Wool preparing process by crystalline silicon based on laser interference induced reaction

A technology of laser interference and crystalline silicon, which is applied in the field of solar photovoltaic applications, can solve the problems of high battery fragmentation rate, difficulty in improving battery efficiency, and inability to prepare polycrystalline silicon wafers with strong alkali solution, so as to achieve the speed of improvement, good industrialization prospects, and avoid disadvantages effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

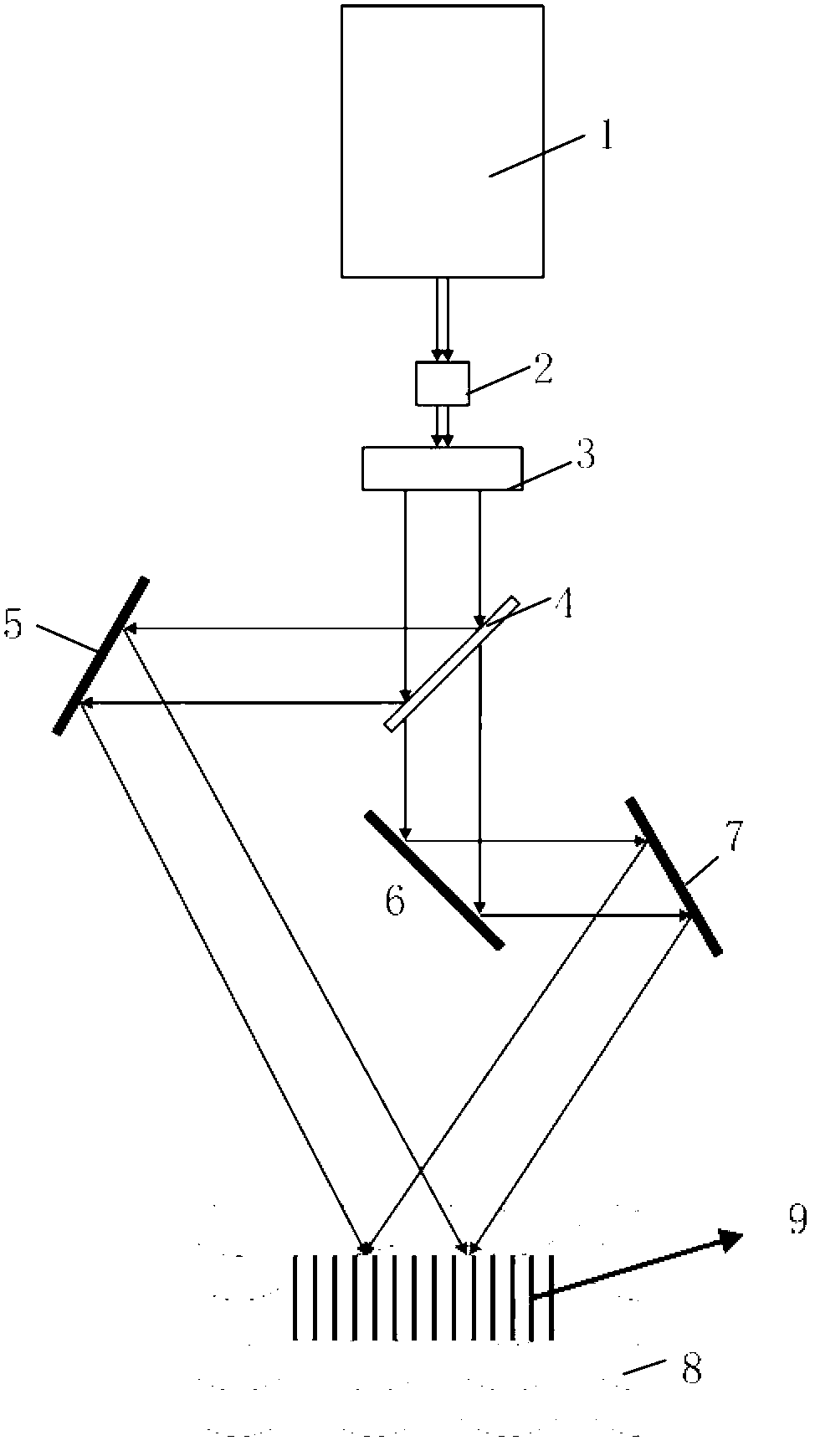

[0031] like figure 1 As shown, a kind of crystalline silicon texturing process based on laser interference induced reaction of the present invention, its specific steps are:

[0032] (1) Etching treatment: removing the mechanical damage on the surface of the sample, i.e. the silicon wafer 9, by etching;

[0033] (2) Put the silicon chip 9 into the strong alkali solution tank 8 equipped with a strong alkaline solution at a certain concentration at room temperature. In this embodiment, the strong alkaline solution can be sodium hydroxide solution, and the strong alkaline solution The temperature is kept at room temperature 25°C or below.

[0034] (3) A chemical reaction occurs by locally heating the crystalline silicon wafer soaked in a strong alkali solution by laser: turn on the laser 1, select the appropriate laser wavelength, pulse frequency, and laser power, and expand the laser beam through the beam expander 2 and 3 After processing, an interference pattern is formed thr...

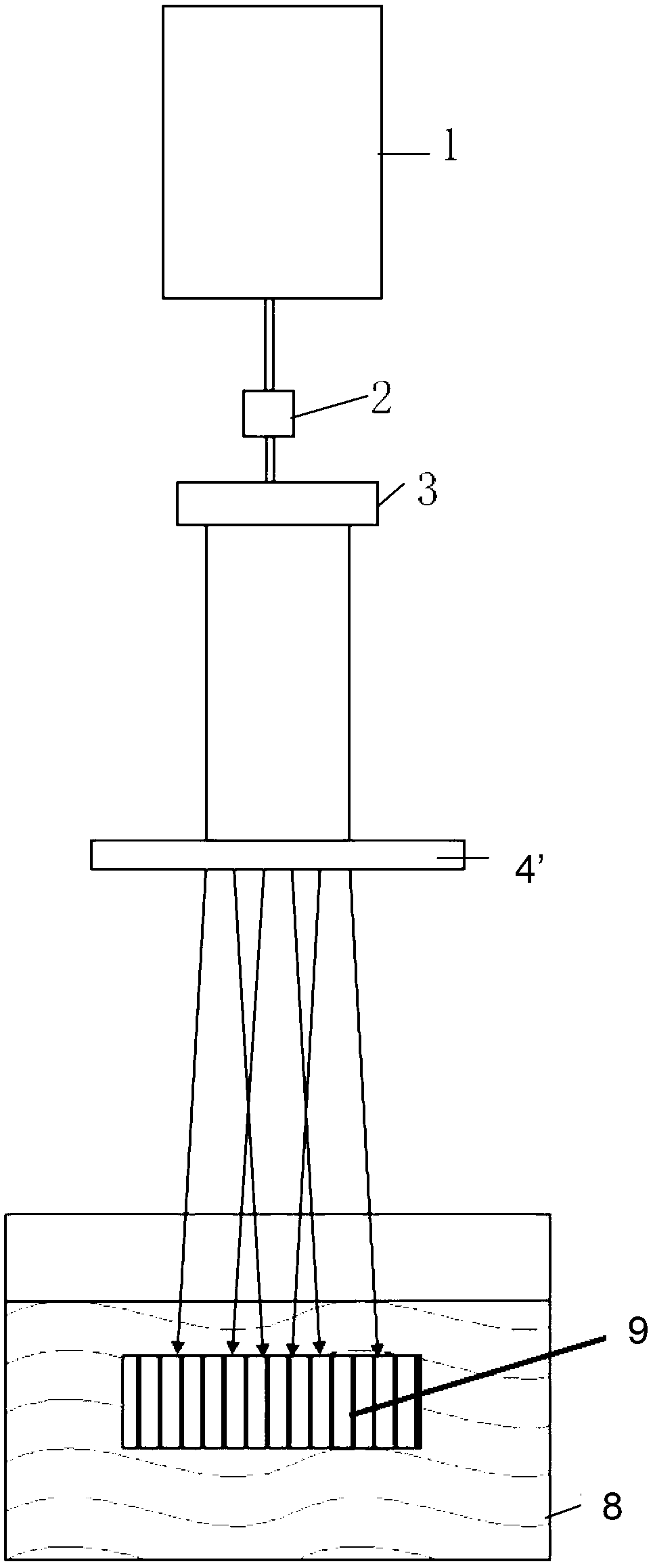

Embodiment 2

[0037] This embodiment is basically the same as the first embodiment above, the difference is: figure 2 As shown, in the above step (3), the grating 4' is used to replace the beam splitter 4 and the mirrors 5, 6, 7 in the first embodiment to form an interference pattern.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com