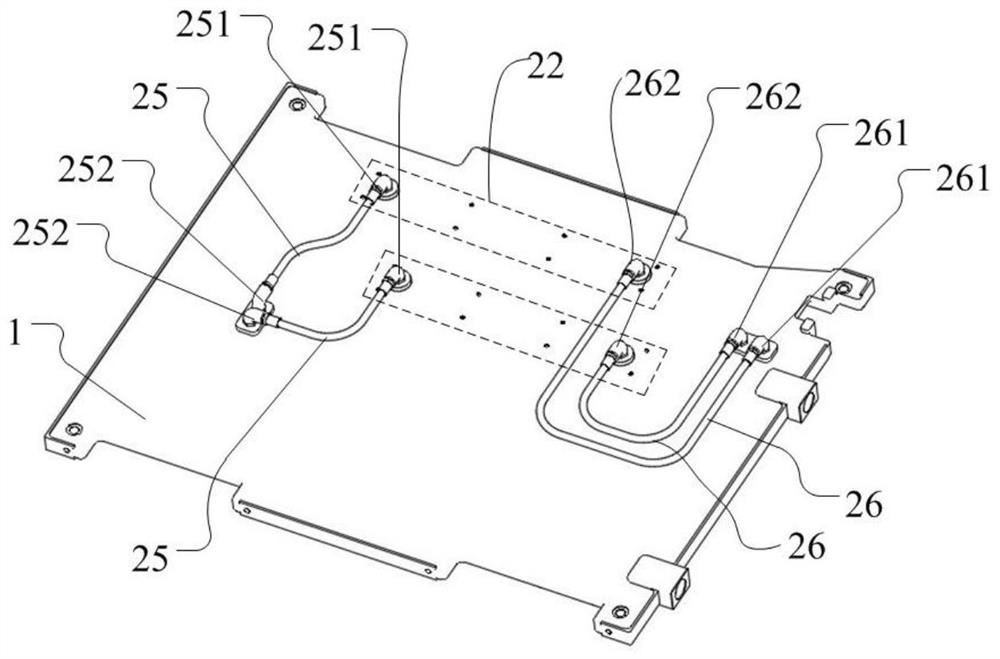

[0030] see attached Figure 1-4 , the embodiment of the present invention provides a high-power fiber laser amplification stage with a replaceable heat exchange module at the fiber entry point, including: an amplification stage liquid cold plate 1 and a fiber entry point heat exchange module 2 .

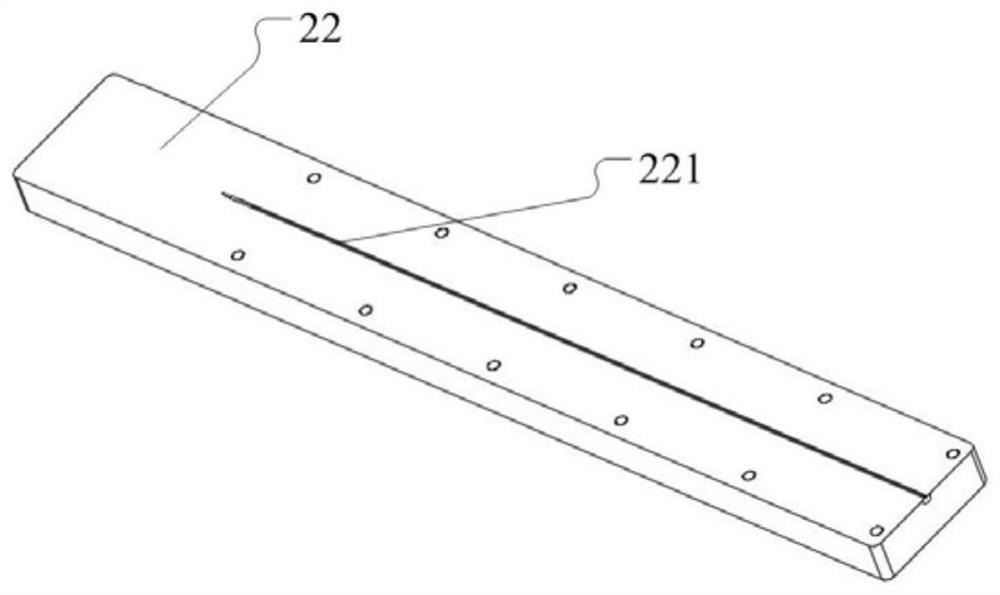

[0031] The fiber entry point heat exchange module 2 is composed of a water cooling cover 21 with a cavity and a water cooling block 22 with a cavity. The water cooling block 22 is detachably connected to the upper surface of the amplification stage liquid cooling plate 1, and the water cooling block 22 is provided with The optical fiber slot 221 and the water cooling cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com