Patents

Literature

510results about How to "Fast heat dissipation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

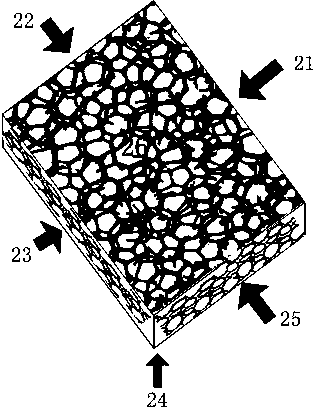

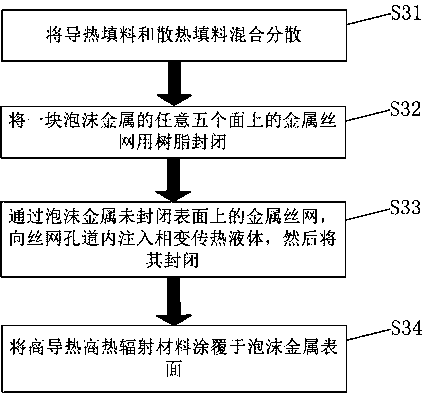

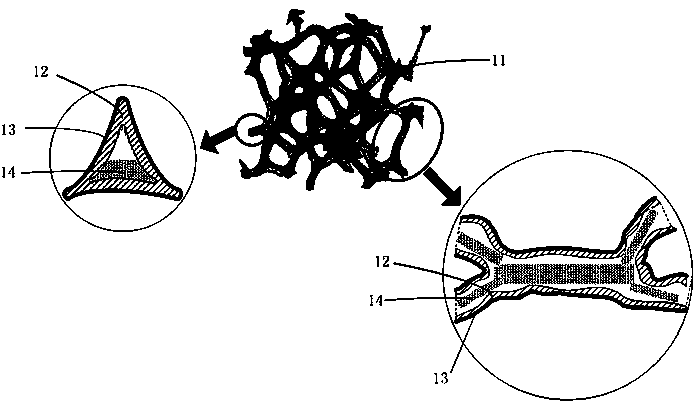

Three-dimensional network porous heat-conducting heat radiation device and preparation method thereof

PendingCN107936777AImprove thermal conductivitySmall specific surface areaSemiconductor/solid-state device detailsSolid-state devicesHeat conductingElectron

The invention relates to a three-dimensional network porous heat-conducting heat radiation device and a preparation method thereof. The three-dimensional network porous heat-conducting heat radiationdevice comprises foam metal, high-heat-conduction high-heat-radiation material and a phase-changing heat transferring material, wherein the heat transferring performance is improved by virtue of the phase-changing heat transferring material filling pores inside a foam metal skeleton wire net, the heat radiation performance is improved by virtue of the high-heat-conduction high-heat-radiation material smeared on the surface of the foam metal skeleton, and the three-dimensional network porous heat-conducting heat radiation device is suitable for the electron industry and solves the heat radiation problem of heating elements and devices.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

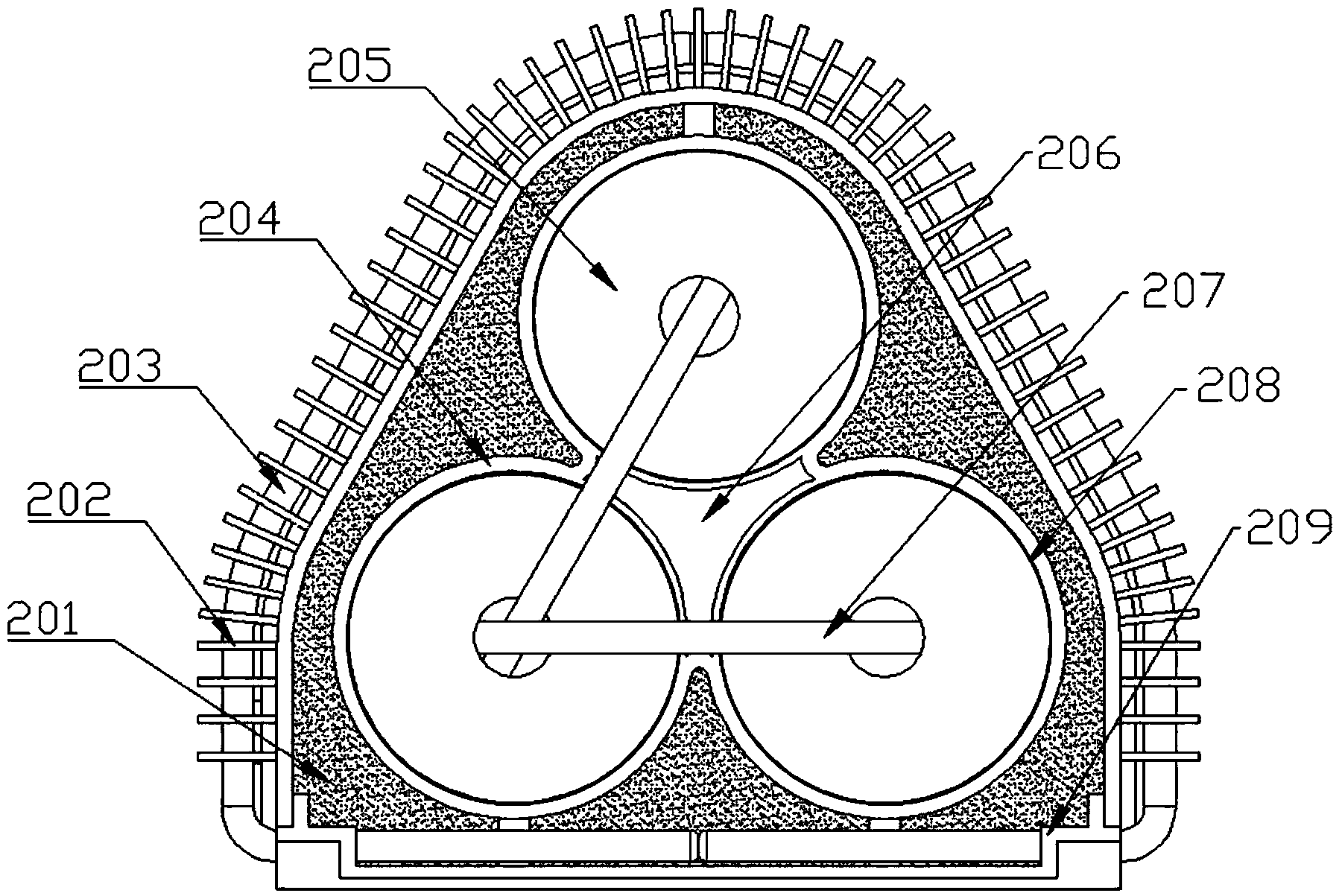

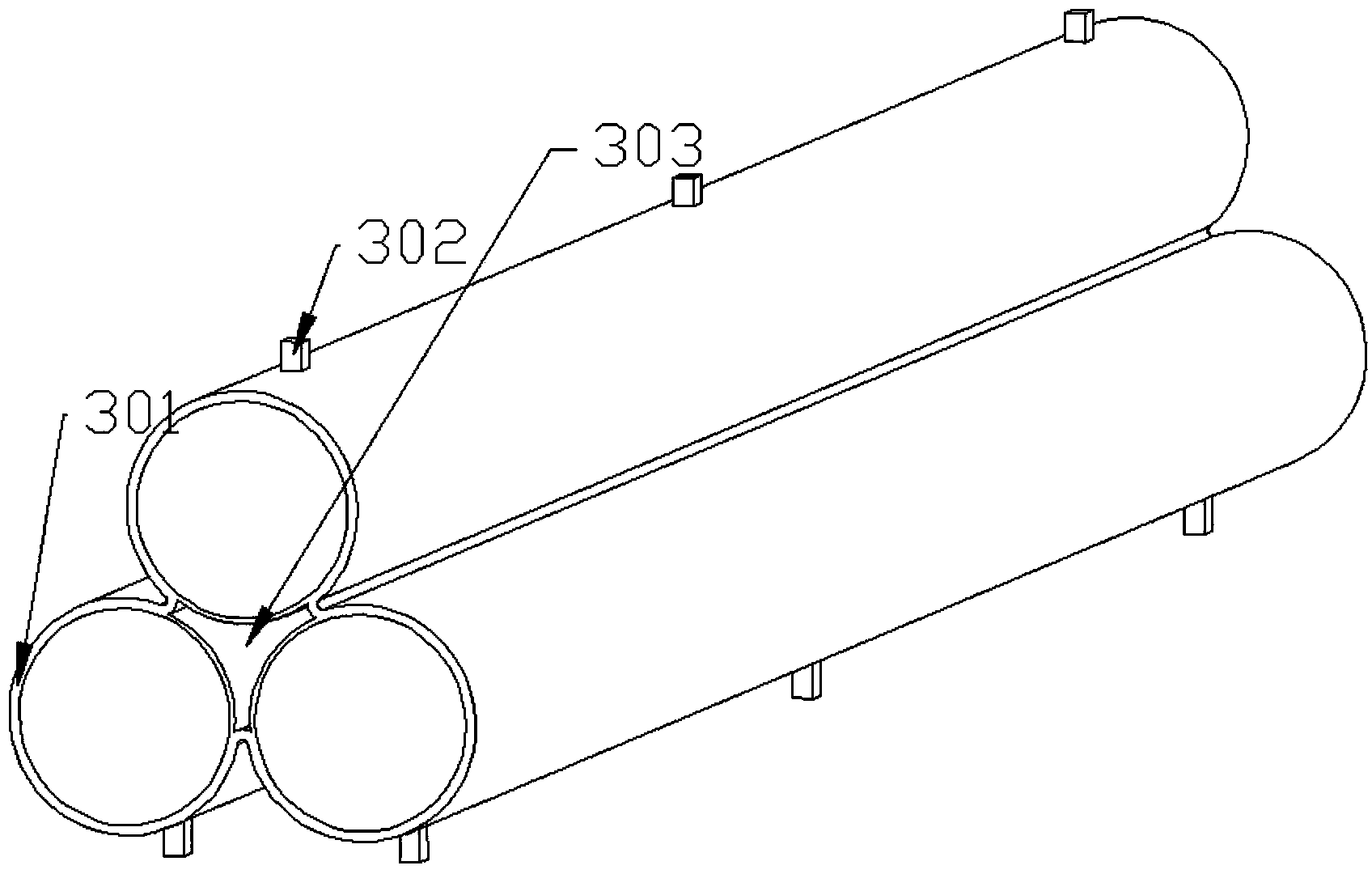

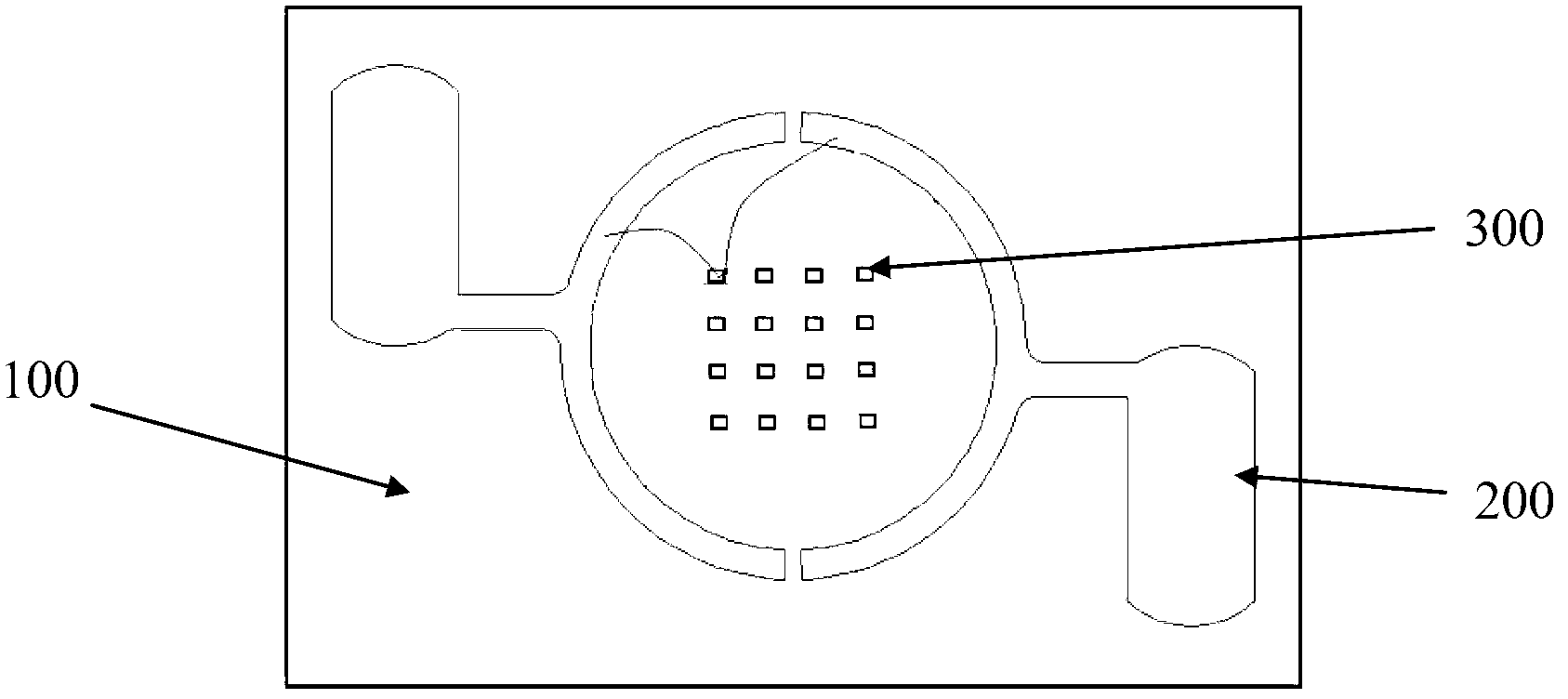

Power battery module based on air, hot pipe and phase-change material coupled cooling

ActiveCN104393366AImprove heat transfer performanceCompact structureSecondary cellsElectrical batteryEngineering

A power battery module based on air, hot pipe and phase-change material coupled cooling belongs to power battery modules. Each cylinder of a trifolium-type sleeve of the power battery module is inside provided with a plurality of cylindrical cell individuals in serial connection, and all cylinder battery groups have same quantity of the cell individuals in serial connection, and are in parallel connection. The power battery module reasonably combines the advantages of air cooling, hot-pipe cooling and phase-change material cooling, a hot pipe exports heat in cell bottoms of which the heat radiation property is relatively bad, a fin is used to export heat in the phase-change material and the hot pipe, and air natural convection or forced convection cooling is reasonably employed for assisting heat radiation of the fin. The battery module is obvious in battery temperature-controlling effect, simple and compact in structure and convenient for mounting and dismounting, and a large battery group can be formed by connecting multiple modules. A plurality of the power battery modules can be properly combined and designed for being applied to various electric equipment driven by power batteries, and wide market prospect is provided.

Owner:CHINA UNIV OF MINING & TECH

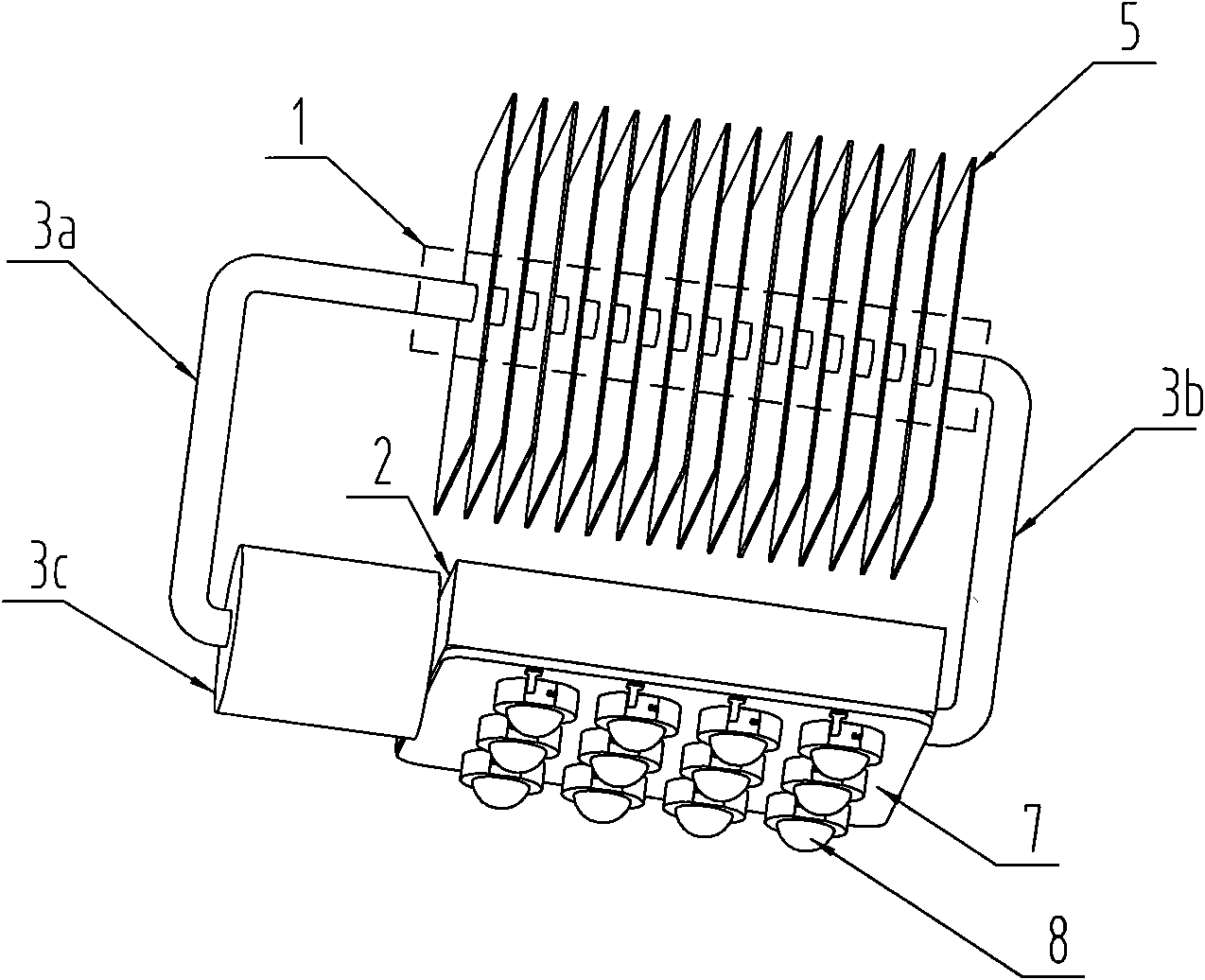

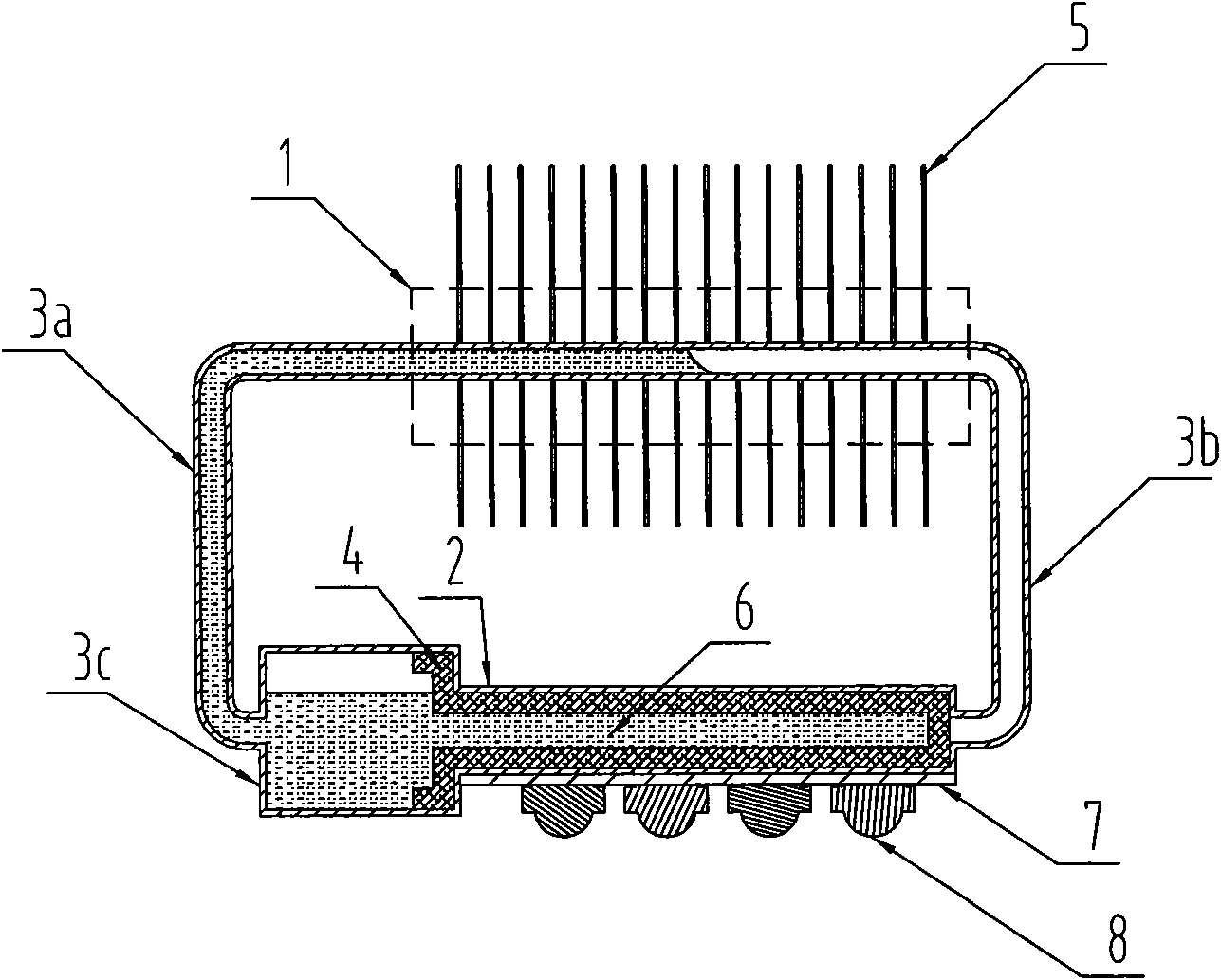

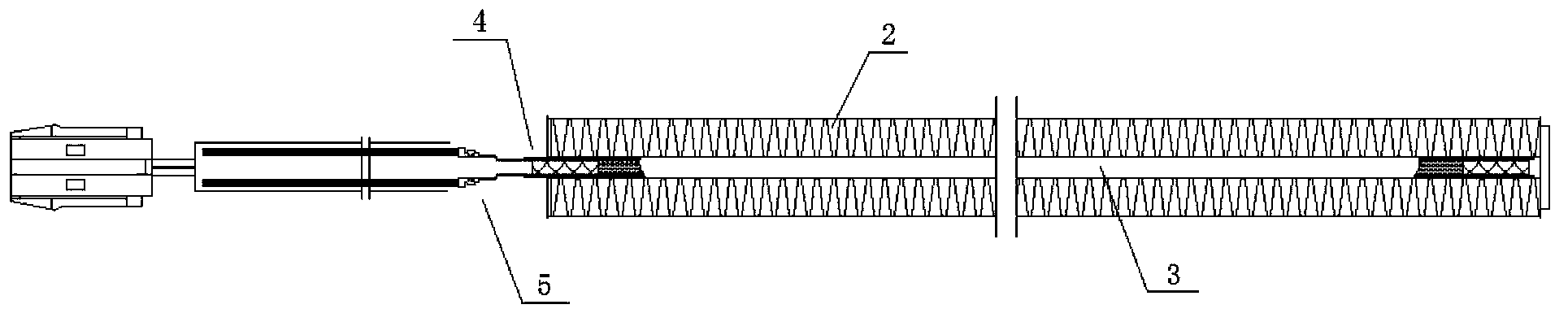

Heat radiation device for loop heat pipe with enhanced evaporation section used in LED lamp

InactiveCN101608788AImprove luminous efficiencyReduce light decay speedPoint-like light sourceSemiconductor/solid-state device detailsRefluxMicro-loop heat pipe

The invention discloses a heat radiation device for a loop heat pipe with an enhanced evaporation section used in an LED lamp. The heat radiation device comprises: a heat pipe, a radiating fin and a working liquid. The heat pipe is a loop pipe with a sealed cavity, comprising: an enhanced evaporation section, a reflux section, a steam section, a compensation chamber and a condensing section; the enhanced evaporation section is arranged at the back of a heat source of the LED lamp; the loop pipe is vacuumed properly, internally provided with a wick structure and filled with a proper amount of working liquid; and the radiating fin is arranged on the condensing section. The heat radiation device has the advantages of reasonable and compact structure, easy production, high heat conduction efficiency and high heat radiation speed. The enhanced evaporation section is contacted with the heat source surface directly and sufficiently, therefore, the heat radiation device can effectively reduce the temperature of the LED modules, solve the heat radiation problem of large-power LEDs, improve the light emitting efficiency of LEDs, reduce the light degradation speed of LEDs and prolong the service life of LEDs. Simultaneously, the heat radiation device can reduce the volume and the weight of LED lamps and improve the adaptability and the use range of the LED lamps.

Owner:史杰

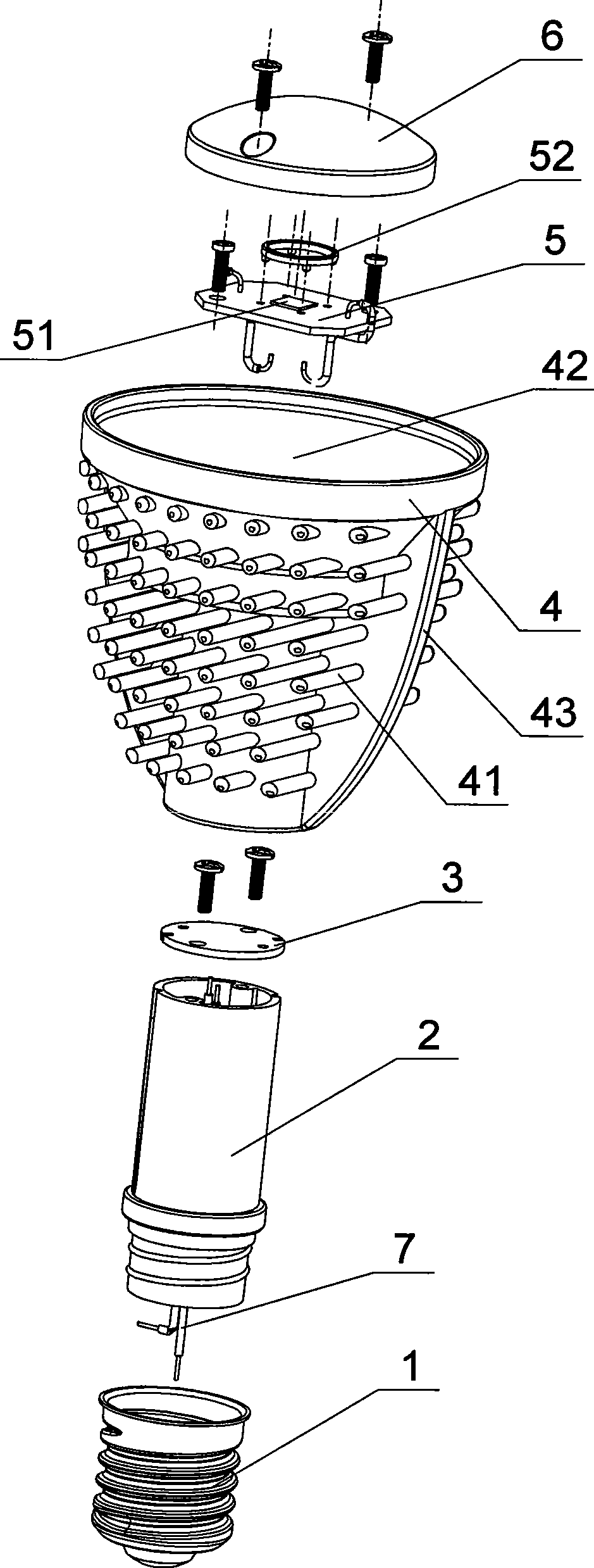

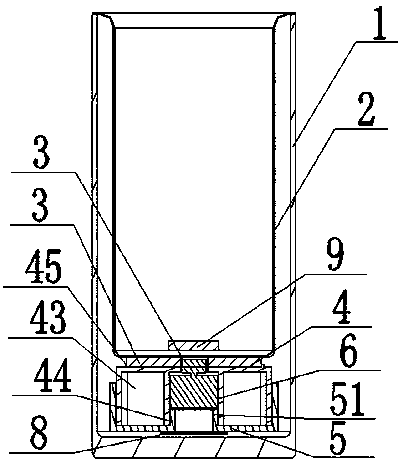

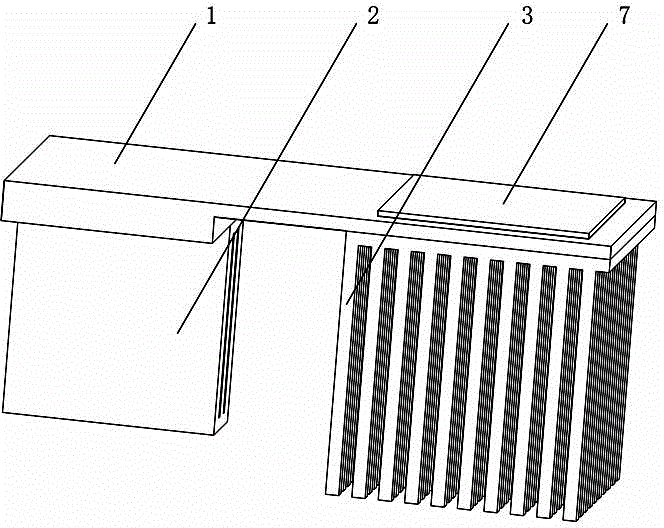

LED bulb

InactiveCN101363610AImprove distributionSmooth circulationPoint-like light sourceSemiconductor/solid-state device detailsEngineeringLight penetration

The invention discloses an LED lamp bulb with an excellent dissipation effect. The LED lamp bulb comprises a lamp head (1), an insulation fixed seat (2) which is fixedly connected with the lamp head (1), a driving circuit board (3) fixedly connected with the insulation fixed seat and an LED chip (51); the driving circuit board (3) is electrically connected with the lamp head (1) and the LED chip (51) through conductors (7) respectively; the LED lamp bulb also comprises a heat dissipation lamp shell (4), and a light penetration protective screen (6); the heat dissipation lamp shell (4) is fixedly connected with the insulation fixed seat (2); the LED chip (51) is connected with a heat dissipation baseplate (5) which is fixedly connected with the heat dissipation lamp seat (4); the light penetration protective screen (6) covers the outside of the heat dissipation baseplate (5) and the LED chip (51); the external wall of the heat dissipation shell (4) is provided with a plurality of heat dissipation rods (41). The LED lamp bulb can be widely applied in the field of LED lamp bulbs.

Owner:NANKER GUANGZHOU SEMICON MFG

Aluminum alloy for automobile wheel hub and automobile wheel hub production process

The invention relates to aluminum alloy for an automobile wheel hub and an automobile wheel hub production process. The aluminum alloy comprises: 0.4%-0.8% of Si, 0.8%-1.2% of Mg, 0.15%-0.4% of Cu, 0.7% of Fe, 0.15% of Mn, 0.25% of Zn, 0.15% of Ti and the balance being Al. The production process includes the following steps: S1, blank preparation; S2, blank forging pretreatment; S3, mold pretreatment; S4, forging; forging with a 55MN-65MN forging machine and packing for 20min-30min to obtain a forging blank; and S5, roll forming; before cooling, transferring a wheel hub into an aging treatment apparatus and heat preserving for 6h-8h at the temperature of 170 DEG C-190 DEG C. The aluminum alloy for the automobile wheel hub has the advantages that weight is light, heat dissipation is fast, strength is high, vibration reducing performance is good, service life is long, and waste wheel hubs can be recycled.

Owner:CHENGDU SUNSHINE ALUMINUM

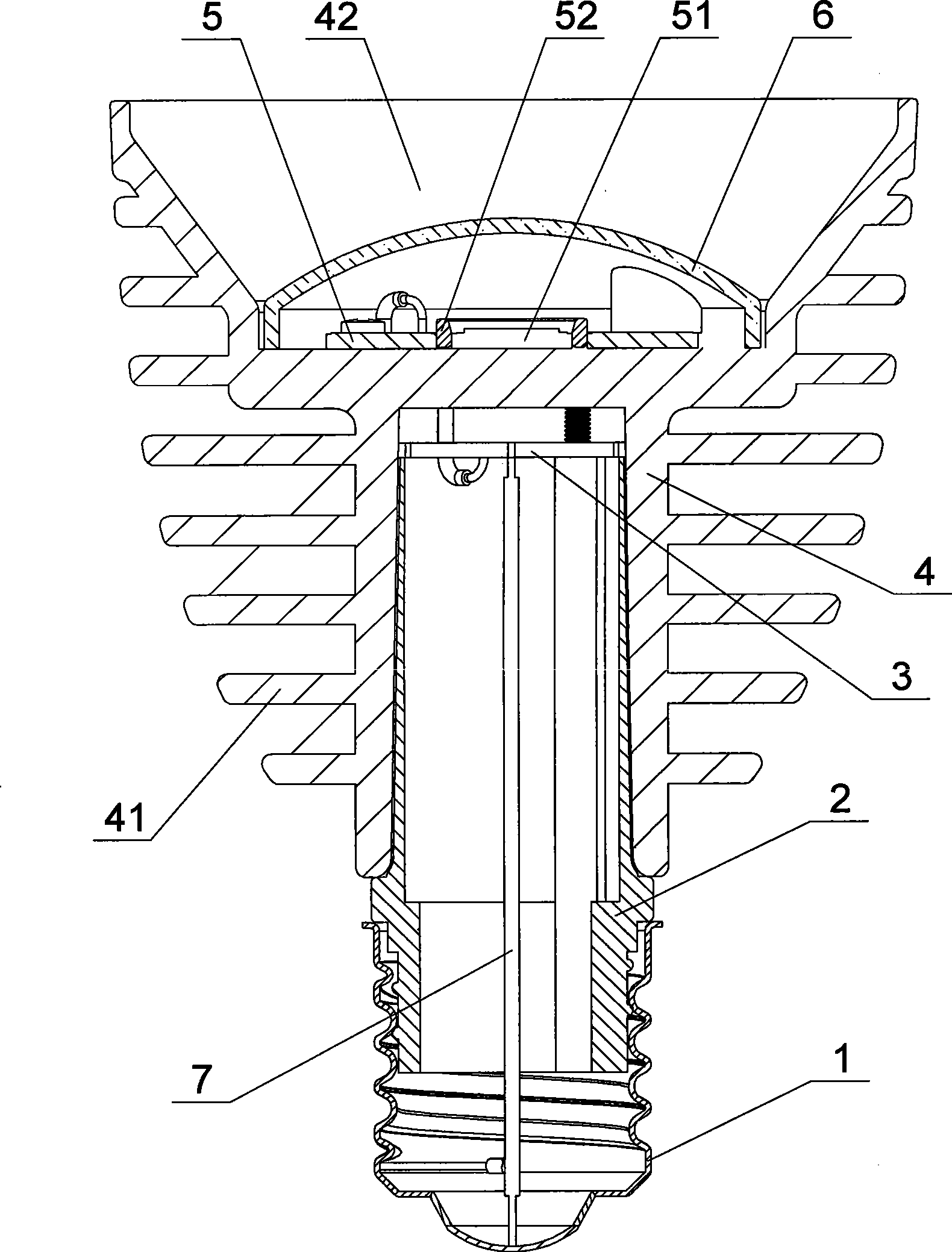

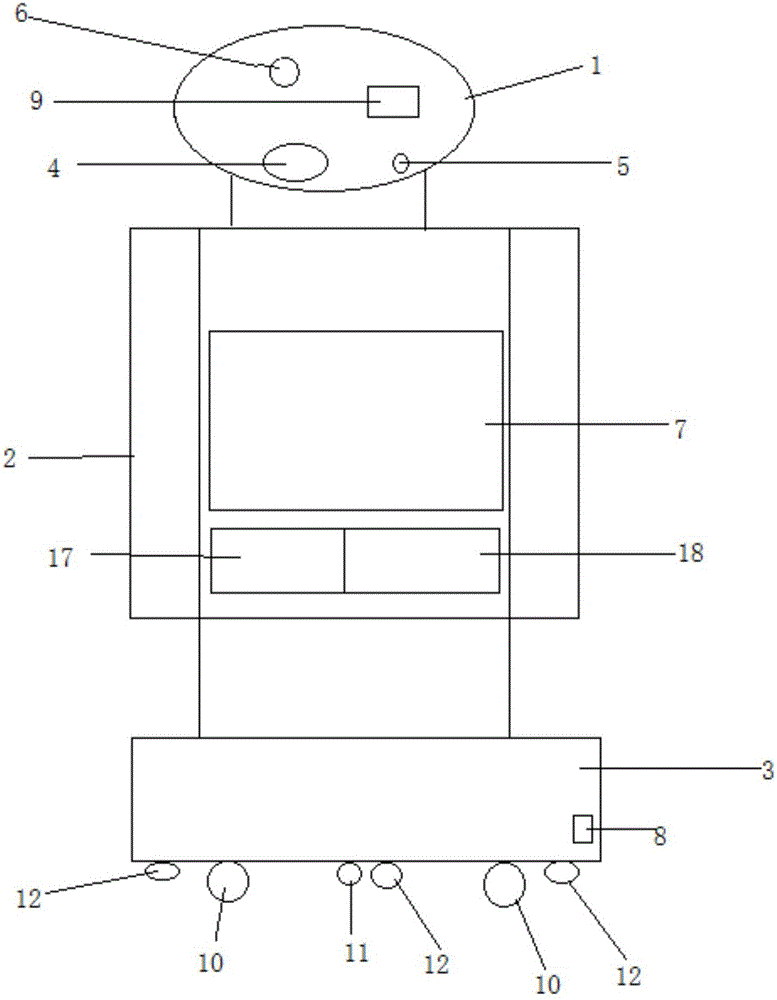

Intelligent business hall robot and indoor walking deviation automatic correction method thereof

PendingCN106054895AImprove recognition accuracyThe case for effective human-computer interactionPosition/course control in two dimensionsVehiclesDrive wheelUltrasonic sensor

The invention provides an intelligent business hall robot and an indoor walking deviation automatic correction method. The robot is provided with a speaker, a microphone, a pick-up head, a touch panel, a switch, a TFT screen, driving wheels, an angle sensor, ultrasonic sensors, driven wheels, a battery, motors, a single-chip microcomputer control module, a barrier-avoiding cruise module, a human induction module, a processor module, a constant-current plate and a display screen. Further provided is a method for adjusting deviations in a walking process by use of the intelligent business hall robot through continuous adjustment of the ultrasonic sensors and the angle sensor. The robot provided by the invention can continuously correct the deviations of the robot in a waling line, can also realize such functions as man-machine interaction, face identification work attendance check, buffer storage and the like, corrects the line while walking in the walking process and realizes linear walking.

Owner:湖南晖龙集团股份有限公司

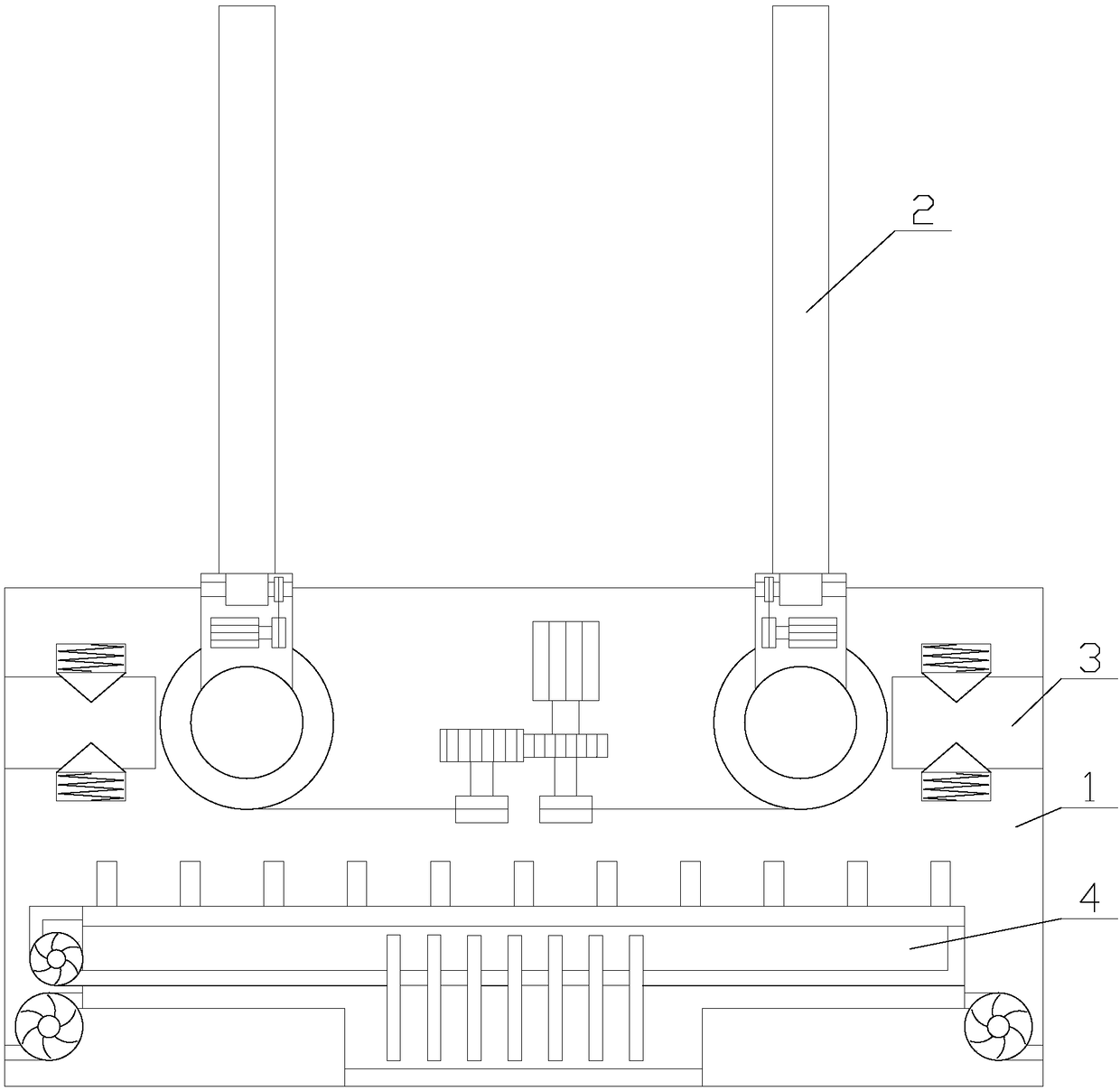

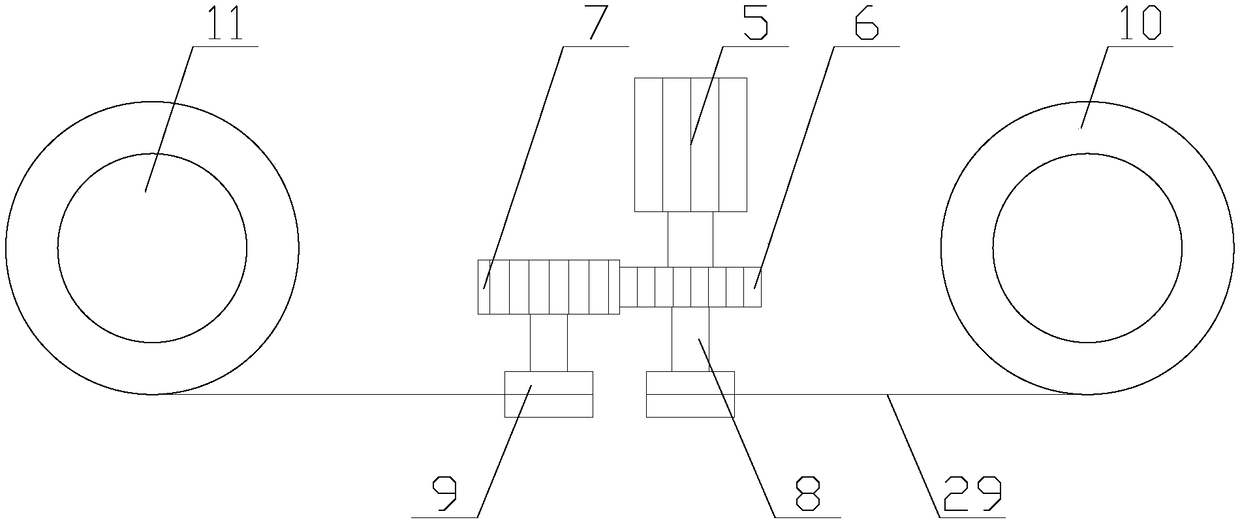

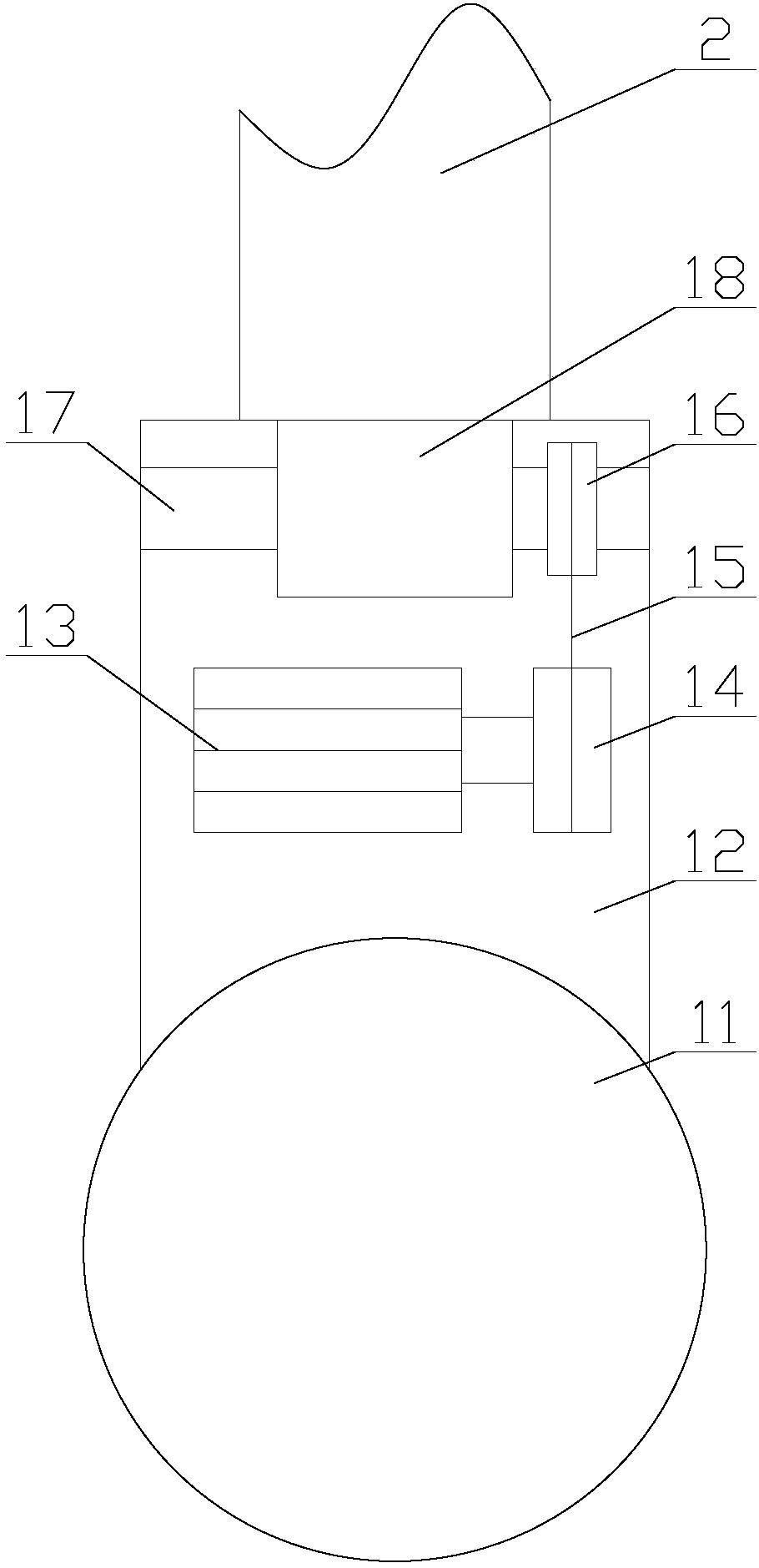

Wireless router with antenna angle regulating and radiating function

ActiveCN108322398AEasy to moveAvoid automatic shutdownData switching networksCooling/ventilation/heating modificationsWireless routerDrive wheel

The invention relates to a wireless router with an antenna angle regulating and radiating function. The wireless router comprises a main body and two antennas, a regulating mechanism, a radiating mechanism and two locking mechanisms; the regulating mechanism comprises a driving unit and two fixed blocks; the driving unit comprises a first motor, a first gear, a second gear and two transmission components; the rotating unit comprises a second motor, a driving wheel, a second fixed rope, a movable wheel, a rotating rod and a connecting block; the radiating mechanism comprises a heat-absorbing plate, a water pump, a radiating pipe, a radiating chamber and two air blowers. The wireless router with the antenna angle regulating and radiating function can regulate the antenna angle according to user demand through a regulating mechanism, thereby increasing the indoor signal coverage distance and strength; the wireless router can realize continuous cooling through the radiating mechanism, thereby preventing the wireless router from automatically turning off due to excessive temperature, so that the people can normally send or receive the information.

Owner:嘉兴觅特电子商务有限公司

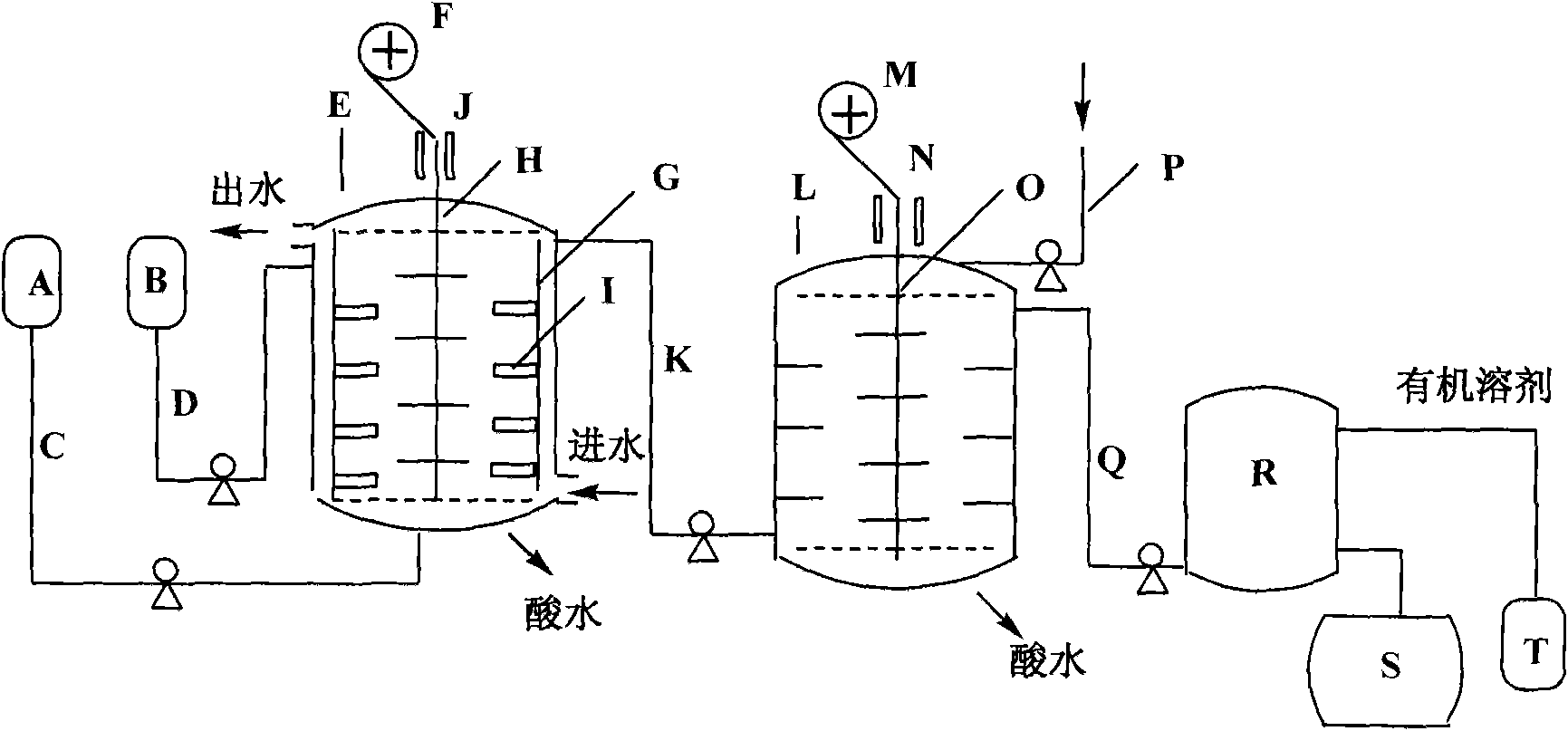

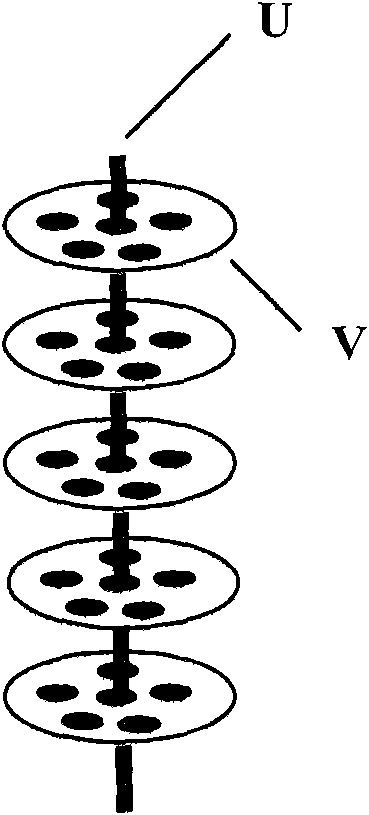

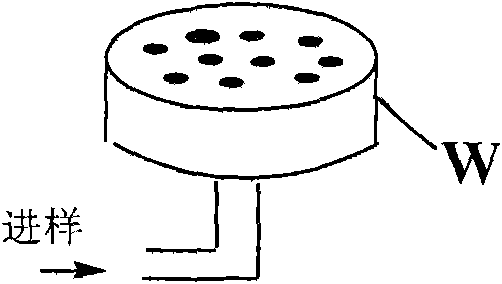

Alkyl silicone continuous production system and production method

The invention relates to an alkyl silicone continuous production system and a production method thereof. The production system comprises a reaction still and a washer; a first reciprocating sieve plate and a second reciprocating sieve plate are respectively arranged in the reaction still and the washer and driven to reciprocate by a motor and an eccenter; a conduit is connected between the reaction still and the washer, a tap water input conduit is arranged on the top of the washer and a water outlet is arranged at the bottom of the washer; alkylsilanol solution flows into the bottom of the washer through a conduit, and a conduit is arranged between the washer and a vacuum distillation tower; the vacuum distillation tower is communicated with a product storage pot through a conduit. The production method includes that alkylchlorosilane reactant solution and hydrolysate are prepared; alkylchlorosilane is hydrolyzed under 1-25 DEG C, the hydrolyzed silanol solution is separated from a settling chamber on the top of the washer, washed in the washer and conducted to the washer bottom through a flowmeter by 0.1-1.0 cubic meters per hour; water is sent in from the washer top through the flowmeter by 0.2-5.0 cubic meters per hour; the silanol solution is washed in countercurrent until the pH value is 6.5-7 and then condensed in vacuum to become alkyl silicone.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

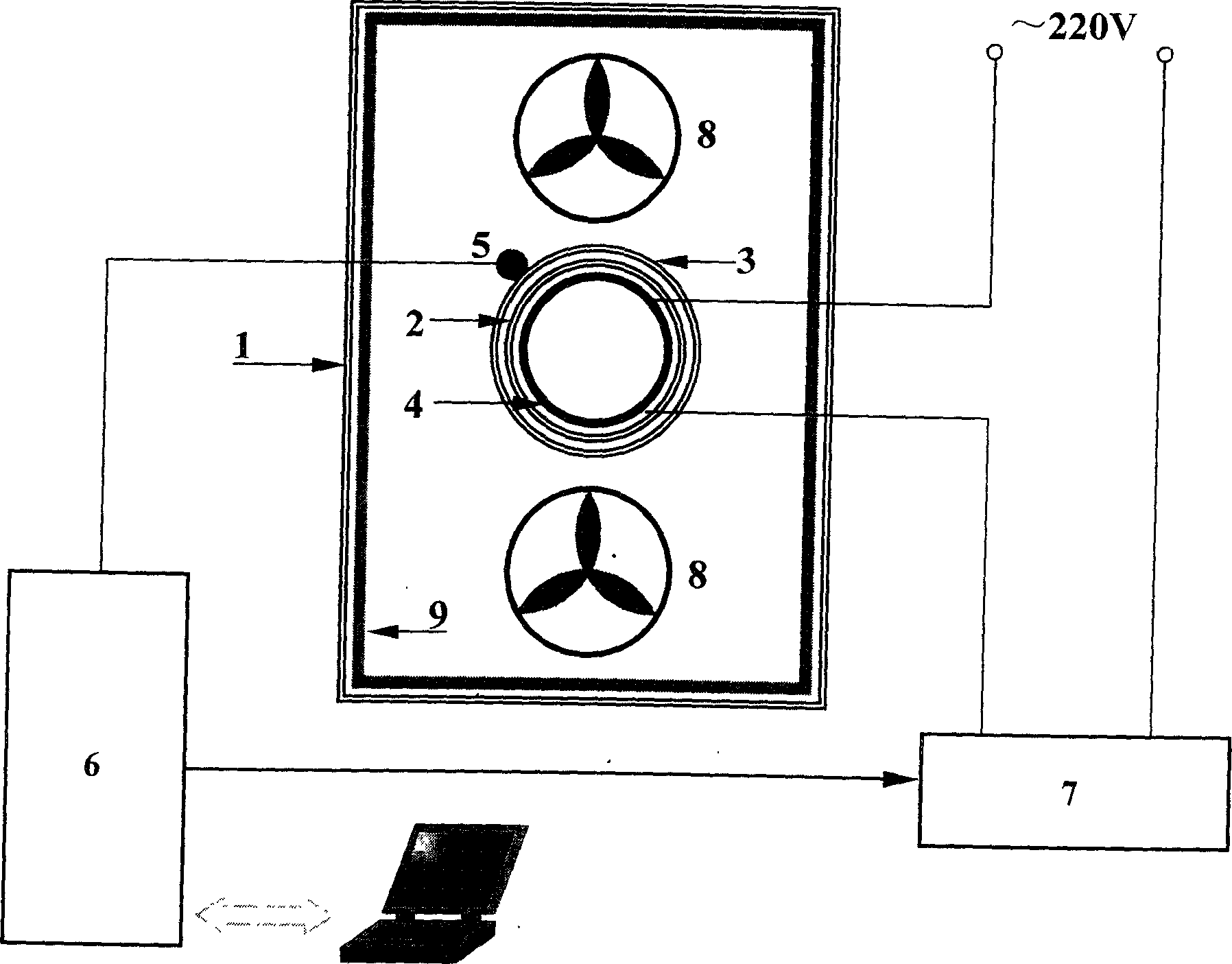

Minisize chromatographic column box with high precision temperature control system

InactiveCN1877319AImprove thermal conductivityImproved coefficient of thermal expansionComponent separationTemperatue controlTemperature controlControl system

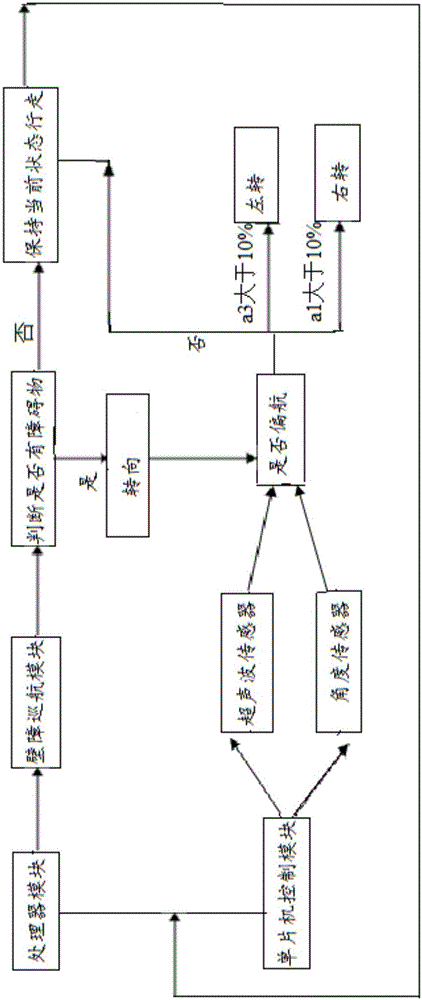

The invention discloses a micro chromatographic column tank which comprises a tank body, capillary column heating frame set in the tank, capillary column bound around the frame, a heating device set on the inner wall of the frame, a precise thermo resistor and a temperature control system set out of the tank. The capillary column heating frame employs metal alloy material; the capillary column employs quartz material; the heating device is flexible electrical heating membrane coated on the inner wall of the frame; the temperature control system includes a temperature control module, the precise thermo resistor connects with the signal input terminal of the temperature control module, the output terminal of the temperature control module connects with the insulating single-phase alternative current modulator module of which one end of the output terminal connects with the heating device, and the other end of the output terminal connects with the input power.

Owner:张西咸 +3

Automatic hot water stirring cup

An automatic hot water stirring cup comprises a cup body and a liner, the upper portion of the liner is connected with the cup body, a containing cavity is formed among the liner, the side wall of thecup body and the bottom of the cup body, one surface of a power generating piece is connected on the outer surface of the bottom of the liner, the other surface of the power generating piece is connected on the upper surface of a metal cup bottom cover, a cup bottom is connected on the lower portion of the cup bottom cover, the cup bottom and the cup bottom cover form a heat-conducting medium containing chamber, a heat-conducting medium is stored into the heat-conducting medium containing chamber, a motor is arranged in the cup bottom cover, the power generating piece is connected with the motor through a PCB (printed circuit board), a shaft of the motor is connected with a magnet, a magnet is arranged at the position corresponding to the inner surface of the bottom of the liner, and themotor drives the magnets to rotate to generate magnetic force, so that water is stirred. The power generating piece of the cup generates power by the aid of the temperature difference of hot water todrive the motor to rotate, the magnet is connected on the shaft of the motor, the motor drives the magnets to rotate to generate the magnetic force, water in the cup is stirred, stirring and cooling are achieved, the integrity of the liner is not broken, and cleaning is facilitated.

Owner:苏州心工匠电子科技有限公司

Tapered cylindrical membrane electrode for oxyhydrogen proton exchange membrane fuel cell

The invention discloses a tapered cylindrical membrane electrode for oxyhydrogen proton exchange membrane fuel cell, which is characterized by comprising an anode in contact with hydrogen, a composite membrane and a cathode in contact with air from inside to outside; the composite membrane is composed of a proton exchange membrane (which usually is a Nafion membrane), an output joint is arranged at a anode plate, a seal ring used for isolating the anode output joint from the composite membrane and the cathode is arranged at the anode output joint and a cathode output joint is arranged at the bottom of the cathode; and the anode is in a cone shape, the composite membrane is in a cone shape matched with the cone shape of the anode, the cathode is a hollow pipe, the outside surface of the cathode hollow pipe is cylindrical and the inner hole of the cathode hollow pipe takes a shape of a cone hole with the same conical degree as the cathode. In the invention, the structure is reasonable and crucially a conical structure is adopted to ensure that a problem of the close fit between the cylindrical oxyhydrogen proton exchange membrane fuel cell electrode and the composite membrane can be solved, therefore, the battery performance can be greatly enhanced, and the manufacture and the assembly can be convenient.

Owner:NANTONG UNIVERSITY

Full spray welding method for boundary of inner cavity of copper alloy glass mould

InactiveCN102806408AImprove performanceIncrease the cost of spray weldingArc welding apparatusPlasma welding apparatusCopper alloyWelding process

The invention discloses a full spray welding method for a boundary of an inner cavity of a copper alloy glass mould. The full spray welding method comprises the following steps: performing rough cutting treatment on the inner cavity of the copper alloy glass mould and confirming the treating size as 45-55% of the size of a spray welded layer; heating a treated to-be-welded mould to be at 750-800 DEG C; performing spray welding treatment on the boundary of the inner cavity of the mould by using a plasma welding machine and continuously keeping the temperature of the mould at 750-780 DEG C during the welding process; and placing the mould after being spray-welded into an annealing furnace and performing annealing treatment. According to the processing method provided by the invention, before the spray welding for the mould, all welding surfaces are subjected to the rough cutting treatment, and due to the control on the treating size, the size of the spray welded layer meets the requirement; a heating gun is used for continuously keeping the temperature of the mould during the spray welding process, so that the carburization of the mould is more effectively controlled; the stability of the size of the spray welded layer is ensured; and the whole property of the mould is increased.

Owner:CHANGSHU JINGGONG MOLD MFG

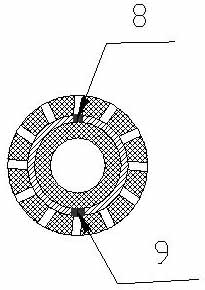

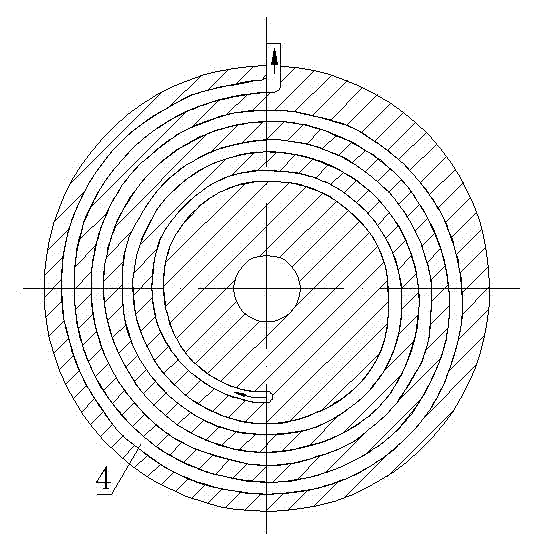

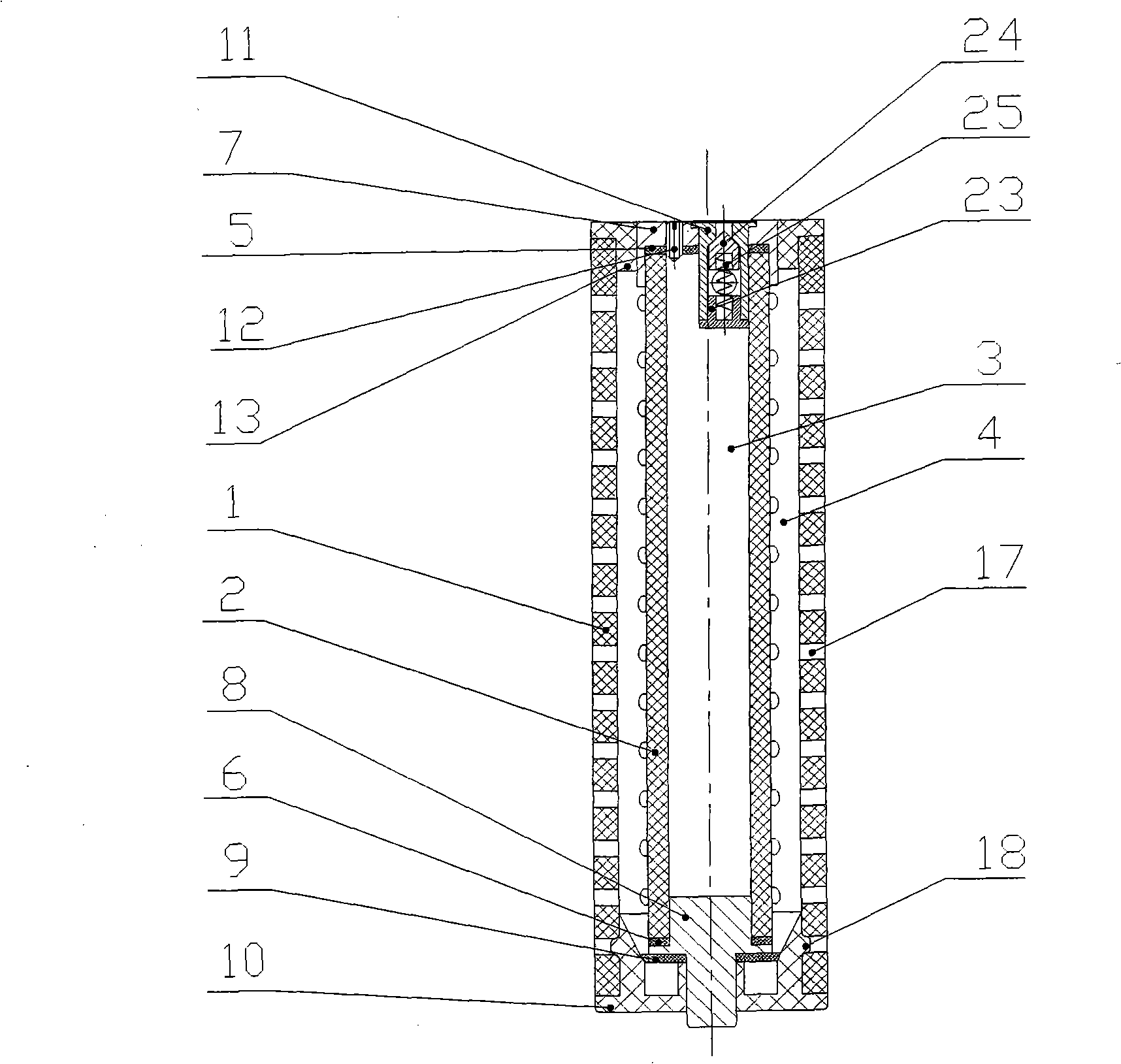

Disc-type permanent magnet motor with sealed cooling structure

InactiveCN102790473AIncrease cooling areaFast heat dissipationCooling/ventillation arrangementSupports/enclosures/casingsWater channelCooling effect

The invention discloses a disc-type permanent magnet motor with a sealed cooling structure. The disc-type permanent magnet motor comprises a casing, and a drive side end cover and a non-drive side end cover which are arranged at the two sides of the casing, shaft holes are arranged at the centers of the drive side end cover and the non-drive side end cover; windings are respectively arranged on the drive side end cover and the non-drive side end cover; and a rotating shaft is arranged between the two shaft holes. The disc-type permanent magnet motor is characterized in that a spiral end cover water channel I and an end cover water channel II are respectively arranged inside the drive side end cover and the non-drive side end cover, and the outlet of the end cover water channel I and the inlet of the end cover water channel II are respectively arranged on the outer brims of the drive side end cover and the non-drive side end cover; a water inlet communicated with the inlet of the end cover water channel I is arranged on the drive side end cover; a water outlet communicated with the outlet of the cover water channel II is arranged on the non-drive side end cover; and the outlet of the end cover water channel I and the inlet of the end cover water channel II are communicated with a plurality of built-in direct water channels distributed along the circumference. The disc-type permanent magnet motor has the advantages that the radiating speed is fast; the cooling effect is good; the power density is high; the service life is long; the temperature of the components is balanced; and the disc-type permanent magnet motor is not burnt up due to local overheat.

Owner:BOHAI UNIV

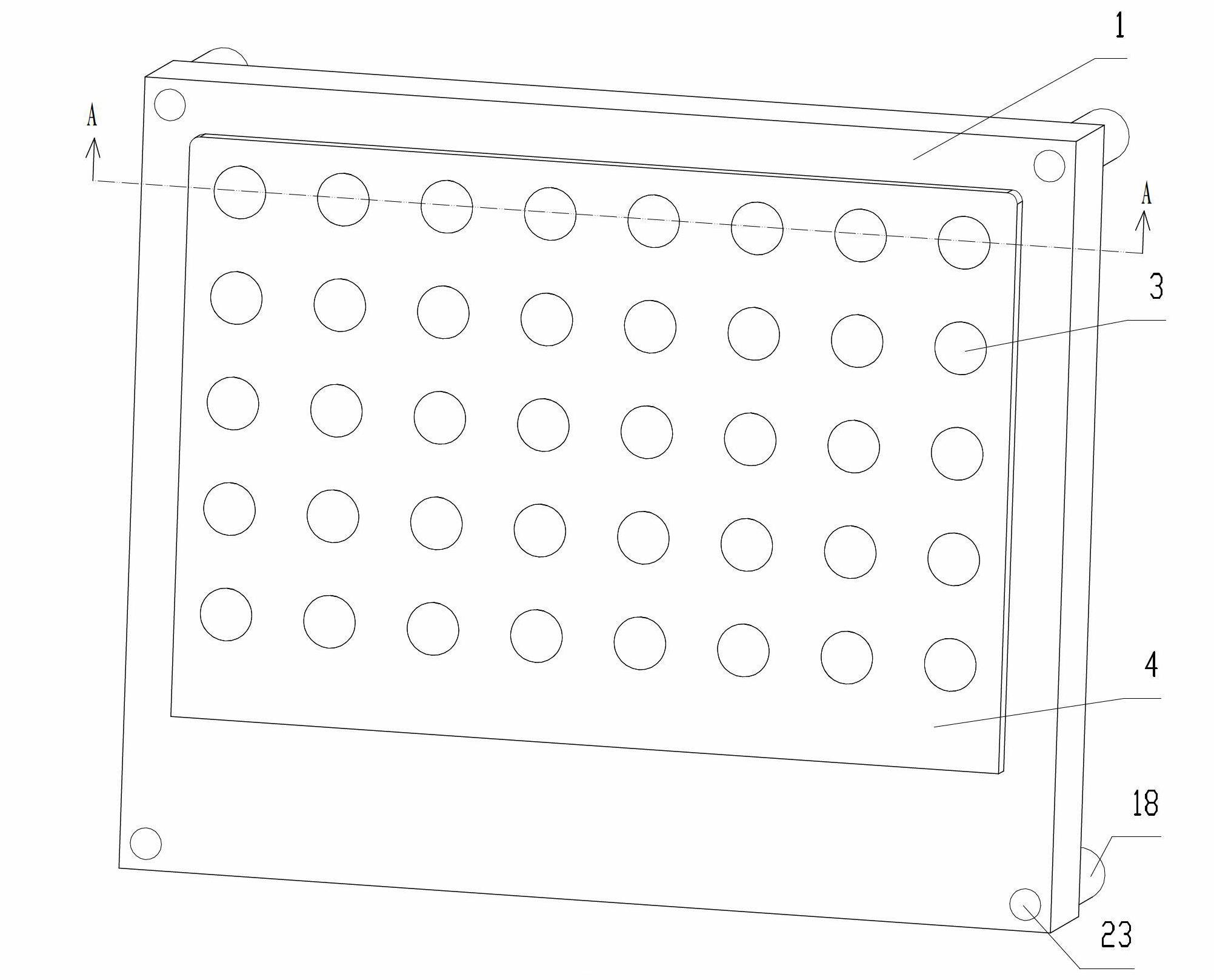

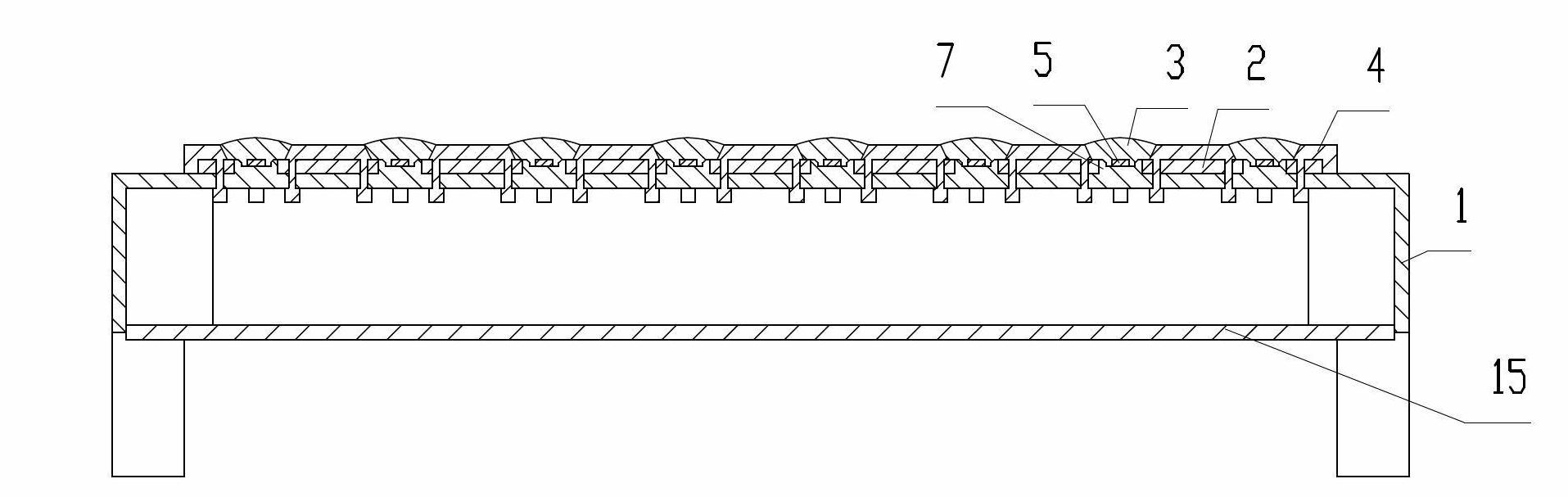

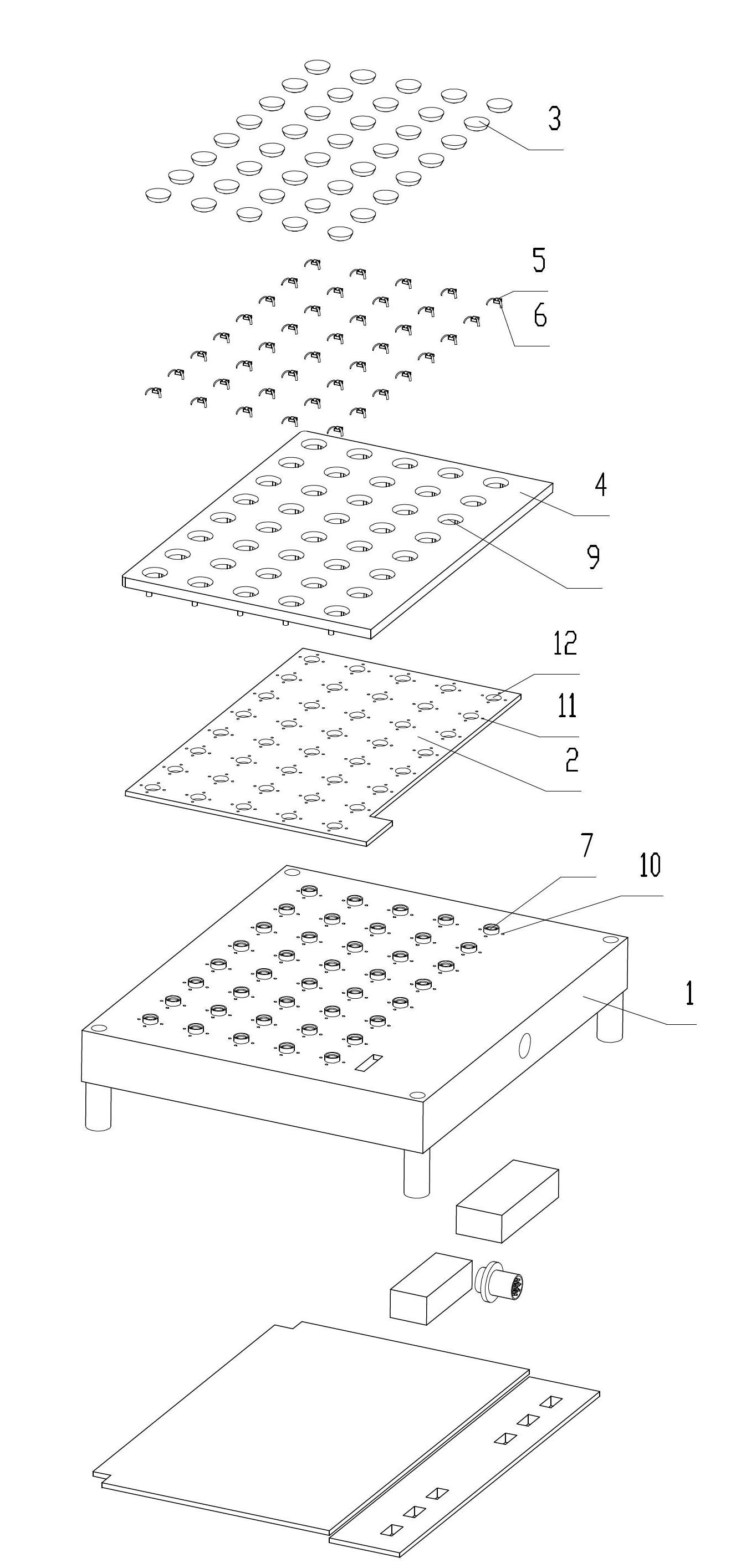

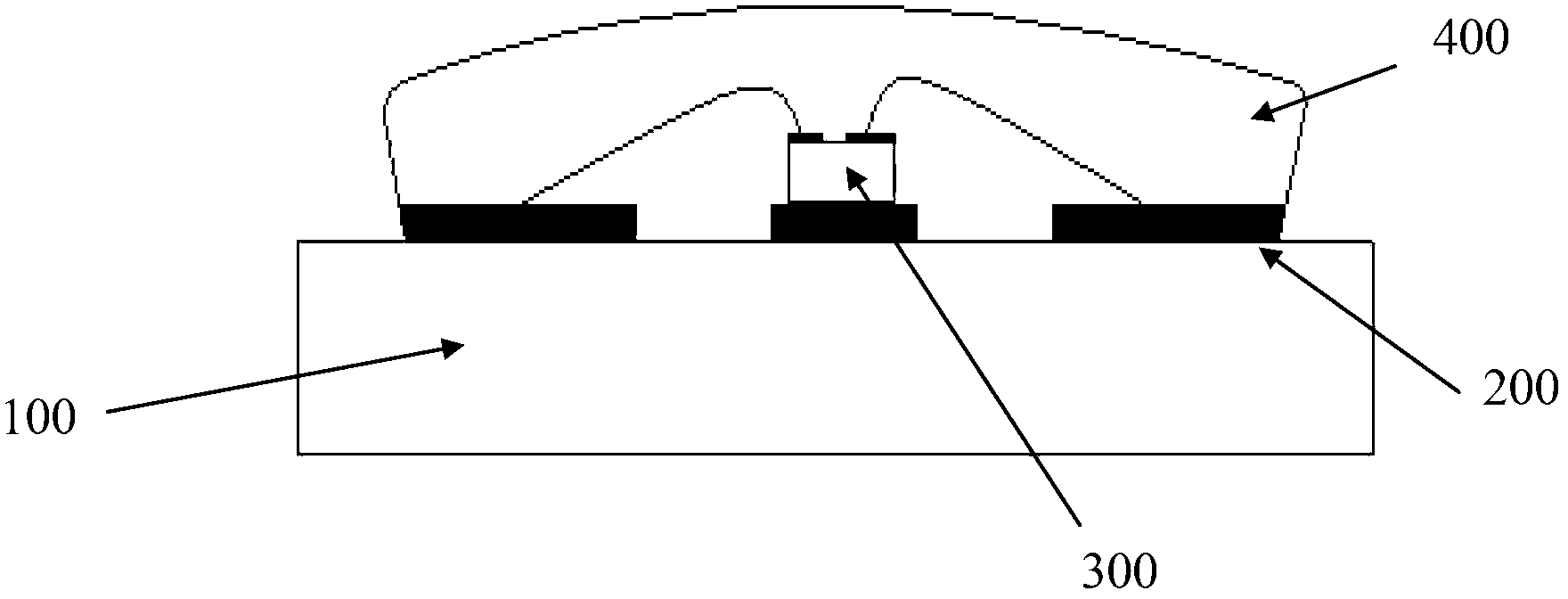

LED (light-emitting diode) dot matrix display screen and combined dot matrix display screen

InactiveCN102682671ACause material deteriorationExtend your lifeCooling/ventilation/heating modificationsIdentification meansDot-matrix displayColloid

The invention discloses an LED (light-emitting diode) dot matrix display screen and a combined dot matrix display screen. The dot matrix display screen comprises a heat-dissipating substrate, a PCB (printed circuit board), an uniformly-arrayed LED light-emitting unit, an imaging controller, a layout circuit conducting layer, a pervious-to-light packaging colloid for packaging LED chips, and a plastic plate forming the pervious-to-light packaging colloid for packaging the LED chips, wherein the LED light-emitting unit comprises more than one LED chips, guide lines and the pervious-to-light packaging colloid; the guide lines electrically connect the LED chips with the layout circuit conducting layer, and the pervious-to-light packaging colloid is used for packaging the LED chips; a hermetically-sealed outer cavity side wall which is hermetically connected with the plastic plate and the heat-dissipating substrate is arranged between the plastic plate and the heat-dissipating substrate; the heat-dissipating substrate, the hermetically sealed outer cavity side wall and the plastic plate defines a hermetically-sealed cavity, and the PCB is accommodated in the hermetically-sealed cavity; and the heat-dissipating substrate, the plastic plate and the pervious-to-light packaging colloid are directly contacted with the outside air. The dot matrix display screen disclosed by the invention has the advantages that of being simple in structure and low in cost and having good waterproof and heat-dissipating effects since the PCB is accommodated in the hermetically-sealed cavity formed by the heat-dissipating substrate, the hermetically sealed outer cavity side wall and the plastic plate.

Owner:东莞市万兴智能科技有限公司

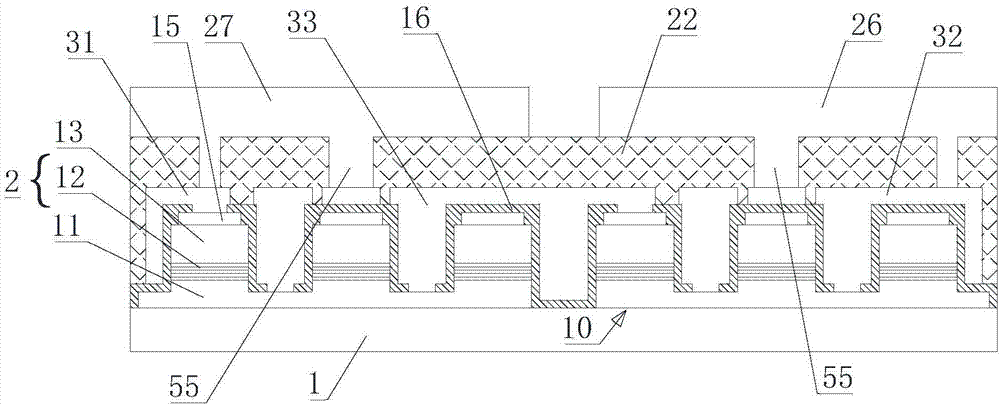

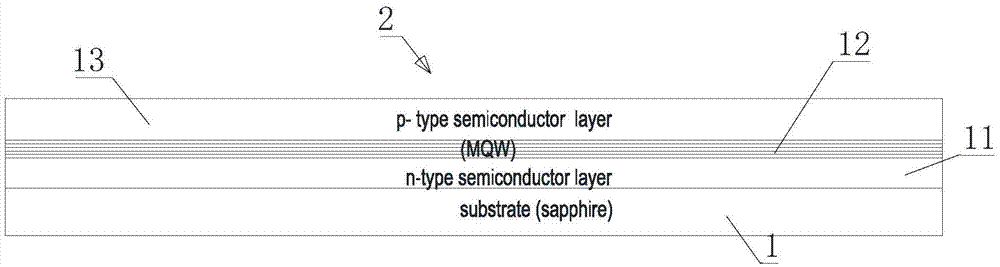

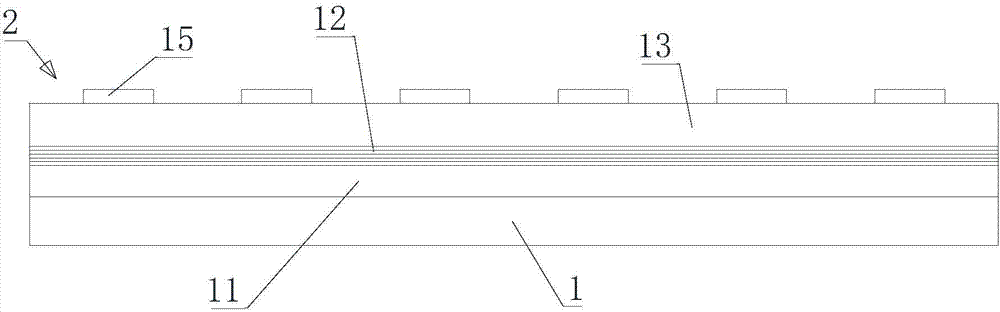

Inverted high-voltage LED chip and preparation method thereof

The invention discloses an inverted high-voltage LED chip and a preparation method thereof. The inverted high-voltage LED chip comprises a substrate and M chips, wherein each chip comprises an N-type gallium nitride layer, a luminous layer, a P-type gallium nitride layer, a reflecting layer, a first insulating layer, a P lead electrode, an N lead electrode and a P-N lead connecting electrode; heat radiation grooves are formed in the P lead electrodes and / or the N lead electrodes and / or the P-N lead connecting electrodes; the second insulating layers cover the surfaces of the P lead electrodes, the P-N lead connecting electrodes and the N lead electrodes and the surfaces of the first insulating layers among the P lead electrodes, the P-N lead connecting electrodes and the N lead electrodes, and fill the heat radiation grooves; heat radiation holes are formed in the second insulating layers; the projection of the heat radiation holes on the horizontal plane is positioned inside the heat radiation grooves; the second insulating layers are deposited on N bonding pads and P bonding pads; the heat radiation holes are filled with heat conduction columns; the heat conduction columns are connected with the P bonding pads and the N bonding pads. Due to the adoption of the heat radiation columns among the P bonding pads, the N bonding pads and the lead electrodes, the inverted high-voltage LED chip is relatively high in heat radiation speed and small in heat radiation amount.

Owner:ELEC TECH PHOTOELECTRIC TECH DALIAN

LED lamp heat radiation device based on synthetic double-jet exciter

ActiveCN104154512ASpeed up circulationPromote circulationPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses an LED lamp heat radiation device based on a synthetic double-jet exciter. The LED lamp heat radiation device comprises a heat radiation component connected with an LED chip heat circuit, and further comprises the synthetic double-jet exciter, and an output port of the synthetic double-jet exciter faces the heat radiation component, and outputs synthetic jet flow to cool the heat radiation component. The heat generated by an LED lamp is guided out and dispersed to surrounding air through the heat radiation component, periodic active reinforced heat radiation is carried out on the heat radiation component through the synthetic jet flow output by the synthetic double-jet exciter, air ventilation and exchange are accelerated, and the device has the advantages of being high in heat radiation speed and simple and compact in structure.

Owner:NAT UNIV OF DEFENSE TECH

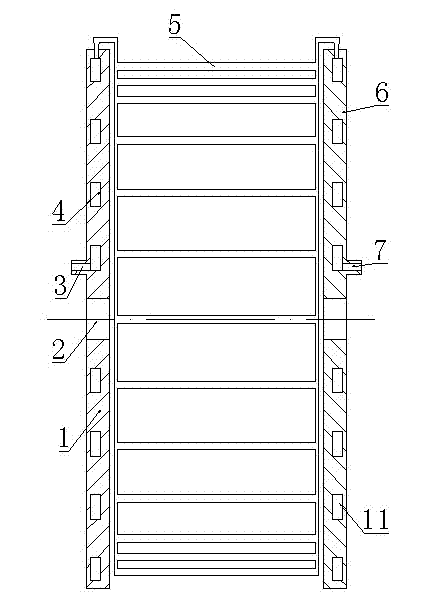

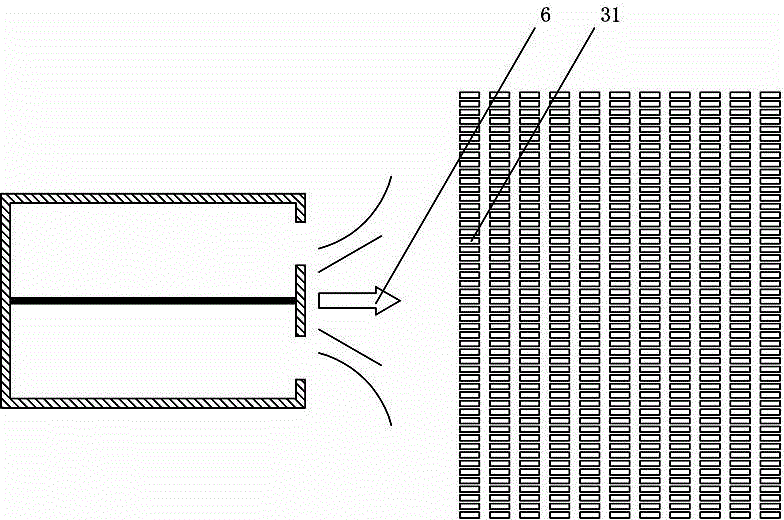

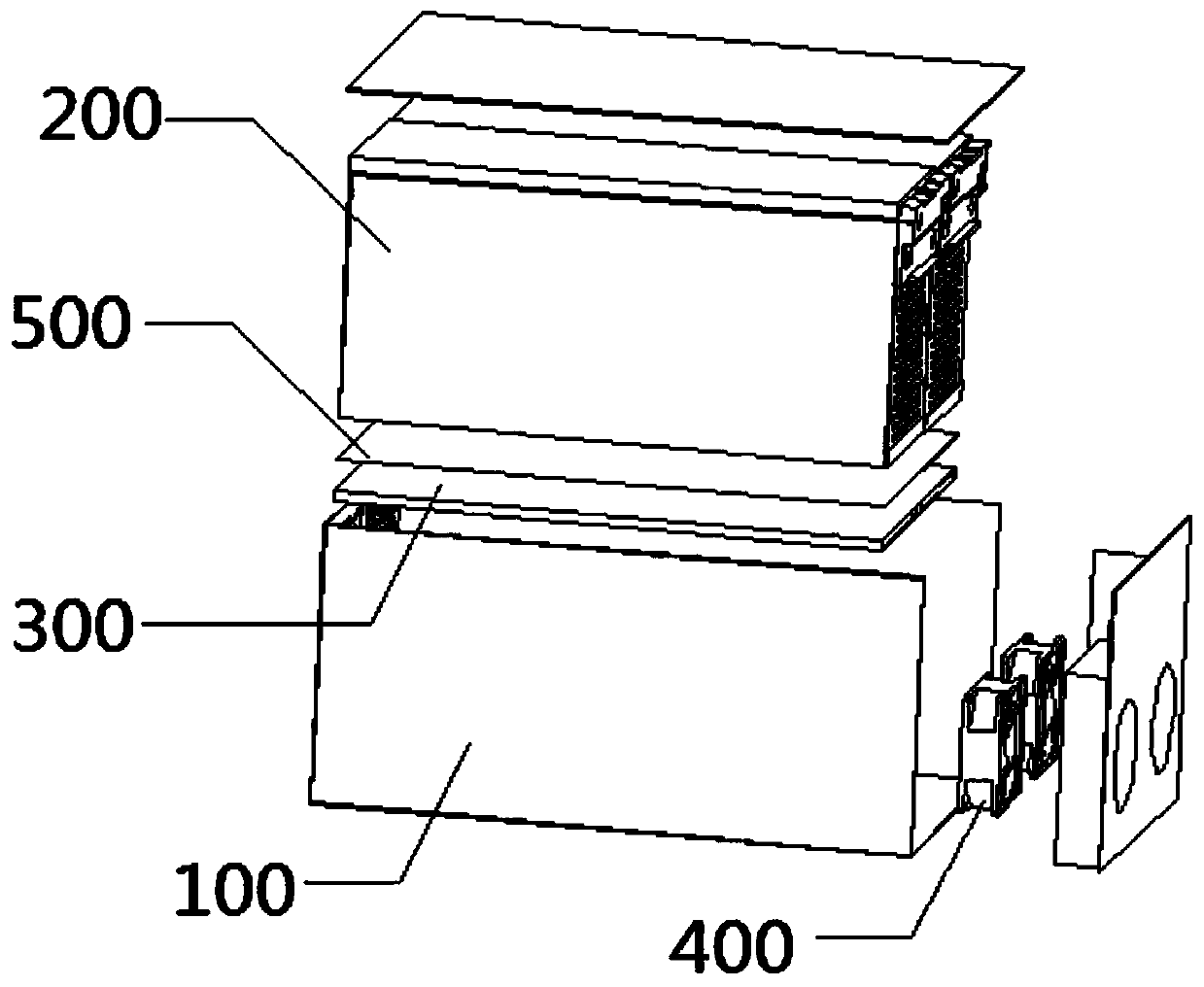

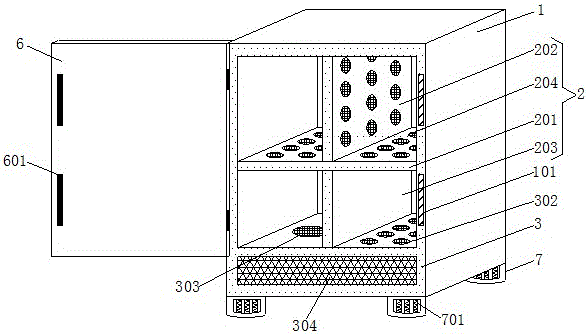

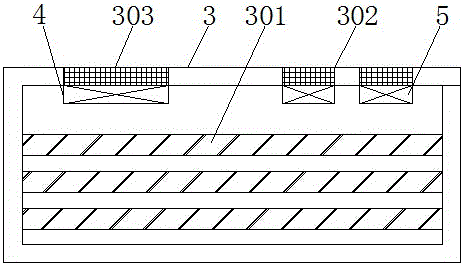

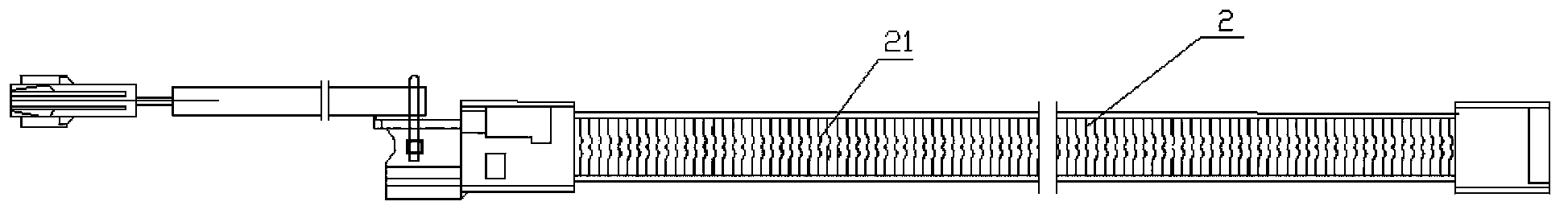

Reverse-flow type double-air-channel cooling system for energy storage module

PendingCN109638379AGood technical effectReduce power consumptionSecondary cellsEnergy storageBattery cell

The invention discloses a reverse-flow type double-air-channel cooling system for an energy storage module. The reverse-flow type double-air-channel cooling system for the energy storage module comprises a box body, an air draft device, an energy storage module and a heat dissipation device. The air draft device, the energy storage module and the heat dissipation device are respectively arranged in the box body, and the energy storage module is arranged on the heat dissipation device; the box body is provided with an air inlet and an air outlet, the energy storage module comprises a pluralityof single battery cells, a gap is formed between every two single battery cells, a first air duct for air to flow is formed by the gap, and the first air duct communicates with the air inlet and the air outlet of the box body; and a second air duct opposite to the first air duct in air flow is arranged in the heat dissipation device, the second air duct communicates with the air inlet and the airoutlet of the box body, and a reverse-flow type double-air-duct cooling system is formed through the first air duct and the second air duct. The reverse-flow type double-air-duct cooling system has the advantages of being good in temperature equalizing effect, safe, efficient, high in initiative, large in heat dissipation area, multiple in heat dissipation ways and the like.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Cylindrical self-breathing prorton exchange membrane fuel cell

InactiveCN101587963ALower impedanceImprove power densityFuel cell heat exchangeCell electrodesEngineeringProton exchange membrane fuel cell

The invention discloses a cylindrical self-breathing prorton exchange membrane fuel cell, includes a shell, a membrane electrode, an anode tube, inside the membrane electrode is a fule chamber, between the shell and the membrane electrode is an air chamber, two ends of the membrane electrode are provided with insulation seal ring, a cathode output member and an anode output member are disposed on cathode end and anode end of battery separately, a water discharge device is disposed on the cathode output member. The invention has rensonable structure and good operation performance.

Owner:NANTONG UNIVERSITY

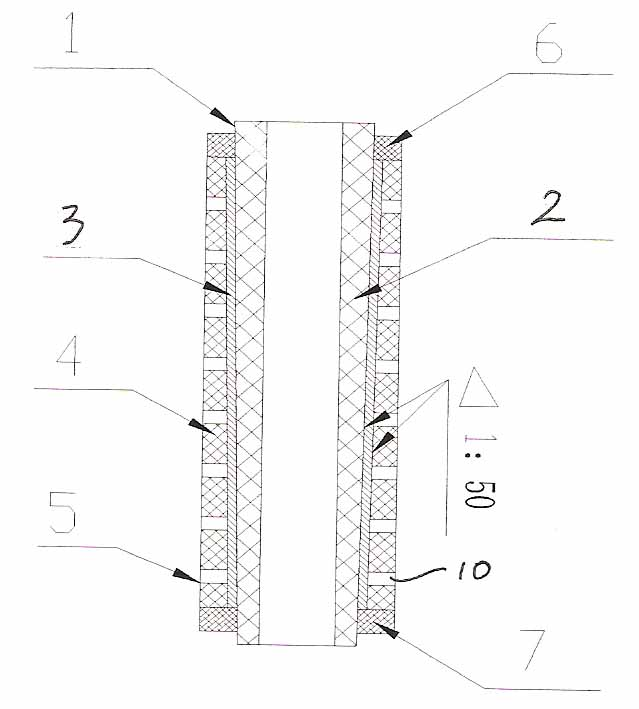

Luminous floor tile

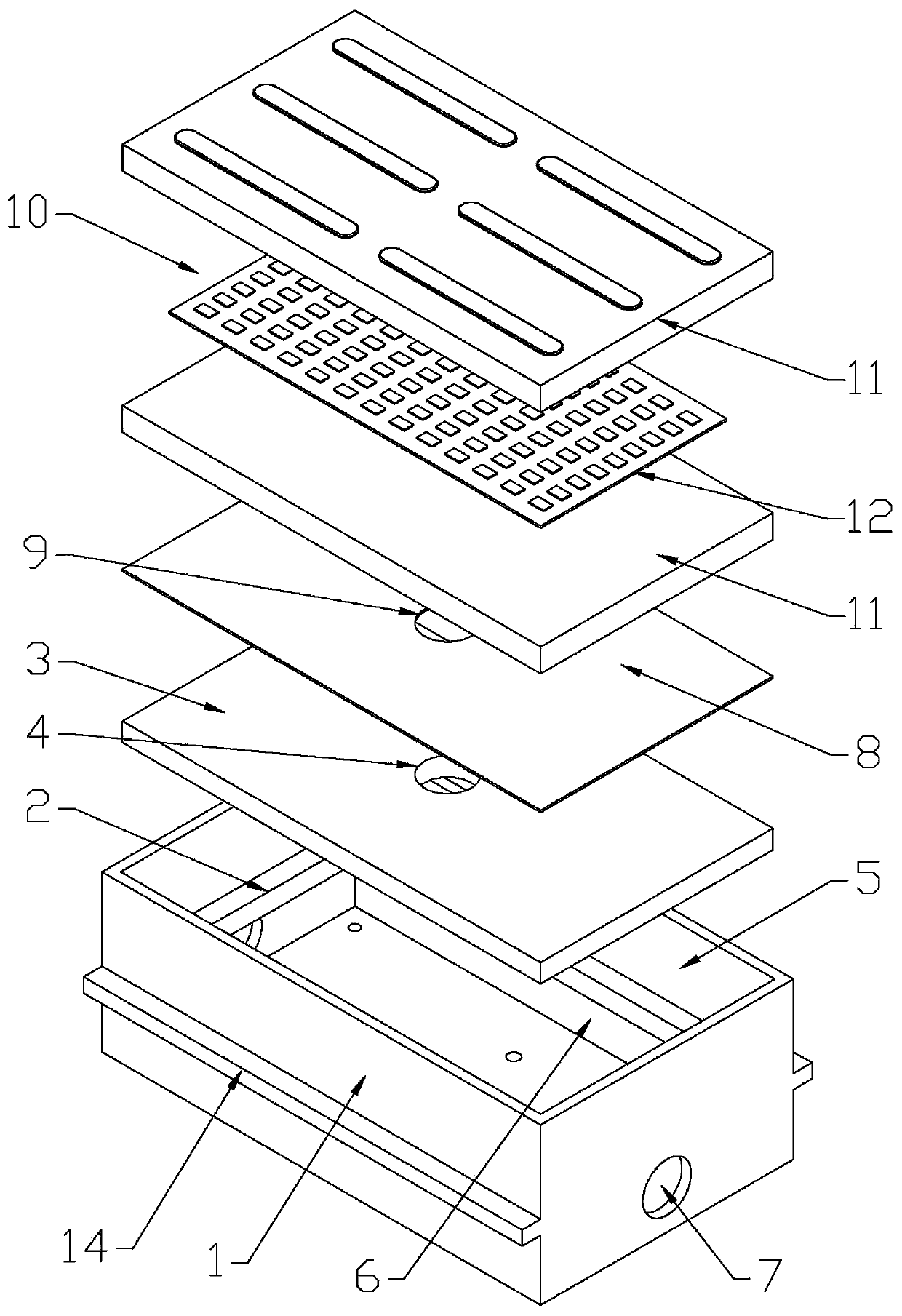

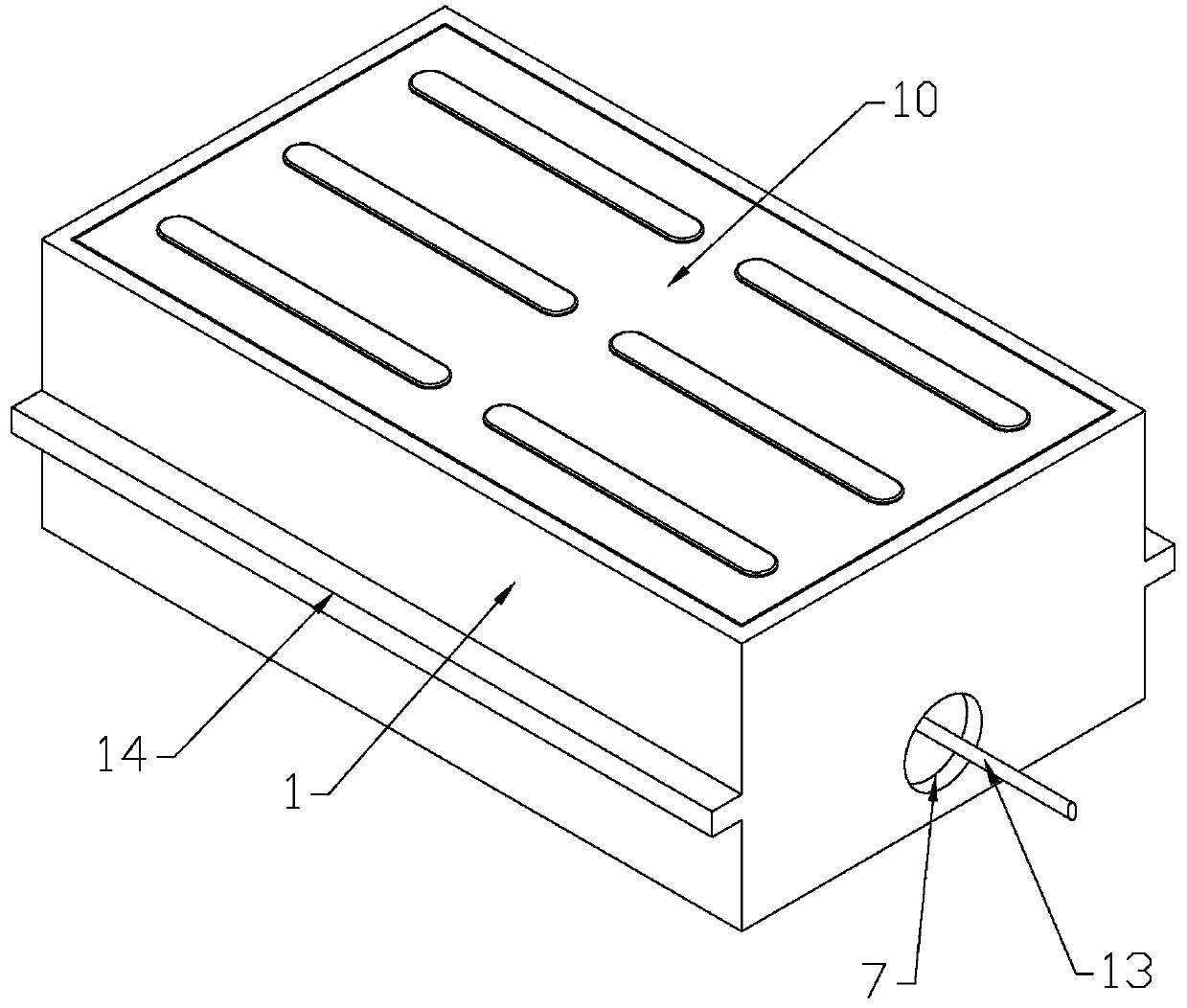

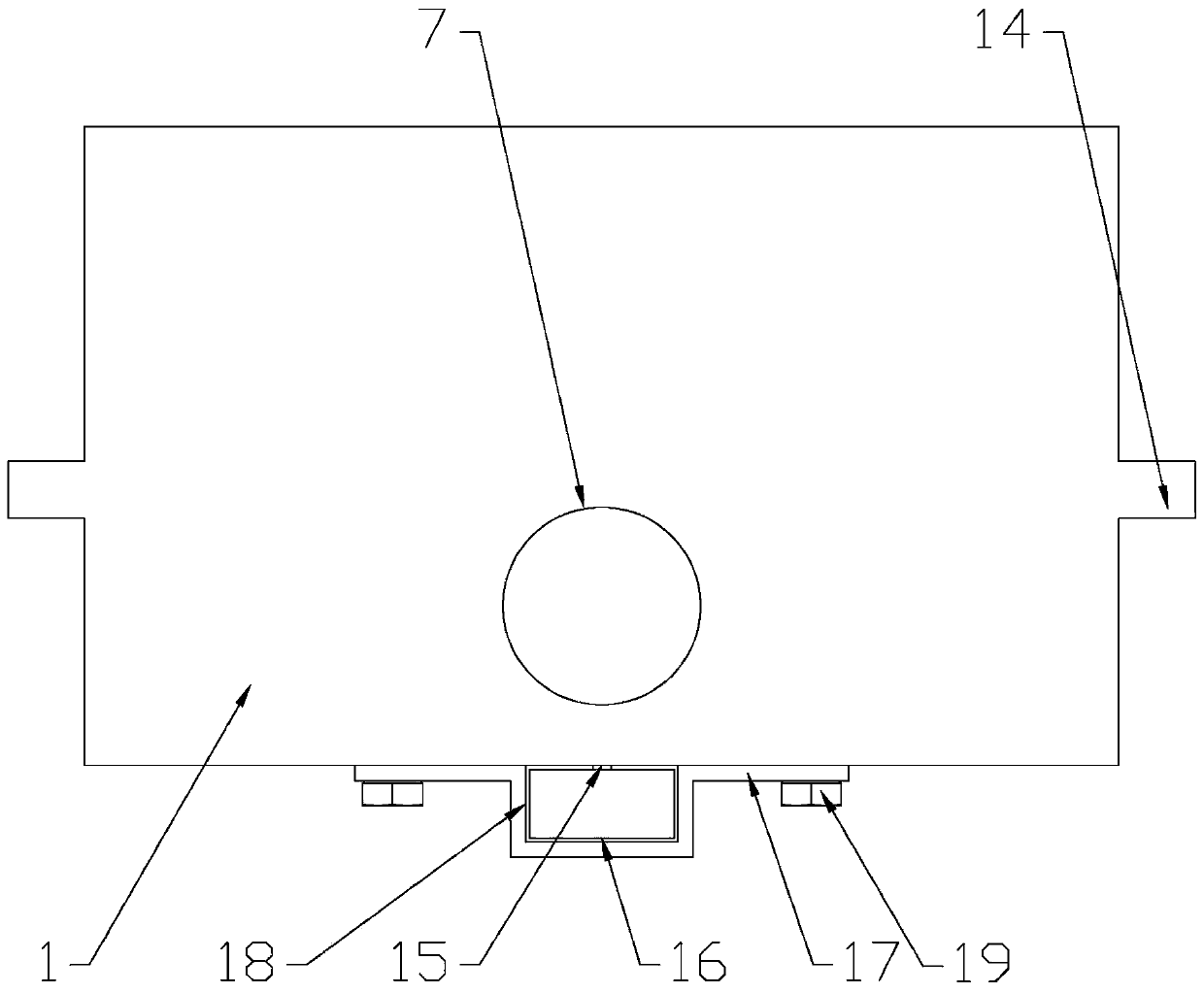

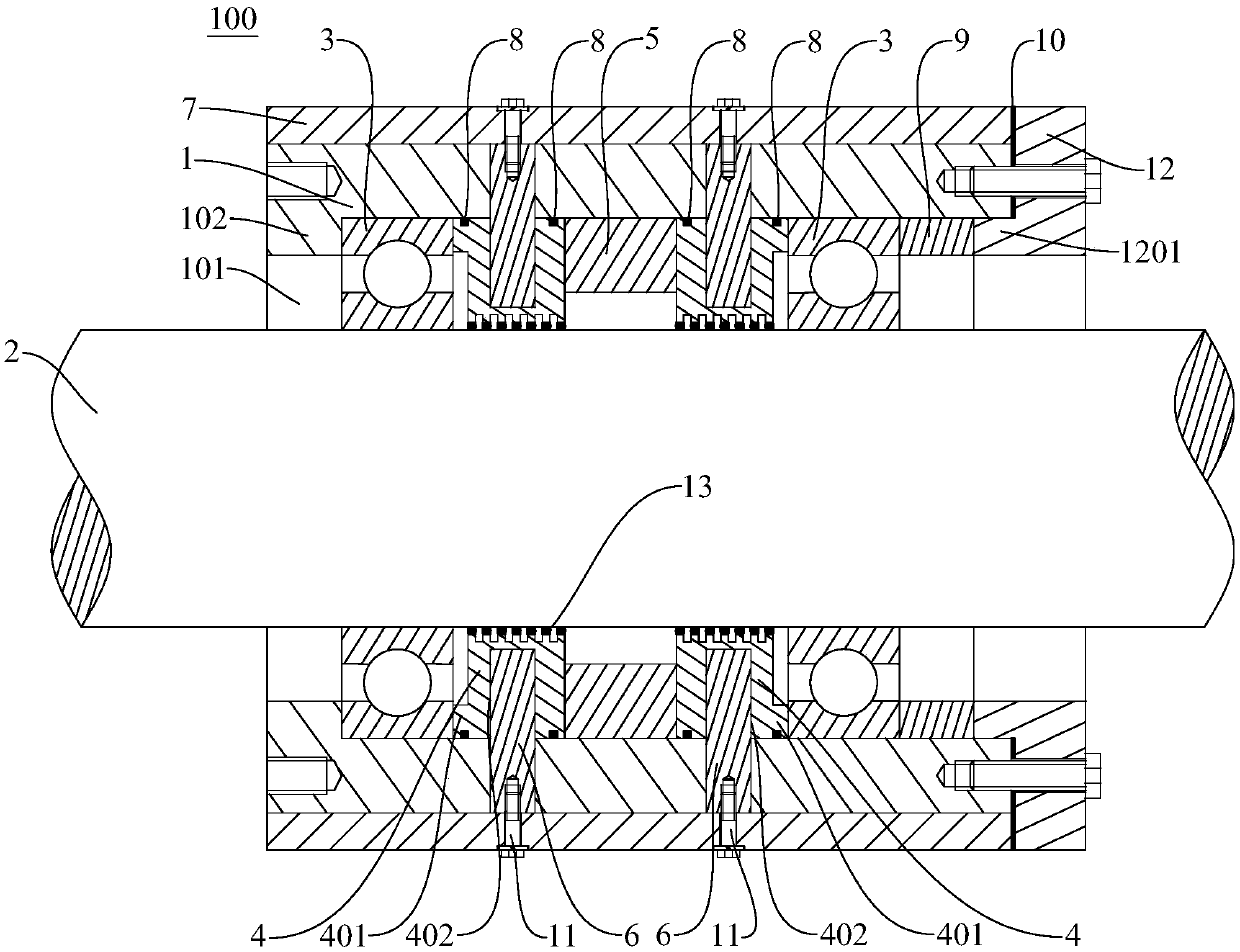

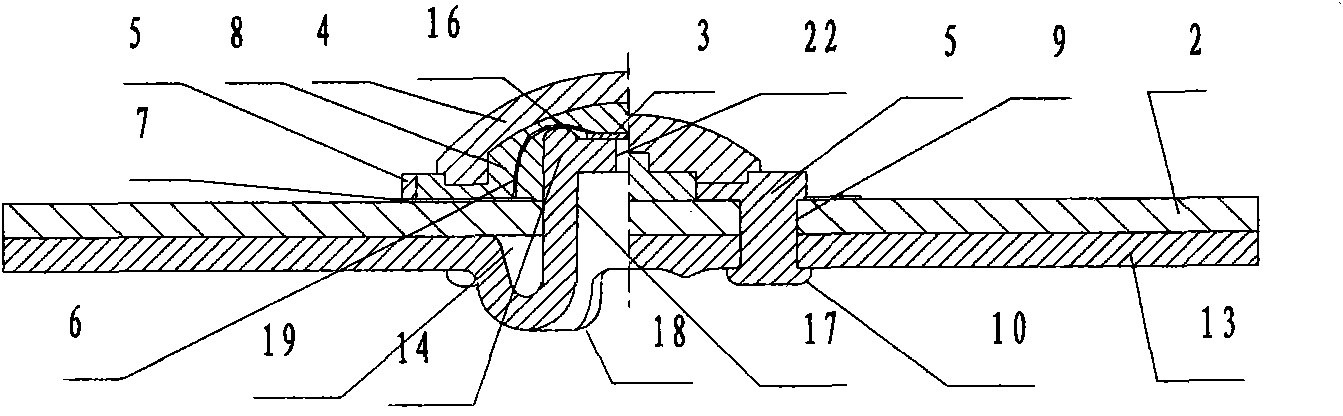

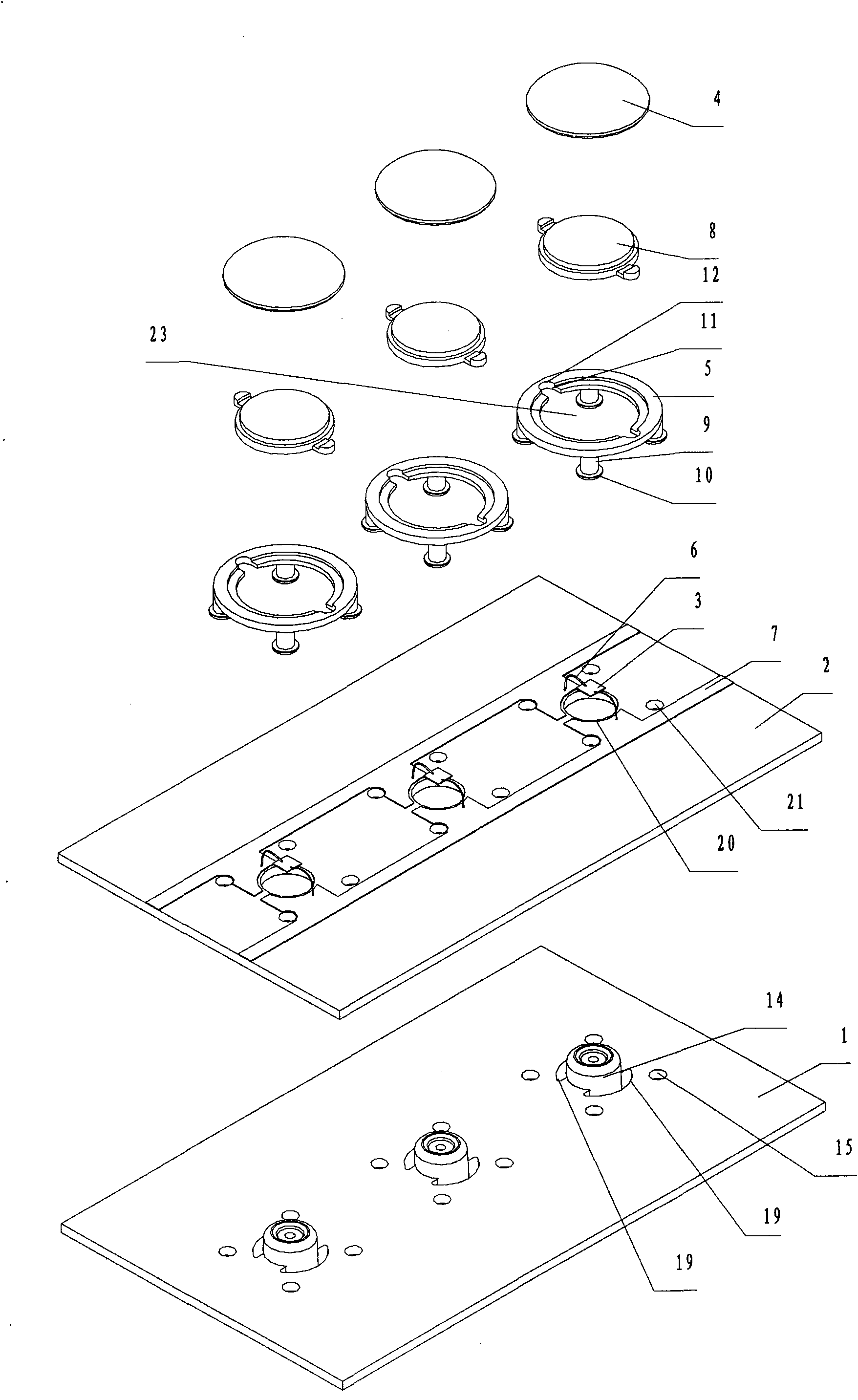

ActiveCN109898382AEven heat dissipationShock mitigationSingle unit pavingsSidewalk pavingsEngineeringCavity wall

The invention discloses a luminous floor tile. The luminous floor tile comprises an installing base (1) and a floor tile module (10). The installing base (1) is a cavity body made of a pressure-resistant material. A cavity wall of the installing base (1) is provided with a support convex platform (2) for supporting a bearing plate (3). The bearing plate (3) is provided with a bearing plate cable hole (4) through which a cable (130) passes, and a cavity of the installing base (1) is separated into an upper floor tile module installing groove (5) and a lower functional cavity (6) by the bearingplate (3). A side wall of the installing base (1) corresponding to the functional cavity (6) is provided with a cable passing hole (7). The cable passing hole (7) is used for, after enabling the cable(13) connected with the floor tile module (10) to be drawn out from the bottom of the floor tile module (10), enabling the cable (13) to successively pass through the bearing plate cable hole (4) andthe cable passing hole (7) and to be outwards stretched out. The luminous floor tile is capable of protecting the floor tile module, improving installing efficiency, and improving stability and electric safety degree after the floor tile module is buried.

Owner:NANTONG TIANCHENG OPTOELECTRONICS TECH CO LTD +2

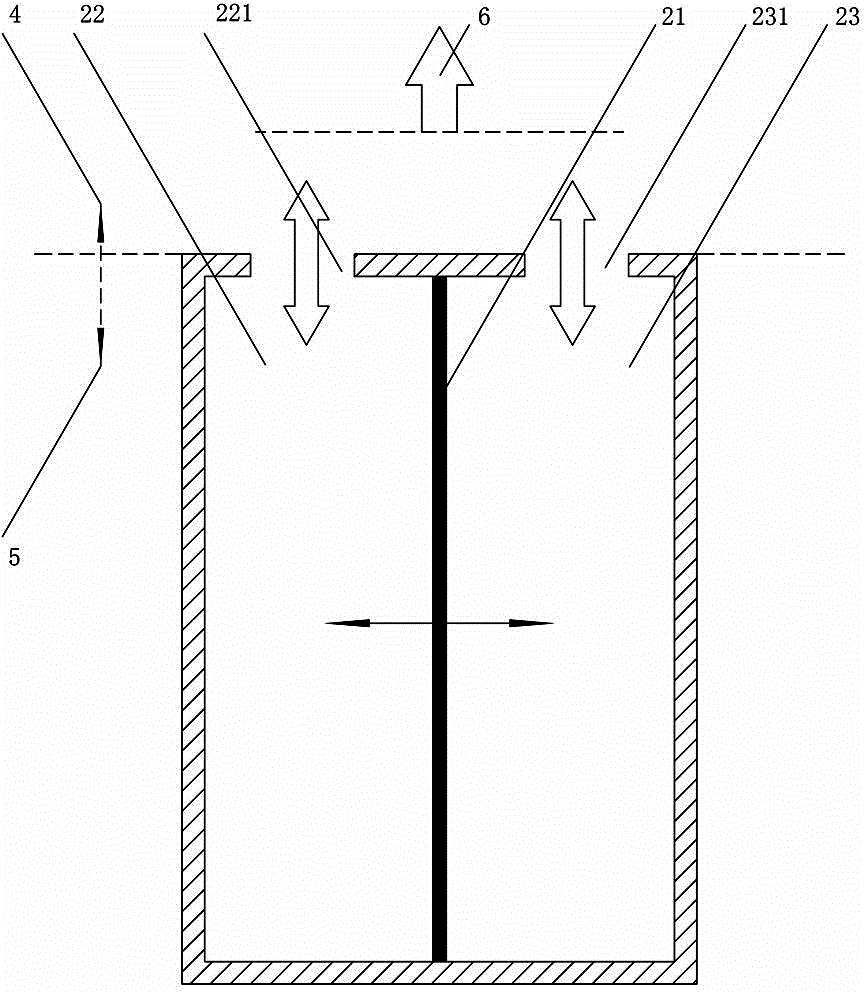

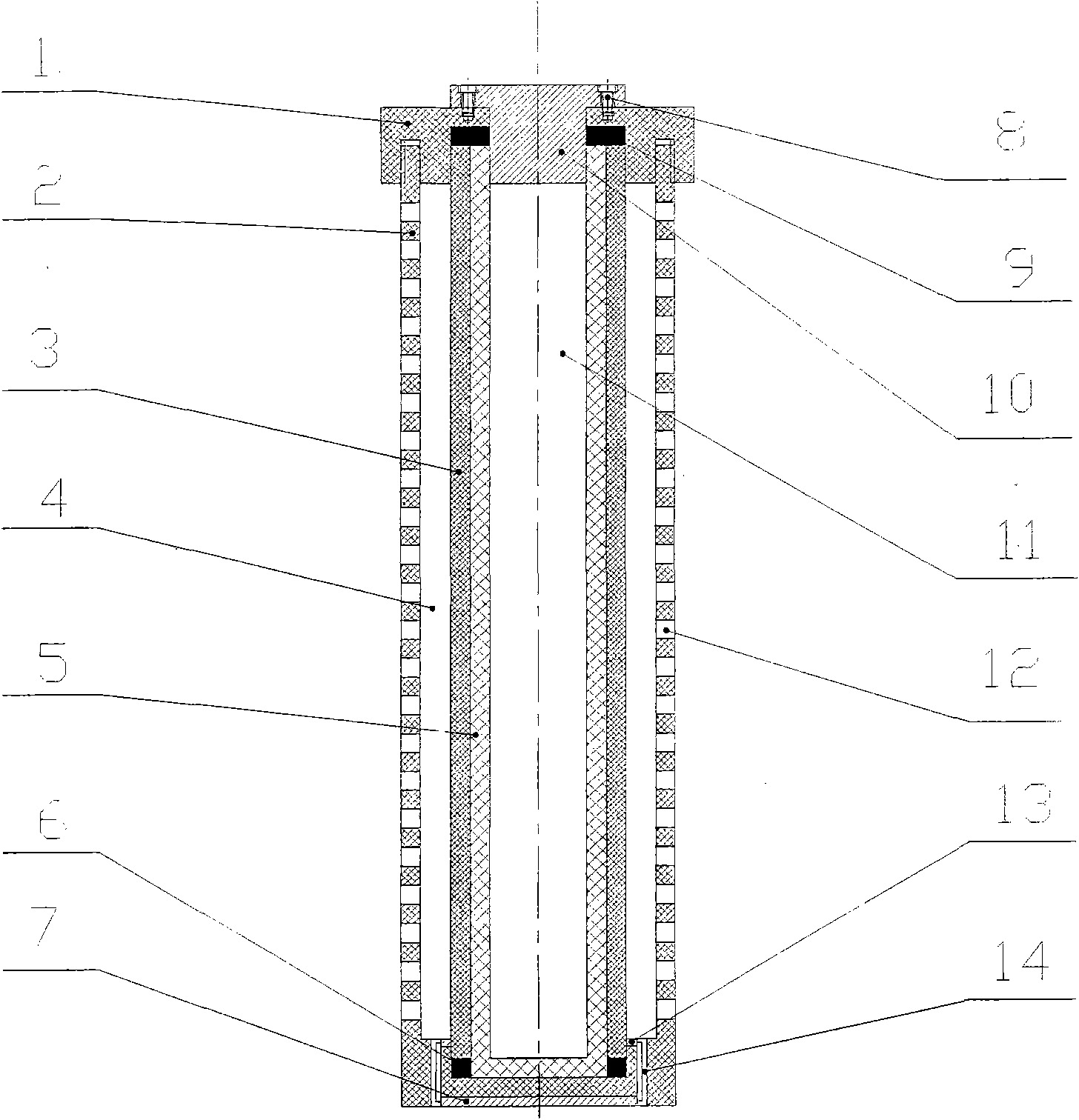

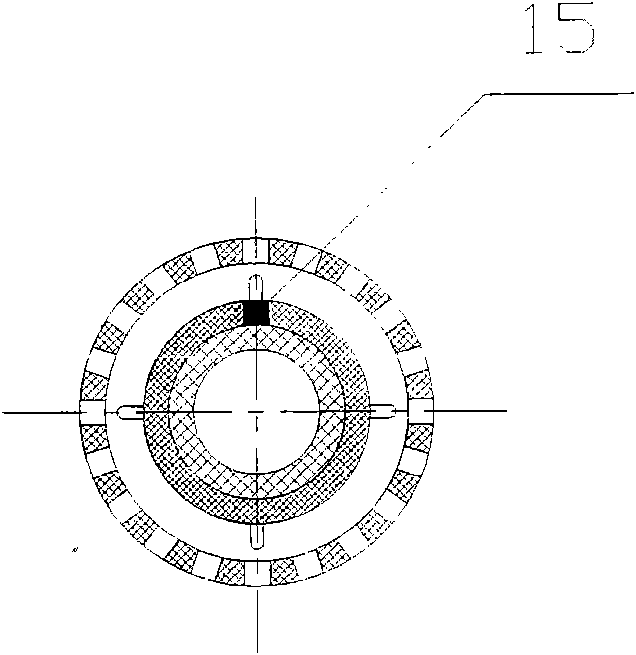

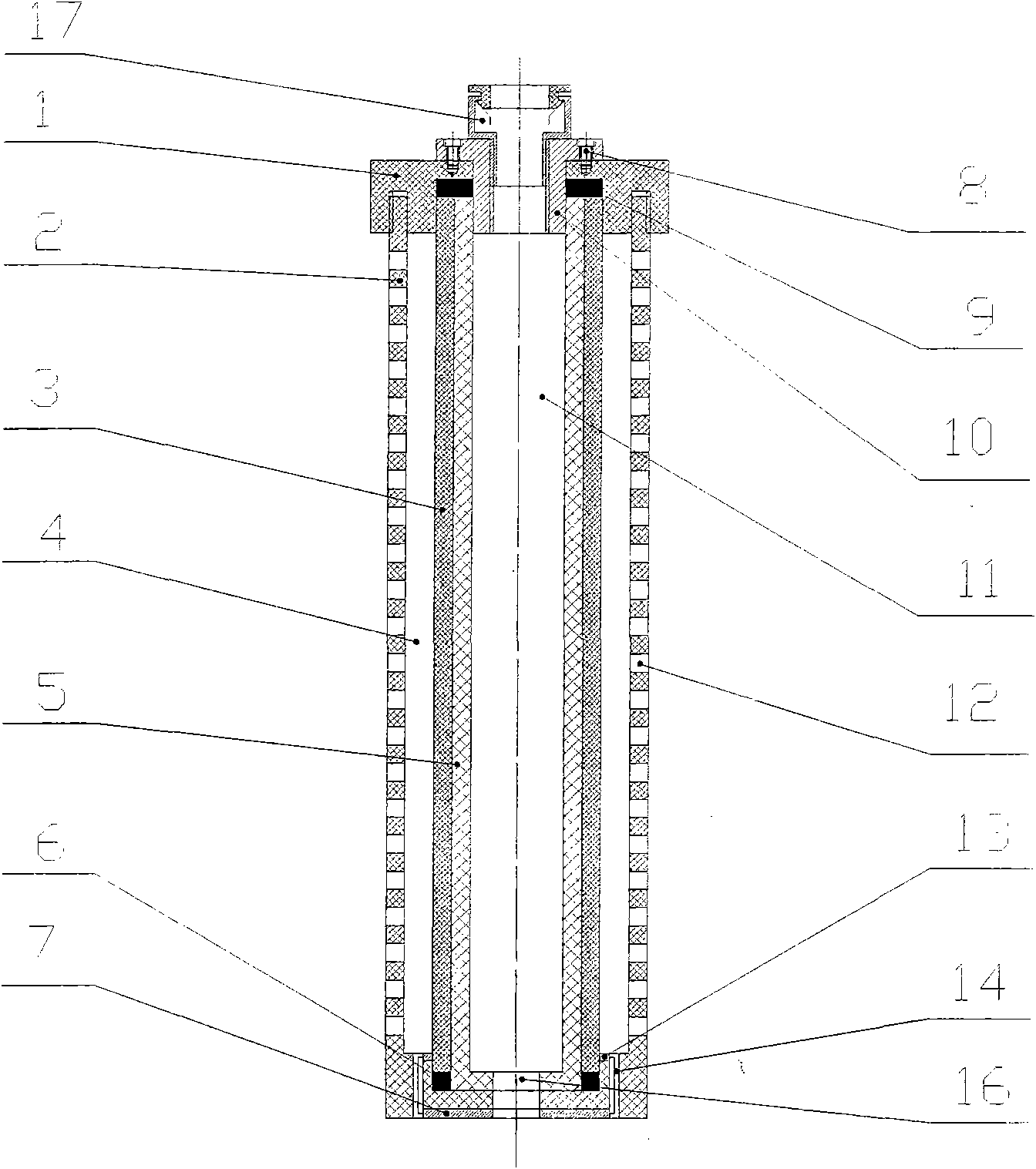

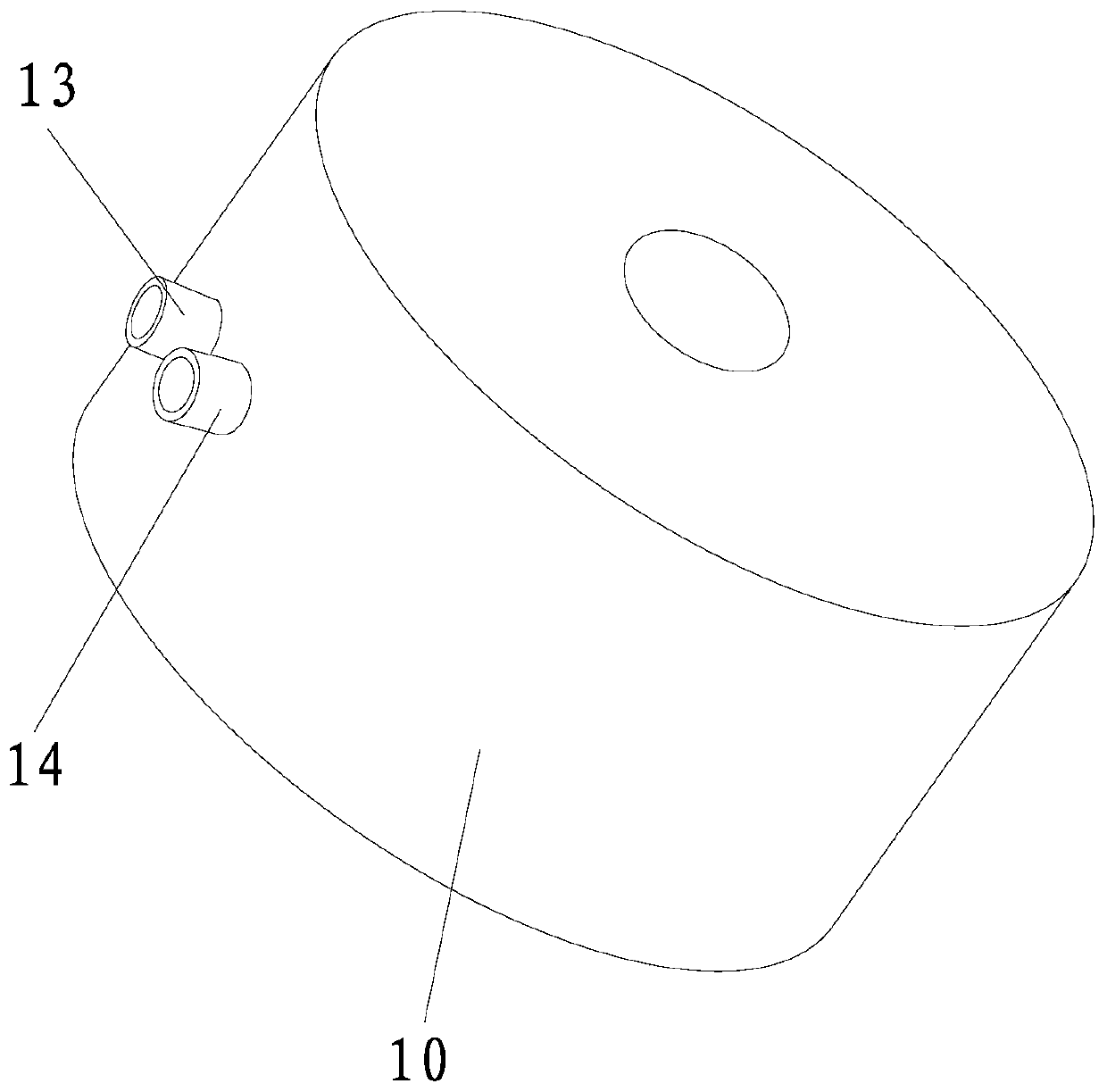

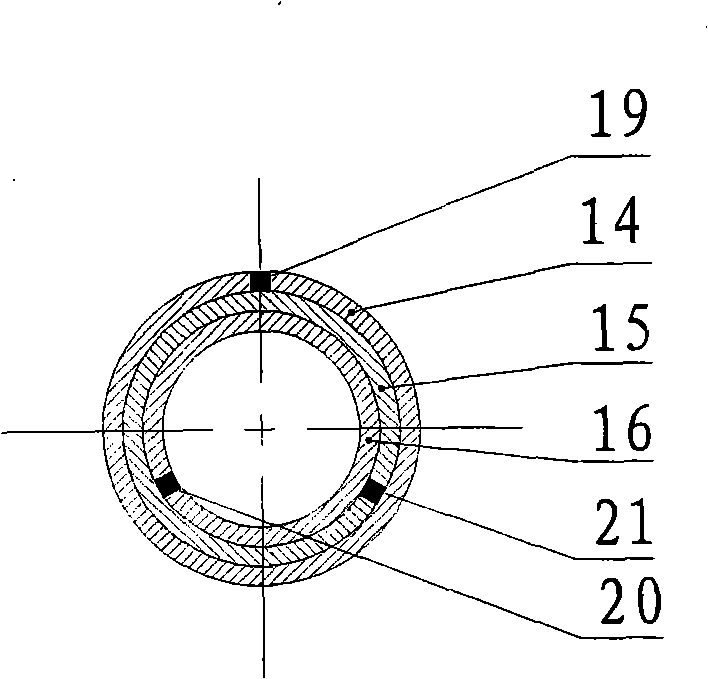

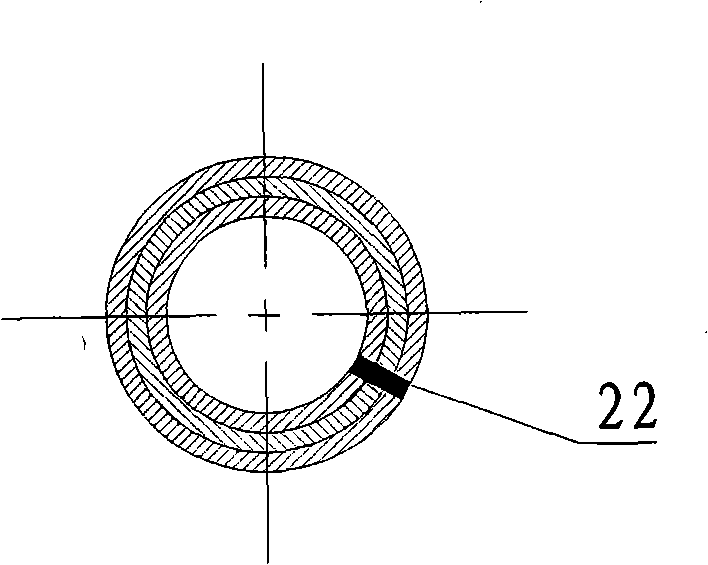

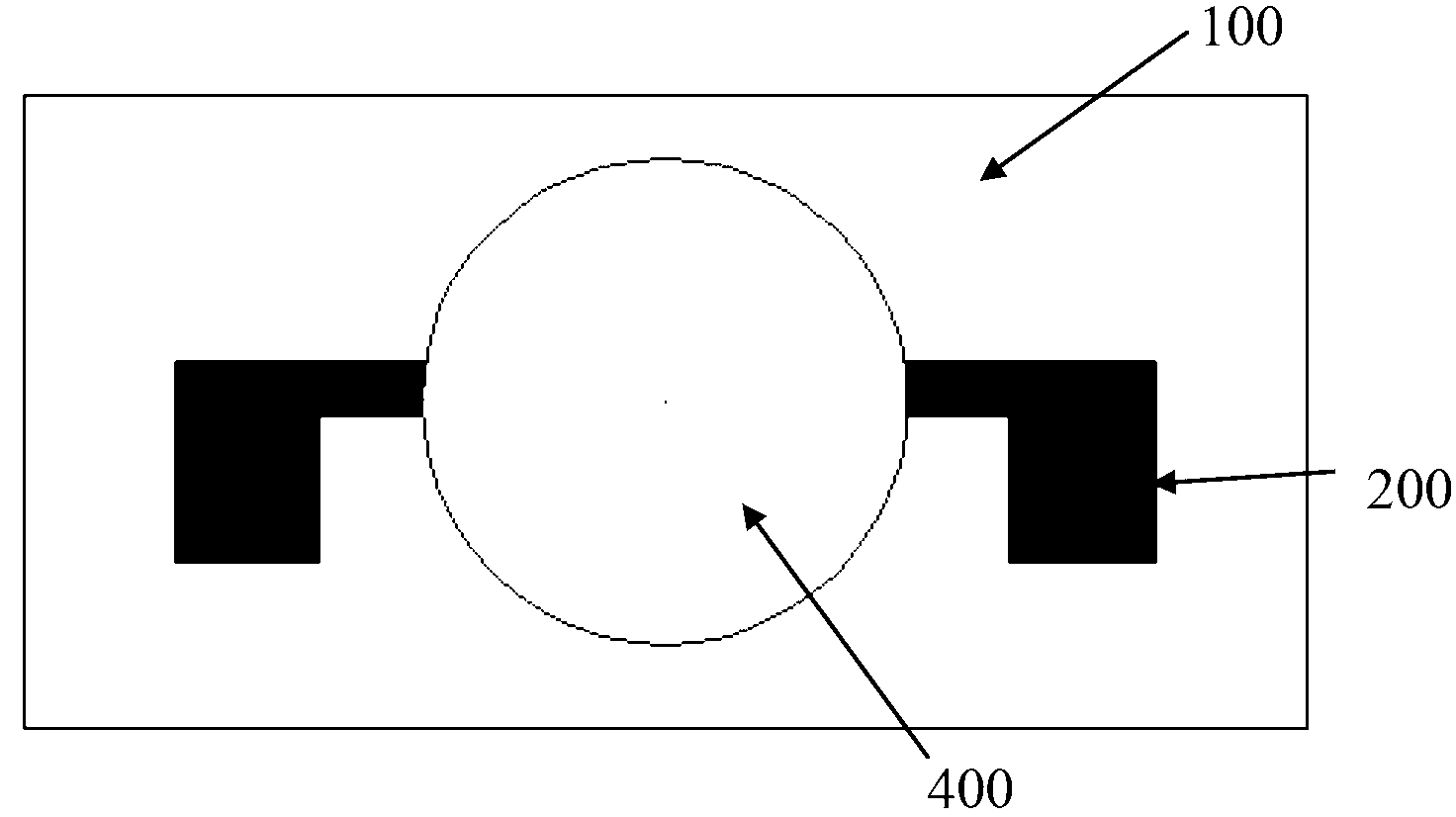

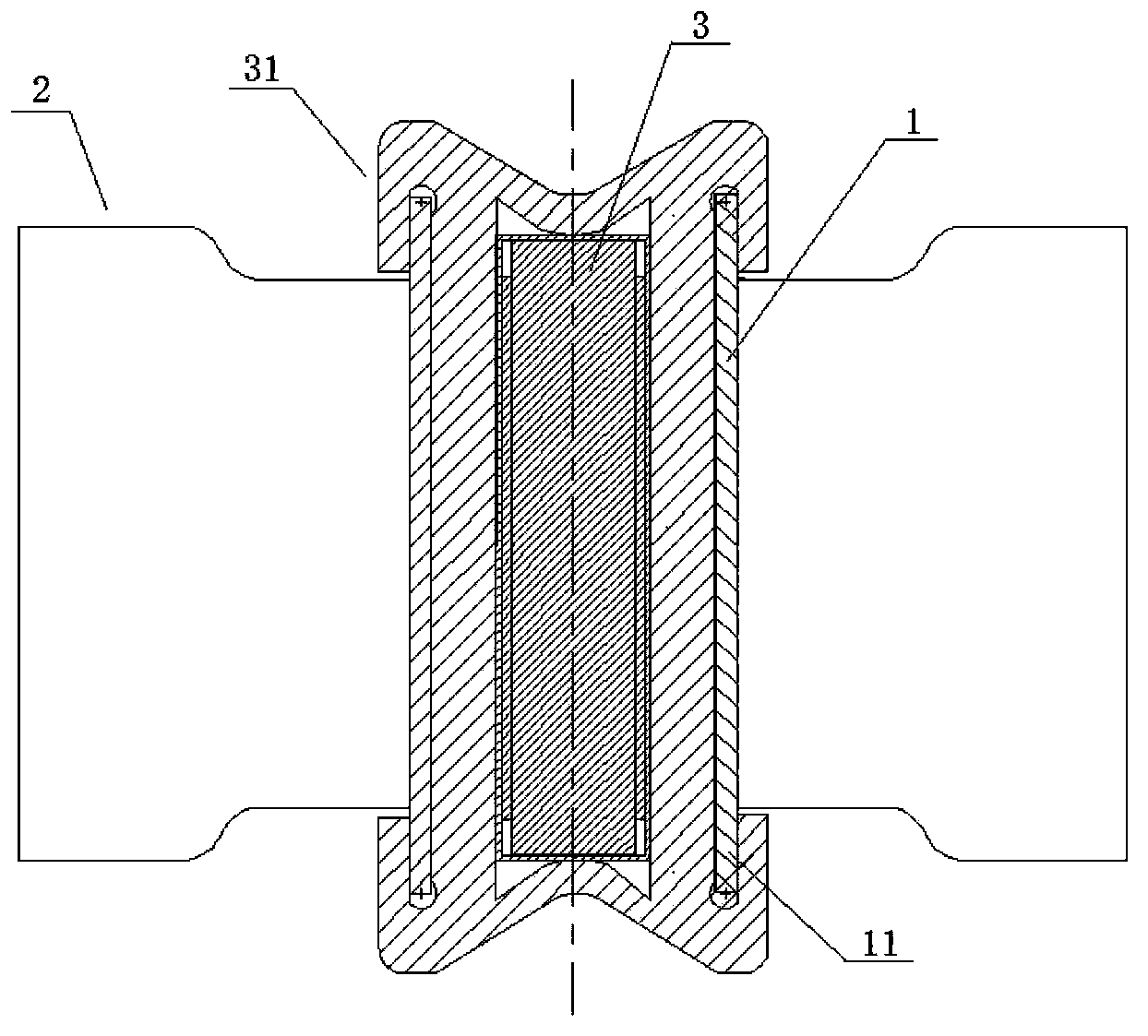

Magnetic liquid sealing device with heat conduction rods and heat dissipation sleeve

The invention discloses a magnetic liquid sealing device with heat conduction rods and a heat dissipation sleeve. The magnetic liquid sealing device comprises a shaft shell, a rotating shaft, two bearings, two pole shoes, a permanent magnet, the heat conduction rods and the heat dissipation sleeve, wherein a shaft chamber is arranged in the shaft shell, the rotating shaft is rotatably arranged inthe shaft chamber, the two bearings are both arranged on the rotating shaft in a sleeve mode, the two pole shoes are both arranged on the rotating shaft in a sleeve mode, and are located between the two bearings, magnetic liquid is adsorbed between the inner peripheral surface of each pole shoe and the outer peripheral surface of the rotating shaft, the outer peripheral surface of each pole shoe is provided with a matched blind hole extending along the radial direction of the pole shoe, the permanent magnet is arranged on the rotating shaft in a sleeve mode and is located between the two poleshoes, the heat conduction rods are inserted into the matched blind holes, the heat dissipation sleeve is arranged on the shaft shell in a sleeve mode, and the heat conduction rods are connected withthe heat dissipation sleeve through connecting pieces. According to the magnetic liquid sealing device with the heat conduction rods and the heat dissipation sleeve, water cooling or circuit heat dissipation is not needed, the structure is simple and the heat dissipation effect is good.

Owner:TSINGHUA UNIV

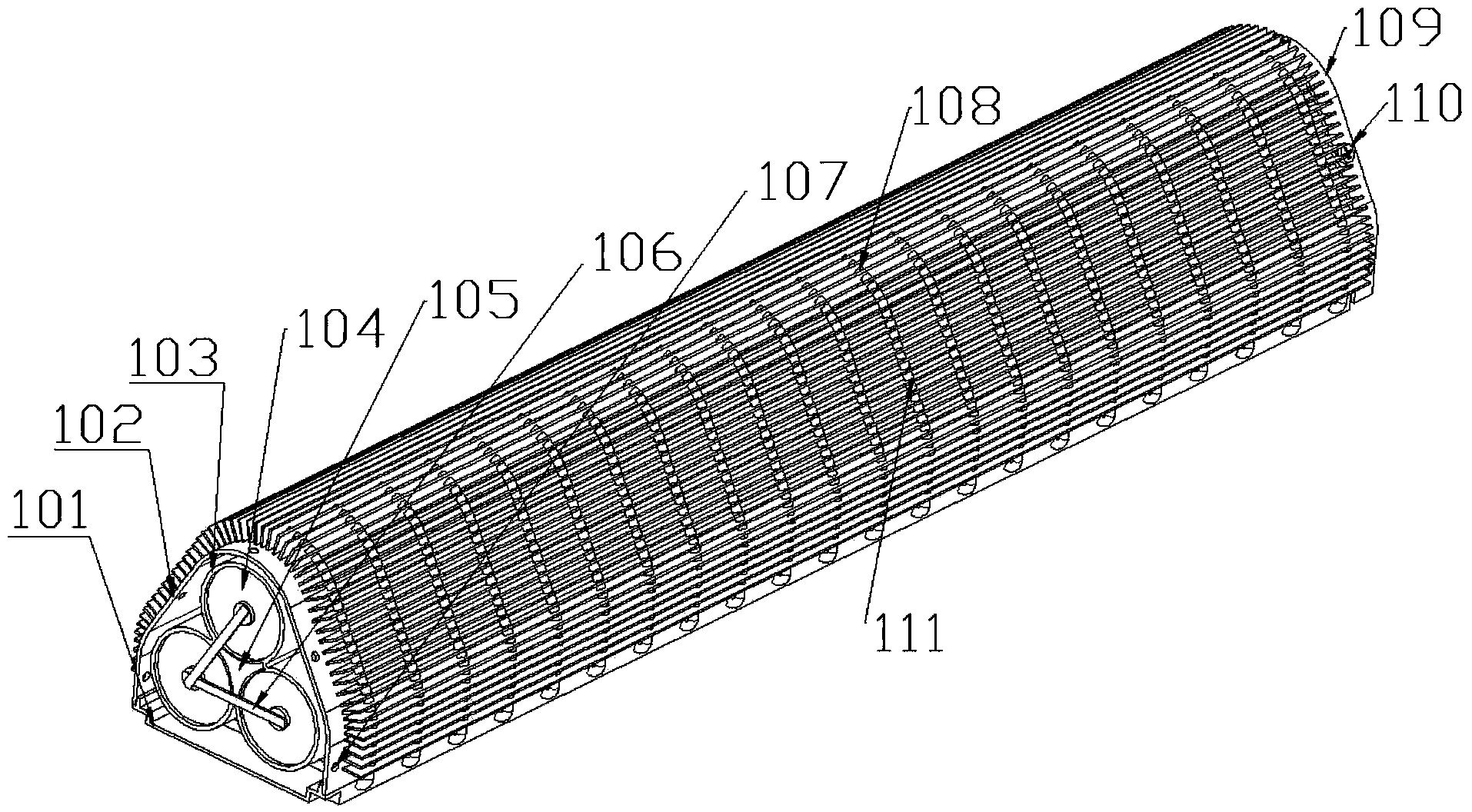

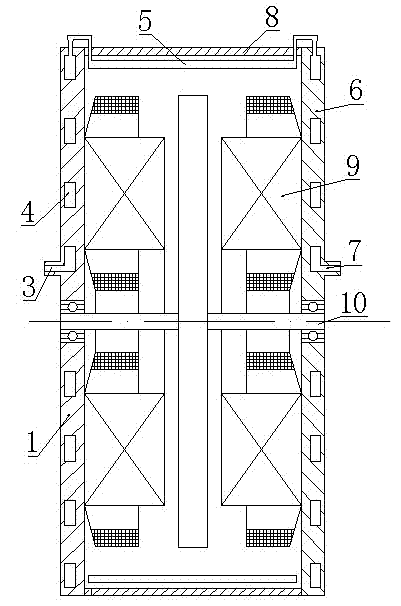

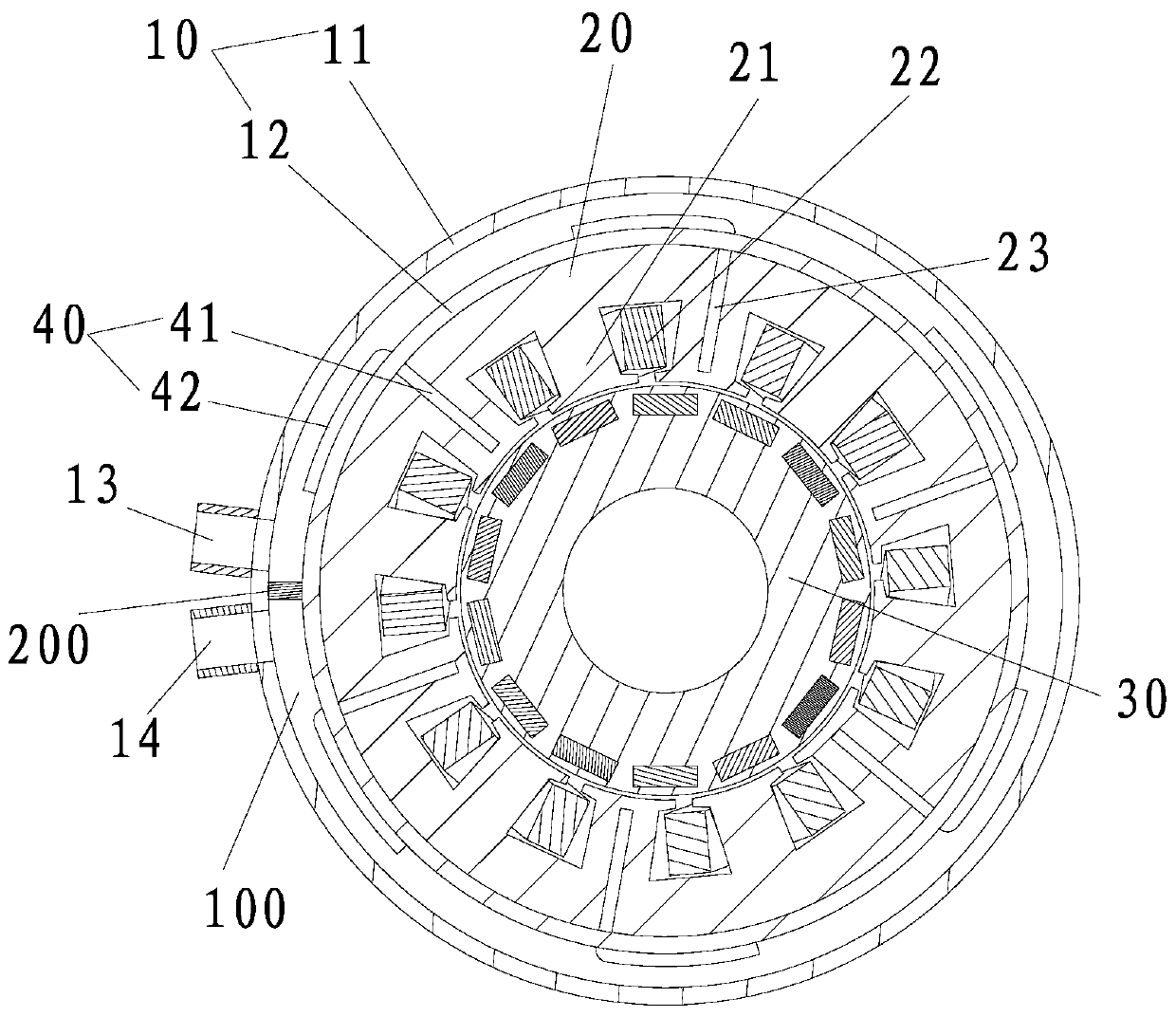

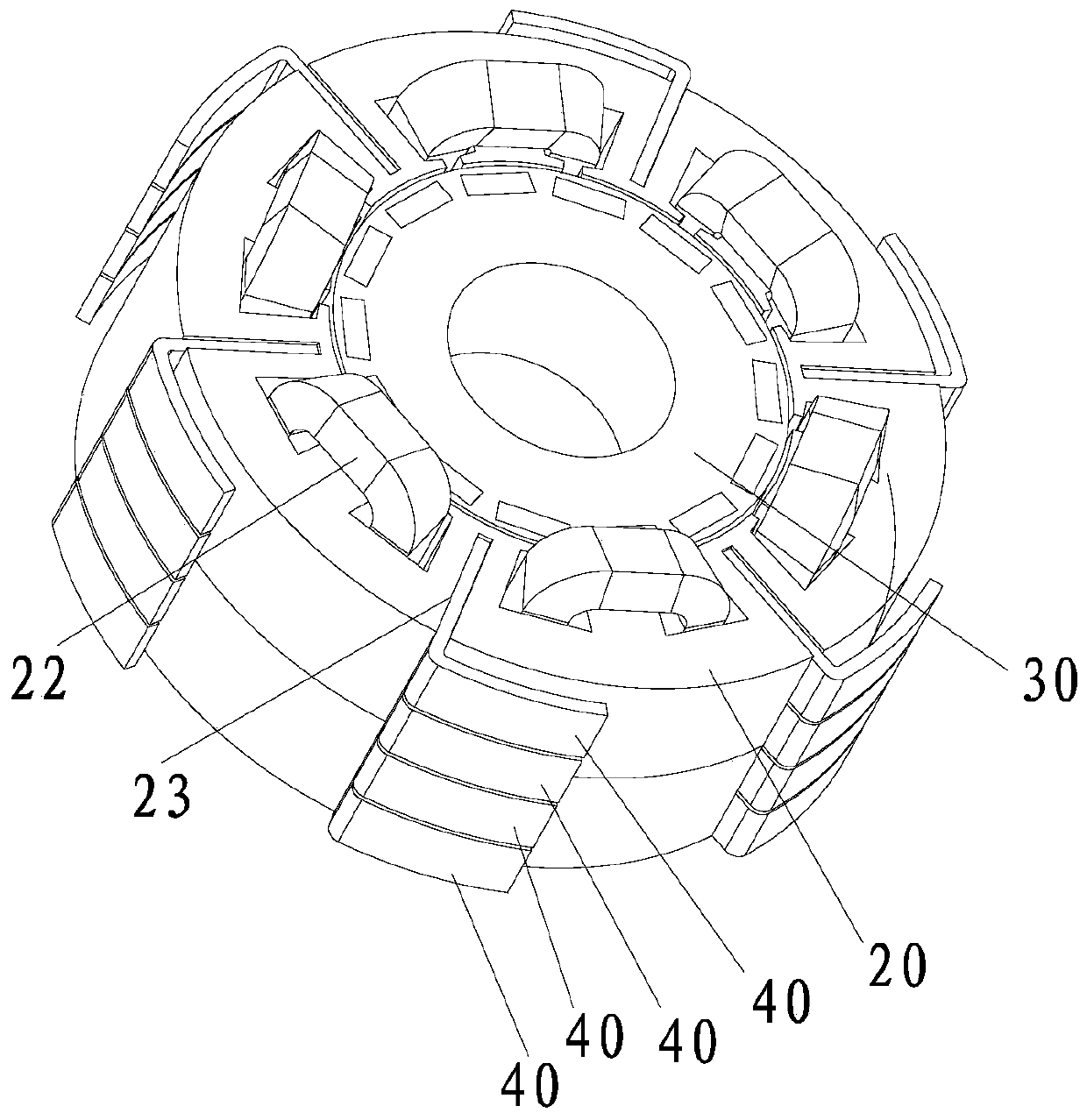

Efficient flux barrier motor based on hybrid cooling technology

ActiveCN109787405AReduce usageRealize the cooling effectMagnetic circuit stationary partsCooling/ventillation arrangementEvaporationEngineering

The invention relates to an efficient flux barrier motor based on the hybrid cooling technology. The efficient flux barrier motor comprises an enclosure, and a stator assembly and a rotor assembly, which are arranged in the enclosure, wherein the enclosure comprises a motor inner shell and a motor outer shell, a cooling liquid passage is formed between the motor inner shell and the motor outer shell, the motor outer shell is provided with a liquid inlet and a liquid outlet, both of the liquid inlet and the liquid outlet communicate with the cooling liquid passage, the stator assembly comprisesa stator, stator teeth formed in the stator and a winding wound in the stator teeth, the efficient flux barrier motor further comprises a heat pipe installed in the stator assembly, the heat pipe hasan evaporation section and a condensation section, the efficient flux barrier motor further comprises a plurality of flux barrier grooves, the flux barrier grooves extend from an outer wall of the stator into the stator teeth, the plurality of flux barrier grooves are arranged along the circumferential direction of the stator, the heat pipe is a heat pipe made of a non-permeability magnetic material, the evaporation section is installed in the flux barrier grooves, and the condensation section is arranged in the cooling liquid passage. The efficient flux barrier motor provided by the invention has the advantages of fast heat dissipation rate and can improve the motor efficiency.

Owner:QUANZHOU INST OF EQUIP MFG

Circular direct methanol fuel cell of high performance and low cost

InactiveCN101335362AEasy to cleanEasy maintenanceFuel cells groupingCell electrodesFuel cellsBiochemical engineering

The invention discloses a column direct methanol fuel cell with good performance and low cost. The cell comprises a shell, wherein, a membrane electrode is arranged in the shell. A battery liquid compartment is arranged in the membrane electrode, an air chamber is arranged between the shell and the membrane electrode, insulating sealing rings are arranged on both ends of the membrane electrode, and a cathode output device and an anode output device are respectively arranged on the cathode end and the anode end of the cell group, a water-diversion gas-barrier membrane is arranged on the exterior of the anode output device, a water collector is arranged on the exterior of the water-diversion gas-barrier membrane, and the cathode output device is provided with a check valve which is communicated with the cell liquid compartment and a pollutant output bolt device. The cell has the advantages of reasonable structure and good working performance.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

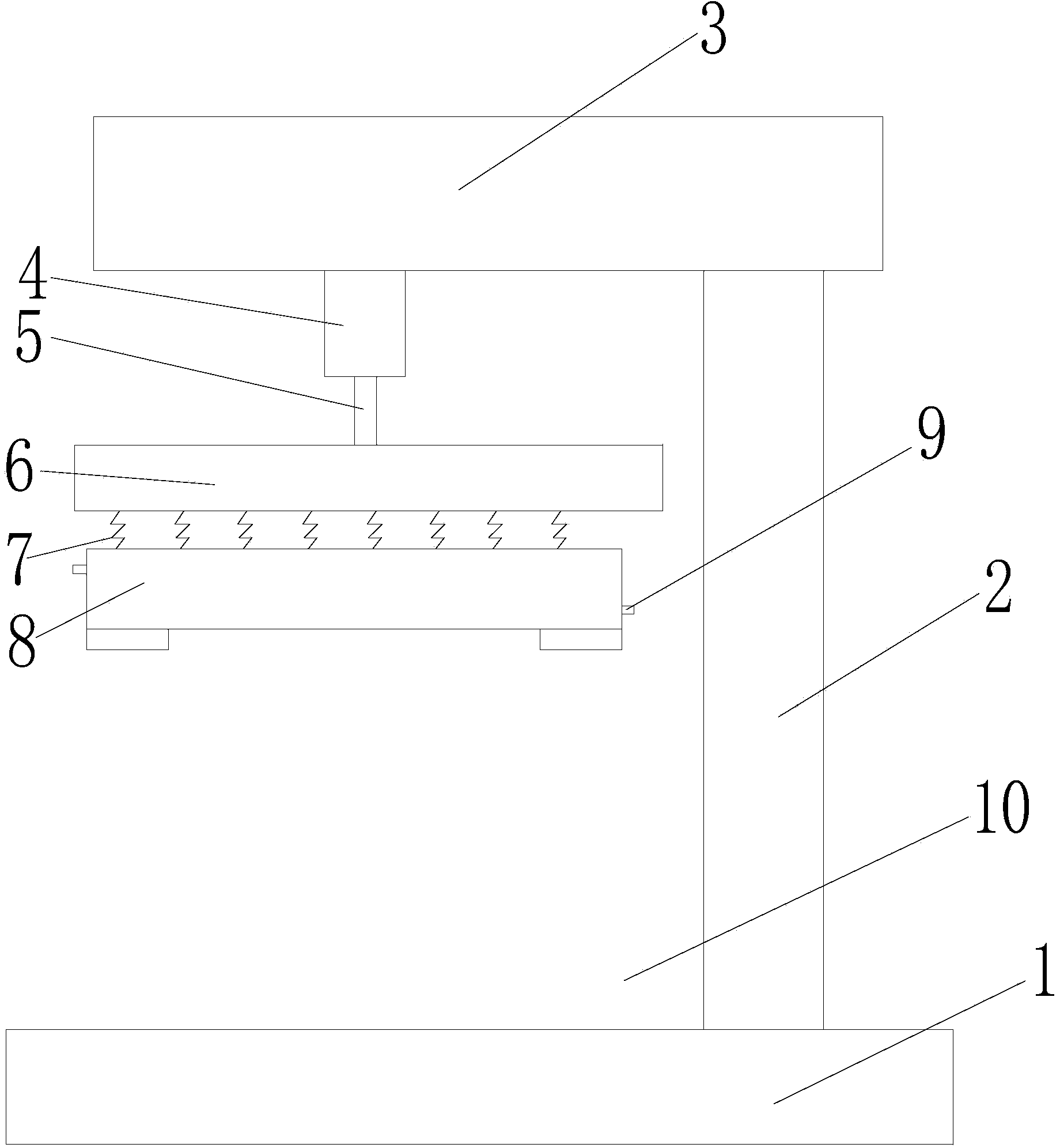

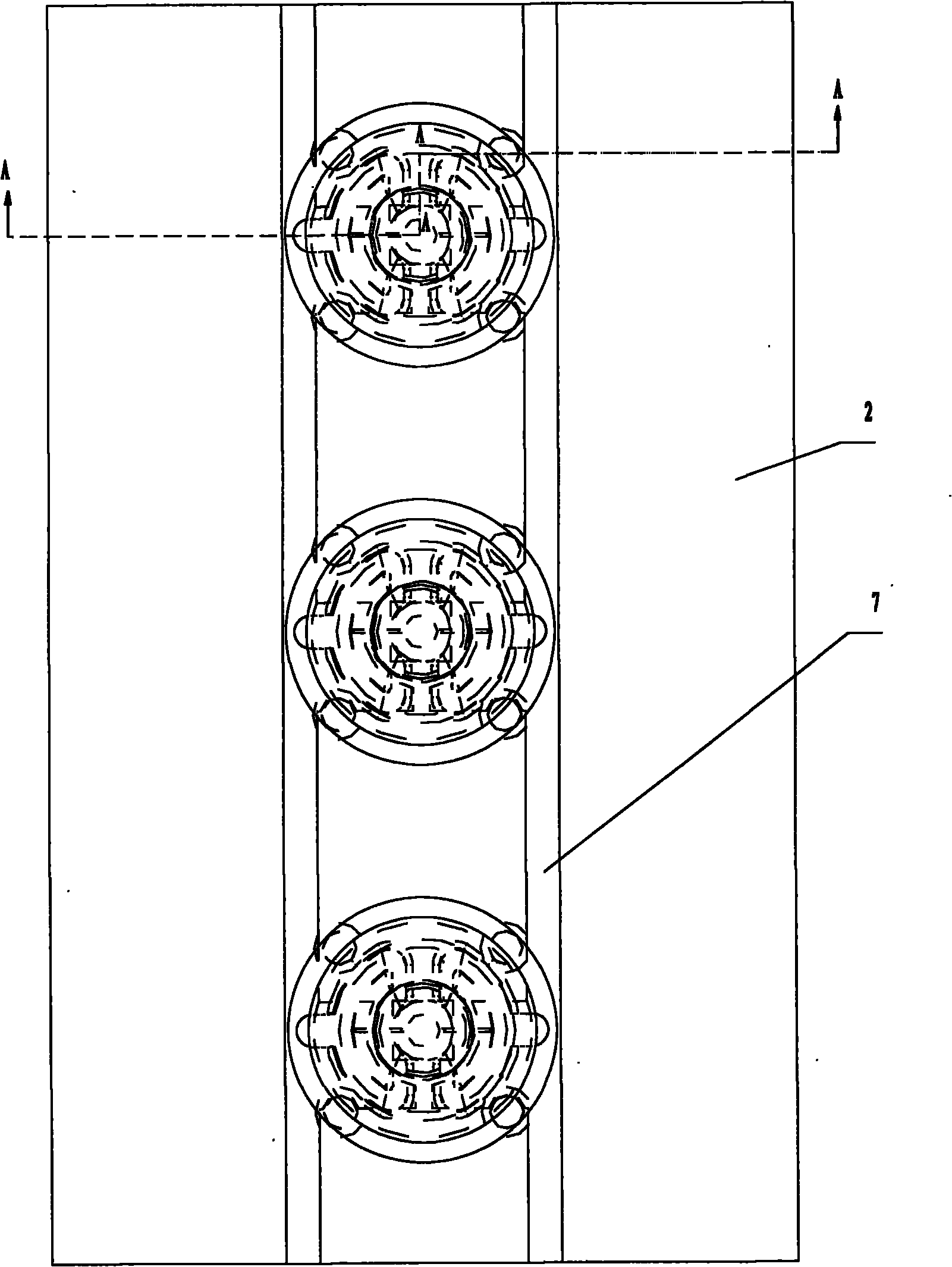

Elastic cooling and pressing fixture for PCB

The invention discloses an elastic cooling and pressing fixture for a PCB. The elastic cooling and pressing fixture for the PCB comprises a support and is characterized by further comprising a cylinder, a movably plate, a plurality of springs, a pressing plate, a cooling pipe and a flexible pipe, wherein the support comprises a base, a supporting beam and a top plate, the supporting beam is arranged on the top of the base, the top plate is arranged on the top of the supporting beam, the cylinder is arranged on the bottom of the top plate, a cylinder rod of the cylinder is connected with the movably plate, the springs are arranged on the bottom of the movable plate, the pressing plate is arranged on the bottoms of the springs, the cooling pipe penetrates through the pressing plate, a water inlet and a water outlet of the cooling pipe are connected through the flexible pipe, the flexible pipe is cooled through a condenser, and an openable hole used for water injection is formed in the cooling pipe. The elastic cooling and pressing fixture for the PCB has the advantages that the structure is simple, the pre-pressing force is balanced, the pressing effect is good, the precision of pressing positions is high, the cooling speed is high, and the machining efficiency and the machining quality can be improved greatly.

Owner:SUZHOU KUEN ELECTRONICS TECH

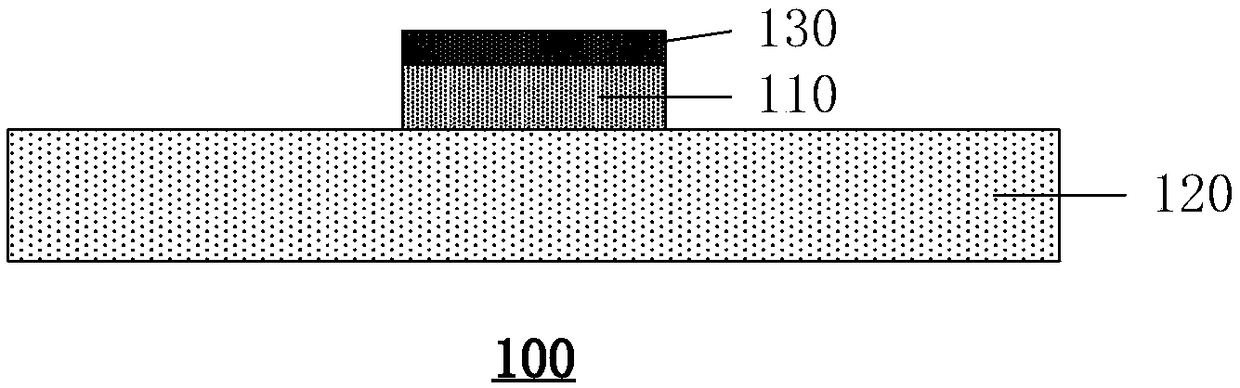

Manufacture method of LED integrated structure

InactiveCN101963296AWorking temperature is suitableReduce thermal resistancePlanar light sourcesPoint-like light sourceHeat resistanceEngineering

The invention discloses a manufacture method of an LED integrated structure, comprises the following process steps: molding a heat dissipation substrate; molding a layout circuit conducting layer; molding a position lens or the plastic part of the lens; carrying out die bonding; electrically connecting an LED chip with the layout circuit conducting layer; and packaging the LED chip and wires. Themethod has the advantages of less process, simple technology, low manufacturing cost, small heat resistance and good heat dissipation of the intermediate link of manufacturing the LED chip and accurate position relation of the lens and the chip, and the LED integrated structure has the advantages of high luminous flux, simple structure, simple assembling, good heat dissipation effect and good optical effect.

Owner:杨东佐

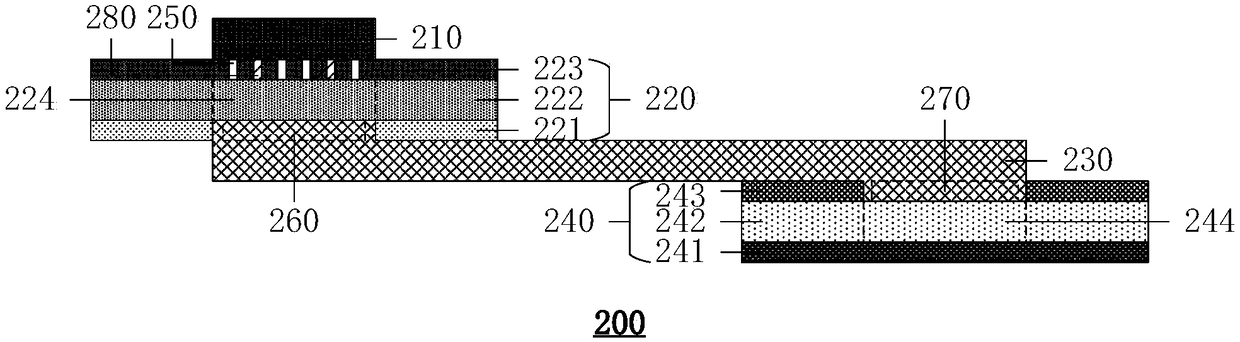

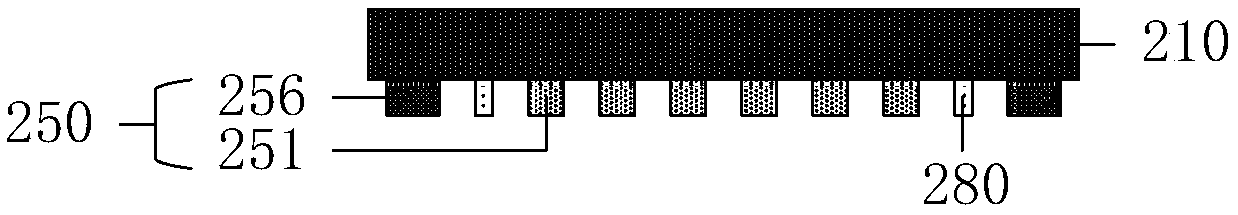

Chip-on-film heat dissipation structure and display device

ActiveCN108933111AWill not overheat abnormallyFast heat dissipationSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneChip on film

The invention provides a chip-on-film heat dissipation structure and a display device. The chip-on-film heat dissipation structure comprises an integrated circuit chip, a first flexible circuit board,a heat conductive sheet and a second flexible circuit board; the integrated circuit chip comprises heat conducting pins, wherein the heat conducting pins are suspended without any potential; the first flexible circuit board includes a first base film, a first metal layer, and a first protective film; the second flexible circuit board includes a second base film, a second metal layer, and a secondprotective film; the integrated circuit chip is fixed on one side near the first protective film and away from the first base film, of the first flexible circuit board; the heat conductive pins penetrate the first protective film and contact the first metal layer; the first base film has a first opening; the first opening exposes a first portion of the first metal layer; the heat conductive sheetextends into the first opening and contacts the first metal layer; the second base film or the second protective film has a second opening, and the second opening exposes a second portion of the second metal layer; the heat conductive sheet extends into the second opening and contacts the second metal layer.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

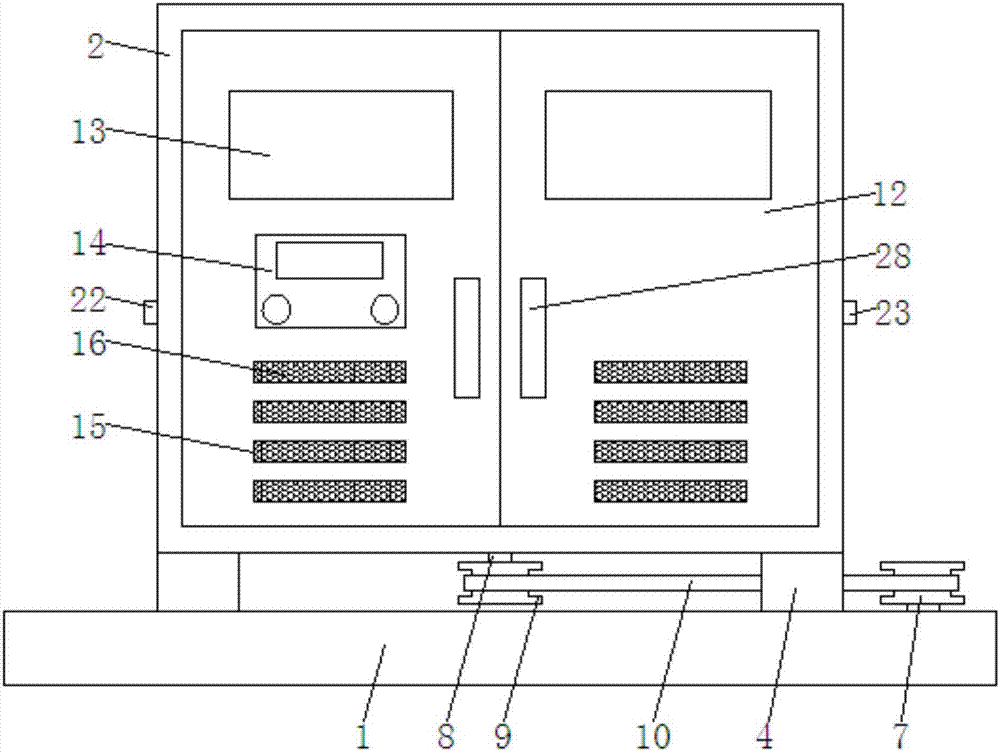

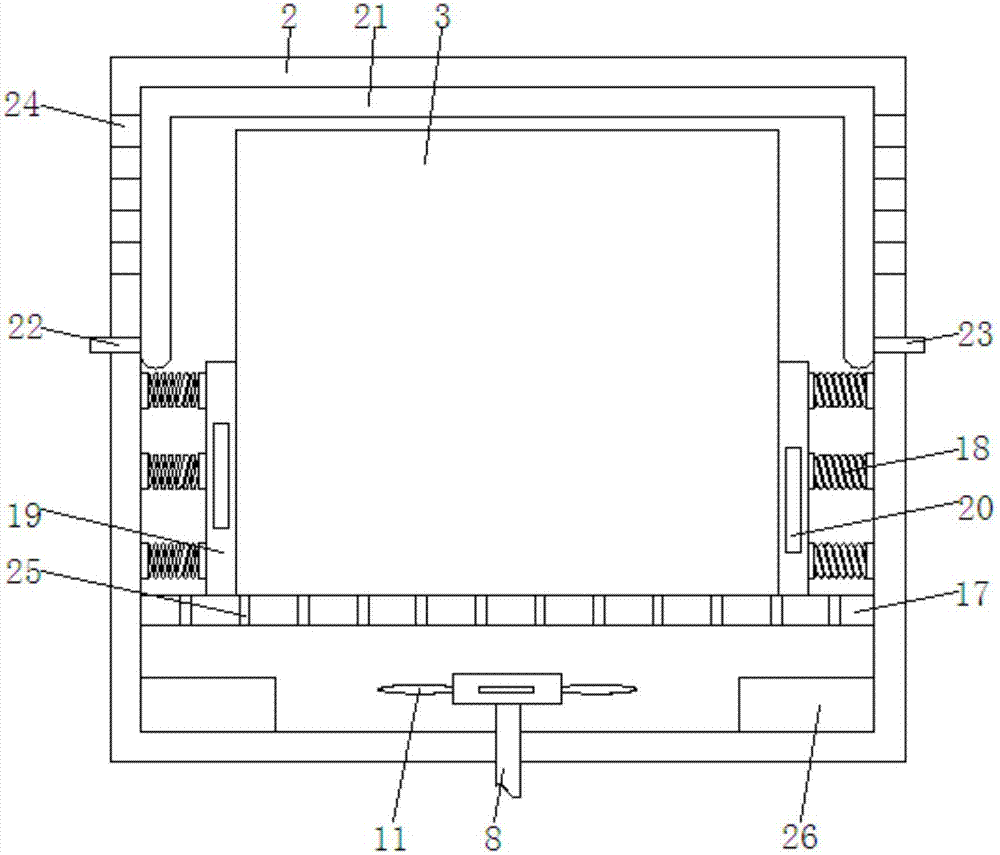

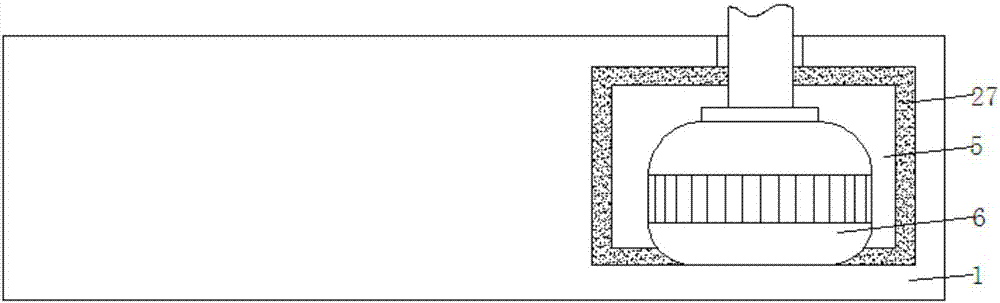

Low-voltage electrical cabinet having circular heat-dissipation function

InactiveCN105703242AHas the function of circulating heat dissipationCircular cooling effect is goodSubstation/switching arrangement cooling/ventilationAnti-seismic devicesLow voltageCooling chamber

The invention discloses a low-voltage electrical cabinet with the function of circulating heat dissipation, which comprises a cabinet body, a partition board is fixedly installed in the cabinet body, the partition board includes a horizontal plate, and the top and bottom of the horizontal plate are respectively fixedly connected with The first vertical plate and the second vertical plate, the horizontal plate and the first vertical plate are provided with air holes arranged equidistantly, the bottom of the cabinet is provided with a base, and a cooling chamber is provided in the base, and cooling Condensation pipes arranged at equal distances are arranged in the room, air delivery holes and exhaust holes are respectively arranged on the base, and fans are arranged at the bottom of the air delivery holes. The low-voltage electrical cabinet with the function of circulating heat dissipation can increase the air convection speed in the low-voltage electrical cabinet, and the heat dissipation speed is faster, so that the low-voltage electrical cabinet has a good circulating heat dissipation effect, and avoids excessive temperature in the cabinet. damage to electrical components, ensuring the reliability of the low-voltage power supply system.

Owner:WUXI JIANLING ELECTRIC APPLIANCE CO LTD

COB (Chip On Board) packaged LED (Light Emitting Diode) light source and manufacturing method

InactiveCN103078049AImprove the light angle and light rangeHigh light efficiencySolid-state devicesSemiconductor devicesFluorescenceLight source

The invention discloses a COB (Chip On Board) packaged LED (Light Emitting Diode) light source. The LED light source comprises a substrate, an electrode, an LED chip and a fluorescent glue, wherein the electrode is arranged on the substrate; the LED chip is arranged on a positive surface of the substrate and is electrically connected with the electrode; the fluorescent glue covers the LED chip; and the substrate is a transparent substrate, and the heat dispersion of the transparent substrate is good. According to the COB packaged LED light source and a manufacturing method thereof provided by the invention, the substrate is changed from an opaque substrate into a cooling transmitting substrate with high efficiency, so that the COB packaged LED light source can shine 360 degrees, an emitting angle and a luminous range of a product are extended, and a lighting effect of the light source is improved. In addition, a substrate material is good in heat dissipation performance and fast in heat dispersion velocity, so that the condition that the fluorescent glue is subjected to aging failure in a high-temperature working environment is avoided, the service life of the fluorescent glue is prolonged, and the thermal resistance and lumens depreciation of the product is reduced. Therefore, the COB packaged LED light source and the manufacturing method can be suitable for a COB packaging technology with high power.

Owner:张刚维 +1

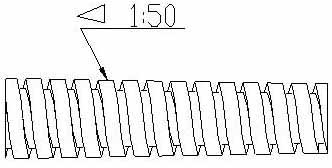

Ceramic PTC heater with corrugate heat radiating fins

InactiveCN103458542AIncrease cooling areaFast heat dissipationAir heatersHeating element shapesConvex structureService time

The invention relates to the technical field of heaters, in particular to a heater. The ceramic PTC heater with corrugate heat radiating fins comprises a heater pipe, the heat radiating fins are arranged on the heater pipe, the heat radiating fins comprise bases, the bases are arranged on the heater pipe, multiple heat radiating protrusions protruding upwards are arranged on the bases in the length direction of the heater pipe, and the heat radiating protrusions form multiple fan-shaped structures with the narrow lower portions and the wide upper portions on the side faces of the heater pipe. Concave-convex structures are arranged on the side faces of the heat radiating protrusions in a width direction. Due to the adoption of the technical scheme, the heat radiating fins of the heater are even in heat radiating, high in heat radiating efficiency and solid and reliable in connection with the heater pipe, the problem of loosening caused by aged mucilage glue is avoided, and the service time is longer.

Owner:SHANGHAI HUAZU IND

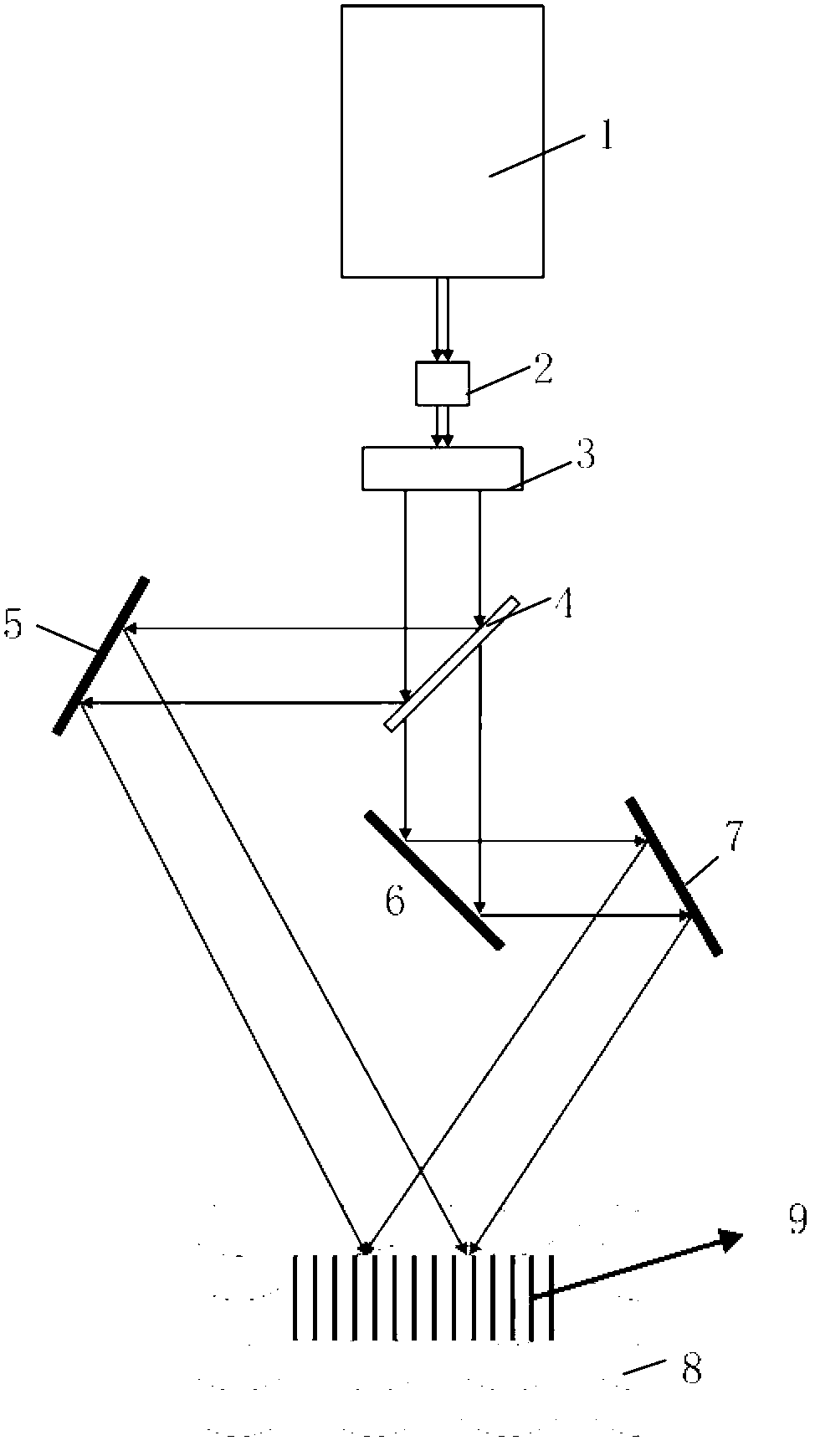

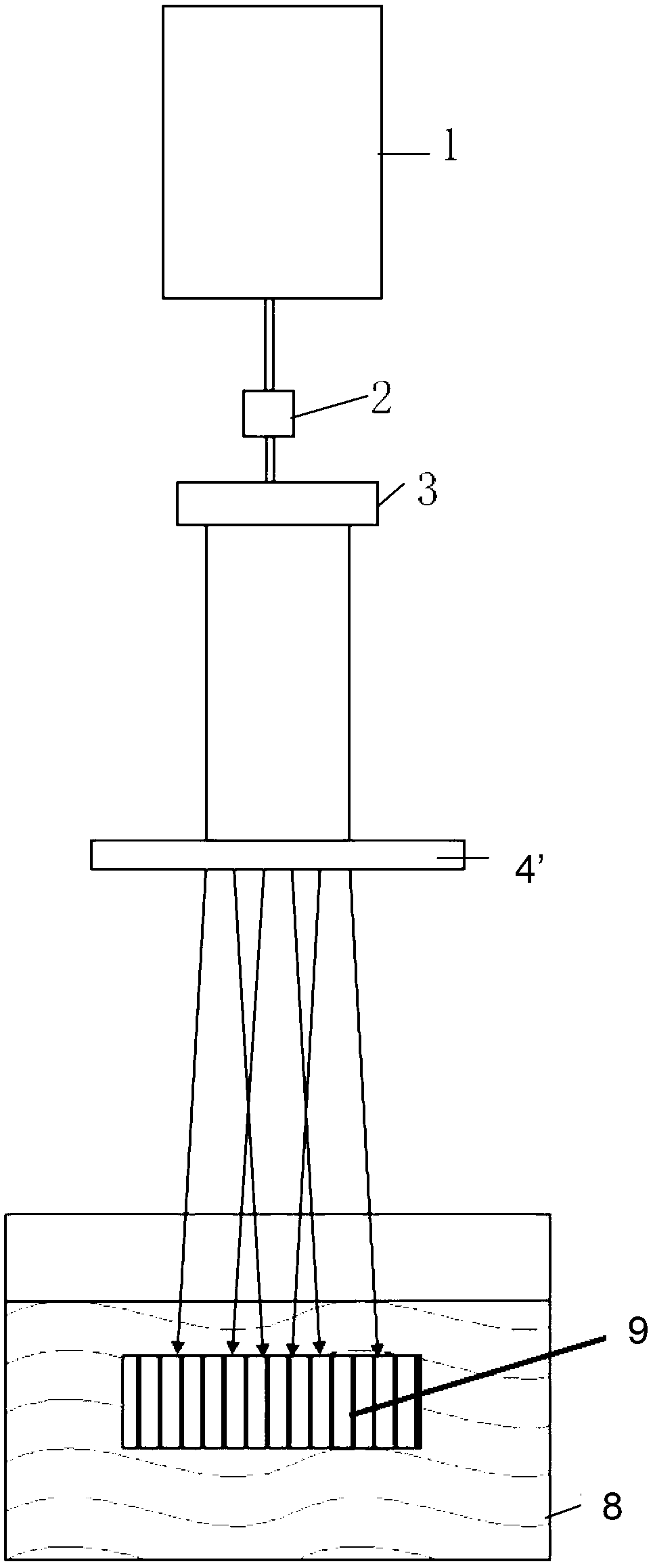

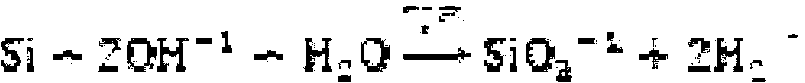

Wool preparing process by crystalline silicon based on laser interference induced reaction

InactiveCN102709163AAddressing Anisotropic ErosionSave energy costsSemiconductor/solid-state device manufacturingPhysical well beingLaser scanning

The invention belongs to the technical field of a solar battery, in particular to a wool preparing process by crystalline silicon based on laser interference induced reaction, which comprises the following steps of: (1) corrosion treatment: corroding a silicon wafer to remove mechanical damage on the surface; (2) placing the silicon wafer in an alkaline solution with a certain concentration at room temperature; (3) locally heating the crystalline silicon wafer dipped in strong base solution by laser; and (4) forming a wool face: scanning the whole silicon wafer by interference laser till an uniform wool face is formed on the surface of the silicon wafer. The wool preparing process is free from a laser with over-high power, and saves the energy sources and the machining cost. The process is controlled within an optical spot and has less affect the silicon wafer in other positions. In addition, the preparing process is simple, convenient and rapid. No toxic gases are generated in the wool preparing process, and adverse effects on health of workers and environment are avoided. The wool preparing process by crystalline silicon based on laser interference induced reaction, provided by the invention, can enhance the speed of the process greatly, has good industrialized prospect, and improves the efficiency of the battery extremely.

Owner:SUN YAT SEN UNIV

Artificial intelligent computer with cold and heat exchange protecting case

InactiveCN106873742AThorough heat dissipationExtended service lifeDigital processing power distributionSurface mountingElectric machinery

The invention relates to the technical field of artificial intelligence, and discloses an artificial intelligence computer with a cooling and heat exchange protection box, including a base, a box body and a machine body, a support rod is installed on the upper surface of the base, and the box is installed on a support The top of the rod, the inside of the right side of the base is provided with an inner groove, the bottom of the inner groove is equipped with a drive motor, and the output shaft of the drive motor passes through the top of the inner groove and connects with the bottom of the drive wheel located above the base. Fixedly connected, the middle part of the bottom surface of the box is plugged with a connecting rod. The artificial intelligence computer with cooling and heat exchange protection box is equipped with fans, through holes, ventilation holes and water cooling pipes. The hot air in the body is cooled to achieve double cooling of the outside of the body. At the same time, it cooperates with the heat dissipation device inside the body to make the heat dissipation more thorough and prolong the service life of the body.

Owner:朱静洁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com